Patents

Literature

129 results about "Nicr alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

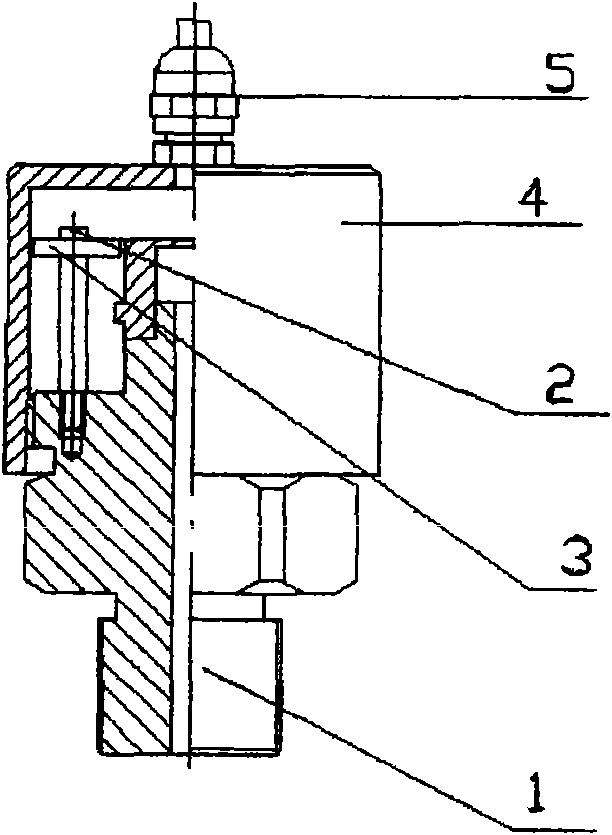

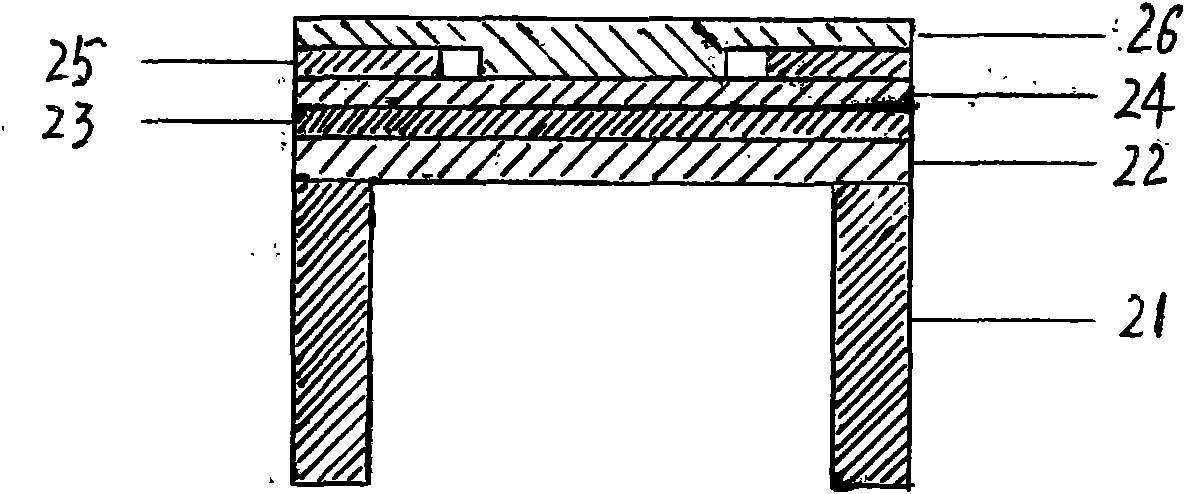

Integrated temperature thin film pressure sensor

InactiveCN101566514AHigh measurement accuracyRealize integrated measurementFluid pressure measurement using ohmic-resistance variationThermometers using electric/magnetic elementsElastomerTemperature sensitive

The invention relates to an integrated temperature thin film pressure sensor, which consists of a suction pressure connecting pipe with threads and a seal ring, a sensitive component, an external circuit board, a shell and a socket connector. A sensitive elastomer is provided with a transition layer, an insulating layer, resistive layers (including a strain resistive layer and a temperature sensitive resistive layer), a welding layer and a passivation protective layer, wherein the resistive layers are connected with the external circuit board through conducting wires. The insulating layer of the sensor is formed by superimposing SiO2 and Ta2O5 or superimposing the SiO2 and Al2O3, the strain resistive layer is formed by photoetching a NiCr alloy layer, the temperature sensitive layer is formed by photoetching Ni metal, and the temperature sensitive layer not only can solve the problem of actual temperature measurement, but also can compensate the temperature sensitivity more precisely so that the pressure measurement is more accurate. The integrated temperature thin film pressure sensor adopts an ion beam sputtering process, thus the long-term stability of the sensor is good, the temperature zero drift is minimum and the comprehensive precision is high.

Owner:SHAANXI ELECTRICAL APPLIANCE RES INST

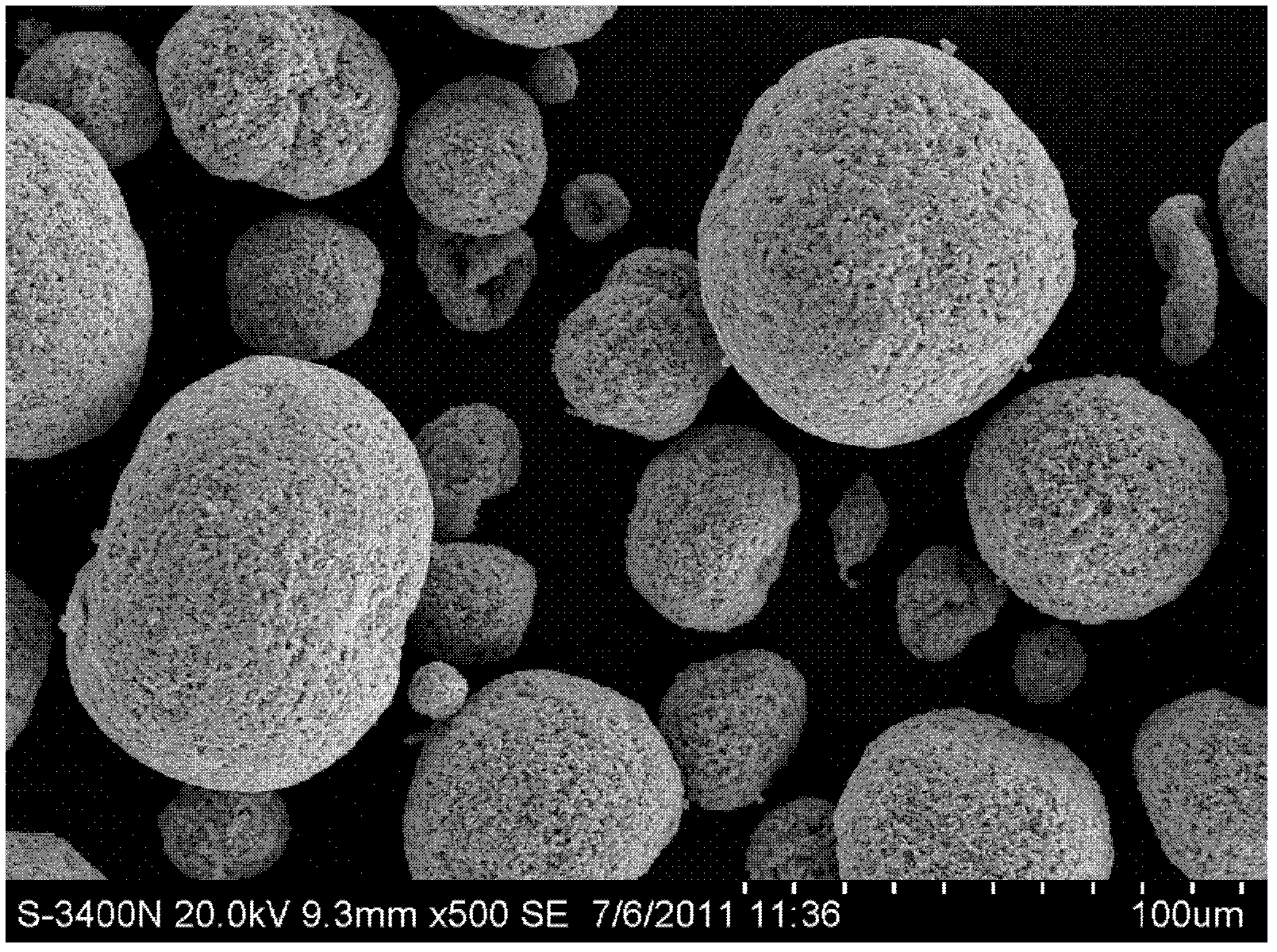

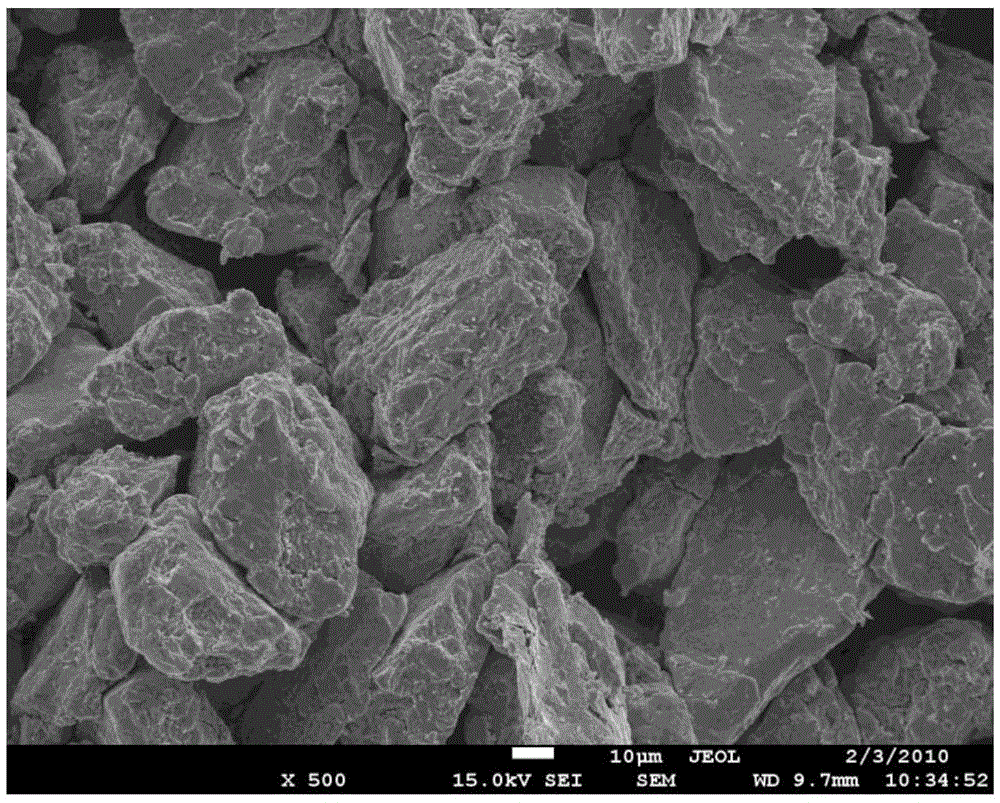

Preparation method of coating containing TiB2 metal ceramic composite powder for thermal spraying piston ring

