Thermal-insulating heat-preserving laminated safety glass and manufacturing method thereof

A technology for thermal insulation and safety glass, applied in chemical instruments and methods, lamination, coating, etc., can solve the problems of large equipment investment, complex process, light pollution, etc., achieve low equipment investment, low heat transfer coefficient, shading Low coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0036] Preparation of thermal insulation coating:

[0037] In 200g polyacrylic acid resin solution, add 10g ITO and 40g ATO powder, then add 1g BYK346 dispersant, 0.1g BYK151 wetting agent and 0.5g BYK352 thickener, in the disperser, at 100 rpm , after stirring and dispersing for 1 hour, grind for another 20 hours to obtain a heat-insulating slurry with a particle size of 10-30 nm; add 200 g of the obtained heat-insulating slurry to 800 g of polyacrylic acid resin solution, and disperse at 500 rpm for 1 hour to obtain a heat-insulating slurry hot paint.

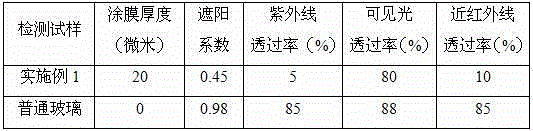

Embodiment 1

[0039] Thermal insulation laminated safety glass:

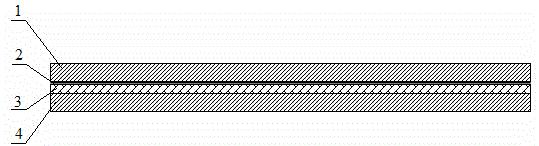

[0040] Such as figure 1 As shown, the heat-insulating laminated safety glass, from top to bottom, is the first layer of glass 1, a transparent heat-insulating coating 2 with a thickness of 20 μm coated on the inner surface of the first layer of glass 1, a 0.38mm PVB film 3 and Second layer of glass4. The transparent heat-shielding coating 2 is formed by coating the heat-shielding coating obtained in Reference Example 1.

[0041] Manufacturing method of thermal insulation laminated safety glass:

[0042] (1) Preparation of transparent heat-insulating coating: apply the heat-insulating coating obtained in Reference Example 1 on the inner surface of the first layer of glass 1 by spraying, control the wet film at about 40-50 μm, and then bake Bake for 20 minutes to form a transparent heat-shielding coating 2;

[0043] (2) Preparation of heat-insulating laminated safety glass: stack the first layer of glass 1 coated with t...

Embodiment 2

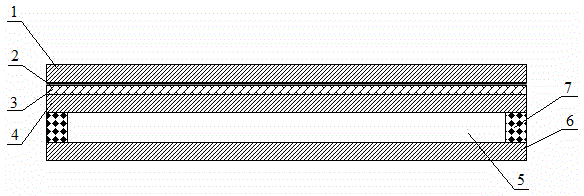

[0045] Thermal insulation laminated safety insulating glass:

[0046] Such as figure 2 As shown, the heat insulation laminated safety insulating glass, from top to bottom, is the first layer of glass 1, the transparent heat insulation coating 2 with a thickness of 20 μm coated on the inner surface of the first layer of glass 1, and the PVB film of 0.38 mm 3 , a second layer of glass 4, a gas spacer layer 5 with a thickness of 12mm and a third layer of Low-E glass 6; the second layer of glass 4 and the third layer of Low-E glass 6 are edge-sealed by a sealant 7 and form a gas gap Layer 5. The transparent heat-shielding coating 2 is formed by coating the heat-shielding coating obtained in Reference Example 1. The sealant 7 is butyl rubber and polyurethane sealant.

[0047] Manufacturing method of thermal insulation laminated safety insulating glass:

[0048] The thermal insulation laminated safety glass and the third layer of Low-E glass obtained in step (2) of Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com