Patents

Literature

465results about How to "High degree of binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural fibre reinforced polylactic acid composite material and method for making same

The present invention belongs to the macromolecular material technical field and concretely relates to natural fibre enhanced polylactic acid composite material and a preparation method thereof. The composite material consists of graft modified polylactic acid and the natural fibre. A concrete preparation step is that a polylactic acid matrix is processed for the graft modification, so as to improve the interface combined degree of the natural fibre and the polylactic acid matrix. Firstly, the polylactic acid is processed for the graft reaction with maleic anhydride under the action of an initiator to prepare the graft modified polylactic acid matrix; then the modified polylactic acid and the natural fibre are compounded to obtain biological full-degraded natural fibre enhanced polylactic acid composite material. Compared with pure polylactic acid, the mechanical performance and the thermal performance of the composite material are all improved, and the composite material can be used for preparing the project plastic with rigorous condition requirement. The composite material of the present invention can be degraded completely in the natural environment after being used and wasted and belongs to environmental friendly material.

Owner:TONGJI UNIV

Plant fiber-reinforced polylactic acid foam material and preparation method thereof

The invention discloses a plant fiber-reinforced polylactic acid foam material, which is prepared from the following components: 20 to 95 percent of polylactic acid, 1 to 60 percent of plant fiber powder, 1 to 5 percent of foaming agent, 1 to 5 percent of nucleating agent, 1 to 5 percent of antioxidant and 1 to 5 percent of bulking agent. The invention also discloses a preparation method for the material. The foam material has the advantages of low apparent density, biodegradability, no environmental pollution, capacity of replacing polyolefin foam materials, wide application in the fields of heat insulation, buffer and packaging, simple preparation process and high production efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

PET (polyester) high-speed spinning finish oil

InactiveCN102115978AImprove the lubrication effectStable coefficient of frictionFibre typesPolyesterPolyethylene glycol

The invention discloses PET (polyester) high-speed spinning finish oil, which comprises the following components in parts by weight: 66-74 parts of smoothing agent, 10-14 parts of emulsifier, 4-8 parts of antistatic agent, 6-10 parts of tow collecting agent and 3-5 parts of additive, wherein the smoothing agent comprises phosphate, polyacrylic ester, and any one or a mixture of plant oil, animal oil, mineral oil and synthetic ester oil, the emulsifier comprises an alkyl ether type surfactant, castor oil polyoxyethylene ether and polyoxyethylene ether laurate, the antistatic agent comprises the cationic surfactant of an ammonium salt and octadecanol phosphate potassium salt, the tow collecting agent comprises polyethylene glycol laurate diester, propylene glycol and rubber pyrolysis oil, and the additive comprises talcum powder, fatty alcohol, fatty acid and acrylic acid. By means of the design disclosed by the invention, the frictional factor is more stable and the oil film strength and the oil flash point are both higher.

Owner:吴江市良燕纺织助剂厂

Full-degradation natural fibre/polylactic acid composite material and preparation method thereof

The present invention belongs to the technological field of the polymer material, provides and relates to a wholly degradable natural fiber and polylactic composite material and the preparation method. The composite material consists of the surface modified natural fiber and the polylactic acid. The specific preparation steps are: first the natural fiber of a certain long diameter is taken and the natural fiber is soaked in the aqueous solution of the coupling agent for 1 to 100 minutes; then the natural fiber is taken out and dried; thus the surface modified natural fiber can be got. Then the polylactic acid is molded and refined in the two-roller smelting machine at a temperature between 100 and 160 Celsius system; after 1 to 20 minutes, the surface modified natural fiber is added to mix and refine. The mixed products are putinto the mold; the mixed products are compressed and molded in the flat vulcanization machine to make the natural fiber and polylactic composite material. Compared with the pure polylactic acid, the mechanical and thermal performances of the composite material are improved; the composite material can be used in the preparation of the engineering plastics with the demanding conditions. The composite material of the present invention can be wholly degraded in the natural environment after being used and wasted, and the composite material belongs to the environmentally friendly material.

Owner:TONGJI UNIV

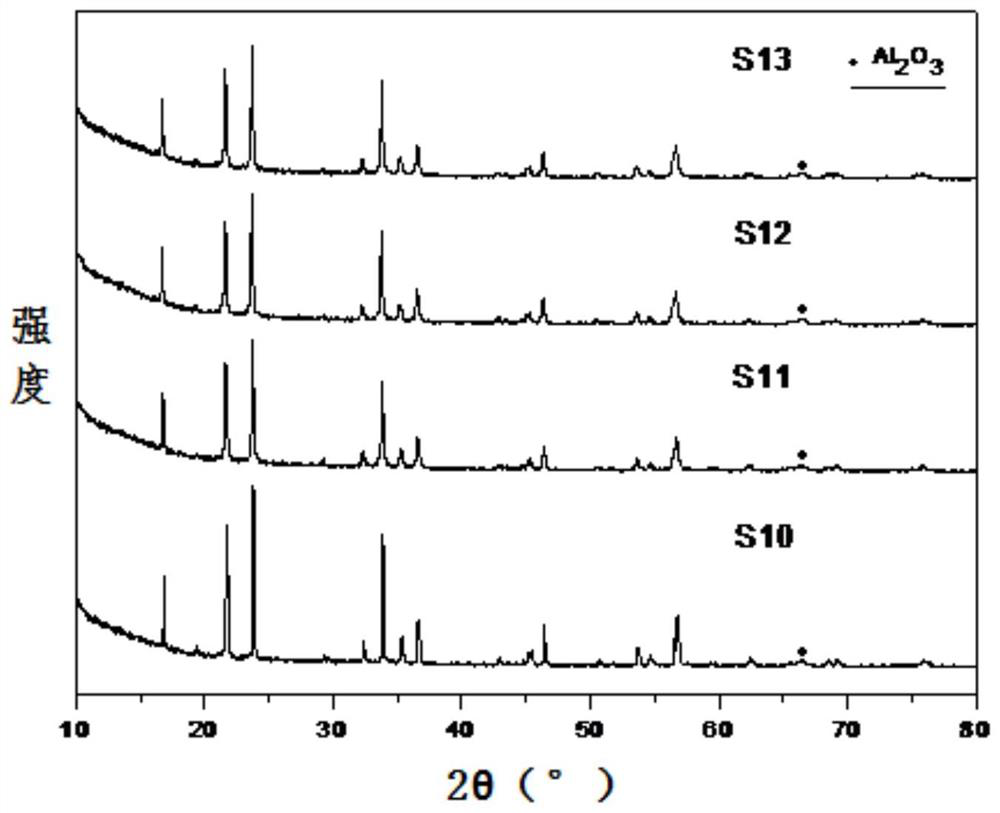

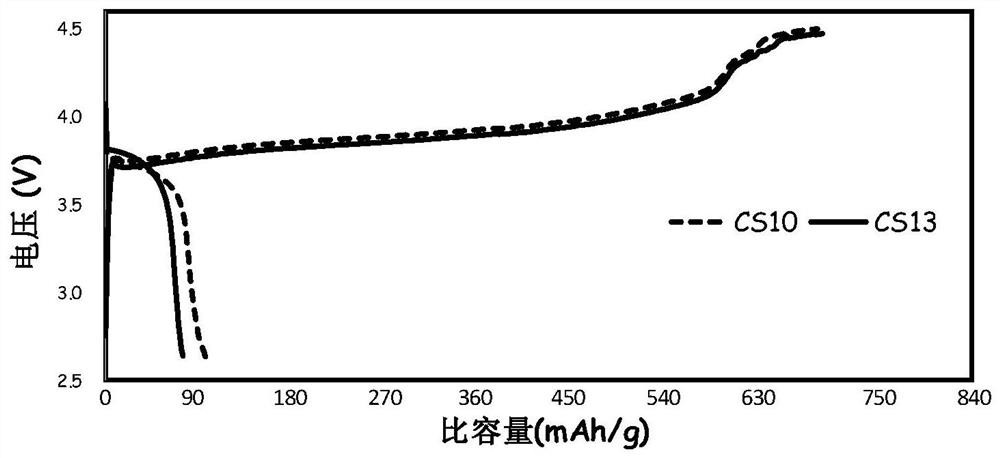

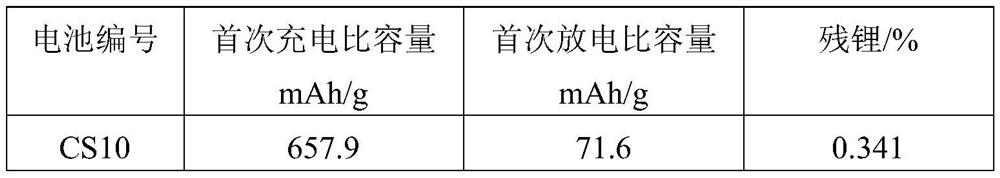

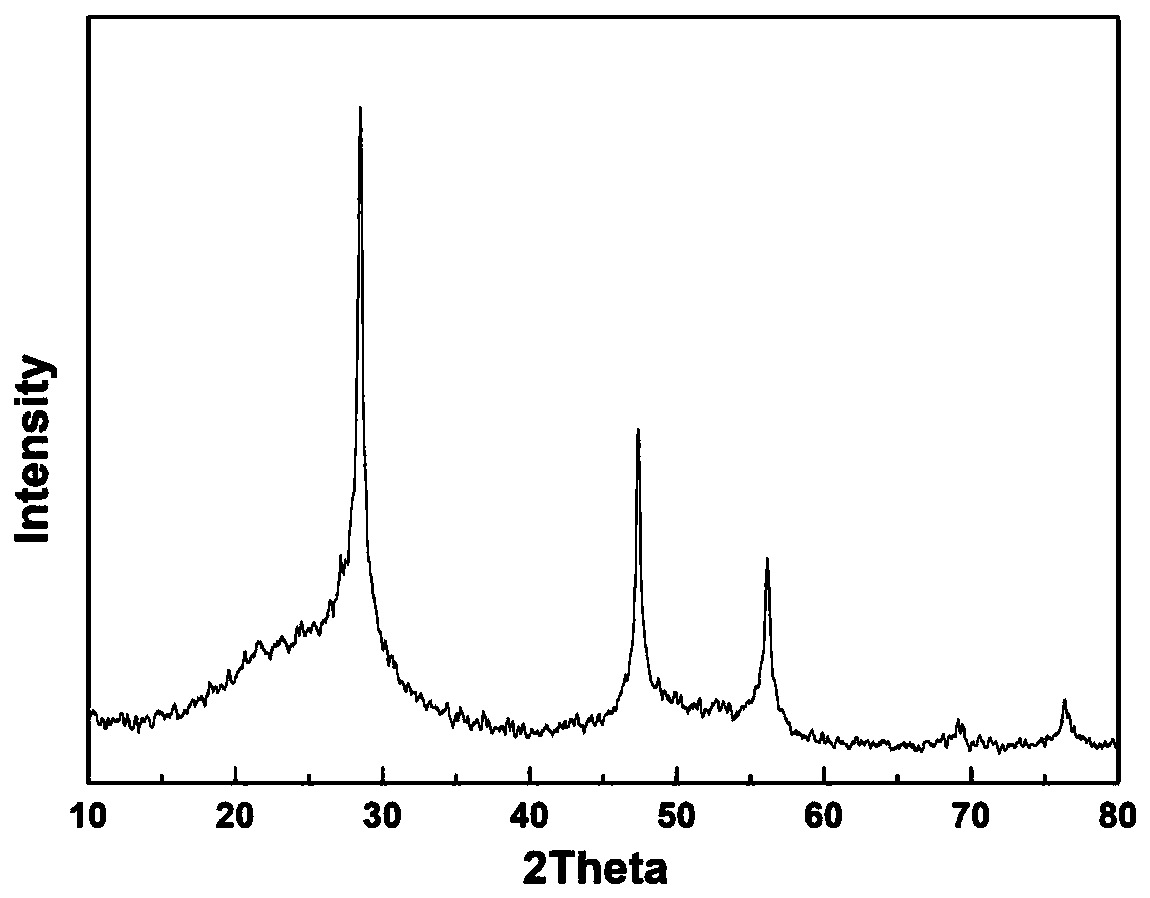

Lithium supplement additive for lithium ion cathode material and preparation method thereof

ActiveCN112490415ATightly boundUniform covering thicknessMaterial nanotechnologyCell electrodesCarbon layerPhysical chemistry

The invention discloses a lithium supplement additive for a lithium ion cathode material. The lithium supplement additive comprises a Li5FeO4 matrix and a coating layer positioned on the surface of the Li5FeO4 matrix, wherein the coating layer comprises a first coating layer carbon layer positioned on the surface of the Li5FeO4 matrix and a second coating layer transition metal oxide layer positioned on the surface of the first coating layer. The invention also discloses a preparation method of the lithium supplement additive, which comprises the following steps: preparing carbon layer coatediron oxide, carrying out wet mixing to prepare surface carbon coated Li5FeO4, mixing with a transition metal ion salt solution and an ammonium hydroxide solution, and carrying out high-temperature sintering to obtain the lithium supplement additive. According to the double-layer coated Li5FeO4 lithium supplementing additive disclosed by the invention, the Li5FeO4 matrix is micron-scale or nano-scale particles, and the particles are uniform and controllable, so that the migration path of electrons and ions is shortened, the lithium supplementing performance of the Li5FeO4 material can be exerted, and the service life of a lithium ion battery is prolonged.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