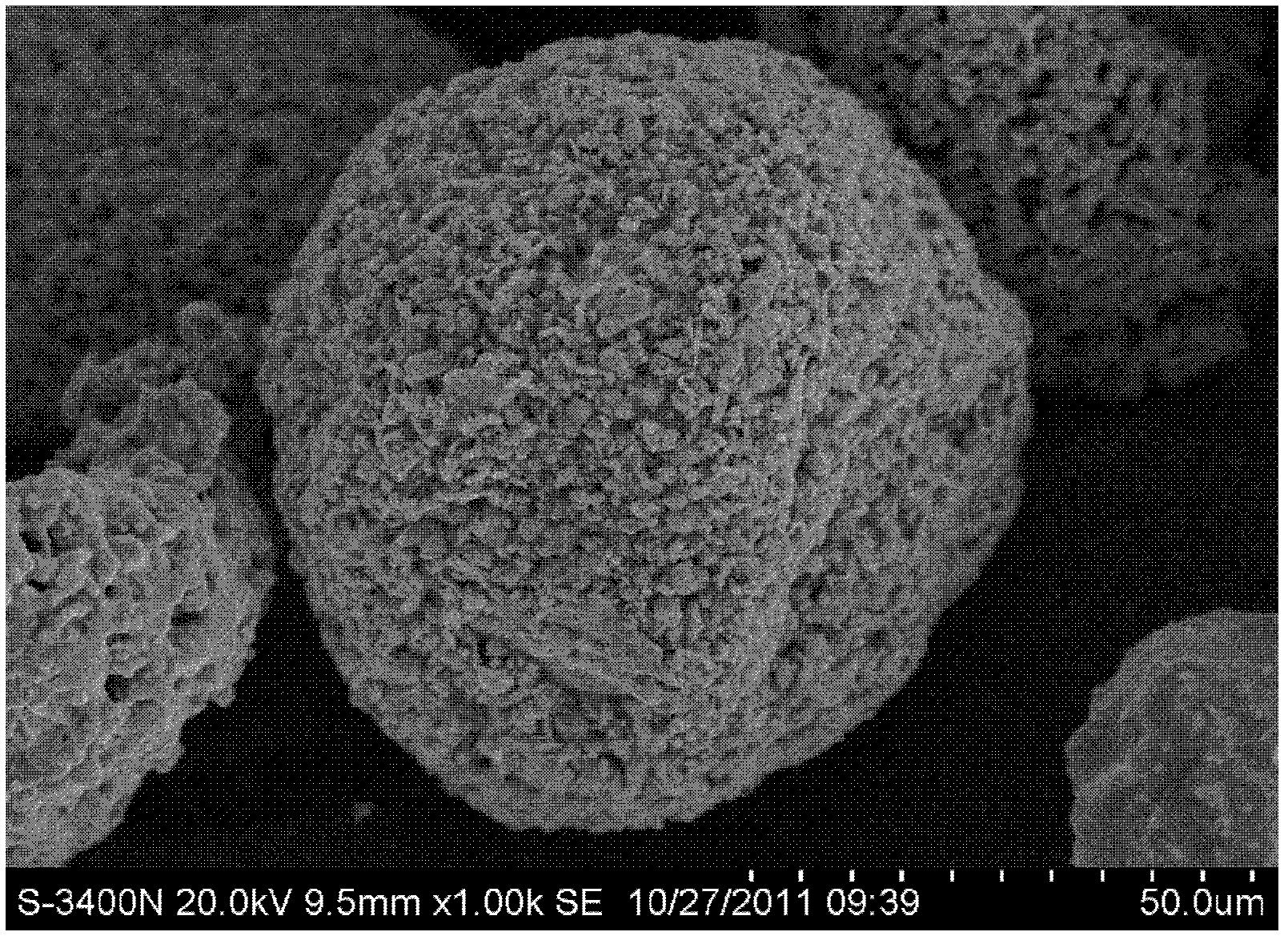

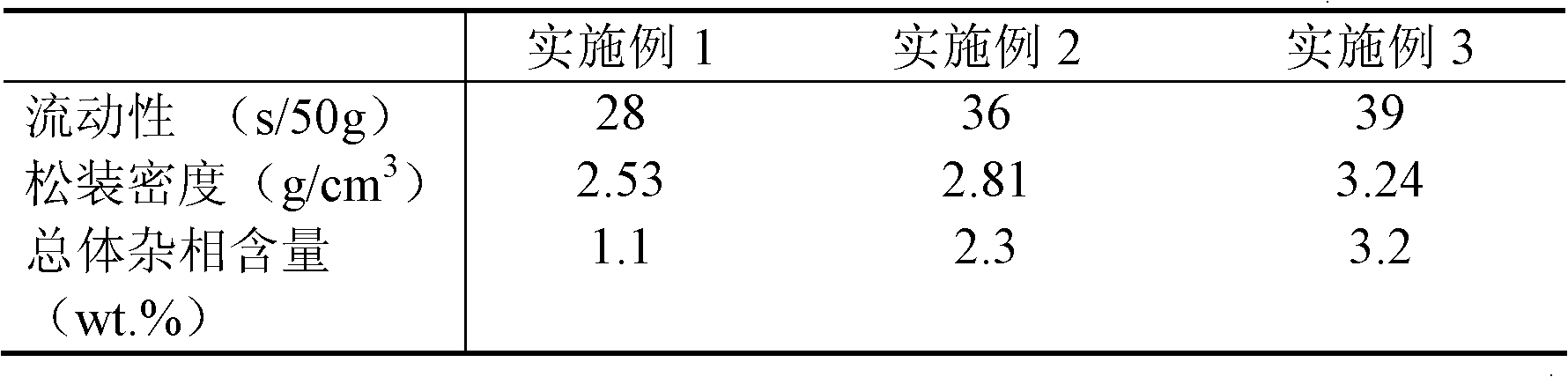

InactiveCN102581292AImprove deposition efficiencyGuaranteed contentMolten spray coatingThermal sprayingPolyvinyl alcohol

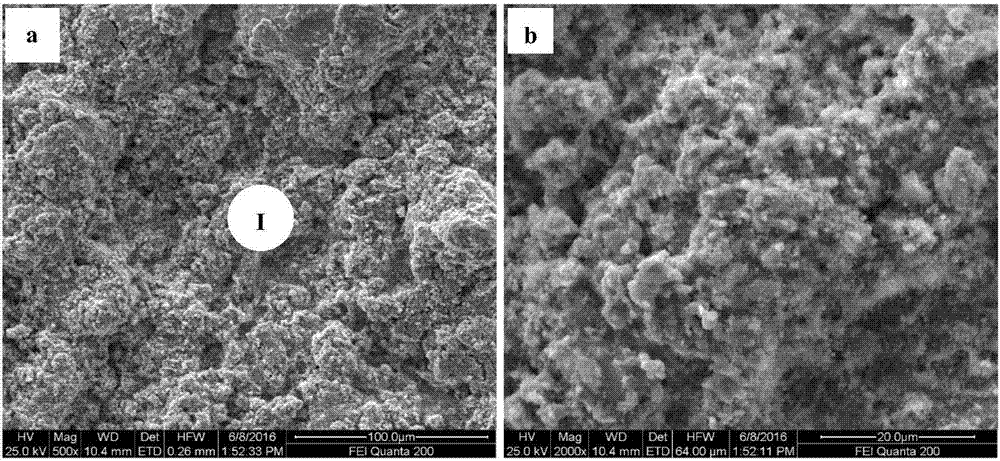

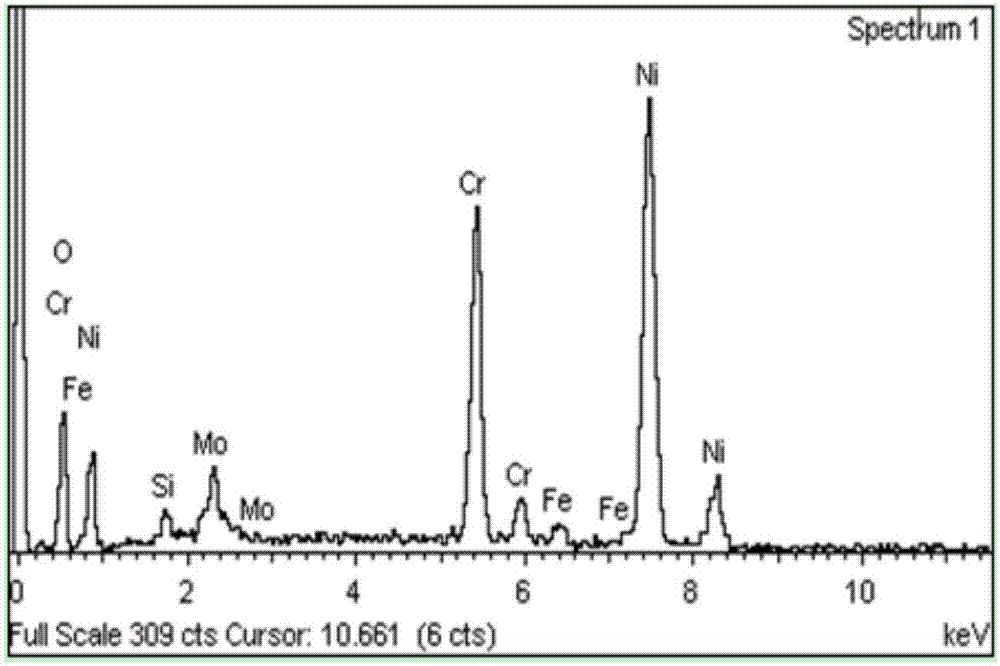

The invention relates to a preparation method of a coating containing TiB2 metal ceramic composite powder for a thermal spraying piston ring, belonging to the field of composite power body technology. The preparation method provided by the invention comprises the following steps: firstly, adopting a ball-milling method to perform mixing and wet grinding on 25-75wt.% TiB2 powder, 25-10wt.% NiCr alloy powder and 50-15wt.% Mo metal powder to obtain mixed powder with the particle size less than 3 micrometers; then mixing the mixed powder with adhesion agent PVA (Polyvinyl Alcohol), dispersing agent and deionized water in proportion in to slurry, performing atomization and granulation of the slurry at the drying temperature rang of 150-250 DEG C and under the atomizing disc frequency range of 140-190Hz through a spray drying device; and finally performing densification treatment on the powder through heat treatment technology and plasma balling technology. For the composite powder prepared by the preparation method of the invention, the particle size is uniformly distributed, the spherical degree, the densification degree and the mobility are good, the deposition efficiency of TiB2 can be improved, and the metal ceramic coating with good wear-resisting property can be prepared.

Owner:BEIJING UNIV OF TECH

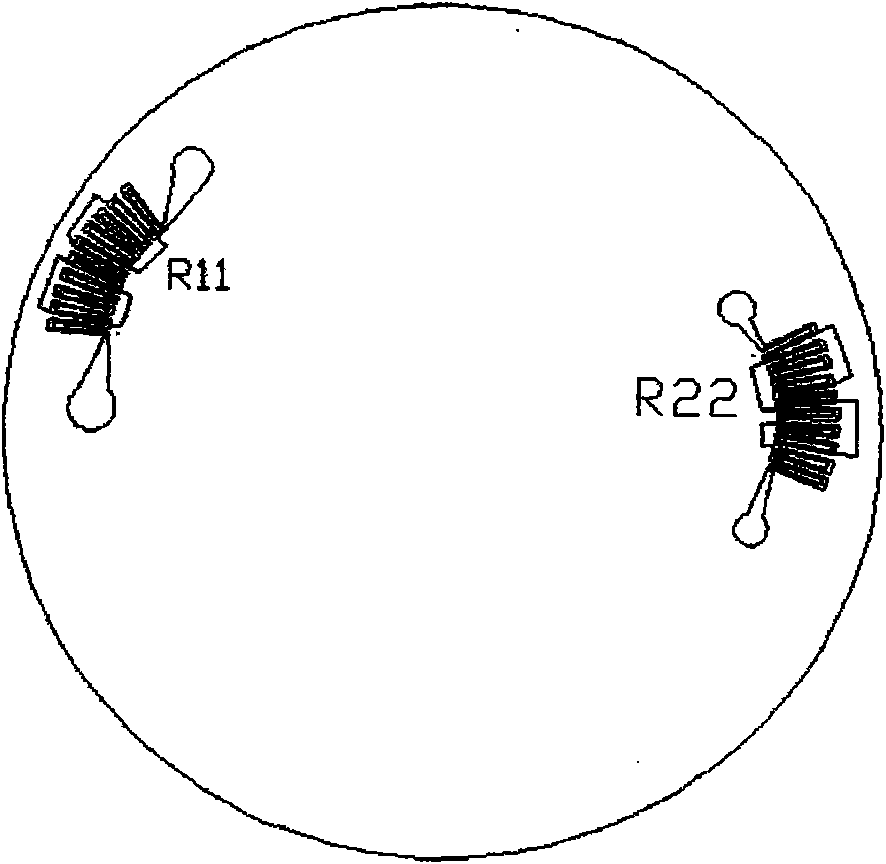

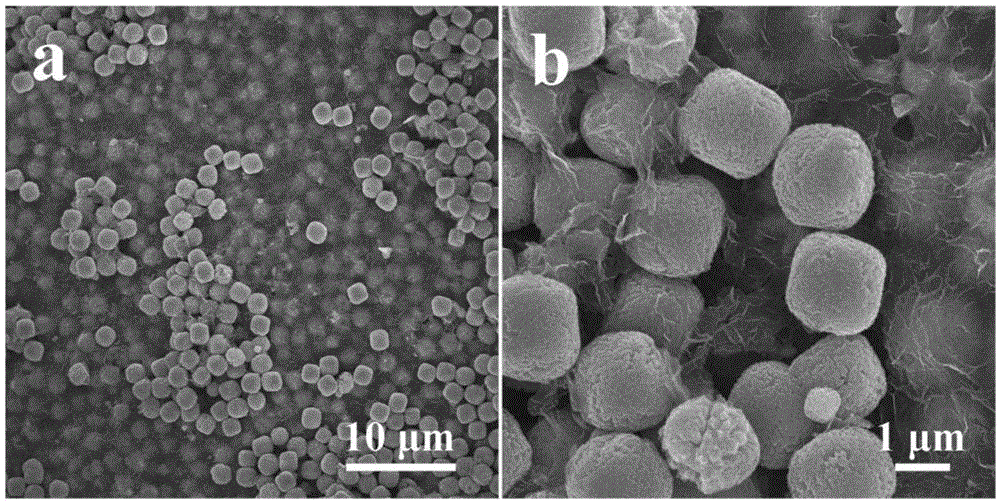

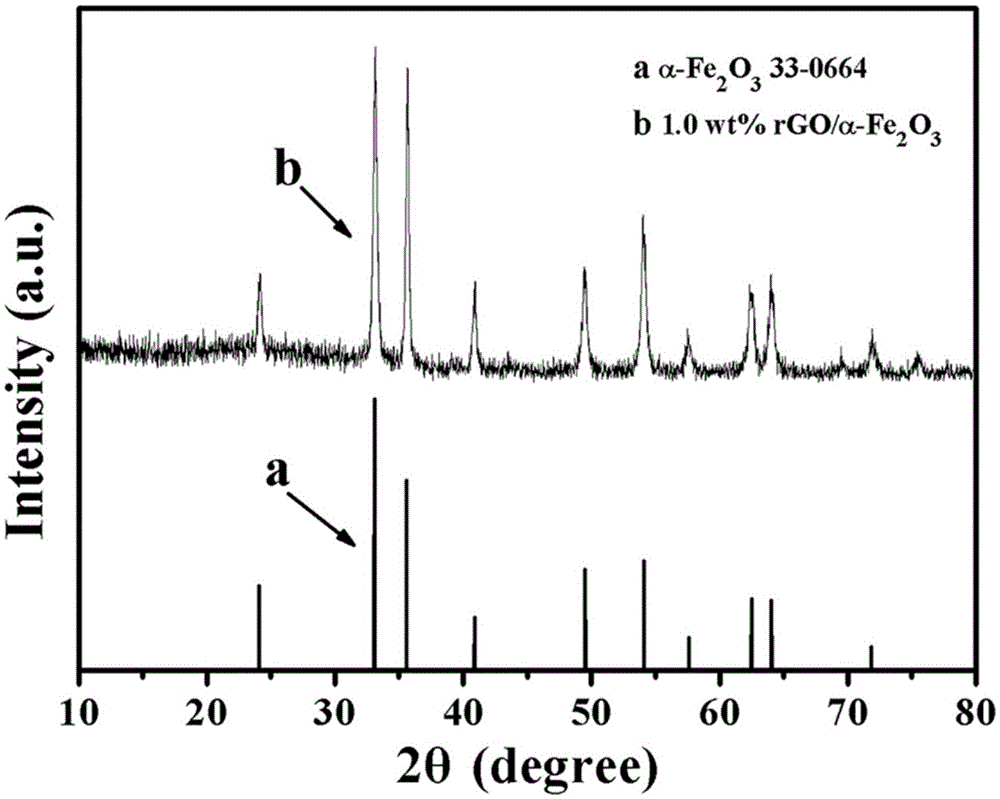

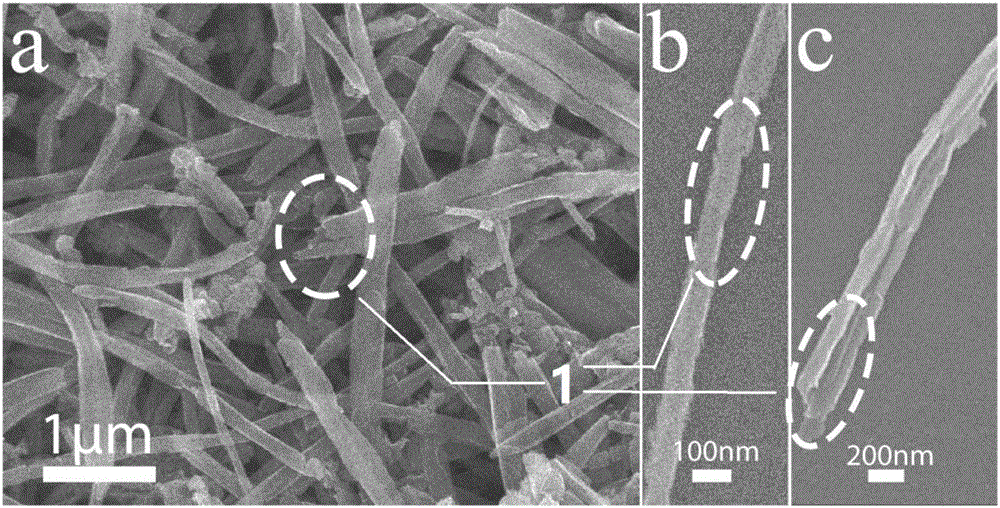

Acetone sensor on basis of compounds with rGO/alpha-Fe2O3 heterogeneous structures and method for preparing acetone sensor

