Patents

Literature

111 results about "Shading coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shading coefficient (SC) is a measure of thermal performance of a glass unit (panel or window) in a building. It is the ratio of solar gain (due to direct sunlight) passing through a glass unit to the solar energy which passes through 3mm Clear Float Glass. It is an indicator of how well the glass is thermally insulating (shading) the interior when there is direct sunlight on the panel or window.

Low shading coefficient and low emissivity coatings and coated articles

InactiveUS20070009747A1Acceptable aestheticImprove reflectivityGlass/slag layered productsCoatingsOrganic filmLow emissivity

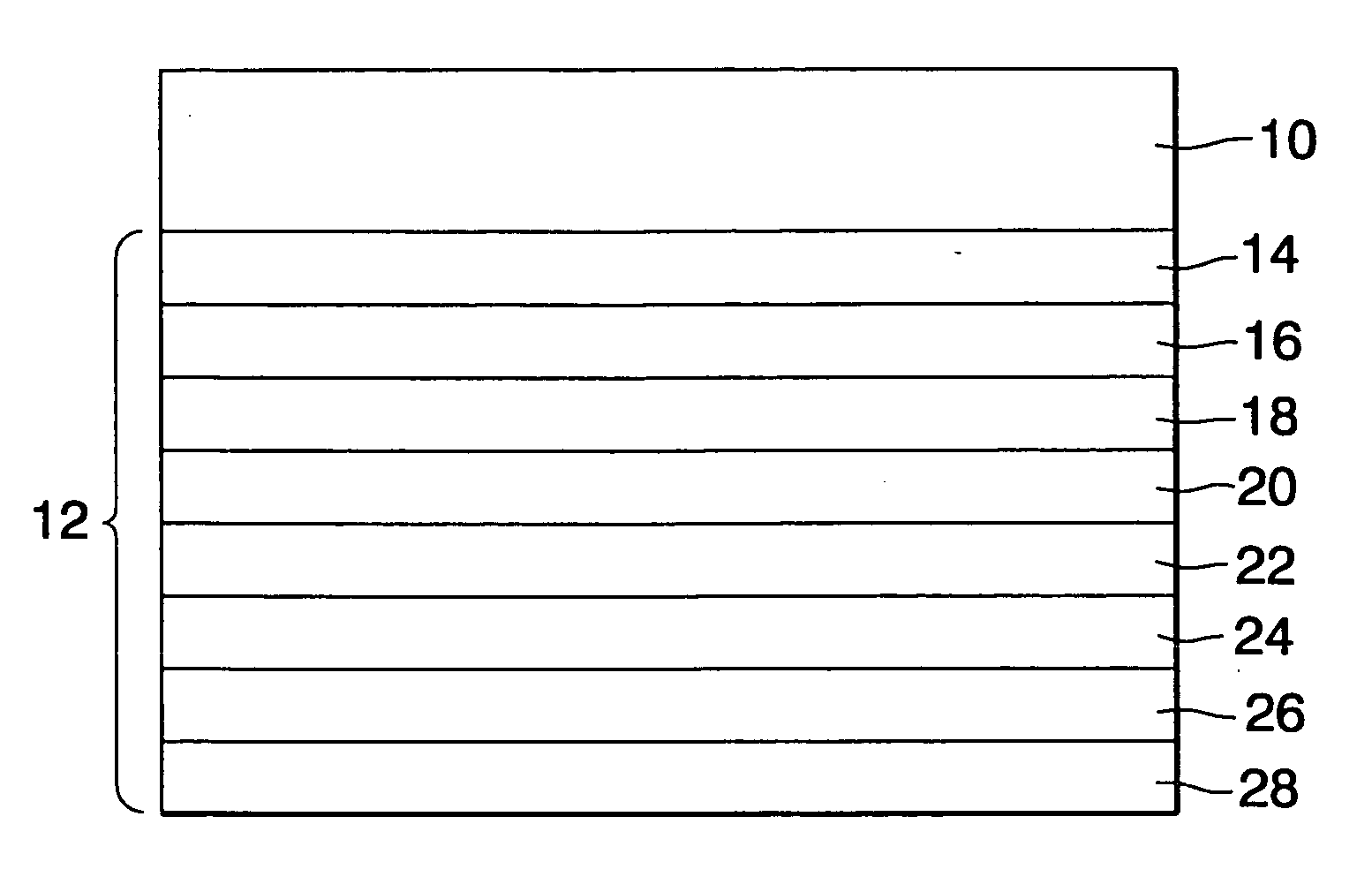

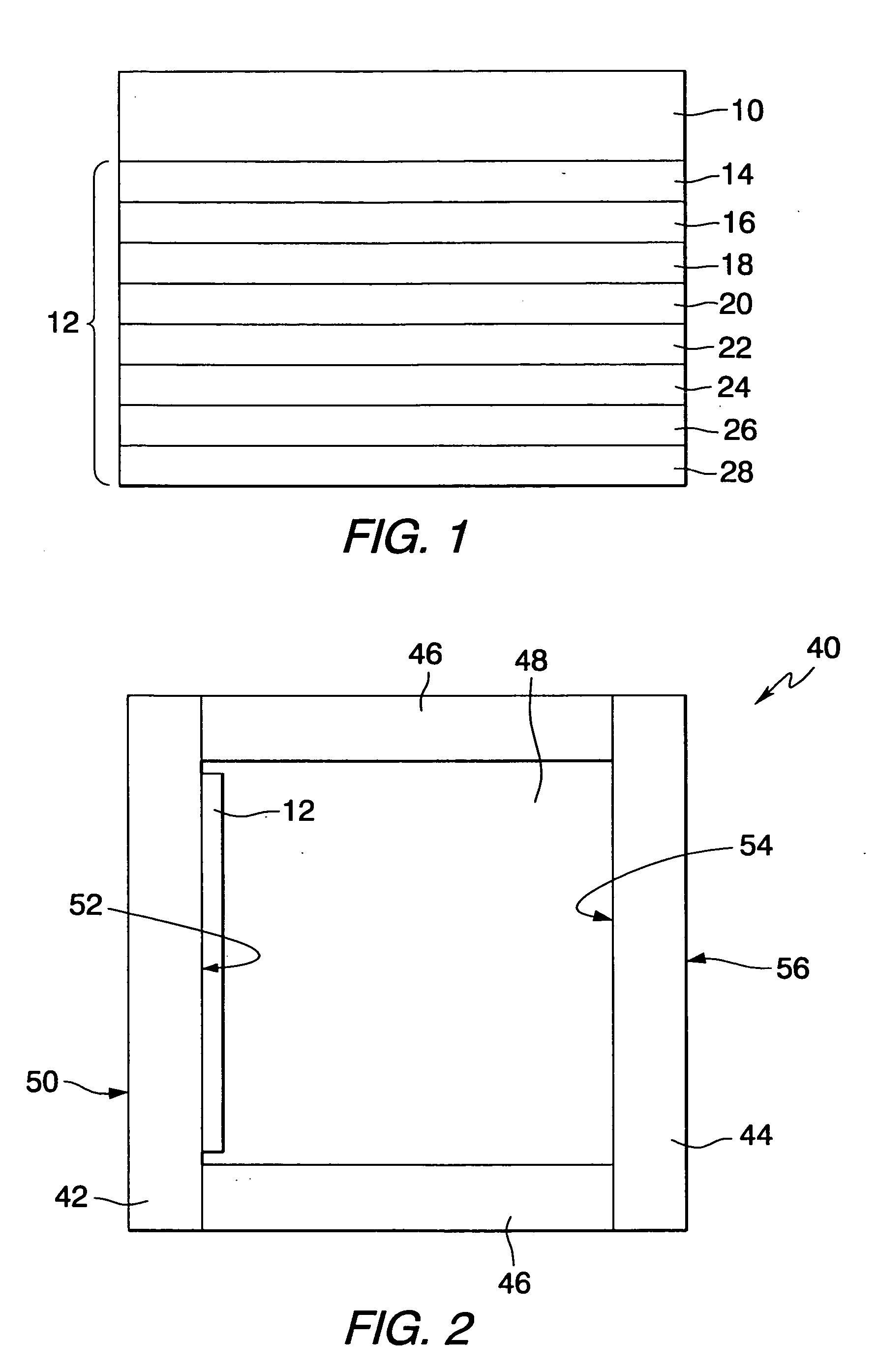

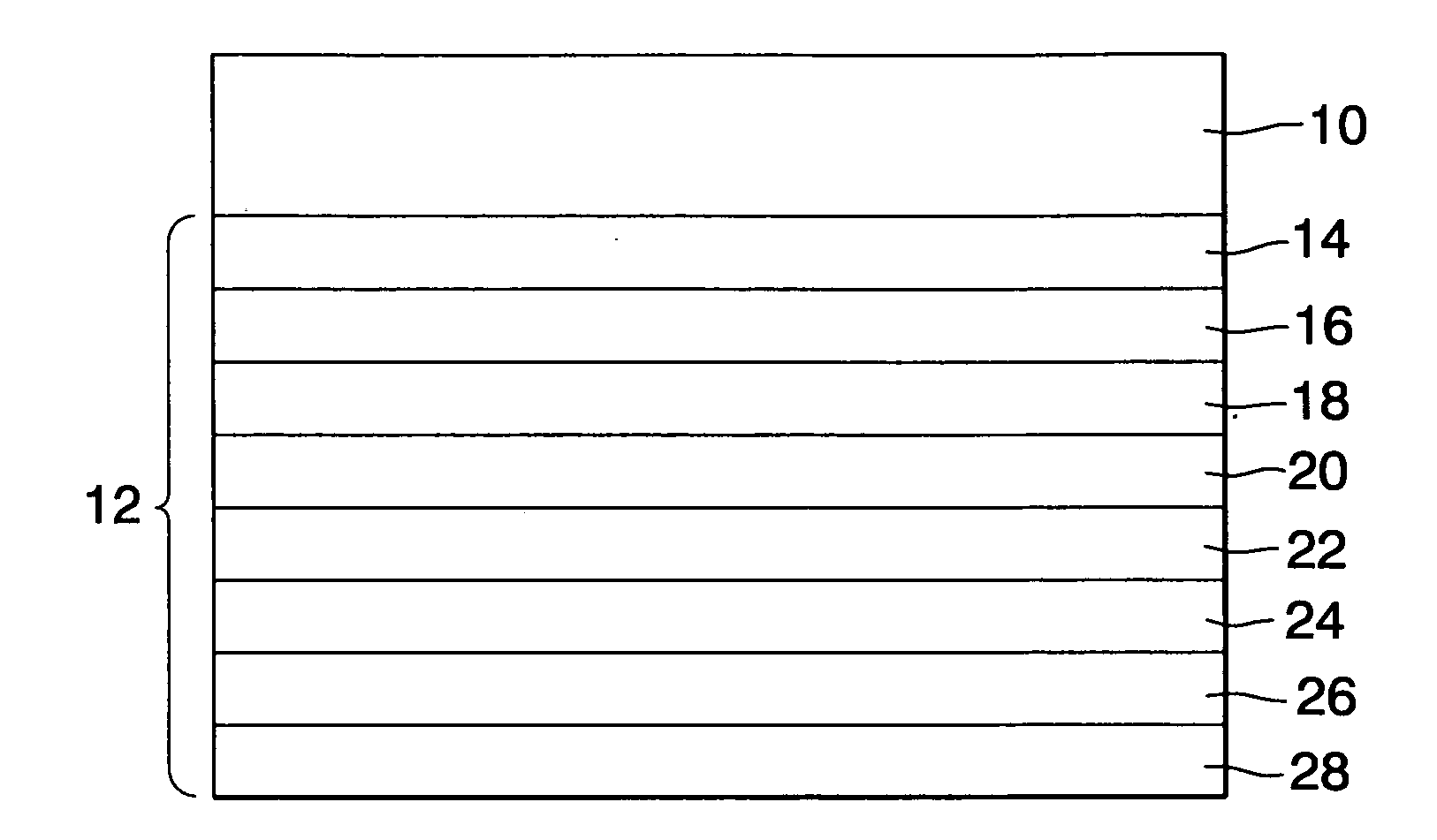

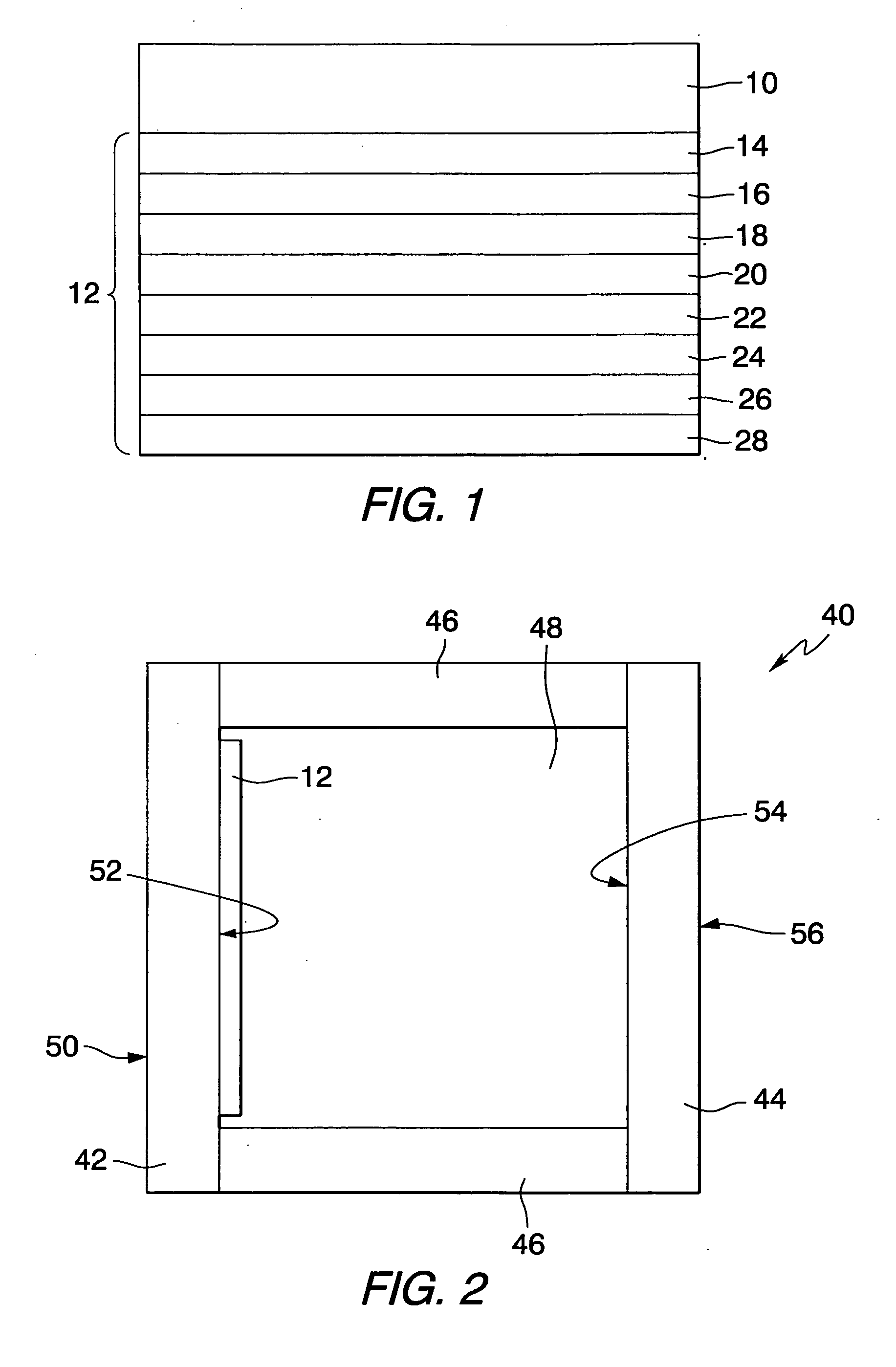

The present invention is directed to a low emissivity, low shading coefficient, multi-layer coating and coated article having a luminous transmission of less than about 70 percent, a shading coefficient less than about 0.44 and a solar heat gain coefficient of less than about 0.38 and a ratio of luminous transmittance to solar heat gain coefficient of greater than about 1.85. The coated article, e.g. an IG unit, has a substrate with at least one antireflective layer deposited over the substrate. At least one infrared reflective layer is deposited over the antireflective layer and at least one primer layer is deposited over the infrared reflective layer. Optionally a second antireflective layer is deposited over the first primer layer and optionally a second infrared reflective layer is deposited over the second antireflective layer. Optionally a second primer layer is deposited over the second infrared reflective layer and optionally a third antireflective layer is deposited over the second primer layer, such that the coated article can have the aforementioned optical properties. Also an optional protective overcoat, e.g. an oxide or oxynitride of titanium or silicon, and / or solvent soluble organic film former may be deposited over the uppermost antireflective layer.

Owner:PPG IND OHIO INC

Low shading coefficient and low emissivity coatings and coated articles

The present invention is directed to a low emissivity, low shading coefficient, low reflectance multi-layer coating and coated article having a visible light transmittance of greater than about 50%, preferably greater than about 55%, a shading coefficient of less than about 0.33 and en exterior reflectance of less than about 30%. The coated article, e.g. an IG unit, has a substrate with a first antireflective layer deposited over the substrate. A first infrared reflective layer is deposited over the first antireflective layer and a first primer layer is deposited over the first infrared reflective layer. A second antireflective layer is deposited over the first primer layer and a second infrared reflective layer is deposited over the second antireflective layer. A second primer layer is deposited over the second infrared reflective layer and a third antireflective layer is deposited over the second primer layer, such that the coated article has a transmittance greater than about 55%, a shading coefficient of less than about 0.33 and a reflectance of less than about 30%. A protective overcoat, e.g. an oxide or oxynitride of titanium or silicon, and / or solvent soluble organic film former may be deposited over the third antireflective layer.

Owner:PPG IND OHIO INC

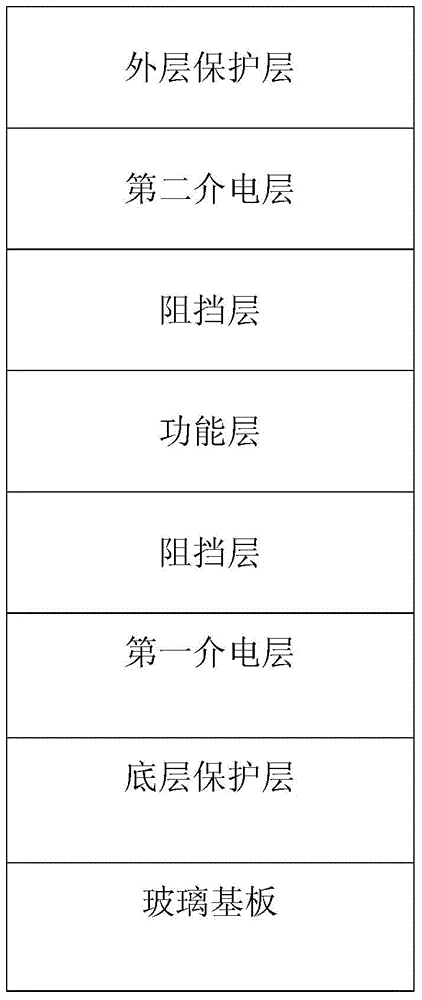

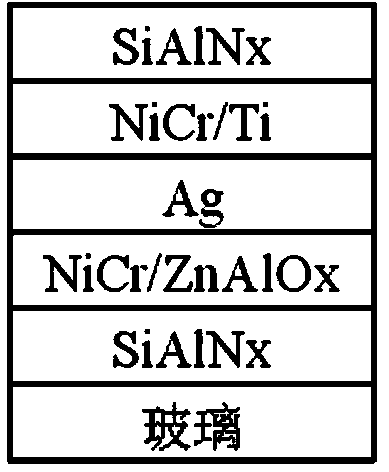

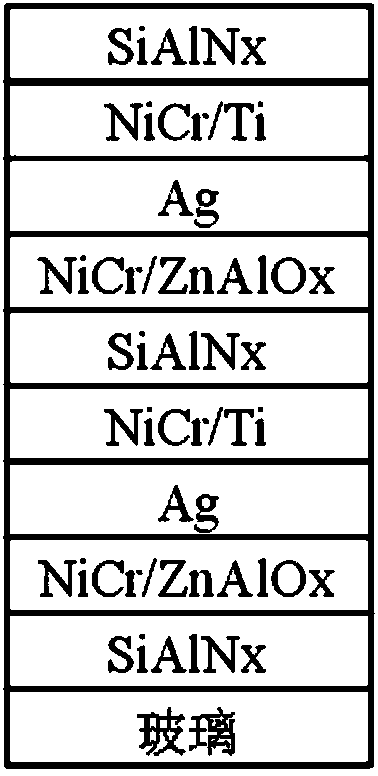

Low-reflection high-sunshade low radiation coated glass with double-silver composite structure and technique

InactiveCN101148329AStrong reflexesLow surface emissivityVacuum evaporation coatingSputtering coatingRadianceTransmittance

The present invention is one kind of coated glass with double silver layer structure and possessing low reflectivity, high shading coefficient and low insolation, and its coating process. The film structure on the glass includes one first dielectric layer, one composite absorption layer, one first silver layer, one first protecting layer, one composite dielectric layer, one second silver layer, one second protecting layer and one second dielectric layer arranged successively on the glass. The glass with the film structure has the advantages of high infrared reflectivity, low surface radiance, high shading performance, medium visible light transmittance, medium visible light reflectivity, etc.

