Patents

Literature

79results about How to "Uniform resistance distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

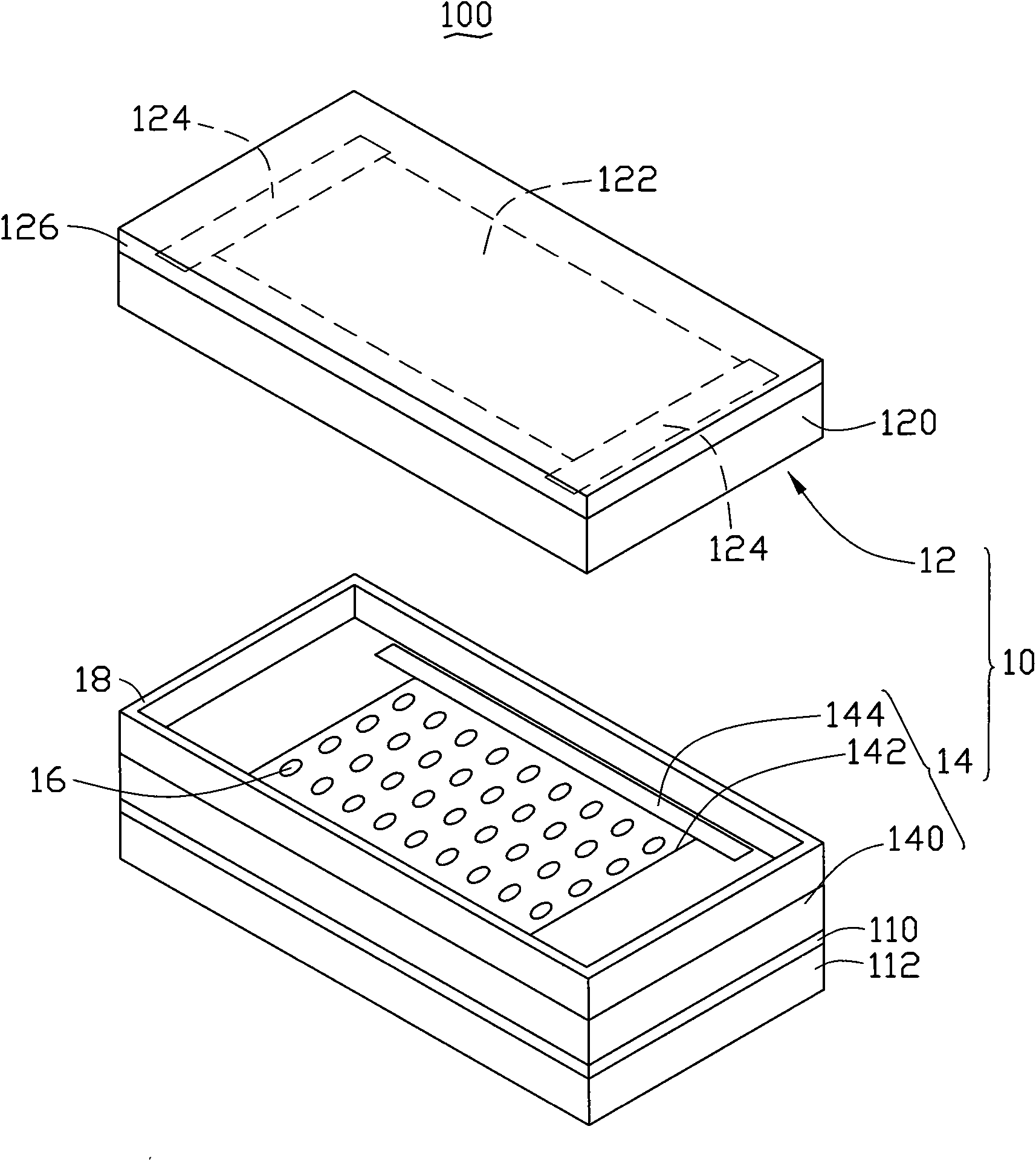

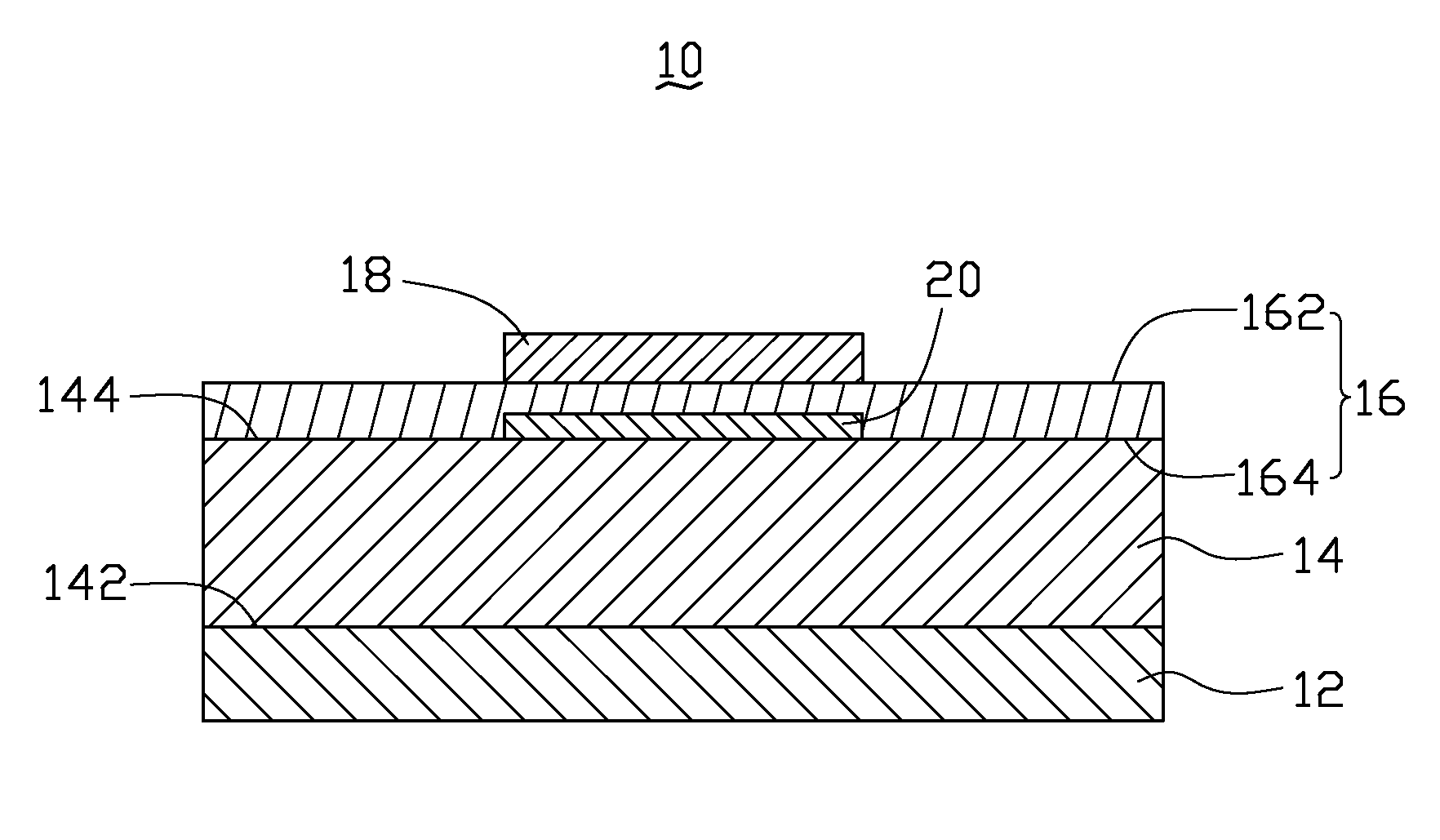

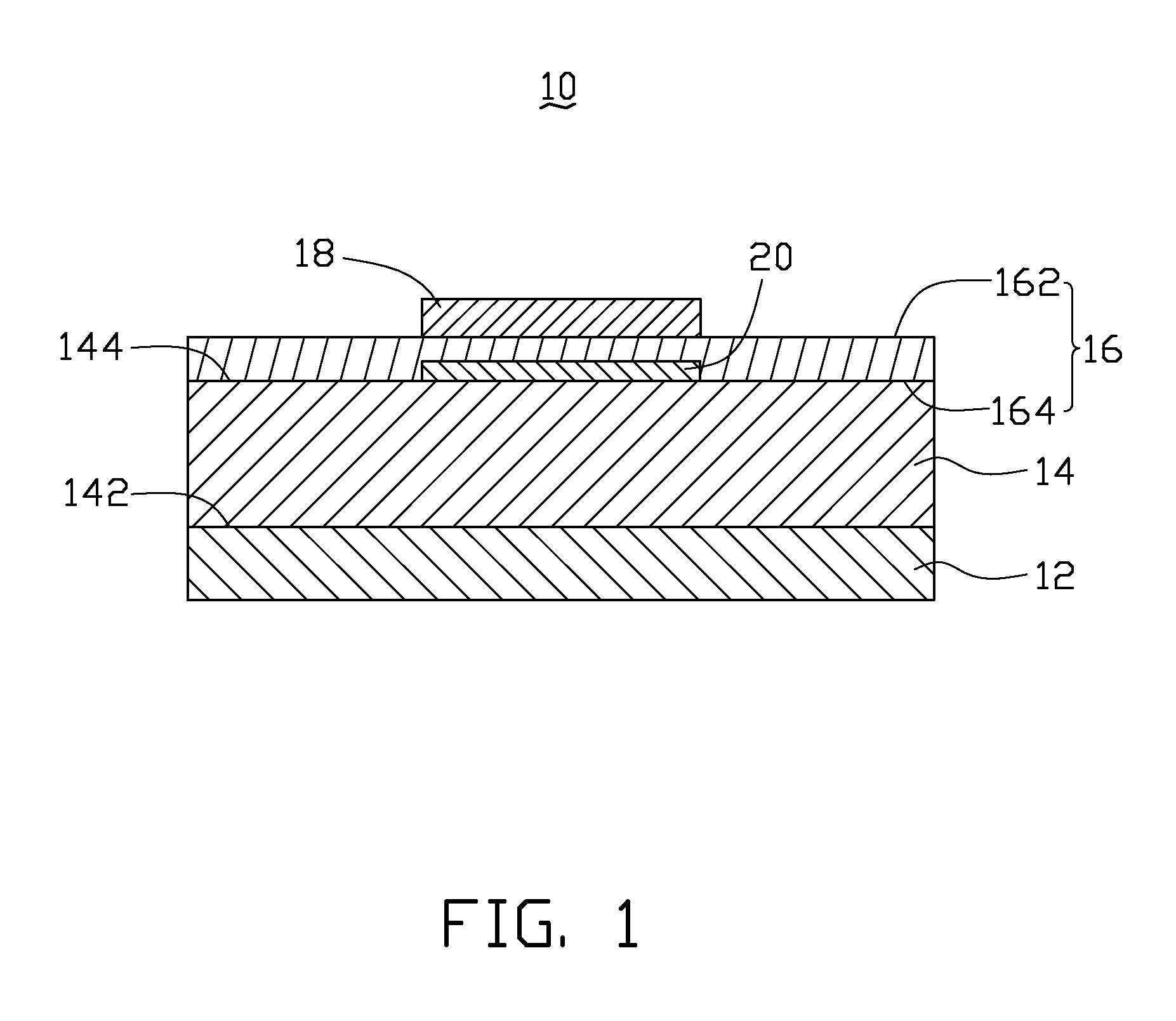

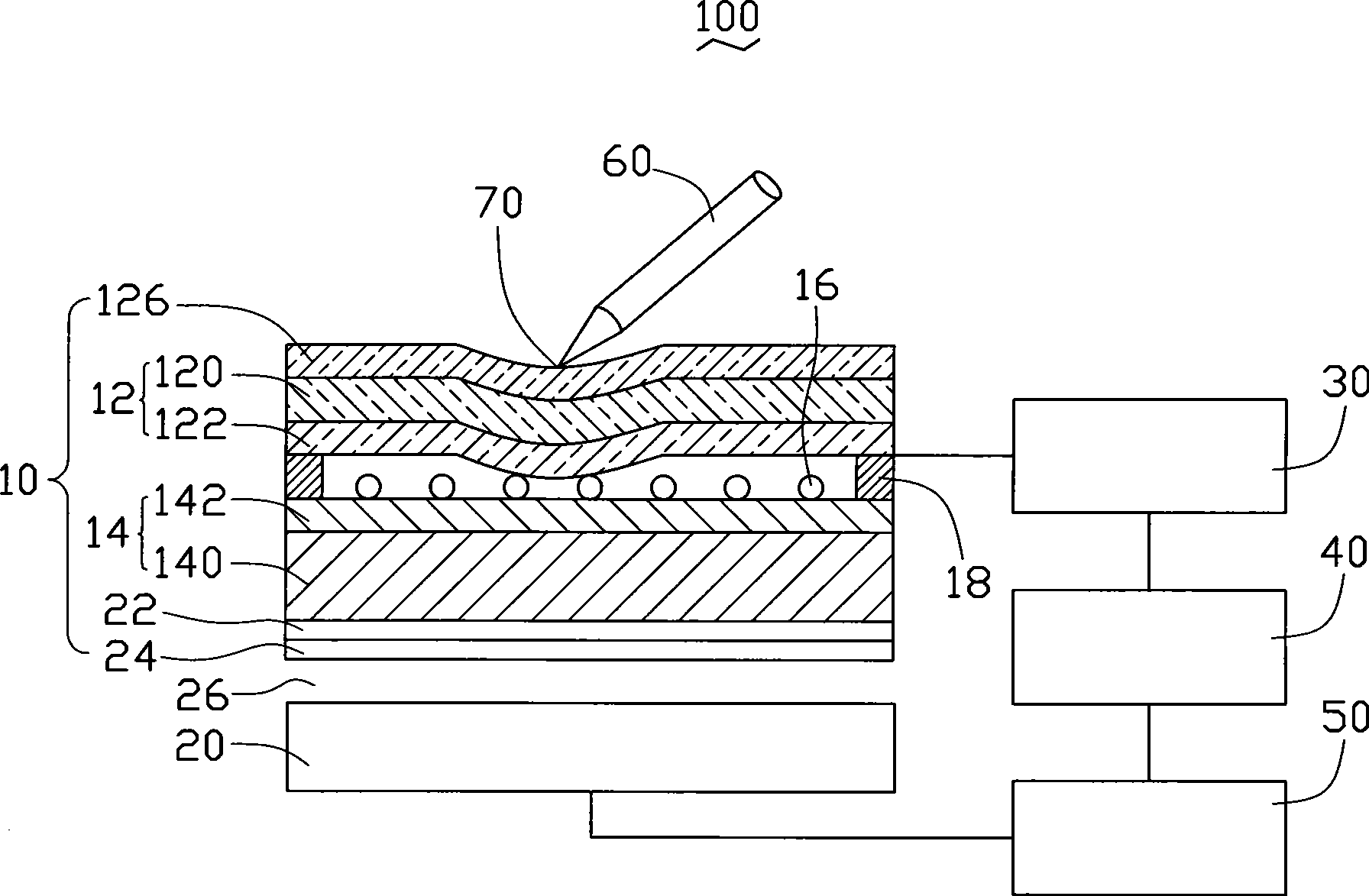

Touch panel and display device using the same

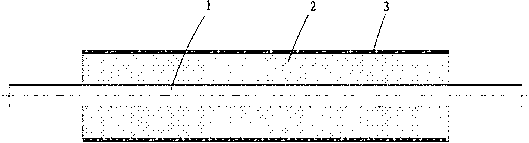

ActiveUS20110032196A1Excellent propertyImprove conductivityInput/output processes for data processingDisplay deviceCarbon nanotube

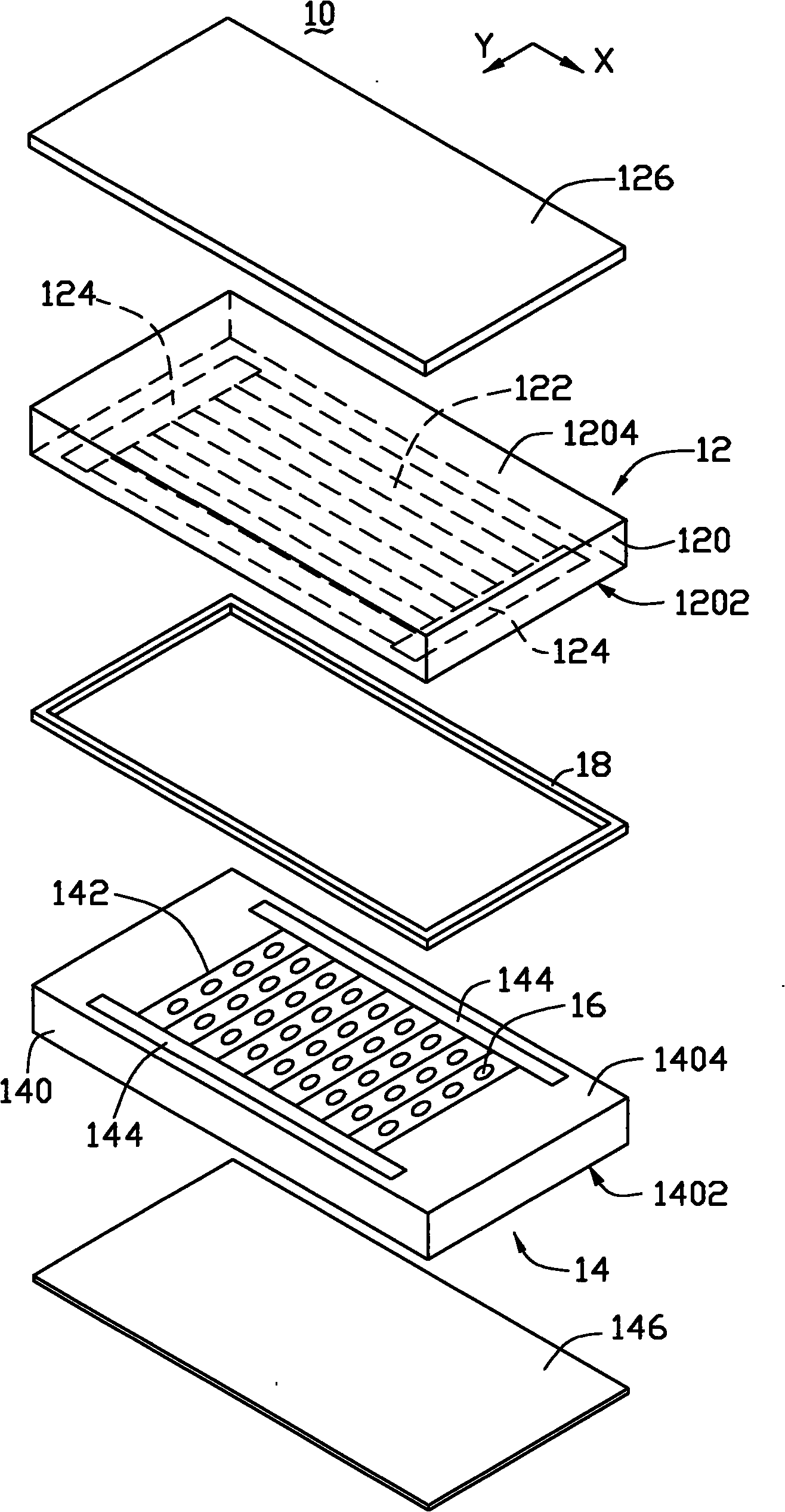

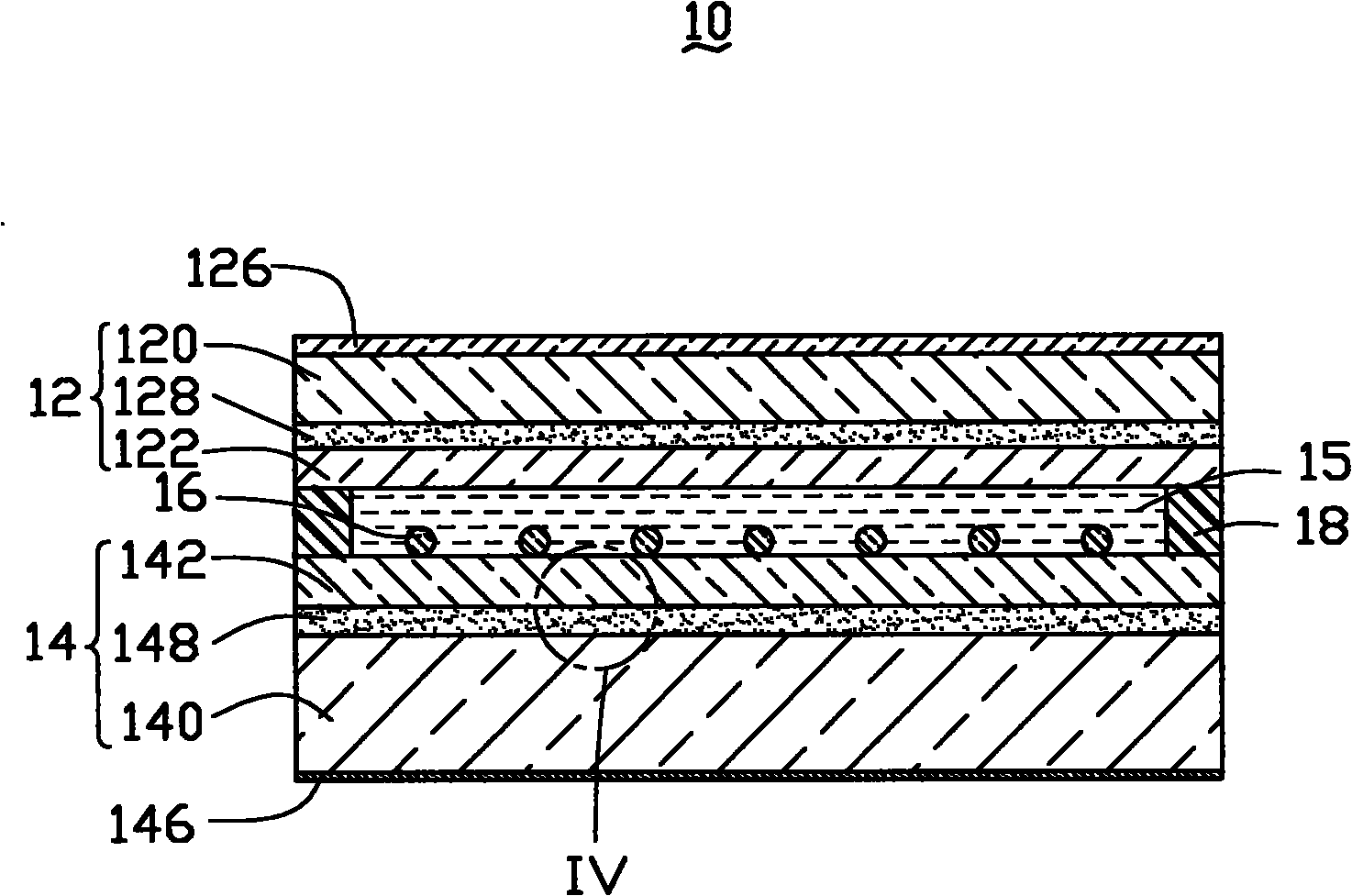

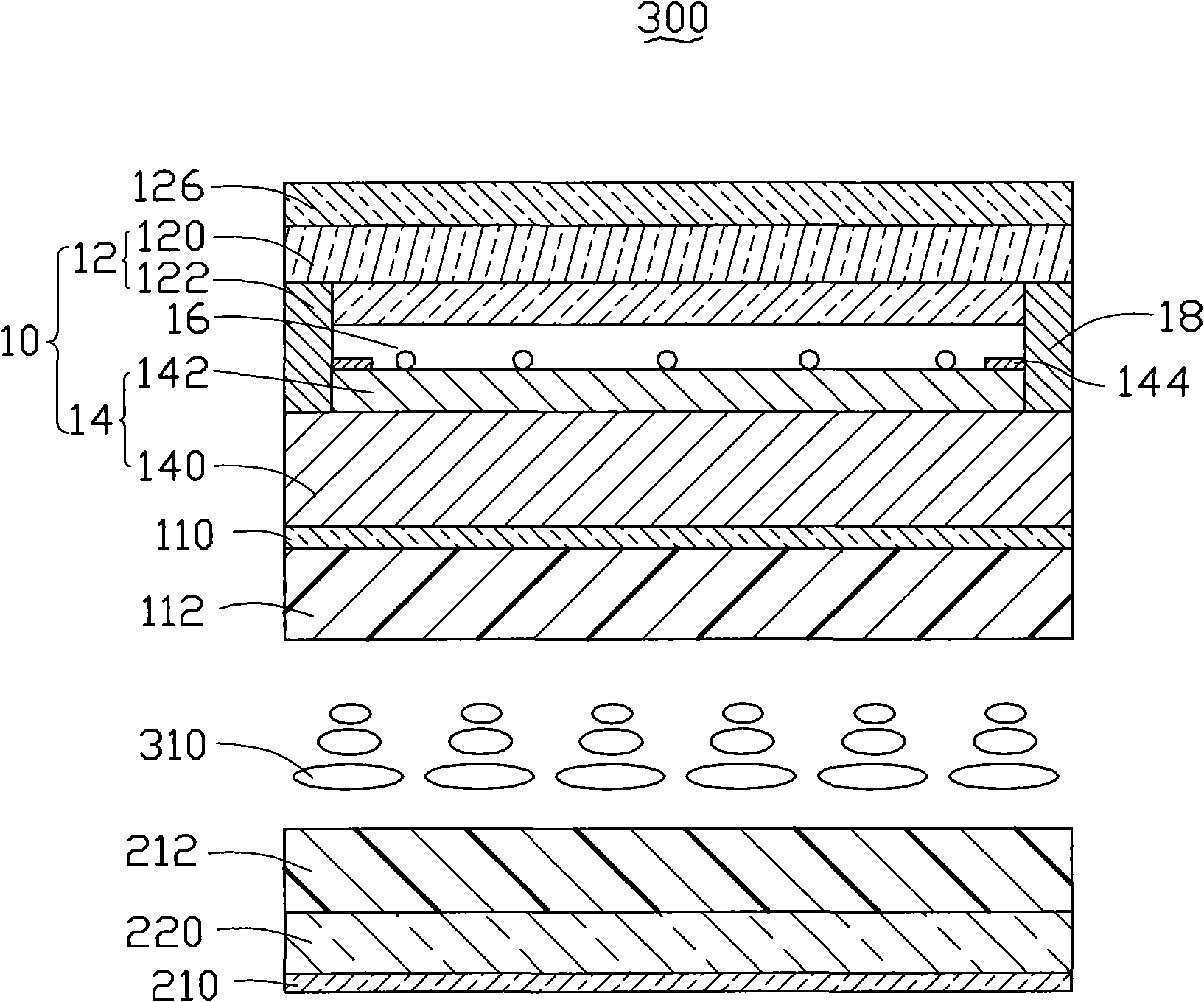

The present disclosure provides a touch panel and a display device employing the same. The touch panel includes at least one transparent layer consisting of a carbon nanotube metal composite layer including a carbon nanotube layer and a metal layer coated on the carbon nanotube layer.

Owner:TSINGHUA UNIV +1

Touch LCD screen

ActiveCN101620327AIncreased durabilityHigh-resolutionStatic indicating devicesSolid-state devicesLiquid-crystal displayCarbon nanotube

The invention discloses a touch LCD screen, which comprises an upper substrate, a lower substrate, and a liquid crystal layer, wherein the upper substrate comprises a touch screen; the lower substrate and the upper substrate are oppositely arranged; the lower substrate comprises a thin film transistor panel; the liquid crystal layer is arranged between the upper substrate and the lower substrate; and a conducting layer of the touch screen comprises a carbon nanotube layer.