InactiveCN105675664AThe synthesis method is simpleLow costMaterial resistanceHeterojunctionChemical reaction

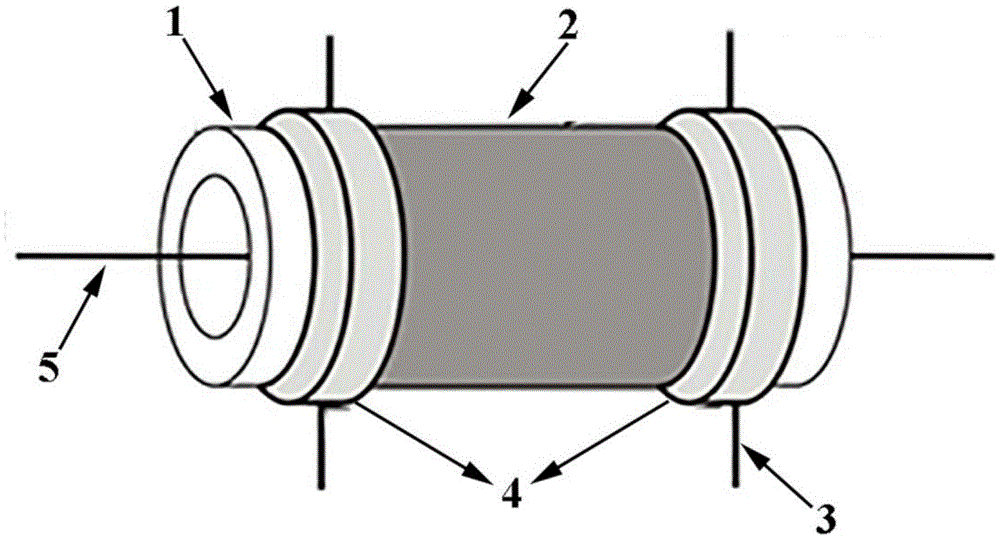

The invention belongs to the technical field of semiconductor metal oxide gas sensors, in particular to a sensor based on rGO / α-Fe 2 o 3 Acetone sensors of heterostructure composites and methods for their preparation. Preparation of rGO / α-Fe by one-step hydrothermal method 2 o 3 Heterostructure composite sensitive materials, using graphene's high specific surface area, gas adsorption capacity, fast carrier transfer rate and good conductivity and its combination with α-Fe 2 o 3 The heterojunction formed between them increases the chemical reaction of the detected gas and forms the charge transfer between the two, thus effectively improving the sensitivity of the sensor to acetone. In addition, the sensor structure used in the present invention is a commercially available Al with 2 ring-shaped gold electrodes 2 o 3 Insulating ceramic tube, coated with ring-shaped gold electrodes and Al 2 o 3 Semiconductor-sensitive materials on insulating ceramic tubes, and through Al 2 o 3 Composed of Nichrome heating coils in insulated ceramic tubes. The device is simple in process, small in size and suitable for mass production, so it has broad application prospects in detecting the content of acetone in the microenvironment.

Owner:JILIN UNIV

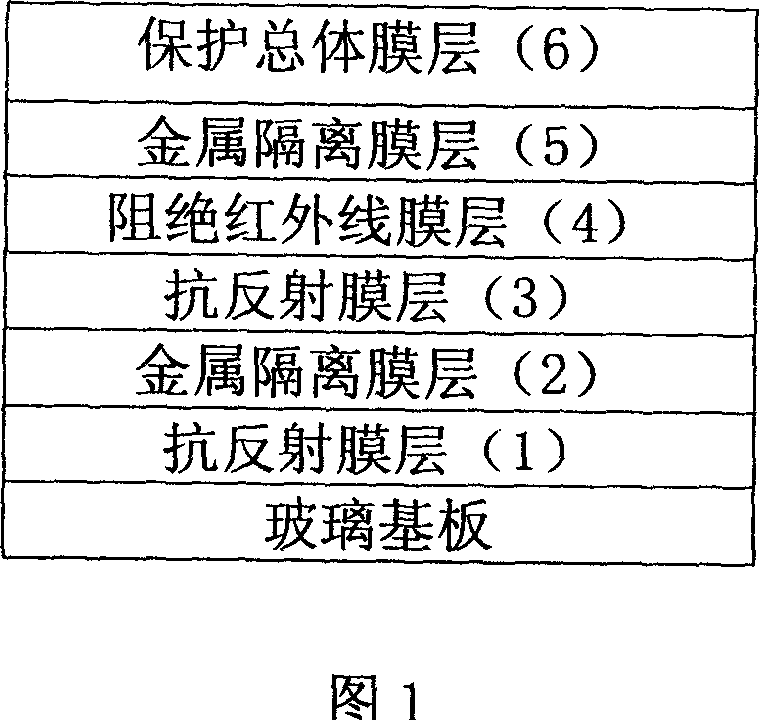

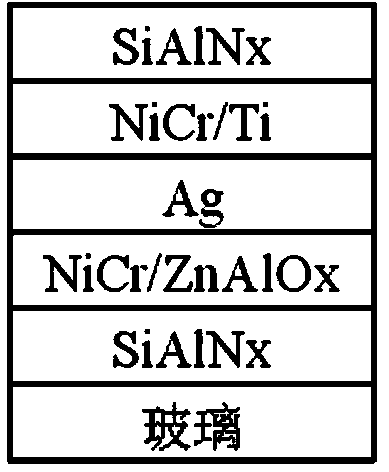

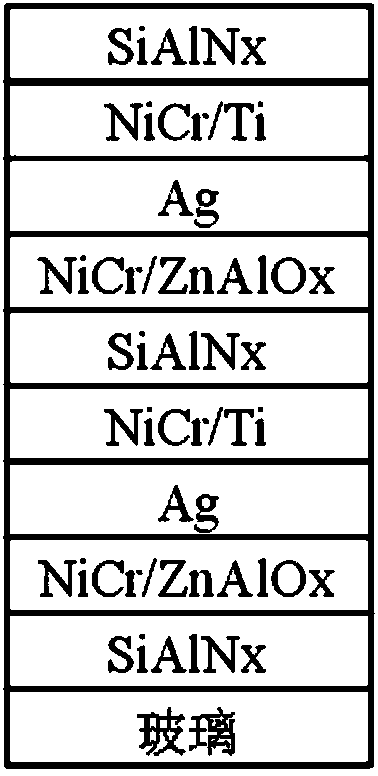

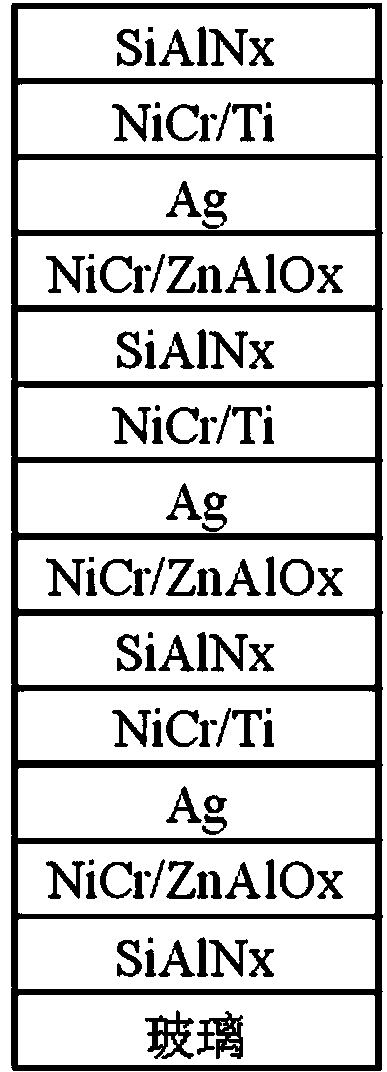

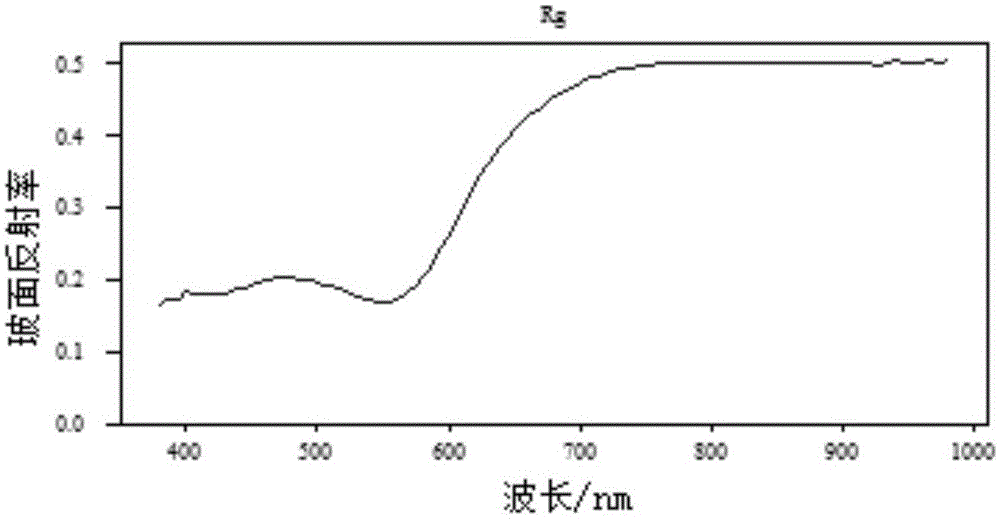

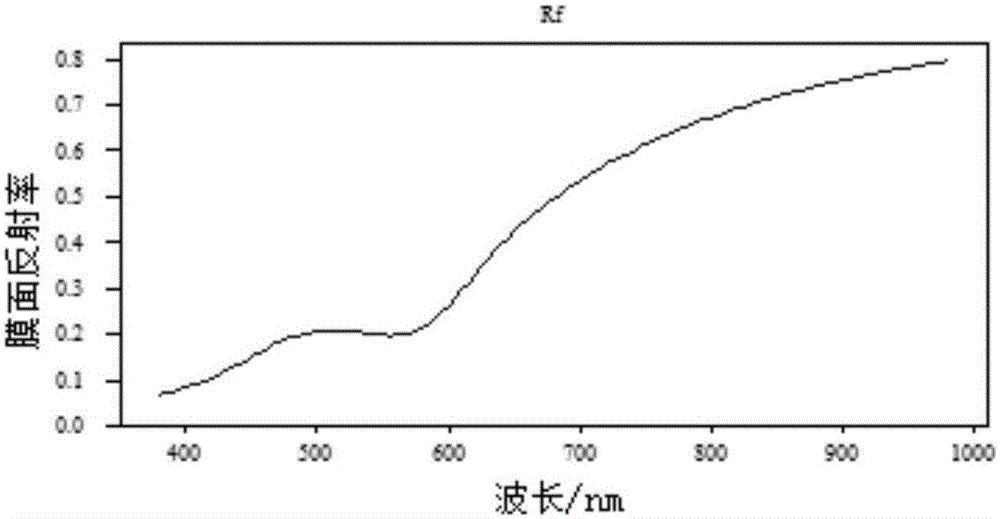

Low radiation coated glass capable of being toughened and its production process

The low radiation coated glass capable of being toughened includes one glass base plate and successively arranged the first isolating metal film of NiCr alloy, an antireflecting film of Si3N4 or Si3N4 plus TiO2, an infrared blocking film of metal Ag, the second isolating metal film of NiCr alloy, and a protecting film of Si3N4, SnO2 plus Si3N4 or TiO2 plus Si3N4. The coated glass may be toughened or heat treated while maintaining its high performance, and has excellent heat isolating performance and high antioxidant performance.