Owner:江门耀皮工程玻璃有限公司

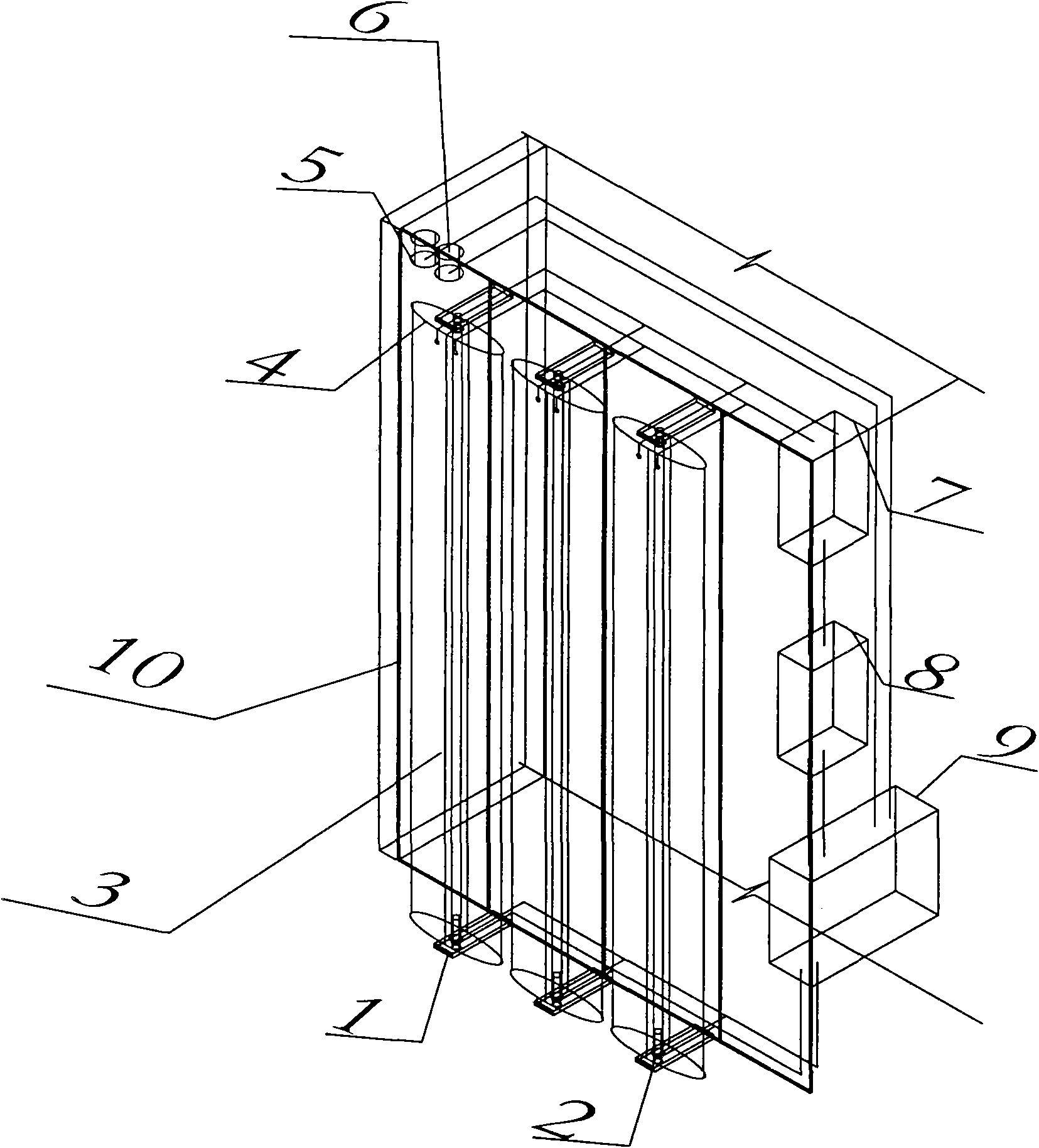

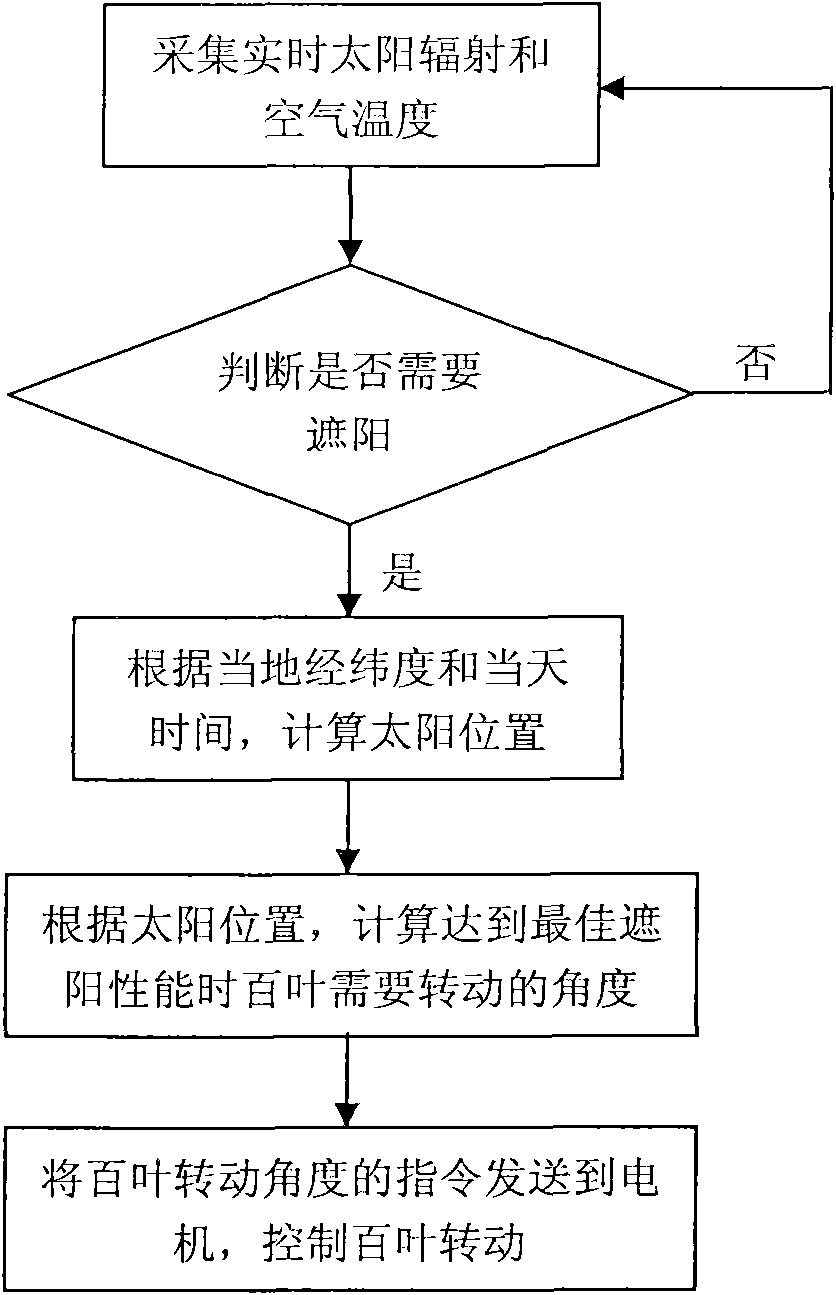

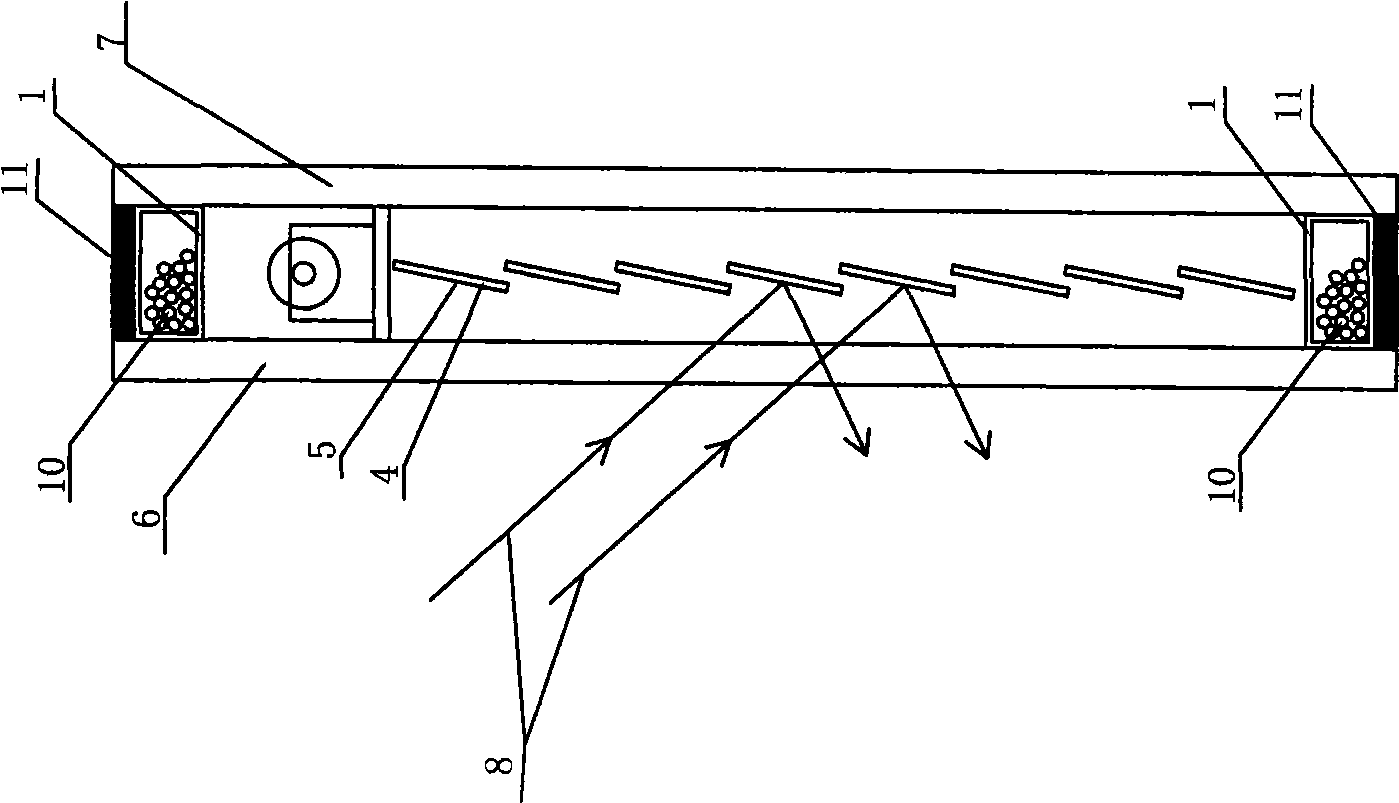

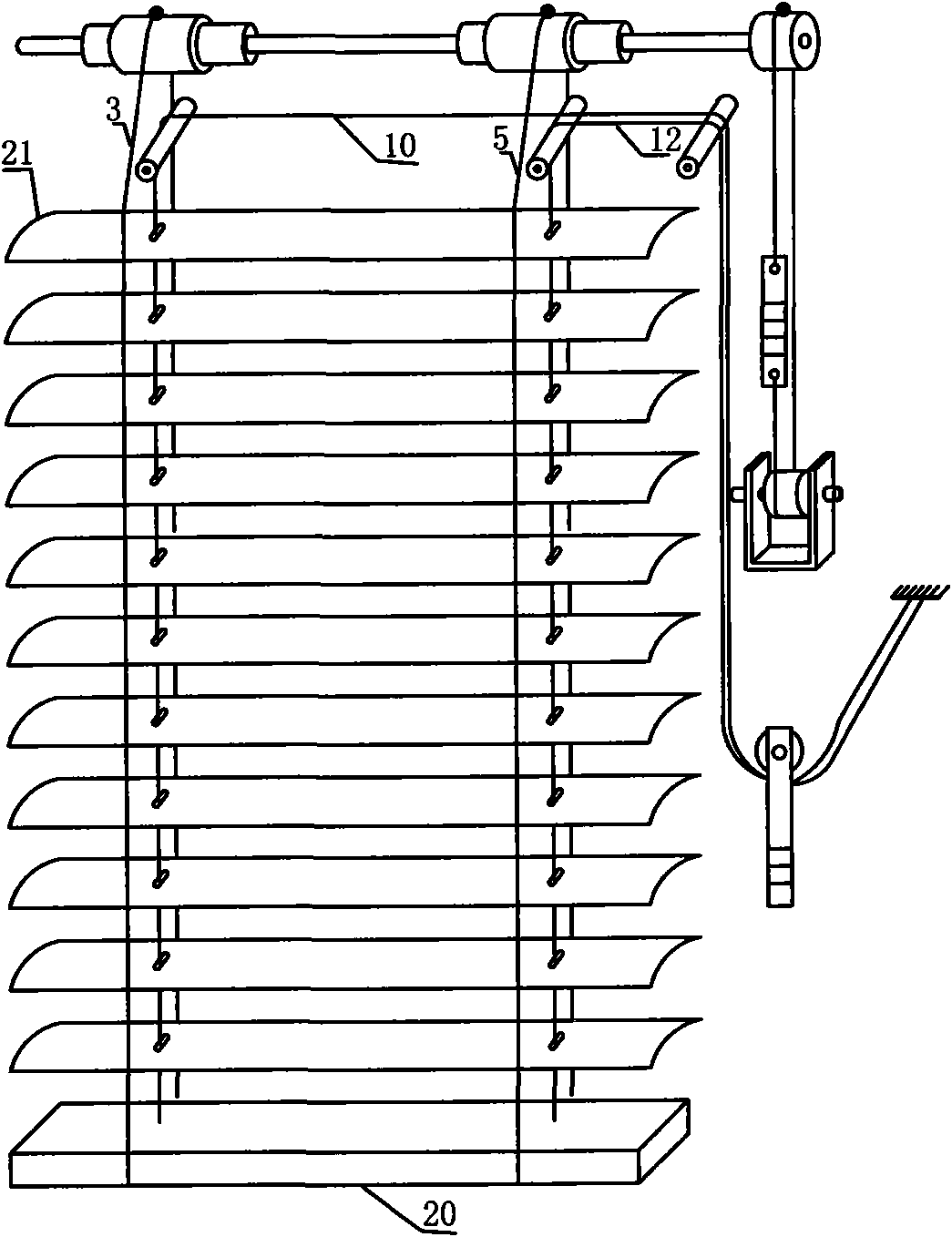

Solar driven vertical louver solar protection device

ActiveCN101787849AImprove processing quality levelShorten construction timePhotovoltaic supportsBatteries circuit arrangementsElectricityEngineering

The invention discloses a solar driven vertical louver solar protection device, which comprises a support frame, a tubular motor, a solar photoelectric film, a vertical louver board, a solar radiation probe, a temperature probe, a controller, a storage battery and a calculator; the solar photoelectric film is attached onto the surface of the vertical louver board, and the solar photoelectric film is connected with the storage battery through the controller so as to charge the storage battery; the tubular motor which is installed inside a rotating shaft of the vertical louver board is electrically connected with the storage battery through a conducting wire; the tubular motor is also connected with the calculator through signals; the solar radiation probe and the temperature probe are respectively installed on the top end of a vertical sunshading board, the solar radiation probe and the temperature probe are respectively connected with the calculator through signals, and the deflection angle of the vertical louver board is calculated according to the data of the sun position and the limited value of the outer sunshading coefficient; and the rotating device controls the vertical louver to rotate according to the calculated best angle so as to realize the best sunshade and lighting effect.