Owner:TSINGHUA UNIV +1

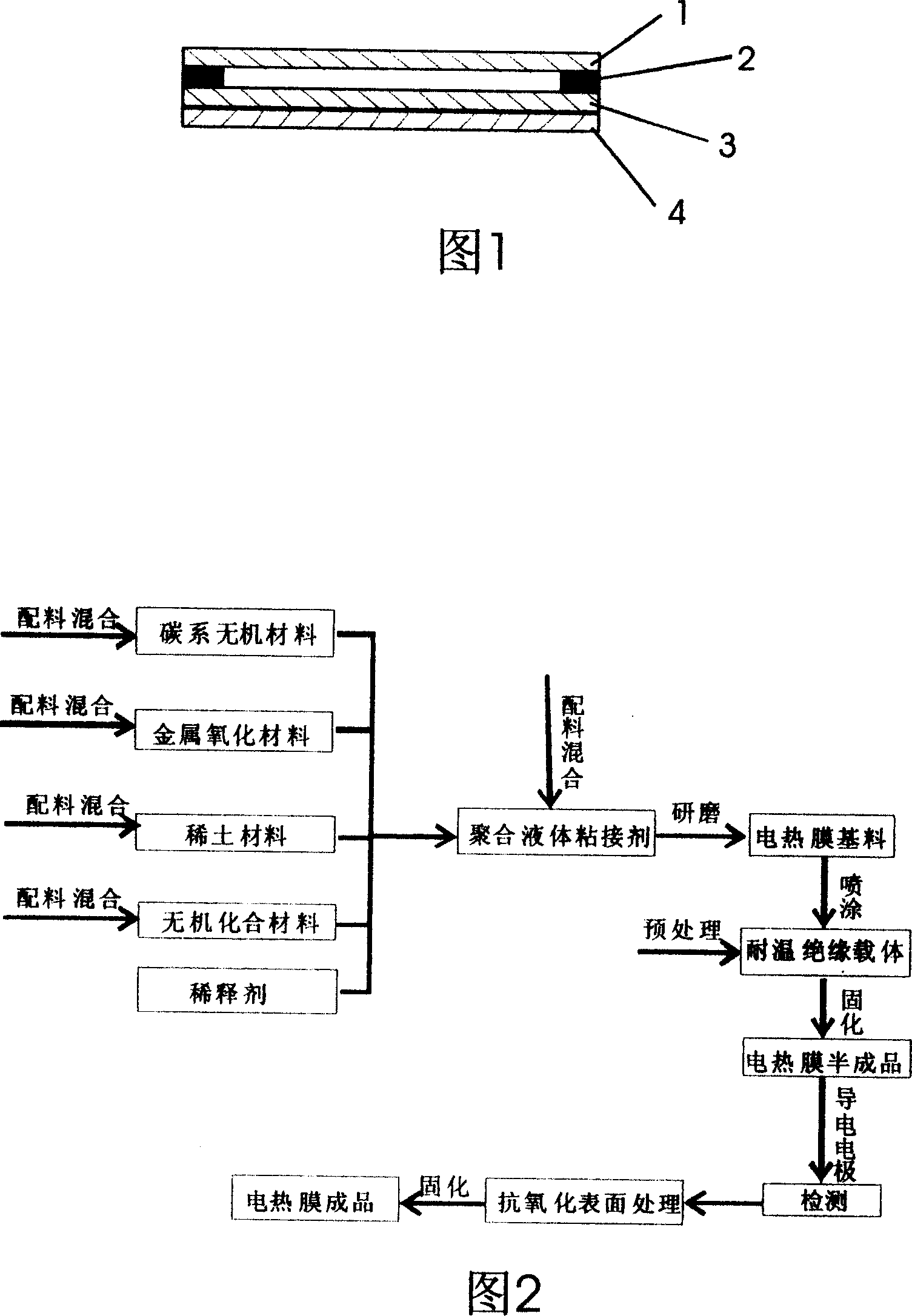

Composite low-voltage electrothermal film and making method

InactiveCN1980494AWide variation in geometryImprove conductivityHeating element materialsManufacturing technologyLiquid medium

The structure of the complex low-voltage electric heating film (CLEHF) consists of the electric heating inorganic compound (EHIC), the hi-temperature durable (HTD) isolator, the electrodes and the anti-oxidation HTD isolation layer. The EHIC consists of the carbon system inorganic material, the rare-earth material, the metal oxide, the inorganic compound and the polymerization liquid medium adhesive. The manufacture technology of CLEHF includes: ingredient configuring, mixing, skiving, spraying, solidifying and forming. With a low work voltage of 12 volts, CLEHF heats up to 100 degrees centigrade in only 50 seconds. This invention possesses advantages of fast response time, high heating efficiency and wide application range. Depending on different features and usages of various heater bodies, different materials are selected to form different shapes of heating films. Therefore, this heating film adapts to all handy low voltage electric heating apparatuses.

Owner:周挺

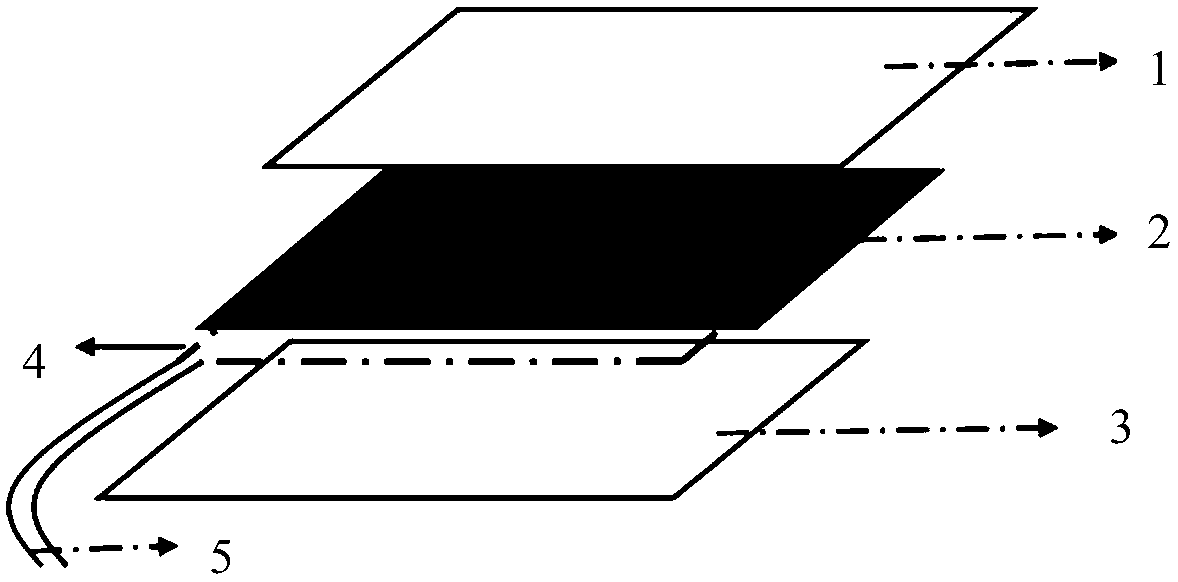

Far infrared flexible wearable heating sheet and preparation method and application thereof

PendingCN108848586AUniform resistance distributionImprove controllabilityHeating element materialsHeating filmFar infrared

The invention discloses a far infrared flexible wearable heating sheet and a preparation method and an application thereof. The preparation method comprises the following steps that at least one flexible heating body and a flexible insulating material layer are provided, wherein each flexible heating body is electrically connected with an electrode; the flexible heating body comprises a carbon material heating film, wherein the carbon material heating film comprises a carbon material layer, parallel electrodes or interdigital electrodes arranged at the two ends and / or on the two sides of the carbon material layer, and high-temperature-resistant insulating layers for covering the two sides of the carbon material layer; and the flexible insulating material layer is arranged on the two opposite sides of the flexible heating body, and lamination and curing are performed by fast pressing or transfer pressing equipment, so that sealing and insulation of the heating body and the electrode arerealized, wherein the carbon material heating film is prepared by wet coating. According to the preparation method, batch consistency preparation of the flexible carbon material heating film is realized by utilizing a wet-process coating technology; and through electrode design, the carbon material heating film can be driven by a low voltage so as to generate heat, and application to the field offlexible wearable heating can be realized finally.

Owner:SUZHOU HANANO MATERIALS TECH LTD

Touch liquid crystal display screen

ActiveCN101625465AIncreased durabilityHigh-resolutionSilicaStatic indicating devicesLiquid-crystal displayCarbon nanotube

The invention relates to a touch liquid crystal display screen, which comprises an upper substrate, a lower substrate and a liquid crystal layer, wherein the upper substrate comprises a touch screen which comprises a plurality of transparent electrodes; the lower substrate is arranged opposite to the upper substrate and comprises a thin film transistor panel; and the liquid crystal layer is arranged between the upper substrate and the lower substrate, wherein the transparent electrodes in the touch screen comprise a carbon nano-tube layer.

Owner:TSINGHUA UNIV +1

Solar cell

InactiveUS20090250113A1Increased durabilityImprove efficiencyPhotovoltaic energy generationSemiconductor devicesCarbon nanotubeSolar cell

A solar cell includes a back electrode, a single crystal silicon substrate, and a carbon nanotube structure. The single crystal silicon substrate includes an upper surface and a lower surface. The back electrode is located on and electrically connected to the lower surface of the single crystal silicon substrate. The carbon nanotube structure is located on and connected to the upper surface of the single crystal silicon substrate. The carbon nanotube structure includes an upper surface and a lower surface.

