Touch screen and preparation method thereof

A touch screen, adhesive layer technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problems of high preparation cost, poor durability, uneven resistance, etc., and achieve raw material cost and process cost. Low, good toughness and mechanical strength, the effect of improving sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

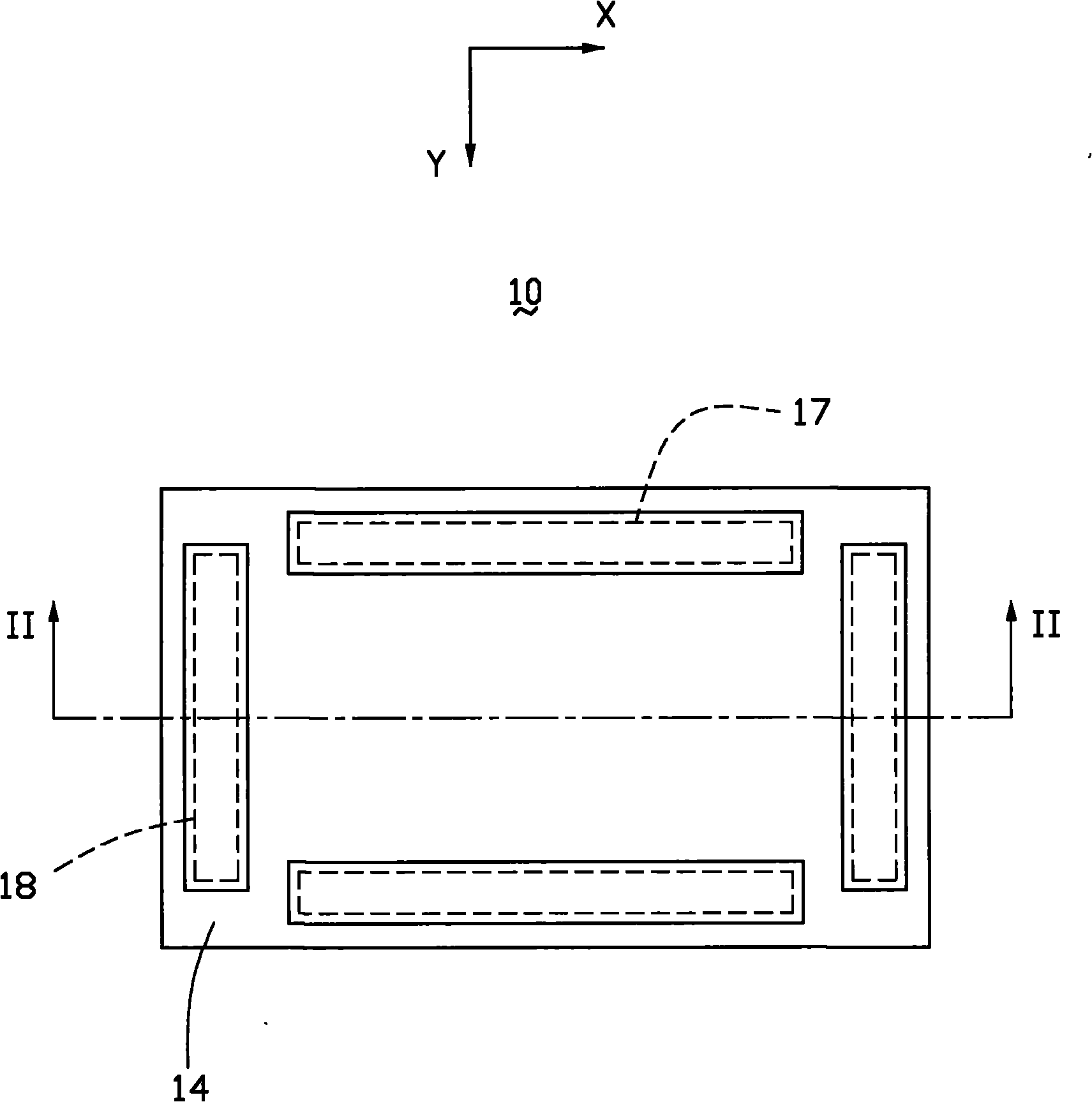

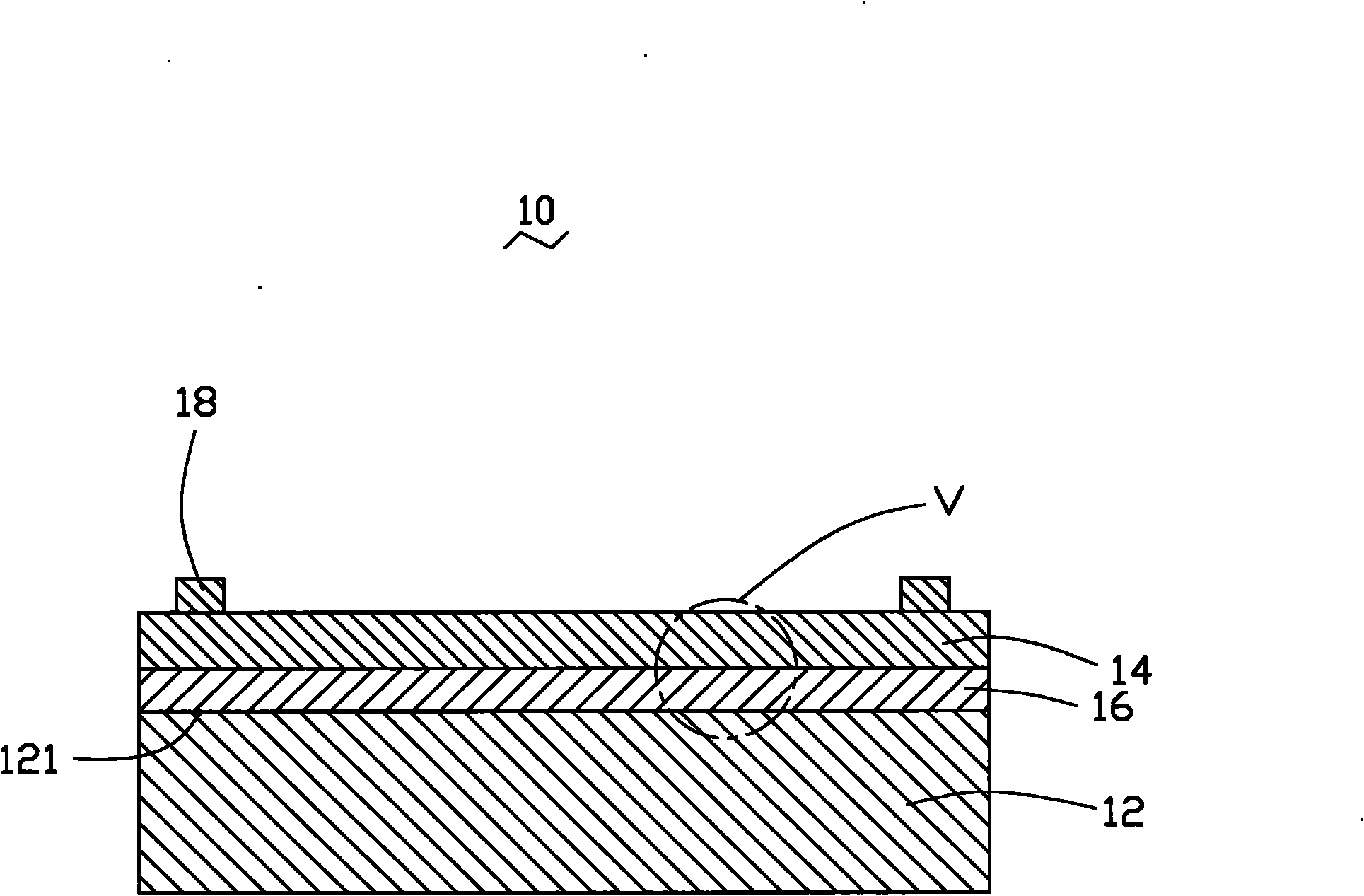

[0059] The present invention provides a method for preparing the above-mentioned touch screen 10, the preparation method comprising the following steps: (w10) providing a substrate with a surface; (w20) forming an adhesive layer to be cured on the surface of the substrate; (w30 ) providing at least one carbon nanotube film; (w40) laying the at least one carbon nanotube film on the surface of the substrate to form a carbon nanotube layer covering the adhesive layer to be cured (w50) applying a pressure to the carbon nanotube layer so that the carbon nanotube layer is partially embedded in the adhesive layer to be cured, and the surface roughness Ra of the carbon nanotube layer is less than or equal to 0.1 micron; (w60) curing the adhesive layer; (w70) forming electrodes.

[0060] see Figure 8 , the preparation method of the touch screen 10 specifically includes the following steps:

[0061] In step (w10), firstly, a substrate 12 having a surface 121 is provided. Secondly, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com