Owner:SOUTH CHINA UNIV OF TECH

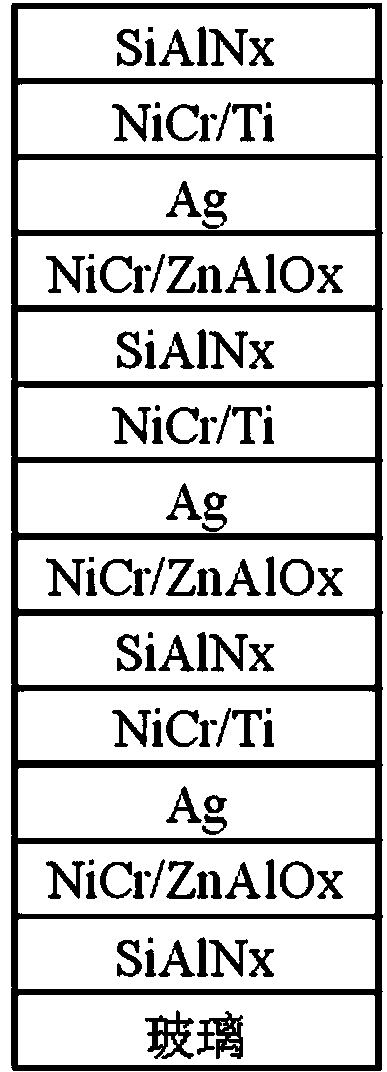

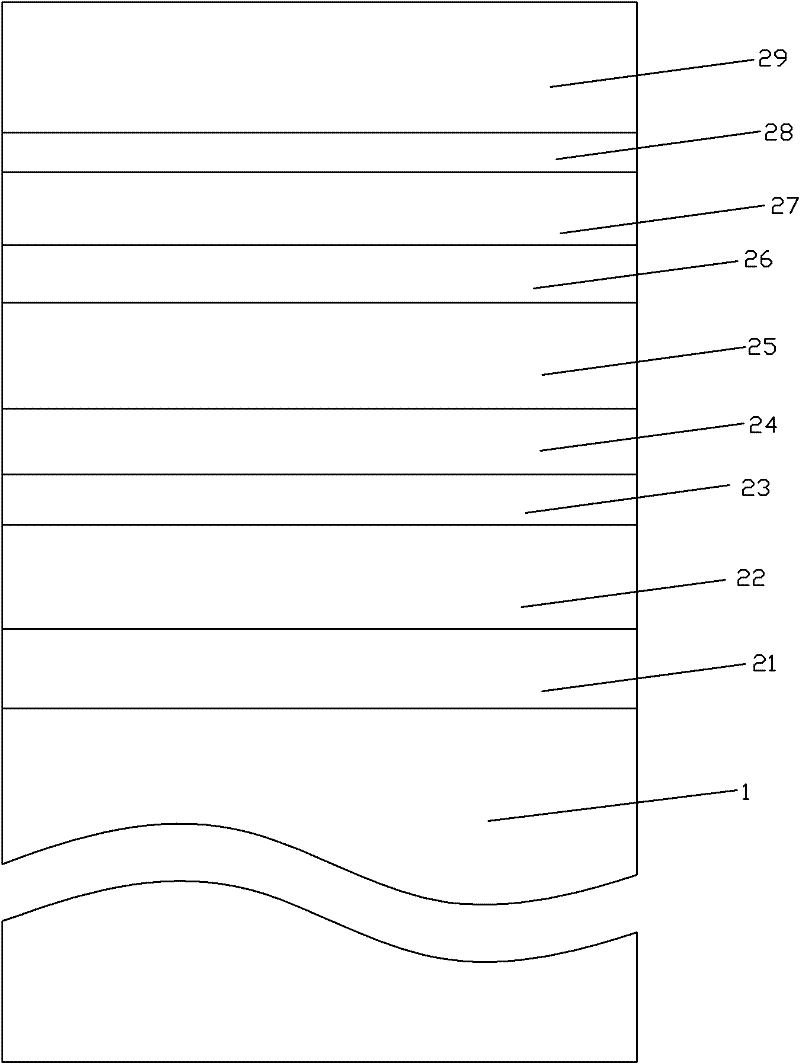

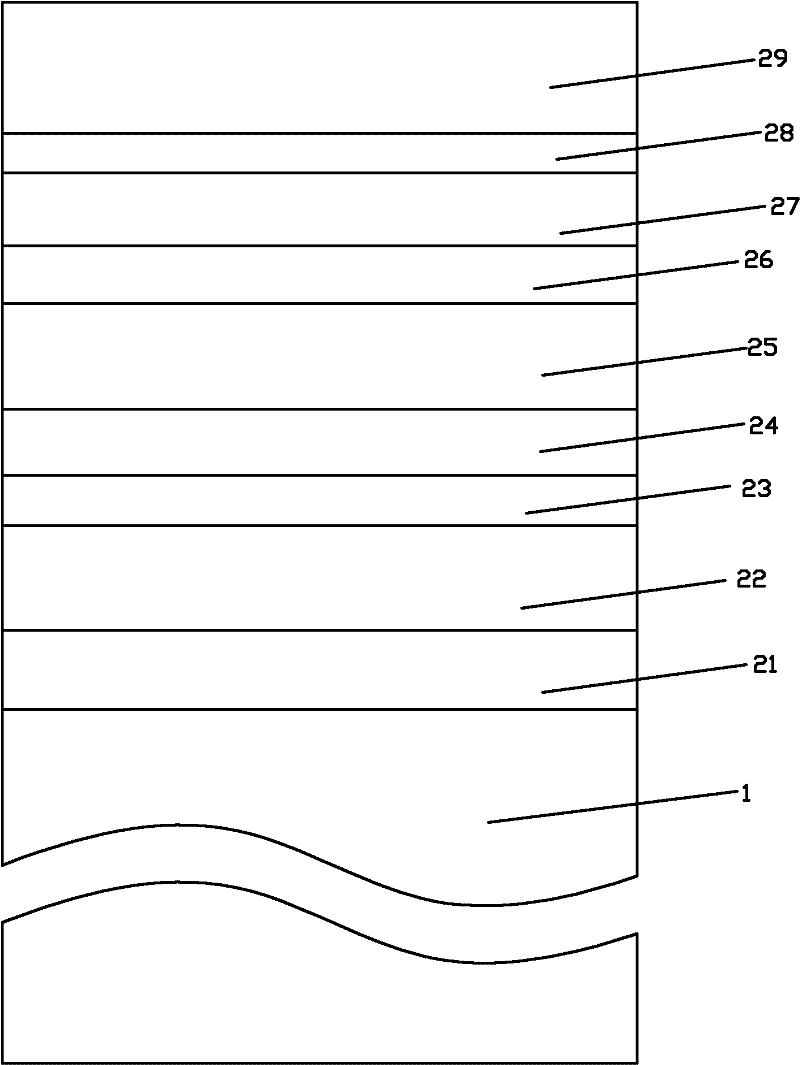

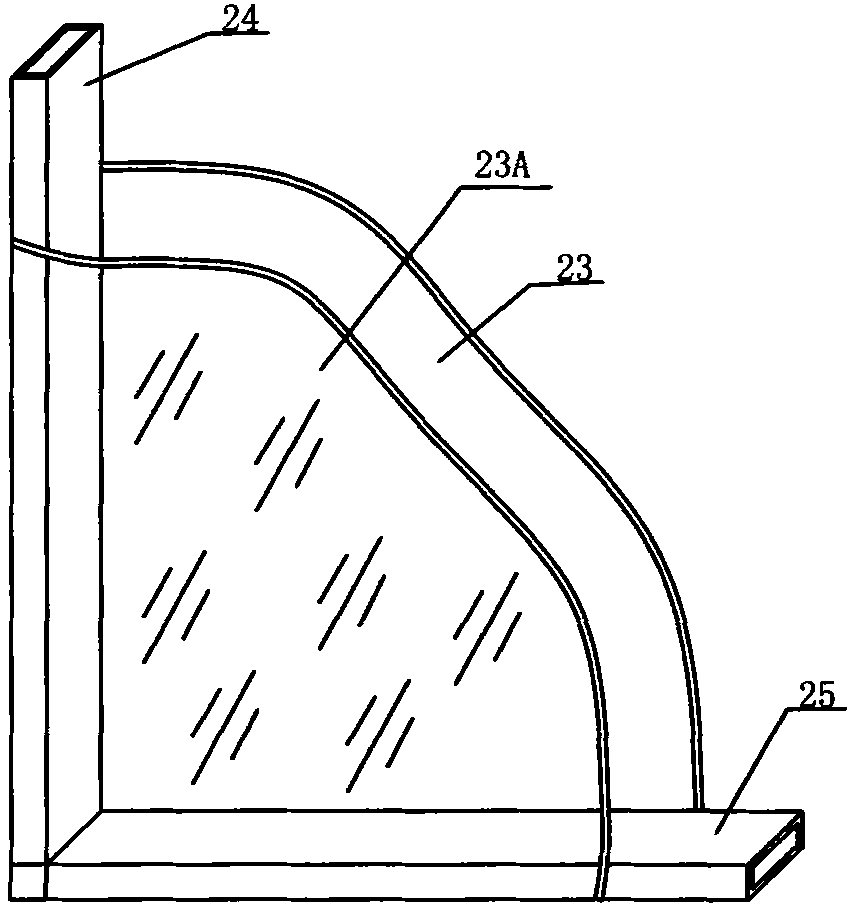

Novel energy-saving toughened three-silver-layer low-radiation coated glass

ActiveCN102350833AHigh hardnessImprove antioxidant capacityVacuum evaporation coatingSputtering coatingProtection layerShading coefficient

The invention provides novel energy-saving toughened three-silver-layer low-radiation coated glass, which is characterized in that: a film structure of the glass sequentially consists of the following layers from a glass substrate to the outside: the glass substrate, a first composite dielectric medium layer (11), a first reflection deduction layer (12), a first silver layer (13), a first protective layer (14), a second dielectric medium layer (21), a second reflection deduction layer (22) plus a second silver layer (23), a second protective layer (24), a third dielectric medium layer (31), a third reflection deduction layer (32), a third silver layer (33), a third protective layer (34), a fourth composite dielectric medium layer (35) and a fourth protective layer (36). The novel energy-saving toughened three-silver-layer low-radiation coated glass has the advantages that: an infrared reflection capacity is higher than that of a double-silver-layer low-radiation film with the same visible light transmission value, the radiation rate on the surface of the film layer is low, the shading coefficient is much lower, and the reflection rate is low; and the film has high hardness and high oxidation resistance, and different cold processing and hot treatment can be carried out after the film coating.

Owner:SHANGHAI YAOHUA PILKINGTON GLASS GROUP +2

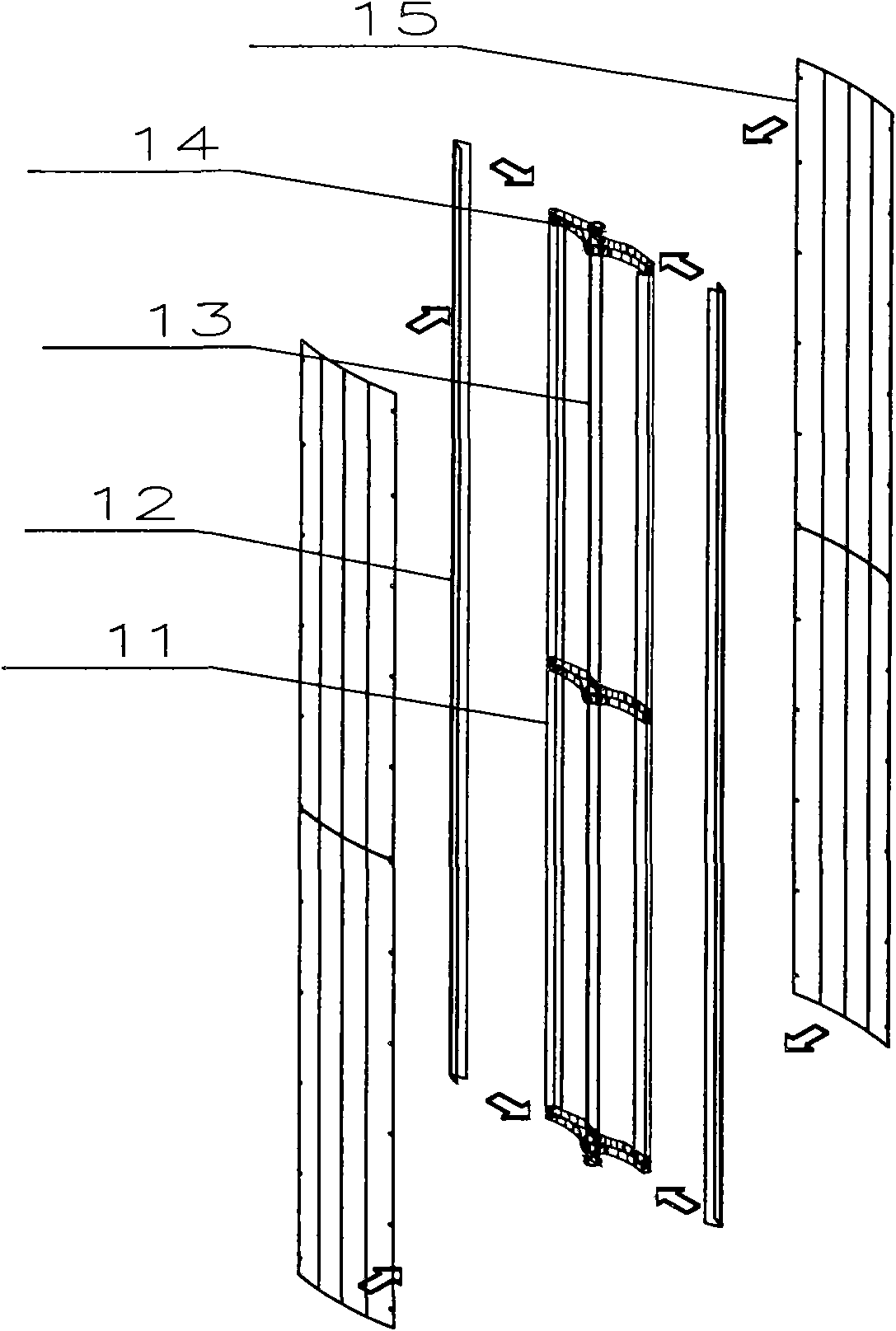

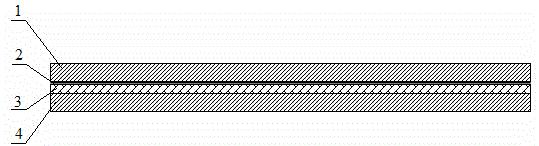

Louvre blade and hollow glass louvre

InactiveCN101519947AIncrease the shading factorImprove insulation effectLight protection screensThermal insulationShading coefficient

The invention discloses a louvre blade with a heat reflection layer on the surface and a hollow glass louvre provided with the louvre blade. The louvre can improve the shading coefficient or the thermal insulation performance of hollow louvre glass and the total energy saving performance of the hollow louvre glass.

Owner:常熟欧泰克建筑节能科技有限公司

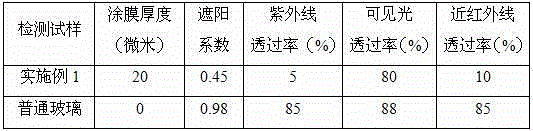

Thermal-insulating heat-preserving laminated safety glass and manufacturing method thereof

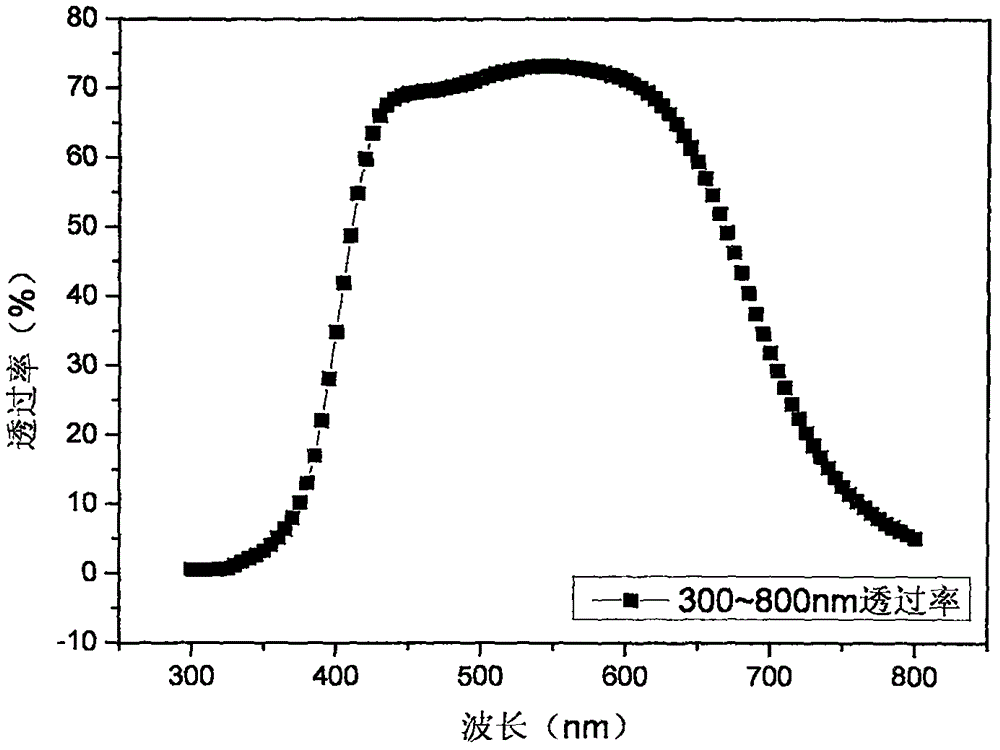

ActiveCN104960277ALow costReduce transmittanceLaminationLamination apparatusPolymer adhesiveThermal insulation

The invention provides a thermal-insulating heat-preserving laminated safety glass and a manufacturing method thereof. The structure of the thermal-insulating heat-preserving laminated safety glass comprises, from top to bottom, a first glass layer, a transparent thermal-insulating coating the inner surface of the first glass layer, a polymer film and a second glass layer; or the thermal-insulating heat-preserving laminated safety glass is further provided with a gas spacing layer and a third glass layer. The manufacturing method comprises the following steps: (1) preparing the transparent thermal-insulating coating; and (2) preparing the thermal-insulating heat-preserving laminated safety glass; or preparing a thermal-insulating heat-preserving laminated safe hollow glass from the thermal-insulating heat-preserving laminated safety glass. The thermal-insulating heat-preserving laminated safety glass or thermal-insulating heat-preserving laminated safe hollow glass has good impact resistance, low shading coefficient, low thermal coefficient, low ultraviolet transmittance, high visible transmittance and low near-infrared transmittance and is capable of preventing radiant heat of the sun entering a room in summer so as to realize thermal insulation and capable of reducing indoor heat loss in winter so as to realize heat preservation.