Owner:林嘉宏

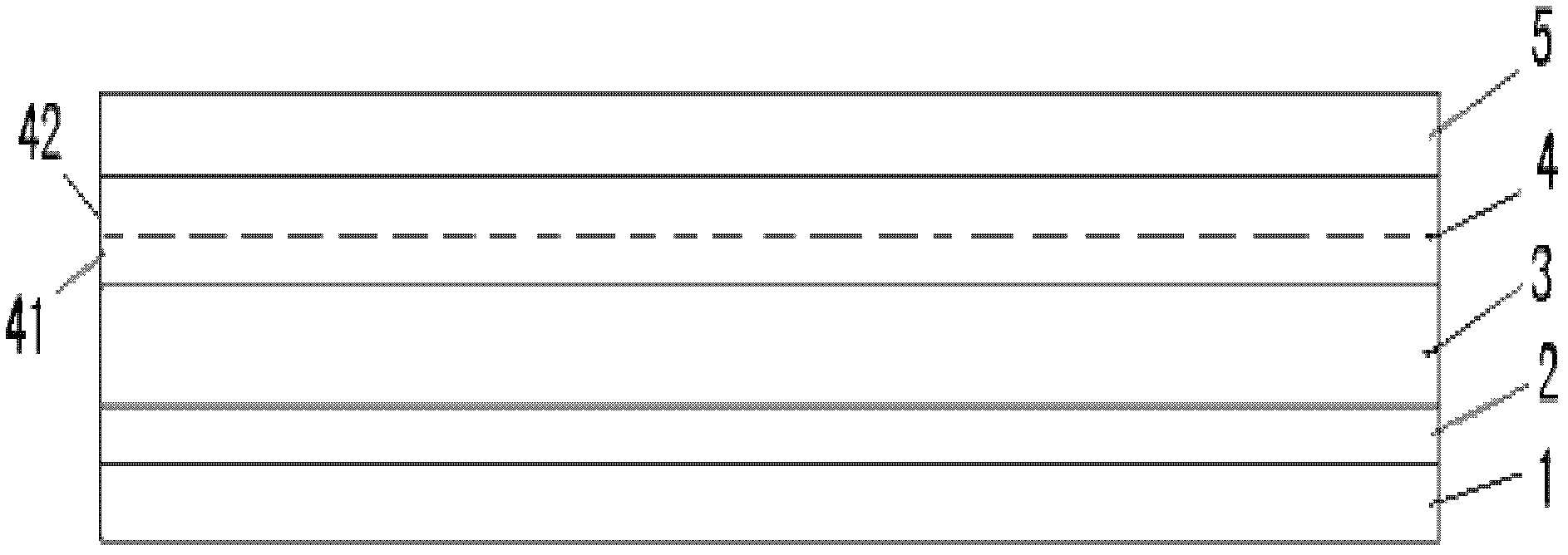

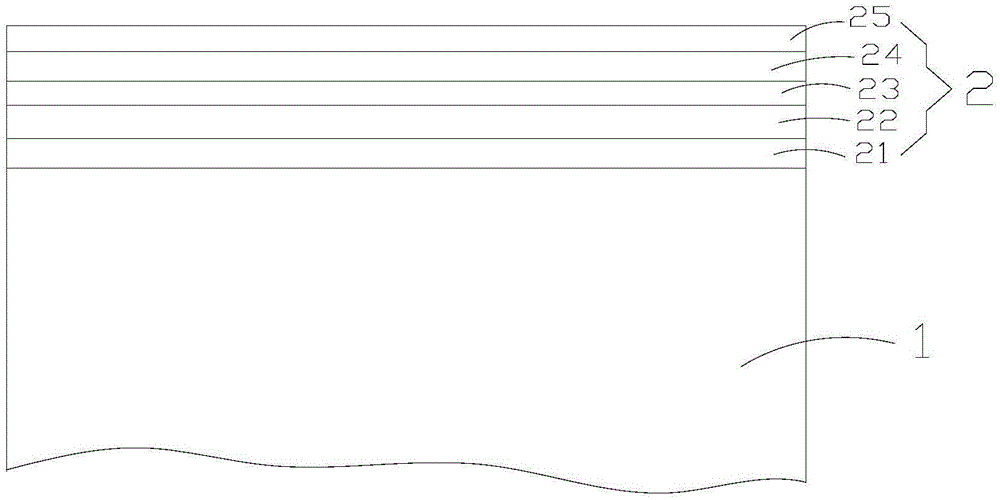

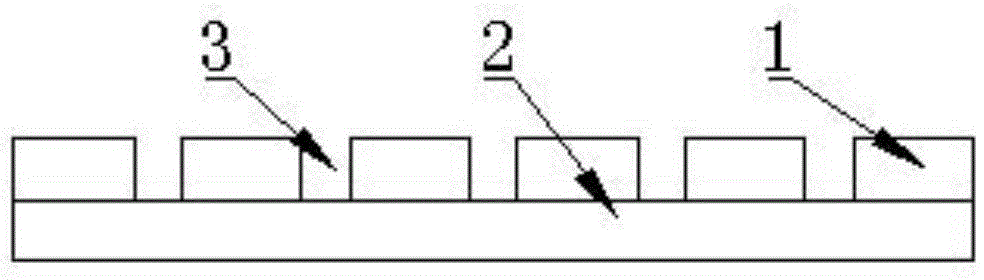

Temperable low-radiation coated glass and preparation method thereof

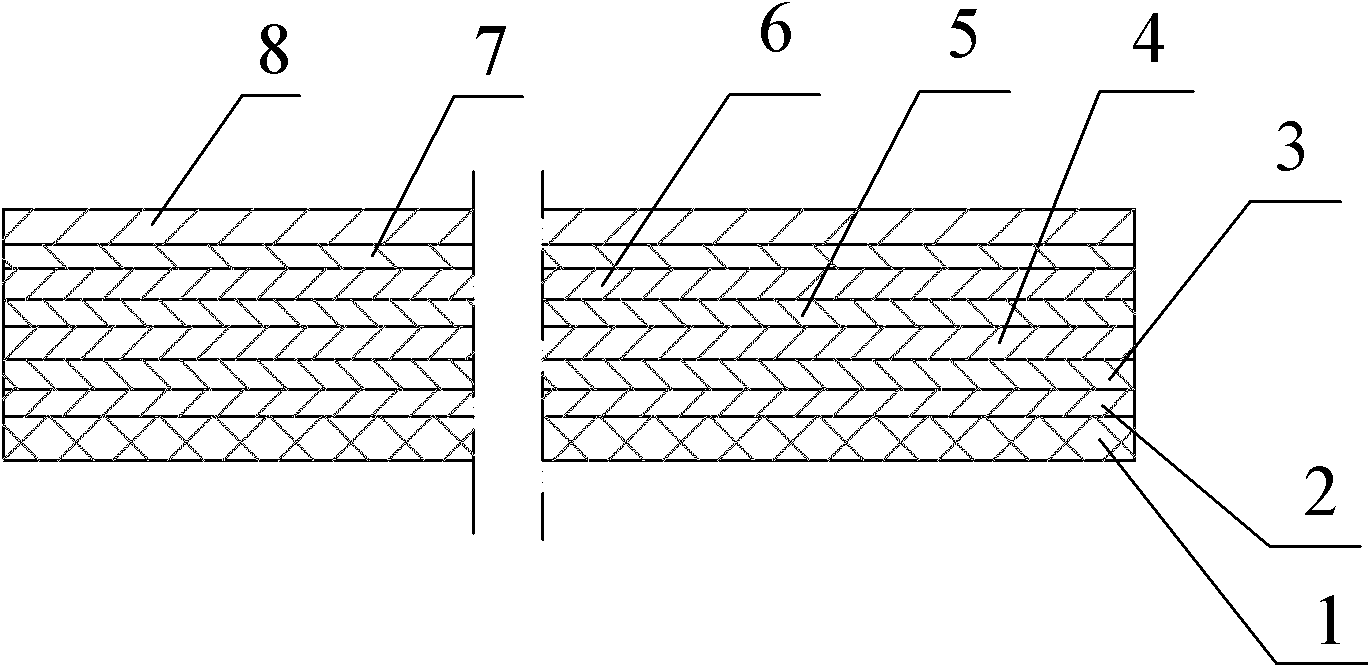

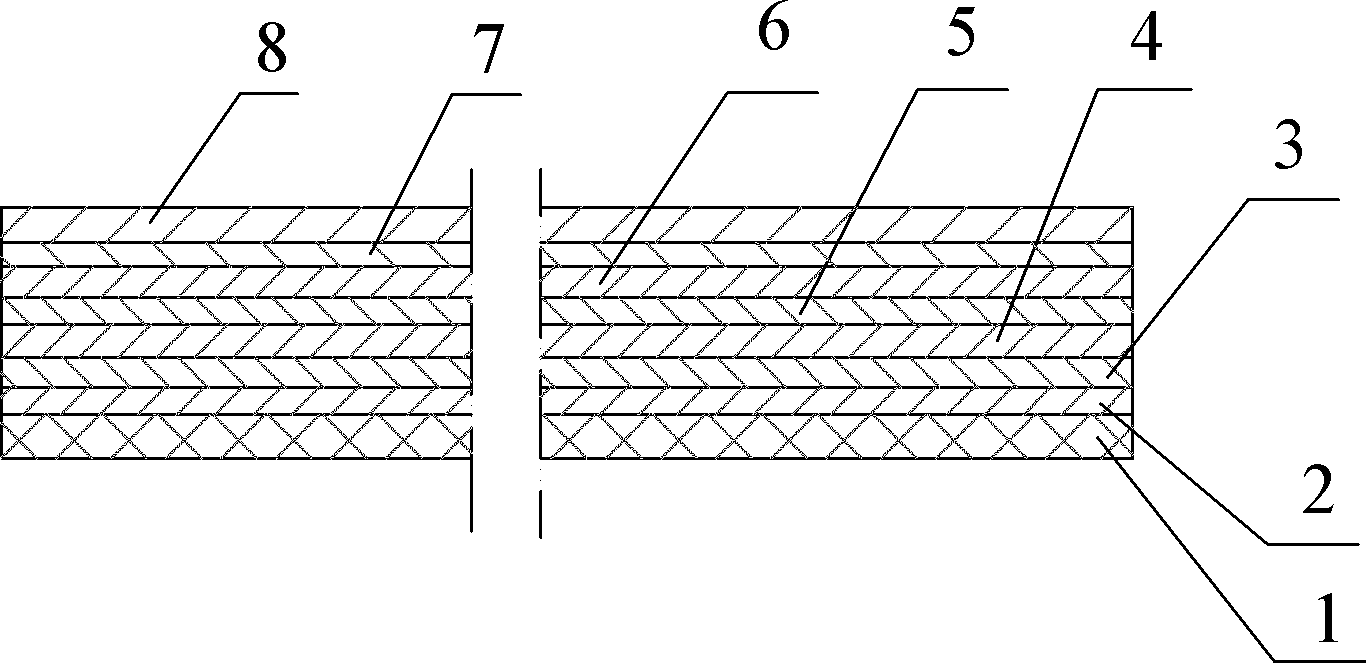

The invention discloses a temperable low-radiation coated glass which is characterized in that a dielectric layer I (2), a dielectric layer II (3), a metal barrier layer I (4), a silver layer (5), a metal barrier layer II (6), a dielectric layer III (7) and a dielectric layer IV (8) are arranged on the surface of a glass substrate (1) from bottom to top in turn; the dielectric layer I (2) is connected with the surface of the glass substrate (1); and the dielectric layer I (2) and the dielectric layer IV (8) are silica layers, the dielectric layer II (3) and the dielectric layer III (7) are stagnate layers of zinc oxide, and the metal barrier layer I (4) and the metal barrier layer II (6) are nichrome alloy layers. Simultaneously, the invention also discloses a method for preparing the temperable low-radiation coated glass. The temperable low-radiation coated glass has the characteristics of good thermal stability, good oxidation resistance, good membrane layer firmness, good wear resistance and alkali resistance and the like.

Owner:HANGZHOU CHUNSHUI COATED GLASS

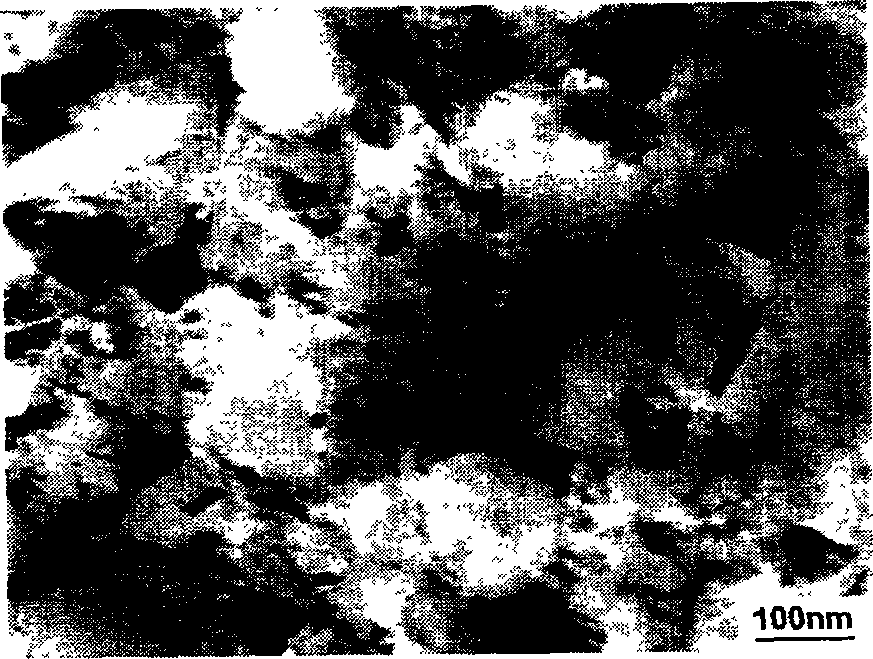

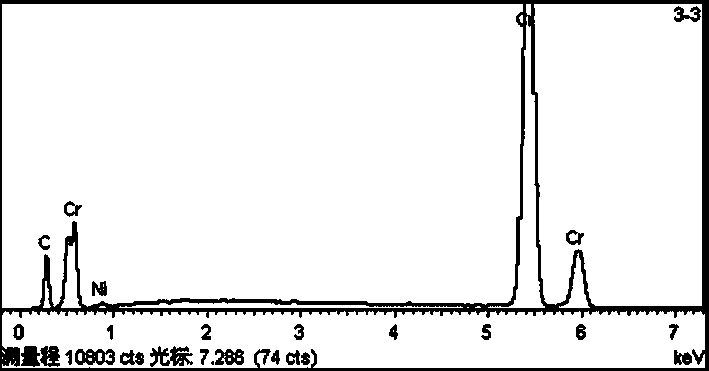

Anti-chlorine ion corrosion Ni-Cr nano composite coating and preparing method and use

InactiveCN1782138AImprove protectionGood resistance to Cl ion corrosionElectrolytic coatingsHydration reactionNicr alloy

The present invention discloses a kind of chlorine ion corrosion resisting nanometer composite Ni-Cr coating and its preparation and application. The nanometer composite Ni-Cr coating is prepared with nanometer metal Ni and Cr powder with Cr content of 4-15 wt%. The preparation process of the nanometer composite Ni-Cr coating is to electroplate Ni and Cr onto Ni substrate through conventional electric co-deposition. The nanometer composite Ni-Cr coating has obviously higher corrosion resistance than NiCr alloy with similar Cr content and composite Ni-Cr coating with micron Cr grains in similar content. The present invention has simple technological process, low cost, and compact and homogeneous coating. The nanometer composite Ni-Cr coating, when set in water solution containing Cl ion, will form hydrated Cr containing oxide and hydroxide to resist corrosion of Cl ion.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aluminum oxide base metal ceramic nozzle material and preparation method thereof

The invention discloses an aluminum oxide base metal ceramic nozzle material and a preparation method thereof. The ceramic nozzle material is prepared by taking alpha-Al2O3 ceramic as a base, adding Cr3C2 and NiCr as reinforced toughening phases and performing mechanical alloying, microwave presintering and hot pressed sintering. The ceramic nozzle material comprises the following components in percentage by volume: 5-30% of Cr3C2-NiCr and 70-95% of alpha-Al2O3, wherein the Cr3C2-NiCr is mixed powder of Cr3C2 powder and NiCr alloy powder; in the mixed powder, the mass percent of the NiCr alloy powder is 15-25%; and in the NiCr alloy powder, the mass percent of Ni is 33-50%. By combining mechanical alloying and microwave presintering, the prepared nozzle material has fine property and favorable applicability; the raw materials are cheap, accessible and abundant in reserves; and the preparation process is reliable in principle and simple to operate, and has broad market prospects.