Owner:TSINGHUA UNIV +1

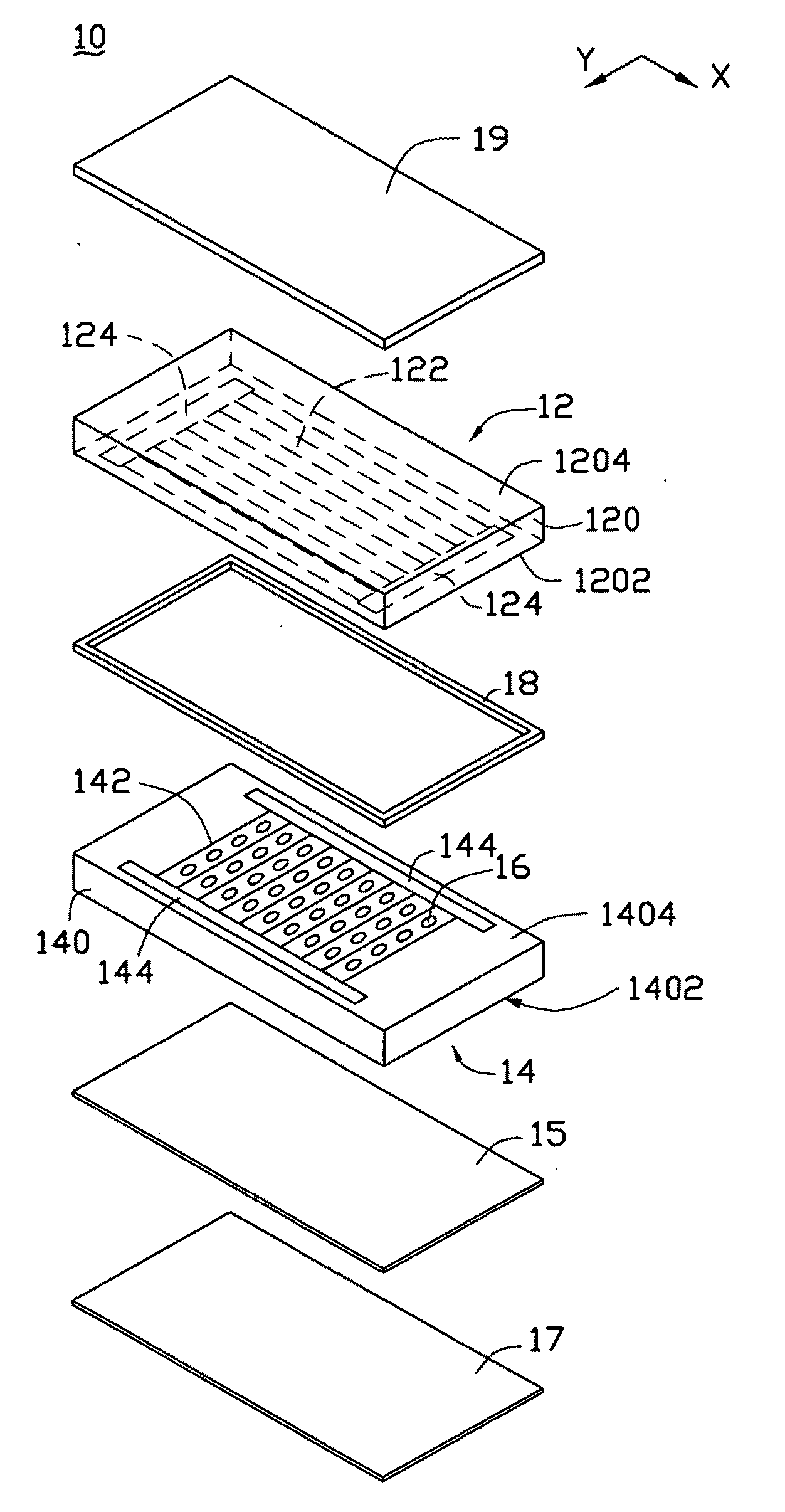

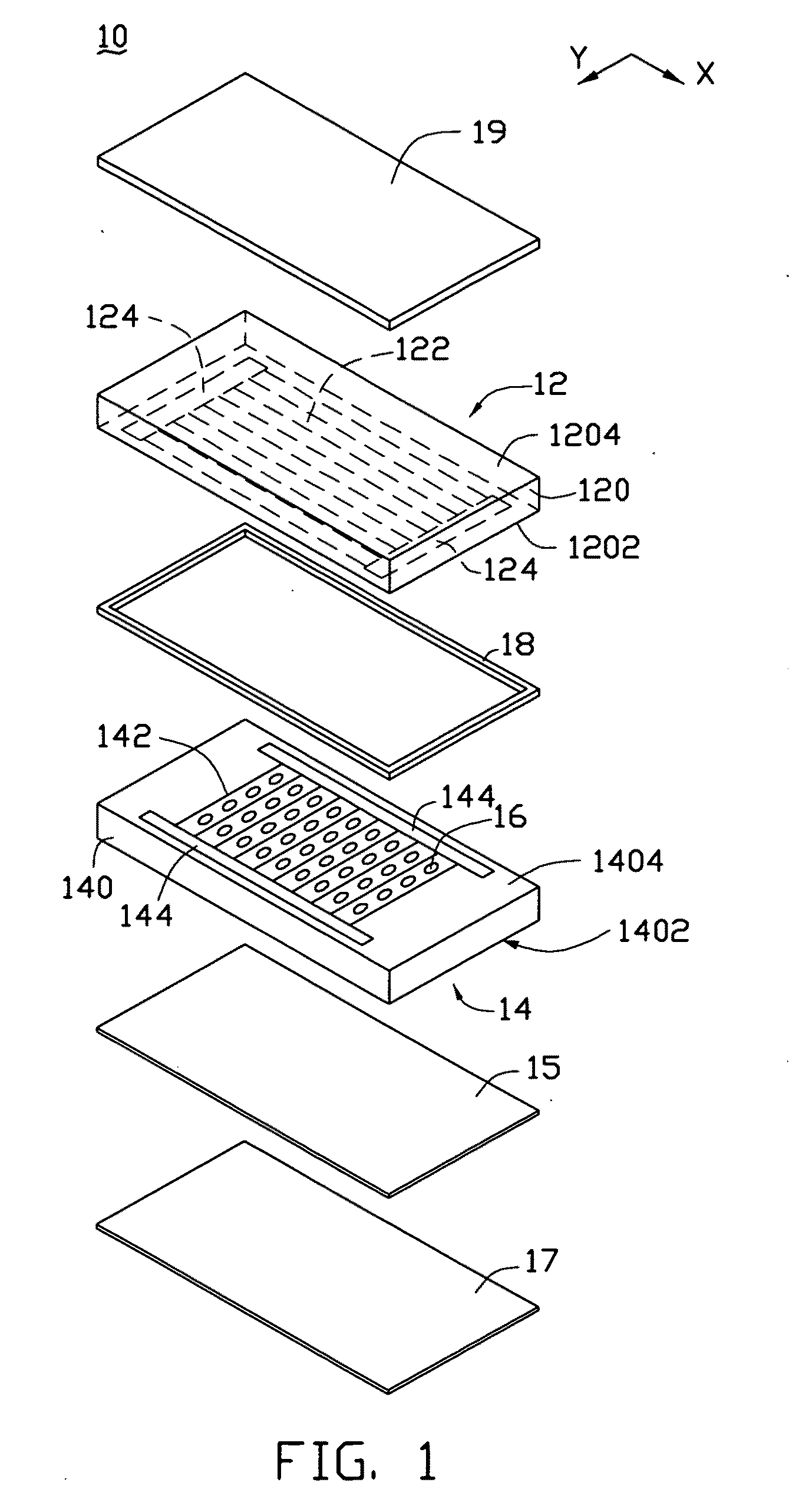

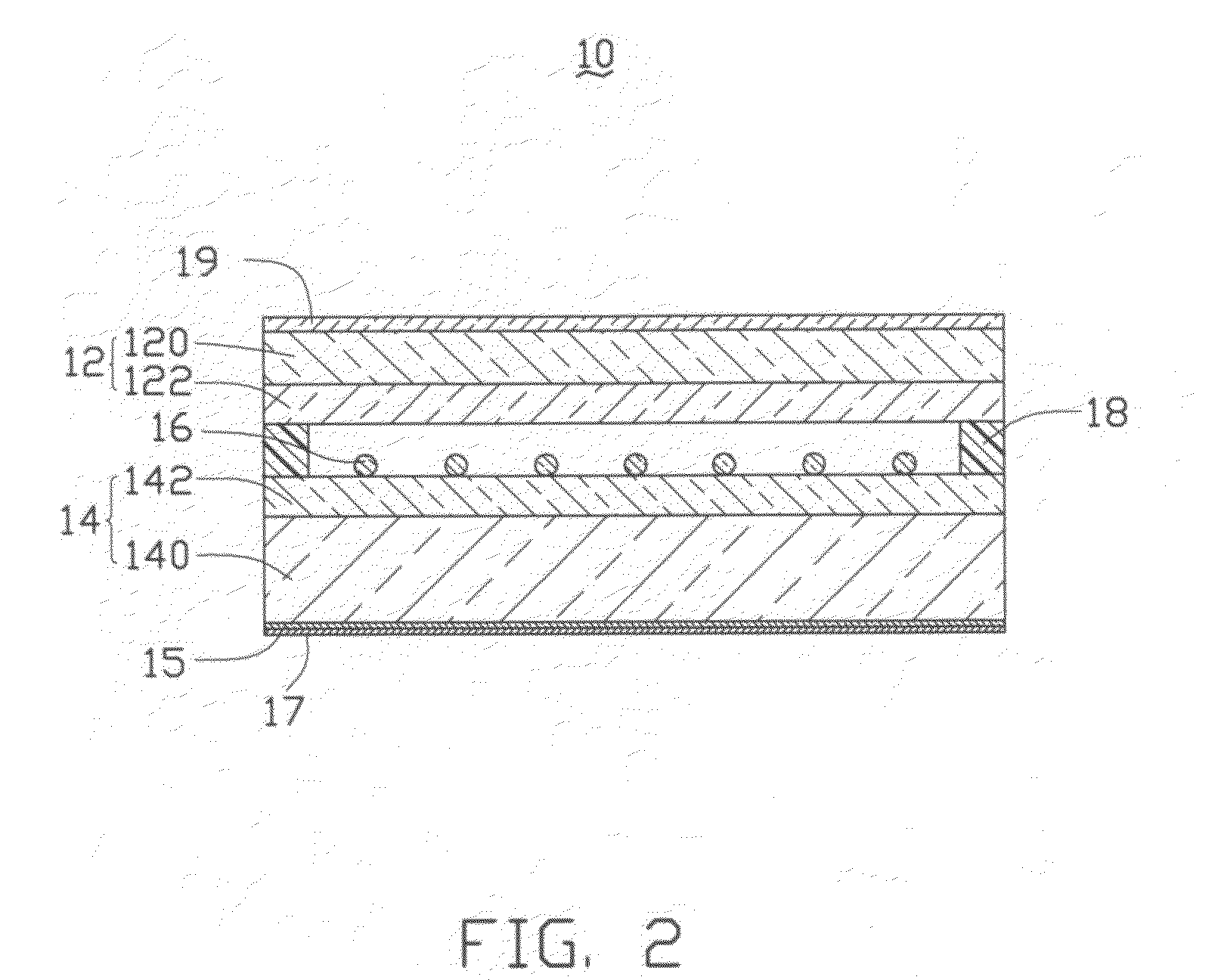

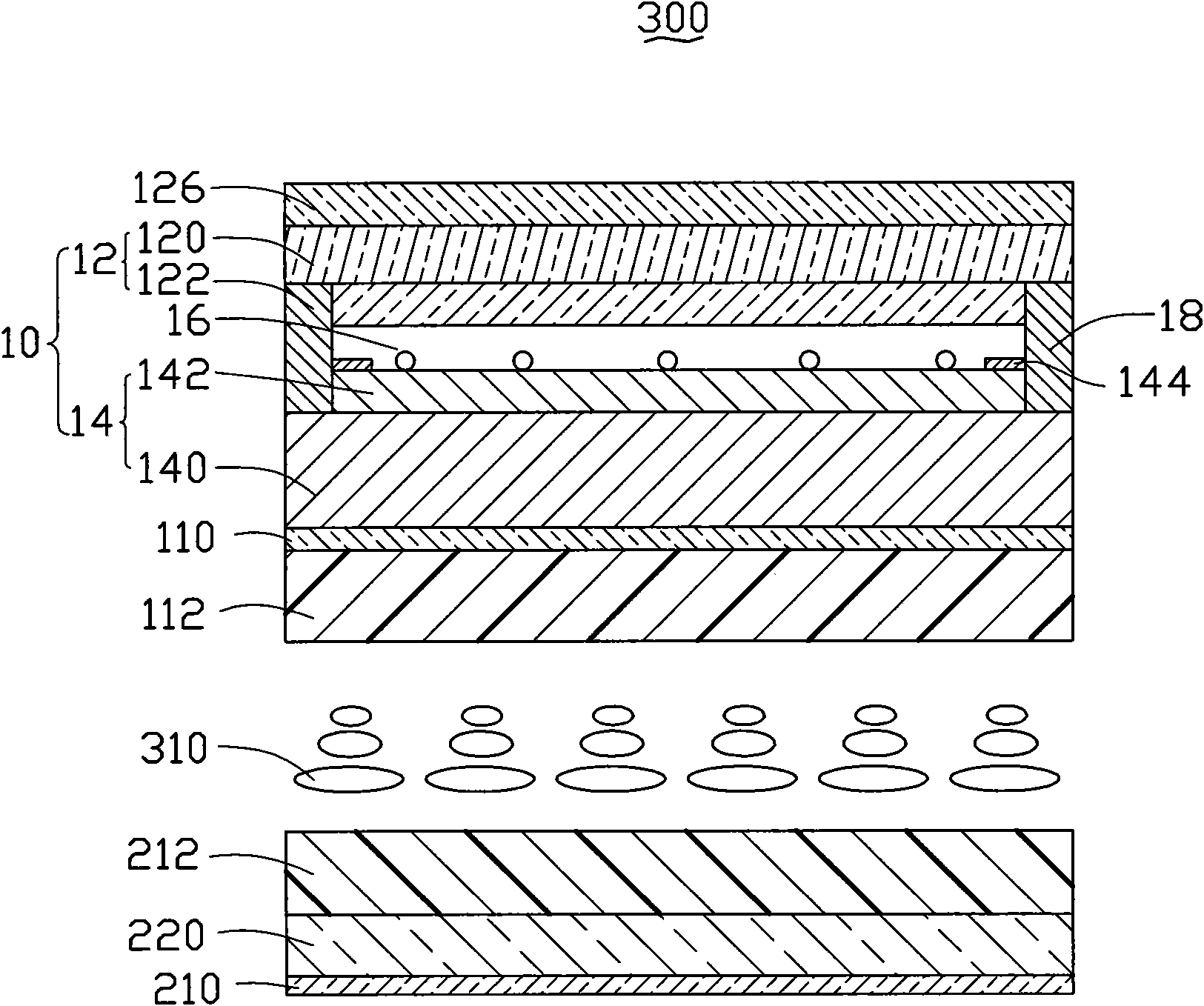

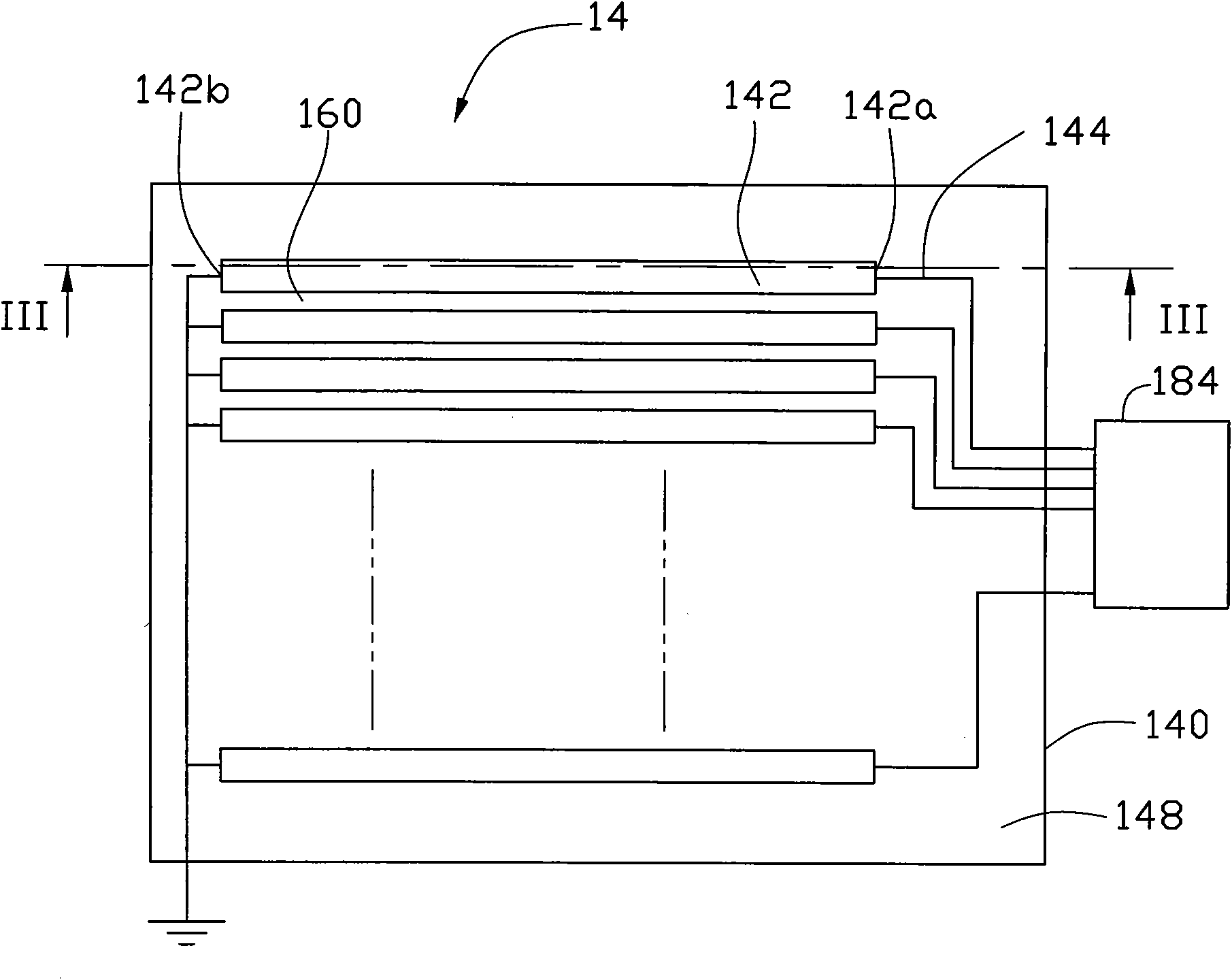

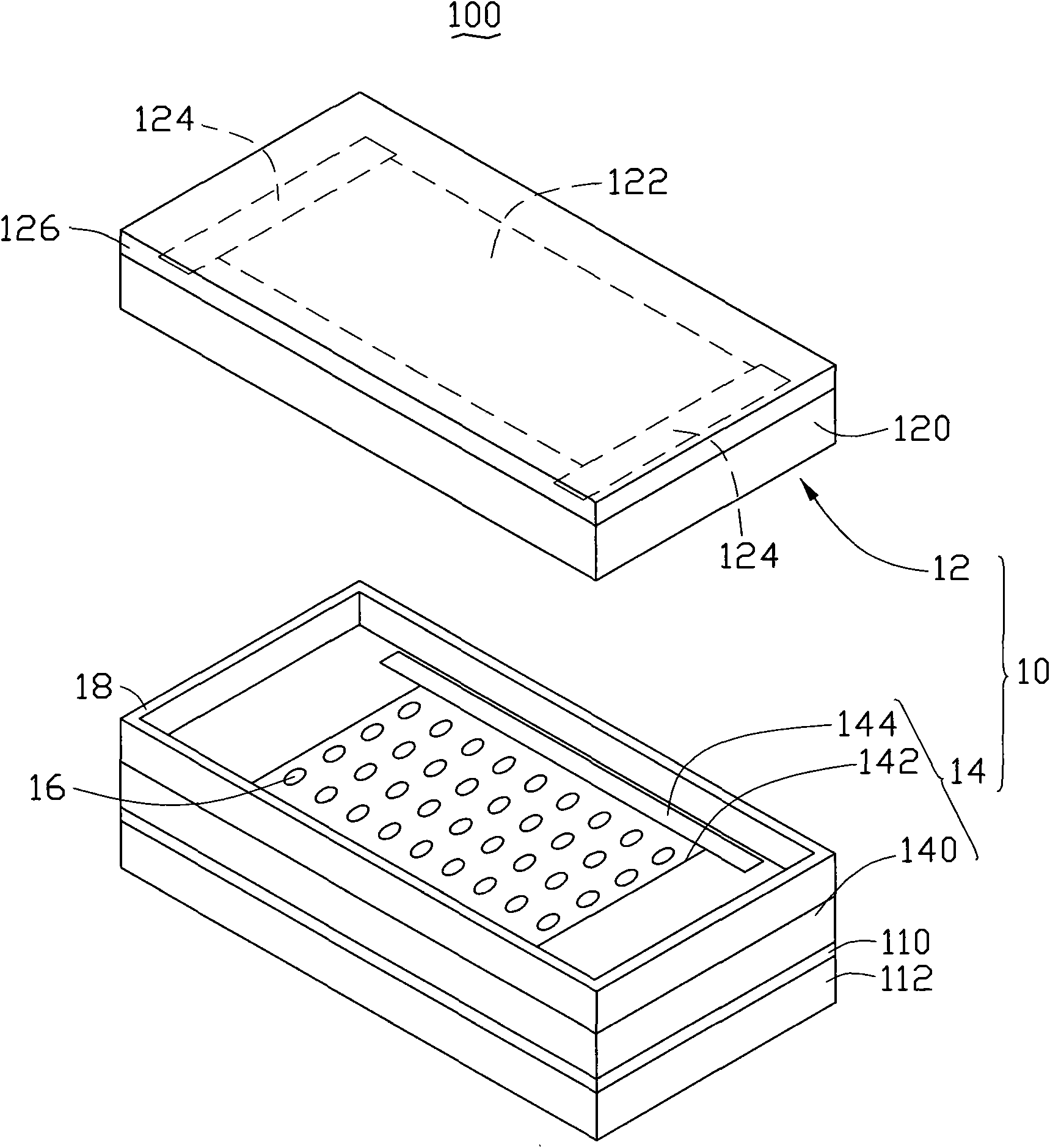

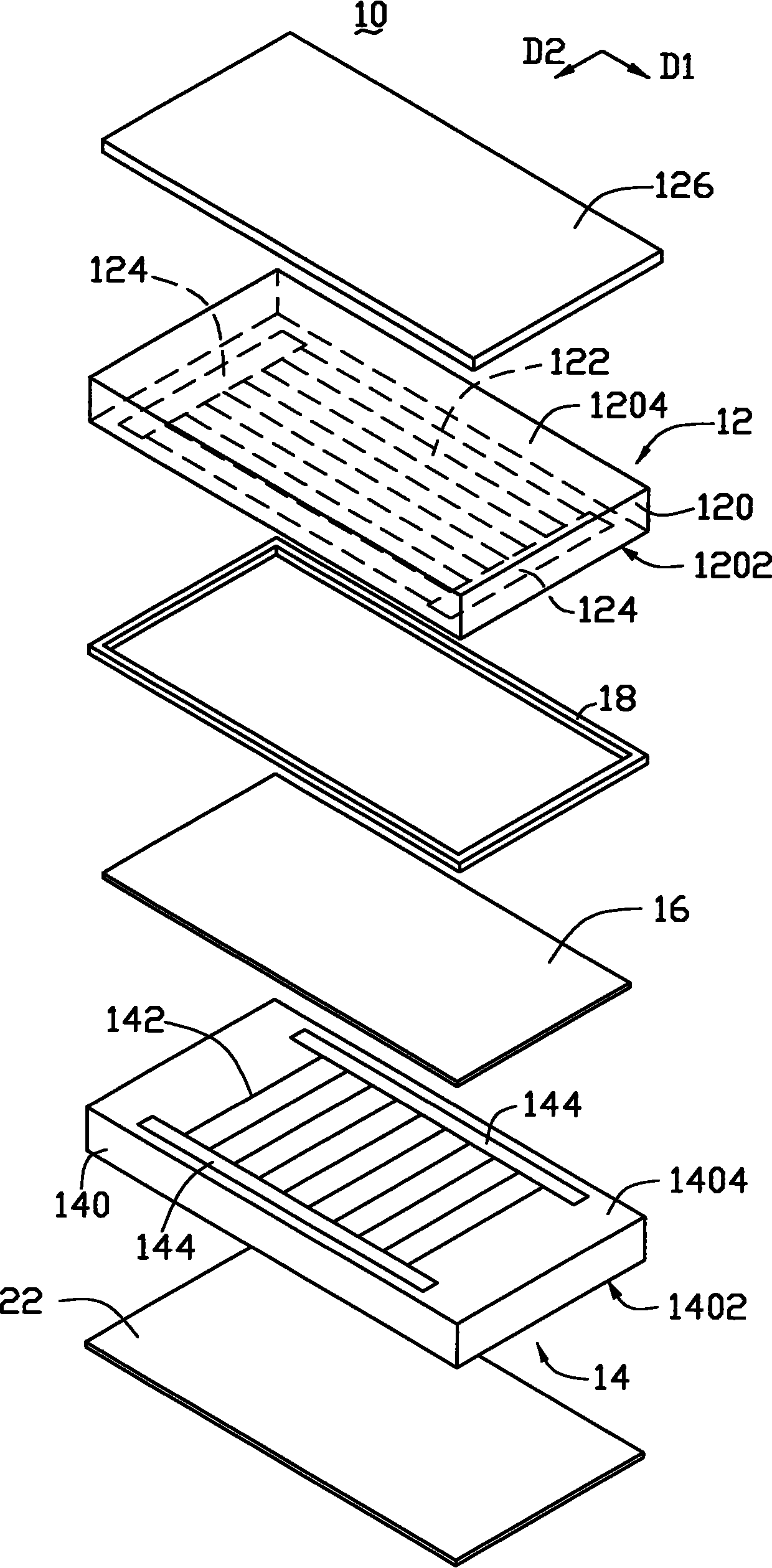

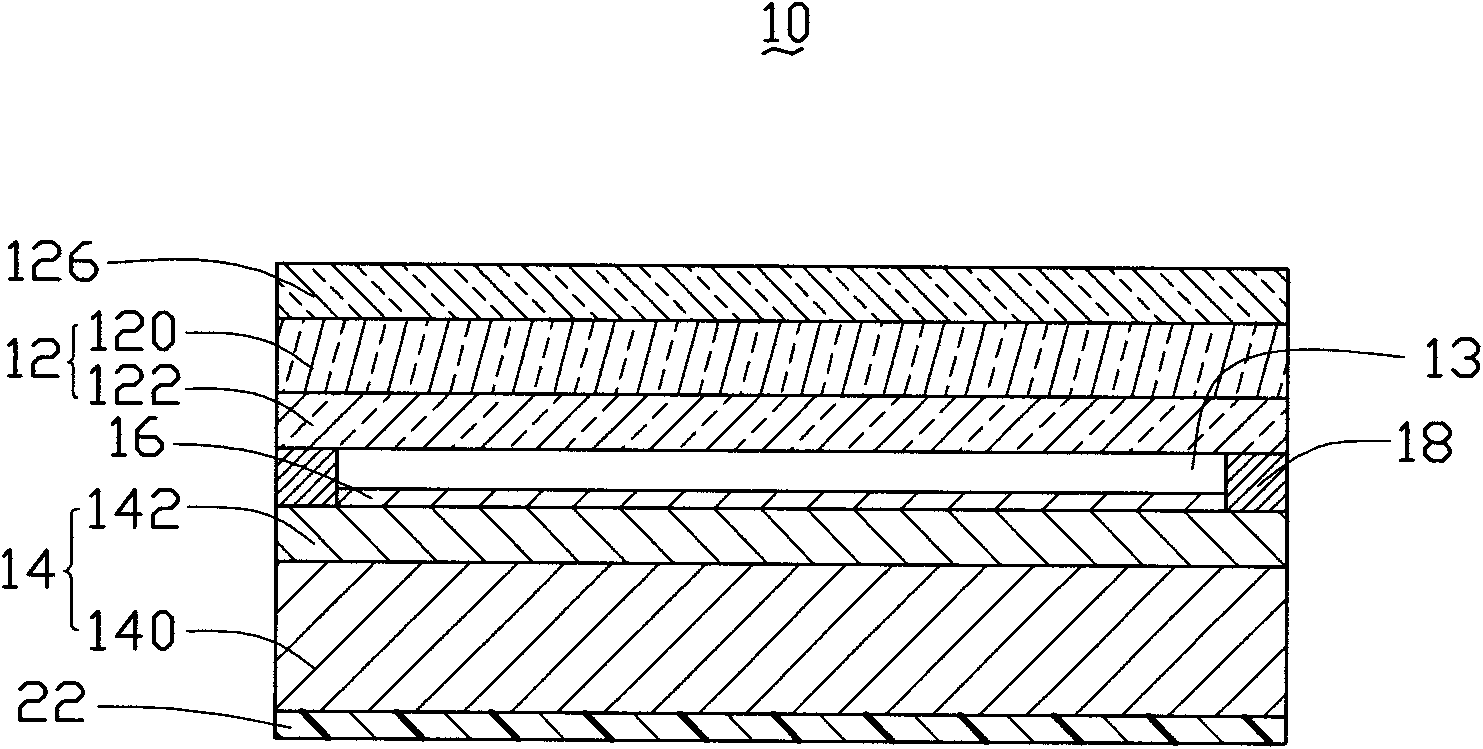

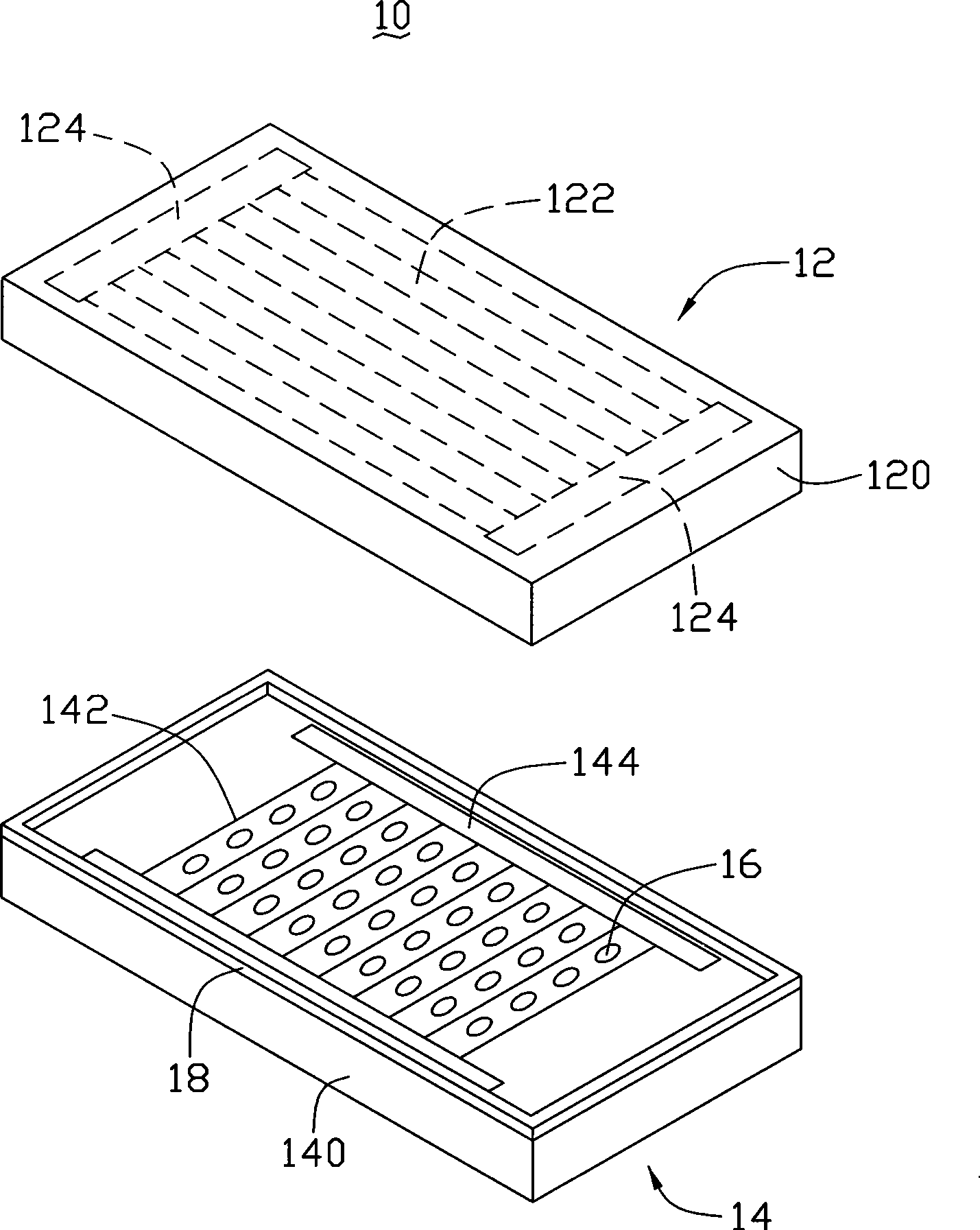

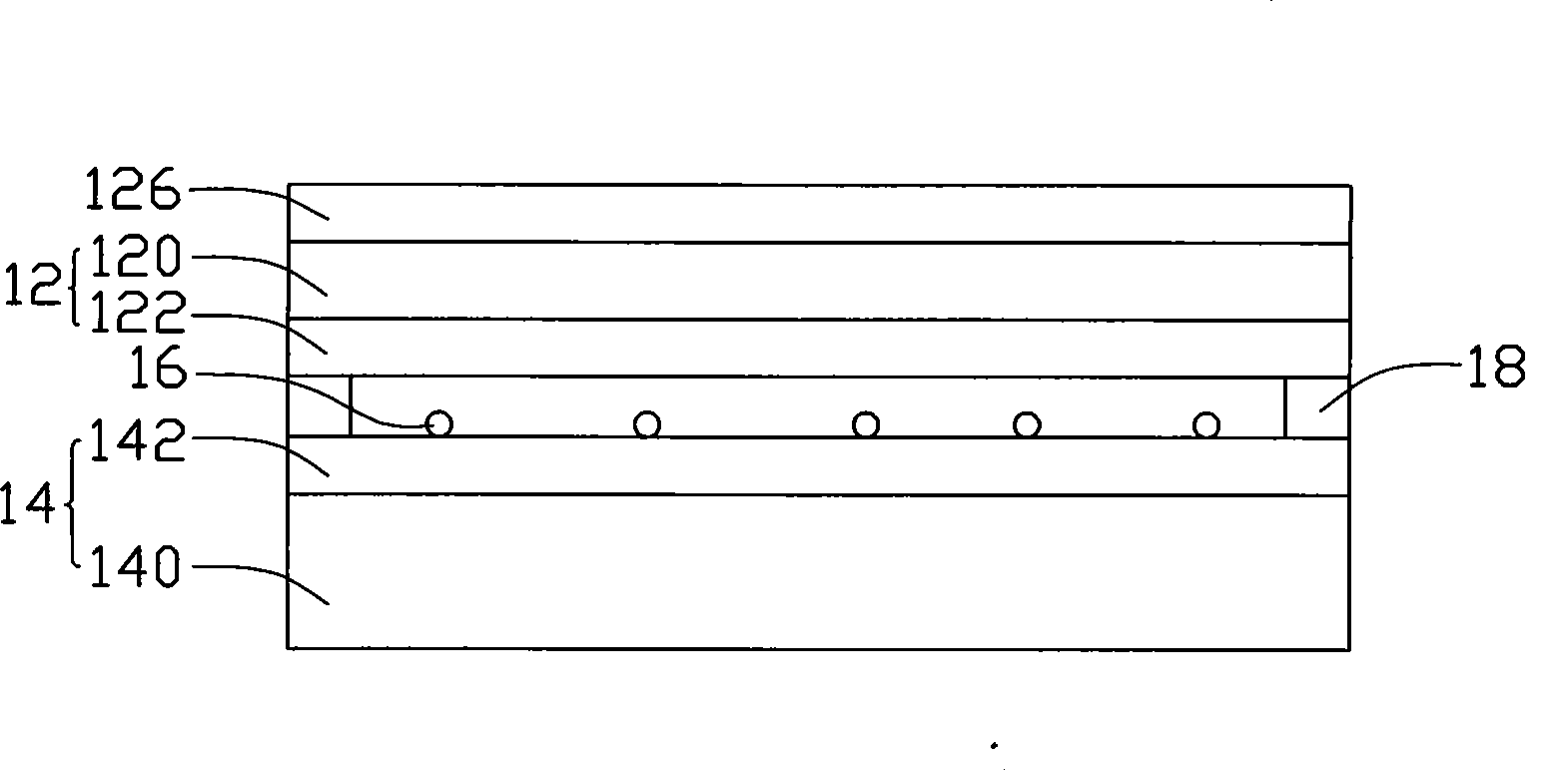

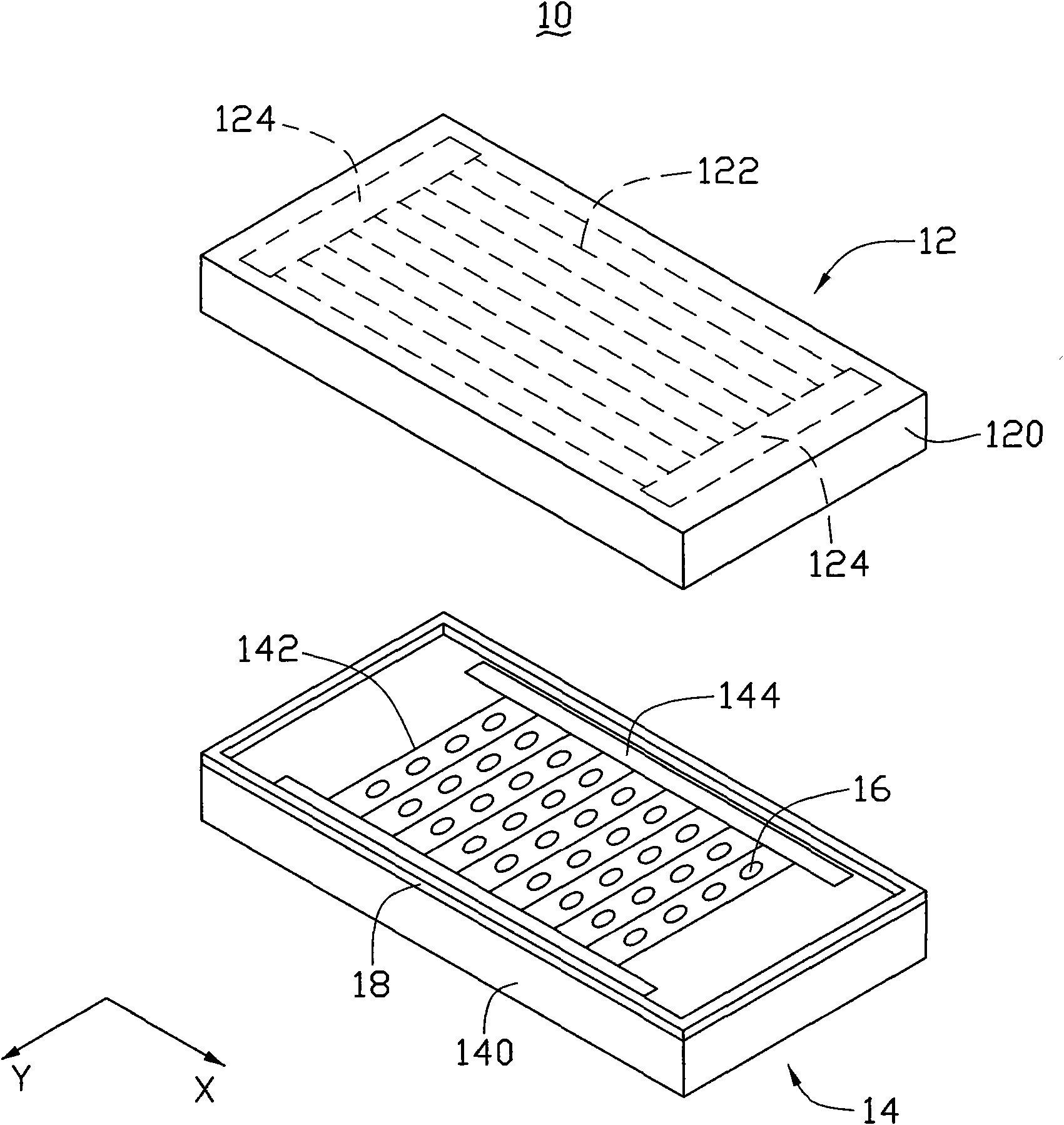

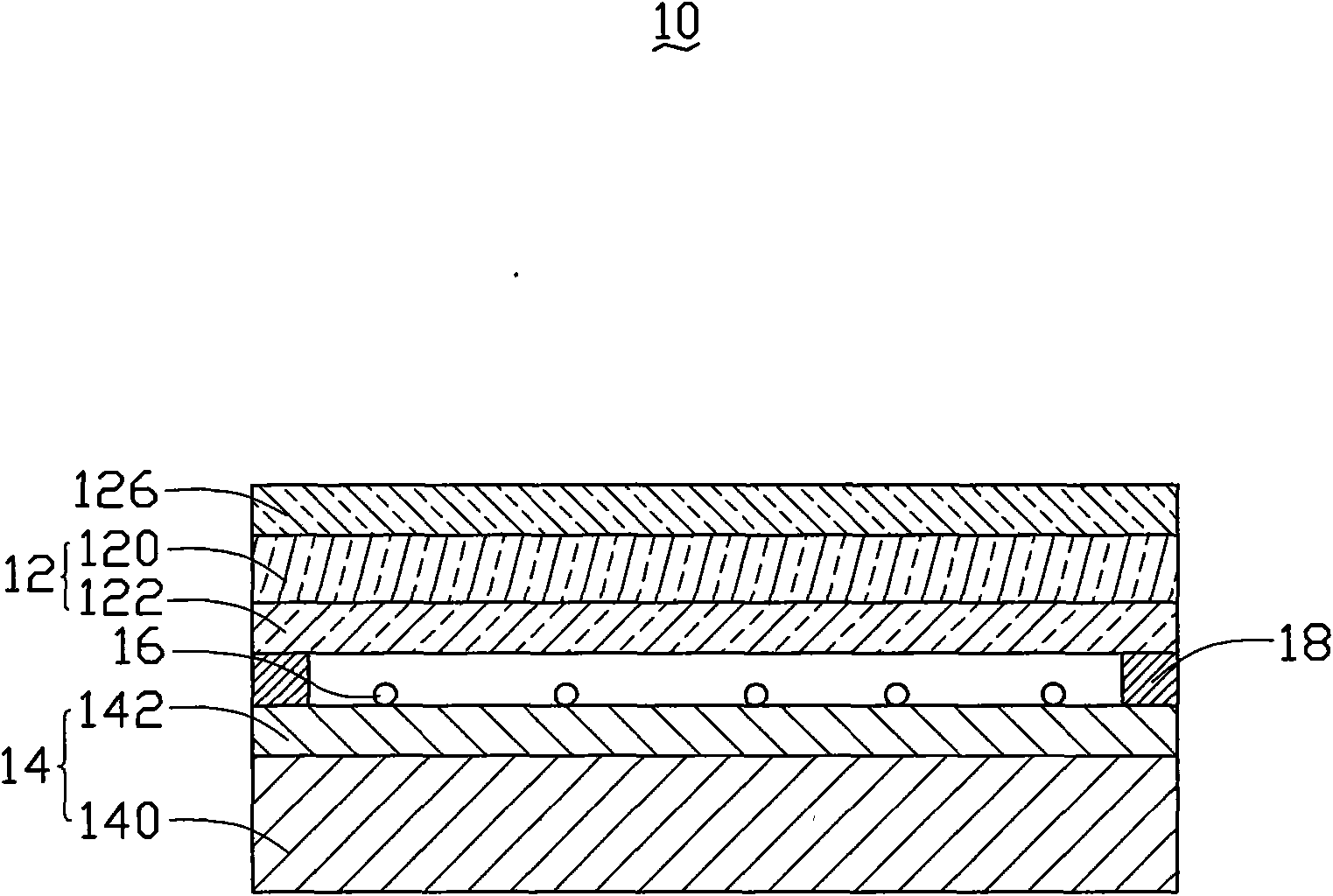

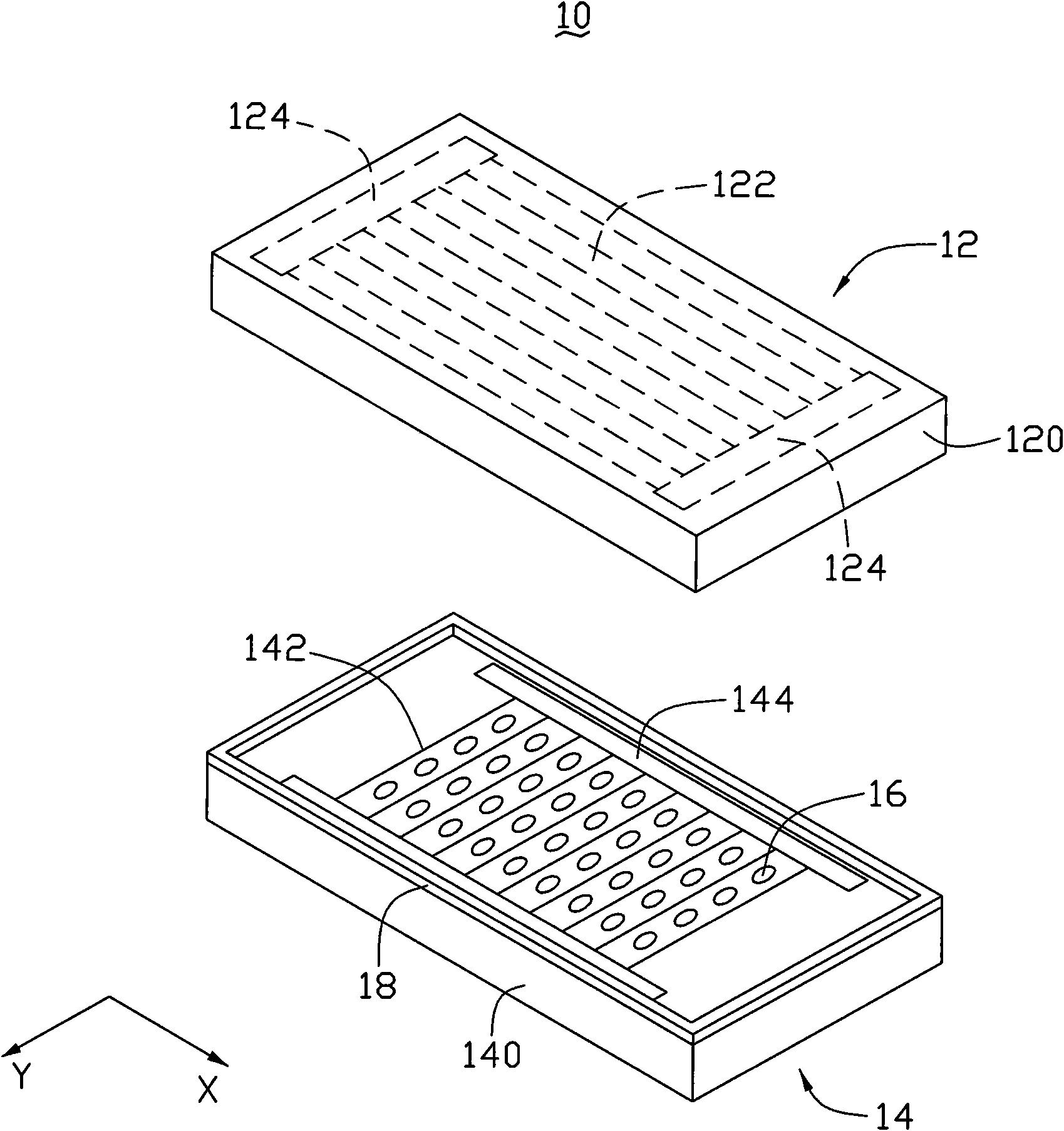

Touch screen and display device

ActiveCN102063213AIncreased durabilityHigh sensitivityAdhesivesInput/output processes for data processingDisplay deviceRefractive index

The invention relates to a touch screen. The touch screen comprises a first electrode plate and a second electrode plate, wherein, the first electrode plate comprises a first transparent conducting layer, the second electrode plate comprises a second transparent conducting layer, and the second transparent conducting layer is oppositely spaced from the first transparent conducting layer; at leastone of the first transparent conducting layer and the second transparent conducting layer is a carbon nanotube layer composed of a plurality of carbon nanotubes, and the carbon nanotubes are arrangedin a preferred orientation manner along the same direction; and a transparent insulator is arranged between a first substrate and a second substrate, and the refractive index of the transparent insulator is greater than that in vacuum. The carbon nanotube layer has the characteristics of lower resistance and good flexibility, and the refractive index of the transparent insulator is greater than that in vacuum, therefore the touch screen has the advantages of better durability, better sensitivity and better accuracy. The invention further provides a display device using the touch screen.