Owner:湖南省华京粉体材料有限公司

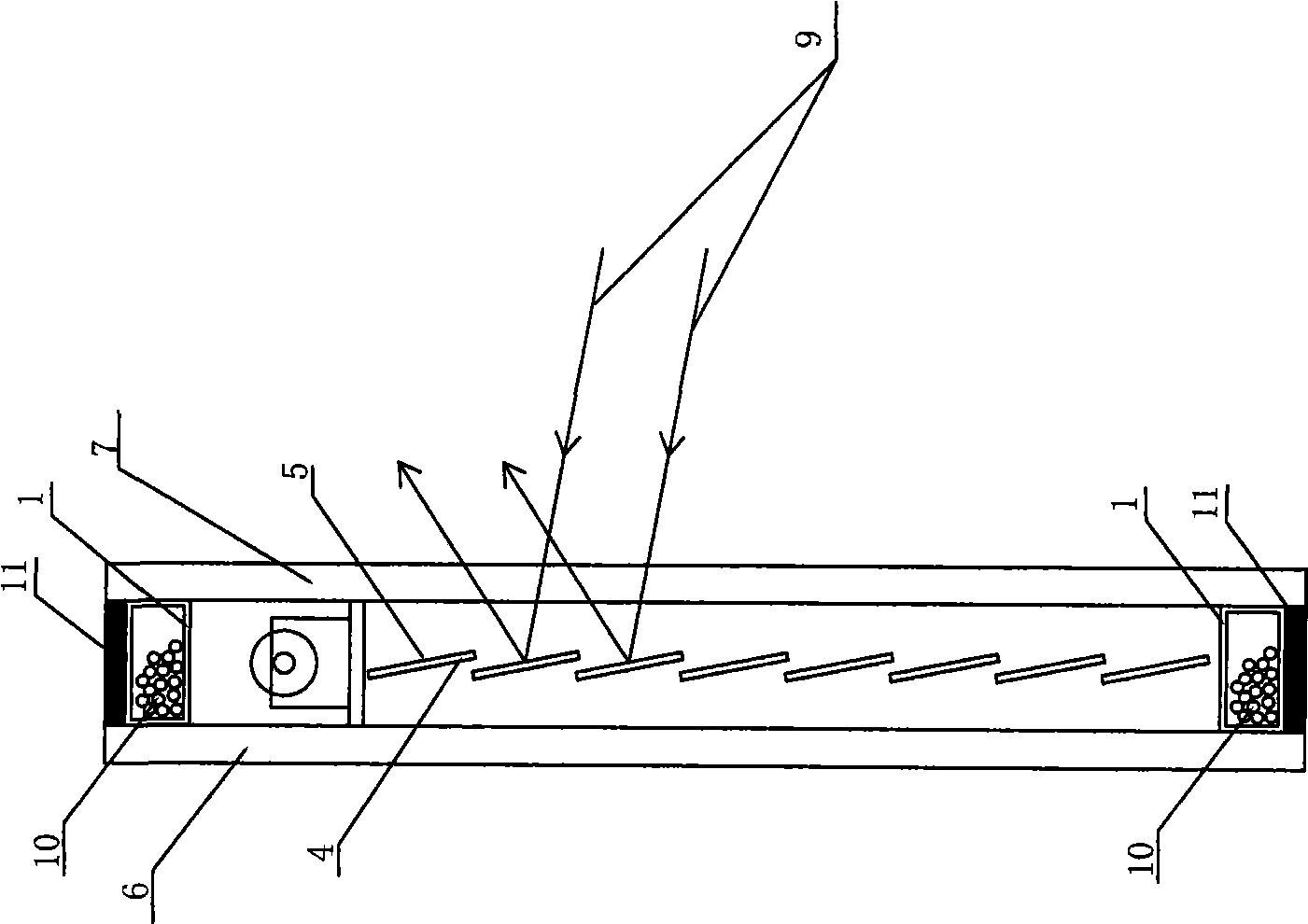

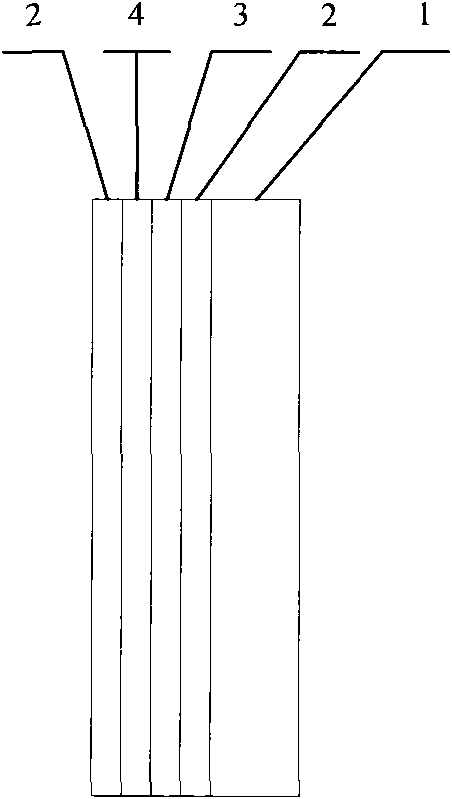

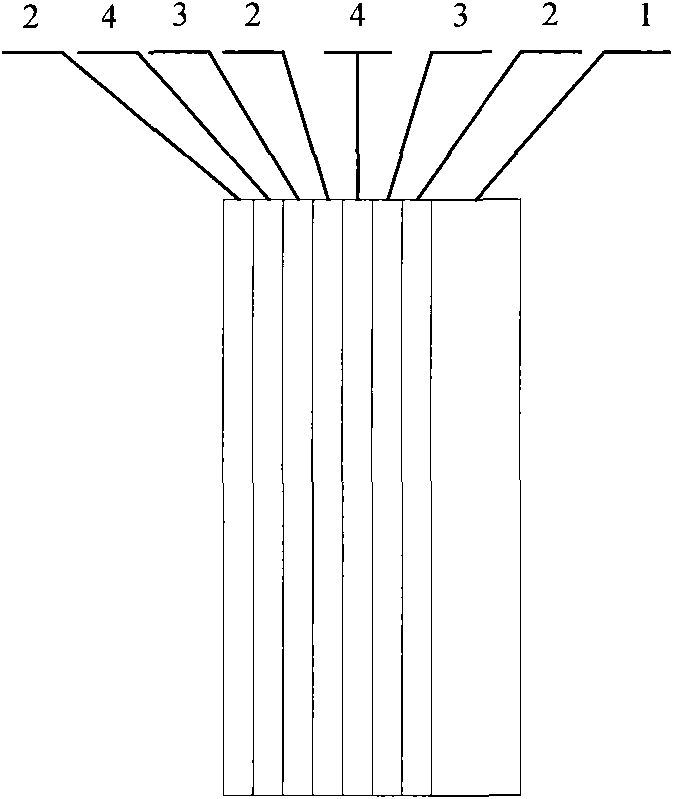

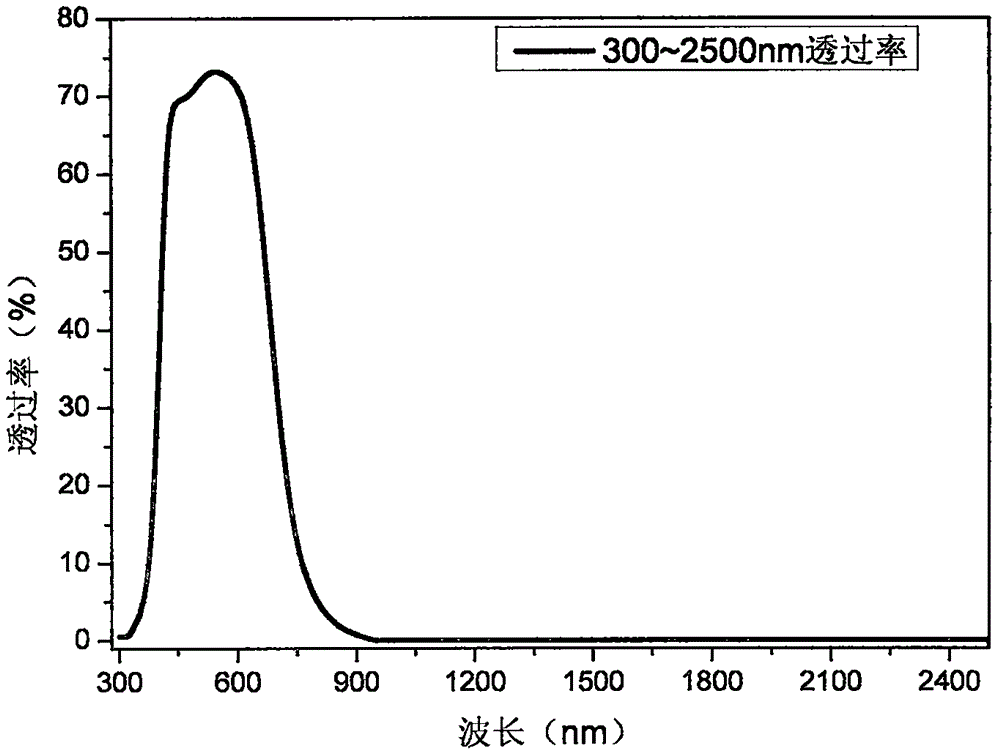

Solar control-low radiation type heat-insulation membrane system

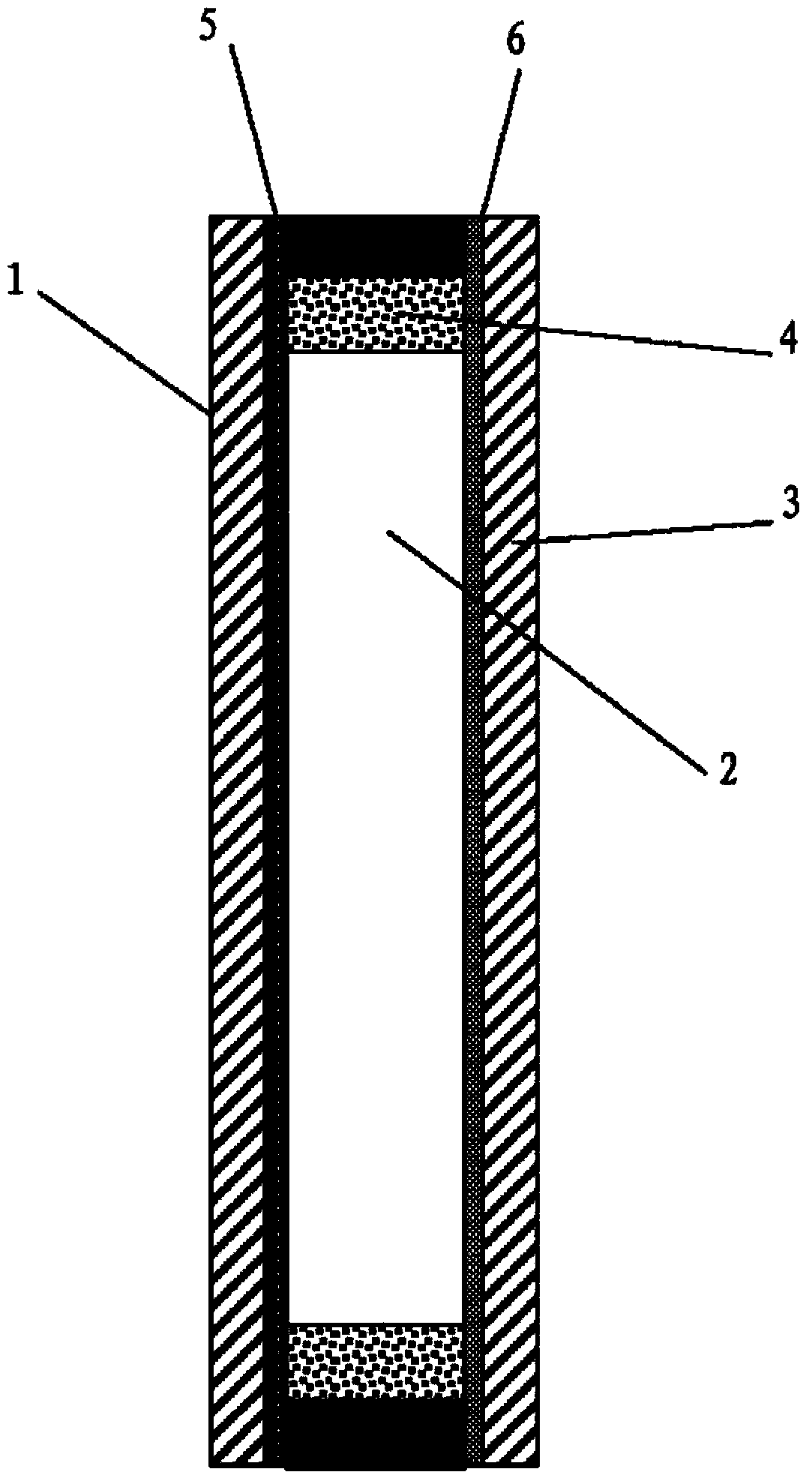

InactiveCN101929590AReduce inflowReduce outflowThermal insulationSynthetic resin layered productsMiddle infraredRadiance

The invention belongs to the technical field of optical coating, and particularly relates to a solar control-low radiation type heat-insulation membrane system, which aims to provide the solar control-low radiation type heat-insulation membrane system capable of functioning in reflecting near infrared rays, middle infrared rays and far infrared rays. The membrane system comprises a PET layer (1), TiO2 layers (2), an Ag layer (3) and a Ti layer (4), wherein the PET layer (1) is a substrate; the first TiO2 layer (2) is covered on the PET layer; the Ag layer (3) is covered on the TiO2 layer (2); the Ti layer (4) is covered on the Ag layer (3); and the second TiO2 layer (2) is covered on the Ti layer (4). The solar control-low radiation type heat-insulation membrane type has low radiance, proper shading coefficient, the functions of sunshade and heat preservation and wide application, can function in reflecting the near, middle and far infrared rays and reduce the inflow and outflow of indoor heat, and is applied in summer, winter and hot and cold regions.

Owner:SOUTHWESTERN INST OF PHYSICS

Method for quickly rooting in ormosia hosie cuttage process

InactiveCN104054497AShorten the cultivation cycleEarly rooting of cuttingsHorticulturePre treatmentPlastic film

The invention discloses a method for quickly rooting in the ormosia hosie cuttage process. The method includes the steps of cutting selection, cutting band girdle treatment, seedling culturing matrix matching, seedling culturing bed building, and cuttage temperature preservation management and protection, wherein the cuttage temperature preservation management and protection is achieved through a method that cuttings are cut on the position 2 cm to 3 cm below the cutting band girdle position where callus is formed, the cutting blades and lateral branches are removed totally, three to six sprouts are left, the scissoring openings of the top ends of the cuttings are flushed with one another and are coated with Vaseline, the cutting roots are immersed in rooting power solutions or rooting agents, the matrix is inserted, a small plastic film arch shed is built, a shading net with the shading coefficient ranging from 60% to 75% covers the small plastic film arch shed, the temperature of the matrix is controlled within 23 DEG C to 28 DEG C, and the water content of the matrix is remained within 60% to 70%. Root systems are formed 15 days to 20 days after cuttage, counted from cuttage time, the cycle of seedling culturing is shortened by 35 days to 100 days, counted from band girdle pre-treatment, the cycle of seedling culturing is shortened by 20 days to 80 days, the actual survival rate after cuttage reaches 90%, the cycle of seedling culturing is shortened greatly, and production cost is saved.

