Repairing method for surface of draught fan blade

A technology for surface repair and fan blades, applied in chemical instruments and methods, inorganic chemistry, coatings, etc., can solve problems affecting fan efficiency, erosion and wear of fan blades, etc., to reduce coating peeling or even failure, and reduce heat loss. Effects of stress and oxidation inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The fan blade surface repair method of this embodiment is applied to the repair of large fan blades, and the steps are:

[0061] Step 1, blade surface pretreatment:

[0062] A. Grind the worn parts of the blades, weld the damaged parts with new materials and then grind them, so that all parts meet the specified requirements;

[0063] B. Remove oil stains, rust stains, oxide skin and welding slag particles on the surface of the blade;

[0064] C. Clean the surface to be sprayed with detergent;

[0065] D. Perform magnetic particle inspection on all welds to ensure that there are no fatal defects such as cracks in the blades;

[0066] E. Roughen the blades before spraying to improve the adhesion of the coating;

[0067] Step 2. Preheating before spraying: place the blade in the preheating device for preheating treatment to eliminate moisture and moisture on the surface to be sprayed, increase the interface temperature between the sprayed particles and the workpiece, and ...

Embodiment 2

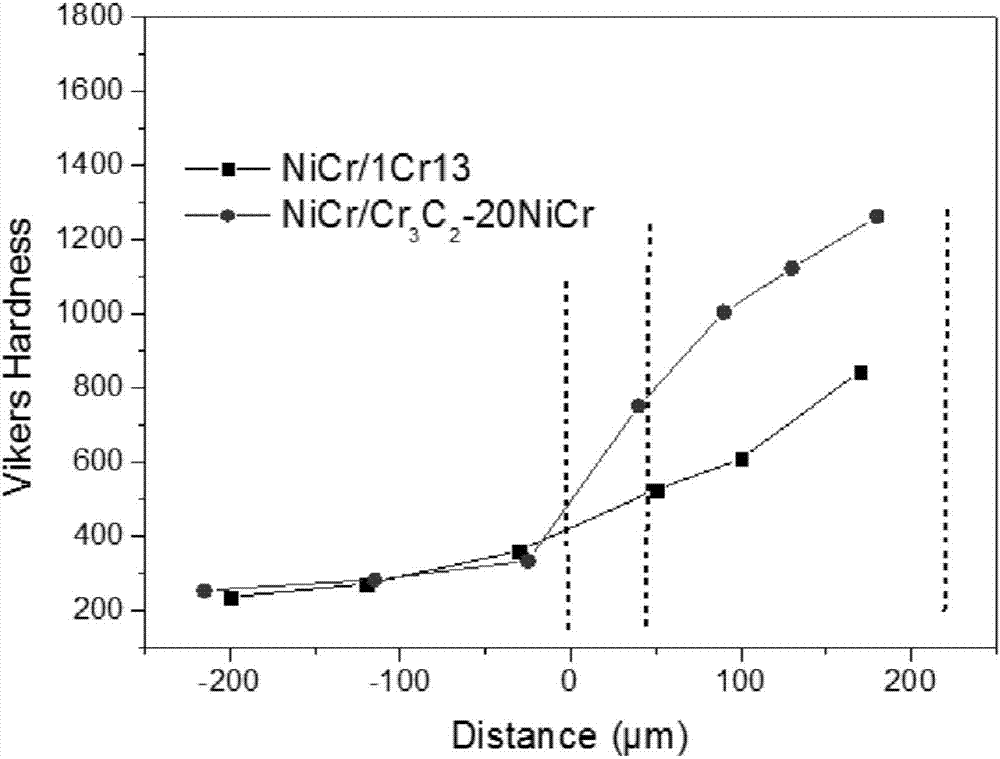

[0076] The fan blade surface repairing method of the present embodiment, basic steps are the same as embodiment 1, and difference and improvement are: in the E step of step one, carry out roughening treatment with 24# special-purpose corundum for thermal spraying; In step two, the preheated The temperature is controlled at about 80°C; in step 3, the base layer is made of NiAl material with a thickness of 0.08mm, which can eliminate the mismatch of the thermal expansion coefficient between the wear-resistant working layer and the base layer of the blade, so as to reduce the friction between the working layer and the blade. The thermal stress caused by the mismatch of the expansion coefficient of the base layer improves the mechanical matching and physical compatibility between the working layer and the blade base layer; the working layer is a WC-12Co composite coating with a thickness of 0.18mm;

[0077] After testing, the alloy coating prepared in Example 2 has strong adhesion,...