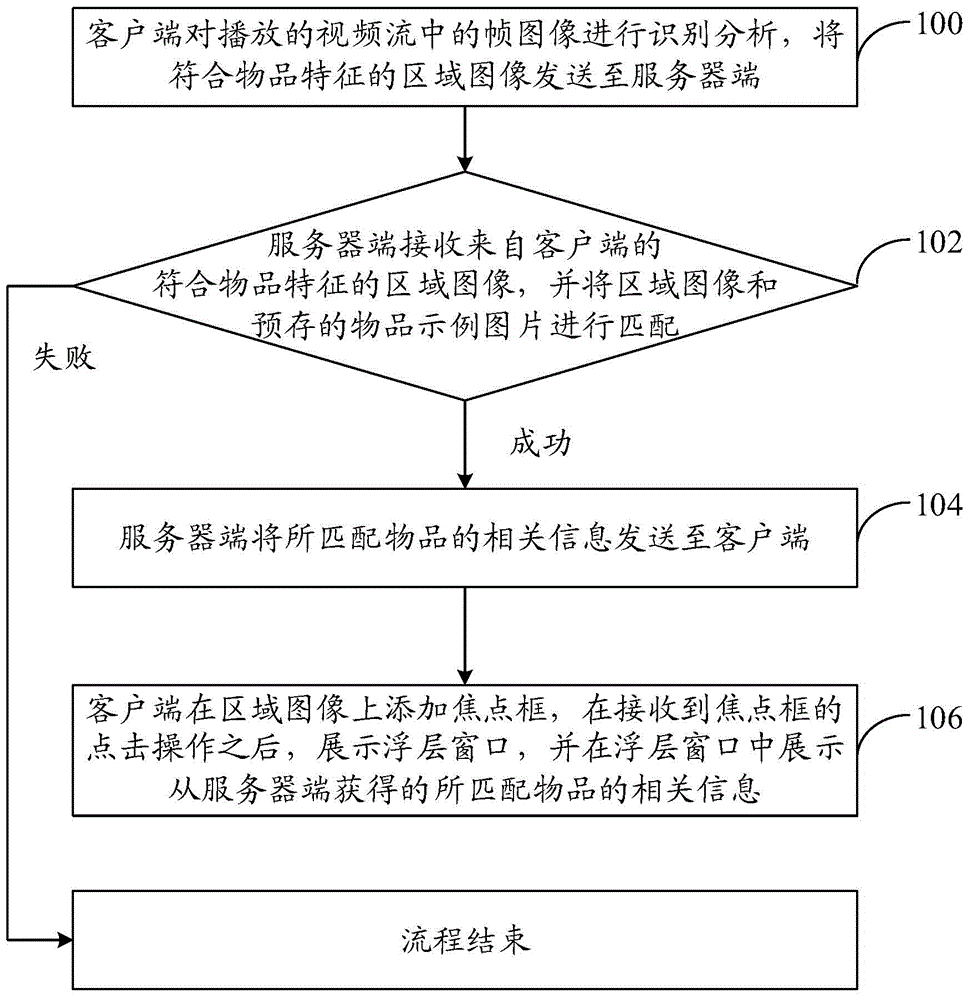

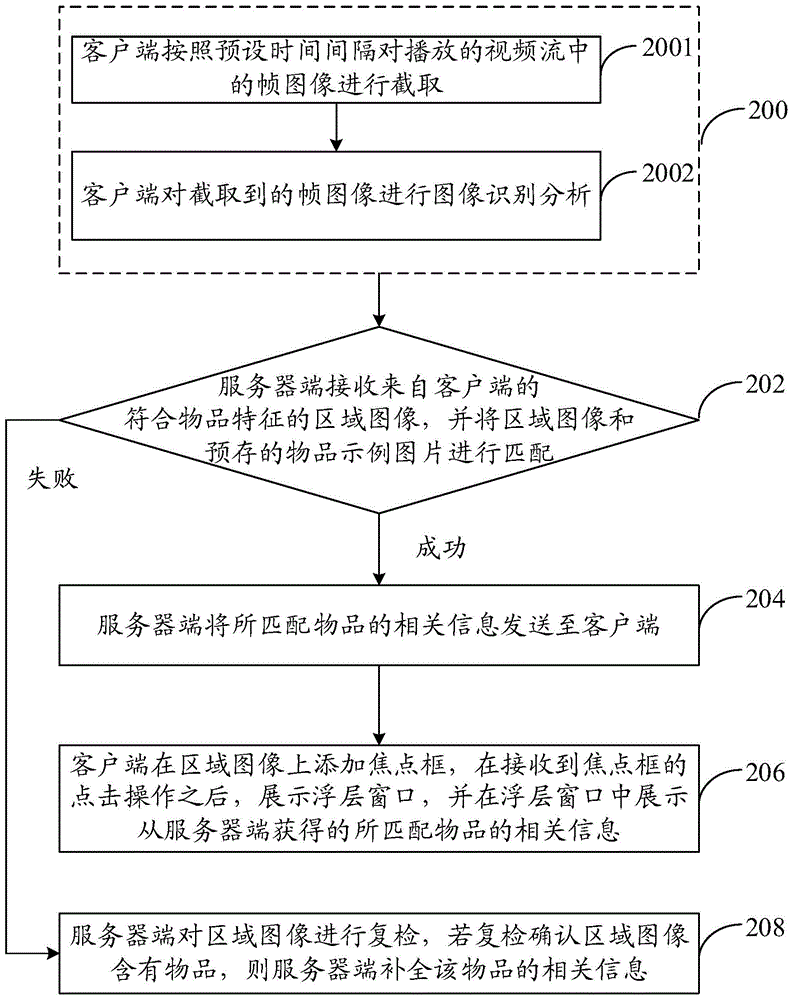

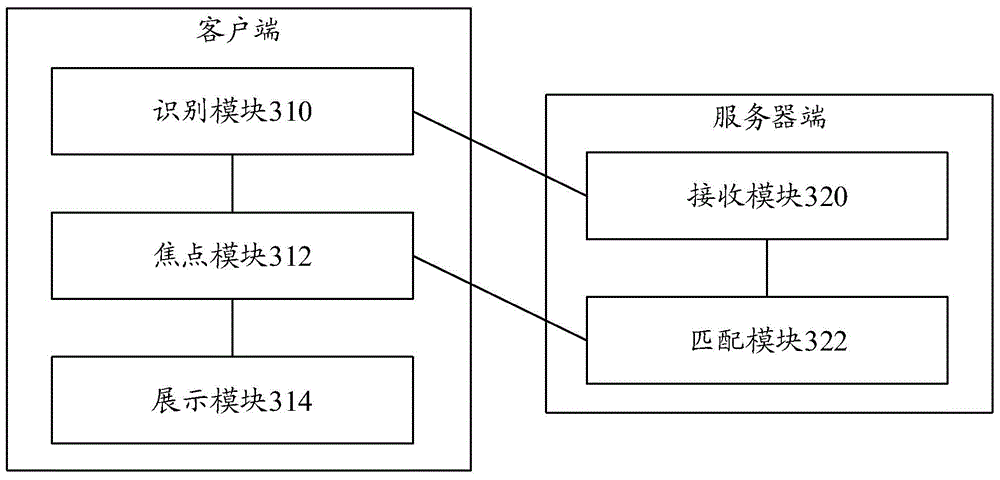

Method and system for presenting article relevant information in video stream

InactiveCN105681918AEasy to understandDoes not affect normal playbackSelective content distributionRelevant informationThe Internet

The embodiment of the invention provides a method and a system for presenting article relevant information in a video stream. The method comprises the following steps that: a client identifies and analyzes a frame image in the played video stream, and transmits a regional image which conforms to an article feature to a server side; when the server side matches the regional image with a pre-stored article sample picture and matching succeeds, the client adds a focus frame to the regional image; and after a click operation of the focus frame is received, the client presents a floating layer window, and presents relevant information, which is acquired from the server side, of a matched article in the floating layer window. In the embodiment of the invention, relevant information of articles is pre-stored in the server side, and the relevant information of the articles is presented in the video stream played by the client, so that the relevant information of the articles can be obtained without searching the articles through Internet and the like, and convenience is brought to know the articles in the video stream.

Owner:LE SHI ZHI ZIN ELECTRONIC TECHNOLOGY (TIANJIN) LTD

Porous silicon monoxide composite material and preparation and application thereof

ActiveCN110854377AControl contentThe pre-processing process is simpleMagnesium silicatesSilicaCarbon coatingComposite material

The invention belongs to the field of lithium ion battery materials, and particularly discloses a porous silicon monoxide composite material. The composite material comprises an inner core, a middle layer compounded on the surface of the inner core and an outer layer compounded on the surface of the middle layer, wherein the inner core is silicon, the middle layer is silicon monoxide and silicateof metal M dispersed in the silicon monoxide, the outer layer is a carbon coating layer, and the metal M is a metal element capable of reducing silicon oxide. The invention also provides a preparationmethod of the composite material and an application of the composite material as a negative electrode active material of a lithium ion secondary battery. Research finds that the composite material has the characteristics of long cycle life, high initial efficiency and the like.