Owner:龙泉市林业总站 +1

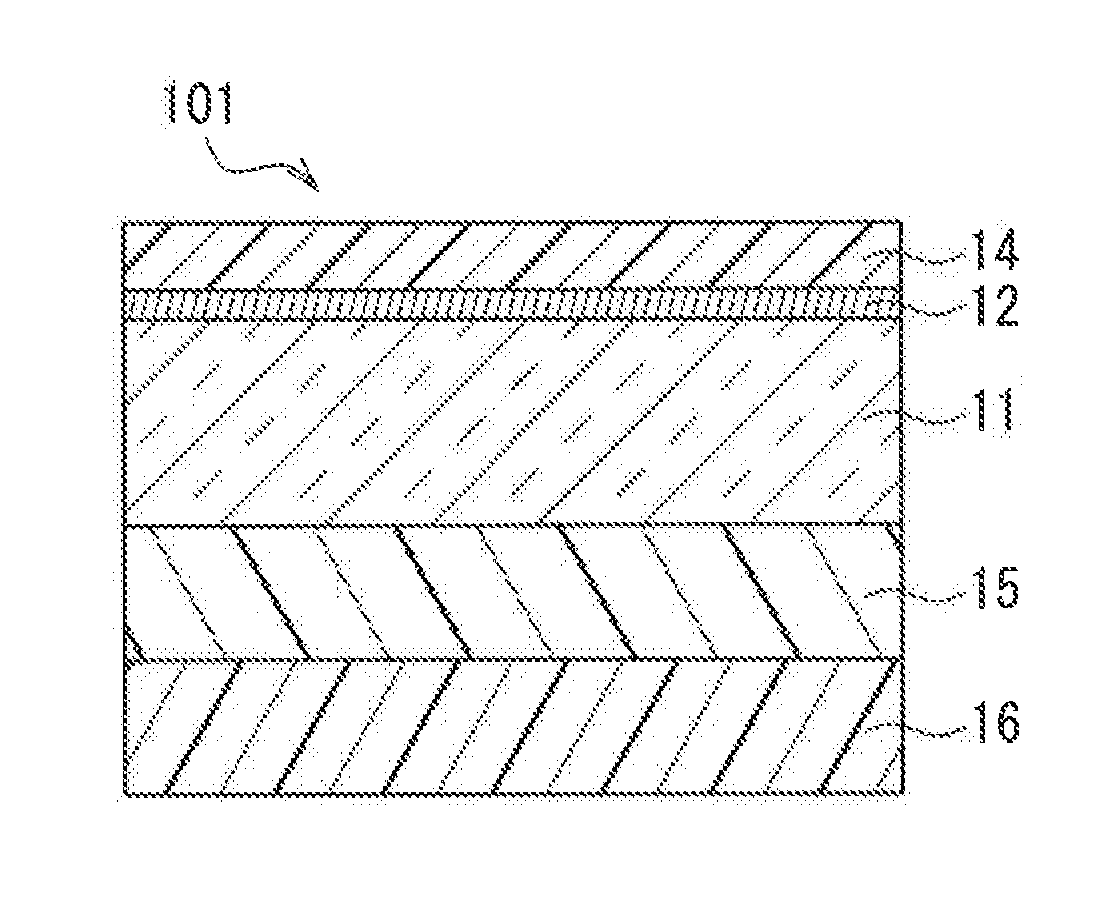

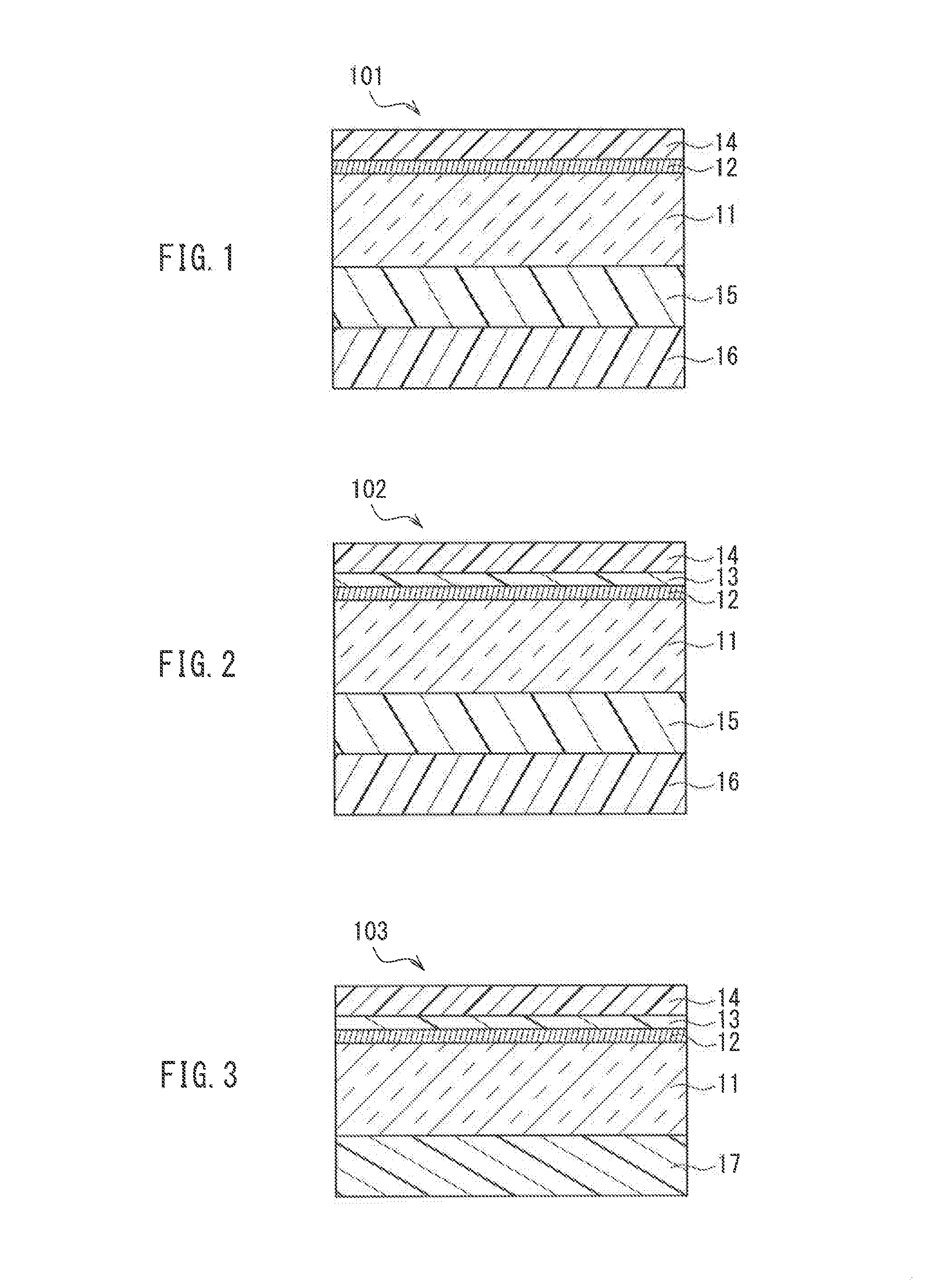

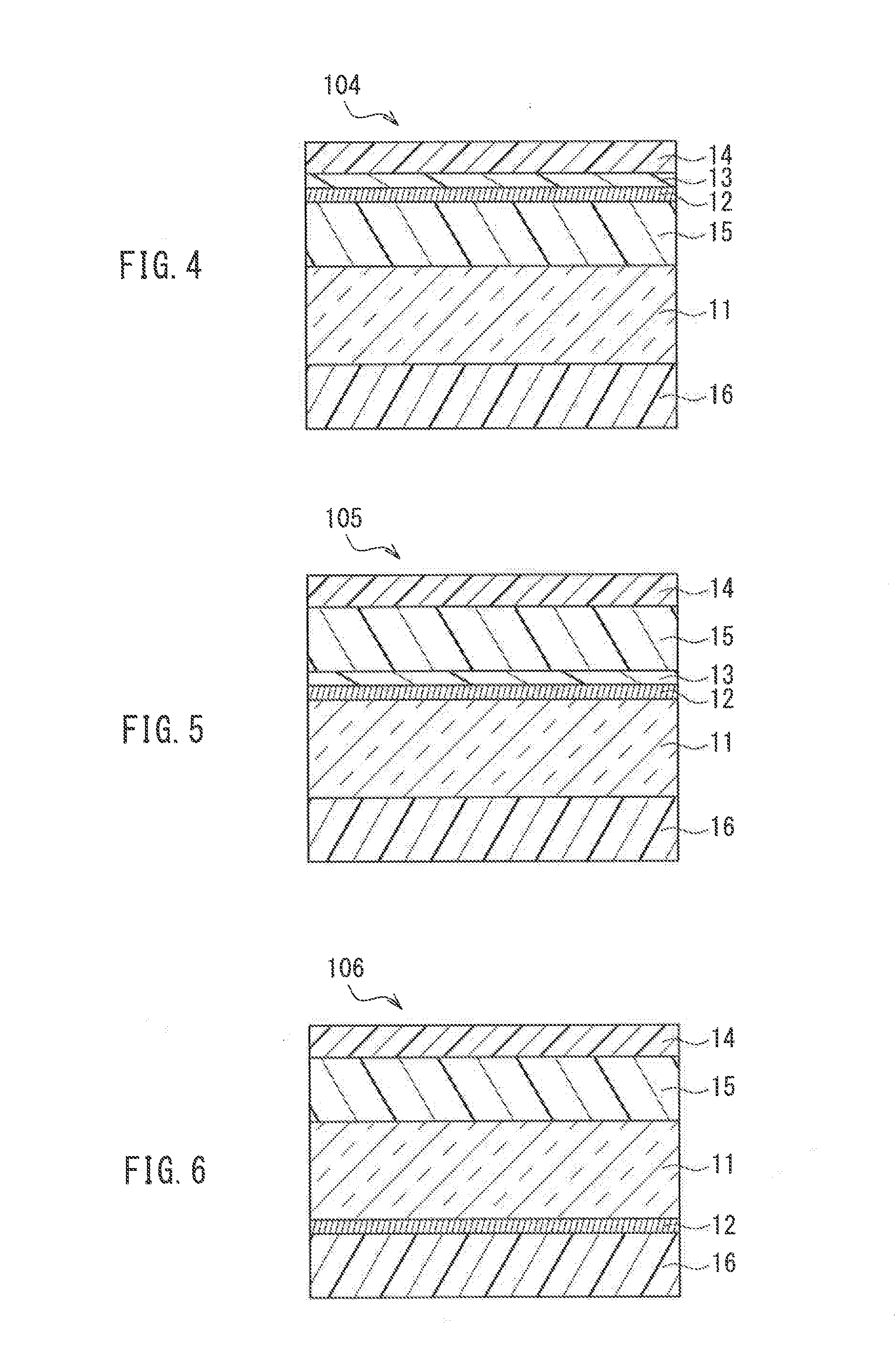

Transparent heat-shielding member

ActiveUS20160282529A1Avoid damageImprove adhesionMirrorsDiffusing elementsReflective layerLight reflectance

A transparent heat-shielding member according to the present invention includes a transparent base substrate, an infrared reflective layer and a transparent screen function layer. The infrared reflective layer includes at least one selected from a metal oxide layer and a metal nitride layer, and a metal layer. The transparent screen function layer is formed of a light diffusing layer. The light diffusing layer contains light diffusing particles and a transparent resin. The light diffusing particles are dispersed in the transparent resin. The transparent heat-shielding member has a visible light reflectance measured in accordance with JIS R3106-1998 of 12% or more and 30% or less, a haze value measured in accordance with JIS K7136-2000 of 5% or more and 35% or less, and a shading coefficient measured in accordance with JIS A5759-2008 of 0.69 or less.

Owner:MAXELL HLDG LTD

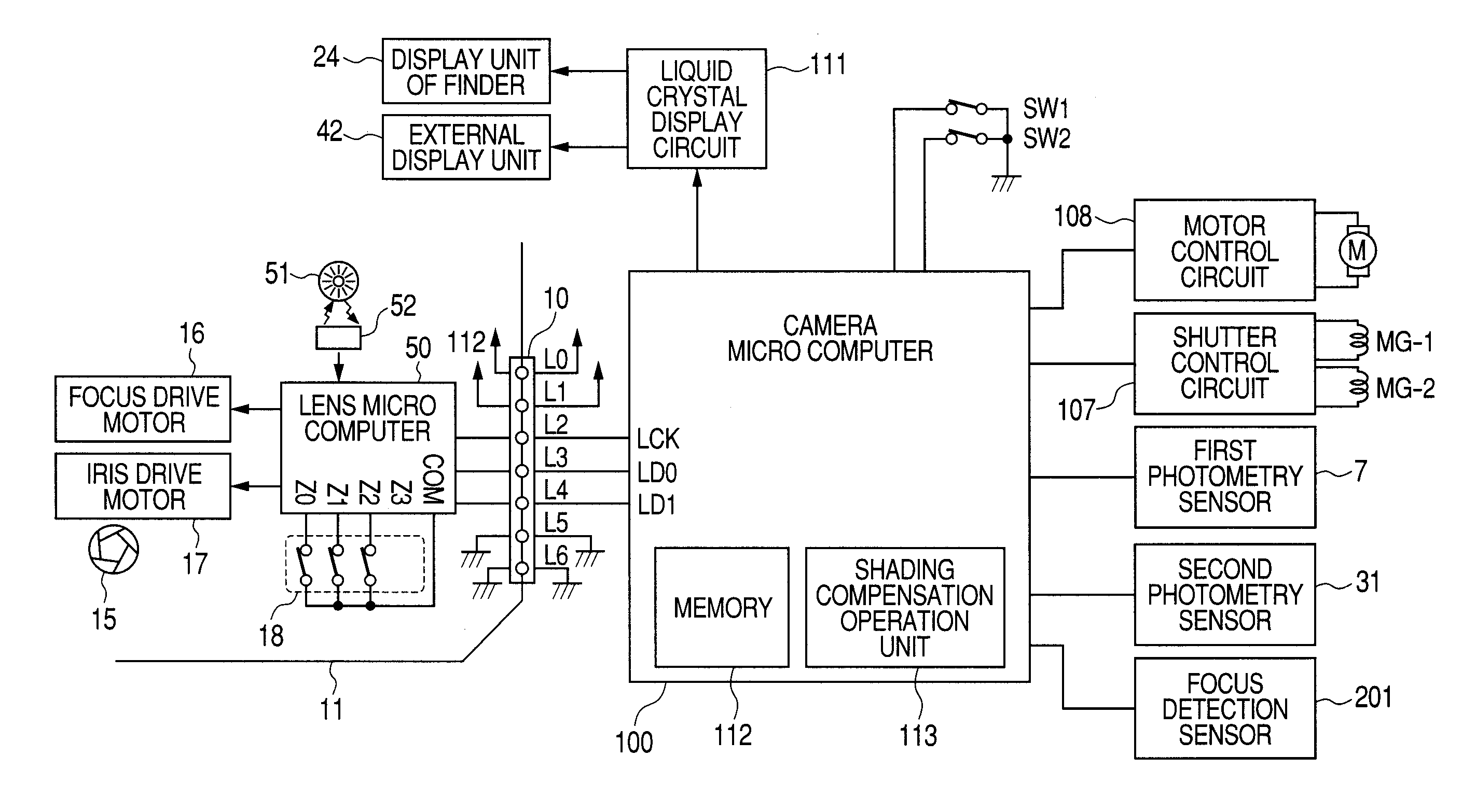

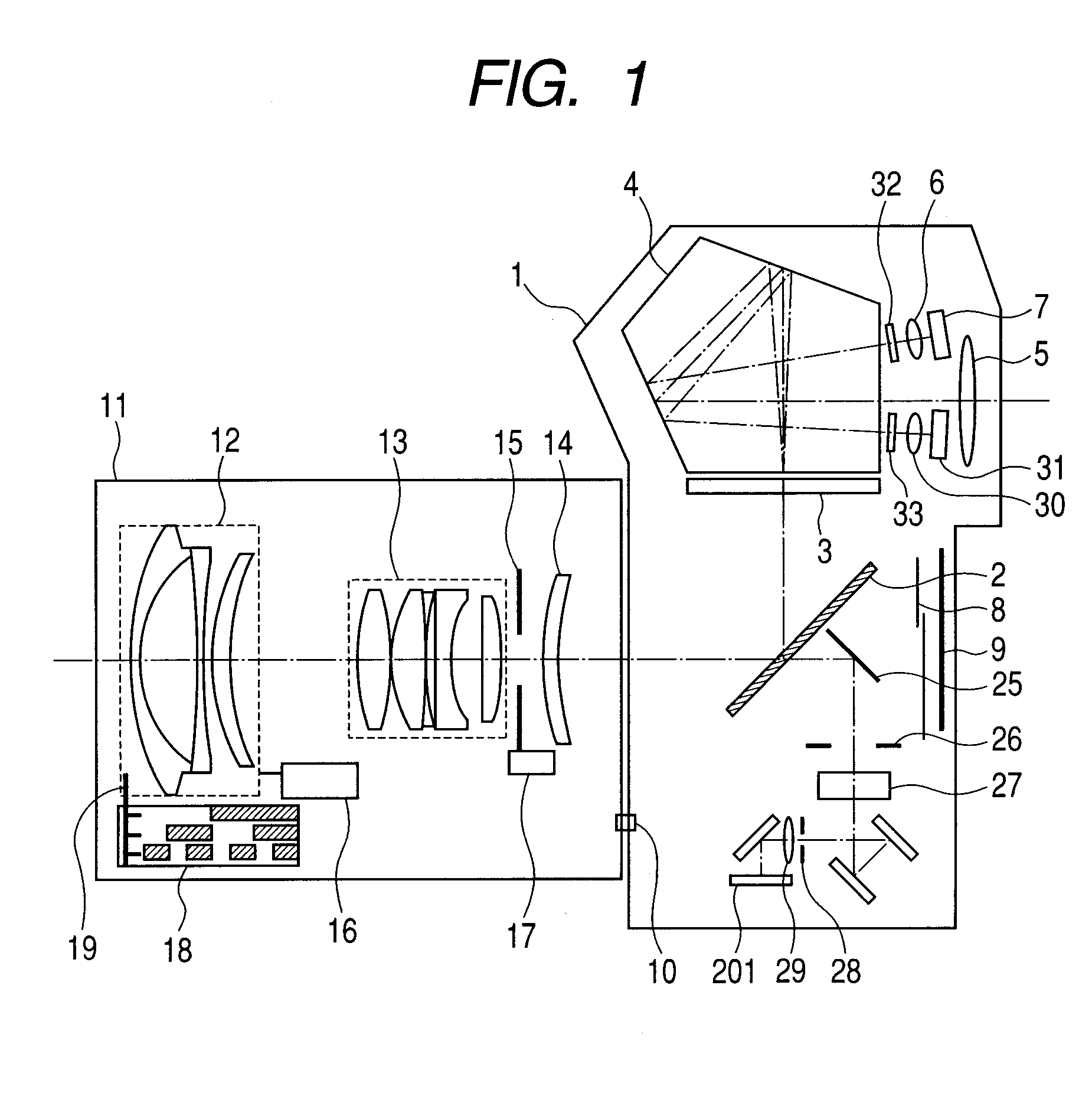

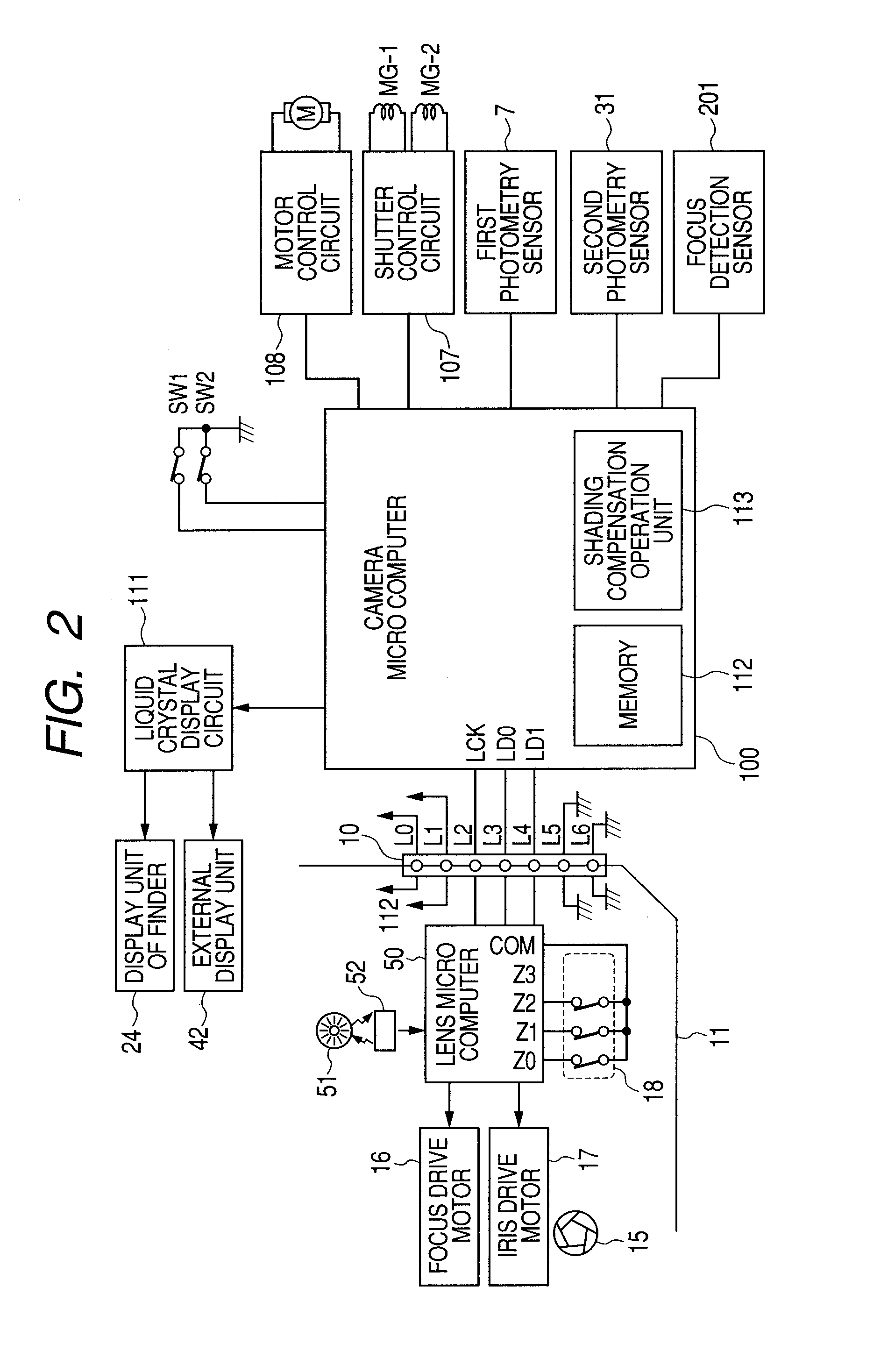

Focus detection apparatus

InactiveUS20100290773A1Improve detection accuracyReduce memory capacityExposure controlMountingsObject basedShading coefficient

A focus detection apparatus that measures, in advance, and stores shading coefficients for light sources of different types, and in a focus detection operation, generates light source information for determining a light source that irradiates an object based on outputs from a plurality of photometry sensors with different spectral characteristics and switches the shading coefficient of a focus detection sensor among shading coefficients stored according to the light source information.

