Modified material and treatment method of low-quality aggregate

A technology for modifying materials and processing methods, which is applied in the field of building materials, and can solve the problems of not being able to achieve effective pore filling and surface coating at the same time, so as to promote secondary hydration/chemical bonding, ensure strength and compactness, and optimize The effect of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The present embodiment provides a kind of processing method of low-quality aggregate, comprising the following steps:

[0068] The composition of the modified material:

[0069] Portland cement 52.5R 50kg; mineral admixture 12.5kg; active powder 5kg; water reducing agent 0.6kg; 3kg metakaolin, 4kg limestone, 2.5kg silica fume; the active powder is nano-silica; the water reducer is ZY-700 polycarboxylate water reducer produced by CNBM Zhongyan Technology Co., Ltd.; the viscosity regulator is BASF Rheoplus420 high-performance viscosity modifier produced by China Co., Ltd.

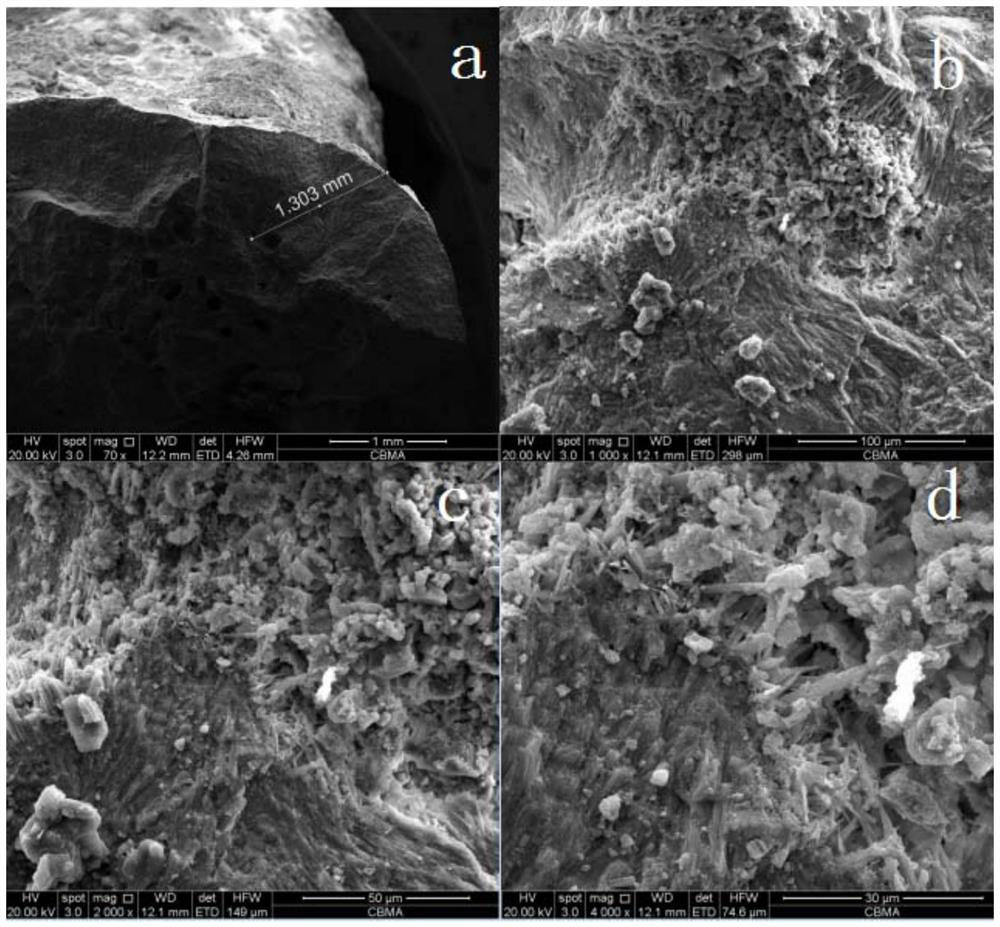

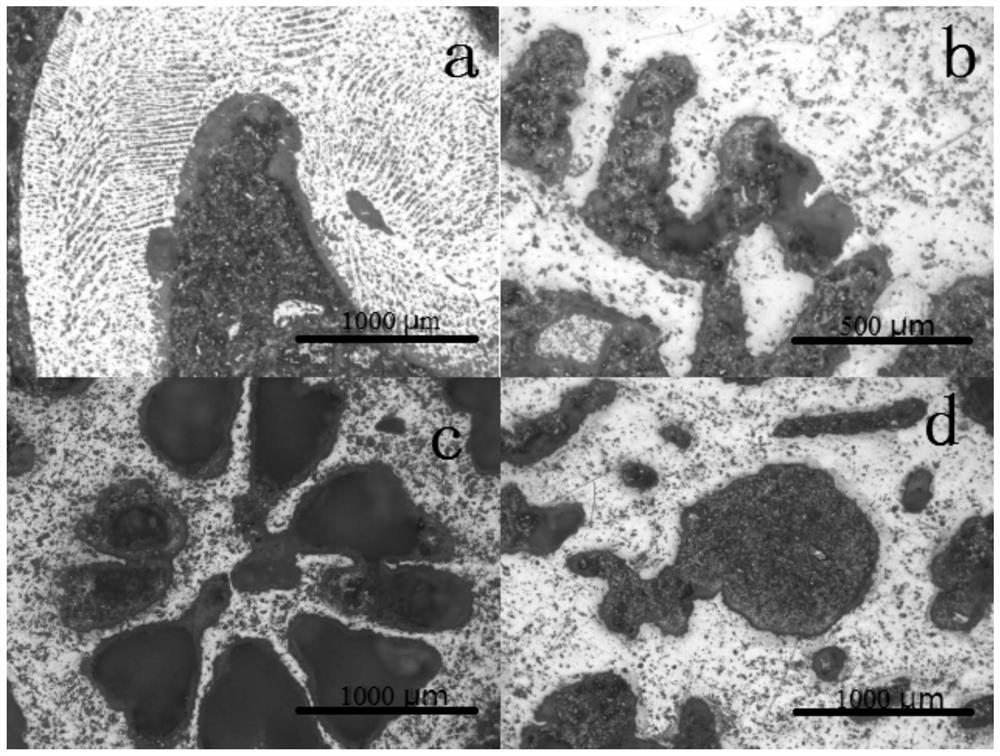

[0070] The processing steps are as follows: 1) Soak 20 kg of the cleaned coral aggregate with 50 kg of water glass solution with a mass fraction of 30% for 4 hours, take it out, and dry it for use; Stir evenly before use; 3) put the coral aggregate to be treated into the impregnation container, inject the modified material, vacuumize, stir for 1 min under a vacuum of 5 kPa, and then stir for 2 min un...

Embodiment 2

[0072] The present embodiment provides a kind of processing method of low-quality aggregate, comprising the following steps:

[0073] The composition of the modified material:

[0074] Portland cement 52.5R 50kg; mineral admixture 15kg; active powder 2kg; water reducing agent 0.2kg; Metakaolin, 4kg limestone; the active powder is nano-silica; the water reducer is ZY-700 polycarboxylate water reducer produced by CNBM Zhongyan Technology Co., Ltd.; the viscosity regulator is Ningbo Zhongshuike Chemical Technology Co., Ltd. The SK-420 viscosity modifier produced by the company.

[0075] The processing steps are as follows: 1) Soak 35 kg of the cleaned coral aggregate with 50 kg of water glass solution with a mass fraction of 5% for 5 hours, take it out, and dry it for use; Stir evenly and set aside; 3) Put the coral aggregate to be treated into an impregnation container, inject the modified material slurry, and then stir for 6 minutes under a high pressure of 0.5 MPa; 4) Dip th...

Embodiment 3

[0077] The present embodiment provides a kind of processing method of low-quality aggregate, comprising the following steps:

[0078] The composition of the modified material:

[0079] Aluminate cement CA-60 46kg; mineral admixture 13kg; active powder 4kg; water reducing agent 0.5kg; 100kg, of which, the composition of the mineral admixture is 5kg fly ash, 4kg metakaolin, 4kg silica fume; the active powder is nano-silica; the water reducer is ZY-700 produced by CNBM Zhongyan Technology Co., Ltd. Polycarboxylate water reducer; viscosity regulator is the Rheoplus420 high-performance viscosity modifier produced by BASF China Co., Ltd.; the expansion agent is the ZY-UEAII type expansion agent produced by CNBM Zhongyan Technology Co., Ltd.; The agent is the SX rosin air-entraining agent produced by Shanxi Sanmus Building Material Chemical Co., Ltd.; the defoamer is a silicone defoamer.

[0080] The processing steps are as follows: 1) Soak 25 kg of the cleaned coral aggregate with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com