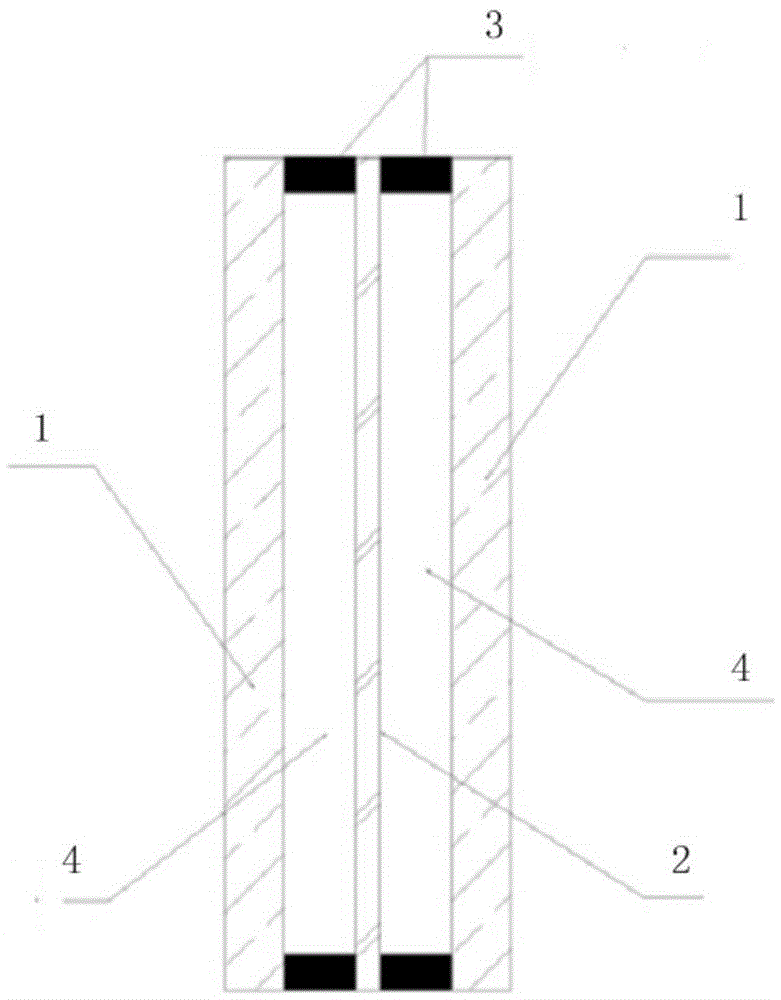

Hollow two-cavity or multi-cavity nanometer composite energy-saving glass and preparing method thereof

A nano-composite, energy-saving glass technology, applied in the field of glass windows, can solve the problems of increased difficulty in construction, small radiation barrier, and increased self-weight of windows.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Preparation of nano-transparent heat-insulating and energy-saving coatings:

[0051] Adopting polyvinyl butyral PVB resin to be dissolved in ethanol to make a liquid resin with a solid content of 20wt%;

[0052]The tungsten oxide nanomaterial doped with lithium and potassium is ground and homogenized at high speed, and dispersed in ethanol under the action of a silane coupling agent to make a uniform 15wt% pre-dispersion;

[0053] Evenly disperse the pre-dispersion in proportion to 30wt% in the liquid resin, disperse at high speed for 1 hour, and make a transparent heat-insulating and energy-saving coating;

[0054] The above steps are carried out in a workshop with a cleanliness level of 10,000, the ambient humidity is controlled at 30-60%, and the ambient temperature is 25-30°C.

[0055] 2. Production of transparent nanocomposite sheet:

[0056] Material selection: select optical grade 2mm PET sheet;

[0057] Coating: Use coating equipment to coat PET sheets wit...

Embodiment 2

[0062] 1. Preparation of nano-transparent heat-insulating and energy-saving coatings:

[0063] Use PET resin with good transparency and good weather resistance to dissolve in methyl ester to make a liquid resin with a solid content of 40wt%;

[0064] Disperse tin-doped indium oxide nanomaterials in a solvent after high-speed grinding and homogenization to make a uniform 40wt% pre-dispersion;

[0065] Evenly disperse the pre-dispersion in proportion to 30wt% in the liquid resin, and disperse at high speed for 1 hour to make a transparent heat-insulating and energy-saving coating;

[0066] The above steps are carried out in a workshop with a cleanliness of 10,000 grades, the ambient humidity is controlled at 30-60%, and the ambient temperature is 25-30°C.

[0067] 2. Production of transparent nanocomposite sheet:

[0068] Material selection: select optical grade 0.1mm acrylic sheet;

[0069] Coating: Use coating equipment to coat the acrylic sheet with a transparent heat-insu...

Embodiment 3

[0074] 1. Preparation of nano-transparent heat-insulating and energy-saving coatings:

[0075] Adopt PC resin with good transparency and good weather resistance to be dissolved in toluene to make a liquid resin with a solid content of 25wt%;

[0076] The antimony-doped tin oxide nanomaterial is ground at high speed, homogenized, and dispersed in toluene under the action of a cellulose dispersant to prepare a uniform 30wt% pre-dispersion;

[0077] Disperse the pre-dispersion 20wt% evenly in the liquid resin, add an appropriate amount of polyurethane leveling agent, disperse at high speed for 3 hours, and make a transparent heat-insulating and energy-saving coating;

[0078] The above steps are carried out in a workshop with a cleanliness of 10,000 grades, the ambient humidity is controlled at 30-60%, and the ambient temperature is 25-30°C.

[0079] 2. Production of transparent nanocomposite sheet:

[0080] Material selection: select optical grade 1mmPC substrate sheet;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com