Owner:SOUTHWEST PETROLEUM UNIV

Plating solution for electroplating tungsten-cobalt-nickel alloy on surface of structural steel

The invention discloses a plating solution for electroplating a tungsten-cobalt-nickel alloy on a surface of structural steel. The plating solution is composed of 12-18 g / L of cobalt sulfate, 80-84 g / L of sodium tungstate, 14-18 g / L of nickel sulfate, 34-38 g / L of boric acid, 30-36 g / L of sodium sulfate, 20-24 g / L of ammonium sulfate, 30-34 g / L of tartaric acid, 11-15 g / L of potassium pyrophosphate, 10-14 g / L of ascorbic acid, 1-3 ml / L of formaldehyde, 2-4 ml / L of dimethyl hexynol, and the balance being water.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

High transmittance toughenable low radiation glass and manufacture method thereof

InactiveCN102336529AHigh visible light transmittanceLow hemispheric emissivityArchitectural glassLow emissivity

The invention relates to high transmittance toughenable low radiation glass and a manufacture method thereof. The high transmittance toughenable low radiation glass comprises a glass substrate of transparent or colored float glass, and is characterized in that: a bottom dielectric layer with a film system structure of Si3N4 / ZnSnOx / ZnO:Al or ZnSnOx / ZnO:Al is arranged above the glass substrate; an infrared reflecting layer of metallic Ag is arranged above the bottom dielectric layer; a metal barrier layer of NiCr alloy is arranged above the infrared reflecting layer; an upper dielectric layer with a film system structure of ZnSnSbOx / Si3N4 is arranged above the metal barrier layer. The beneficial effects of the invention are as follows: since composite dielectric layers are employed for the glass provided in the invention and all the film layers are reasonably arranged, the obtained glass can undergo toughening or heat treatment, and the treated glass can retain original properties and has high visible light transmittance and a low hemisphere radiant ratio; a single sheet of the toughened coated glass has visible light transmittance of 85% and a hemisphere radiant ratio below 0.10, and is extensively applicable to the field of architectural glass.

Owner:SHANGHAI NORTH GLASS COATING TECHNOLOGY INDUSTRIAL CO LTD +2

Glass for increasing blueness of printing decorative glass based on coating method and preparation method thereof

ActiveCN107098598AIncrease the sensory effect of viewing angleStay crystal clearCoatingsComposite filmPrinting ink

The invention discloses glass for increasing blueness of printing decorative glass based on a coating method. The glass comprises a glass substrate, and a transitional film layer, a metal film layer, a protective film layer, a printing pattern layer and a protective printing ink layer which are successively arranged on the glass substrate, wherein the transitional film layer is a composite film layer of SiOX and TiOX or a composite film layer of SiOX and SnOX, wherein x is 1.7-2.0; the metal film layer is a metal Ti film layer or a NiCr alloy film layer; and the protective film layer is a silicon dioxide film layer. According to the glass for increasing blueness of printing decorative glass based on the coating method provided by the invention, the reflectivity is low, the glass can display blue metallic luster, and the color does not change along with the change of the visual angle.

Owner:JIANGSU XIUQIANG GLASSWORK CO LTD

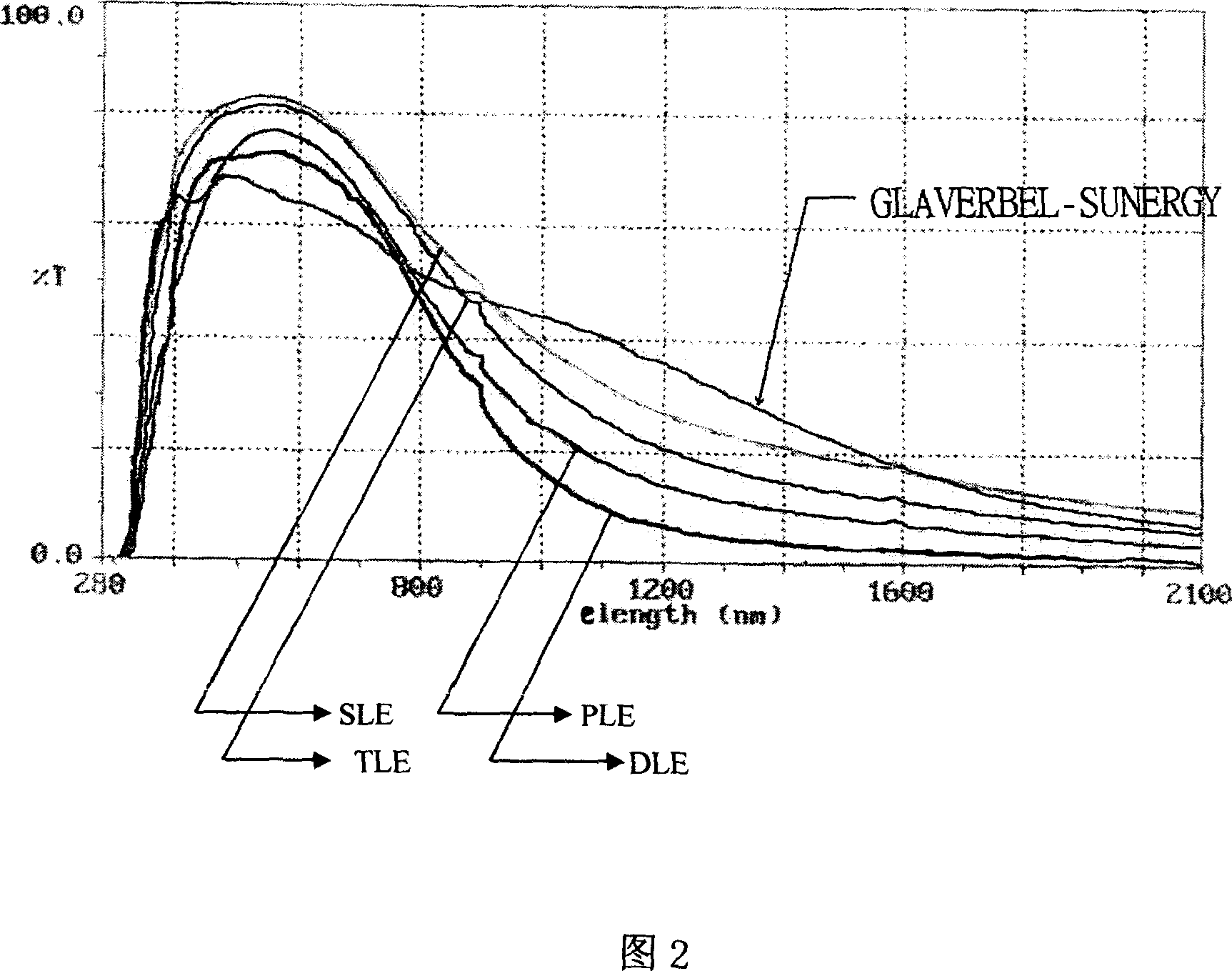

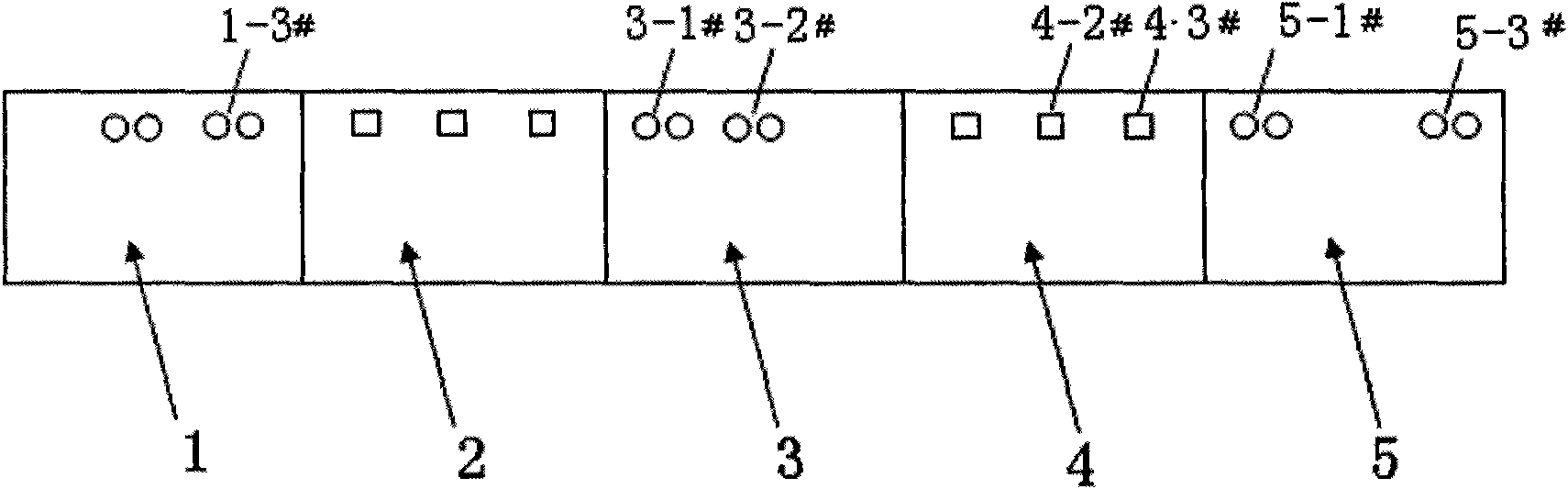

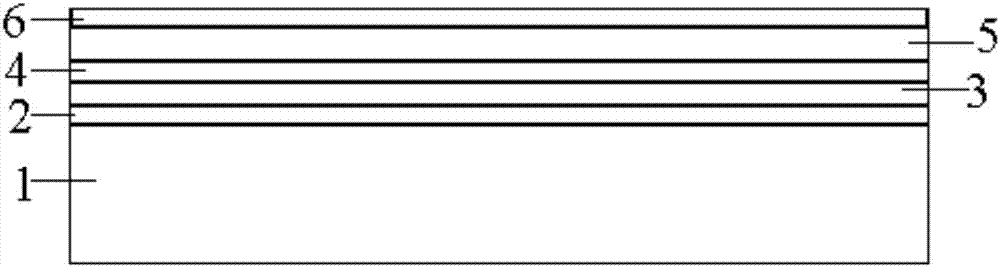

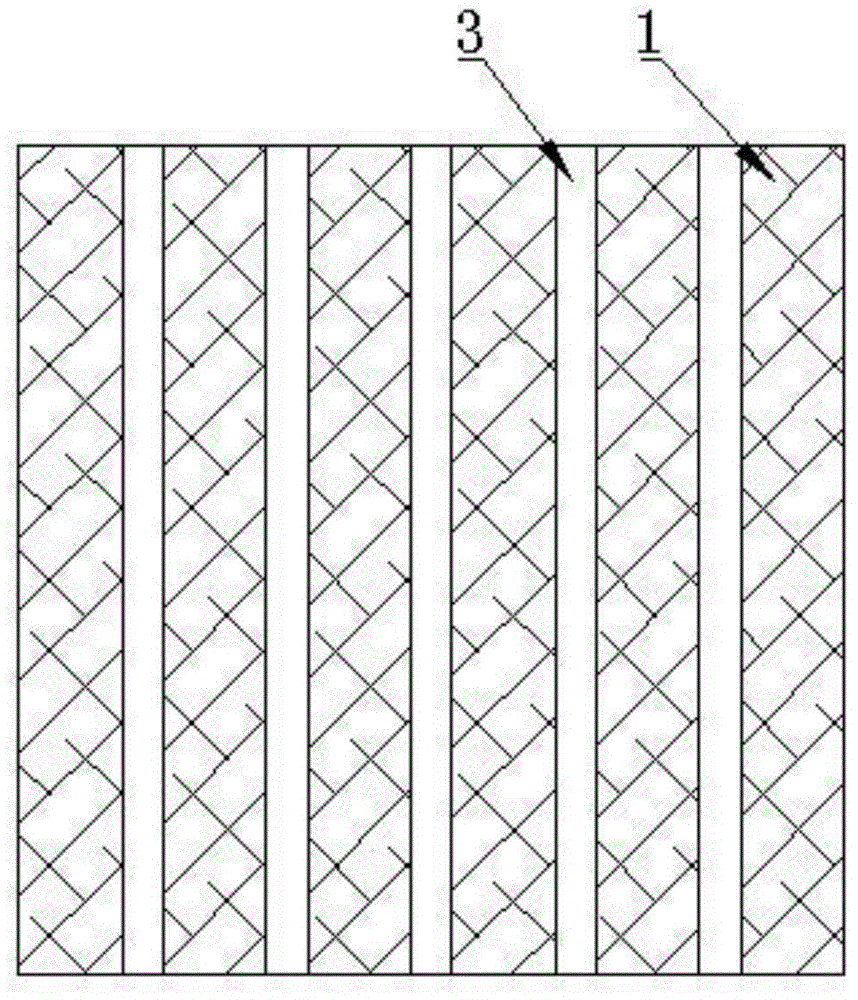

NiCr system flat plate solar energy spectrally selective absorbing coating and preparation method thereof

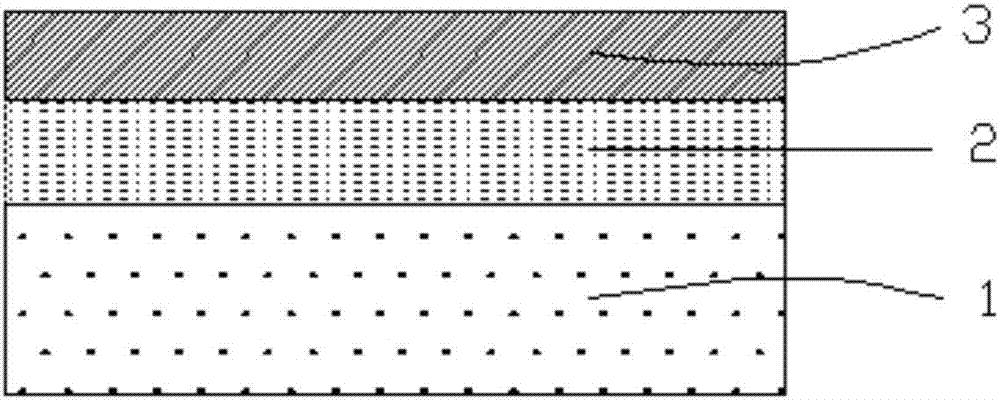

ActiveCN102615879AImprove corrosion resistanceGood optical performance parametersVacuum evaporation coatingSputtering coatingSputteringNicr alloy

The invention relates to a NiCr system flat plate solar energy spectrally selective absorbing coating and a preparation method thereof. The coating comprises a substrate, wherein a transition layer, an infrared reflecting layer, an absorbing layer and an antireflection layer are arranged on the substrate from inside to outside in sequence by a direct current (DC) magnetron sputtering method; and the absorbing layer is formed by a first sublayer and a second sublayer. The preparation method is characterized by adopting NiCr alloys as conducting particles and comprises the following steps of: (1) selecting the substrate, and preparing the transition layer on the substrate by a metal target DC magnetron sputtering method; (2) preparing the infrared reflecting layer on the transition layer by the metal target DC magnetron sputtering method, wherein the metal target is a pure metal Cu or Al target; (3) preparing the absorbing layer on the infrared reflecting layer by the NiCr alloy target DC magnetron sputtering method; and (4) preparing the antireflection layer on the absorbing layer by the metal target DC magnetron sputtering method. The coating has the advantages of high deposition rate and short production cycle, and the adopted materials can meet the environmental requirement. The coating and the preparation method can be widely applied to the technical field of solar heat utilization materials.