Owner:CANON KK

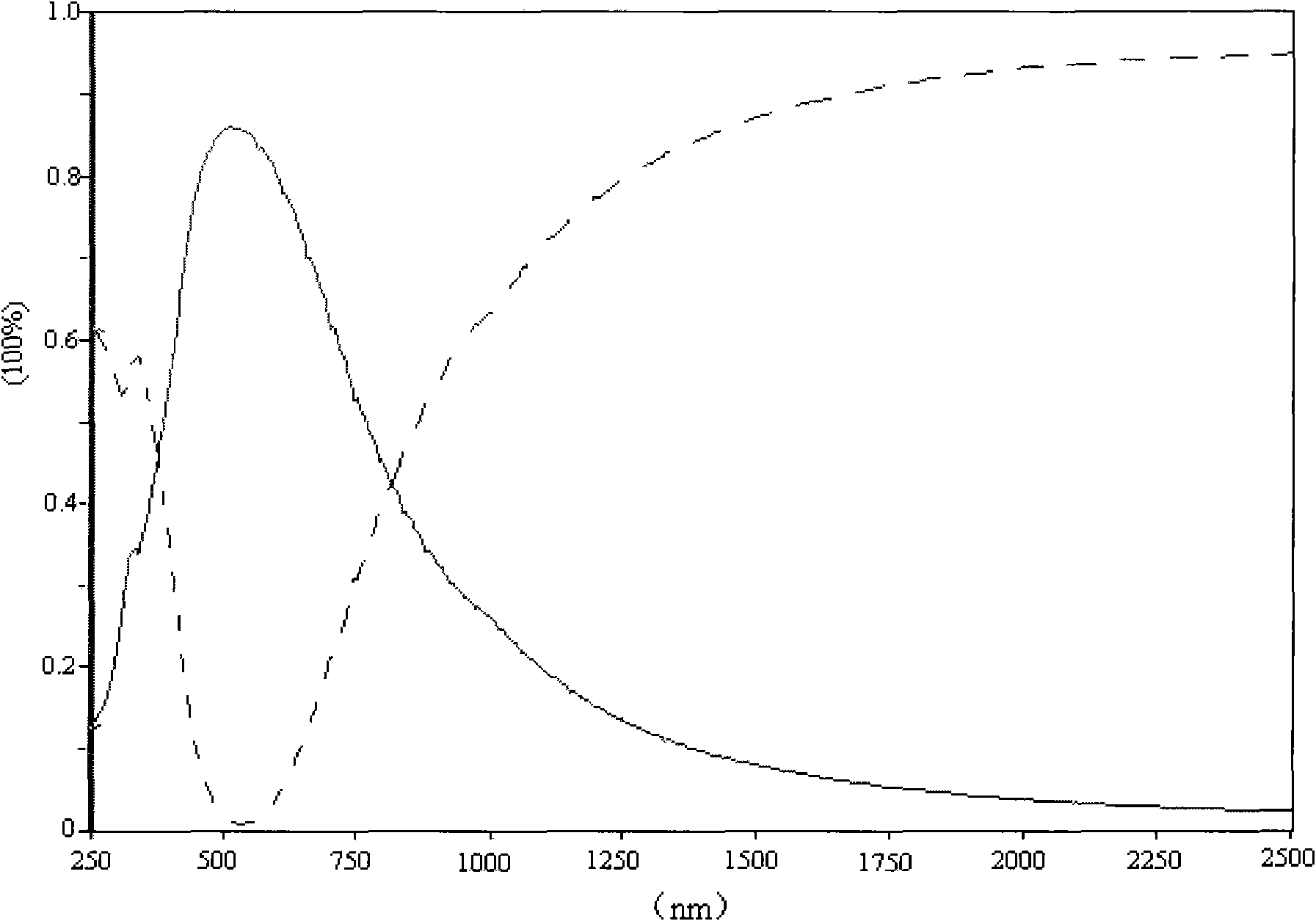

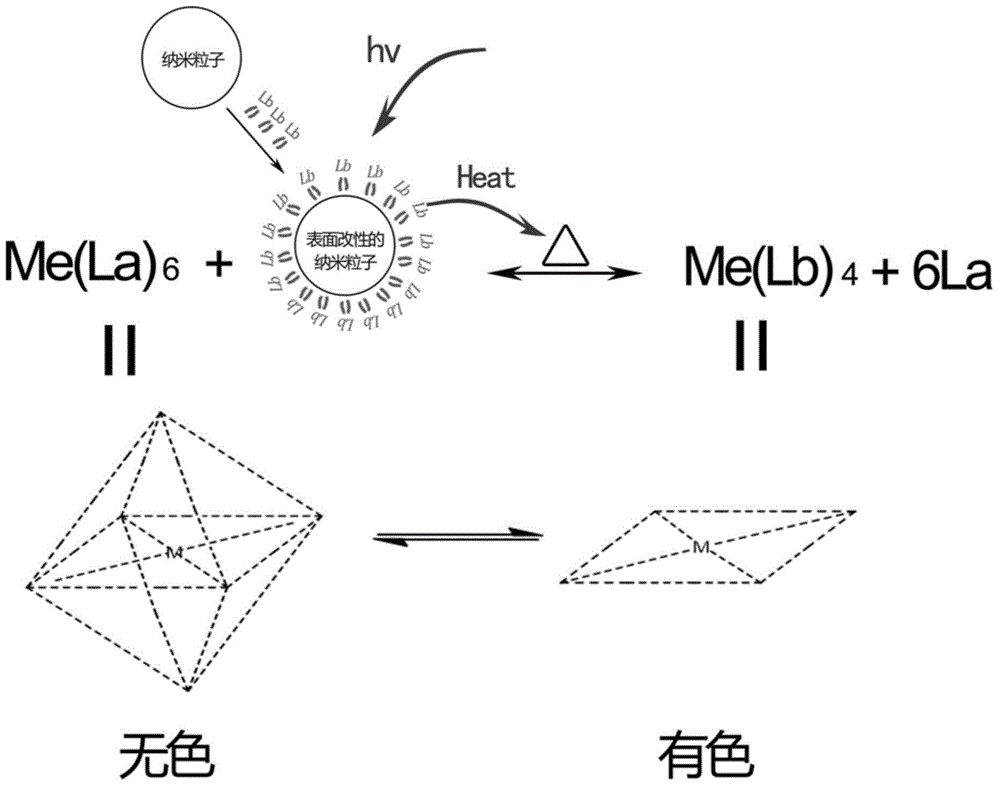

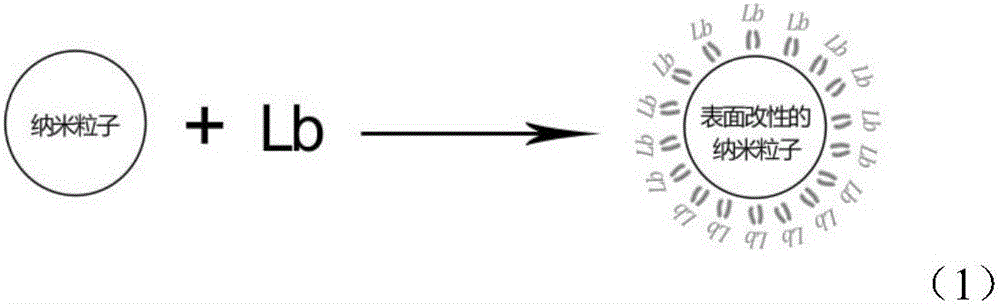

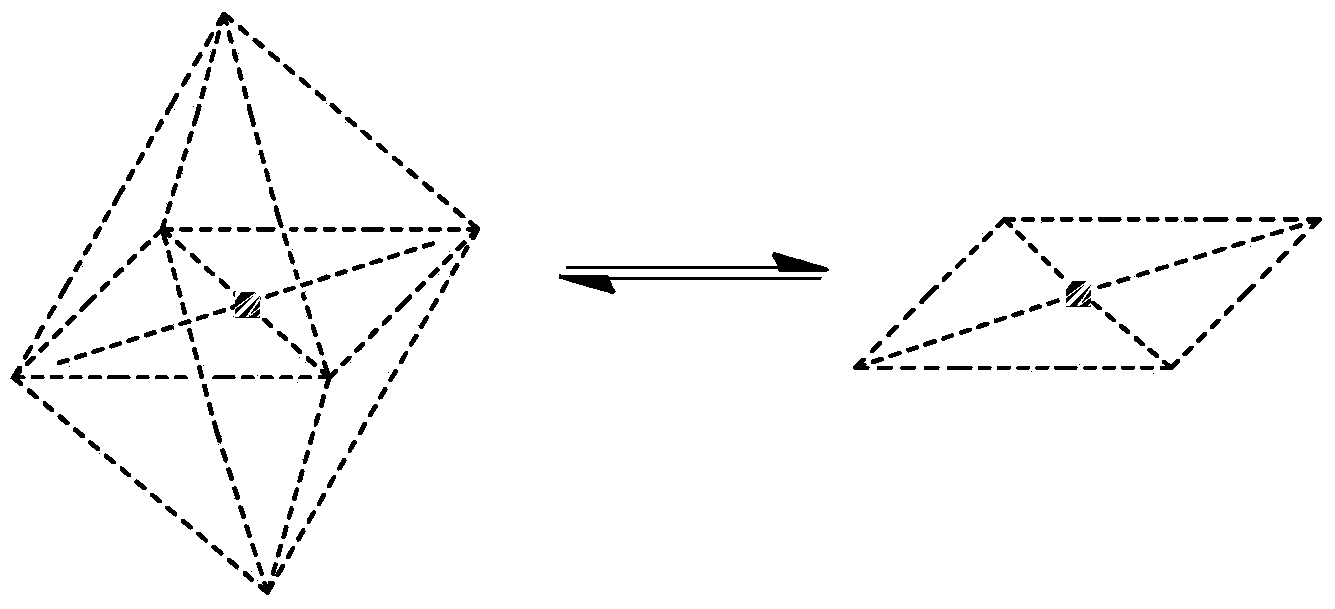

Nano-composite optothermal response system, resin material and smart glass

InactiveCN105713238AEasy to adjustStrong absorption capacityProtective equipmentSynthetic resin layered productsUltravioletSmart glass

The invention discloses a nano-composite optothermal response system, a resin material and smart glass.The system is formed in the mode that after transition metal ions, alpha or beta alcoholic hydroxyl surface-modified heat-absorption nano materials, halide and organic nitrogen compounds and / or phosphorus compounds are mixed, the nano materials are subjected to optothermal conversion, and organic transition metal complexes are subjected to conformation conversion.The system can respond to both light and heat, and the color and the light transmissivity are autonomously changed according to changes of environment temperature and light intensity.The optothermal response resin material has wide application prospects in the fields of glass curtain walls, building door and window glass, automobile glass, agricultural greenhouses and the like.The optothermal response smart glass has a high shading coefficient in low-temperature seasons, the shading coefficient can be automatically reduced in burning-hot, high-temperature and strong-sunshine summer, and the advantages that ultraviolet rays are completely shielded, the heat conduction efficiency is low and the sunlight shading coefficient autonomously changes are achieved.

Owner:付国东

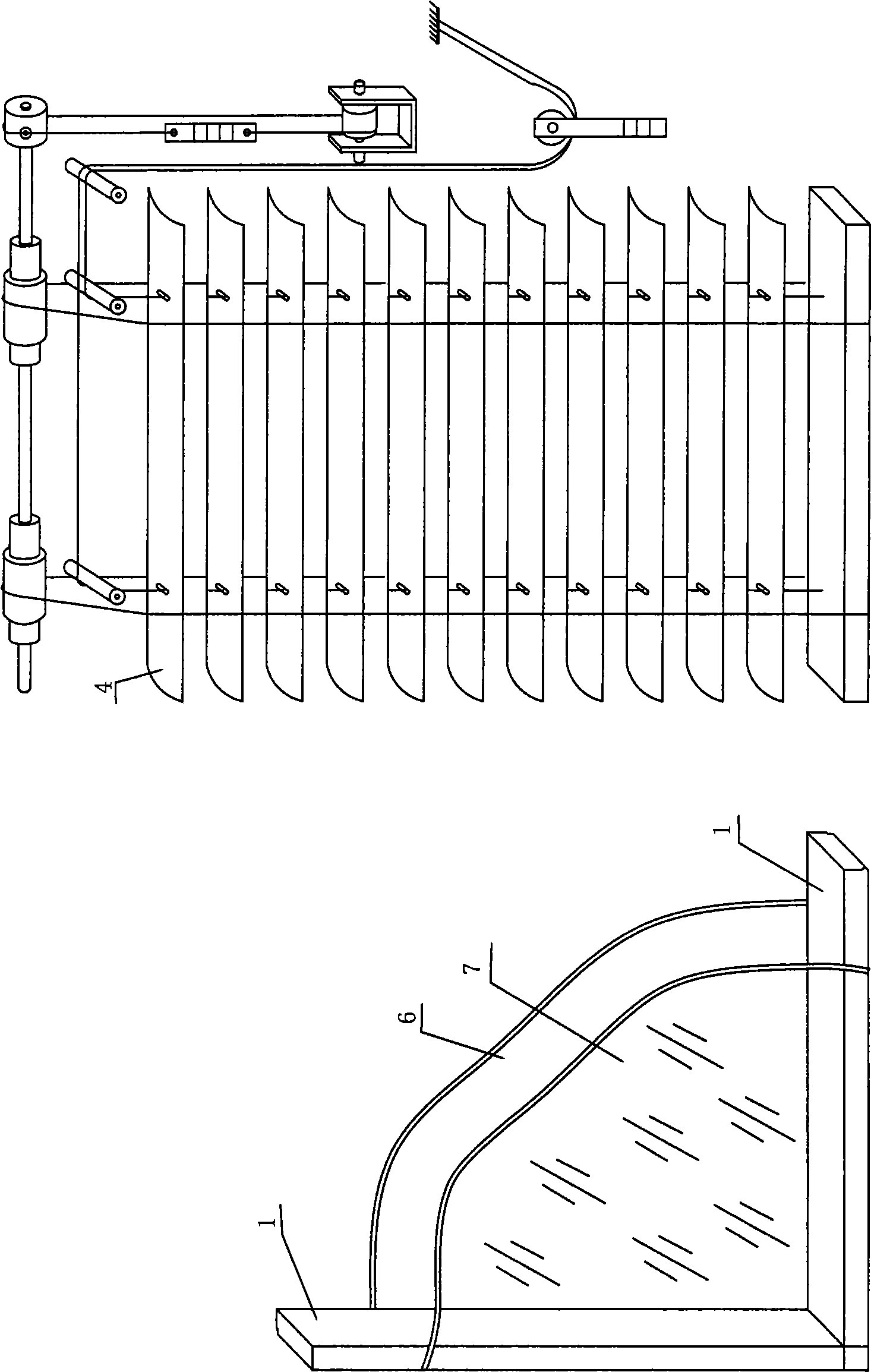

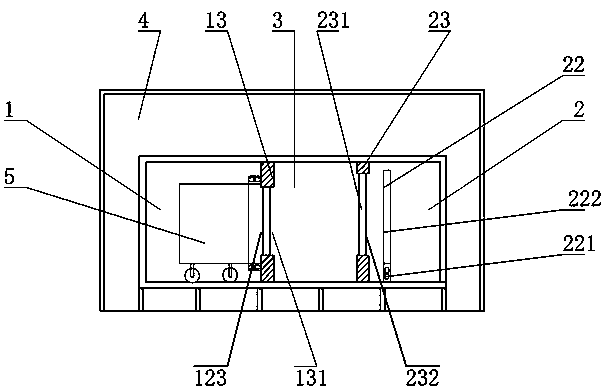

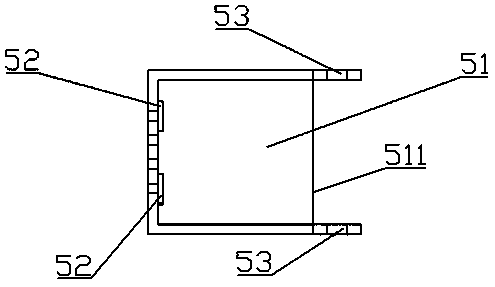

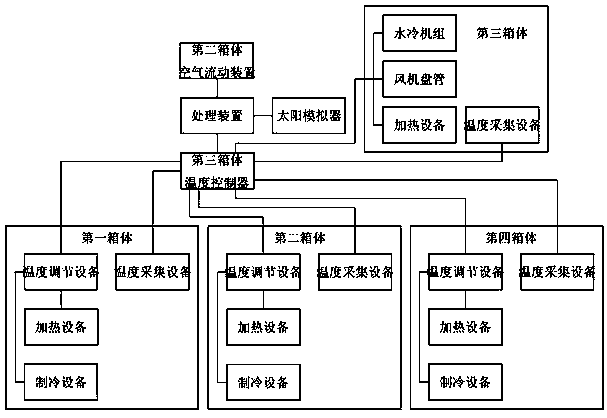

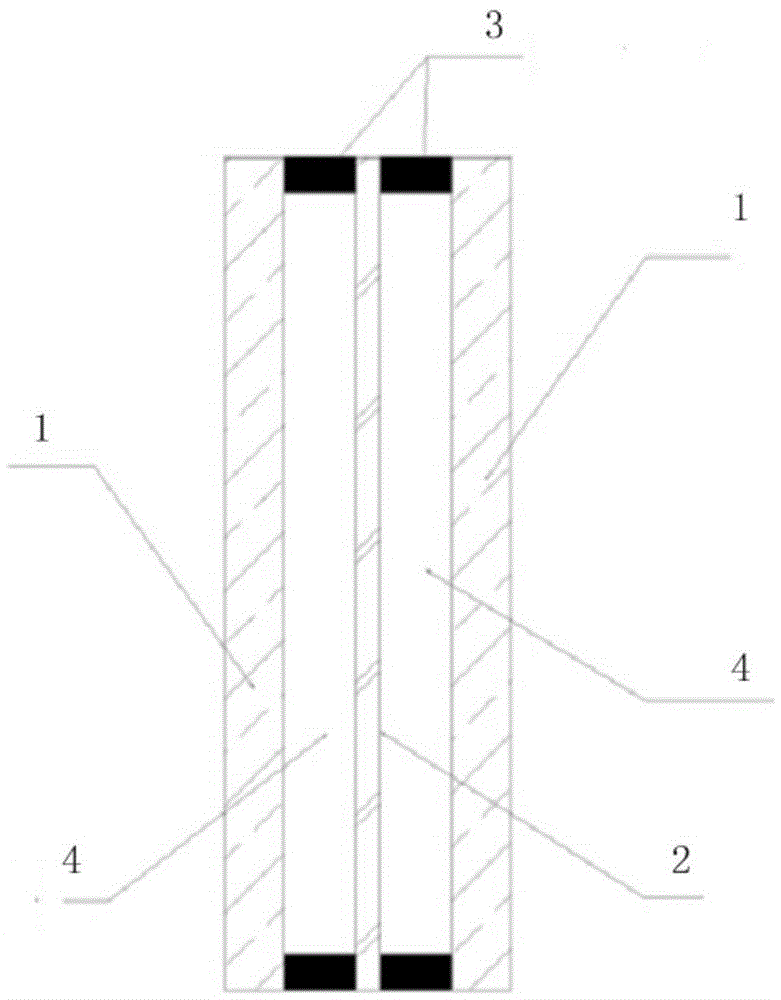

Thermotechnical testbed for detecting heat preservation and sunshading performance of external door-and-window system

ActiveCN103383300ASolve the problems of long experiment period and non-repeatabilityMaterial heat developmentOptical apparatus testingEngineeringHeat conservation

The invention discloses a thermotechnical testbed for detecting heat preservation and sunshading performance of an external door-and-window system. The thermotechnical testbed for detecting the heat preservation and sunshading performance of the external door-and-window system comprises a first box body simulating outdoor environment of summer, a second box body simulating outdoor environment of winter, a third box body simulating indoor environment and a fourth body used for protection. The first box body is connected with the third box body, the first box body and the third box body are provided with a first shared vertical face, a first test hole is formed in the first shared vertical face, and the first test hole is provided with a first test piece frame on one side of the first box body. The thermotechnical testbed for detecting the heat preservation and sunshading performance of the external door-and-window system has the advantages that the box bodies which simultaneously simulate the outdoor environment of summer and the outdoor environment of winter are arranged, and the detection of the shading coefficient, the solar heat gain coefficient, the heat transfer coefficient and other multiple thermotechnical properties of the door-and-window sunshading system can be met.

Owner:SHANGHAI JIANKE TECHN ASSESSMENT OF CONSTR

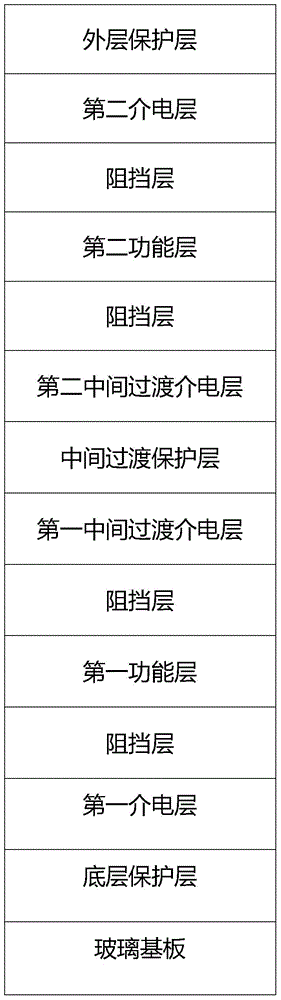

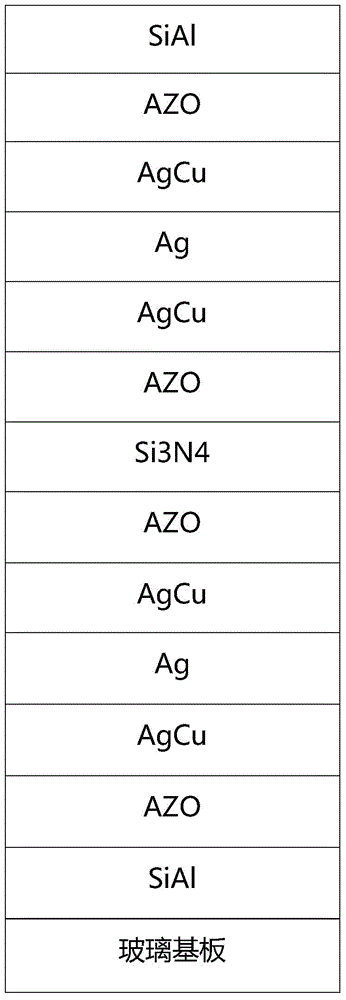

Low-radiation coated glass containing silver-copper alloy and preparation method of low-radiation coated glass

ActiveCN104786591ALow emissivityLow shading factorGlass/slag layered productsMetal layered productsRadianceShading coefficient

The invention discloses low-radiation coated glass. The low-radiation coated glass comprises at least one functional layer containing silver or sliver alloy, and is characterized by further comprising an AgCu alloy barrier layer. Compared with the traditional LOW-E glass, the low-radiation coated glass has the advantages that the optical and thermal properties are more excellent, the radiance and the shading coefficient are lower, the U value is low, the color is neutral, the properties are excellent and stable, the silver layer can be guaranteed to be not oxidized and discolored as far as possible during a tempering process, the properties of all film layers are more stable, and the properties of products are guaranteed to be always the same before and after tempering.