Owner:CENT SOUTH UNIV +1

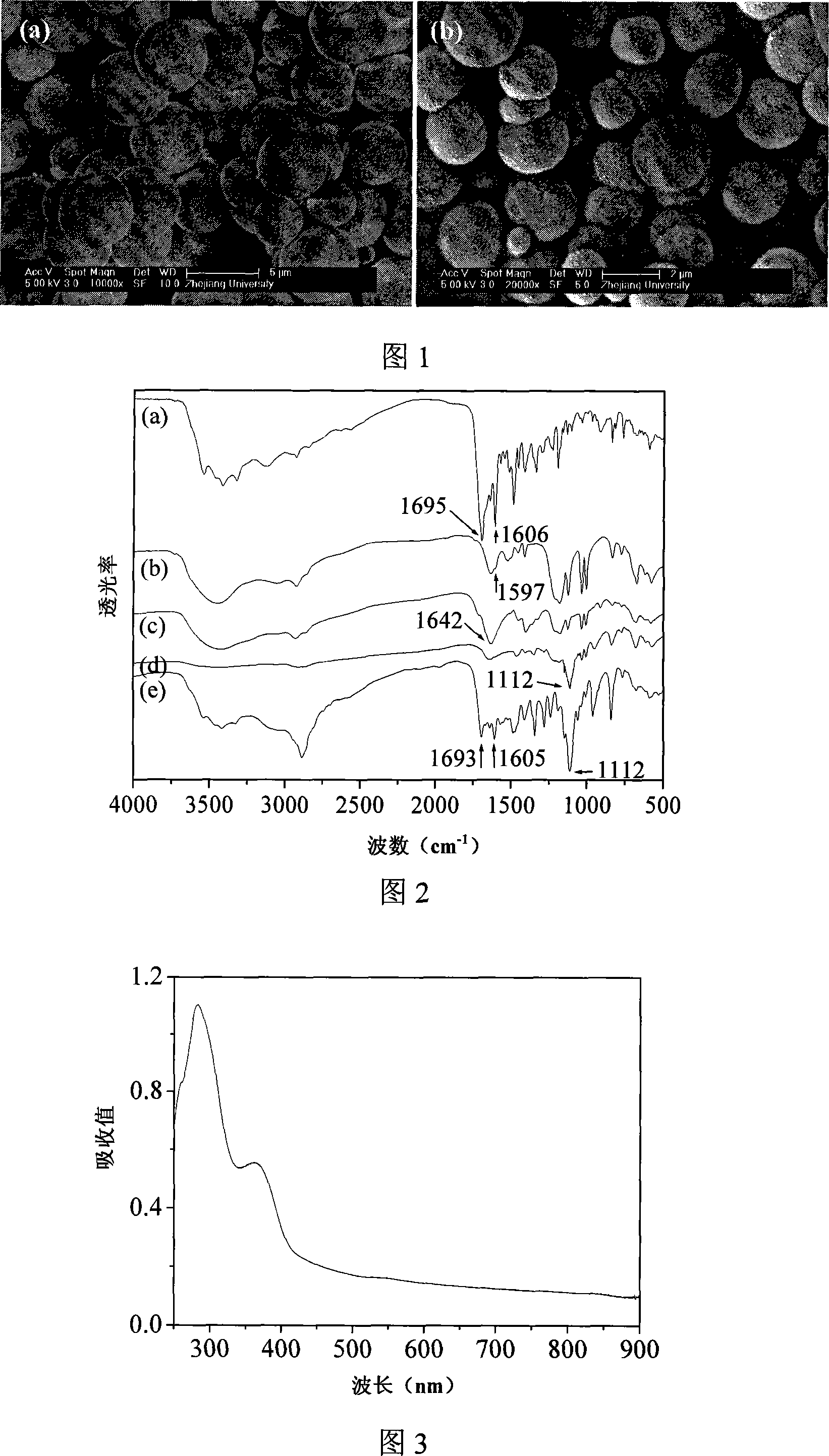

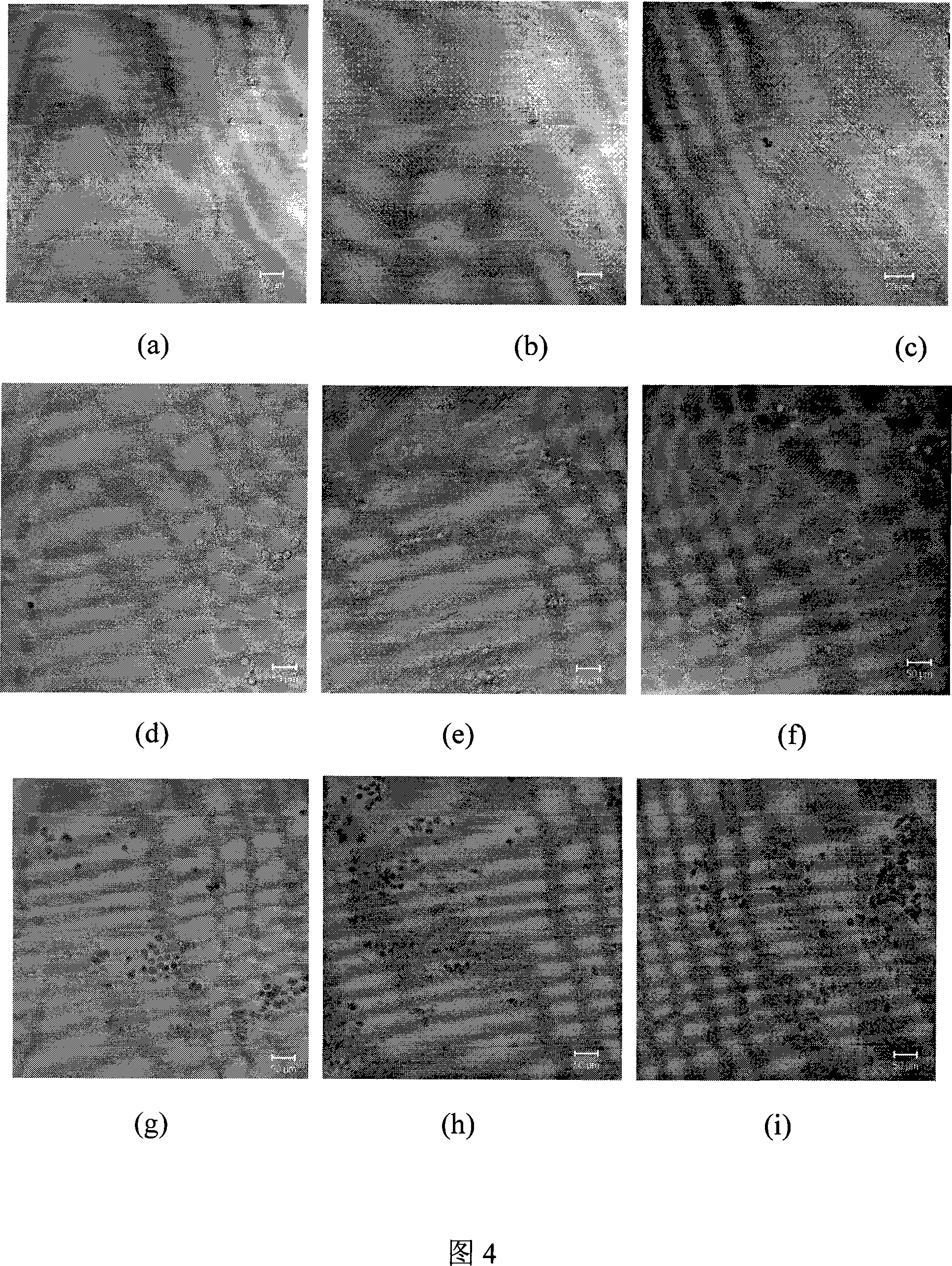

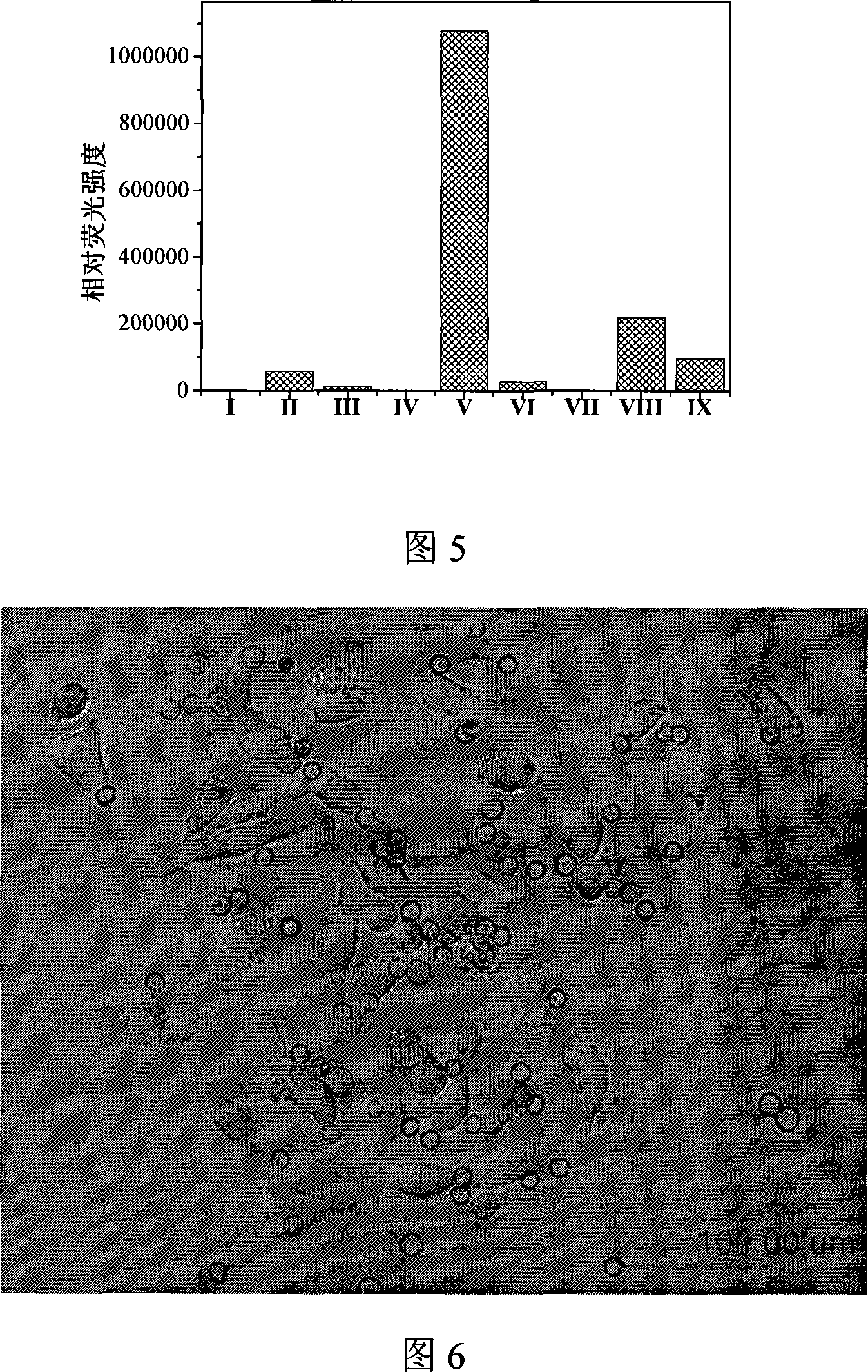

Method for preparing microcapsule having function of specific connecting with tumor cell

InactiveCN101099727AHigh degree of bindingHigh drug loadingPharmaceutical non-active ingredientsAntineoplastic agentsPolyethylene glycolMicroparticle

The present invention discloses a preparation method of microcapsule which can be specifically combined with tumor cell. Said preparation method includes the following steps: adopting removable colloidal particles as template, utilizing layer-by-layer self-assembly method to make polyelectrolyte with opposite charges be assembled on the surface of colloidal particles, then utilizing polyethylene glycol and tumor cell identification ligand to make modification, finally making the colloidal particles be dissolved or decomposed so as to obtain the invented polymer hollow microcapsule containing tumor cell identification ligand.

Owner:ZHEJIANG UNIV

Alcohol-rejection proton conducting composite film and preparation method thereof

InactiveCN103367773AImprove alcohol resistanceReduce resistanceSynthetic resin layered productsFuel cell detailsComposite filmPolymer science

The invention discloses an alcohol-rejection proton conducting composite film and a preparation method thereof. The alcohol-rejection proton conductive composite film is characterized in that a grapheme layer is composited in parallel with polymer proton conducting films and is adhered to one sides of the polymer proton conducting films or clamped between the two polymer proton conducting films. The preparation method comprises the following steps of: attaching the grapheme layer to one sides of the polymer proton conducting films by developing copper-base chemical vapor deposition grapheme or rotatably spraying grapheme aqueous dispersion / oxidized grapheme water solution, and further clamping the grapheme layer between the two polymer proton conducting films by utilizing a hot-pressing process. According to the alcohol-rejection proton conducting composite film, the alcohol-rejection performance of the film can be remarkably improved on the premise that the electric conductivity of protons of a polymer proton conducting film body is not influenced; the alcohol-rejection proton conducting composite film can be obtained by utilizing diversified methods; the preparation process is simple, and most areas of the grapheme layer are single-layered, so that the resistance caused to the proton conduction in the film body is relatively low.

Owner:TIANJIN UNIV +1

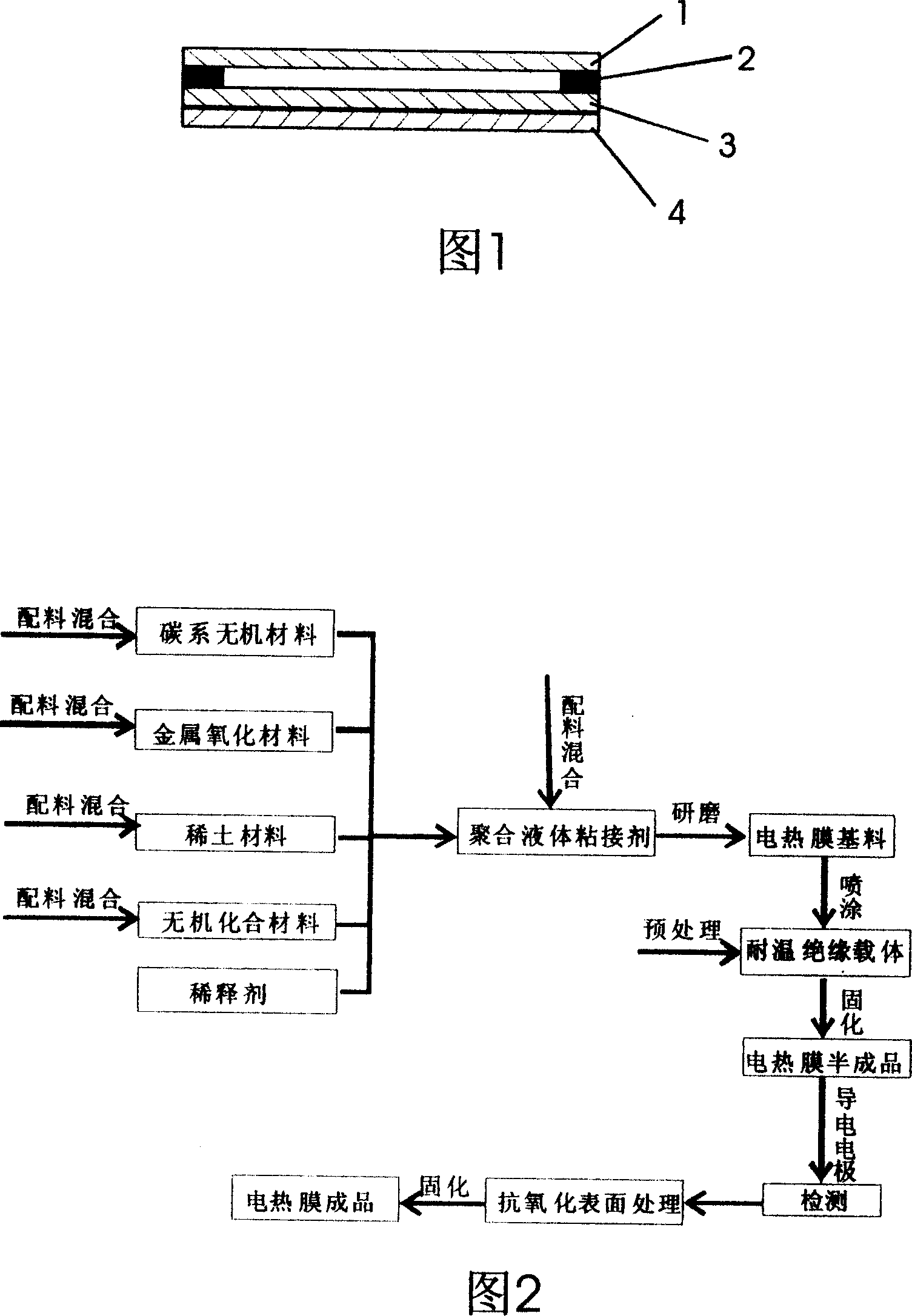

Composite low-voltage electrothermal film and making method

InactiveCN1980494AWide variation in geometryImprove conductivityHeating element materialsManufacturing technologyLiquid medium

The structure of the complex low-voltage electric heating film (CLEHF) consists of the electric heating inorganic compound (EHIC), the hi-temperature durable (HTD) isolator, the electrodes and the anti-oxidation HTD isolation layer. The EHIC consists of the carbon system inorganic material, the rare-earth material, the metal oxide, the inorganic compound and the polymerization liquid medium adhesive. The manufacture technology of CLEHF includes: ingredient configuring, mixing, skiving, spraying, solidifying and forming. With a low work voltage of 12 volts, CLEHF heats up to 100 degrees centigrade in only 50 seconds. This invention possesses advantages of fast response time, high heating efficiency and wide application range. Depending on different features and usages of various heater bodies, different materials are selected to form different shapes of heating films. Therefore, this heating film adapts to all handy low voltage electric heating apparatuses.

Owner:周挺

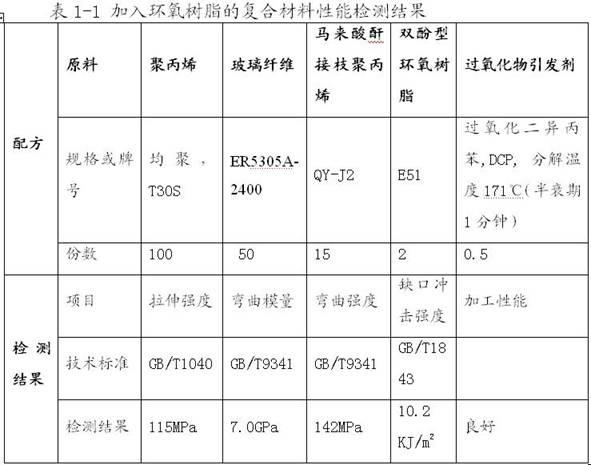

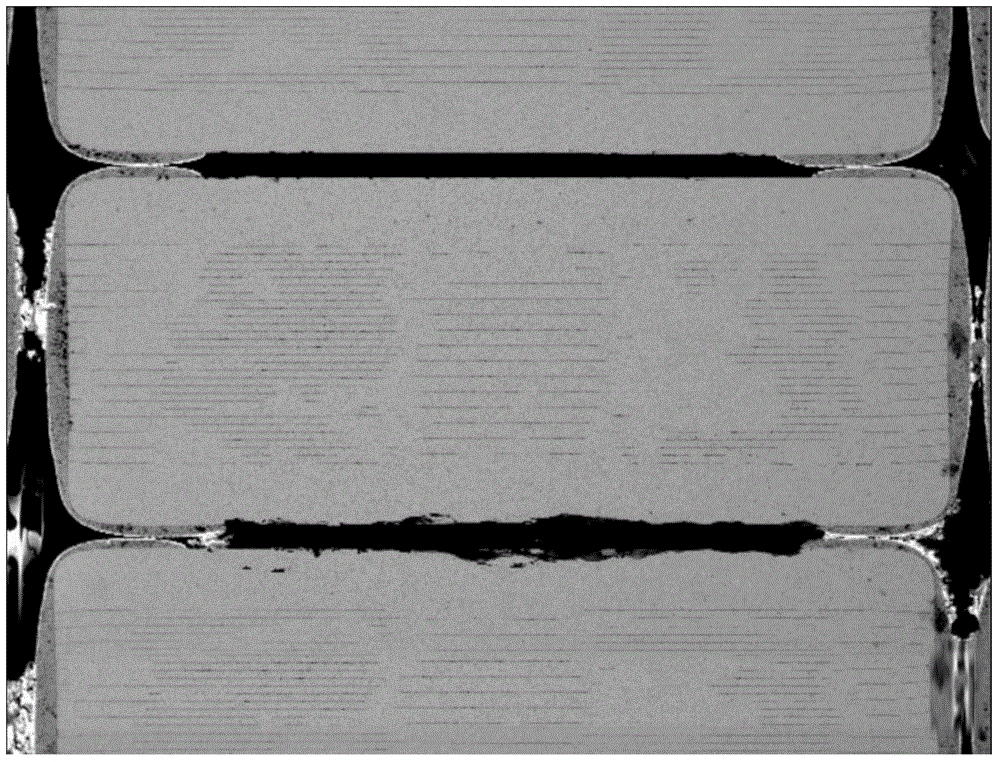

Polypropylene/fiberglass composite material and preparation method thereof

The invention discloses a polypropylene / fiberglass composite material and a preparation method thereof. The polypropylene / fiberglass composite material is prepared from the following raw materials in parts by weight: 100 parts of polypropylene, 15-50 parts of fiberglass, 5-15 parts of maleic anhydride grafted polypropylene, 0.2-0.5 part of peroxide initiator and 0.5-2 parts of epoxy resin. The preparation method of the polypropylene / fiberglass composite material comprises the steps of: uniformly mixing weighed polypropylene, maleic anhydride grafted polypropylene and the peroxide initiator according to the ratios, adding to the upstream feeding port of a screw extruder at the temperature of 160-230 DEG C and mixing; synchronously carrying out epoxy resin surface coating treatment on the fiberglass, weighing the fiberglass before and after coating, calculating the addition amount of epoxy resin according to the weight difference of the fiberglass before and after coating, introducing to the downstream fiberglass adding port of the screw extruder, and by virtue of the shearing action of the screw extruder, shearing the fiberglass into about 0.2-0.5 mm and uniformly dispersing the fiberglass in a base material; and extruding, drawing and granulating. The material is good in strength, rigidity and impact ductility, simple in process, low in cost and high in production efficiency.