Owner:北京桑达太阳能技术有限公司

Technology for electroplating tungsten-cobalt-nickel alloy on surface of structural steel

The invention discloses a technology for electroplating a tungsten-cobalt-nickel alloy on a surface of structural steel. A plating solution adopted in the technology is composed of 12-18 g / L of cobalt sulfate, 80-84 g / L of sodium tungstate, 14-18 g / L of nickel sulfate, 34-38 g / L of boric acid, 30-36 g / L of sodium sulfate, 20-24 g / L of ammonium sulfate, 30-34 g / L of tartaric acid, 11-15 g / L of potassium pyrophosphate, 10-14 g / L of ascorbic acid, 1-3 ml / L of formaldehyde, 2-4 ml / L of dimethyl hexynol, and the balance being water. The technology comprises the steps of washing and activating the structural steel; then putting the structural steel in the above plating solution; taking stainless steel as an anode; adjusting a pH value to 7.5-8.5 with ammonia water; heating to a temperature of 50-60 DEG C; controlling a current density at 12-16 A / dm<2> and electroplating for 20-30 minutes.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Copper-nickel alloy electroplating bath and plating method

Owner:DISPOL CHEMICALS CO LTD

Ceramic glue spreader for paper packaging

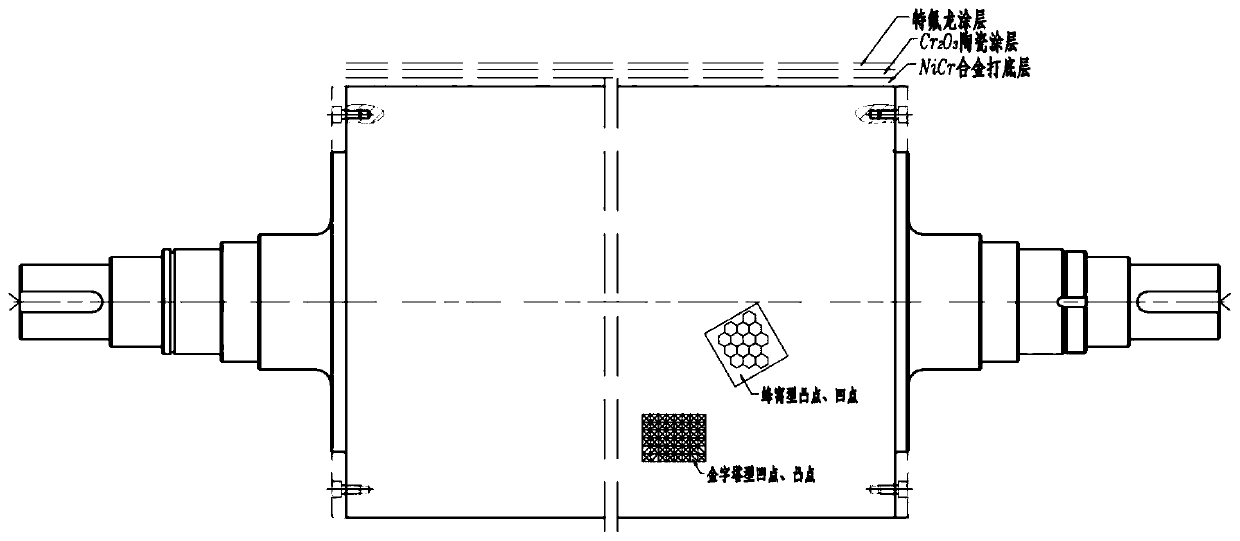

InactiveCN111036481AReduce lossEmission reductionLiquid surface applicatorsMechanical working/deformationCeramic coatingLaser engraving

The invention discloses a ceramic glue spreader for paper packaging. The ceramic glue spreader comprises a steel roller arranged on the middle part of the ceramic glue spreader, nichrome priming coatof 0.15 mm is sprayed on the surface of the steel roller to protect an iron core from long-term corrosion by glue, a ceramic coating of 0.3-0.4 mm is sprayed on the outer layer of the nichrome primingcoat, a non-contact and pressureless laser engraving process is used on the ceramic coating to carry out net pattern carving on the ceramic surface, according to the difference of the viscosity of the glue, a Teflon anti-stick coating is sprayed on the surface of the ceramic coating, and the ceramic glue spreader is prepared. The roller surface accuracy, circular runout and roundness of the laserengraved ceramic glue spreader can finally reach within 0.005 mm, the glue spreading gap can be controlled within 0.05 mm, glue loss is reduced by about 20%, the spreading amount of the glue is moreeconomical, only a shorter drying time is required, energy consumption and carbon emission are reduced, the service life of the ceramic glue spreader can reach more than 6 times that of a chrome plated glue spreader, and meanwhile, environmental pressure caused by hard chromium electroplating is not caused.

Owner:CHANGZHOU YUDONG ROLLER MFG CO LTD

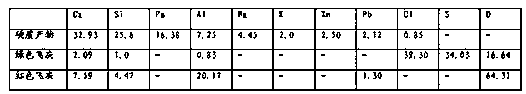

Method for manufacturing prestress steel strand coated with nichrome powder

ActiveCN103639402AHigh strengthImprove toughness and strengthMolten spray coatingRope making machinesWire rodPre stress

The invention discloses a method for manufacturing a prestress steel strand coated with nichrome powder. The method for manufacturing the prestress steel strand coated with the nichrome powder comprises the following steps that (1) the nichrome powder comprises, by weight, 0.5-3.2% of Re, 48-54% of Ni, 18-32% of Cr, 1.6-5.5% of Si, 0.3-0.8% of S, 0.5-2.2% of C, 10-16% of Fe, 1.2-10% of Mn, and 1-2.5% of composite rear earth; (2) a plurality of wire rod steel wires are fed into a heating furnace; (3) the nichrome powder is evenly sprayed on the surfaces of the wire rod steel wires through a spray gun; (4) the wire rod steel wires are stranded through a stranding machine to form the steel strand which is of a steel wire rope shape; (5) the steel strand enters a quenching device; (6) the nichrome powder is evenly sprayed on the surface of the steel strand again through the spray gun; (7) the steel strand enters a layer winder to be packaged. According to the method for manufacturing the prestress steel strand coated with the nichrome powder, the strength, wear resistance and corrosion resistance of the steel strand are improved.

Owner:TIANSHUN GROUP

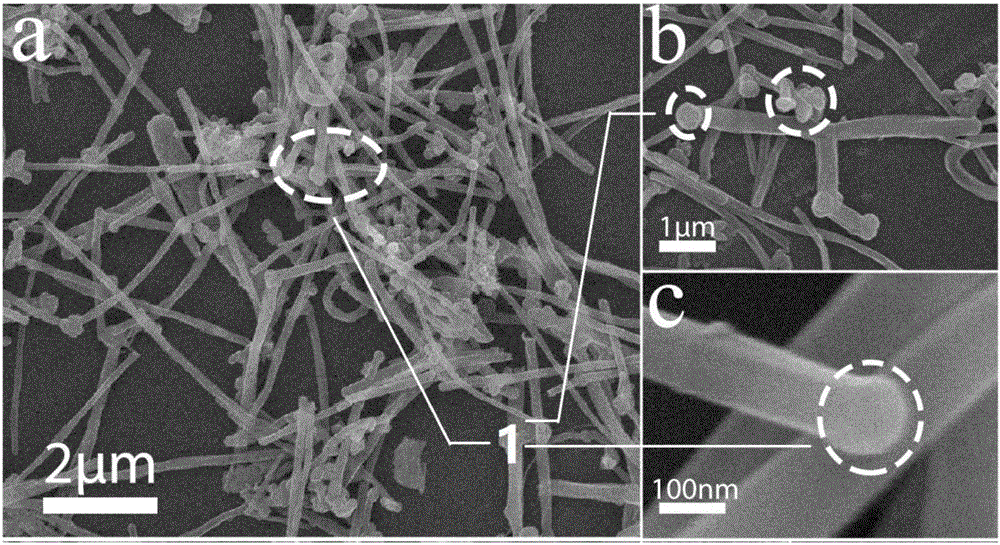

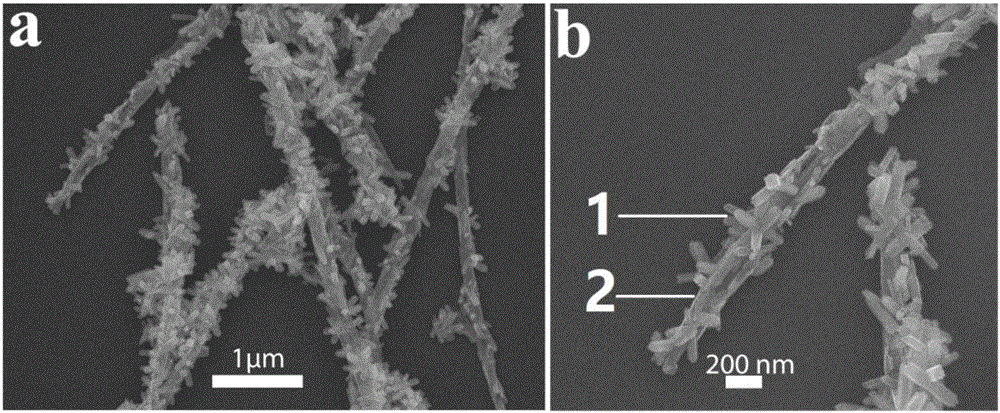

CNTs@alpha-Fe2O3 heterojunction composite material-based acetone gas sensor and preparation method thereof

ActiveCN106770493AHigh sensitivityExcellent gas sensitivityMaterial resistanceHeterojunctionHigh volume manufacturing

The invention discloses a CNTs@alpha-Fe2O3 heterojunction composite material-based acetone gas sensor and a preparation method thereof, and belongs to the technical field of gas sensors. The acetone gas sensor comprises an insulating alumina ceramic tube substrate with two parallel and separate annular gold electrodes on the outer surface, a semiconductor metal oxide gas sensitive material coated on the outer surface of the insulating alumina ceramic tube substrate and the gold electrodes, and a nichrome heating coil arranged in the insulating alumina ceramic tube, wherein each gold electrode is provided with a platinum wire; the sensitive material is a CNTs and alpha-Fe2O3 nano-rod-compounded heterojunction hierarchical structure nanomaterial. The sensor has the advantages of being simple in structure, low in price, relatively small in volume, solid and durable, is suitable for massive production; and the gas-sensitivity characteristic testing result shows that the sensor can detect low-concentration acetone, has excellent long-term stability and has an important application prospect in detection and alarming of acetone leakage in industrial production and medical detection.

