Preparation method of flexible transparent super capacitor

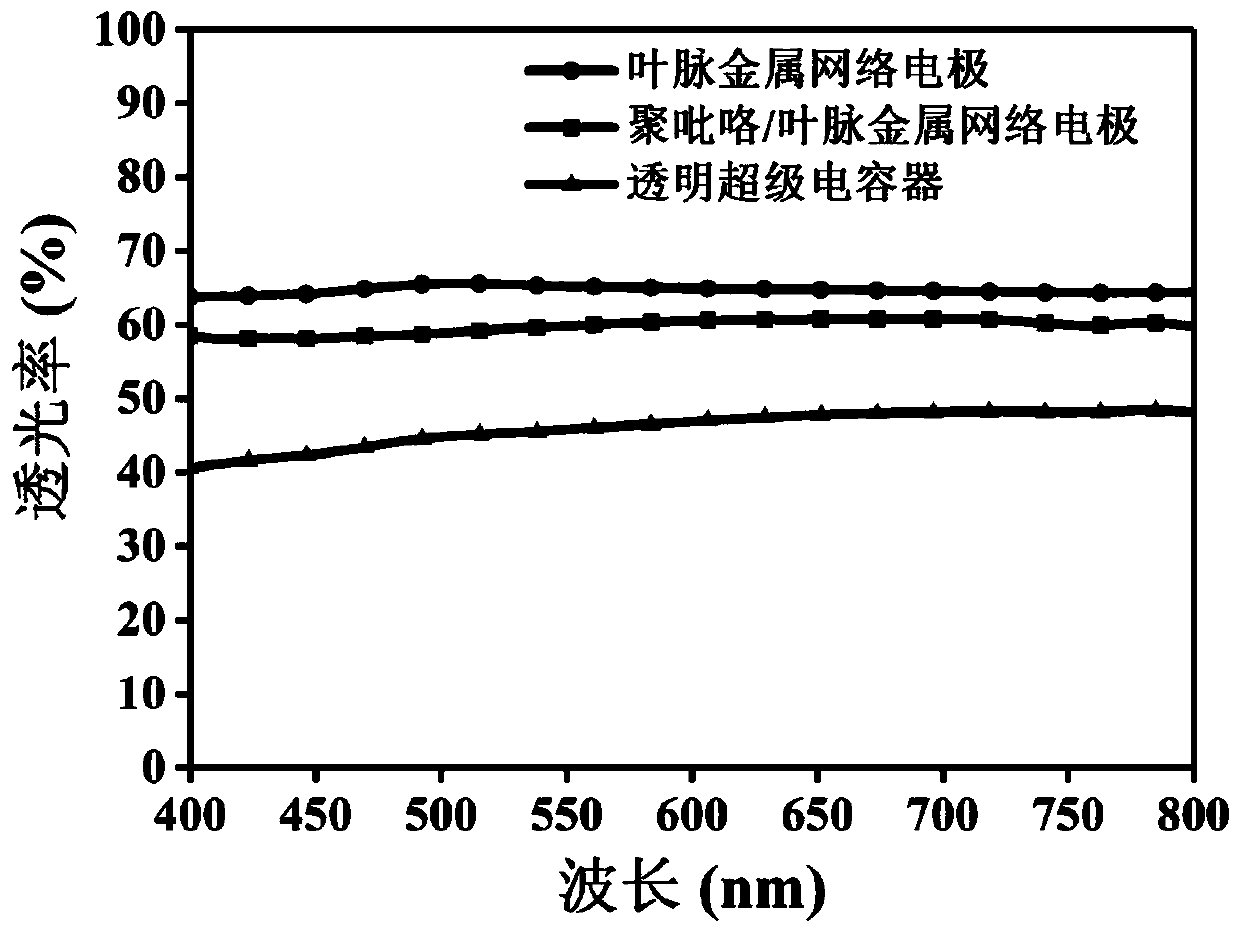

A supercapacitor, transparent technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of not being able to adapt to the flexible bending of wearable devices, the specific capacity of transparent supercapacitors, and the shortage of rare metal indium resources, etc. Achieve the effects of reducing electron transport resistance, good electrochemical performance and optical performance, and ensuring light transmission properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