Owner:GUIZHOU UNIV

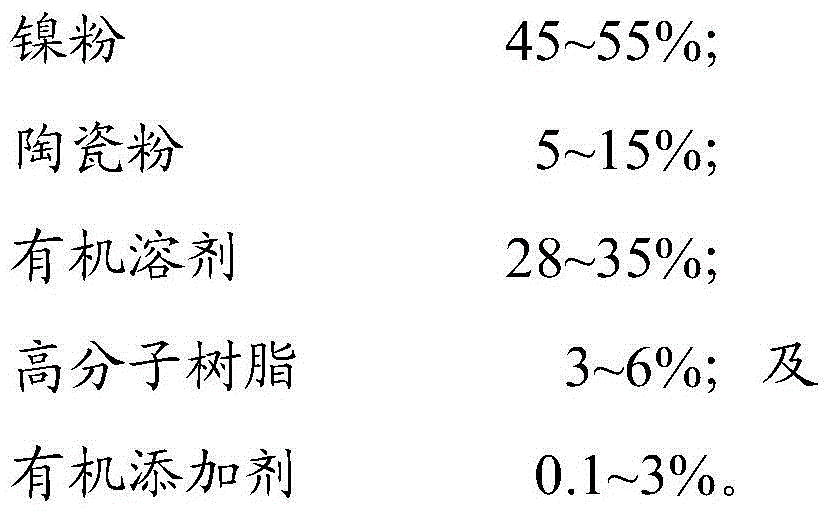

Inner electrode paste

ActiveCN104576043AGood electrode continuityImprove continuityFixed capacitor electrodesNickelLarge capacity

The invention relates to inner electrode paste, which is prepared from the following components by mass percent: 45%-55% of nickel powder, 5%-15% of ceramic powder, 28%-35% of an organic solvent, 3%-6% of macromolecule resin and 0.1%-3% of an organic additive. The inner electrode paste is obtained by appropriate proportioning of the nickel powder, the ceramic powder, the organic solvent, the macromolecule resin and the organic additive; the inner electrode paste has the advantage of good electrode continuity after being sintered by the nickel powder, the silk-screen printing property is not affected, and the phenomenon of net sticking or net jamming is unlikely to appear; the ceramic powder is capable of restraining shrinkage of an inner electrode layer, and effectively restraining cracking and layering of chips; the nickel powder and the ceramic powder can be evenly and stably dispersed in a paste system by the organic additive; the condition that a required pattern is completely and evenly printed by the inner electrode paste can be ensured by the macromolecule resin and the organic solvent; the inner electrode paste can meet the usage requirements of high-frequency and high-capacity multi-layer ceramic capacitors.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

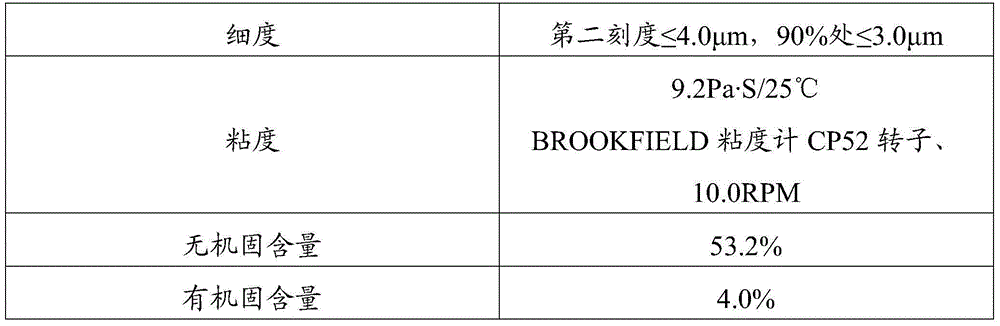

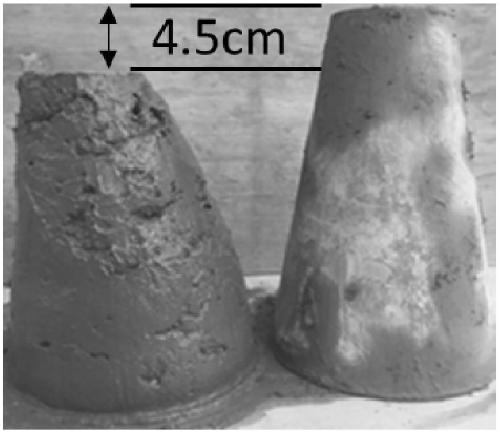

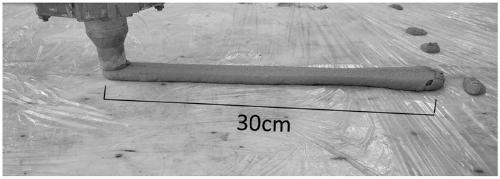

Plant fiber reinforced geopolymer for 3D printing of Zhaozhou Bridge, and preparation method thereof

InactiveCN109400031ALow water absorptionAvoid crackingAdditive manufacturing apparatusCement productionFiberCalcium hydroxide

The invention relates to a plant fiber reinforced geopolymer for 3D printing of the Zhaozhou Bridge, and a preparation method thereof. The plant fiber reinforced geopolymer comprises, by weight, 0.95-1.35 parts of fly ash, 0.025-0.055 part of calcium hydroxide powder, 0.015-0.035 part of plant fiber, 0.03-0.09 part of slag, 0.08-0.13 part of silica fume, 0.05-0.08 part of clay, 1.2-1.4 parts of quartz sand, 0.65-1.2 parts of composite alkali activators, 0.005-0.012 part of sodium bentonite, 0.005-0.009 part of viscosity modifier, 0.02-0.05 part of polyvinyl alcohol treatment solution, 0.0035-0.0065 part of coupling agent and 0.05-0.15 part of water. The plant fiber reinforced geopolymer with the plant fibers as toughening materials has the advantages of low cost, low density, regenerability and environmental protection, and is beneficial to promotion of the practical engineering application of 3D printing geopolymer materials.

Owner:HEBEI UNIV OF TECH

Super black and misty leather surface treatment agent and preparation method thereof

The invention relates to a super black and misty leather surface treatment agent which is prepared by mixing the following components in parts by weight: 100 parts of solvent type PU, 10-20 parts of flatting powder, 5-10 parts of wax and 200-250 parts of solvent, wherein the solvent type PU is prepared by reaction of diisocyanate, polylol, chain extenders, catalysts and light stabilizers under the condition of existence of organic solvents. Compared with the original common black and misty leather surface treatment agent, the super black and misty leather surface treatment agent obviously increases the blackness and the haze of coatings, improves the crumpling resistance, the wear resistance and the scratch resistance of coatings, and enables leathers to have waxy effect.

Owner:JIAXING HEXIN CHEM IND

Polyester composite fiber with intelligent surface, and preparation method and application thereof

InactiveCN109385893ASpecial surface structureImprove hydrophilicity and hydrophobicityPhysical treatmentLiquid repellent fibresOil waterPolyester composite

The invention discloses a polyester composite fiber with an intelligent surface, and a preparation method and application thereof. The polyester composite fiber comprises a polyester fiber matrix andparticles covering the polyester fiber matrix, wherein the particles and the polyester fiber matrix are chemically bonded; preferably, the particles are polymer particles; more preferably, the particles are polymer particles with environmental response; thus, covering of the surface of the polyester fiber matrix with the particles can improve the hydrophilicity and hydrophobicity of the fiber andendows the fiber with certain environmental response. The preparation method comprises the following steps: preparing the polyester fiber matrix having reactive groups on the surface at first; then preparing the particles having reactive functional groups; and finally, mixing the polyester fiber matrix and the particles for a reaction so as to obtain the polyester composite fiber. The polyester composite fiber of the invention can be used for smart textiles, non-woven fabrics, porous films, composite materials and oil-water separators, preferably for smart textiles and oil-water separators.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

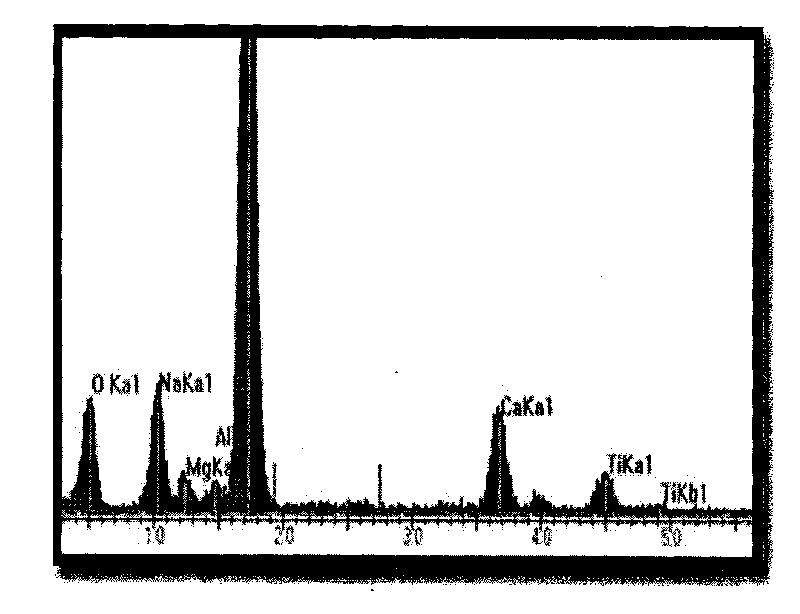

Preparation method of titanium dioxide dense film for dye-sensitized solar cell

InactiveCN101697321APromote the process of industrializationImprove performanceLight-sensitive devicesSolid-state devicesSulfateSlurry

In the invention, industrial-grade titanyl sulfate is used as a titanium source to prepare aqueous titanium dioxide collosol which is suitable for film coating, the titanium dioxide collosol is rotationally coated to form a film, and after high-temperature heat treatment, a high-performance nano-titanium dioxide dense film is obtained. The combination degree between the titanium dioxide film and a matrix is improved and the contact between an electrolyte with a photoanode is effectively prevented so as to reduce electronic complex. Thus, the battery performance is improved substantially, and due to low slurry cost, the industrialization process of the dye-sensitized solar cell is promoted.

Owner:IRICO

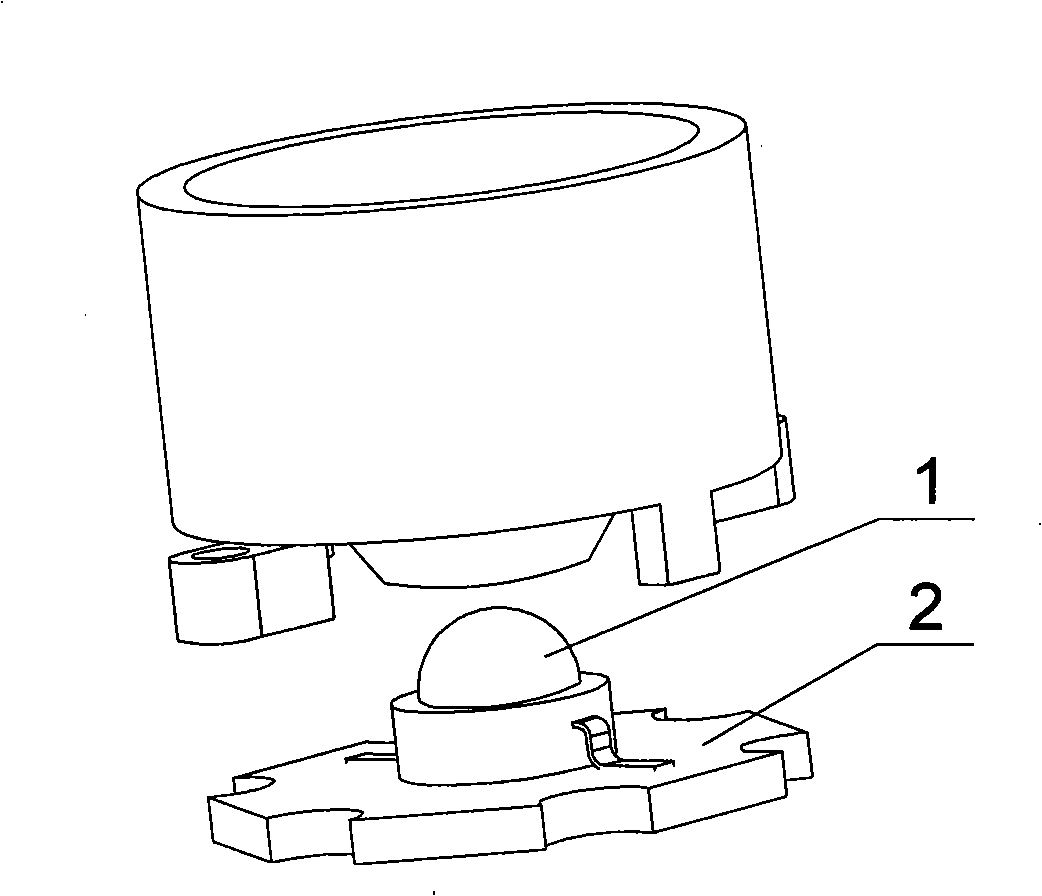

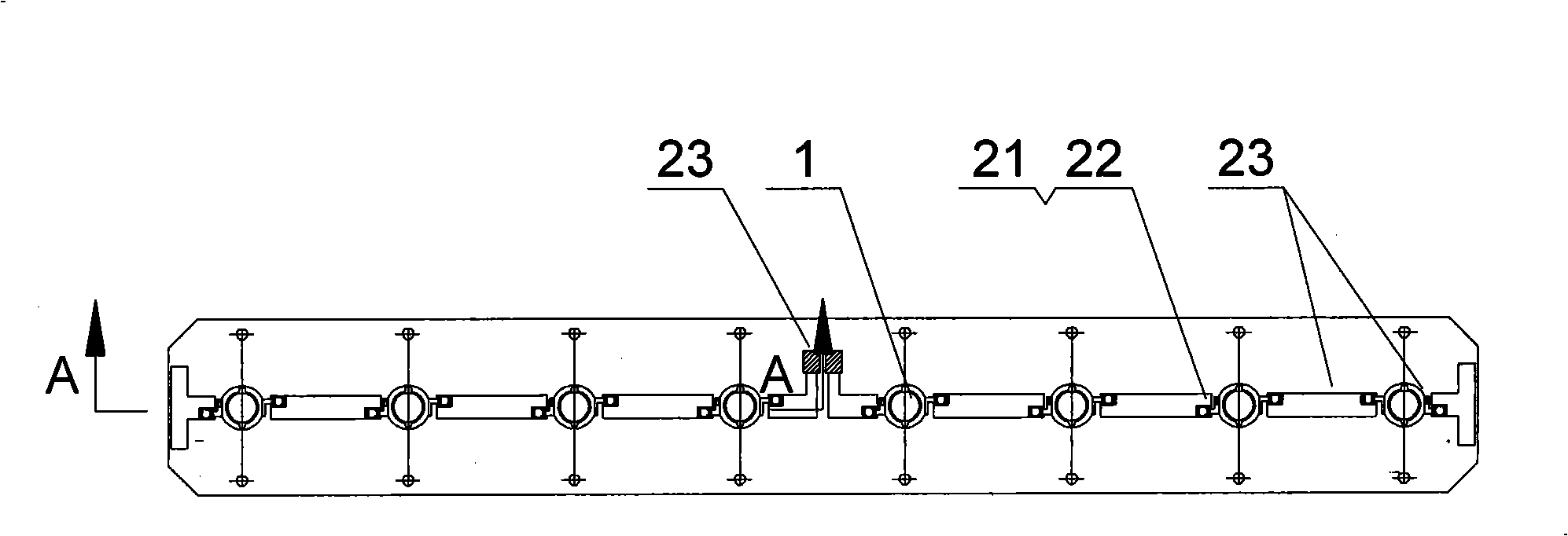

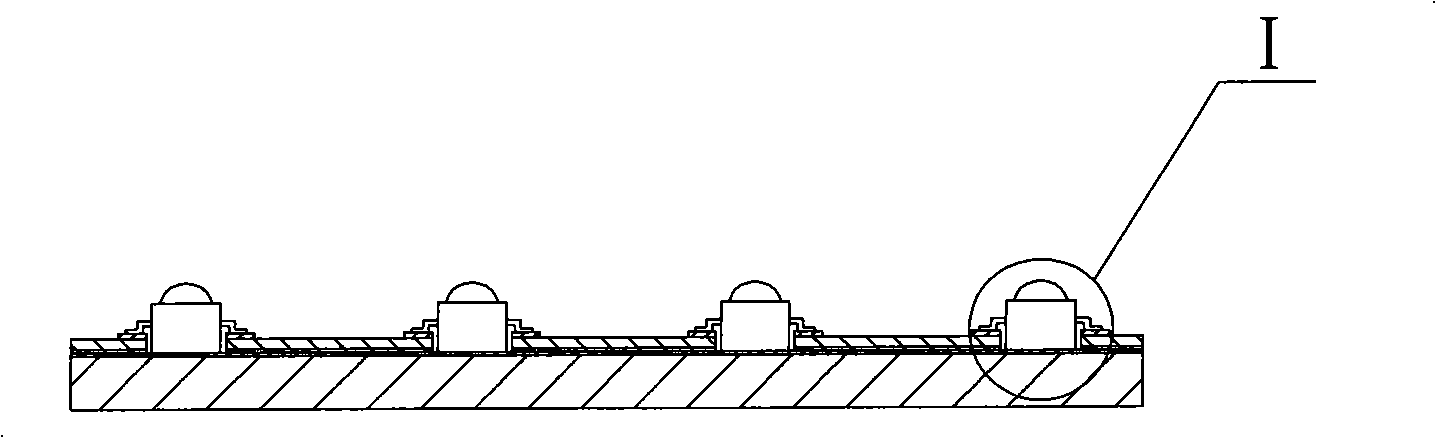

High-power LED aluminum substrate integrated module

InactiveCN101494219AImprove overall lifespanImprove cooling effectPoint-like light sourceElectric circuit arrangementsBasementComputer module