Owner:BEIJING FUNATE INNOVATION TECH

Touch LCD screen

ActiveCN101620328AIncreased durabilityHigh transparencyStatic indicating devicesSolid-state devicesLiquid-crystal displayCarbon nanotube

The invention discloses a touch LCD screen, which comprises an upper substrate, a lower substrate, and a liquid crystal layer, wherein the upper substrate comprises a touch screen; the lower substrate and the upper substrate are oppositely arranged; the lower substrate comprises a thin film transistor panel; the liquid crystal layer is arranged between the upper substrate and the lower substrate; a conducting layer of the touch screen comprises a first carbon nanotube layer; and a semiconductor layer of a thin film transistor on the thin film transistor panel comprises a second carbon nanotube layer.

Owner:TSINGHUA UNIV +1

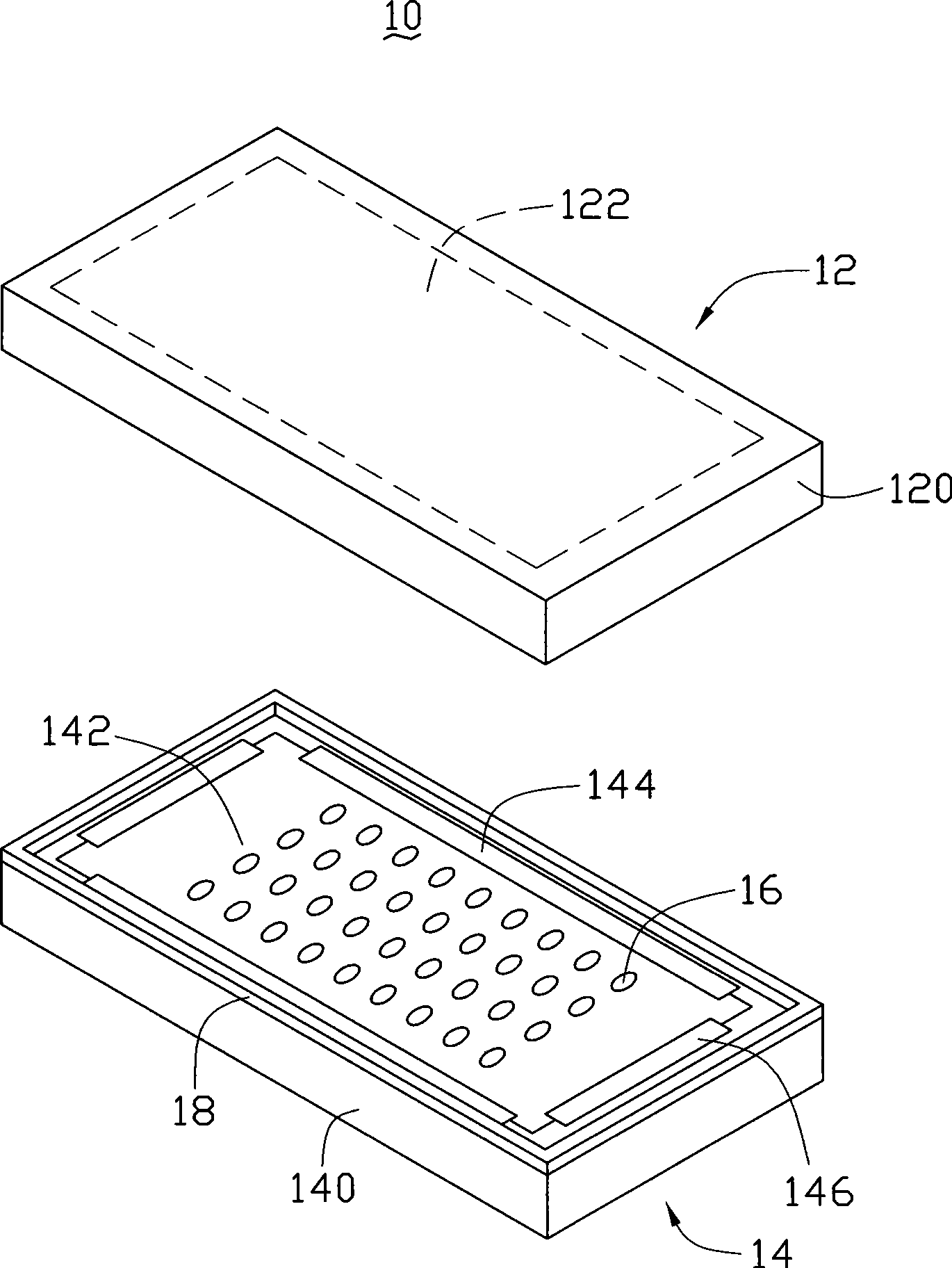

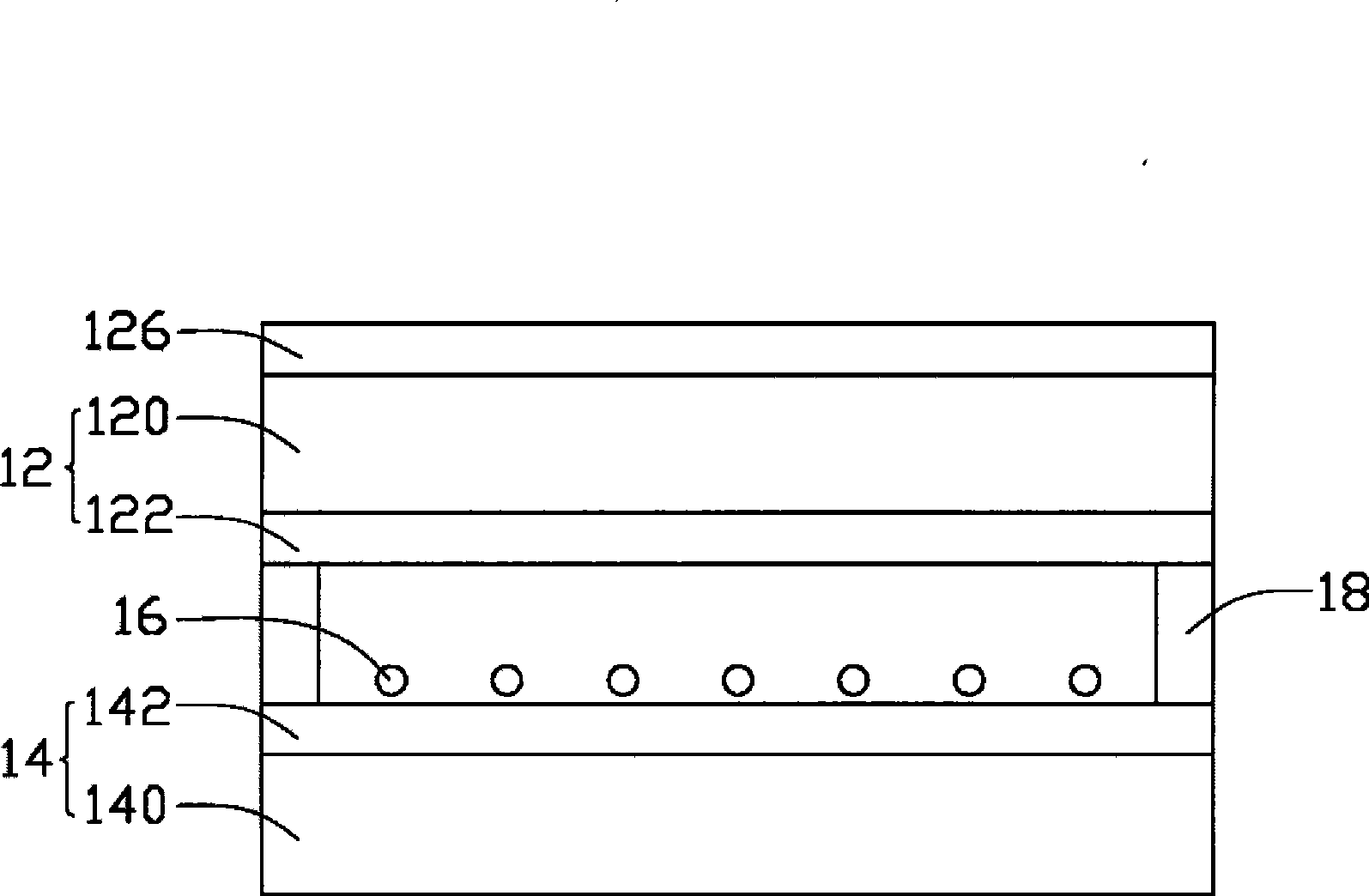

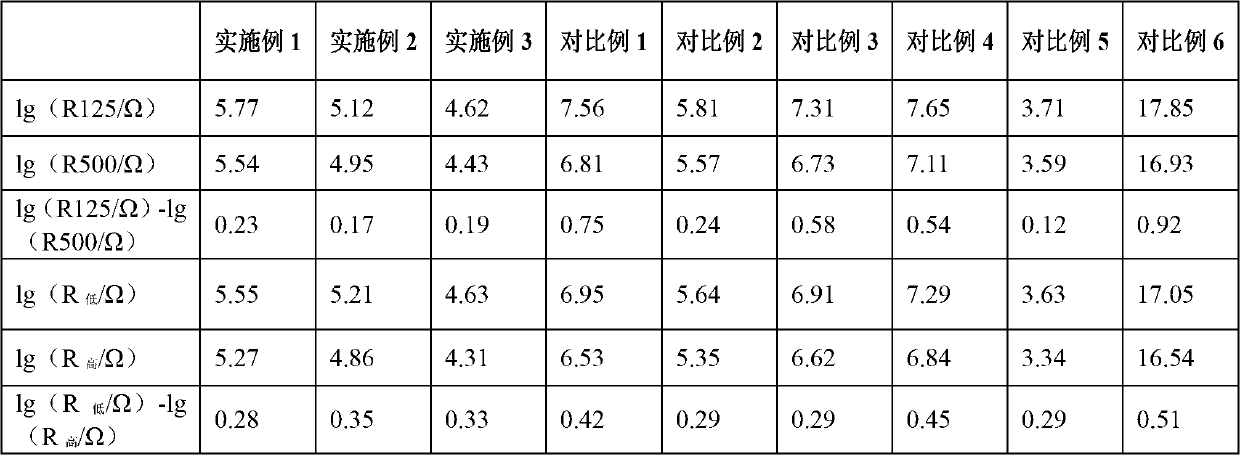

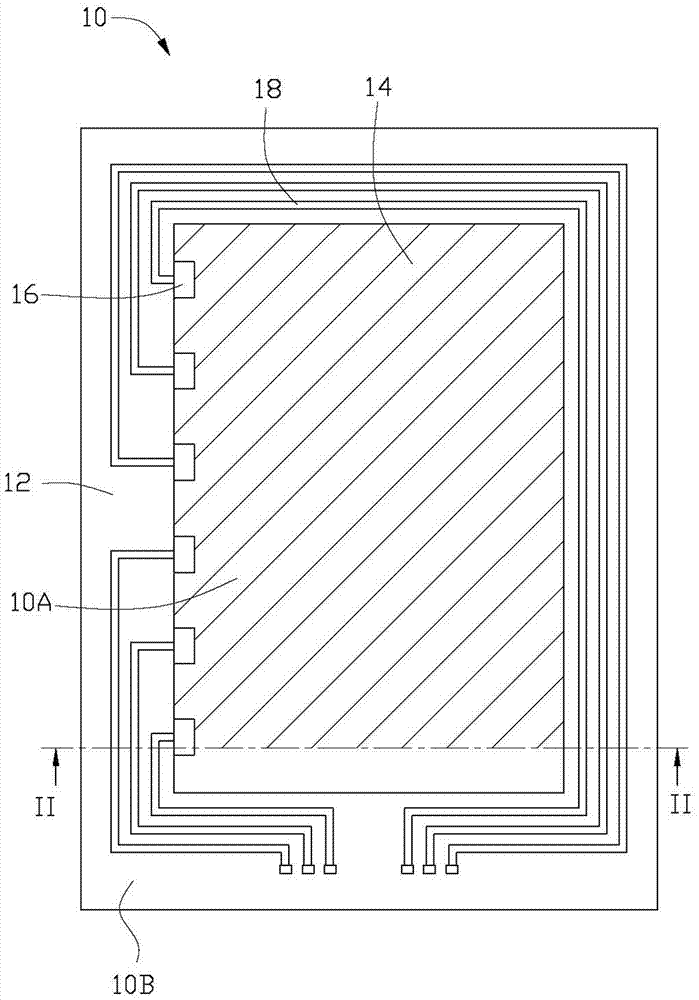

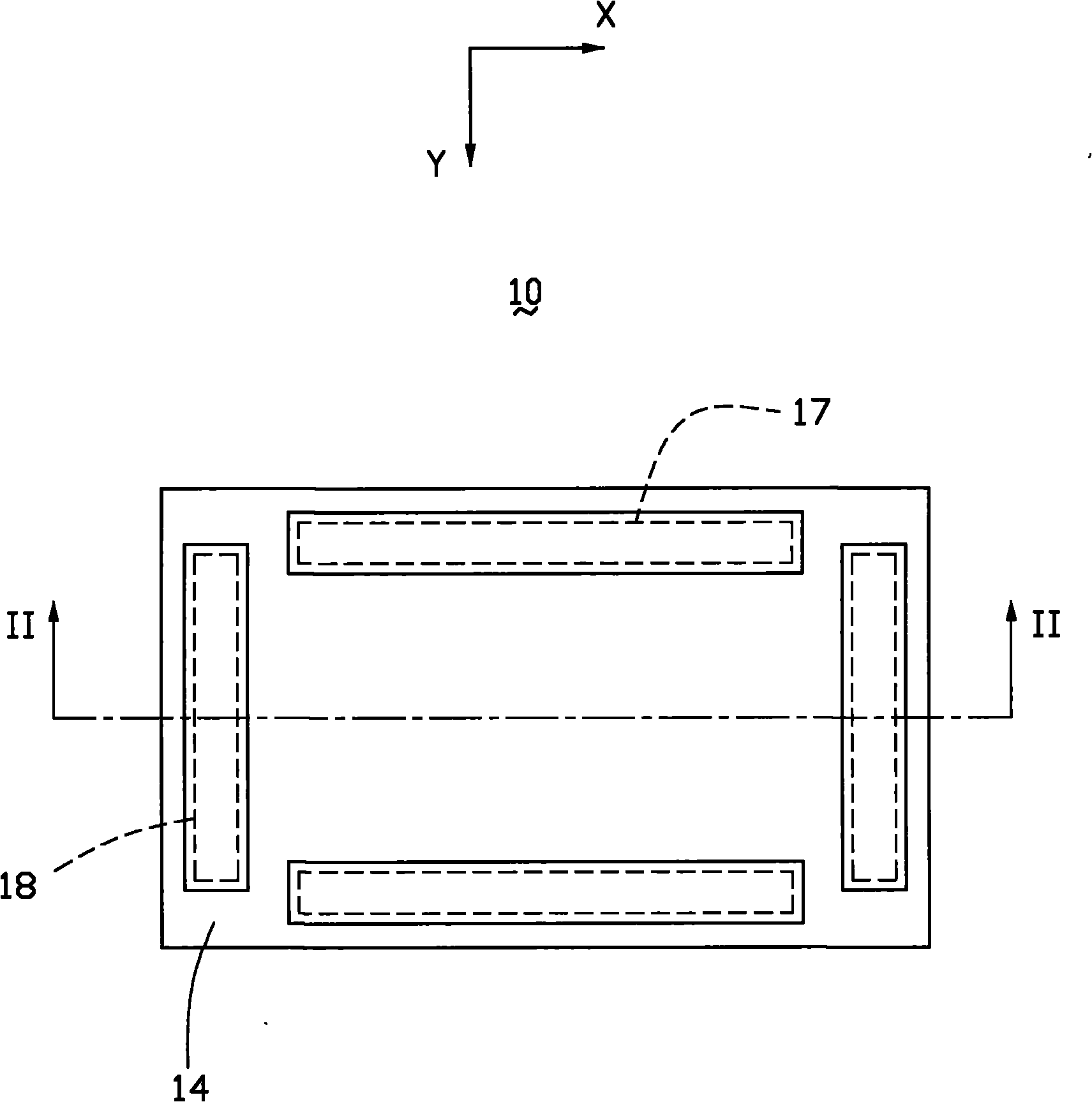

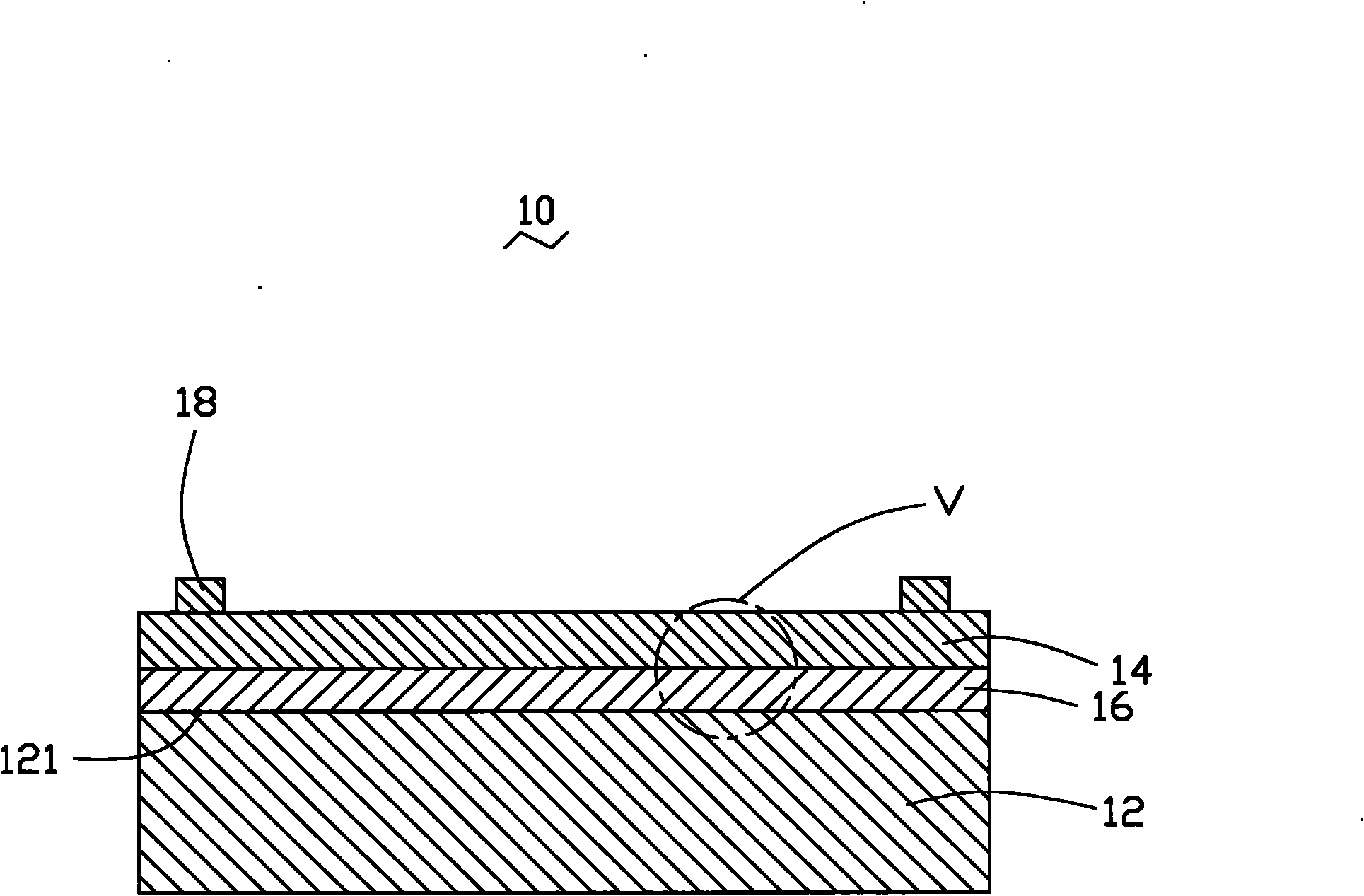

Touch screen and display device

ActiveCN102063214AUniform resistance distributionUniform light transmission effectInput/output processes for data processingCarbon nanotubeDisplay device

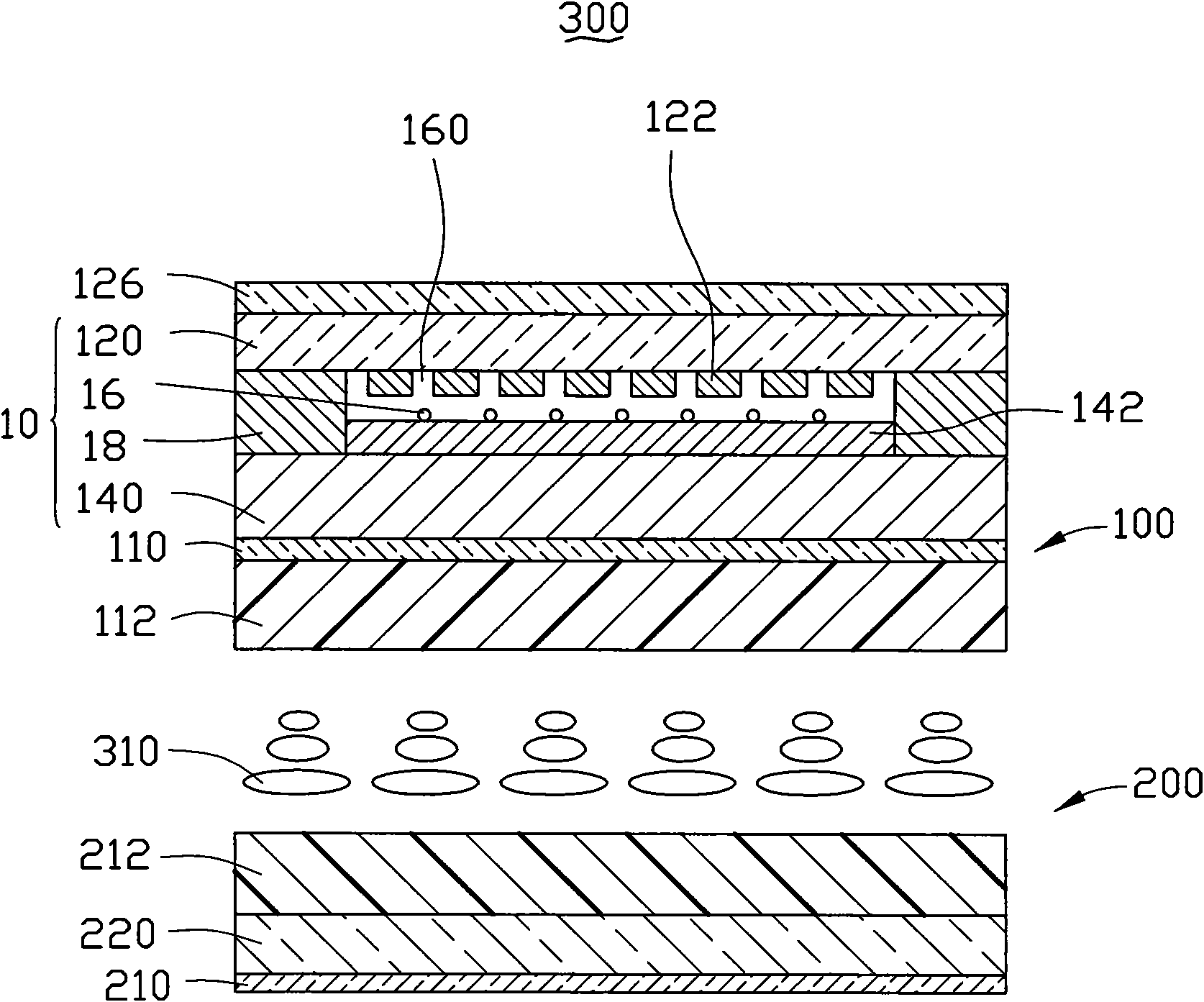

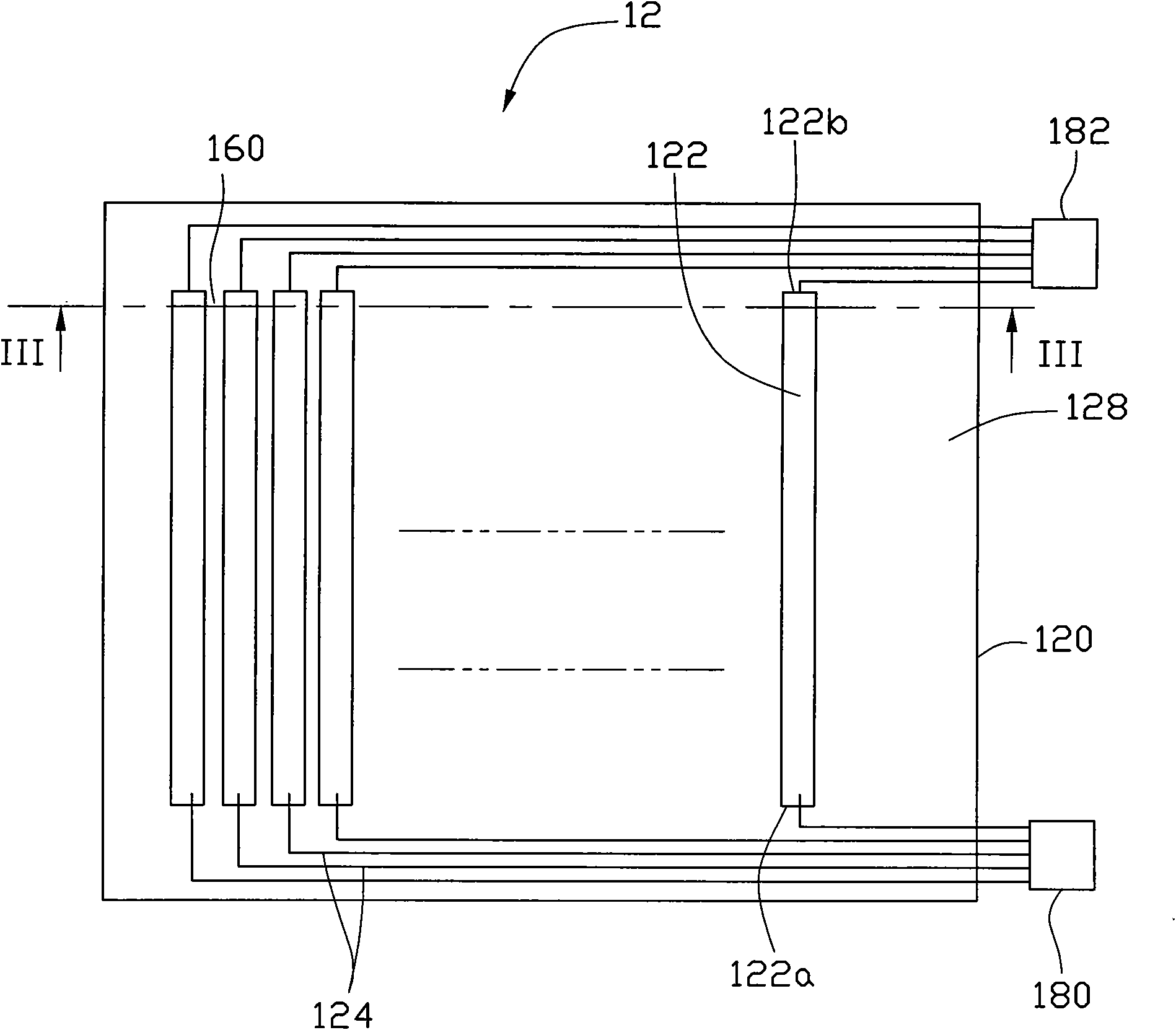

The invention relates to a touch screen and a display device employing the touch screen. The touch screen comprises a first electrode plate and a second electrode plate, wherein the first electrode plate comprises a first substrate, a first conductive layer and two first electrodes; the first conductive layer is arranged on the surface of the first substrate; the two first electrodes are electrically connected with the first conductive layer; the second electrode plate and the first electrode plate are arranged at intervals; the second electrode plate comprises a second substrate, a second conductive layer and two second electrodes; the second conductive layer is arranged on the surface of the second substrate and is opposite to the first conductive layer; and the two second electrodes are electrically connected with the second conductive layer. The touch screen also comprises a transparent insulating layer arranged between the first conductive layer and the second conductive layer; and at least one of the first conductive layer and the second conductive layer comprises a carbon nanotube structure.