Owner:台玻成都玻璃有限公司

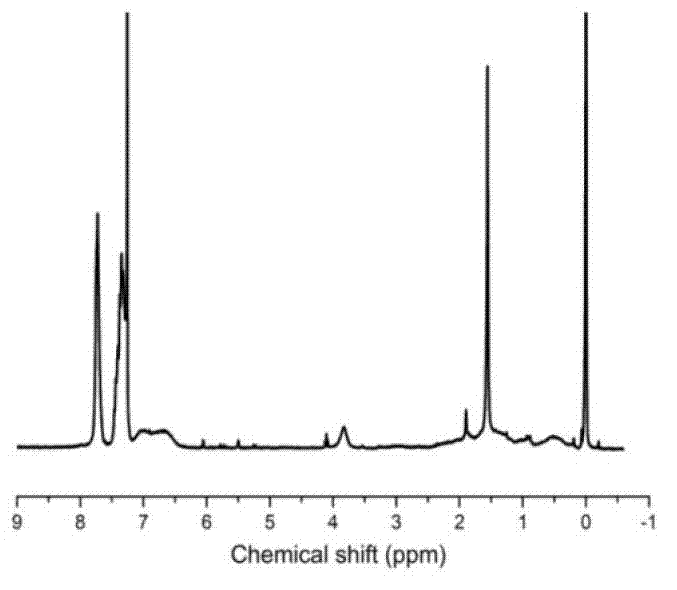

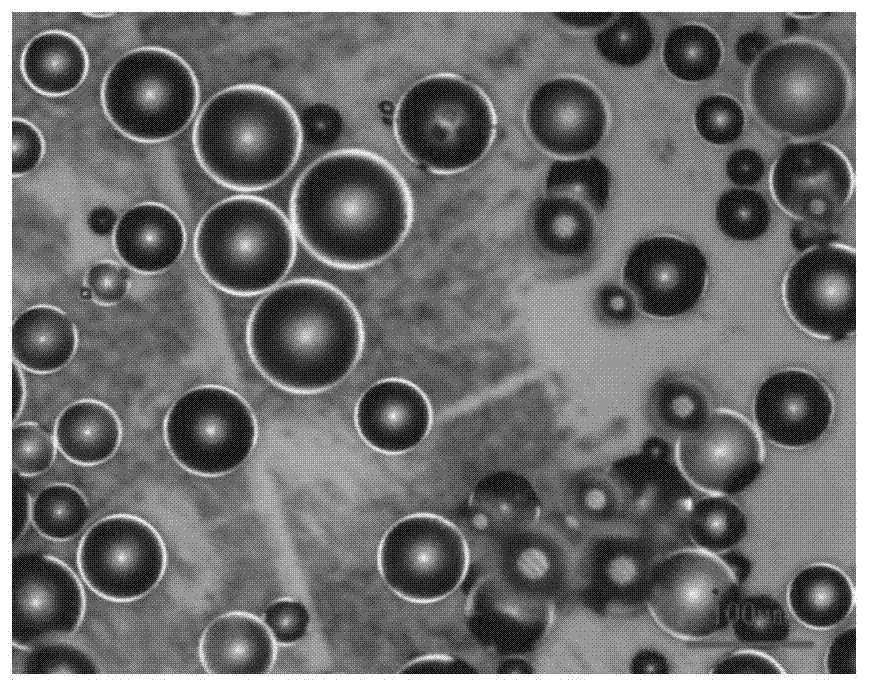

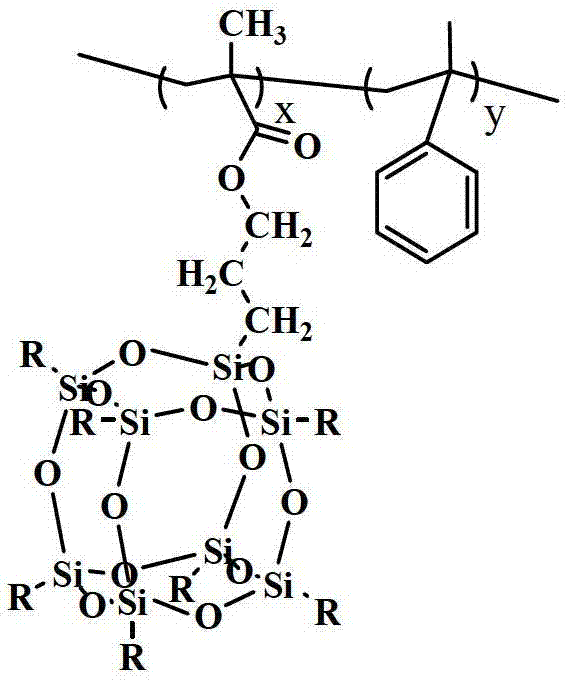

Optical diffusion agent for acrylic optical diffusion board and preparation method of optical diffusion board

ActiveCN103193914ACorrosion resistanceImprove thermo-oxidative stabilityDiffusing elementsPolymethyl methacrylateSilsesquioxane

The invention relates to an optical diffusion agent for an acrylic optical diffusion board and a preparation method of the optical diffusion board. The acrylic optical diffusion board comprises the following components in percentage by mass: 97.0-99.5 percent of polymethyl methacrylate and 0.5-3.0 percent of the optical diffusion agent which is a random copolymer of styrene and methylacryloyl propyl phenyl polyhedral oligomeric silsesquioxanes (MAPhPOSS). After the MAPhPOSS is copolymerized with styrene, even if the using amount of styrene monomers is small, the contribution of a nanoscale inorganic core can reach the same shading coefficient and light scattering property, and organic MMA groups in the POSS can avoid phase separation due to excessive addition amount, so that the optical diffusion board is uniform in surface, phase separation stripes are avoided, and a good diffusion body is obtained. The acrylic optical diffusion board can be applied to the field of outdoor photoelectric display of outdoor lamps, advertising light boxes, billboards, light source covers and the like with light-emitting diodes (LEDs) as light sources.

Owner:XIAMEN UNIV +1

Hollow two-cavity or multi-cavity nanometer composite energy-saving glass and preparing method thereof

InactiveCN105525837AReduce the heat transfer coefficient K valueTo achieve the purpose of comprehensive energy savingUnits with parallel planesUltravioletSealant

The invention discloses hollow two-cavity or multi-cavity nanometer composite energy-saving glass, which comprises two pieces of glass, one or more than one transparent nanometer composite sheet material, glass press strips and sealant, wherein the transparent nanometer composite sheet material is clamped in an air layer between the two pieces of glass by the glass press strips, and divides the air layer between the two pieces of glass into two or more than two parts. The high-transparency high-heat-isolation anti-ultraviolet energy-saving nanometer composite sheet material is used for being clamped in the middle of the air layer of the hollow glass and dividing the air layer of the hollow glass into two or more than two parts, so that the heat transmission coefficient K value of window glass is obviously reduced; meanwhile, the sun shading coefficient S<C> value of the window glass is reduced; and the comprehensive energy-saving goal is achieved.

Owner:BEIJING SINO HIGEE SCI & TECH +2

Cutting propagation method of Litsea coreana trees

ActiveCN104145706AOvercome the problem of high environmental and climate dependenceHelp scale developmentPlant protective coveringsRoot growthLitsea coreana

The invention discloses a cutting propagation method of Litsea coreana trees. The cutting propagation method comprises the following steps of (1) selecting a suitable cutting land and preparing the cutting land; (2) selecting semiligneous branches, pruning the branches to retain 2cm-4cm lengths, and retaining 0.5-1.5 pieces of leaves on each branch; (3) cutting the branches subjected to pruning onto ridges according to line spacing of 4cm-6cm and row spacing of 2cm-3cm; (4) setting up an arch shed, covering the arch shed with sunshade nets and keeping the shading coefficient in the sheds to range from 95 percent to 98 percent; (5) keeping the soil wet after cutting, and spraying root growth liquid and nutrients again; (6) performing illumination training after cutting for 370-380 days, pulling open the sunshade nets at the two ends of the arch shed firstly, and then puling open all the sunshade nets after 2-4 days to perform full exposure training. The cutting propagation method of the Litsea coreana trees is low in cost, high in survival rate and free of limit of environmental climate.

Owner:青川县老鹰茶资源开发研究中心

Moringa oleifera cuttage seedling nursing method

InactiveCN106376388AImprove survival rateEasy plantingCultivating equipmentsHorticultureGreenhouseMoringa pterygosperma

The invention discloses a moringa oleifera cuttage seedling nursing method. The method comprises steps of cutting slip selection, cutting slip processing, cutting slip management and transplantation. A cuttage bed is formed by yellow soil, river sand and plant ash; the yellow soil, river sand and plant ash are high-temperature disinfected, and then cuttage is conducted; segmentation mangemetn is conducted after the cuttage; parameters of temperature, humidity, shading coefficient and ventilation of a greenhouse is adjusted, so cutting slip survival rate can be improved and seedling nursing cost can be reduced; and moringa olefera promotion and plantation can be facilitated.

Owner:铜仁市万山区清泉种养殖农民专业合作社

Optothermal response system, resin material and optothermal response smart glass

The invention discloses an optothermal response system, an optothermal response resin material prepared by using the optothermal response system as a polymer processing aid, and optothermal response smart glass. The system is obtained by mixing transition metal ions, a polyhydric alcohol ligand compound, a light-sensitive halide and an organic nitrogen compound and / or a phosphorus compound and then performing conformational transition on the mixture by use of an organic transition metal compound. The optothermal response system has double response to light and heat, and is capable of autonomously changing in intensity of color and light transmissivity according to the change of the environment temperatures and the light intensity. The optothermal response resin material has a wide application prospect in the fields such as glass curtain walls, building door and window glass, automobile glass and agricultural greenhouse films. The optothermal response smart glass has relatively high shading coefficient in seasons of relatively low temperatures, and is capable of automatically reducing the shading coefficient in hot high-temperature summer with strong sunlight, and thus has the advantages of complete ultraviolet shielding, low heat conduction efficiency and autonomous sunlight shading coefficient change.

Owner:青岛至慧新材料科技有限公司

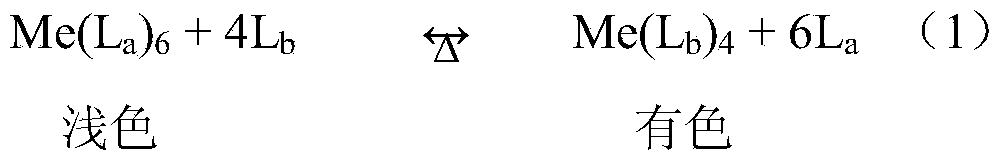

High-performance double-silver low-radiation energy-saving glass

PendingCN107471785AAvoid damageImprove performanceGlass/slag layered productsDomestic wallsEngineeringProtection layer

The invention discloses high-performance double-silver low-radiation energy-saving glass, which belongs to the field of an eco-friendly energy-saving building material. The structure of an energy-saving glass membrane layer comprises, in sequence, a glass substrate, a first base layer which is a silicon nitride layer, a second seed layer which is a zinc oxide layer, a third functional layer which is silver layer, a fourth protective layer which is a nickel cadmium layer, a fifth dielectric layer which is a silicon nitride layer, a sixth dielectric layer which is a tin zinc oxide layer, a seventh seed layer which is a zinc oxide layer, an eighth functional layer which is a silver layer, a ninth protective layer which is a nickel cadmium layer, a tenth dielectric layer which is an aluminum zinc oxide layer, an eleventh layer which is a silicon nitride layer, and a twelfth protective layer which is a graphite layer. Through arrangement of a coating membrane layer material on the glass substrate and arrangement of a membrane layer thickness, the energy-saving glass reflects gray and blue colors outdoors, and has visible light transmittance between 42-60%. The energy-saving glass is excellent in performance, has a shading coefficient less than 0.3 and selectivity coefficient more than 1.4, and is quite suitable for hot areas that have high environment temperature all the year round and intense average sunshine.

Owner:SICHUAN NANBO ENERGY SAVING GLASS CO LTD

Alumroot cuttage rapid propagation method

ActiveCN107135927AStable genetic traitsIncrease production costClimate change adaptationGreenhouse cultivationGreenhouseCoir

Disclosed is an alumroot cuttage rapid propagation method. The method comprises the steps that an alumroot female parent garden adopting a container cultivation mode is built, the garden is built inside a plastic greenhouse with the shading coefficient being 50%, and the temperature inside the greenhouse is 6-35 DEG C; a cutting medium is formed by mixing coco coir, turf, vermiculite and perlite with the volume ratio being 2-3:1:0.5:0.2-0.5; the cuttage time is the first ten days of March to the middle ten days of October; leaf stalk roots of mature leaves of alumroot female parents together with buds are sheared as cutting slips; after disinfection treatment is performed on the cutting slips, the cutting slips are dipped into a rooting agent containing naphthylacetic acid and indolebutyric acid and then are subjected to cuttage into tree aperture disks, the aperture disks are placed on a seedbed inside the greenhouse, a small shed is installed on the seedbed, the shading coefficient inside the small shed is 70-80%, and the relative air humidity is 80-90%; seedling hardening is performed. By adopting the method, after cuttage is performed for 39-58 d, the planting percentage reaches 95% or above, the rooting situation is good, the cost is low, operation is easy, sprout characters are stable, and sprouts can be produced in a large-scale and standardized mode.

Owner:FLOWER RES INST OF YUNNAN ACAD OF AGRI SCI

Offline low-emissivity glass coated film system

InactiveCN104029440ALow shading factorReduce visible light reflectanceVacuum evaporation coatingSputtering coatingLow emissivityOxygen

The invention discloses an offline low-emissivity glass coated film system. According to the invention, an original metal Ti layer or a NiCr alloy is replaced with a nitrogen zinc oxide film layer in an existing offline low-emissivity glass coated film system. The nitrogen zinc oxide film layer is prepared by a magnetron sputtering method; nitrogen acts as a sputtering gas and a technological gas in the magnetron sputtering film coating process, and meanwhile, trace oxygen is introduced according to the practical product performance. Relatively low visible light reflectance is kept as well as the sun shading coefficient is low. The offline low-emissivity glass coated film system is gentle in color, can meet the neutral color requirement easily, is low in angle color deviation, and is excellent in abrasion resistance and outstanding in processing property, the finished product rate of the system is effectively improved, and the production cost is lowered.

Owner:HANGZHOU DIANZI UNIV +1

Low-radiation temperable double-silver LOW-E glass

The invention discloses low-radiation temperable double-silver LOW-E glass, which comprises a glass substrate, wherein nine film layers are adjacently compounded in sequence on the composite surface of the glass substrate from inside to outside. The low-radiation temperable double-silver LOW-E glass is characterized in that: a first film layer, i.e., an innermost layer is an Si3N4 layer; a second layer is a TiO2 layer; a third layer is a ZnAlOx layer; a fourth layer is an Ag layer; a fifth layer is a TiO2 layer; a sixth layer is a ZnAlOx layer; a seventh layer is an Ag layer; an eighth layer is an NiCrOx layer; and a ninth layer is an Si3N4 layer. The low-radiation temperable double-silver LOW-E glass has the advantages of low radiation rate which is less than or equal to 0.03, good energy saving effect, lower shading coefficient in comparison to the same type of product with the same penetration rate, avoidance of the situation of damaging the film layers when the temperature is 700 DEG C in maximum in a tempering heating process, small color difference after tempering and high film layer uniformity.

Owner:中山市格兰特实业有限公司

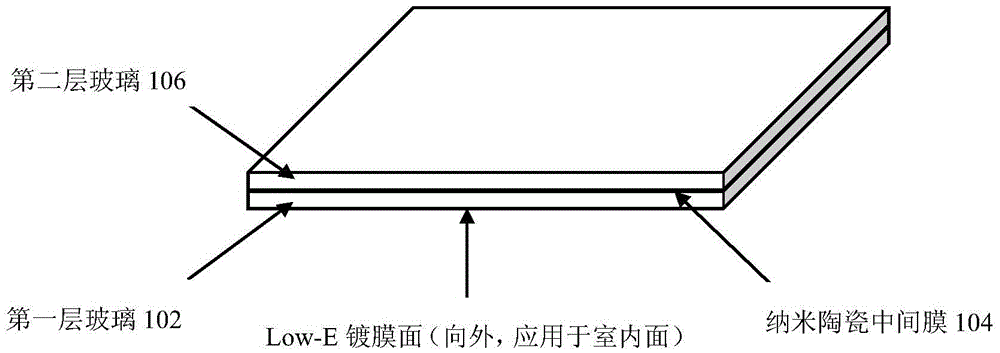

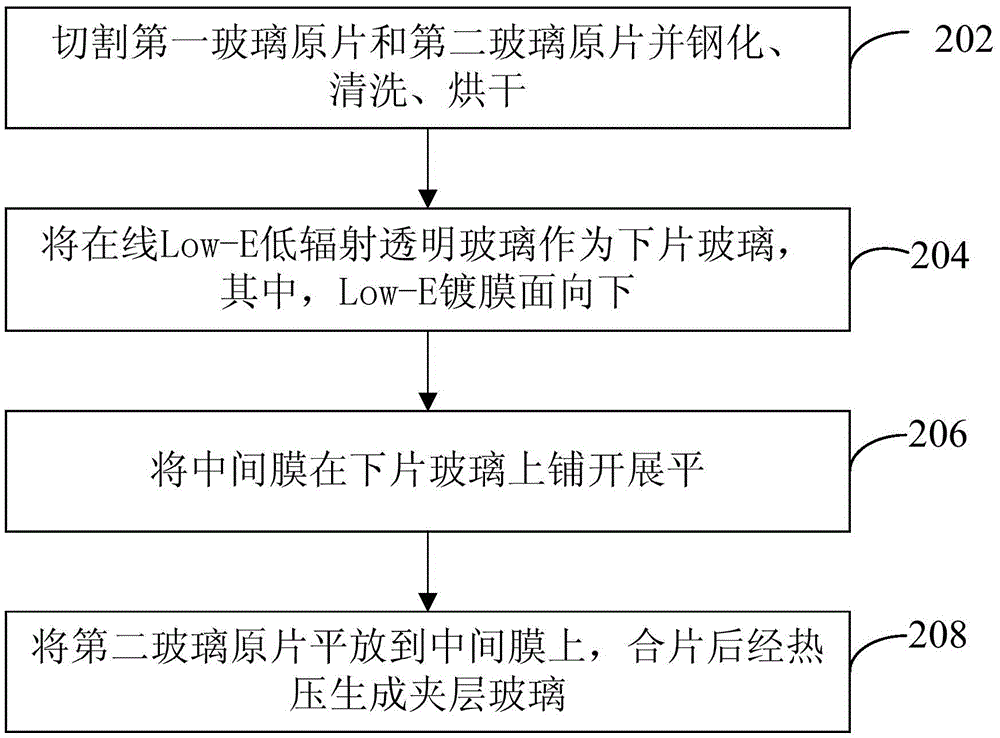

Laminated glass and manufacturing method thereof

ActiveCN105599397APreserve transparencyRetain hazeLamination ancillary operationsLayered product treatmentAir conditioningToughened glass

The embodiment of the invention discloses a laminated glass and a manufacturing method thereof. Specifically, the laminated glass comprises: a first layer of glass, a second layer of glass, and an intermediate film between the two layers of glass, wherein the first layer of glass is an online Low-E low radiation transparent glass, the second layer of glass is ordinary transparent glass or tempered glass, and the intermediate film is a modified PVB film doped with a tungsten oxide nano-ceramic material. The scheme involved in the invention can substantially reduce the heat transfer coefficient and shading coefficient of the laminated glass so as to enhance the winter heat preservation and summer heat insulation performance, is especially suitable for reducing air-conditioning energy consumption in summer, and can achieve very good energy-saving effect.