Embodiment 3

[0079] The basic steps of the method for repairing the surface of fan blades in this embodiment are the same as those in Embodiment 1. The differences and improvements are as follows: step 4, hole sealing treatment: the spraying method is used to carry out sealing treatment on the metal sprayed layer. When spraying, it should be diluted with ketone, aromatic hydrocarbon and absolute ethanol as diluent. After spraying, it should be dried in the air for 30-60 minutes, and fully cured in 1-5 hours.

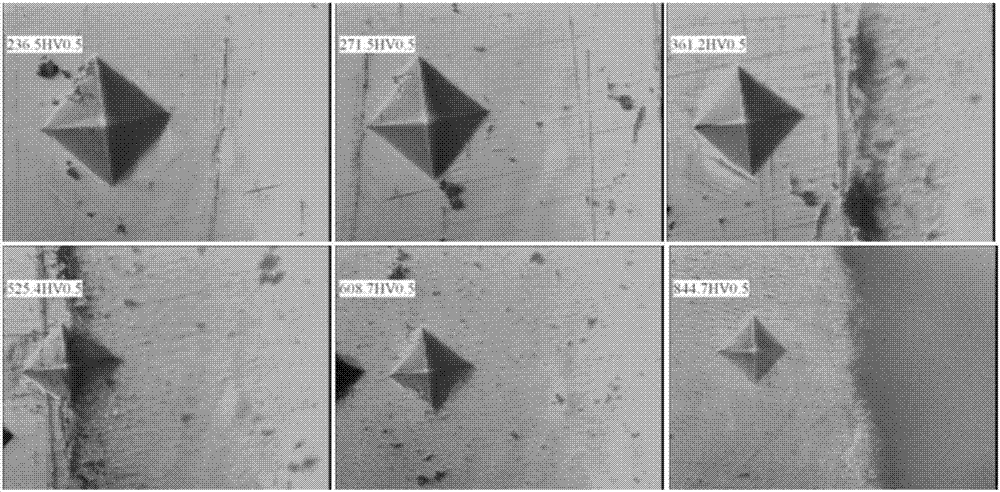

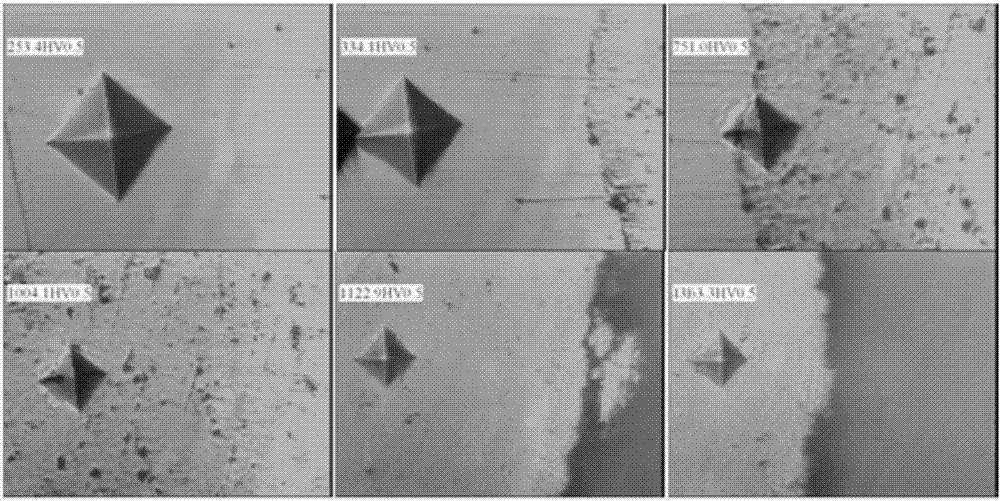

[0080] The working layer adopts NiCr-Cr 3 C 2 Composite coating with a thickness of 0.20mm. NiCr alloy has excellent heat resistance, corrosion resistance, high temperature oxidation resistance and other properties, and also plays the role of bonding phase. Cr 3 C 2 It has good high-temperature hardness and high-temperature oxidation resistance, and acts as a hard phase. In the coating, it also mainly plays the role of dispersion strengthening of the second phase particles, which c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com