Owner:BEIJING FUNATE INNOVATION TECH

Touch screen and display device

ActiveCN101458607AExcellent mechanical propertiesGood toughness strengthMaterial nanotechnologyConductive layers on insulating-supportsCarbon nanotubeDisplay device

Owner:TSINGHUA UNIV +1

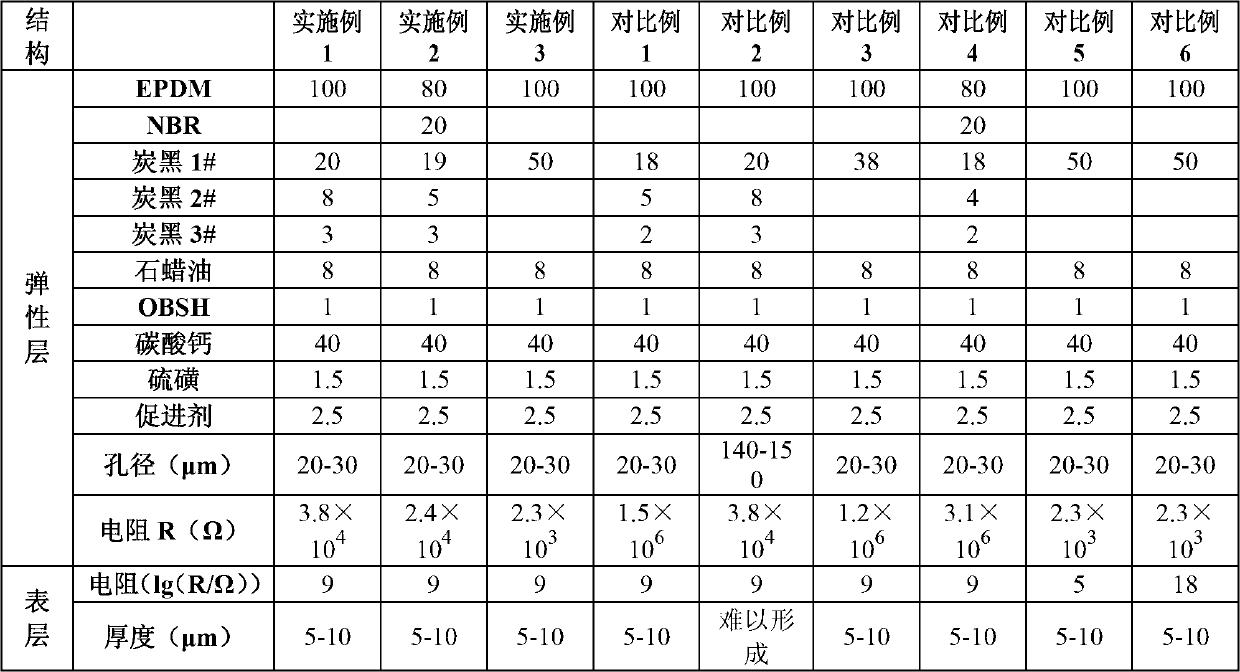

Conductive rubber roller and imaging device

ActiveCN103105761AMeet the resistance value requirementsLow voltage dependencePolyurea/polyurethane coatingsElectrographic process apparatusSurface layerBulk fill

The invention provides a conductive rubber roller. The conductive rubber roller comprises a metal shaft core, an elastic layer packed outside the metal shaft core and a surface layer formed outside the elastic layer, wherein the elastic layer consists of rubber A and at least one of conductive fillers filled in the rubber A; the threshold value range of the conductive fillers in the rubber is as follows: a conductive filler valve is greater than or equal to Zb and is less than or equal to Yb; and b / Yb+c / Yc+...q / Yx is greater than or equal to 1 if the filling fractions of the conductive fillers B, C,...X in the rubber A are respectively set to be b, c,...q. According to the conductive rubber roller provided by the invention, the filling number of the conductive fillers of the elastic layer is limited, and an integral resistance value of the rubber roller is adjusted according to the resistance difference between an inner layer structure and an outer structure layer, so that the conductive rubber roller is less in dependency to voltage, and is less fluctuated by the environment change, the resistance is even in distribution, and the increase of the rigidity of the rubber roller since a mass of the conductive fillers are filled into the elastic layer can be avoided; and therefore, not only can the cost of the material be reduced, but also the whole flexibility of the rubber roller can be guaranteed. The invention further discloses an imaging device which comprises the conductive rubber roller.

Owner:SHENZHEN LEPUTAI TECH CO LTD

Touch screen panel

InactiveCN102819336AIncreased durabilityHigh sensitivityInput/output processes for data processingCarbon nanotubeEngineering

The invention relates to a touch screen panel. The touch screen panel is defined into two areas, namely a touch area and a routing area; the touch screen panel comprises an insulated base with a surface, an adhesive layer, a transparent conductive layer, at least one electrode, and a conductive circuit, wherein the adhesive layer is arranged on the surface of the insulated base; the transparent conductive layer comprises a carbon nano tube layer and is fixed on the surface of the insulated base through the adhesive layer; at least one electrode is electrically connected with the transparent conductive layer; the conductive circuit is electrically connected with the at least one electrode; the transparent conductive layer is just arranged on the touch area; the conductive circuit is just arranged on the surface of the adhesive layer in the routing area, and the touch screen panel further comprises a carbon nano tube wire arranged between the conductive circuit and the adhesive layer.

Owner:TIANJIN FUNA YUANCHUANG TECH +1

Polytetrafluoroethylene (PTFE) base electrothermal thick film and manufacturing method thereof

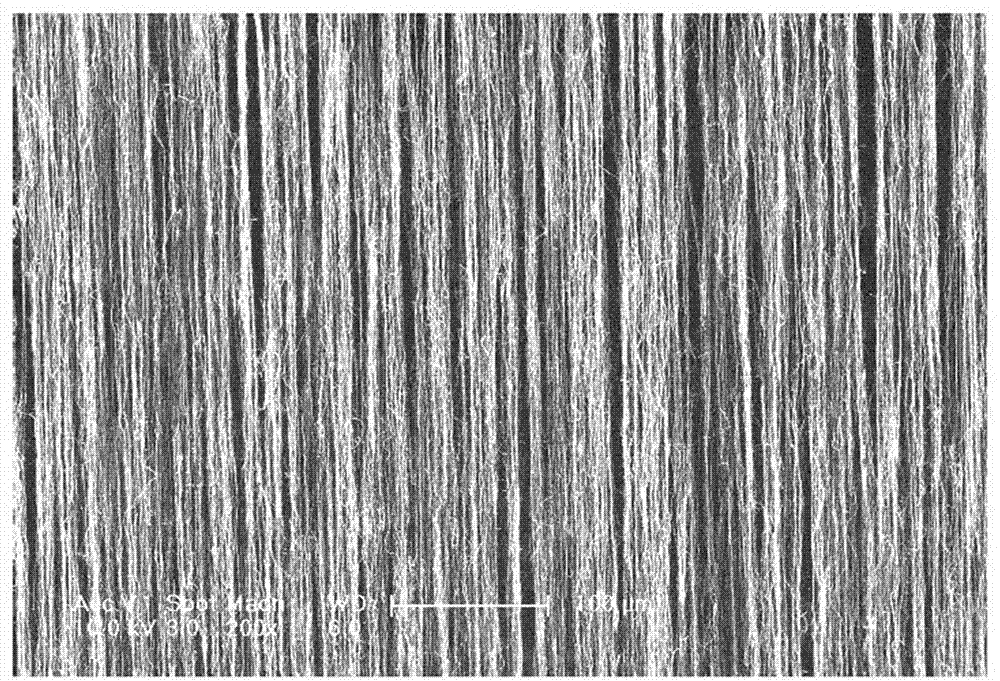

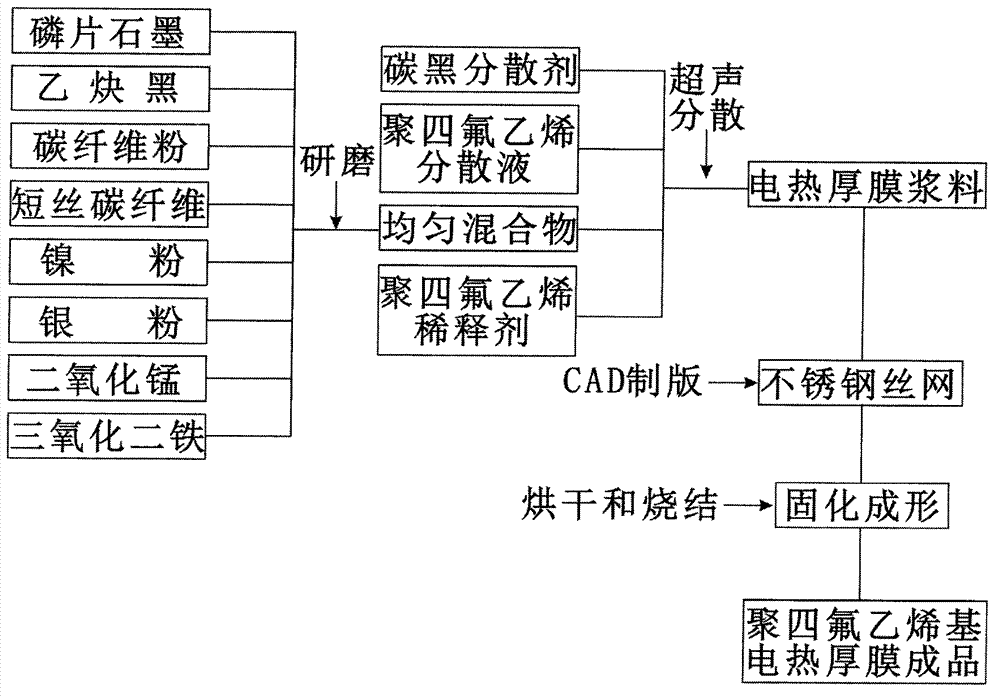

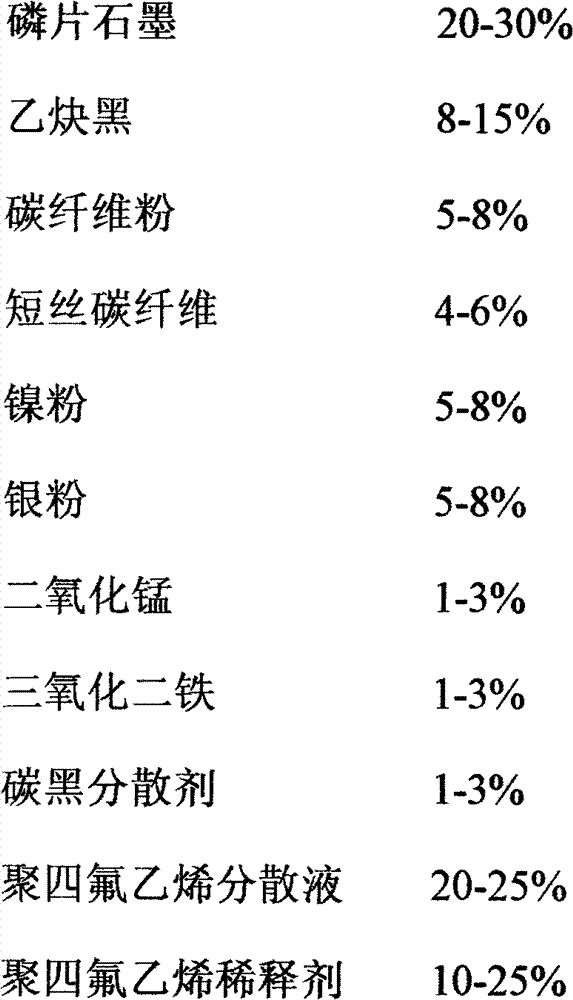

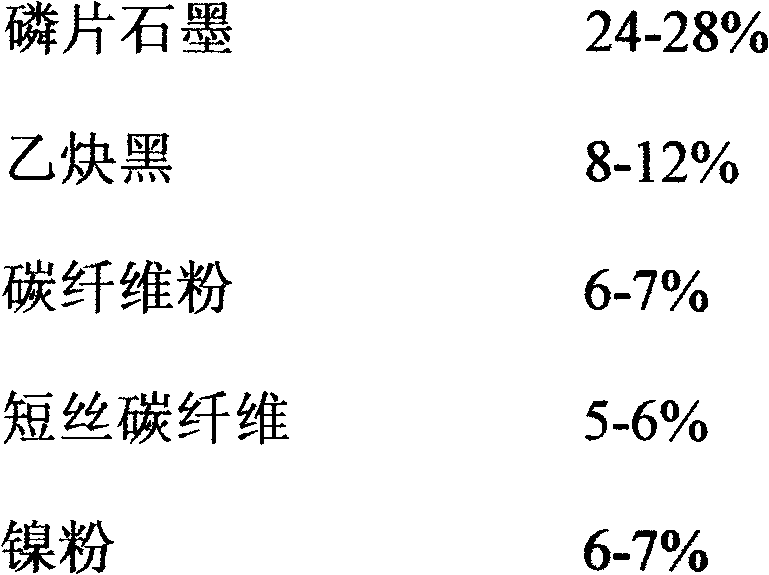

The invention discloses a polytetrafluoroethylene (PTFE) base electrothermal thick film, comprising the following materials according to percentage by weight: 20-30% of flake graphite, 8-15% of acetylene black, 5-8% of carbon fiber powder, 4-6% of short carbon fiber, 5-8% of nickel powder, 5-8% of silver powder, 1-3% of manganese dioxide, 1-3% of iron sesquioxide, 1-3% of carbon black dispersant, 20-25% of PTFE dispersion liquid and 10-25% of PTFE diluent. The invention also discloses a manufacturing method of the PTFE base thick film, comprising the steps of grinding and uniformly mixing the flake graphite, the acetylene black, the carbon fiber powder, the short carbon fiber, the nickel powder, the silver powder, the manganese dioxide and the iron sesquioxide according to the proportion, mixing and ultrasonically dispersing the mixture, the carbon black dispersant, the PTFE dispersion liquid and the PTFE diluent according to the proportion to prepare a electrothermal thick film paste, and drying and sintering the electrothermal thick film paste, after a through printing process so as to manufacture the PTFE base electrothermal thick film. The manufacturing method provided by the invention is applicable to high-voltage electrothermal equipment, good in stability and using effect, and is not demoulded.

Owner:CIXI SOVONO ELECTRIC APPLIANCE

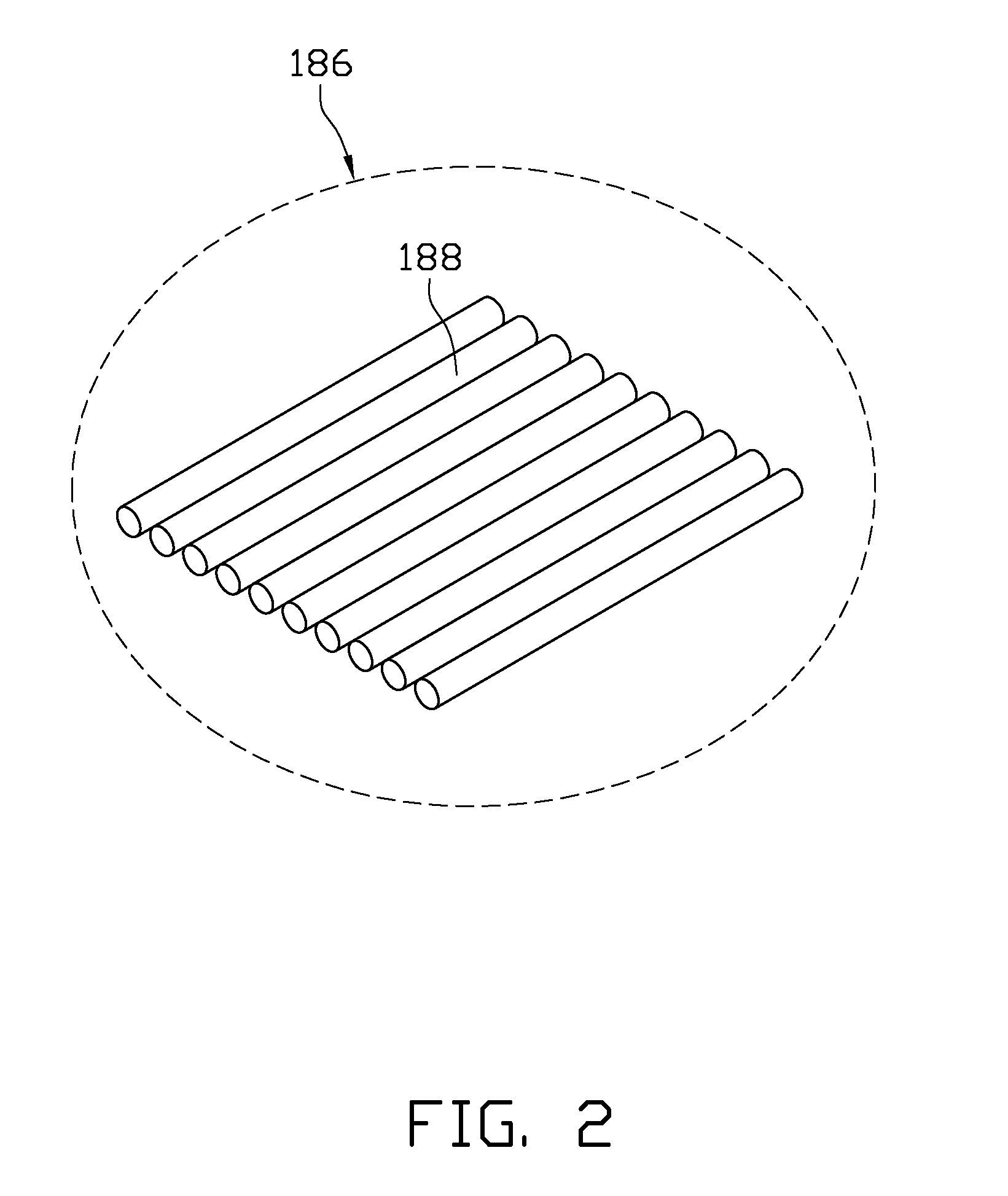

Touch screen and display equipment

ActiveCN101464764AIncreased durabilityHigh resolutionLayered productsIndividual molecule manipulationCarbon nanotubeTouchscreen

The invention relates to a touch screen, which includes a first electrode plate and a second electrode plate, wherein, the first electrode plate includes a first matrix and a first conducting layer arranged on the lower surface of the first matrix; the second electrode plate and the first electrode plate are arranged at internals; the second electrode plate includes a second matrix and a second conducting layer arranged on the upper surface of the second matrix; and at least one of the first conducting layer and the second conducting layer includes a plurality of parallel carbon nano tube long lines arranged at internals. The invention further relates to a display unit using the touch screen, which includes the touch screen and display equipment.

Owner:TSINGHUA UNIV +1

Novel nano-carbon-fiber heating floor and preparation method thereof

ActiveCN105155815AImprove conductivityHigh strengthLighting and heating apparatusElectric heating systemCarbon fibersInsulation layer

The invention provides a novel nano-carbon-fiber heating floor and a preparation method thereof. The preparation method comprises the following steps: (1) placing nano polyacrylonitrile fibers prepared by electrostatic spinning in a roasting oven, performing heat treatment by using air as a medium, and performing carbonization treatment under nitrogen environment so as to obtain carbonized nano polyacrylonitrile fibers; (2) stirring plant protoplasm fibers and a cationic surface active agent under a closed condition and normal temperature till a uniform mixture is obtained, adding the carbonized nano polyacrylonitrile fibers and nano graphite powder in the mixture, stirring the carbonized nano polyacrylonitrile fibers, the nano graphite powder and the mixture at a high speed, and preparing sheet type flexible macromolecule materials by a hot-pressing technology; (3) fixing metal-sheet electrodes at both ends of the sheet type flexible macromolecule materials by a silver solution so as to form a conductive heating layer; and (4) shearing a solid-wood layer, an insulation layer, the conductive heating layer, a temperature control layer, another solid-wood layer and a surface treatment layer with appropriate sizes from bottom to top, and performing combination so as to form the nano-carbon-fiber heating floor.

Owner:浙江康辉木业有限公司

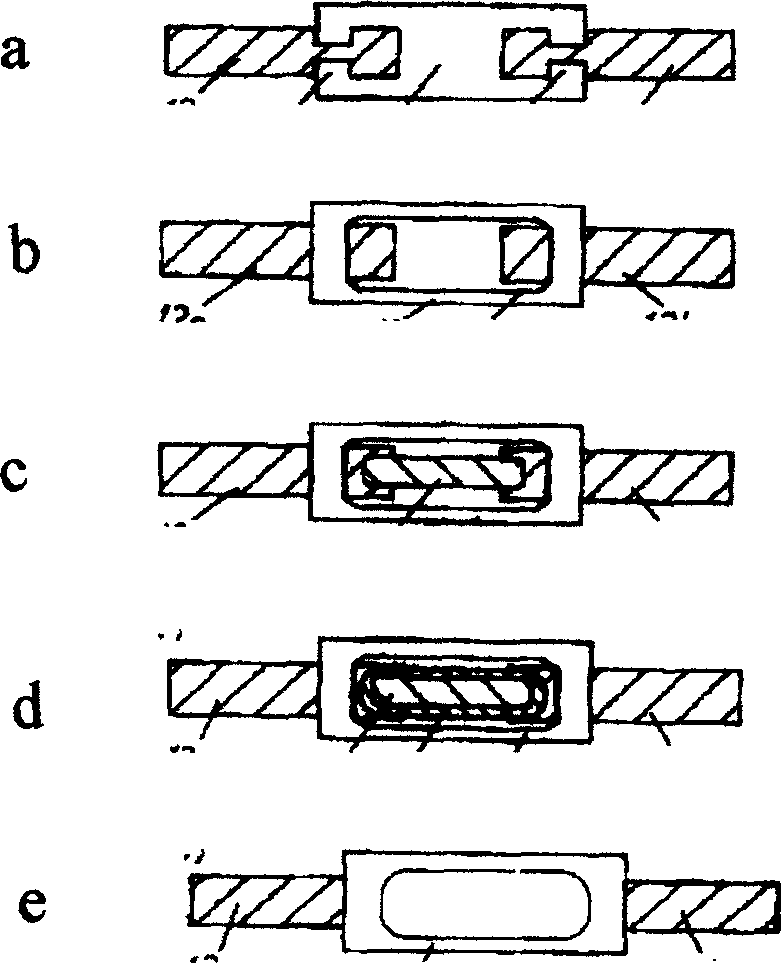

Method for mfg. alloy type temp fuse

InactiveCN1591729AUniform resistance distributionImprove continuityHeating/cooling contact switchesEmergency protective devicesRoom temperatureAlloy

The persent invention relates to an alloy type temperature fuse and its production method. Said temperature fuse consists of plastic lower film, electrode connecting sheet, fusible alloy wire and plastic upper film. Its production method includes the following steps: hot-pressing the electrode connecting sheet on the plastic lower film, spot-welding low fusion point alloy wire on opposite two ends of two electrode connecting sheets and adding flux, finally covering it and hot-pressing plastic upper film. It is characterized by that when the low fusion point alloy wire is welded on opposite two end points of two electrode connecting sheets, said invention adopts cold-pressure welding method, i.e. does not heat low fusion alloy wire and does not adopt fusion welding mode, the low fusion alloy wire can be directly pressed on the surface of end portion of electrode connecting sheet under the room temperature or temperature below alloy fusion point.