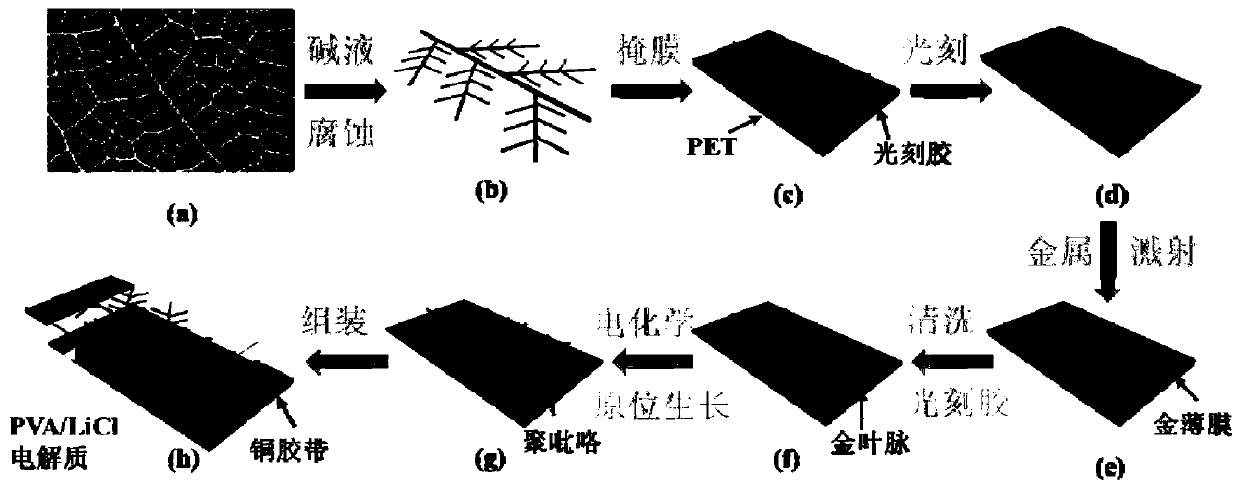

[0047] Such as figure 1 As shown, the present embodiment 1 provides a method for preparing a flexible transparent supercapacitor based on the leaf vein metal network, comprising the following steps:

[0048] (1) Preparation of leaf vein mask

[0049] The method for preparing the leaf vein mask is detailed here.

[0050] (1) The leaves selected in this embodiment are magnolia leaves, choose mature magnolia leaves, clean the surface dust with deionized water, cut off the thick part of the veins, and dry for later use.

[0051] (2) Submerge the treated leaves in 0.1g / mL NaOH solution, heat to 70°C and keep warm for 3 hours, take them out after the leaves turn brown, and gently scrape off the mesophyll tissue between the vein structures with a fine brush, After cleaning, rinse with deionized water and absolute ethanol for 1 min respectively, and dry in a drying oven at 60° C. for 3 h for later use, and the preparation of the leaf vein mask is completed.

[0052] (2) Preparation...

Embodiment 2

[0095] The preparation method of the flexible transparent supercapacitor based on the leaf vein metal network provided in this embodiment comprises the following steps:

[0096] (1) Preparation of leaf vein mask

[0097] The method for preparing the leaf mask is detailed here.

[0098] (1) The leaves selected in this embodiment are magnolia leaves, choose mature magnolia leaves, clean the surface dust with deionized water, cut off the thick part of the veins, and dry for later use.

[0099] (2) Submerge the treated leaves in 0.1g / mL NaOH solution, heat to 70°C and keep warm for 3 hours, take them out after the leaves turn brown, and gently scrape off the mesophyll tissue between the vein structures with a fine brush, After cleaning, rinse with deionized water and absolute ethanol for 1 min respectively, and dry in a drying oven at 60° C. for 3 h for later use, and the preparation of the leaf mask is completed.

[0100] (2) Preparation of leaf vein patterns by photolithograph...

Embodiment 3

[0134] The preparation method of the flexible transparent supercapacitor based on the leaf vein metal network provided in this embodiment comprises the following steps:

[0135] (1) Preparation of leaf vein mask

[0136] The method for preparing the leaf mask is detailed here.

[0137] (1) The leaves selected in this embodiment are magnolia leaves, choose mature magnolia leaves, clean the surface dust with deionized water, cut off the thick part of the veins, and dry for later use.

[0138] (2) Submerge the treated leaves in 0.1g / mL NaOH solution, heat to 70°C and keep warm for 3 hours, take them out after the leaves turn brown, and gently scrape off the mesophyll tissue between the vein structures with a fine brush, After cleaning, rinse with deionized water and absolute ethanol for 1 min respectively, and dry in a drying oven at 60° C. for 3 h for later use, and the preparation of the leaf mask is completed.

[0139] (2) Preparation of leaf vein patterns by photolithograph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com