Owner:南京亚鼎光学有限公司

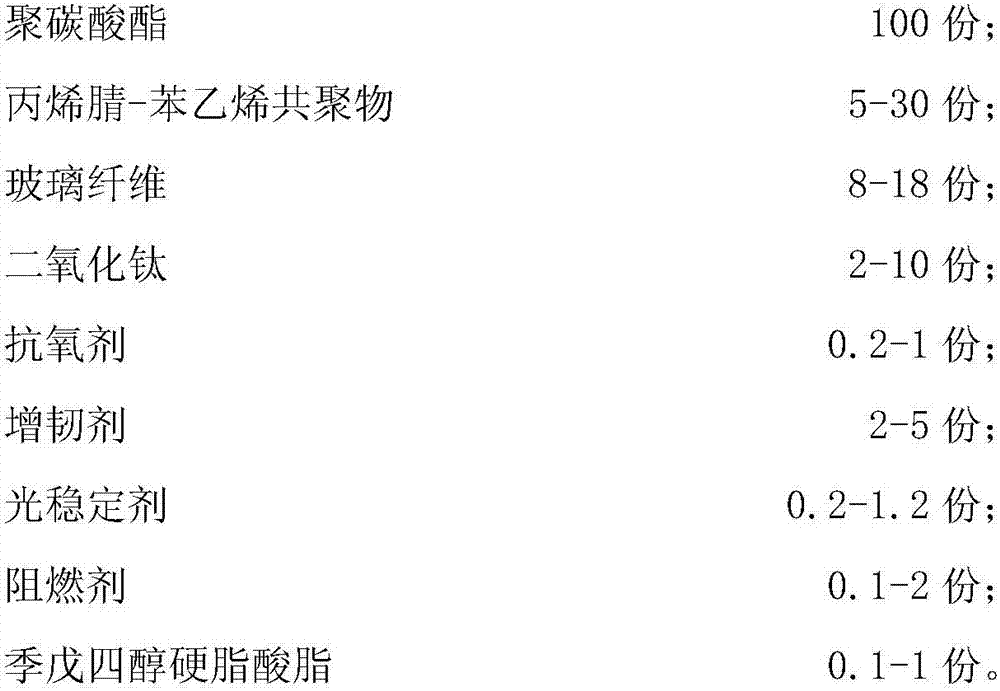

High-shading-coefficient PC/GF (polycarbonate/glass fiber) composite material and preparation method thereof

The invention discloses a high-shading-coefficient PC / GF (polycarbonate / glass fiber) composite material and a preparation method thereof. The high-shading-coefficient PC composite material is characterized by being prepared from, by mass, 100 parts of polycarbonate, 5-30 parts of acrylonitrile-styrene copolymer, 8-18 parts of glass fibers, 2-10 parts of titanium dioxide, 0.2-1 part of an antioxidant, 2-5 parts of a toughening agent, 0.2-1.2 parts of a light stabilizer, 0.1-2 parts of a flame retardant and 0.1-1 part of pentaerythritol stearate. The high-shading-coefficient PC / GF composite material has great mechanical properties and light shielding effects.

Owner:东莞市骄阳塑胶科技有限公司

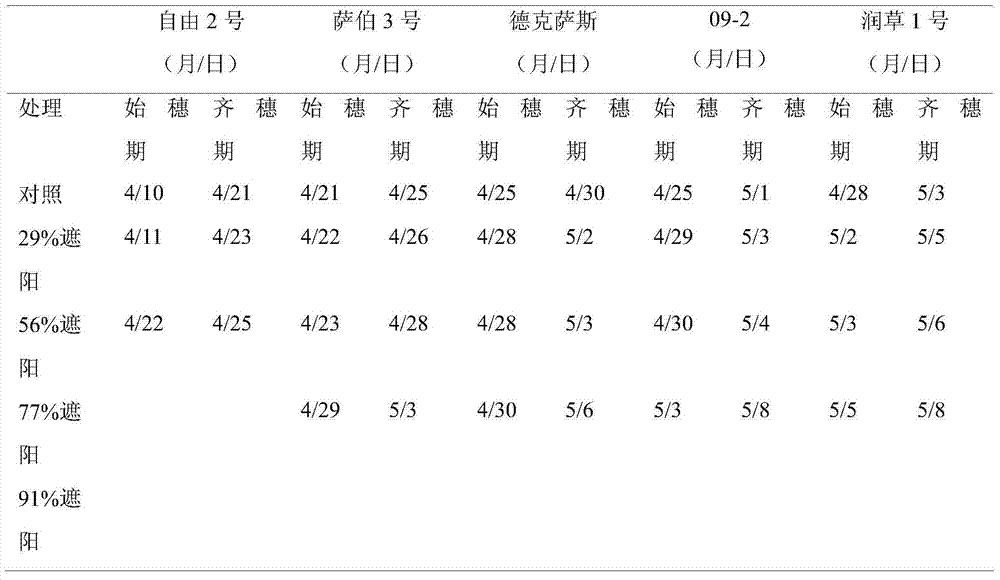

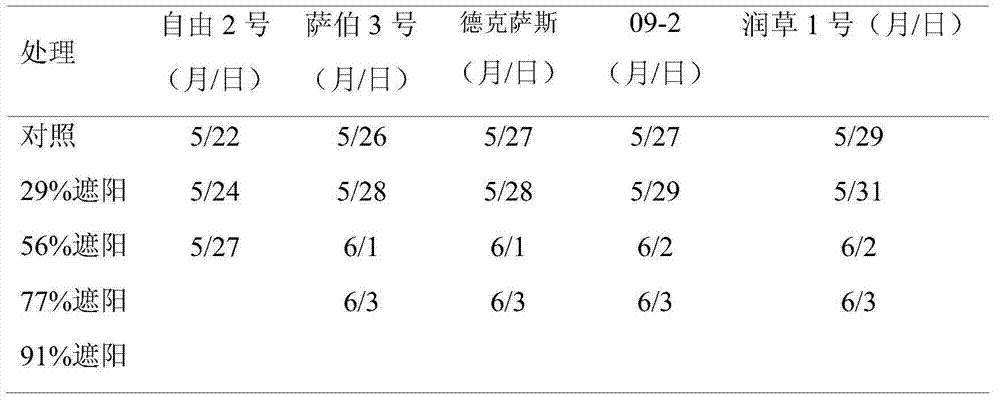

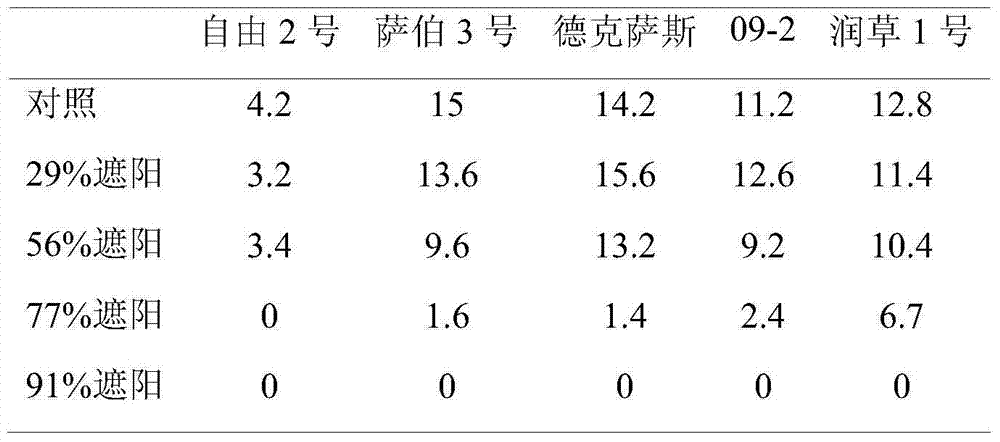

Method for planting runcao I on large shade condition

The invention discloses a method for planting runcao I of a new grass variety of a grass family on the large shade condition. According to the large shade condition, the shading coefficient ranges from 75% to 92%. The specific planting method includes the steps of sowing of grass seeds, water consumption, prevention and control over diseases, pests and weed, fertilizer requirements, the number of clipping times, dwarf and robust measurements and the like. By the method for planting the runcao I on the large shade condition, the runcao I, a new product in the grass family, can grow well under the condition of shading of 75-92%, and can also flower and bear fruit normally. The method for planting the runcao I on the large shade condition saves energy sources and production cost, and organic agriculture is achieved; a large number of land resources are saved, so that the economic benefits are high; the method plays an active role in preventing water and soil losses, and thus the method meets the requirement that energy conservation and environment protection, urban landscape greenbelt construction, improvement of economic benefits and full utilization of the land resources are combined.

Owner:镇江润祥农业科技有限公司

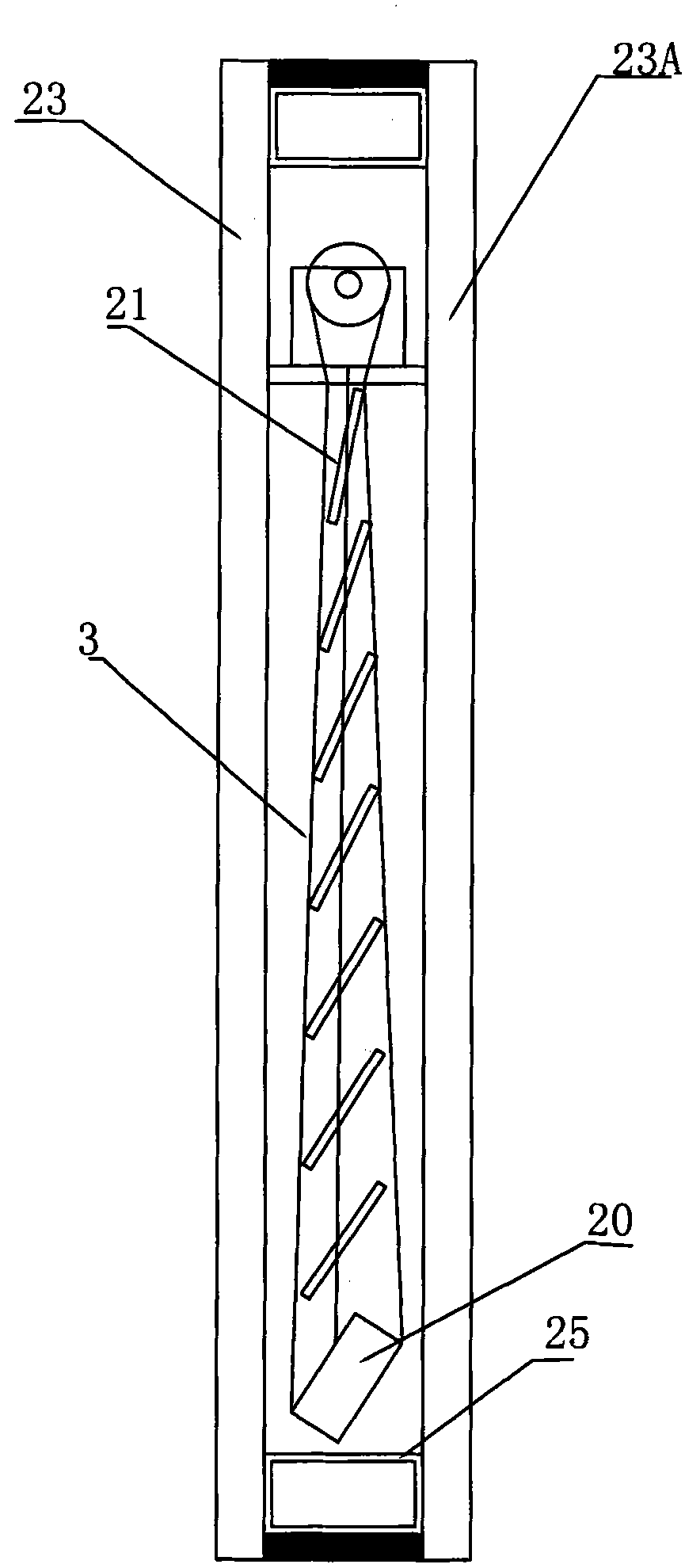

Blind in hollow glass

InactiveCN101994477ASmooth flipHigh shieldingLight protection screensUnits with parallel planesThermal insulationEngineering

The invention discloses a blind in hollow glass. The upper part and the lower part of the blind are both provided with blind turning control structures; the upper part and the lower part of the blind are turned simultaneously during blind turning, and the blind turning degrees of the upper part and the lower part are the same, thereby improving the shielding performance, the shading coefficient, the thermal insulation property and the total energy saving performance of the hollow blind glass.

Owner:常熟欧泰克建筑节能科技有限公司

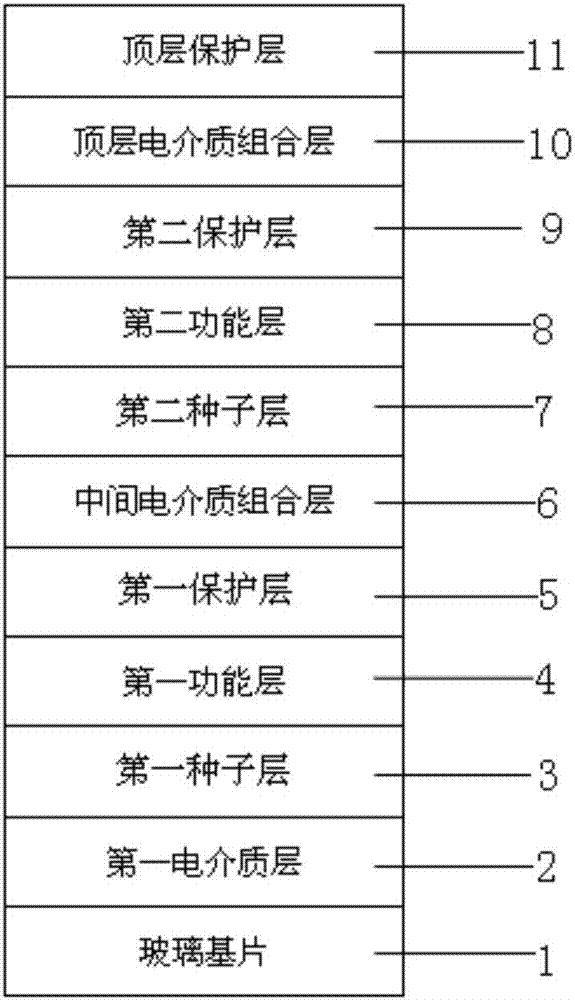

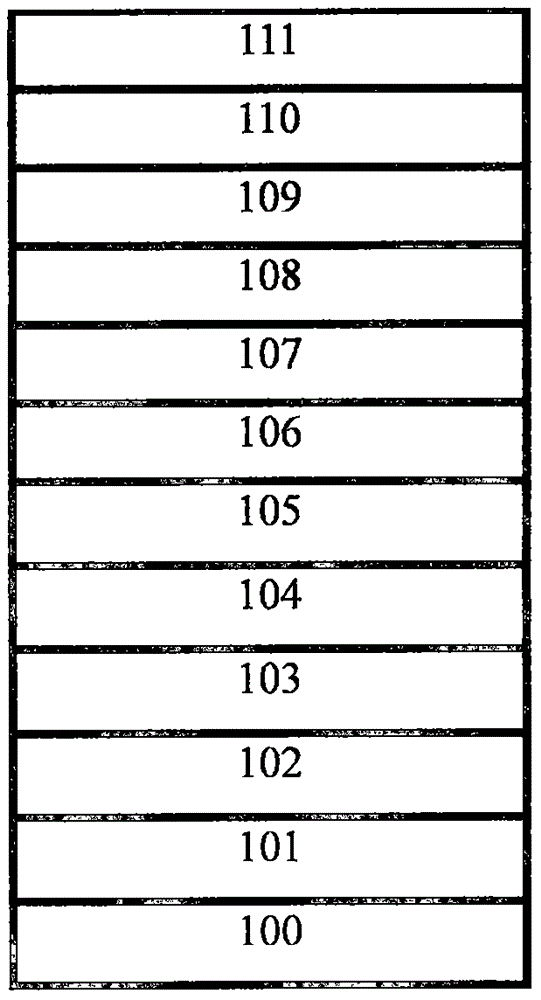

Neutral transmittance color double-silver low radiation glass and preparation method thereof

The invention provides neutral transmittance color double-silver low radiation glass and a preparation method thereof through special design. On one surface of a float glass substrate, a multilayer thin film is deposited in a magnetron sputtering coating manner and has the following structure comprising: a first metal oxide layer (101), a first oxide layer (102), a first metal titanium (103), a first silver layer (104), a second oxide layer (105), a second metal oxide layer (106), a second silver layer (107), a second metal titanium (108), a third oxide layer (109), a third metal oxide layer (110) and a titanium oxide protective layer (111). The double-silver low radiation glass has low shading coefficient and stable optical performance and can be processed in later process, has neutral transmittance color and is an excellent selection for high-grade building glass.

Owner:BEIJING JINJING WISDOM CO LTD

Hollow glass with double-layer low-radiation coating film

InactiveCN103850592ALower heat transfer coefficientLow shading factorUnits with parallel planesCoated surfaceRadiance

The invention relates to a hollow glass with a double-layer low-radiation coating film. The hollow glass comprises sunshade type low-radiation film-coated glass, spacing cavities, high-penetrating low-radiation film-coated glass and spacing strips, wherein the sunshade type low-radiation film-coated glass and the high-penetrating low-radiation film-coated glass are respectively spliced on the two sides of the spacing strips; the film-coated surface of the sunshade type low-radiation film-coated glass and the film-coated surface of the high-penetrating low-radiation film-coated glass are both faced to the spacing cavities; sealed spacing cavities are formed between the sunshade type low-radiation film-coated glass, the high-penetrating low-radiation film-coated glass and the spacing strips. The hollow glass with the double-layer low-radiation coating film provided by the invention has the characteristics of excellent energy-saving property, low radiance, low heat transfer coefficient, low shading coefficient and moderate light transmittance.

Owner:洛阳新晶润工程玻璃有限公司

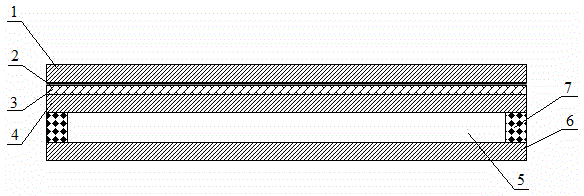

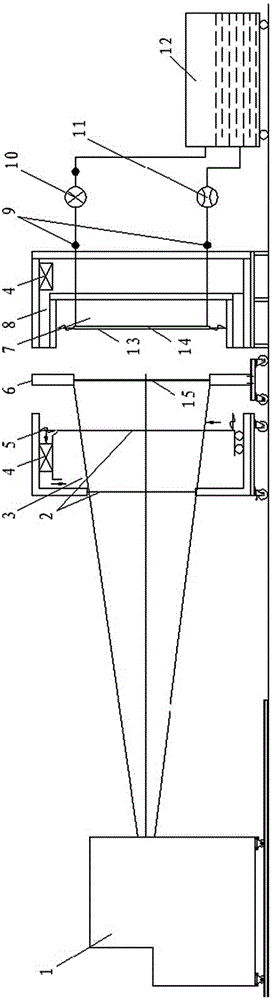

Building window and door shading coefficient testing device

The invention relates to a building window and door shading coefficient testing device. The building window and door shading coefficient testing device comprises a solar power simulator for simulating sunlight, an external environment box for simulating outdoor environment parameters of a building, a test part frame for fixing a part to be tested, a heat metering box for measuring solar energy penetrating through the tested part, and an internal environment box for simulating indoor environment parameters of the building, which are sequentially arranged on a straight line, wherein the heat metering box adopts water to cool and meter heat; and temperature-sensing elements are arranged in the internal environment box, the metering box and the external environment box. According to the building window and door shading coefficient testing device, the large-area reflective solar energy simulator utilizes four xenon lamps as a light source and can focus solar energy on an optical integral mirror through twice reflection, so that radiation with radiation area of more than 2.25m<2>, irradiance up to 500W / m<2>, uniform distribution and an incident angle within 10 degrees can be achieved on a test part mounting plane, and a natural light source can be really simulated.

Owner:CHINA ACAD OF BUILDING RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com