Owner:BYD CO LTD

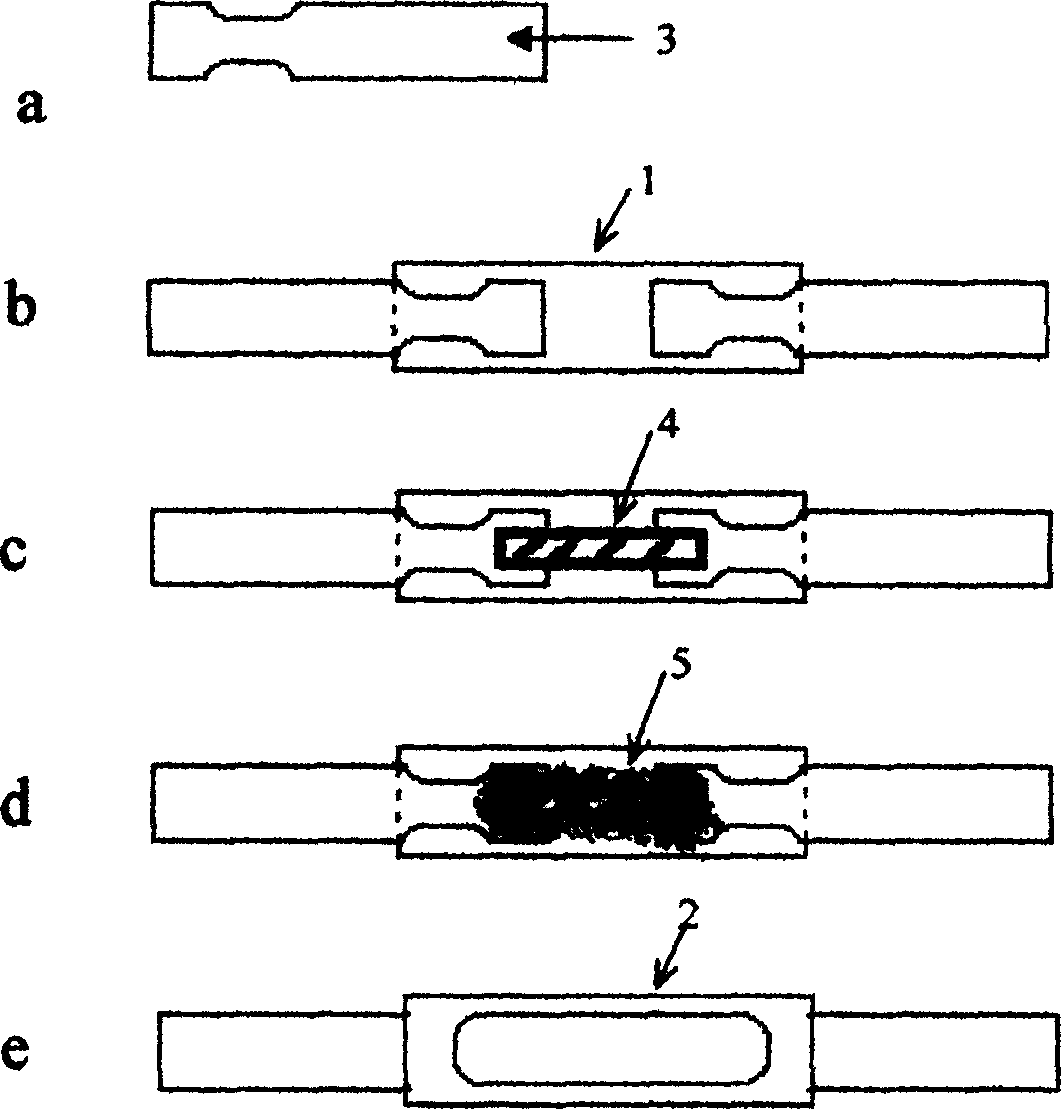

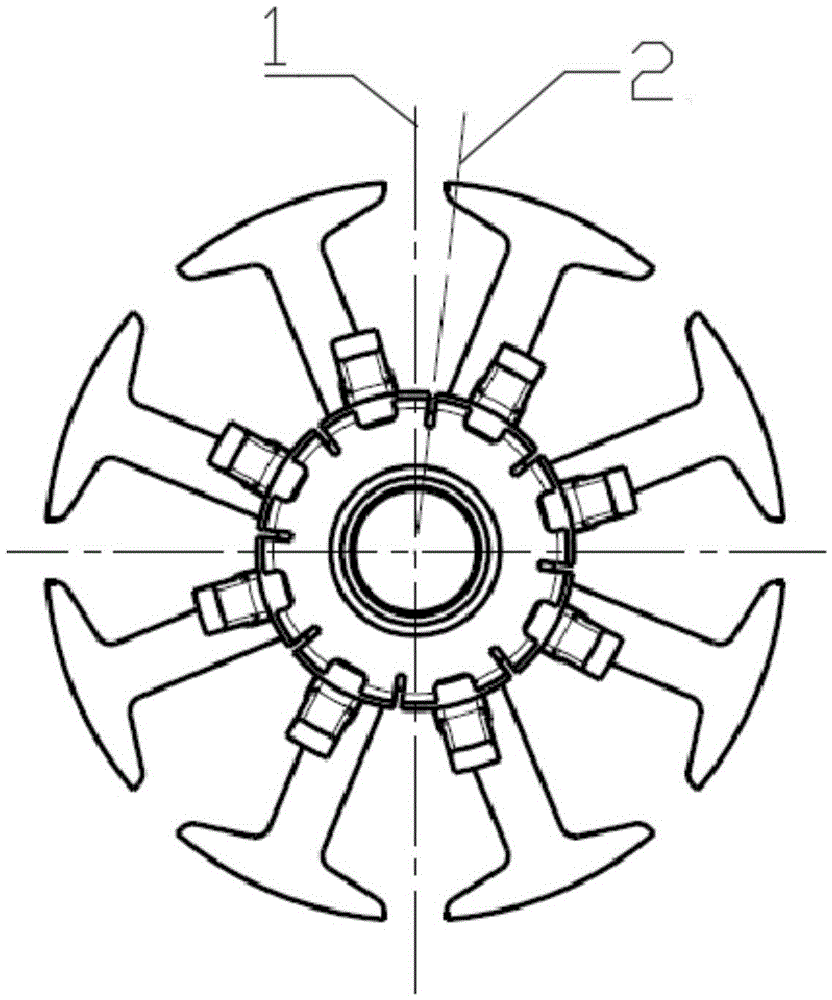

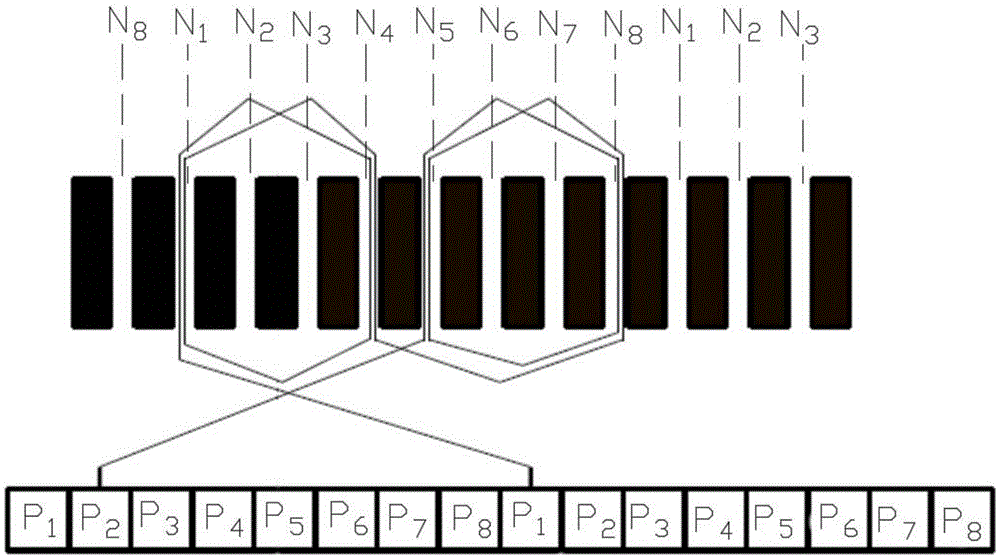

Motor rotor winding method

ActiveCN105634219ASmall stall torque deviationReduce energy lossManufacturing dynamo-electric machinesElectric machineMagnetic poles

The invention discloses a motor rotor winding method, which comprises a rotor rotating shaft, an insulating sleeve and a coil, wherein the insulating sleeve and the coil sleeve the rotor rotating shaft; the insulating sleeve is sequentially sleeved with a commutator and a winding skeleton; a magnetic pole group is arranged on the outer side surface of the winding skeleton; eight line through grooves are sequentially arranged on the winding skeleton along the circumference; the line through grooves are sequentially numbered N1, N2, N3, N4, N5, N6, N7 and N8 along the circumference; the commutator is sequentially provided with eight brass hooks along the circumference; the brass hooks are sequentially numbered P1, P2, P3, P4, P5, P6, P7 and P8 along the circumference; an included angles between the central line of an armature stack and the central line of the corresponding commutator is 4.5-8.5 degrees; the central line of the commutator is close to a left pole end of a rotor. By double groove-crossing, double groove-crossing is required for each winding of each hook, so that the resistance of a motor rotor winding is evenly distributed; the stalling torque deviation of the motor is relatively small; the energy loss of the motor is reduced; and the service lifetime of the motor is prolonged.

Owner:HAIAN LIANKE AUTOMOBILE PARTS

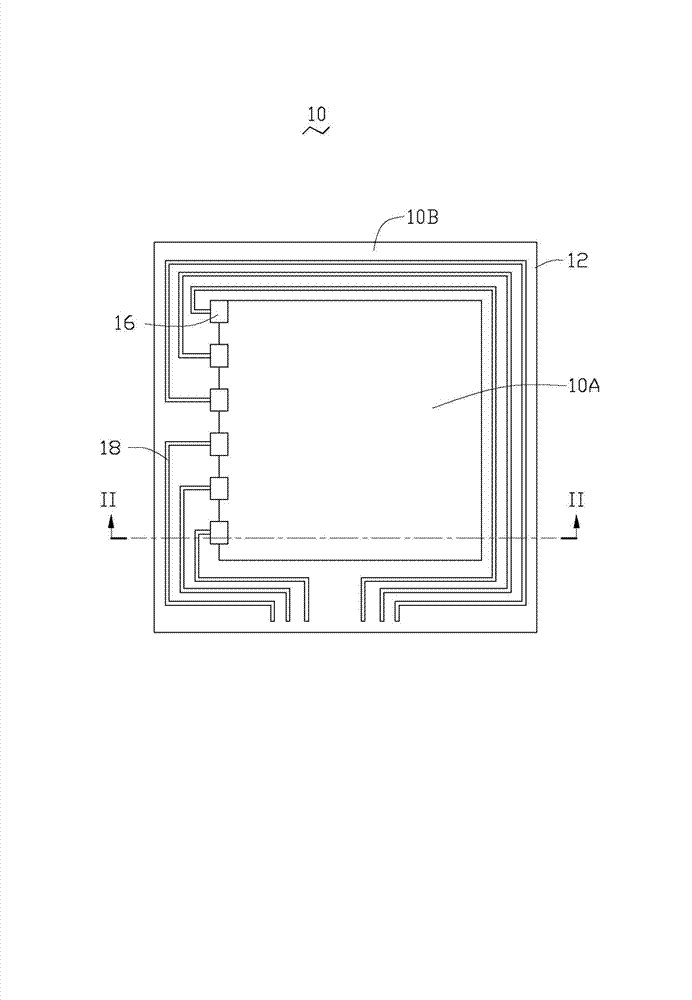

Touch screen and display device

ActiveCN101930305AIncreased durabilityHigh resolutionLayered productsInput/output processes for data processingDisplay deviceCarbon nanotube

The invention relates to a touch screen and a display device using the same. The touch screen comprises a first electrode plate and a second electrode plate, wherein the first electrode plate comprises a first matrix and two first electrodes; the second electrode plate comprises a second matrix and two second electrodes; the first electrode plate further comprises a plurality of first carbon nano pipe structures arranged on the surface of the first matrix at intervals, two ends of each first carbon nano pipe structure are respectively electrically connected with the two first electrodes; the second electrode plate further comprises a plurality of second carbon nano pipe structures arranged on the surface of the second matrix at intervals, two ends of each second carbon nano pipe structure are respectively electrically connected with the two second electrode, and the second carbon nano pipe structures are arranged opposite to the first carbon nano pipe structures.

Owner:TSINGHUA UNIV +1

Touch screen panel and touch screen

InactiveCN102819366AIncreased durabilityHigh sensitivityInput/output processes for data processingCarbon nanotubeElectrical and Electronics engineering

The invention relates to a touch screen panel. Two areas including a touch area and a routing area are defined on the touch screen panel. The touch screen panel comprises an insulating substrate, a transparent conductive layer, at least one electrode and a conductive circuit, wherein the insulating substrate is provided with a surface; the transparent conductive layer comprises a carbon nano tube layer; the electrodes are electrically connected with the transparent conductive layer; the conductive circuit is connected with the electrodes; the transparent conductive layer is only arranged on a portion, which is positioned on the touch area, of the surface of the insulating substrate; and the conductive circuit is only arranged on a portion, which is positioned on the routing area, of the surface of the insulating substrate.

Owner:TIANJIN FUNA YUANCHUANG TECH +1

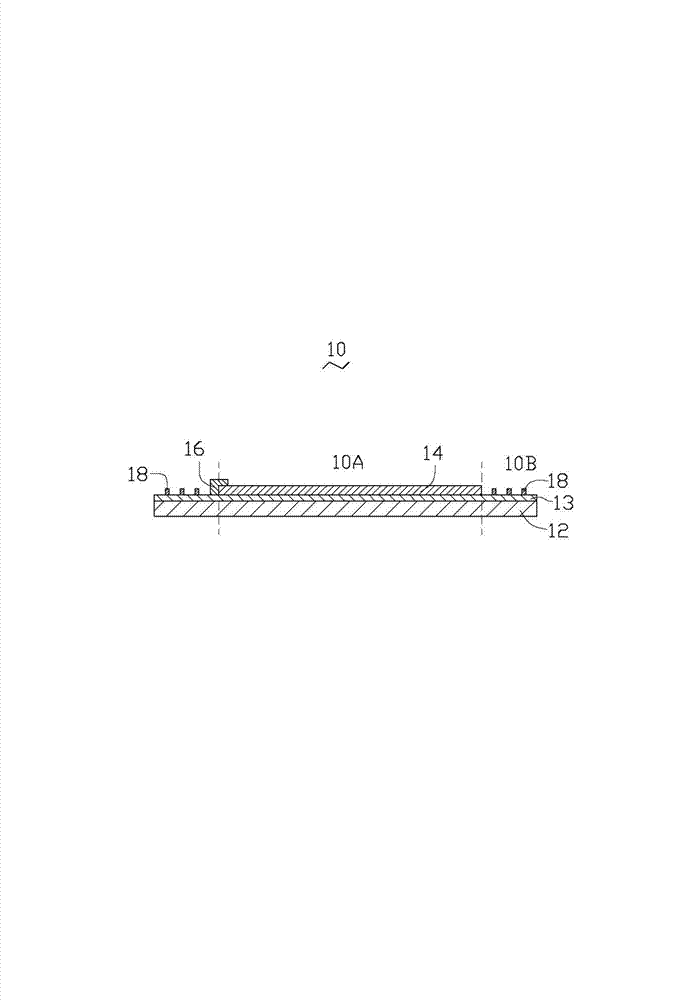

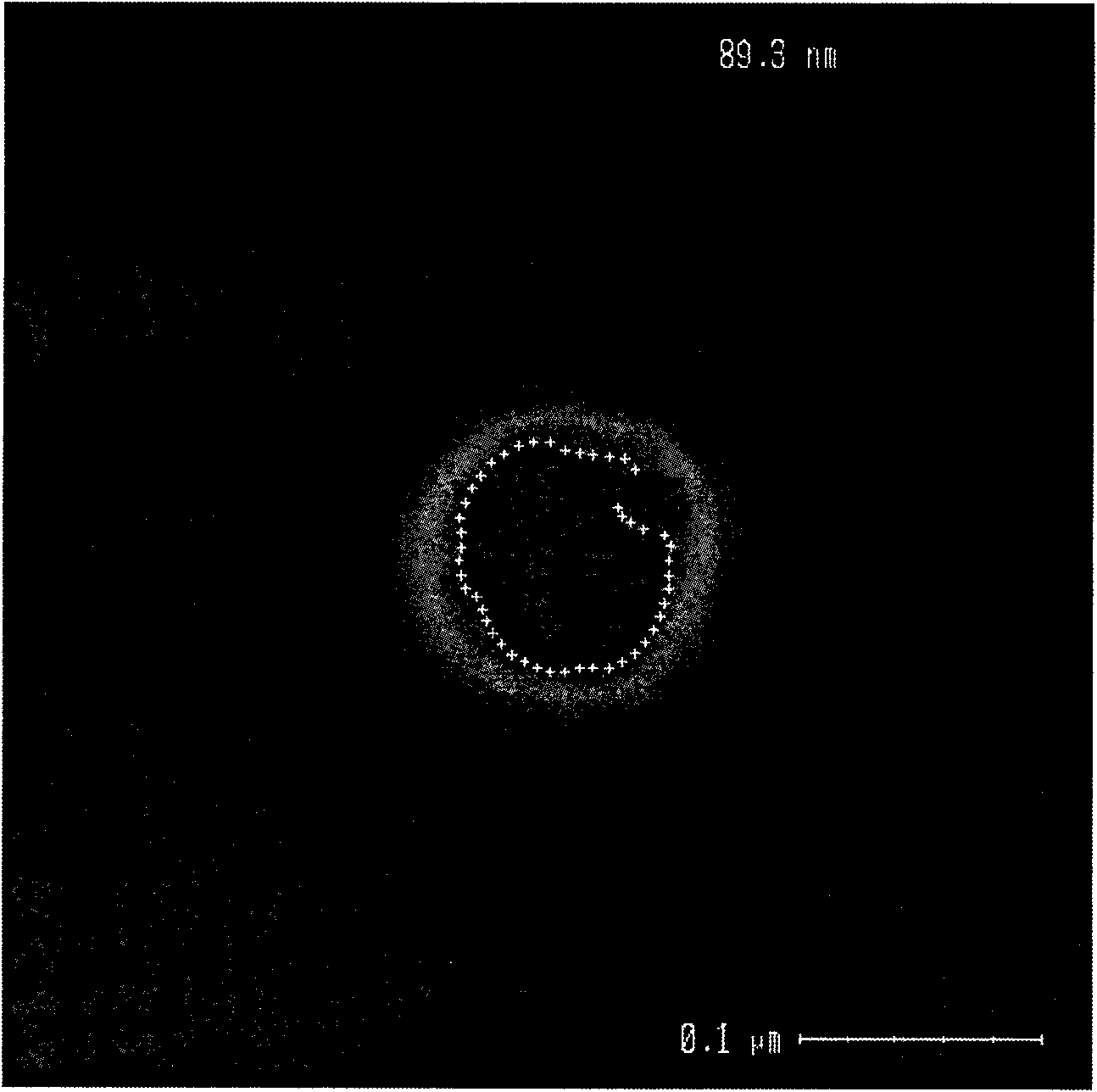

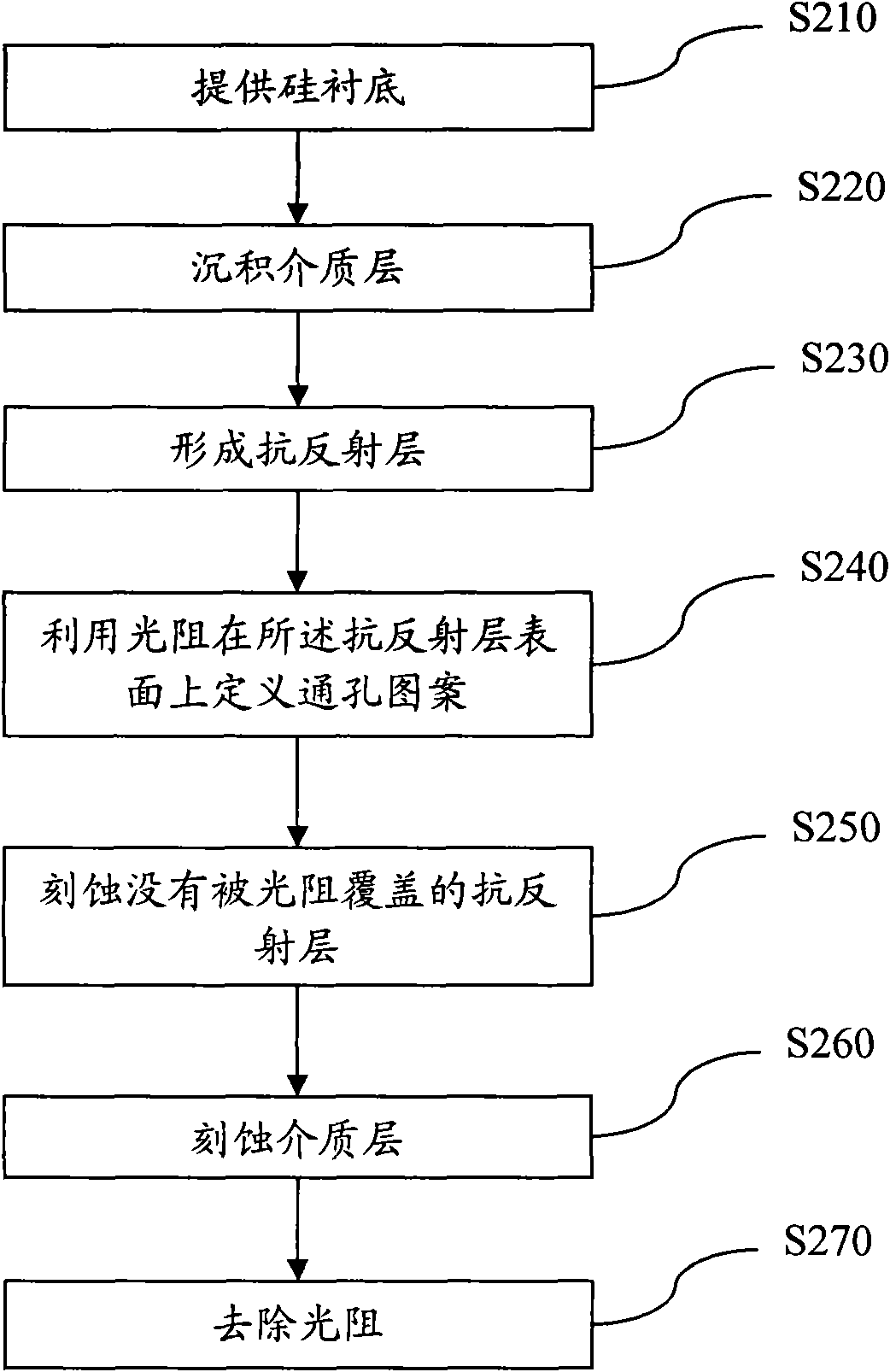

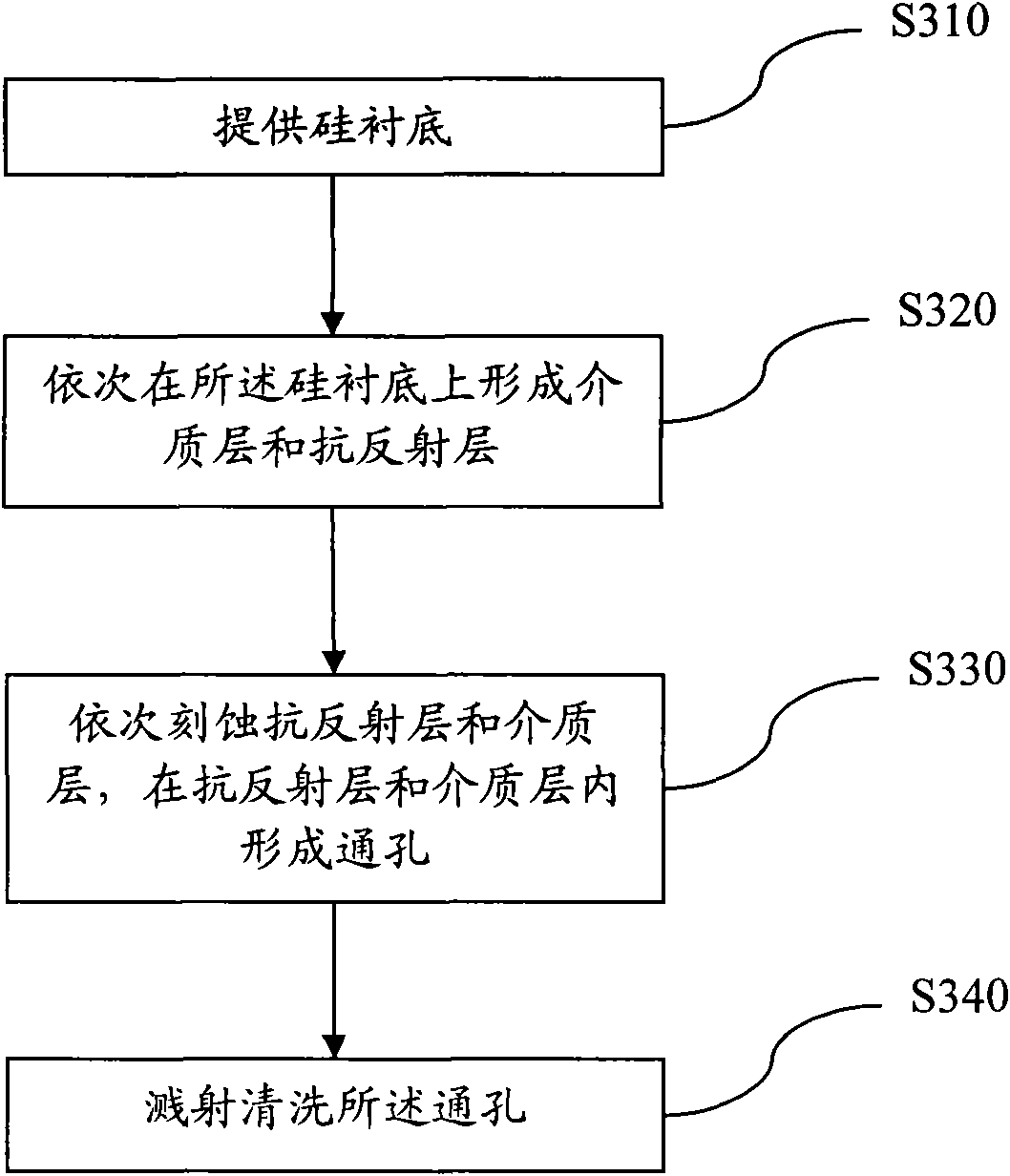

Through hole forming method

InactiveCN101866877AUniform resistance distributionClear edgesSemiconductor/solid-state device manufacturingMedia layerSilicon

The invention discloses a through hole forming method, which comprises the following steps: providing a silicon substrate; forming a medium layer and an anti-reflection layer on the silicon substrate in sequence; etching the anti-reflection layer and the medium layer in sequence, and forming through holes in the anti-reflection layer and the medium layer; and sputtering and cleaning the through holes. In the through hole forming method, a sputtering and cleaning step is added after a main through hole etching step so as to remove redundant polymers generated in the etching process and byproducts generated by etching light resistors to ensure that the side walls of the through holes are smooth and the edges thereof are clear, and thereby, the resistance distribution of the through holes is even.