The invention discloses an LED street lamp, aiming at providing a high power LED aluminum base plate integrated module with excellent heat elimination performance and effectively prolonged service life. The high power LED aluminum base plate integrated module comprises an LED (1) and an aluminum base plate (2). The aluminum base plate (2) comprises an aluminum plate (20); an insulated oxidization layer (25) is covered on the upper surface of the aluminum plate (20); a basement film (21) and a conducting film (22) are arranged on the insulated oxidization layer (25) in sequence; the conducting film (22) forms a circuitous pattern; the basement film (21) is matched with the contour of the conducting film (22); a plurality of welding films (23) are arranged on the conducting film (22); the chip of the LED (1) is stuck to the insulated oxidization layer (25); and a lead foot of the LED (1) is welded on the welding film (23). The LED street lamp can be widely applied to the lighting field.

Owner:珠海泰坦新能源系统有限公司

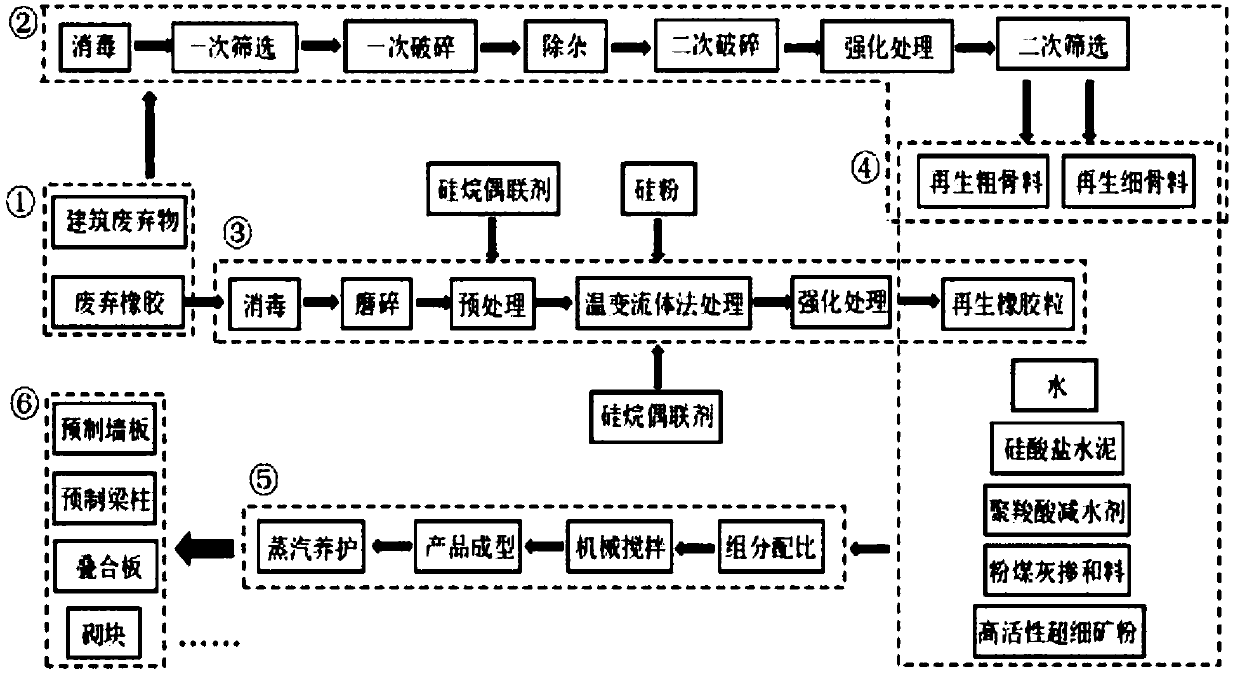

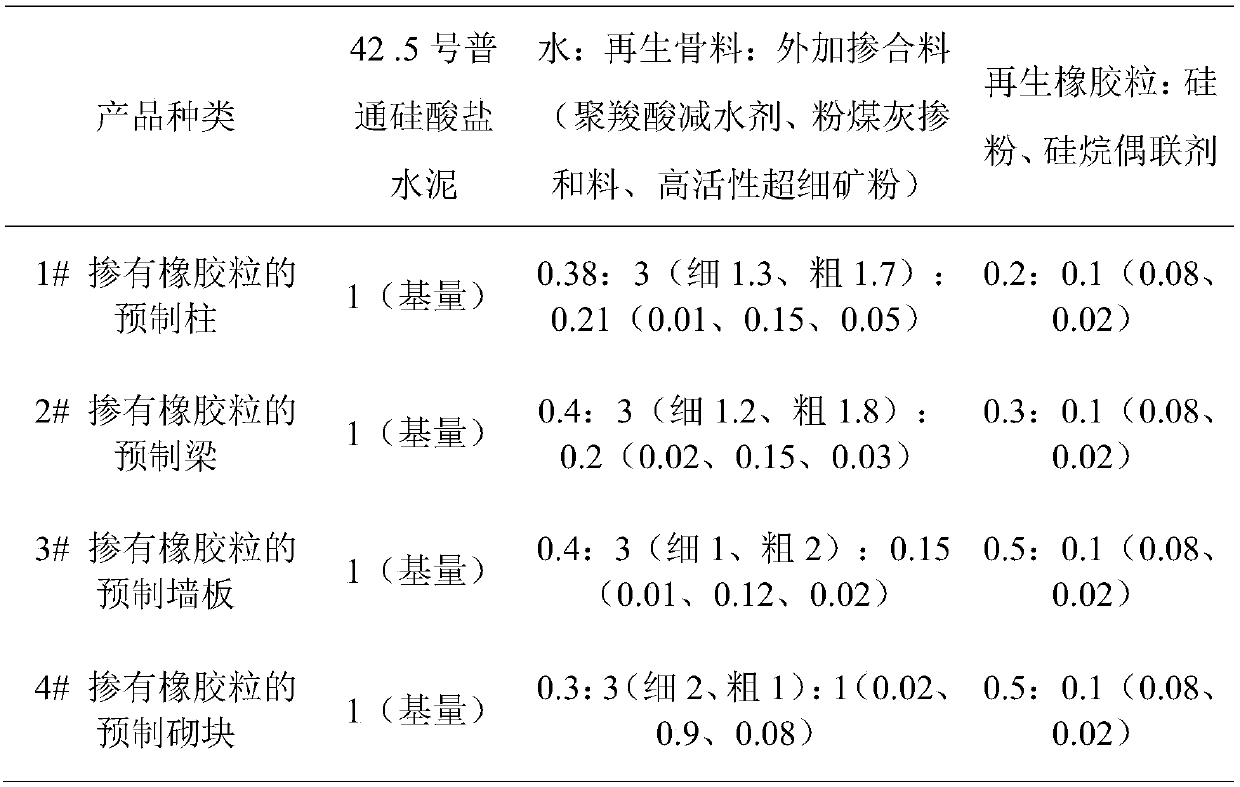

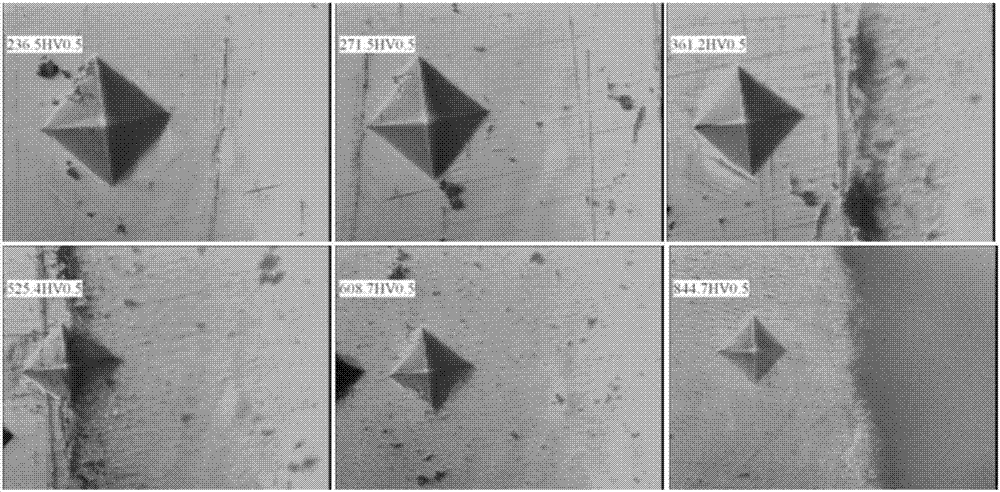

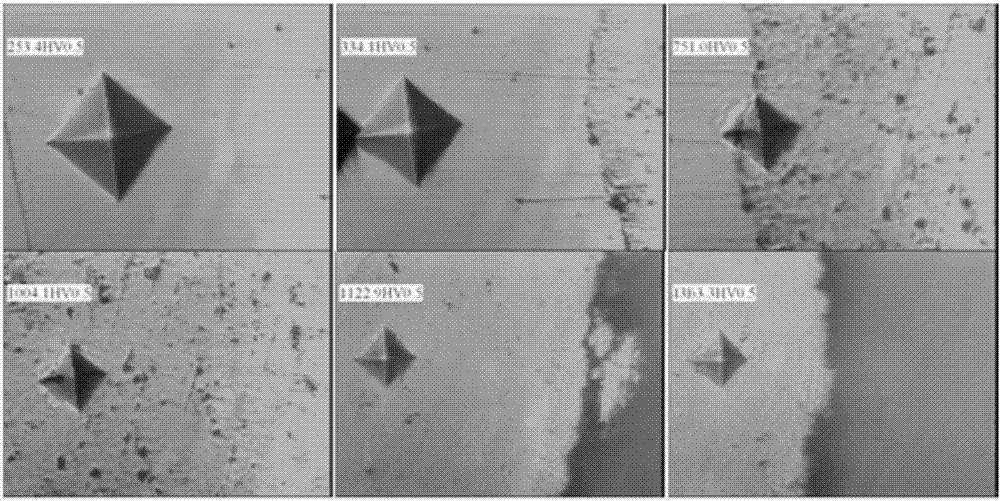

Recycled concrete doped with rubber particles as well as preparation method and application thereof

The invention provides recycled concrete doped with rubber particles as well as a preparation method and application thereof. Construction garbage is disinfected, broken, decontaminated, sieved, strengthened and the like to prepare recycled aggregates; abandoned rubber tyres and the like are used for preparing rubber particles through technologies including disinfection, breaking, preprocessing, temperature change fluid method processing, strengthening processing and the like; the obtained recycled composite aggregates, silicate cement, water and other mineral admixture are mixed to prepare different concrete products, including recycled concrete prefabricated wall panels, building blocks and the like doped with rubber particles, through a subsequent technology by controlling different proportions. The concrete prepared with the method has the advantages of environment protection, low price, stable mechanical property, good durability and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

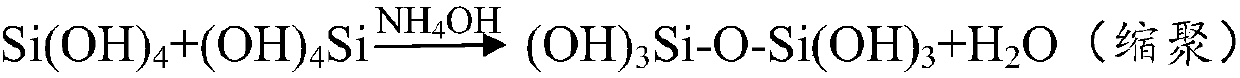

Repairing method for surface of draught fan blade

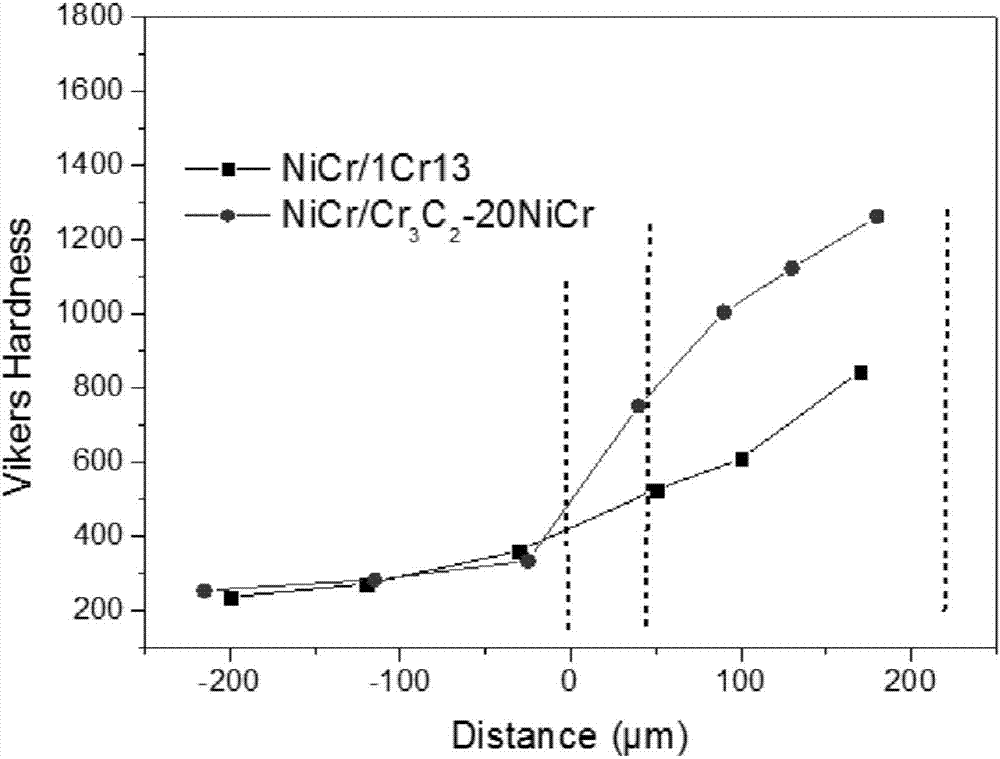

InactiveCN107254650ASolve lossSolve the problem of longevityMolten spray coatingCarbon compoundsPre treatmentMulti element

The invention discloses a repairing method for the surface of a draught fan blade and belongs to the technical field of draught fan repairing. According to the repairing method for the surface of the draught fan blade, the method comprises the steps of blade surface pre-treatment, preheating before spraying, preparation before material spraying, ultrasonic spraying and hole sealing treatment. According to a spraying material, an NiAl material is chosen and used to conduct bottoming, and the problem that the material thermal expansion coefficients of an abrasion-resisting work layer and a blade base layer are not matched can be solved, so that thermal stress caused by the fact that the expansion coefficients of the work layer and the blade base layer are not matched is reduced, and the mechanical matching and physical compatibility between the work layer and the blade base layer are improved. The work layer is a WC-12Co composite coating or an NiCr-Cr3C2 composite coating. According to the repairing method for the surface of the draught fan blade, by optimizing the repairing steps, multi-element alloy coating components and distribution, the good erosion and abrasion resistance performance is achieved, and the technical problem that the efficiency of a draught fan is affected due to draught fan blade erosion and abrasion is solved.

