Far infrared flexible wearable heating sheet and preparation method and application thereof

A far-infrared and heating sheet technology, applied in the field of far-infrared heating, can solve problems such as difficulty in ensuring industrial mass production, uneven film resistance, and low product yield, and achieve improved blood microcirculation, uniform resistance distribution, Fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] One aspect of the embodiments of the present invention provides a method for preparing a far-infrared flexible wearable heating sheet, which includes:

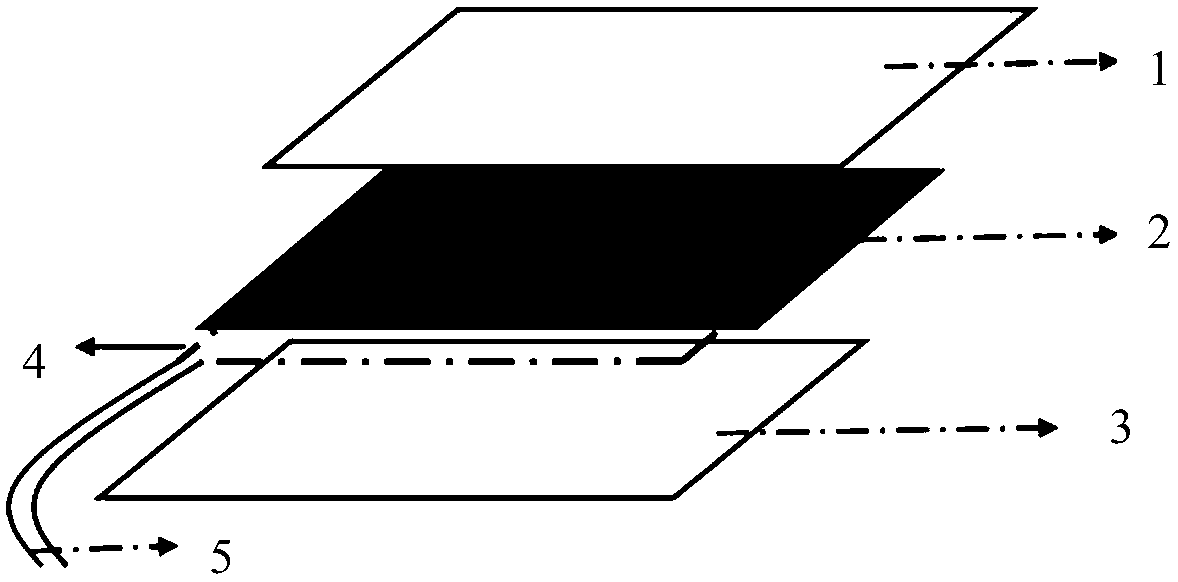

[0044] Provide a flexible heating body and a flexible insulating material layer, the flexible heating body is electrically connected to electrodes, the flexible heating body includes a carbon material heating film, and the carbon material heating film includes a carbon material layer, which is arranged at both ends of the carbon material layer And / or parallel electrodes or interdigitated electrodes on both sides and high temperature resistant insulating layers covering both sides of the carbon material layer;

[0045] The flexible insulating material layer is arranged on opposite sides of the flexible heating element, and pressed and solidified by using fast pressure or pressure transmission equipment, so as to realize the sealing and insulation of the heating element and the electrode;

[0046] Wherein, the carbon mate...

Embodiment 1

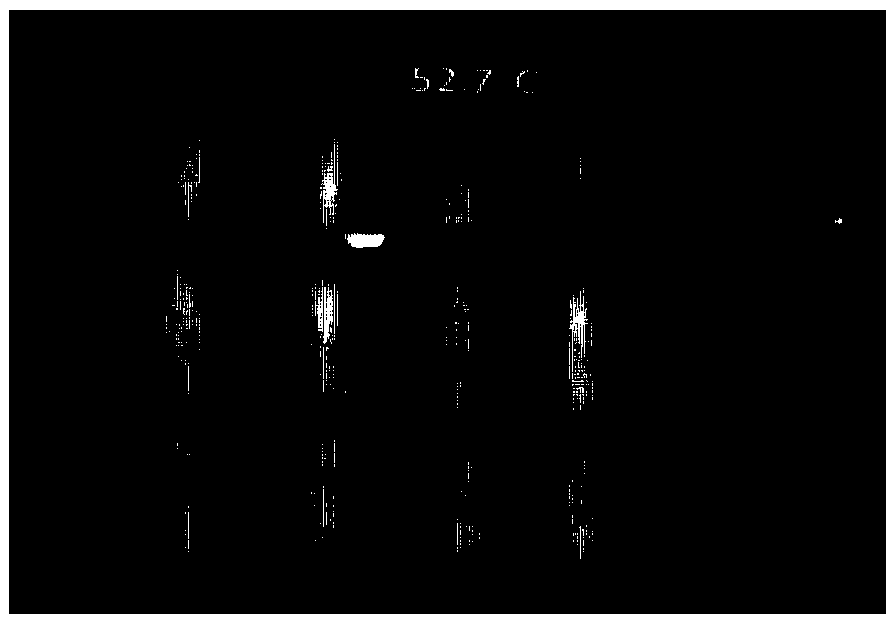

[0093] This embodiment provides a carbon nanotube wearable heating sheet, and the heating sheet uses carbon nanotubes as heating elements. The manufacturing method of the heating element is to prepare a flexible heating layer of carbon nanotubes with a thickness of 50 μm on the substrate by wet coating. Carbon nanotube powder is dispersed in water-based or oil-based polymer solution, and is dried by coating to form a self-supporting flexible conductive film; the electrodes on the conductive film are designed and configured according to the required power, generally It is necessary to design multi-point electrodes, simulate and conduct actual heating tests through thermal analysis software to achieve uniform heating effects. After the multi-point electrodes are connected in series and parallel, they are drawn out in the form of USB twin wires. The internal resistance of the heating element is 5Ω; after the heating element is cut / perforated, it is laminated with the upper and l...

Embodiment 2

[0096] A graphene wearable heating sheet of this embodiment, the heating sheet uses graphene as a heating element. The manufacturing method of the heating element is to prepare a graphene flexible heating layer with a thickness of 45 μm on the substrate by wet coating. Graphene powder is dispersed in water-based or oil-based polymer solution, and is dried by coating to form a self-supporting flexible conductive film; the electrodes on the conductive film are designed and configured according to the required power. Through the design method of multi-point electrodes, the simulation and actual heating test are carried out through thermal analysis software, and the effect of uniform heating can be realized. After the multi-point electrodes are connected in series and parallel, they are drawn out in the form of USB twin wires. The internal resistance of the heating element is 5Ω; after cutting / punching, the heating element is bonded with the upper and lower films to achieve insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com