Owner:SEMICON MFG INT (SHANGHAI) CORP

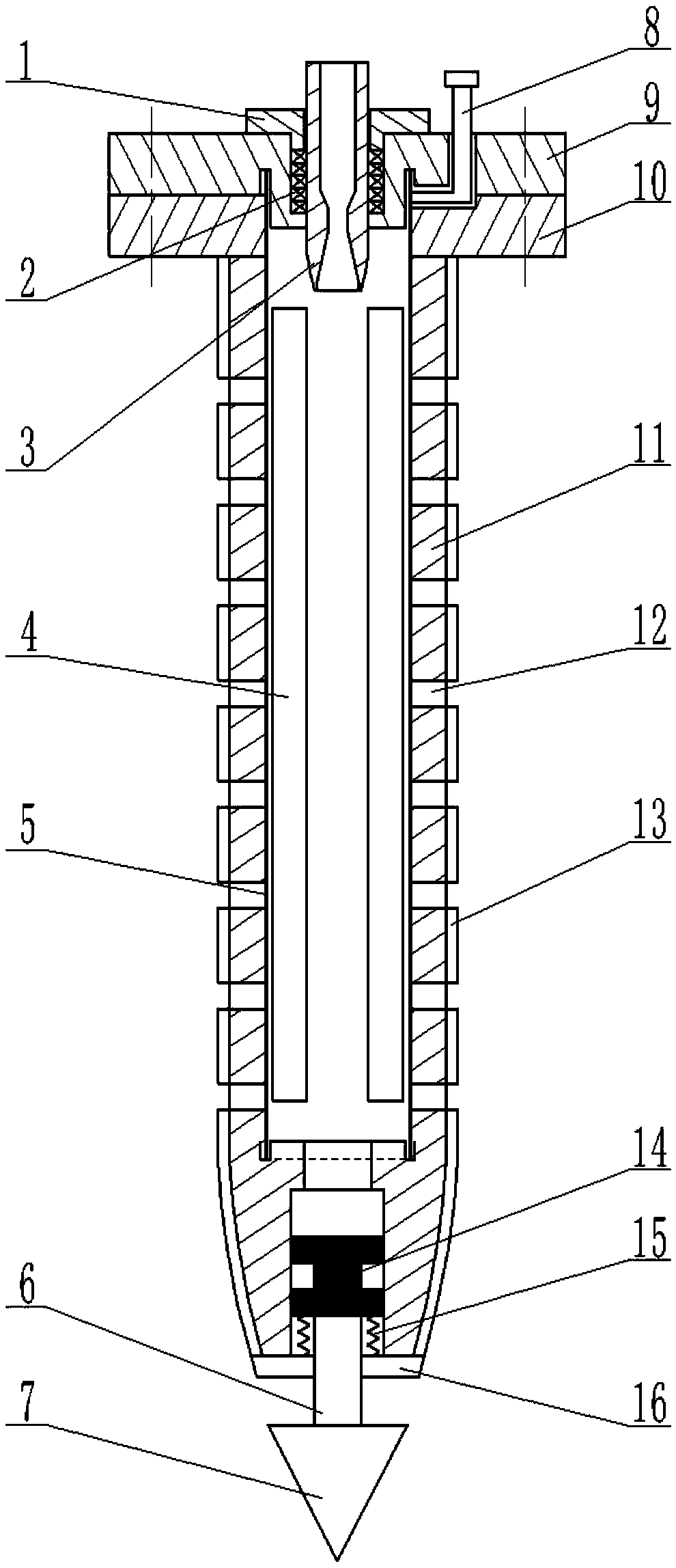

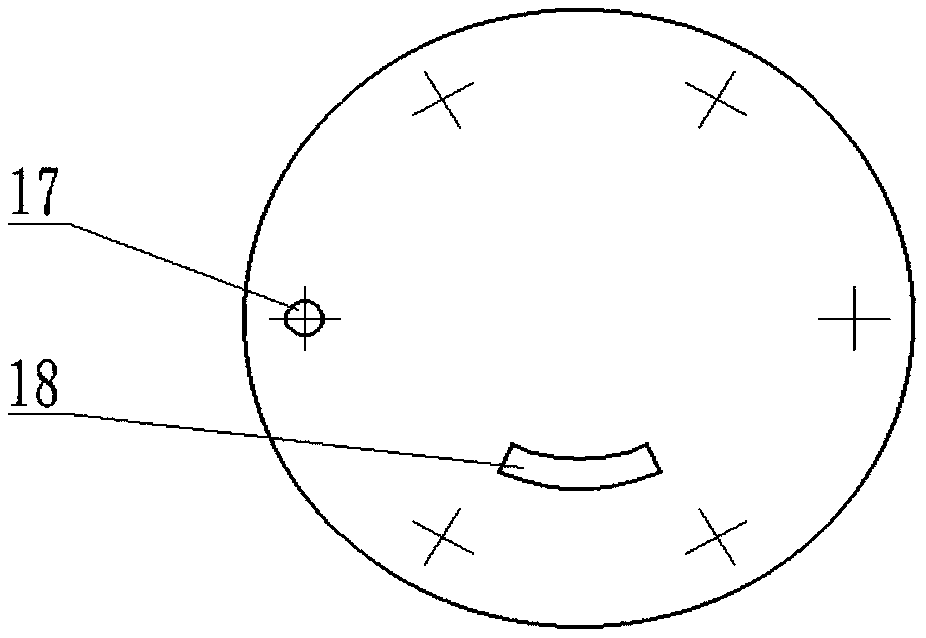

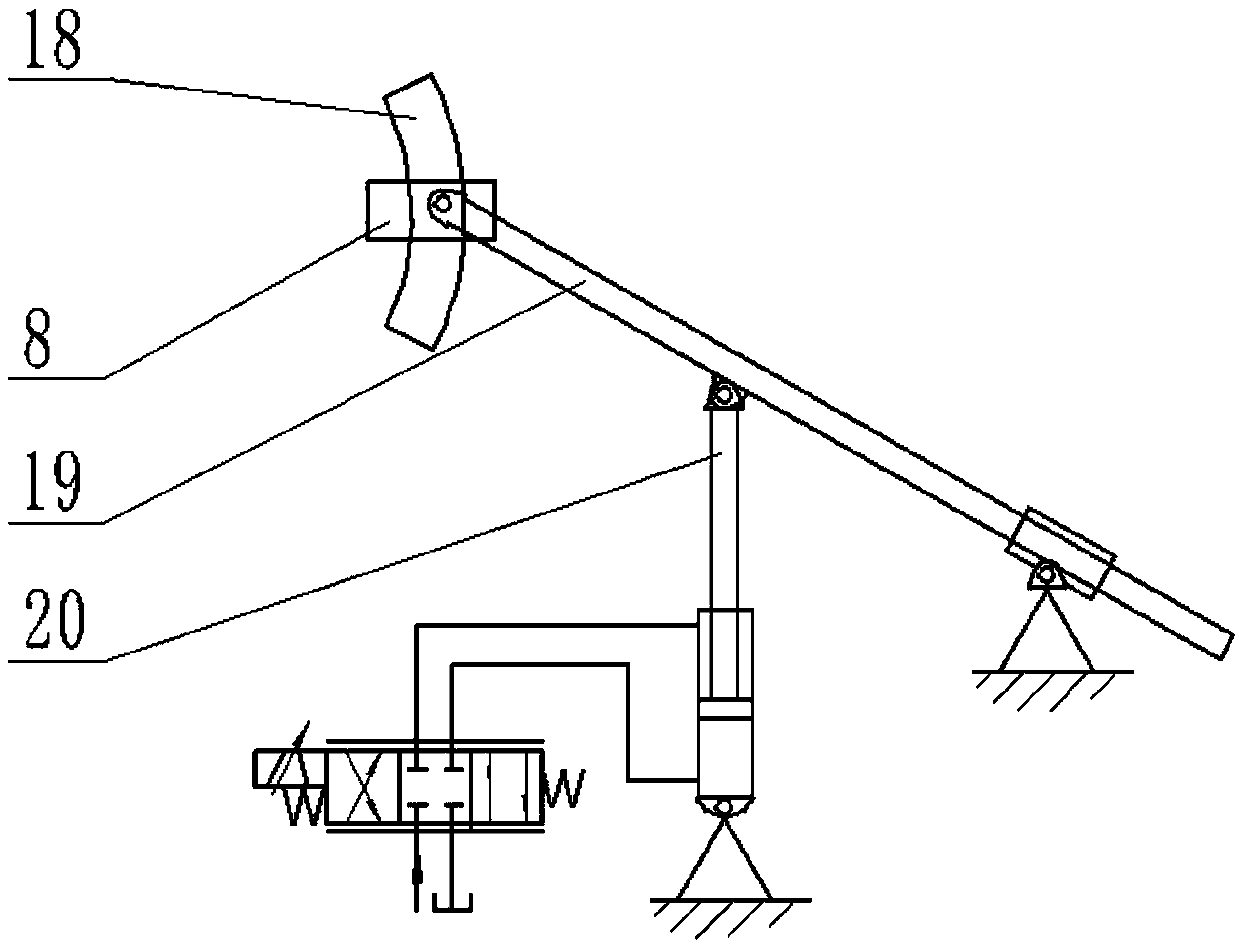

Pneumatic soil deep loosening head and working method thereof

PendingCN108668526ASolve the difficulty of entering the soilUniform resistance distributionHand equipmentsGas explosionPiston

The invention discloses a pneumatic soil deep loosening head and a working method thereof. A baffle plate is arranged inside a shell, and a spray hole can be opened or closed when the baffle plate ispositioned at different angles. When the spray hole is closed, high gas pressure acts on the surface of a piston at the lower end, and equipment enters soil. When the spray hole is opened, compressedgas is sprayed from the spray hole, and the soil is loosened by gas explosion. The piston and a spring form a soil chiseling mechanism, when pulse gas pressure acts on the piston, the soil chiseling mechanism vertically moves to chisel the soil, the shell is pressed down by the aid of external force, and the deep loosening head can be easily inserted into the soil. The deep loosening head can be used for loosening the soil, can also be used for entering the soil and solves the problems that implements difficultly enter the soil, excessive force is applied to the implements, stress is concentrated and the like in the prior art. Resistance is uniformly distributed, and the implements more easily enter the soil.

Owner:CHANGAN UNIV

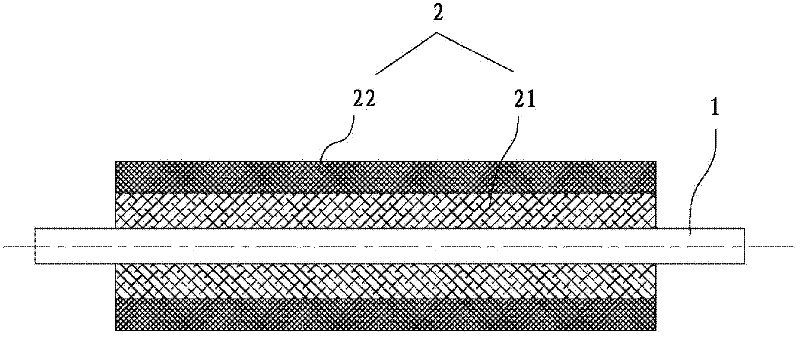

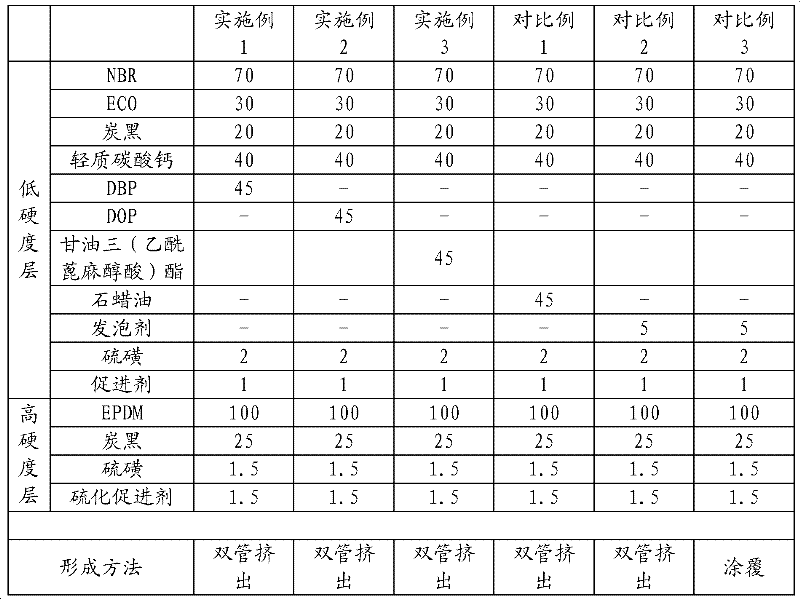

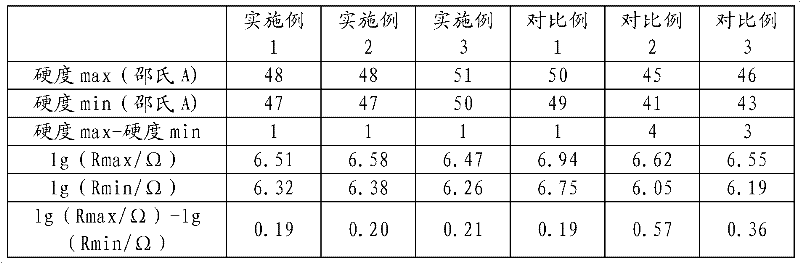

Conductive rubber roller and imaging device

ActiveCN102566371AImprove electrical performanceReach the hardness requirementElectrographic process apparatusSolubilityRubber material

The invention provides a conductive rubber roller which comprises a metal shaft core and a rubber layer wrapped on the metal shaft core, wherein the rubber layer comprises a low-hardness base layer formed by polar rubber materials and a high-hardness covering layer formed by nonpolar rubber materials formed on the outside surface of the low-hardness base layer; a softener is filled in the low-hardness base layer; and the solubility parameter Delta A of the softener filled in the low-hardness base layer, the solubility parameter Delta B of rubber components of the high-hardness covering layer, and the solubility parameter Delta C of rubber components of the low-hardness base layer have the following relational expression: (Delta A- Delta B) is greater than or equal to 2.8 (J / cm<3>)<1 / 2>; and | Delta A- Delta C | is less than or equal to 1.5 (J / cm<3>)<1 / 2>. According to the invention, the migration of the softener from the low-hardness base layer to the high-hardness covering layer is effectively prevented, and the pollution to photosensitive members is avoided in the process of using the conductive rubber roller, and therefore, both the hardness requirement of the whole rubber layer is ensured, and the conductive rubber roller has softness, the resistance fluctuation caused by environment and time changes is small, and the resistance is distributed uniformly. The invention also provides an imaging device with the conductive rubber roller.

Owner:SHENZHEN LEPUTAI TECH CO LTD

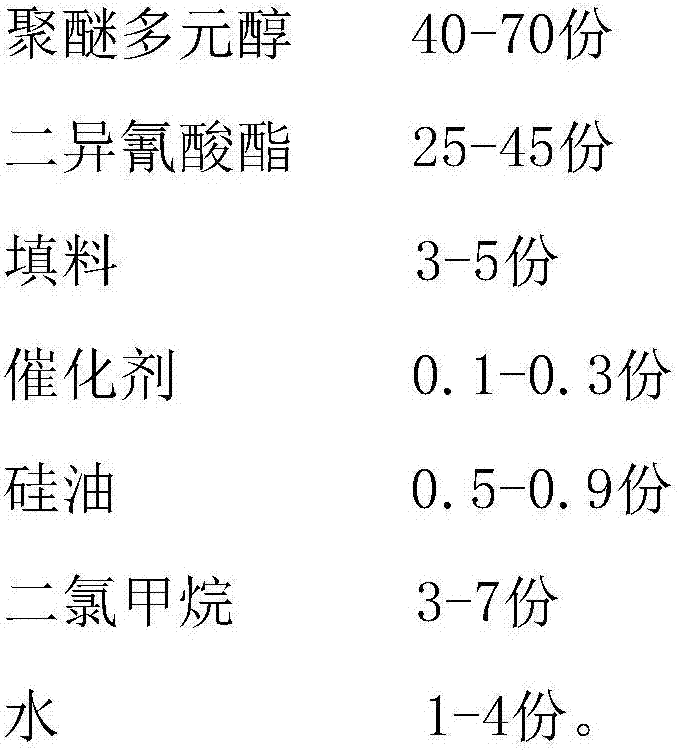

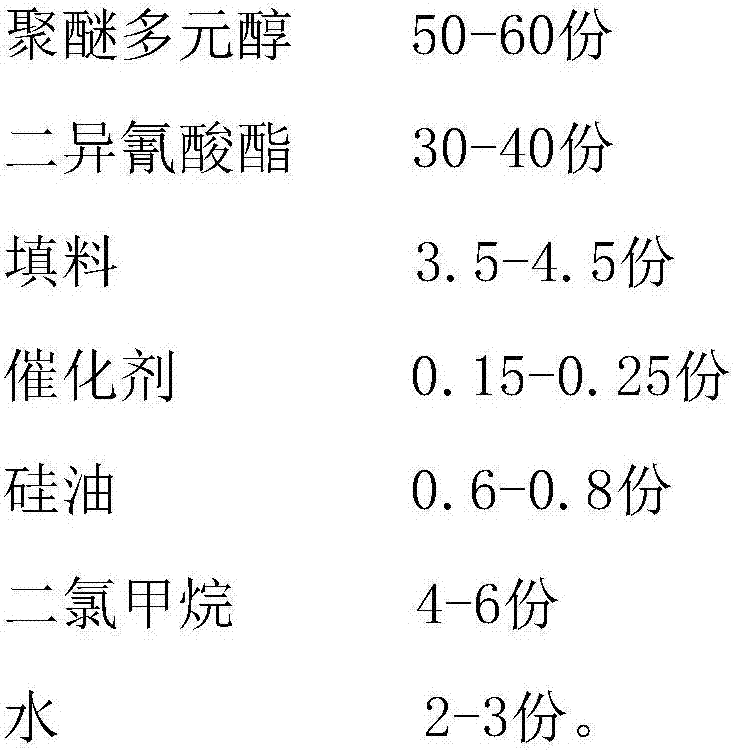

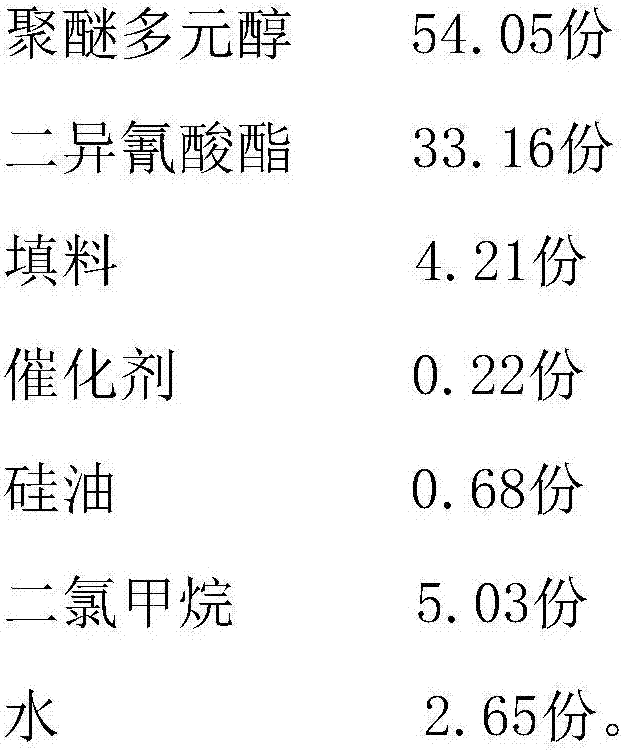

Electrical-conductivity polyurethane charging roller and preparation method thereof

ActiveCN108003603AGood flexibility at low temperatureImprove hydrolysis resistanceElectrographic process apparatusCorona dischargePolyolEngineering

The invention relates to the technical field of charging roller, and in particular, relates to an electrical-conductivity polyurethane charging roller and a preparation method thereof; the electrical-conductivity polyurethane charging roller includes a roller shaft and an electrical conductive polyurethane layer sleeving the outer side of the roller shaft; the electrical conductive polyurethane layer is prepared from the following raw materials in parts by weight: 40-70 parts of polyether polyol, 25-45 parts of diisocyanate, 3-5 parts of a filler, 0.1-0.3 part of a catalyst, 0.5-0.9 part of silicone oil, 3-7 parts of dichloromethane, and 1-4 parts of water. The charging roller has the advantages of good electrical conductivity, good mechanical performance, good durability and long servicelife.

Owner:DONGGUAN WALTON RUBBER & PLASTIC NEW MATERIAL CO LTD

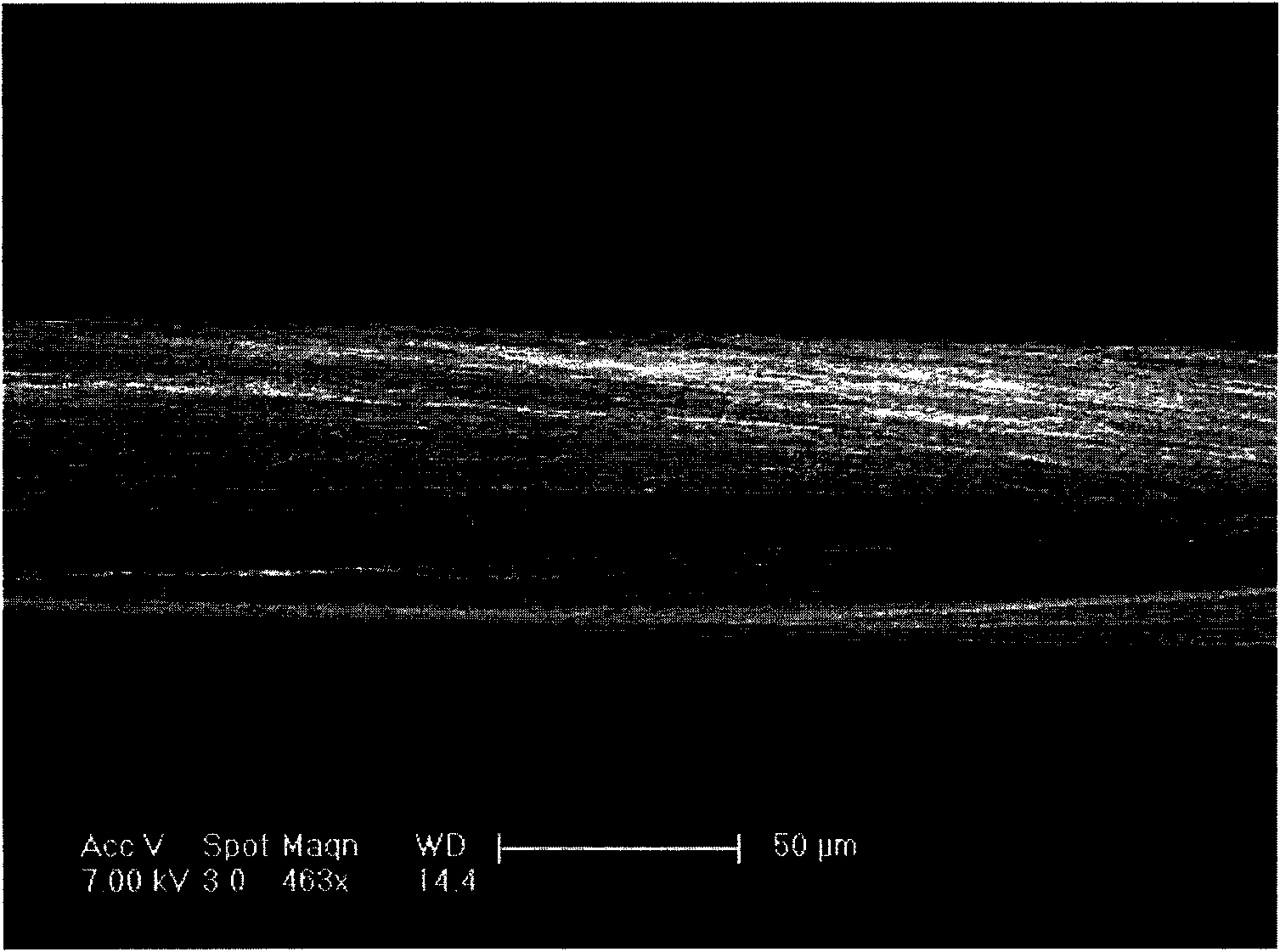

Touch screen and preparation method thereof

ActiveCN102109917AIncreased durabilityHigh sensitivityInput/output processes for data processingPliabilitySurface roughness

The invention relates to a touch screen and a preparation method thereof. The touch screen comprises a transparent conducting layer, a gluing layer and a substrate; the transparent conducting layer comprises a carbon nano tube layer; the carbon nano tube layer is fixed on the substrate through the gluing layer; and the surface roughness Ra of the carbon nano tube layer is less than or equal to 0.1 microns. In a preparation method of the touch screen provided by the invention, the carbon nano tube layer is planished by a planishing tool to ensure that the surface roughness Ra of the carbon nano tube layer is less than or equal to 0.1 microns. The carbon nano tube layer has the characteristics of uniform resistance value distribution and high flexibility, so that the touch screen has high durability and sensitivity.

Owner:BEIJING FUNATE INNOVATION TECH

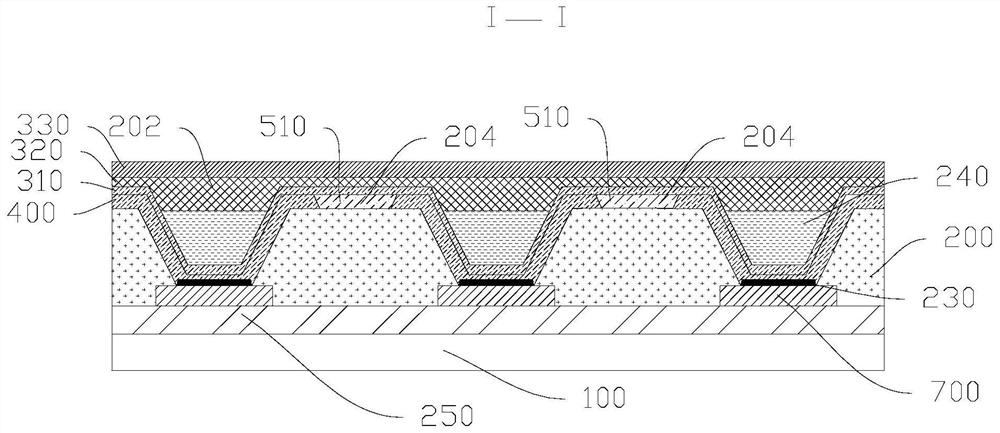

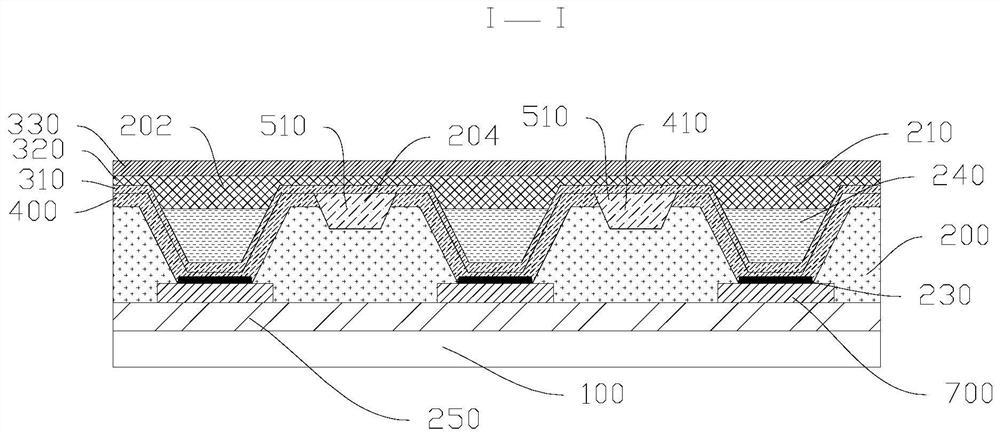

Display panel and display device

PendingCN111799313AEvenly distributedUniform resistance distributionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceThin membrane

The invention relates to a display panel and a display device. The display panel comprises a substrate, a pixel defining layer, a plurality of light emitting layers, a first packaging layer, a plurality of polarizing layers and a second packaging layer. The pixel limiting layer is arranged on the substrate. The pixel limiting layer is provided with a plurality of first grooves arranged at intervals. The first packaging layer covers the pixel defining layer and the plurality of light emitting layers. The plurality of polarizing layers are respectively arranged in the plurality of first groovesand are positioned on one side, far away from the substrate, of the first packaging layer. The second packaging layer covers the plurality of polarizing layers and the first packaging layer. In each first groove, the polarizing layer is arranged between the first packaging layer and the second packaging layer. After external light enters the display panel, reflected light cannot be emitted from the display panel, the interference to human eyes is avoided, the polarizing layers are integrated in a thin film packaging structure, and the thickness of the display panel is reduced.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

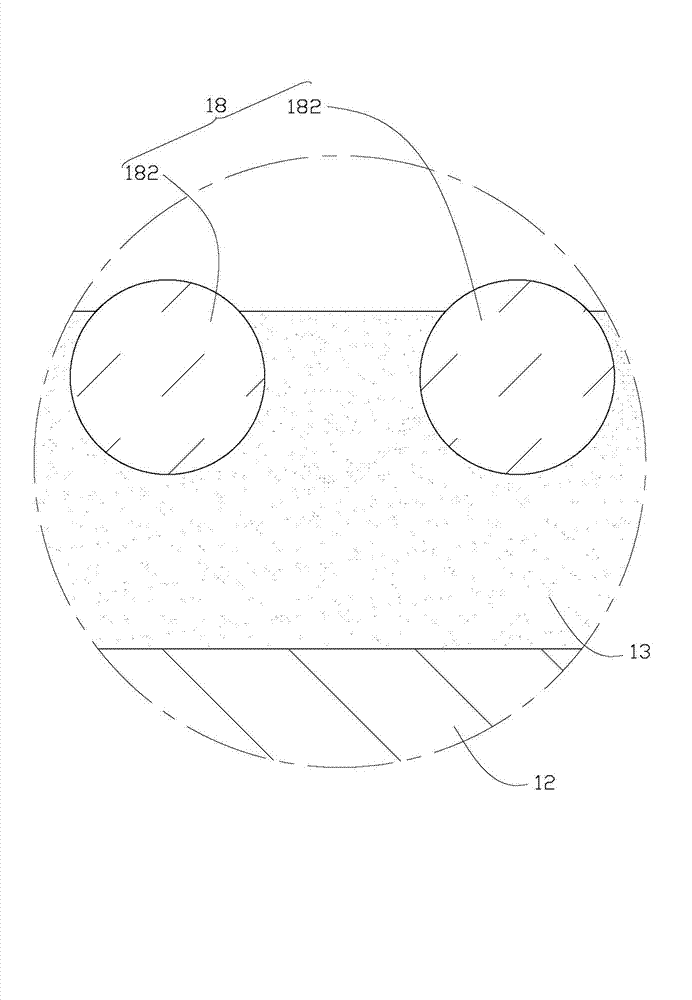

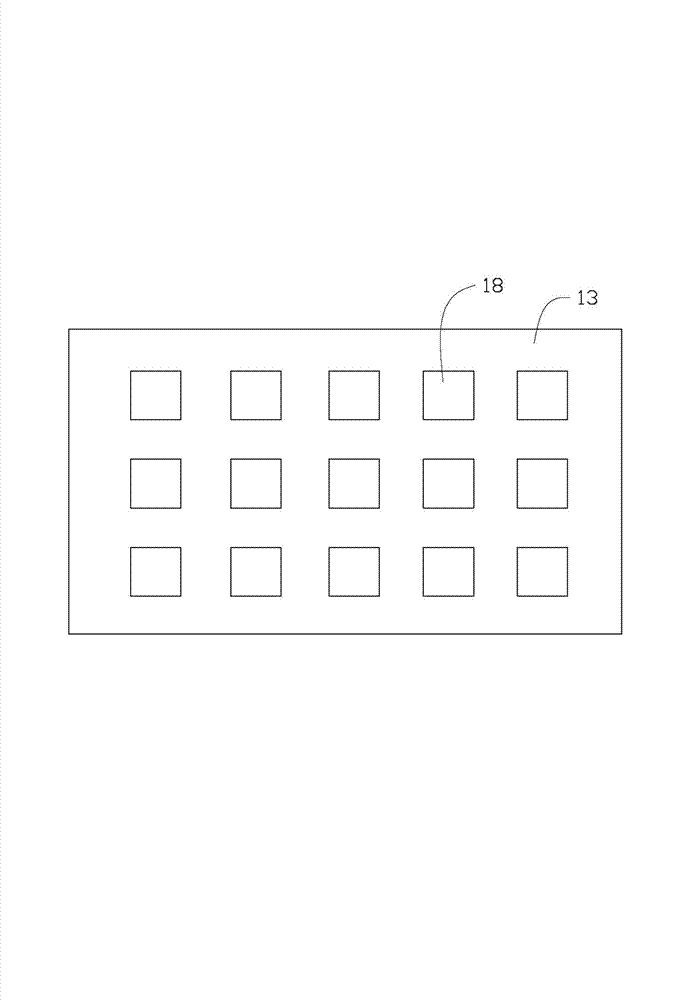

Patterned conducting element

InactiveCN102820073AExcellent mechanical propertiesGood toughness strengthConductive layers on insulating-supportsCarbon-silicon compound conductorsCarbon nanotube

The invention relates to a patterned conducting element. The patterned conducting element specifically comprises a base, an adhesive layer and a patterned carbon nanotube layer, the adhesive layer is arranged on one surface of the base, and the surface of the patterned carbon nanotube layer is partly embedded in the adhesive layer and is partly exposed outside the adhesive layer.