Owner:安徽威龙再制造科技股份有限公司

Spinel micro-powder castable for steel ladle and method for preparing prefabricated part from the castable

The invention relates to the technical field of refractory materials, and provides a spinel micro-powder castable for a steel ladle and a method for preparing a prefabricated part from the castable. The spinel micro-powder castable for the steel ladle is prepared from the following components in parts by mass: 25-40 parts of tabular corundum particles, 15-25 parts of white corundum particles, 15-20 parts of fused magnesia-alumina spinel particles, 8-12 parts of white corundum fine powder, 6-10 parts of alpha-Al2O3 micro powder, 3-5 parts of sintered spinel micro powder, 6-7 parts of cement, 1-2 parts of steel fibers and 1-3 parts of additives. Through the sintered spinel micro powder, the castable is more compact, the porosity is reduced, the pore diameter is reduced, and meanwhile, the generation of calcium hexaluminate (CA6) is promoted, so that the matrix structure is optimized. The castable has high normal-temperature strength and high-temperature strength and excellent high-temperature breaking strength, slag corrosion resistance and thermal shock resistance, and the service life of a steel ladle material is effectively prolonged.

Owner:北京利尔高温材料股份有限公司

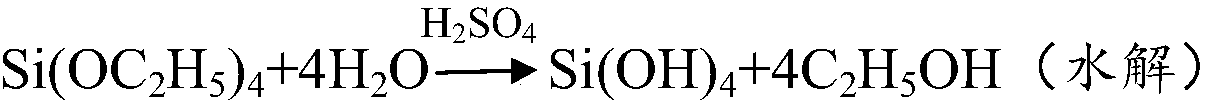

Preparation method of lightweight thermal insulating wall material of expanded perlite-SiO2 aerogel

The invention discloses a preparation method of a lightweight thermal insulating wall material of expanded perlite-SiO2 aerogel. The preparation method comprises the following steps of by taking TEOSas a precursor, EtOh as a solvent and H2SO4 and NJ3.H2O as catalysts, adopting acid / alkali two-step catalytic reaction to prepare SiO2 sol, then stirring the SiO2 sol until the sol turns into gel, performing ageing, solvent exchange, surface modification and online temperature raising drying, mixing coal ash, water glass, a polyurethane foaming agent and cement with a product, adding a mixture ina mixer, adding a proper amount of water, uniformly stirring and mixing, performing maintenance to prepare a thermal insulation block, standing for a period of time under the natural condition, and then sending a the thermal insulation block into an autoclave reaction kettle for maintenance to prepare the lightweight thermal insulating wall material. By adopting the preparation method provided bythe invention, in the production process of a novel coal ash porous thermal insulation material, the energy is saved, the main raw material is a solid waste, the cost is low, and the manufactured thermal insulation material accords with the quality requirement with the strength and the thermal insulation performance reaching the standard.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Modified material and treatment method of low-quality aggregate

The invention belongs to the technical field of building materials, and specifically relates to a modified material and treatment method of a low-quality aggregate. The modified material of the low-quality aggregate provided by the invention comprises the following components in percentage by mass: 46-50% of cement, 10-15% of a mineral admixture, 2-5% of an active powder, 0.2-0.6% of a water reducing agent, 0.001-0.004% of a viscosity adjusting agent, 0-3.2% of an expanding agent, 0-0.12% of an air entraining agent, and 0-0.0007% of a defoaming agent. The modified material provided by the invention can realize effective filling and coating modification of the low-quality aggregate through the cooperation between the components, and the adjustment of the use amount, and especially through the cooperation of the specific use amount of the cement, active powder and viscosity adjusting agent, the surface tension and viscosity of the modified material can be effectively adjusted, and a porepenetration amount and a shell coating thickness are coordinately optimized. The combined use of the inorganic and organic components promotes the secondary hydration / chemical bonding of a slurry layer, and improves the strength of an interface between the aggregate and the slurry layer. The cylindrical compress strength of the aggregate after modification treatment is increased by 40% or more, acrushing value is reduced by 30% or more, and a water absorption rate in 24 h is reduced by 15% or more.

Owner:CHINA BUILDING MATERIALS ACAD

Method for preparing high-performance phosphogypsum-based self-leveling mortar

InactiveCN110436874AImprove interface pore structureReduce and suppress expansionCelluloseHigh fracture

The invention relates to the technical field of building materials, and discloses a method for preparing a high-performance phosphogypsum-based self-leveling mortar. The method comprises the followingsteps: S1, obtaining raw materials comprising 40-60 parts of phosphorus building gypsum, 15-22 parts of cement, 10-24 parts of fly ash, 3-10 parts of stone powder, 1.5-4 parts of a redispersible latex powder, 0.05-0.15 part of cellulose ether, 0.02-0.06 part of a nano-carbon fiber, 0.3-0.8 part of a water retaining agent, 0.1-1.3 parts of a water reducer, 0.1-0.4 part of an anti-settling agent, 0.01-0.08 part of a defoaming agent and 30-42 parts of fine sand aggregates; and S2, mixing the materials obtained in step S1, stirring the obtained mixture until uniformity, and adding water accounting for 13-15% of the total weight of the mixture and performing stirring until uniformity when the mortar is used. The reinforcement of a phosphogypsum-based self-leveling material and the high fracture toughness of the carbon fiber effectively reduce and inhibit the expansion of matrix cracks, and greatly improve the interfacial pore structure of the self-leveling material. The method of the invention improves the bonding degree of the interface of the phosphogypsum matrix, increases the toughness of the phosphogypsum matrix and increases the overall strength.

Owner:DEQING YANGTAI BUILDING MATERIAL

Supported mercury remover and preparation method thereof

ActiveCN103418231AEasy to prepareLow costDispersed particle separationActive componentMetallic sulfide

The invention discloses a supported mercury remover. The active components at least comprise MSSH and carriers, wherein M is a metal which can generate a trivalent ion. The invention further discloses a preparation method of the mercury remover on the basis of the disclosure of the mercury remover. The mercury remover has a very high binding force for mercury, the binding strength between the mercury remover and mercury is stronger than that between the metal sulfide and mercury, and thus the problem of low utilization rate of metal sulfide in the mercury removing process, causing by the bad binding force between the metal sulfide and mercury and low mercury capacity during the mercury removing process, is solved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

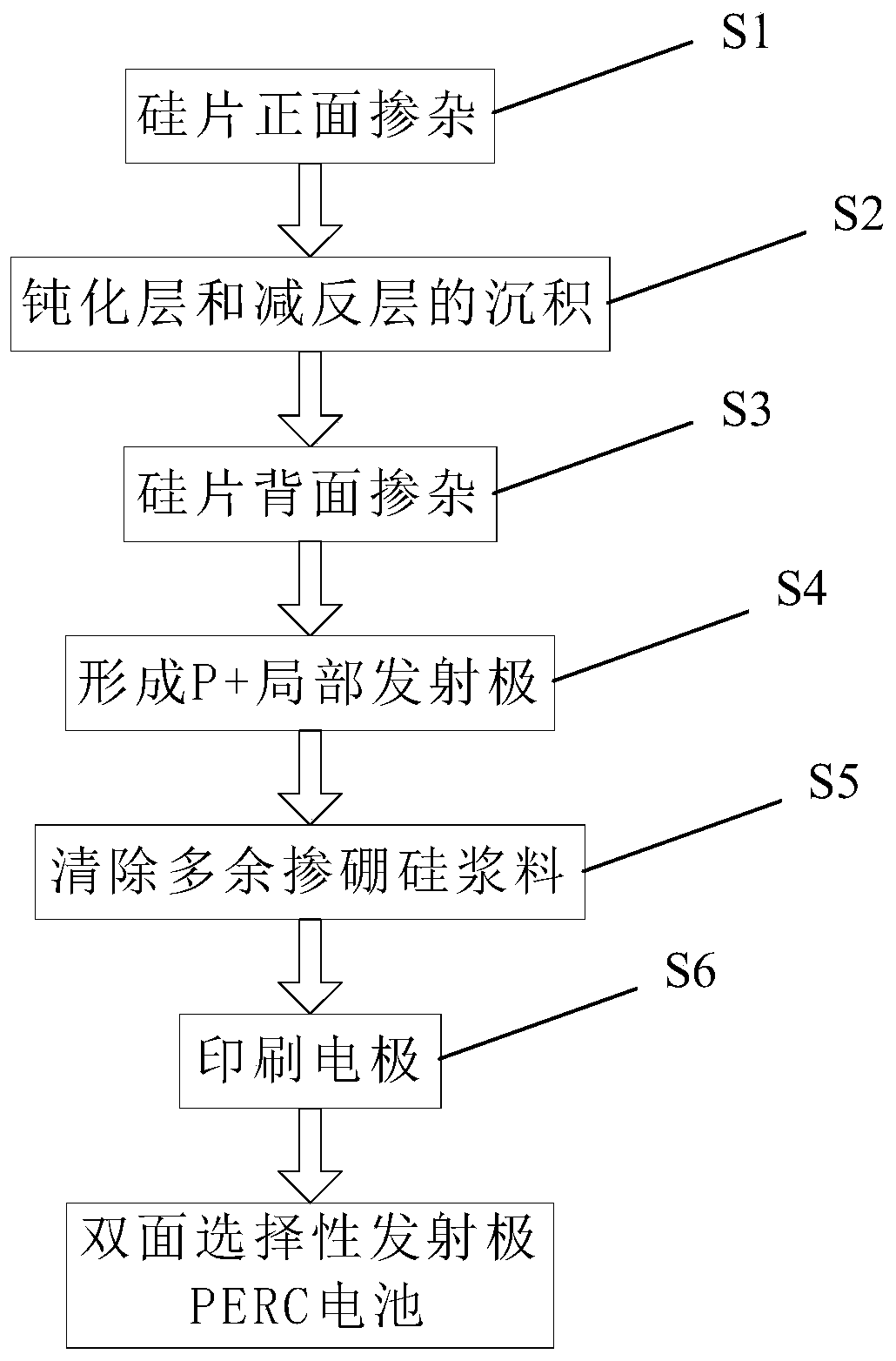

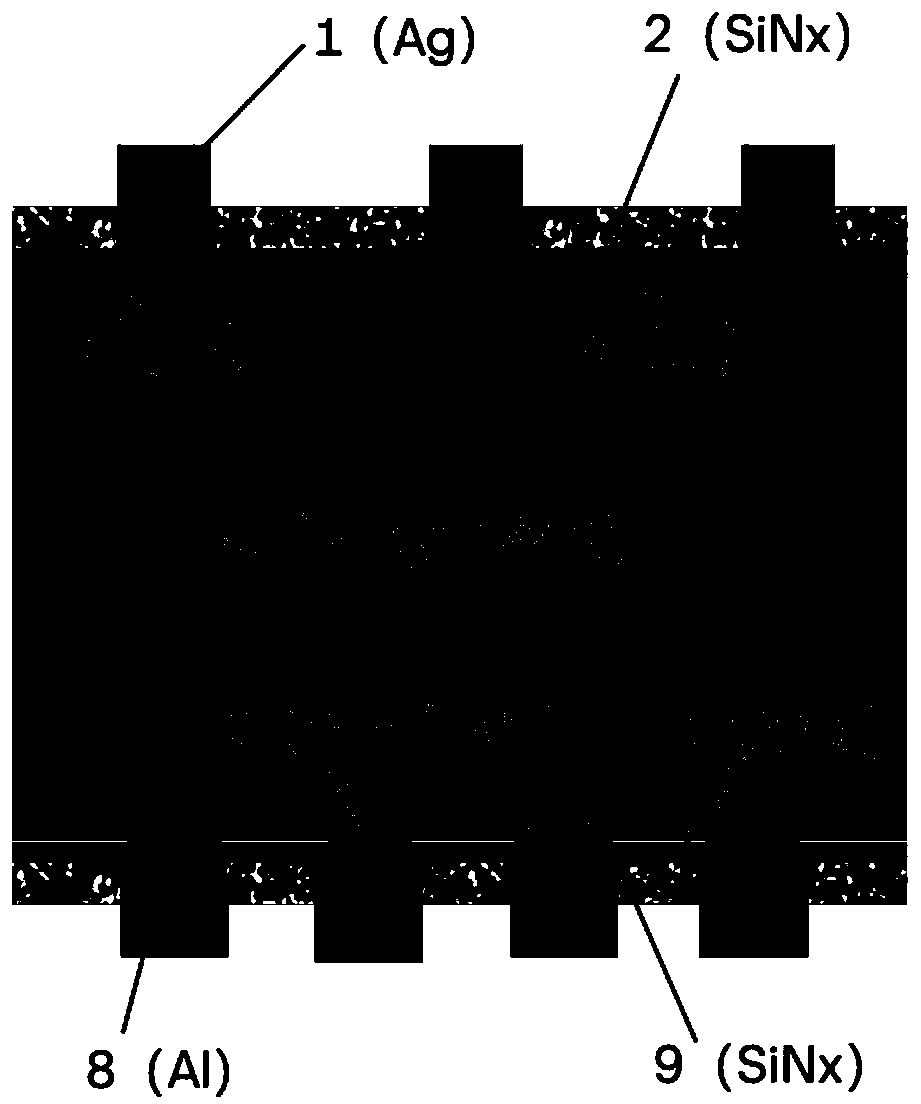

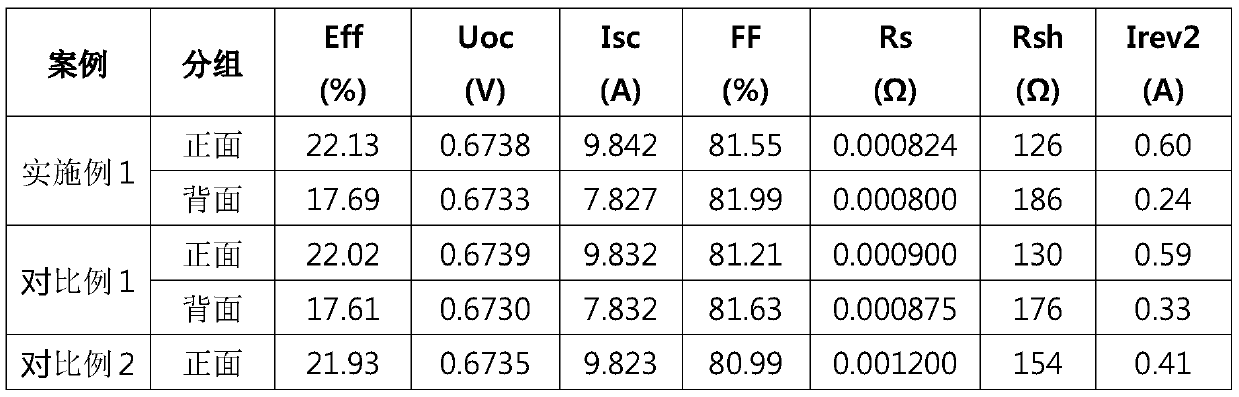

Preparation method of PERC battery as well as double-faced selective emitter PERC battery

InactiveCN110504332AImprove efficiencyIncrease the duplex rateFinal product manufactureSemiconductor devicesOhmic contactSlurry

The invention discloses a preparation method of a double-faced selective emitter PERC battery. The preparation method comprises the steps of doping the front of a textured P type silicon wafer and then completing deposition of a back passivation layer, a back antireflection layer, a front passivation layer and a front antireflection layer; the preparation method is characterized by also comprisingthe following steps: printing boron-silicon-doped slurry on the back passivation layer of the silicon wafer and drying, and then driving boron into a silicon substrate of the silicon wafer by adopting lasers in a region where the slurry is printed, thus a P+ emitter is formed; meanwhile, forming a linear open window, eliminating redundant boron-silicon-doped slurry by adopting a cleaning fluid and then performing secondary drying, printing front and back electrode slurry on the silicon wafer, and performing high temperature sintering, thus forming an electrode. The preparation method disclosed by the invention adds a drying step after boron slurry is printed, so that laser alignment accuracy is further improved, and product quality is improved; and a step of cleaning and removing the redundant boron-silicon-doped slurry after use of the lasers, so that local ohmic contact quality is improved.

