Composite low-voltage electrothermal film and making method

A manufacturing method and technology of electric heating film, which are applied in the manufacture of electric heating devices, composite low-voltage electric heating film and its manufacturing field, can solve the problems of insufficient heating temperature, thick material, poor safety of high voltage, etc., and reach the range of geometric shape variation. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

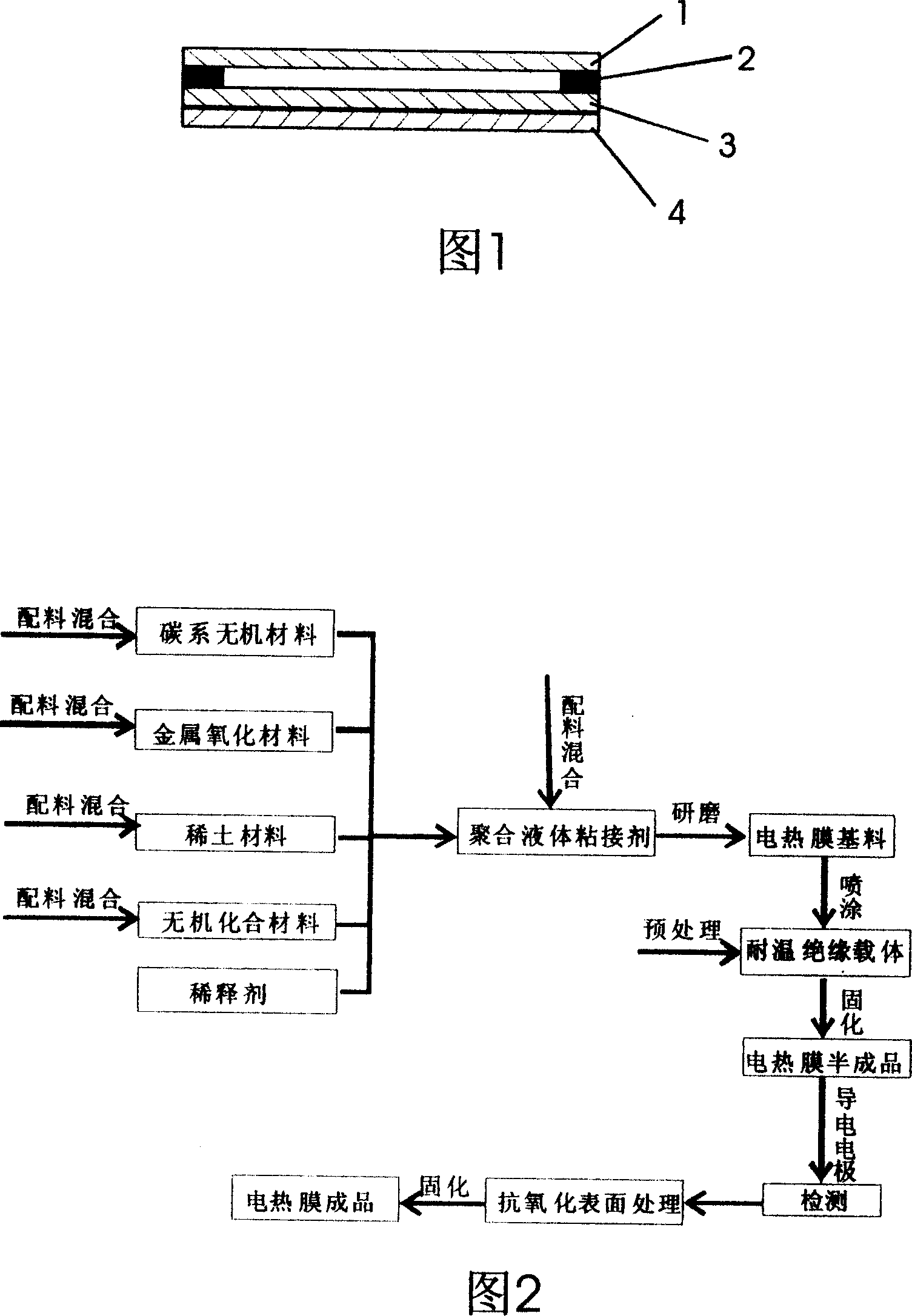

[0029] A composite low-voltage electric heating film is a low-voltage electric heating film with a composite structure. Please refer to Figure 1 for its composite structure. The upper and lower surfaces of the composite low-voltage electric heating film are anti-oxidation and temperature-resistant insulating layers and glass fibers for alkali removal. Connected, the electrothermal film is coated with conductive silver paste, and the wires are drawn out.

[0030] The percentage weight ratio of each component of the composite low-voltage electric heating film is:

[0031] Carbon-based inorganic materials 21%

[0032] Metal oxide material 25%

[0033] Inorganic compound material 10%

[0034] Rare earth materials 4%

[0035] Polymerized liquid medium adhesive 40%

[0036] Anhydrous ethanol (diluent) appropriate amount

[0037]The components of the composite low-voltage electrothermal film in Example 1 are calculated based on the optimal percentage weight ratio of its internal...

Embodiment 2

[0039] A composite low-voltage electric heating film is a low-voltage electric heating film with a composite structure. Please refer to attached drawing 1 for its composite structure. The electrothermal film is coated with conductive silver paste, and lead wires are drawn out.

[0040] The percentage weight ratio of each component of the composite low-voltage electric heating film is:

[0041] Carbon-based inorganic materials 25%

[0042] Metal oxide material 15%

[0043] Inorganic compound material 15%

[0044] Rare earth materials 3%

[0045] Polymerized liquid medium adhesive 42%

[0046] Anhydrous ethanol (diluent) appropriate amount

[0047] The components of the composite low-voltage electrothermal film in Example 2 are calculated based on the optimal percentage weight ratio of the internal structure.

Embodiment 3

[0049] A composite low-voltage electric heating film is a low-voltage electric heating film with a composite structure. Please refer to Figure 1 for its composite structure. The upper and lower surfaces of the composite low-voltage electric heating film are anti-oxidation and temperature-resistant insulating layers and insulation layers The stainless steel is connected, and the weight ratio of the insulating layer of the stainless steel with the insulating layer is 80% organic silicon insulating resin, insulating oxide 10% magnesium oxide and insulating oxide 10% titanium oxide are uniformly mixed, sprayed on the surface of the stainless steel and dried in an oven at 250°C for 2 -Dried for 5 hours, the electrothermal film is coated with conductive silver paste, and leads are drawn out.

[0050] The percentage weight ratio of each component of the composite low-voltage electric heating film is:

[0051] Carbon-based inorganic materials 30%

[0052] Metal oxide materials 18%

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com