Owner:TIANJIN FUNA YUANCHUANG TECH +1

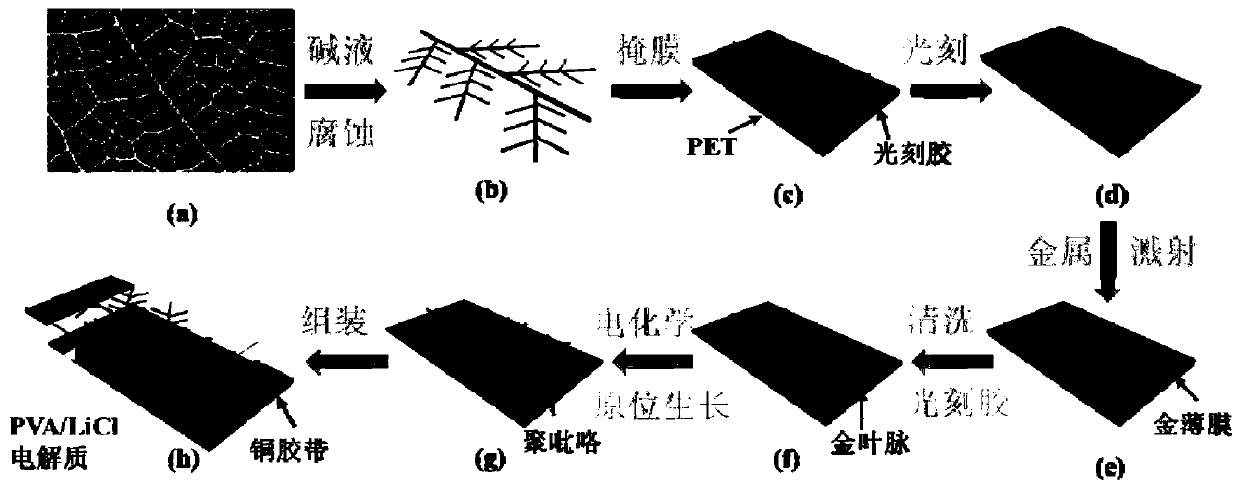

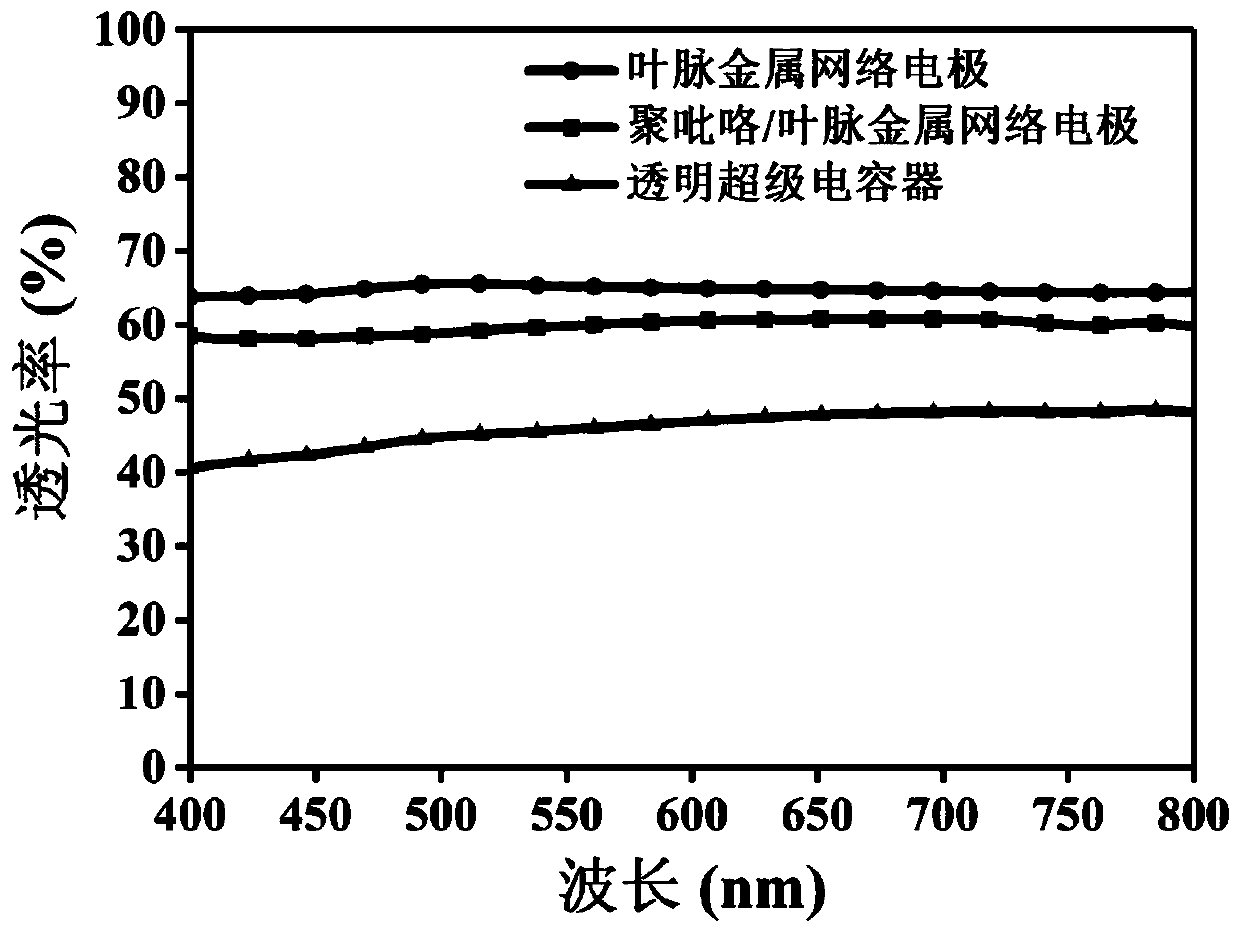

Preparation method of flexible transparent super capacitor

InactiveCN110400703AEfficient collectionEfficient transportHybrid capacitor electrodesHybrid/EDL manufactureTransmittanceSingle electrode

The invention discloses a preparation method of a flexible transparent super capacitor. The preparation method comprises steps of (1), preparing leaf veins; (2), preparing a flexible film having linesof the leaf veins; (3), preparing a leaf vein electrode; (4), preparing a flexible transparent single electrode; (5), preparing transparent gel electrolyte; and (6), assembling a flexible transparentsuper capacitor. The preparation method is advantaged in that the prepared capacitor has large specific capacity, good light transmittance and low cost and further has good mechanical bending performance, electrochemical performance and optical performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

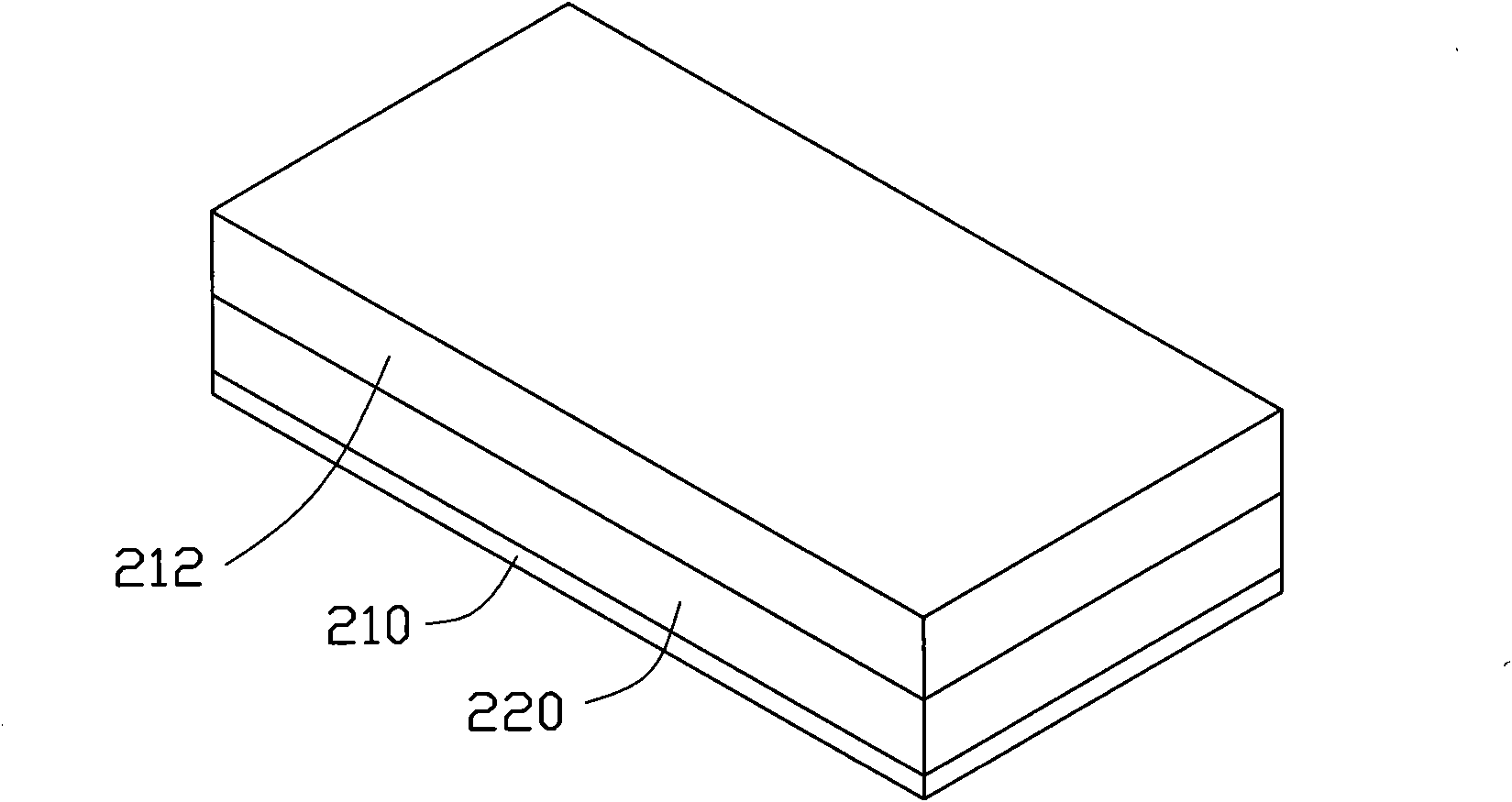

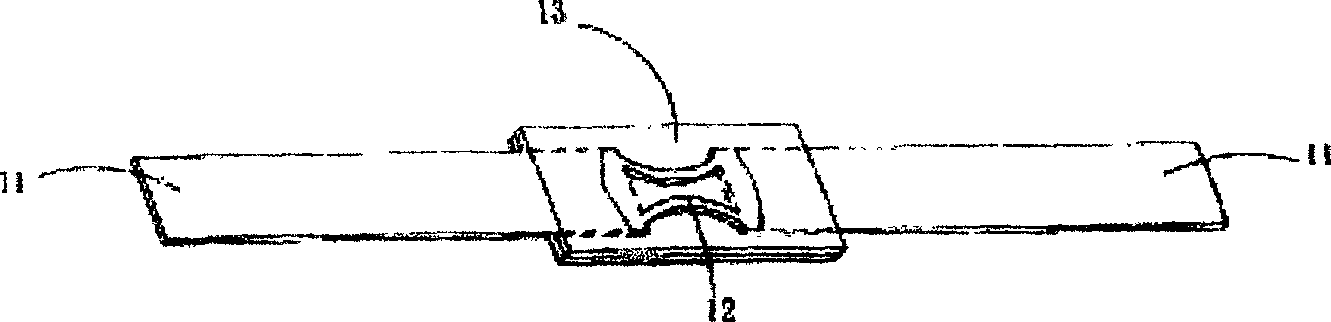

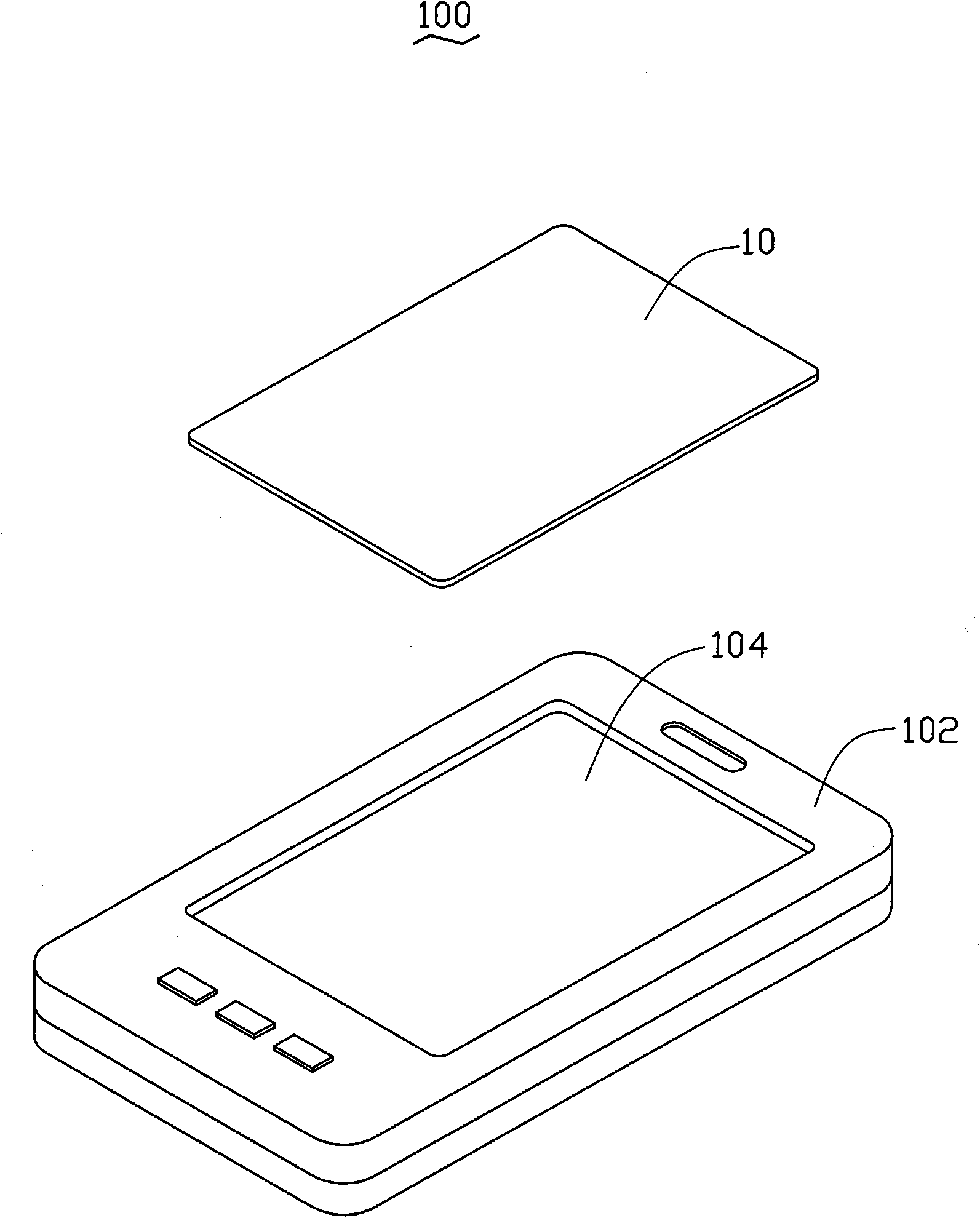

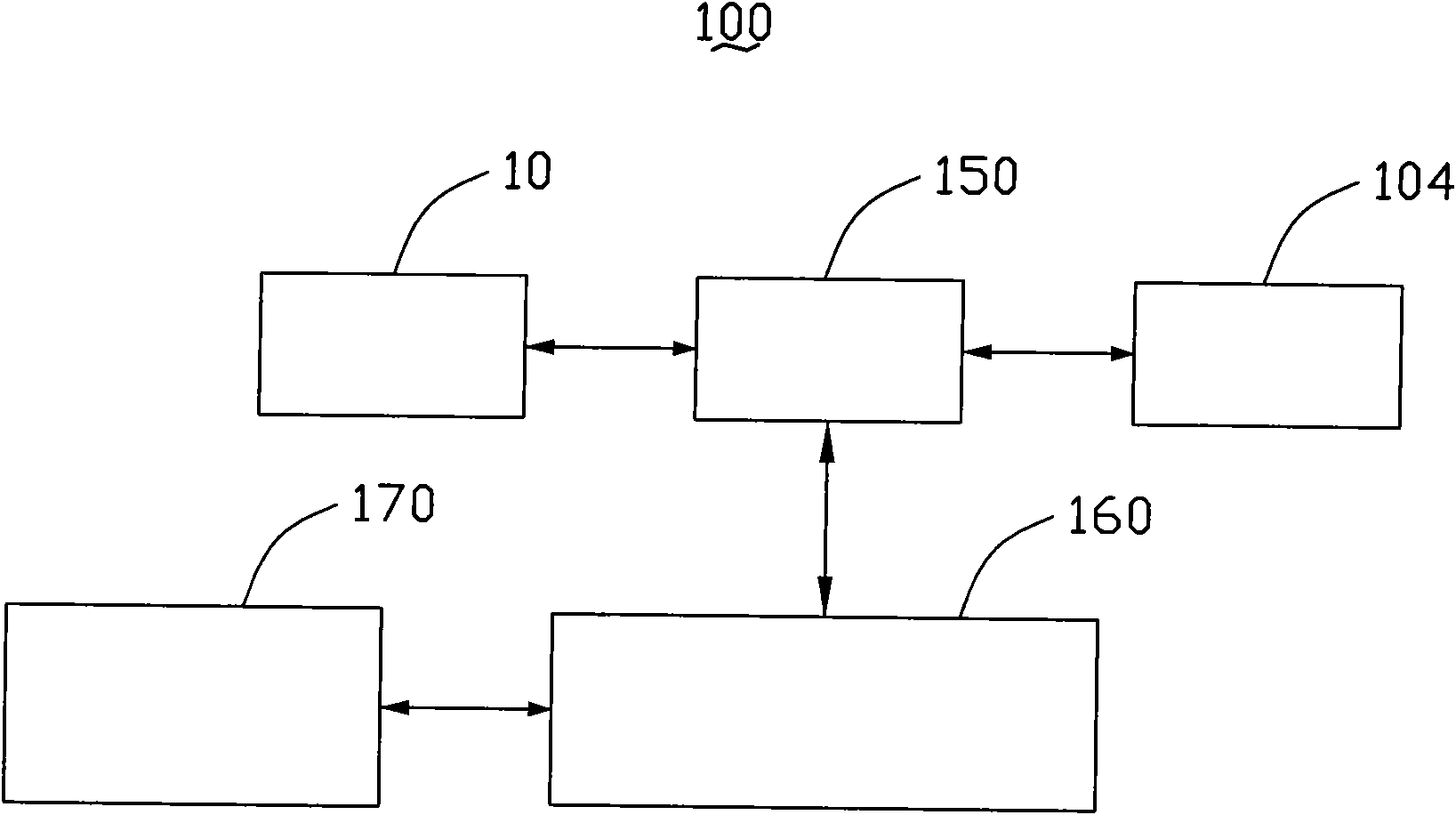

Personal digital assistant

ActiveCN101655720AHigh transparencyImprove mechanical propertiesDigital data processing detailsInput/output processes for data processingCarbon nanotubeTouchscreen

The invention relates to a personal digital assistant, which comprises a body, wherein the body is provided with a display screen and a touch screen. The touch screen is arranged on the surface of thedisplay screen and comprises at least one transparent conducting layer which is a carbon nano tube layer.

Owner:TSINGHUA UNIV +1

Method for preparing n-type crystalline silica double-side solar cell

InactiveCN105826432APrecise and controllable doping concentrationUniform resistance distributionFinal product manufactureVacuum evaporation coatingAir atmosphereHigh density

The invention discloses a method for preparing n-type crystalline silica double-side solar cell, and the method comprises the steps of texturing a silicon chip surface and cleaning; depositing a silicon oxide film where boron is heavily doped on the side that demands boron diffusion through CVD method or PVD method, and the thickness is 20-200nm; depositing an oxide film where phosphor is heavily doped on the side that demands phosphor diffusion through the CVD method or PVD method, and the thickness is 20-200nm; performing high temperature diffusion at a normal pressure in clean air atmosphere or oxygen atmosphere to obtain a doped n-type layer and a doped p-type layer at the same time; removing and cleaning by a wet chemical method of a silicon chip double-side oxide; depositing a silicon chip double-side passivation antireflection coating; preparing a silicon chip double-side grid line electrode; and processing anti-creeping treatment to the silicon chip edge. The diffusion technology is relatively simple; the doped concentration of the doping layer is accurate and controllable; the dying problem of the surface due to over high density can be avoided; and the square resistance of the obtained doping layer is distributed evenly. The prepared n-type crystalline silica double-side solar cell has an excellent performance, and the manufacture cost is low.

Owner:NANCHANG UNIV

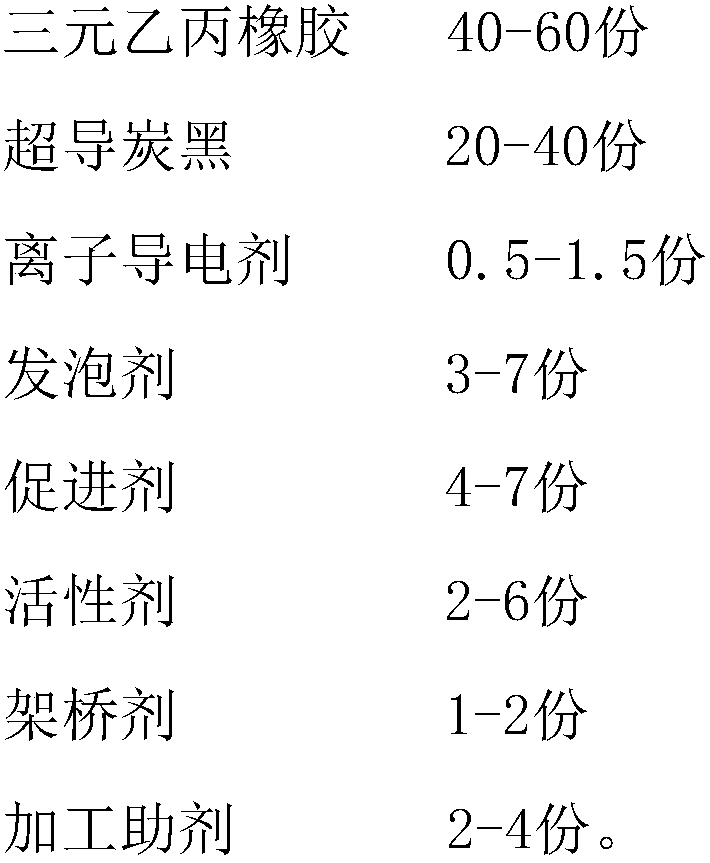

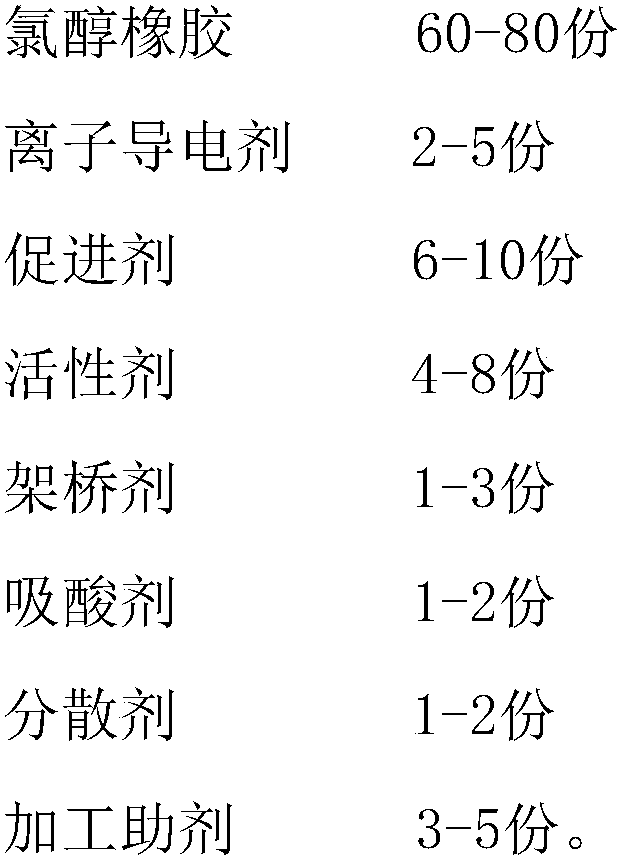

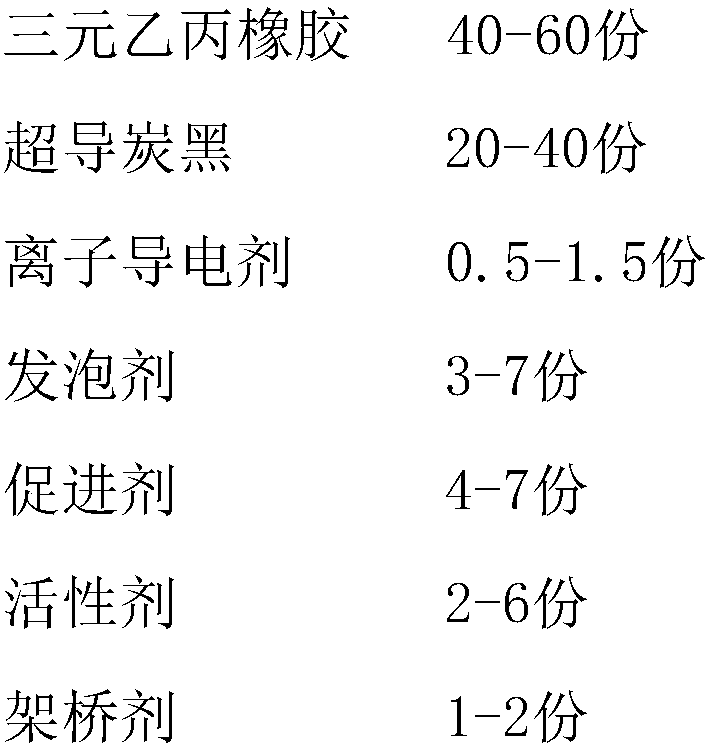

ECO (Epichlorohydrin) ion-conducting type spongy charging roller and preparation method thereof

InactiveCN107915905AAvoid reunionPrevent subsidenceElectrographic process apparatusCorona dischargeFoaming agentEthylene-propylene-diene-monomer

The invention relates to the technical field of charging rollers and particularly relates to an ECO (Epichlorohydrin) ion-conducting type spongy charging roller and a preparation method thereof. The ECO ion-conducting type spongy charging roller comprises a roller shaft, a foaming-conducting sponge layer sheathed at the outer side of the roller shaft and an ECO ion-conducting rubber layer sheathedat the outer side of the foaming-conducting sponge layer, wherein the foaming-conducting sponge layer is prepared from the following raw materials in parts by weight: 40-60 parts of ethylene-propylene-diene monomer rubber, 20-40 parts of superconducting carbon black, 0.5-1.5 parts of ion conducting agent, 3-7 parts of foaming agent, 4-7 parts of accelerator, 2-6 parts of active agent, 1-2 parts of bridging agent and 2-4 parts of processing aid. The ECO ion-conducting type spongy charging roller is good in conductivity, mechanical property and durability and long in service life.

Owner:DONGGUAN WALTON RUBBER & PLASTIC NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com