Owner:HANWHA SOLARONE QIDONG

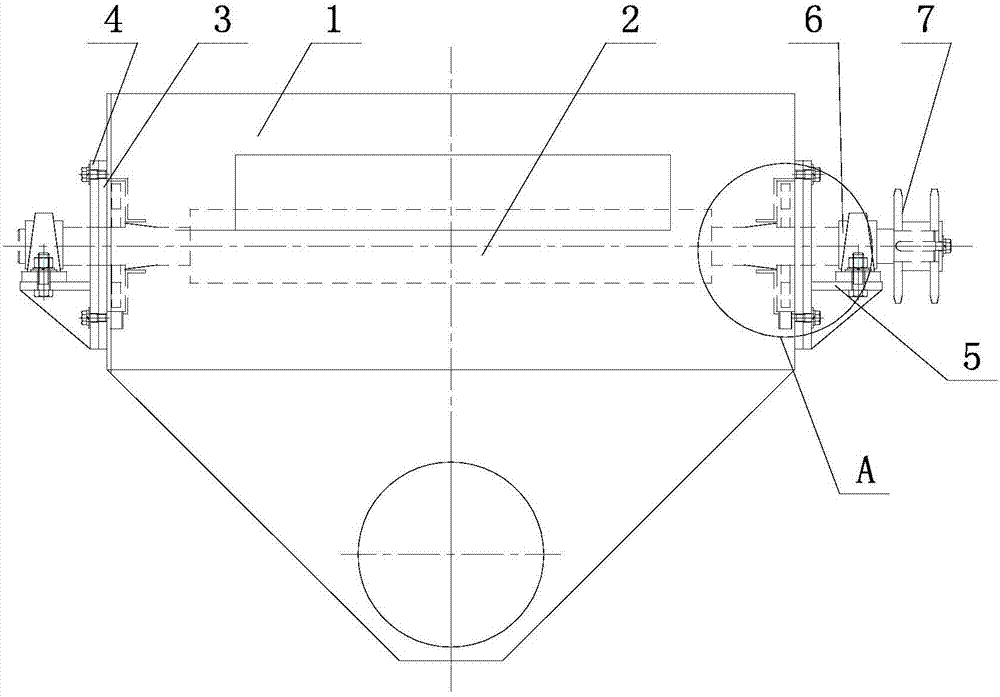

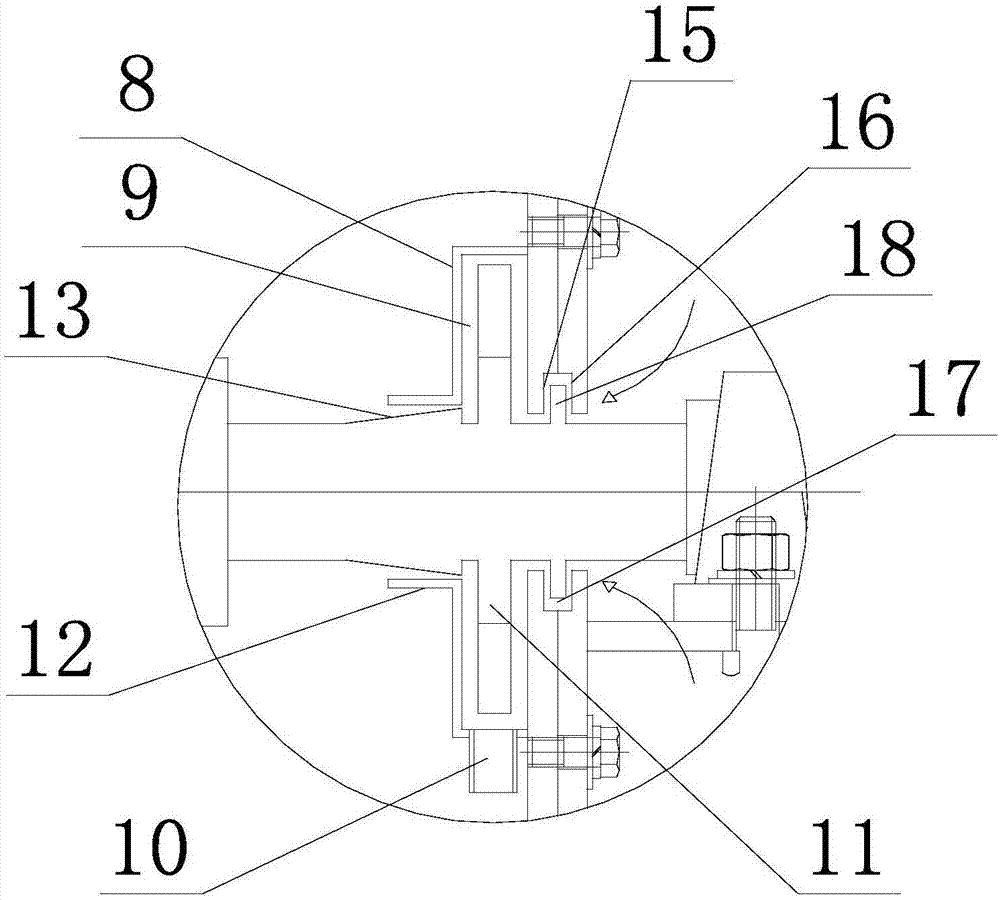

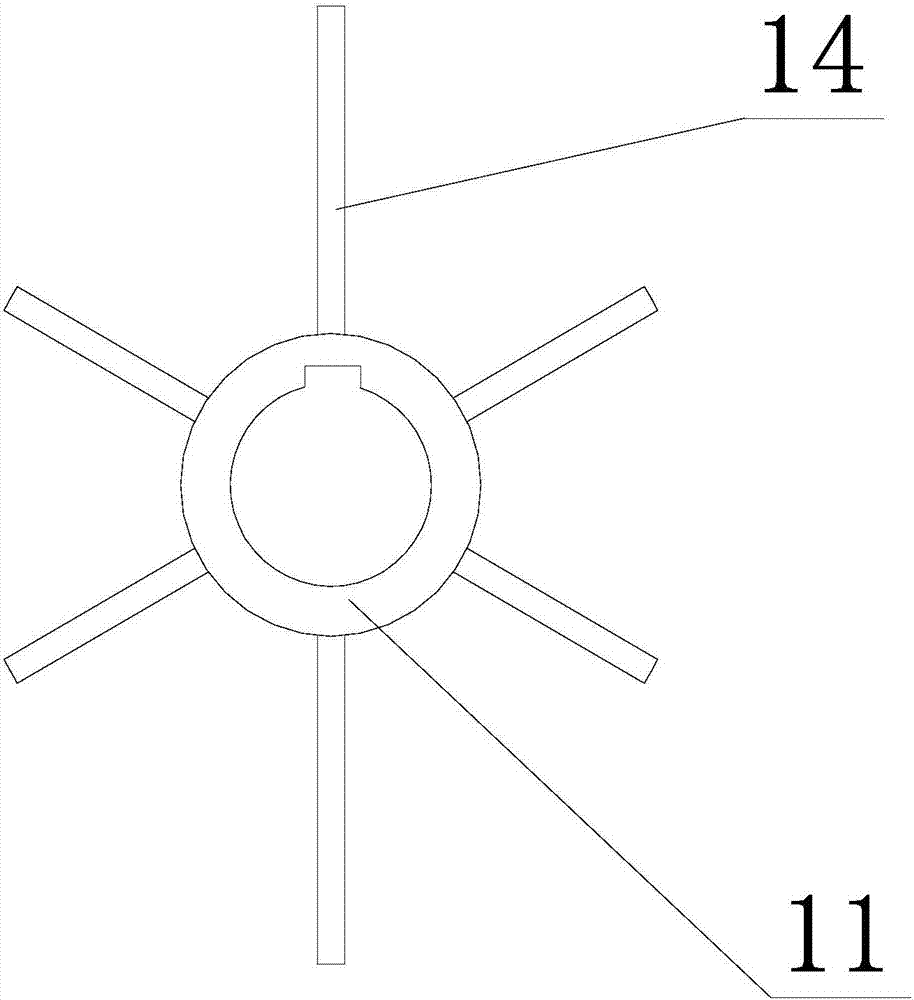

Shot blasting machine roller way with shot leakage preventing device

PendingCN107457710AReduce entrySimple structureFurnace typesAbrasive machine appurtenancesStructural engineeringMechanical engineering

The invention discloses a shot blasting machine roller way with a shot leakage preventing device. The shot blasting machine roller way comprises a roller way horizontally arranged in a shot blasting machine body; shaft heads at two ends of the roller way respectively penetrate through two side walls of the shot blasting machine body to extend out; the axis of the length direction of the roller way is overlapped with the axis of the shot blasting machine body; bearings respectively sleeve the shaft heads at two ends of the roller way; bearing bases sleeve the bearings; the bearings on two sides and the bearing bases are totally identical, and are symmetrically arranged; a leakage preventing cover is arranged on the side wall in the shot blasting machine body, and sleeves the roller way; an annular cavity is formed in the leakage preventing cover; a discharge port is formed below the leakage preventing cover; the roller way is provided with an air blowing blade in the corresponding position of the annular cavity; an annular baffle plate outwards extends to one side of the leakage preventing cover; the roller way is provided with a conical table in the corresponding position of the annular baffle plate; and when the conical table approaches the leakage preventing cover, the outer diameter is gradually increased.