Owner:JILIN UNIV

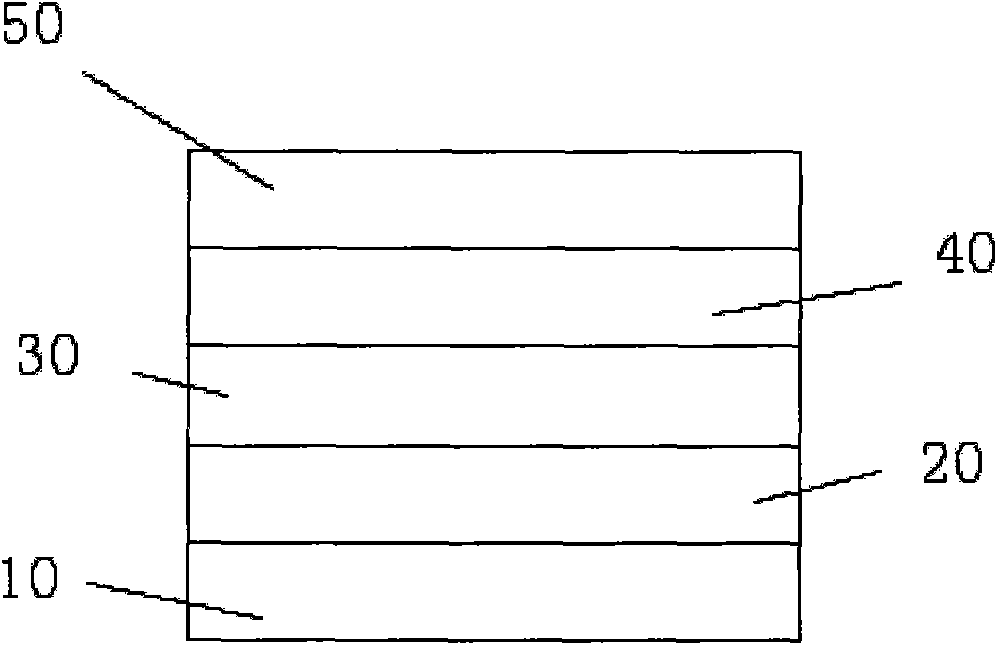

Electric heating antibacterial coating and preparation method thereof

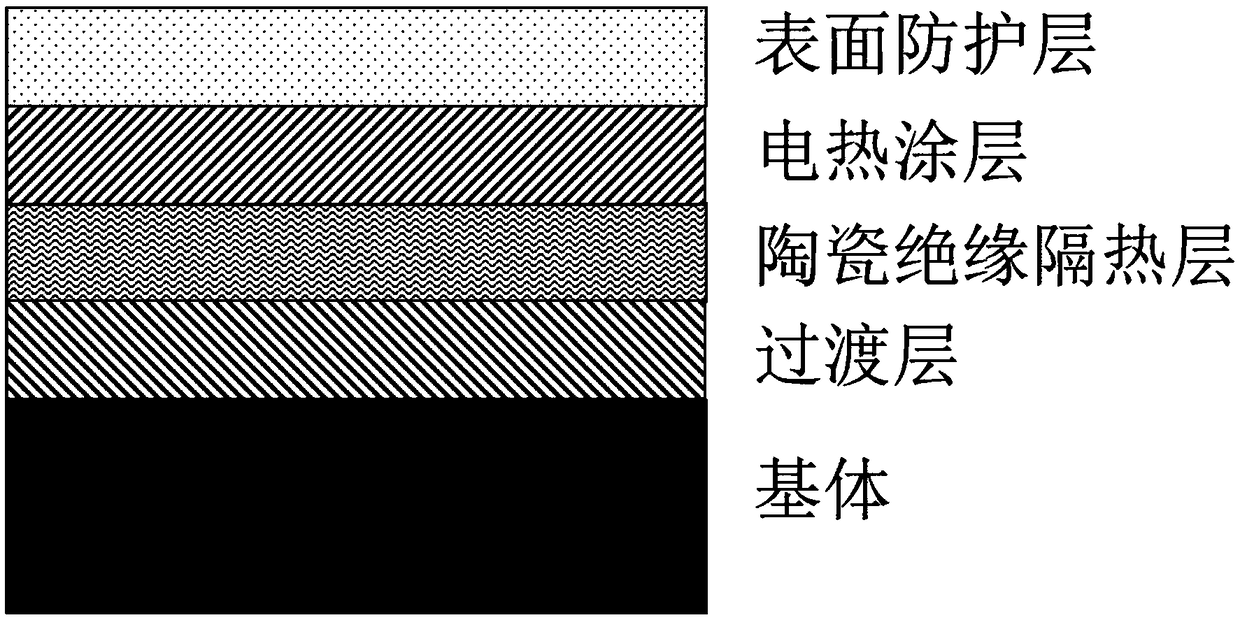

ActiveCN109112462ARapid antibacterial effectImprove antibacterial propertiesMolten spray coatingSuperimposed coating processLow voltageThermal insulation

The invention discloses an electric heating antibacterial coating, which consists of a matrix, a transition layer, an insulation and thermal insulation layer, an electric heating layer and a surface protective layer sequentially from the bottom to top; and the material of the electric heating layer is chosen from at least one of NiCr alloy, NiCrFe alloy, NiFe alloy, NiCu alloy, FeCrAl alloy and AlNiFe. The electric heating antibacterial coating provided by the invention does not require the addition of antibacterial agent, and under the condition of low-voltage electrification, a quick, effective antibacterial effect can be achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High-temperature-corrosion-resistant alloy coating of boiler heating surface and preparation method thereof

ActiveCN107034427AReduce porosityUniform and dense surfaceMolten spray coatingPorosityThermal spraying

The invention discloses a high-temperature-corrosion-resistant alloy coating of a boiler heating surface and a preparation method of the high-temperature-corrosion-resistant alloy coating of the boiler heating surface. The high-temperature-corrosion-resistant alloy coating comprises a NiCrAlY alloy priming coating and an Incone1625 / NiCr alloy finishing coating. The preparation method of the high-temperature-corrosion-resistant alloy coating comprises the steps that (1) Incone1625 alloy powder and NiCr alloy powder are evenly mixed according to a ratio, and spherical composite alloy powder is prepared and dried and stands for use; (2) the surface of a matrix is cleaned and roughened; (3) the surface of the matrix is coated with NiCrAlY alloy powder through a thermal spraying technology, so that the priming layer is formed; (4) the priming layer is coated with the spherical composite alloy powder through the thermal spraying technology, so that the finishing layer is formed; and (5) cooling is conducted, and then the high-temperature-corrosion-resistant alloy coating is obtained. The high-temperature-corrosion-resistant alloy coating prepared through the preparation method has the advantages of being low in porosity, uniform and dense in surface and good in high-temperature corrosion resistance, achieving that all the layers are tightly combined and the like, the service life of the boiler can be prolonged, and cost can be reduced.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Offline low-emissivity glass coated film system

InactiveCN104029440ALow shading factorReduce visible light reflectanceVacuum evaporation coatingSputtering coatingLow emissivityOxygen

The invention discloses an offline low-emissivity glass coated film system. According to the invention, an original metal Ti layer or a NiCr alloy is replaced with a nitrogen zinc oxide film layer in an existing offline low-emissivity glass coated film system. The nitrogen zinc oxide film layer is prepared by a magnetron sputtering method; nitrogen acts as a sputtering gas and a technological gas in the magnetron sputtering film coating process, and meanwhile, trace oxygen is introduced according to the practical product performance. Relatively low visible light reflectance is kept as well as the sun shading coefficient is low. The offline low-emissivity glass coated film system is gentle in color, can meet the neutral color requirement easily, is low in angle color deviation, and is excellent in abrasion resistance and outstanding in processing property, the finished product rate of the system is effectively improved, and the production cost is lowered.

Owner:HANGZHOU DIANZI UNIV +1

Preparation method of NiCrAl foam metal

ActiveCN104232971AImprove antioxidant capacityHigh resistivitySolid state diffusion coatingNicr alloyMetal

The invention relates to a preparation method of an electrical heating alloy, and particularly relates to a preparation method of an NiCrAl foam metal. The preparation method comprises the following steps of: preparing a foam NiCr alloy by adopting a sintering process; aluminizing by adopting a powder embedding method on the basis of the foam NiCr alloy to form the NiCrAl foam metal, wherein a penetrating agent comprises nickel-aluminum alloy powder, Al2O3 powder and NH4Cl. The preparation method disclosed by the invention overcomes the defects of the traditional electrical heating alloy; and the produced NiCrAl foam metal has excellent oxidation resistance and resistivity.

Owner:YANCHENG XINYANG ELECTROTHERMAL MATERIAL CO LTD

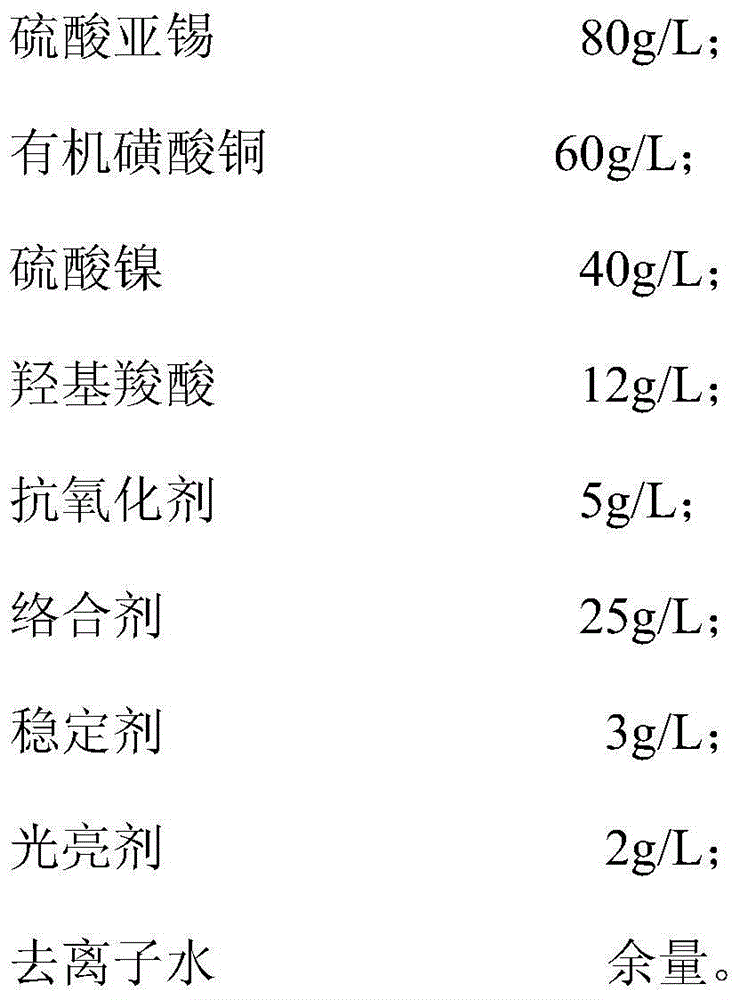

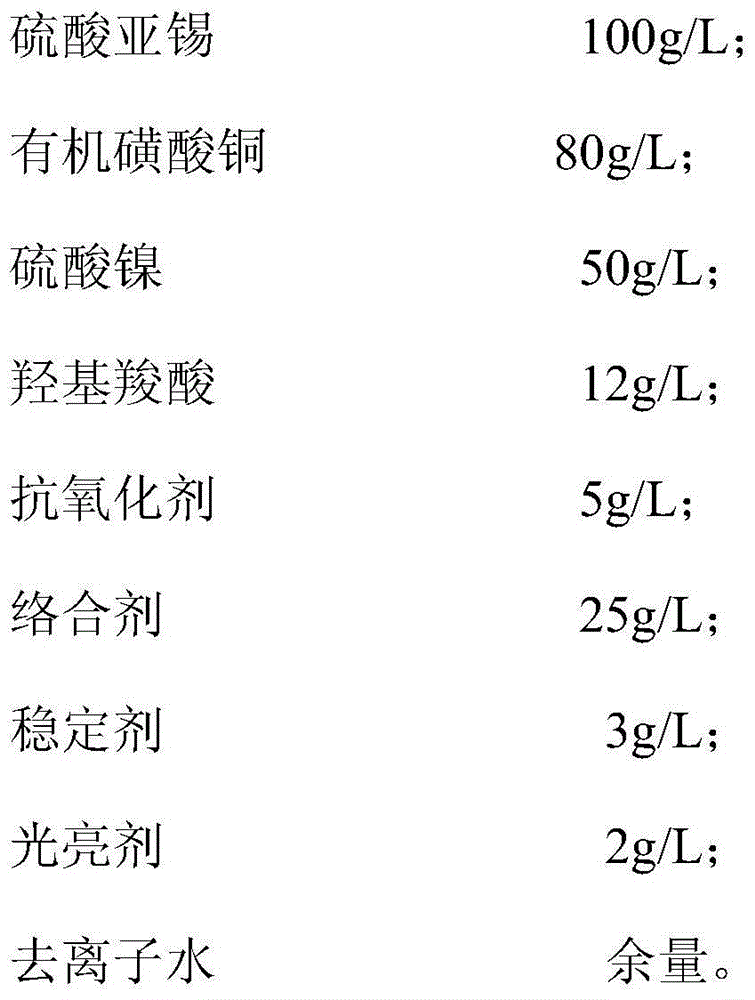

A tin-copper-nickel alloy electroplating solution and an electroplating method thereof

A tin-copper-nickel alloy electroplating solution and an electroplating method thereof are disclosed. The electroplating solution comprises 80-150 g / L of stannous sulfate, 60-100 g / L of organic copper sulfonate, 40-80 g / L of nickel sulfate, 10-20 g / L of hydroxy carboxylic acid, 0.5-15 g / L of an antioxidant, 20-35 g / L of a complexing agent, 1-5 g / L of a stabilizing agent and 1-5 g / L of a brightener, with the balance being deionized water. The electroplating solution is simple in composition, low in cost, high in stability, low in toxicity, safe and environmental friendly. A plating layer prepared by electroplating is free of crystal whisker, good in thermal stability, good in malleability, high in processability and not liable to crack.

Owner:无锡永发电镀有限公司

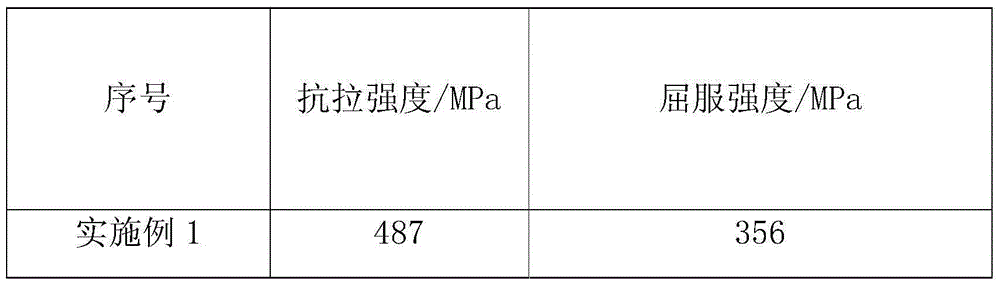

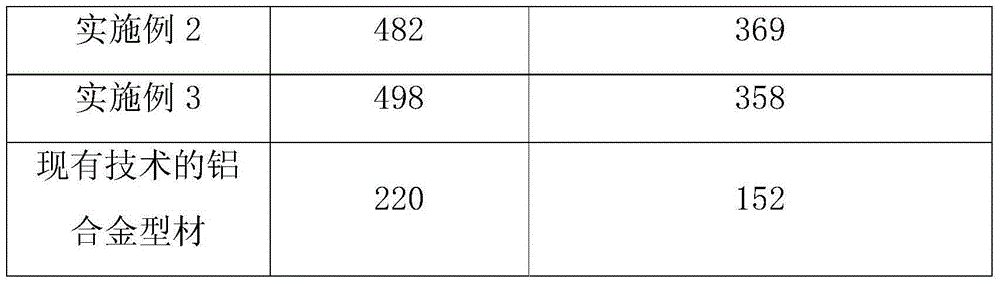

High-strength aluminum alloy profile and manufacturing technique thereof

The invention discloses a high-strength aluminum alloy profile and a manufacturing technique thereof and relates to the field of aluminum alloy materials. The high-strength aluminum alloy profile is composed of, by mass, 3%-5% of magnesium, 1%-4% of silicon, 2%-4% of iron, 0.5%-1% of copper, 1.3%-1.8% of manganese, 0.1%-0.5% of strontium, 0.5%-0.8% of zirconium, 0.5%-0.8% of titanium, 2%-9% of nichrome and the balance aluminum. The invention further discloses the manufacturing technique of the high-strength aluminum alloy profile. The manufacturing technique comprises the three main steps of material preparation, smelting, and homogenization treatment and extrusion forming. Compared with a traditional technique, the manufacturing technique is simple, technical requirements can be met easily, and the strength of the manufactured aluminum alloy profile is improved; meanwhile, the properties such as the corrosion resistance and the weather fastness are improved, and thus the service life of the aluminum alloy profile in a complicated environment is prolonged.