Owner:江苏飞腾铸造机械有限公司

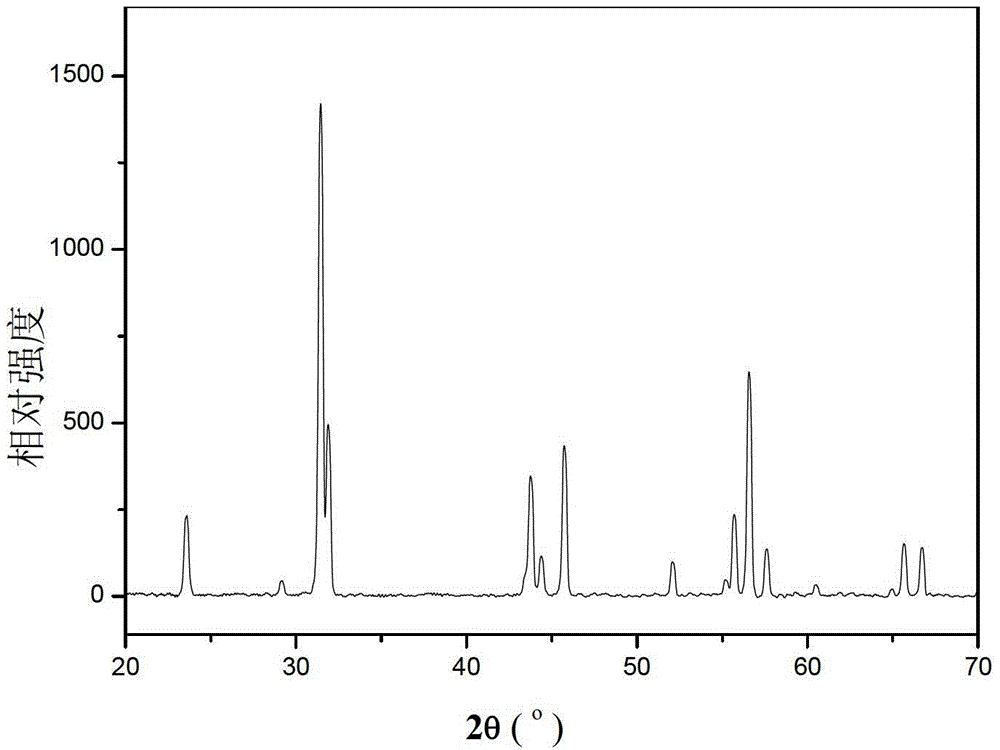

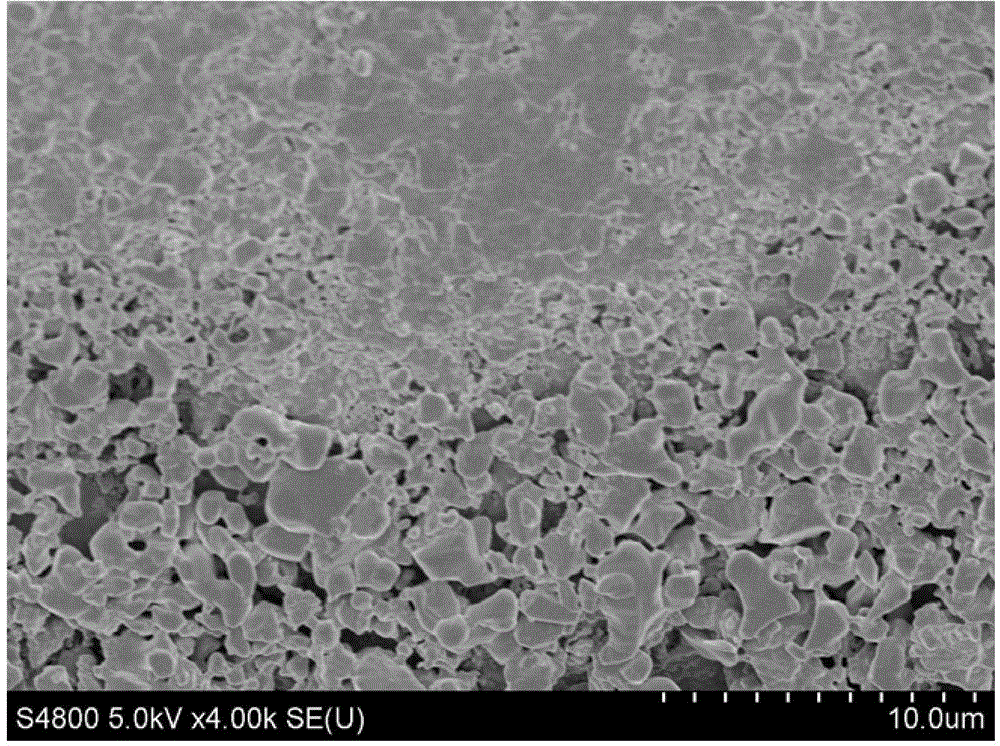

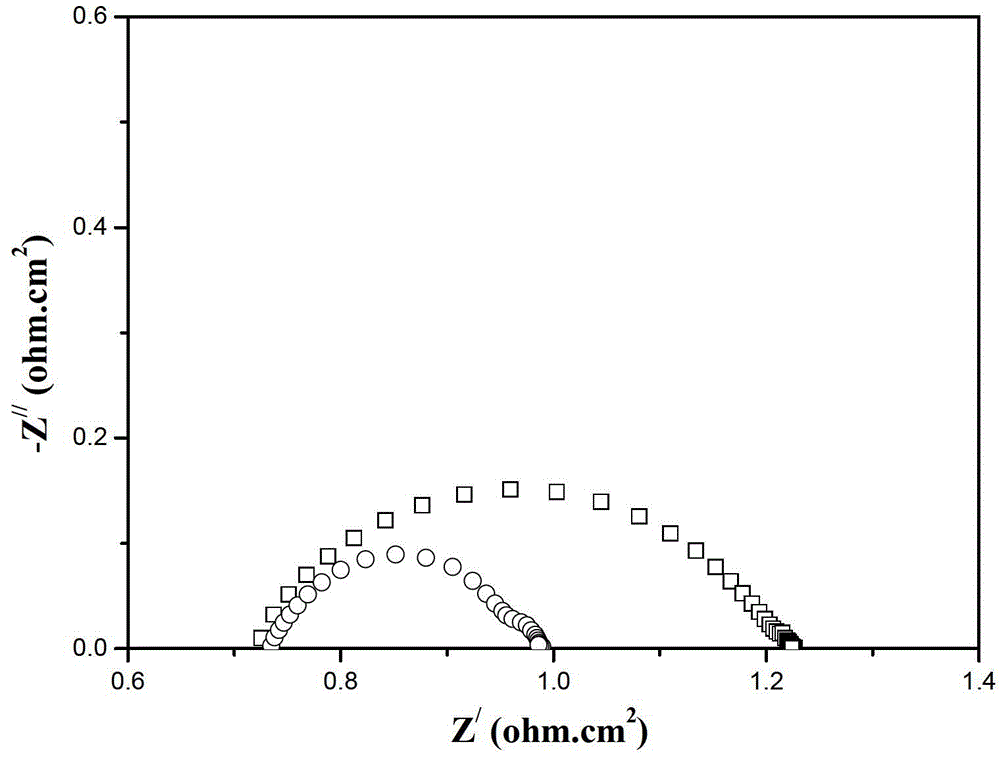

Solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 and preparation method thereof

InactiveCN103151533AImprove electrochemical performanceIncreased mixed conductivityCell electrodesComposite cathodeFuel cells

The invention relates to a solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 and a preparation method thereof. The invention relates to a cell composite cathode material and a preparation method thereof, aiming at solving the problem that the catalytic activity and electro-chemical property of the cathode material are pool. The solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 is made of Ln2CuO4 and solid electrolyte Ce0.9Gd0.1O1.95; the method comprises the steps of: I. weighing; II. preparing mixed stock; III. preparing a prefabricated body; and IV. preparing the solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95. According to the solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 and the preparation method thereof, the reaction active site of the cathode is extended into the overall cathode material, the active region of the oxygen reduction reaction can be enlarged, and the electrochemical property of the cathode can be improved. The preparation method is used for preparing solid oxide fuel cell composite cathode.

Owner:HEILONGJIANG UNIV

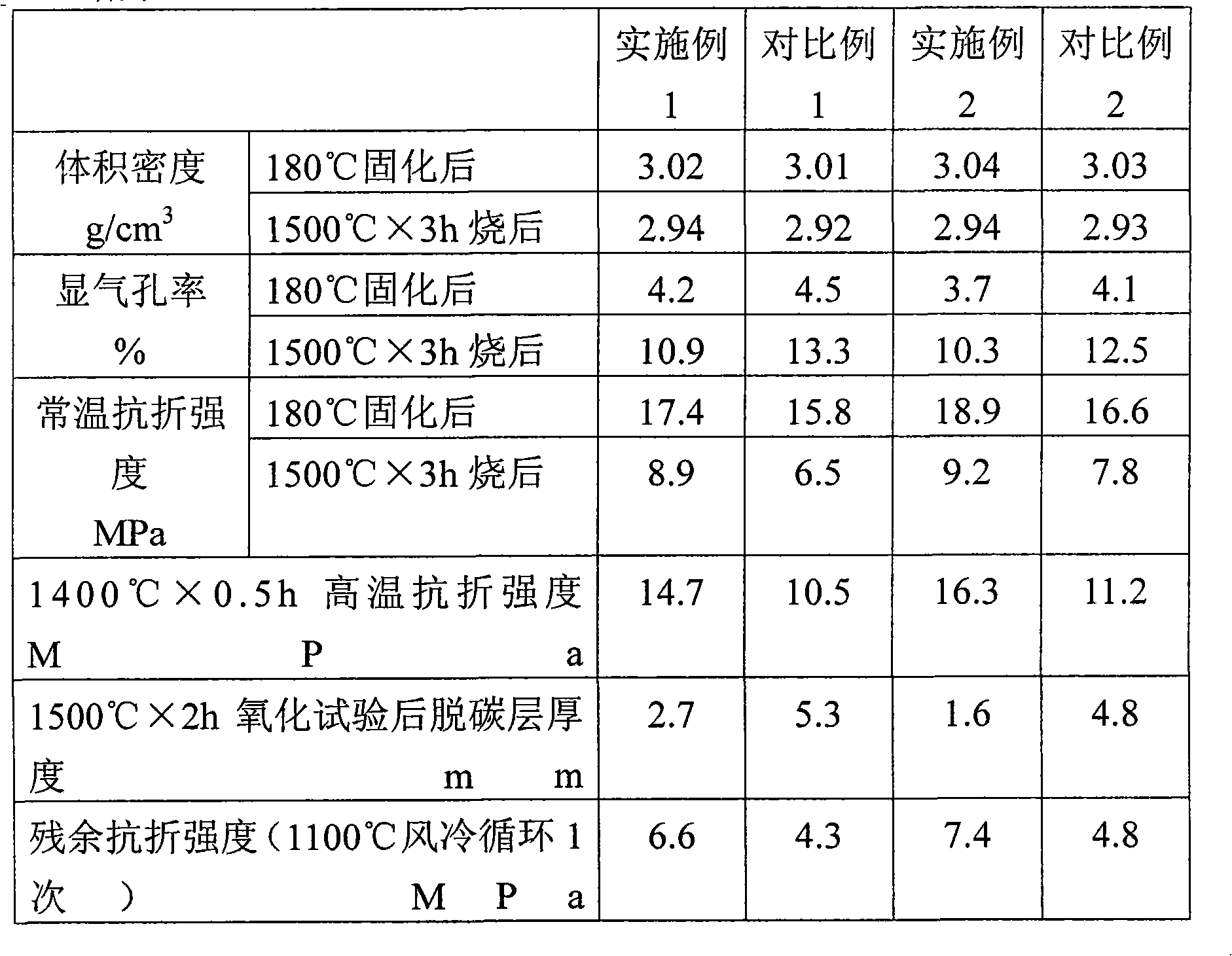

Low-carbon magnesia carbon brick containing nanometer zinc oxide

A low-carbon magnesia carbon brick containing a nanometer zinc oxide is characterized in that the low-carbon magnesia carbon brick comprises the four following raw materials by weight percentage: 80-94wt% of electric melting magnesia particles, 1-5wt% of crystalline flake graphite, 1-3wt% of metal Al and 1-5wt% of nanometer zinc oxide, and 2-4wt% of a phenol formaldehyde resin with the quantity of the weight percentage sum of the four raw materials. The low-carbon magnesia carbon brick utilizes the characteristics of the nanometer zinc oxide powders such as fine granularity, high activity at high temperature, moderate price, and the like to improve the microstructure of the low-carbon magnesia carbon brick, prompts the used metal Al antioxidant to sufficiently play the role and prepares the low-carbon magnesia carbon brick with excellent comprehensive performance and moderate price. The prepared low-carbon magnesia carbon brick can be used for the steel-making furnace, the refining furnace and the lining of the steel ladle in the steel metallurgical industry, reduces the carbon added in the molten steel, reduces the temperature reduction of the molten steel and is beneficial for improving the quality of the steel and saving the energy resource.

Owner:ZHENGZHOU UNIV

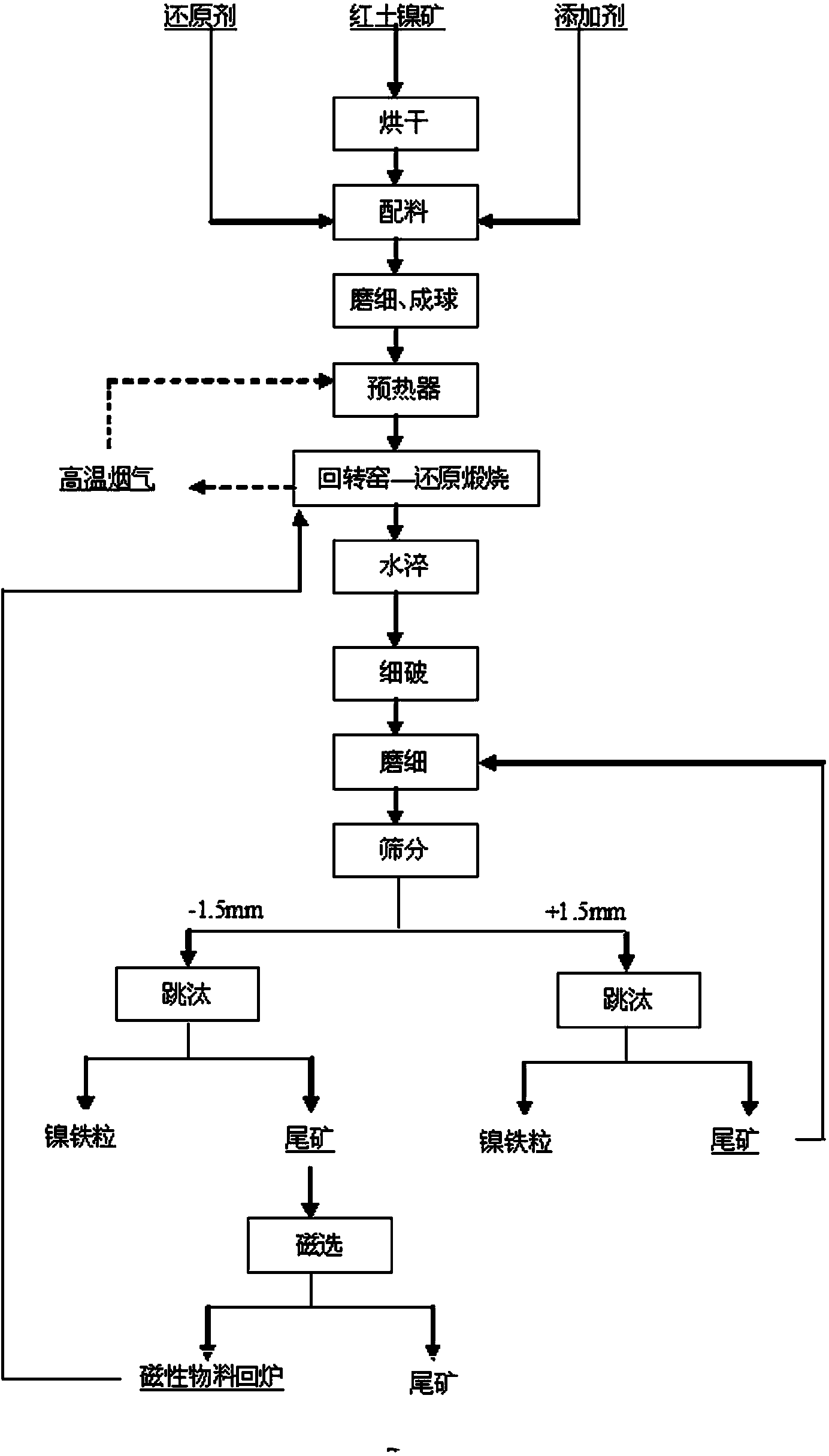

Method for producing nickel-iron particles by using coal-based reducing agent to directly reduce laterite nickel ore

InactiveCN104032058AImprove reduction efficiencyIncrease the degree of mixingRotary drum furnacesMagnetic separatorEngineering

The invention discloses a method for producing nickel-iron particles by using a coal-based reducing agent to directly reduce laterite nickel ore, belongs to the technical field of metallurgy chemical engineering, and concretely relates to a method for producing nickel-iron particles by utilizing a rotary kiln to directly reduce laterite nickel ore. The method comprises: drying laterite nickel raw ore, adding coal and additives, mixing, performing dry grinding, and preparing balls; pre-heating, then sending into the rotary kiln and performing reduction calcining; performing water quenching on materials discharged from the kiln, then performing fragmentation and fine grinding, and then performing jigging separation, so as to obtain the nickel-iron particle product, and separating a magnetic material from a tail ore part discharged from a jigging machine by using a magnet separator, returning to the kiln for reutilization. Waste heat of the tail gas of the rotary kiln is used to perform preheating drying on the raw material. The method has the characteristics of simple production, convenient operation, low energy consumption, environment friendliness and high nickel-iron recovery rate.

Owner:章钦成 +2

Anti-corrosion spraying process based on polytetrafluoroethylene material

InactiveCN110394290AHigh hardnessImprove wear resistancePretreated surfacesCoatingsFluorocarbonWear resistance

The invention discloses an anti-corrosion spraying process based on a polytetrafluoroethylene material. The anti-corrosion spraying process based on the polytetrafluoroethylene material comprises thefollowing steps that 1, the surface treatment is carried out on a rolled steel, specifically, the cleaning treatment is carried out on the surface of the rolled steel firstly, sundries and stains on the surface of the rolled steel is washed and cleaned by using pressure water of 290 Kpa, and the time length is 10-15min; then an abrasive paper is used for grinding treatment, projections on the surface of the rolled steel is polished uniformly, and the roughness of the surface of the rolled steel reaches about 20 microns; a fluorocarbon diluting agent is used to wipe the surface of the rolled steel cleanly, and exposing and airing are carried out to obtain the clean and polished rolled steel. According to the anti-corrosion spraying process based on the polytetrafluoroethylene material, through the multiple spraying step process and the anti-corrosion function of the polytetrafluoroethylene material, the adhesiveness of the coating rolled steel is improved, the coating is not prone to fall off in use, and the quality of the rolled steel is improved; and meanwhile, the combination degree among primer, finish paint and the rolled steel is improved, the gap condition is avoided in the coating, the anti-corrosion property and the wear resistance of the rolled steel are greatly improved, and a good application prospect is realized.

Owner:江苏优氟防腐科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com