Owner:ANHUI LANT ALUMINUM

Novel aluminium and zinc corrosion resistance nichrome and furnace roller manufacturing method by adopting same

ActiveCN103409697AImprove corrosion resistanceExtended service lifeHot-dipping/immersion processesChemical compositionSurface layer

The invention discloses novel aluminium and zinc corrosion resistance nichrome and a furnace roller manufacturing method by adopting the nichrome. The novel aluminium and zinc corrosion resistance nichrome comprises the following chemical constituents in weight percent: 0.1% to 0.2% of C, 1% to 1.2% of Si, 0.8% to 1.2% of Mn, 22% to 23% of Cr, 10.5% to 12.5% of Ni, smaller than or equal to 0.03% of P, smaller than or equal to 0.02% of S, 0.4% to 0.5% of Nb, 0.8% to 1.2% of Mo, 8.5% to 10.5% of W, 0.08% to 0.12% of Re, and the balance of Fe. The nichrome is long in service life, the procurement cost of a manufacturer using sink rolls can be reduced, and frequent replacement can be avoided at the same time, besides, the labor intensity is lowered, and the production efficiency is improved; the furnace roller is manufactured in a centrifugal casting method, under the action of a centrifugal force, tungsten alloy of a centrifugal cast sink roll is distributed in a grading manner from the inside out in content, and the surface layer is rich in tungsten, so that the surface rigidity, the wearing resistance and the corrosion resistance of the furnace roller can be improved.

Owner:烟台市中拓合金钢有限责任公司

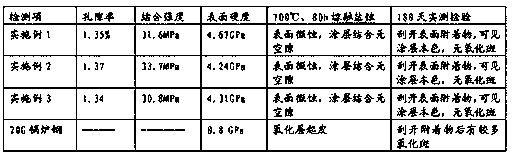

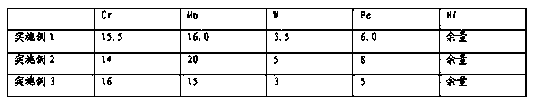

Spraying material for heating surface of boiler tube of garbage incinerator and construction process thereof

The invention discloses a spraying material for a heating surface of a boiler tube of a garbage incinerator and a construction process thereof. The spraying material for the heating surface of the boiler tube of the garbage incinerator is an alloy material, with resistance to corrosion and resistance to scouring, designed for analysis of corrosion components of garbage. The alloy material is prepared by adding Mo and W hard phase elements based on a NiCr alloy base material. The NiCrMoW alloy is coated on the tube wall of the boiler tube by way of high speed electric arc spraying. In this way,the NiCrMoW alloy with high hardness and high resistance to corrosion can be sprayed to the heating surface of the boiler tube, the porosity of a coating is not greater than 1.5%, and the coating hasrelatively high stability.

Owner:常熟浦发第二热电能源有限公司

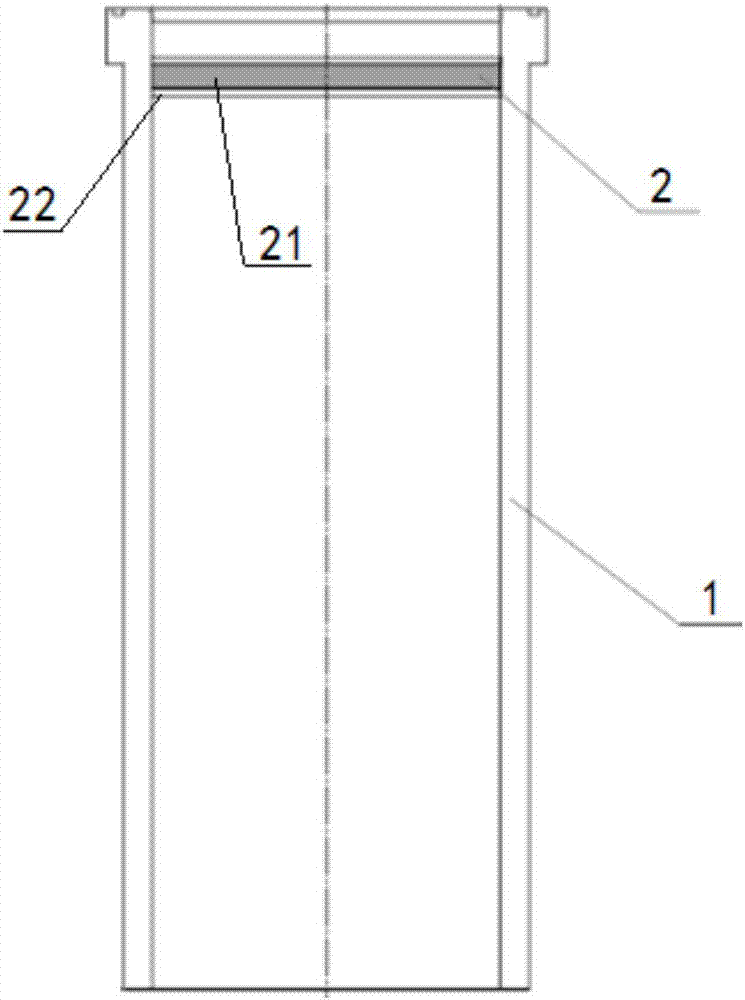

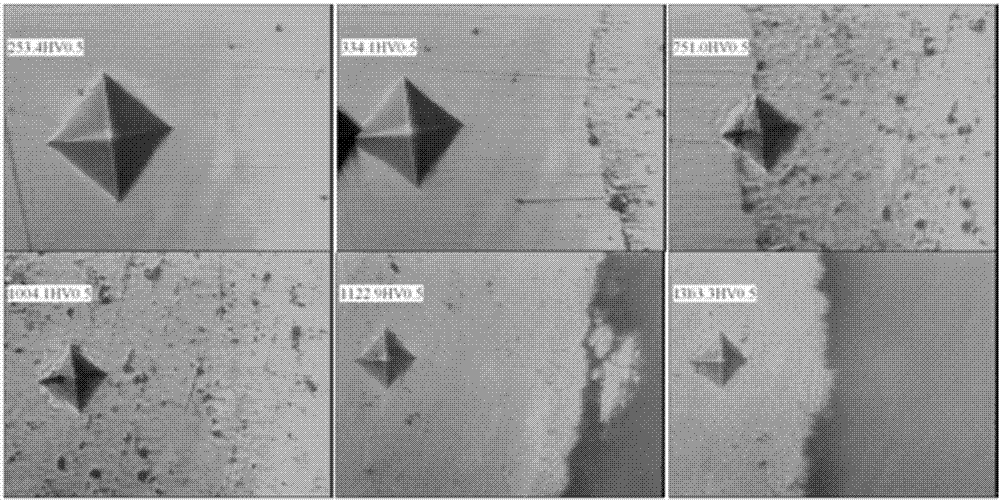

Boron cast iron air cylinder sleeve carbon scraping ring coating and preparation and spraying method thereof

InactiveCN106978581AIncrease the amount addedReduce spalling or even failureMaterial nanotechnologyMolten spray coatingCarbon depositCast iron

The invention discloses a boron cast iron air cylinder sleeve carbon scraping ring coating and a preparation and spraying method thereof and belongs to the technical field of improvement of air cylinder sleeves. The boron cast iron air cylinder sleeve carbon scraping ring coating is arranged on the neck of an air cylinder sleeve. The carbon scraping ring coating is a nicr-Cr3C2 composite coating. Nicr alloy has excellent heat resistance, corrosion resistance, high-temperature oxidation resistance and other properties and also achieves a binding phase function. Cr3C2 has good high temperature hardness and high-temperature oxidation resistance and achieves a hard phase function. The component of the air cylinder sleeve is boron cast iron. According to the boron cast iron, boron is added into gray cast iron, and different-amount cast iron containing boron cementite or ledeburite structures can be obtained in a metallographic structure. With increase of the boron content, microhardness is improved, but adding of too much boron can also cause lowering of toughness. Through the boron cast iron air cylinder sleeve carbon scraping ring coating and the preparation and spraying method thereof, the problems that a large number of carbon deposits are very liable to be accumulated on the surface of a piston, and the structure of a carbon scraping ring part is low in hardness and is liable to damage can be solved.

Owner:安徽威龙再制造科技股份有限公司

Cesium releasing agent for realizing low-temperature controlled release of cesium and manufacturingmethod of releaser used for cesium releasing agent

The invention discloses a cesium releasing agent for realizing low-temperature controlled release of cesium and a manufacturing method of a releaser used for the cesium releasing agent, belonging to the field of cesium releasing agents for third-generation low-light level night vision devices and releasers used for the cesium releasing agents. The cesium releasing agent comprises a cesium salt and a reducing agent, wherein the cesium salt is cesium chromate or cesium tungstate, and the reducing agent is a modified ZrVFe getter. The releaser is produced by processing an NiCr alloy pipe, a Cs steam escape outlet is formed through laser boring in the pipe, the middle part of the pipe is filled with the cesium releasing agent and is subjected to press molding, and meanwhile two ends of the pipe are clamped to be flat so as to be used as heating electrodes. If being put into a low-light level night vision device, the manufacturedreleaser is found to have the cesium releasing temperature of 300-500 DEG C and the cesium releasing frequency of 300-400 times and to be freeof releasing harmful impurity gases and controllable in release rate and release amount; and the steam escape outlet of the releaser is reasonably designed, and the evaporation uniformity of Cs on a photoelectric cathode is good, so that the performance of the photoelectric cathode with negative electron affinity (NEA) is remarkably improved.

Owner:GRIMAT ENG INST CO LTD

Rose gold low-emissivity coated glass and preparing method and application thereof

ActiveCN105314888AImproved effect of reflecting rose goldAdvanced production technologyBuilding componentsLow emissivityLight pollution

The invention provides a rose gold low-emissivity coated glass and a preparing method and application thereof. The rose gold low-emissivity coated glass comprises a glass substrate and a functional film layer deposited on the surface of the glass substrate. The functional film layer at least comprises a first dielectric layer, a second dielectric layer, a core dielectric layer, a protection layer and a third dielectric layer which are sequentially deposited outwards from the glass substrate layer by layer. The first dielectric layer is a silicon oxide film layer, the second dielectric layer is a zinc oxide film layer, the core dielectric layer is a copper film layer, the protection layer is a nichrome film layer, and the third dielectric layer is a silicon oxide film layer. Float glass serves as the glass substrate. The rose gold low-emissivity coated glass is capable of achieving the effects of rose gold low emissivity and low in reflectivity, generates no light pollution and is suitable for industrial production and application in multiple fields, the oxidation resistance is remarkably improved, and the storage life can be prolonged.

Owner:XINYI GLASS WUHU

Sink roll multicomponent alloy coating and preparing and spraying method thereof

InactiveCN106929788AGood resistance to high temperature oxidationSolve lossMaterial nanotechnologyHot-dipping/immersion processesHeat resistanceHardness

The invention discloses a sink roll multicomponent alloy coating and a preparing and spraying method thereof, and belongs to the technical field of sink roll repair. The sink roll multicomponent alloy coating sequentially comprises a sink roll base layer, a transition layer and a work layer from inside to outside, the transition layer is a NiCrAlY spraying layer, NiCrAlY is sprayed to the sink roll base layer to serve as a metal bonding layer, that is the transition layer, and the problem of mismatching of material heat expansion coefficients between a wear-resisting heat-resisting work layer and the sink roll base layer can be solved; the work layer is the NiCr-Cr3C2 composite coating, the NiCr alloy has the excellent heat resistance, corrosion resistance, high-temperature oxidation resistance and other properties, Cr3C2 has the good high-temperature hardness and high-temperature oxidation resistance, the hard phase effect is achieved, the coating is not soluble in zinc liquid and is not wetted, coating peeling and even failures caused by heat impact can be greatly reduced, and the technical problems are solved.

Owner:安徽威龙再制造科技股份有限公司

Soft magnetic alloy of nickel-chromium in use for base plate of body case of magnetic head in instrument for checking paper money

A soft-magnetic NiCr alloy used for the base plate of the casing for the magnetic head of paper money tester contains Ni (39.5-41.5 Wt %), Cr (7.80-8.80), Mn (0.3-0.6), Si (0.15-0.30) and Fe (rest). Its advantages are high magnetic shielding and anti-corrosion performance, not rusting and high machinability.

Owner:GUANGDONG IRON & STEEL INST +1

Method of metalizing reverse side of single pipe core

ActiveCN104894521AReasonable workmanshipEasy to operateVacuum evaporation coatingSputtering coatingSputteringMetallurgy

The invention discloses a method of metalizing the reverse side of a single pipe core. A glass ceramics substrate is divided into glass ceramics partition strips, and the glass ceramics partition strips are adhered to a film glass ceramics substrate as a substrate, so that a pipe core holding groove is formed between two adjacent glass ceramics partitions strips; the reverse side of the single pipe core is upwards placed in the pipe core holding groove of a pipe core holding die and the pipe core holding die is sent into a sputtering chamber of a magnetron sputtering platform; argon is introduced in the sputtering chamber to be used as a reactant gas; the pipe core is firstly subjected to reactive sputtering and then is subjected to magnetron sputtering; an adherency barrier layer is deposited on the reverse side of the pipe core by using a NiCr alloy target; a welding layer is deposited on the reverse side of the pipe core by using an Au target material with the purify of 99.99%; and after sputtering is completed, the die is taken out, and the pipe core subjected to sputtering treatment is placed in a chip box. The invention has the advantages that the technology is reasonable; the operation is simple; the reverse side metalizing treatment can be carried out on the single pipe core with a relatively small size; and the method is suitable for industrial production.

Owner:JINZHOU 777 MICROELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com