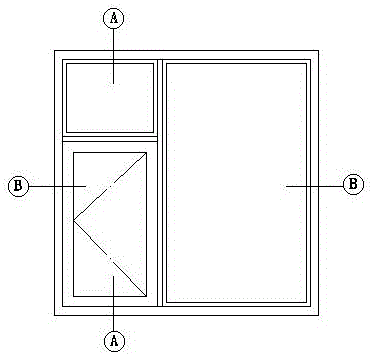

Double-cavity heat-insulating and temperature-preserving inward casement window structure

A technology of heat insulation and inner casement, which is applied in the arrangement of windows/doors, building components, and wing sashes, etc., which can solve the problem of reducing the heat transfer coefficient, changing the K value of the heat transfer coefficient by the heat insulation strip, and reducing the heat transfer coefficient. K value and other issues, to achieve the effect of strengthening the sealing effect, better and lasting thermal insulation effect, and improving the K value of the heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

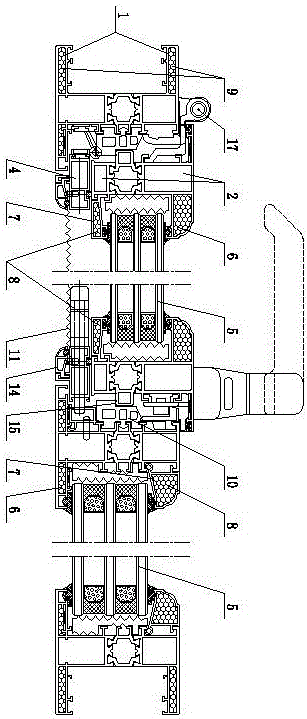

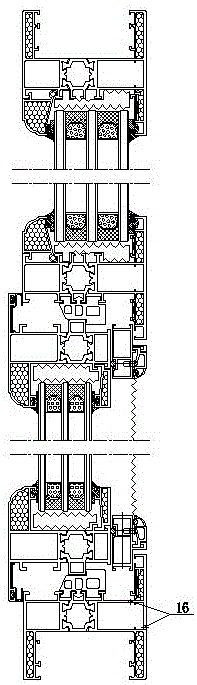

[0037] The window frame 1 and the sash profile 2 are connected together by an external hinge 17, the sash profile 2 and the glass 5 are provided with a thermal insulation cavity I6 at one side of the sash profile 2, and the other side of the sash profile 2 is fixed with the glass 5. The glass buckle 7, the fixed glass buckle 7 and the thermal insulation cavity II8 are arranged inside, and the thermal insulation cavity I6 and the thermal insulation cavity II8 are respectively arranged on both sides of the glass 5 to form a double-cavity structure. The thermal insulation cavity I6, the thermal insulation cavity II8, and the thermal insulation cavity III9 are filled with thermal insulation material, and the thermal insulation material is polyvinyl chloride foaming agent. The glass 5 is a hollow structure, and the outside of the glass 5 is provided with LOW-E low-emissivity coated glass. A rain-blocking rubber strip 10 is arranged inside the sash profile 2 . The window sash profi...

Embodiment 2

[0039] The window frame 1 and the sash profile 2 are connected together by a built-in invisible hinge 18, the window frame 1 and the sash profile 2 have no protruding edges, and the structure is more beautiful and compact. The joint end of the window sash profile 2 and the glass 5 is provided with a thermal insulation cavity I6, and the joint end of the window sash profile 2 and the glass 5 on the other side is provided with a fixed glass buckle 7, and the fixed glass buckle 7 and the inner heat preservation cavity are arranged. Cavity II8, insulation cavity I6 and insulation cavity II8 are respectively arranged on both sides of glass 5 to form a double cavity structure. The thermal insulation cavity I6, the thermal insulation cavity II8, and the thermal insulation cavity III9 are filled with thermal insulation material, and the thermal insulation material is polyvinyl chloride foaming agent. The glass 5 is a hollow structure, and the outside of the glass 5 is provided with LO...

Embodiment 3

[0041] The window frame 1 and the sash profile 2 are connected together by a built-in invisible hinge 18, the window frame 1 and the sash profile 2 have no protruding edges, and the structure is more beautiful and compact. The buckle 6 of the sash profile 2 and the buckle 6 on the other side form the sash profile 2 with the glass 5, and the window frame 1 forms a thermal insulation cavity III9 to form a double-cavity structure of the window frame. The glass 5 is a hollow structure, and the outside of the glass 5 is provided with LOW-E low-emissivity coated glass. A rain-blocking rubber strip 10 is arranged inside the sash profile 2 . The window sash profile 2 is connected to the heat insulation strip 15 of the combined window sash and the rain-proof rubber strip 10 is in close contact with each other. Described gauze curtain 11 is or nylon mesh. Described gauze curtain 11 is installed on the nylon gauze fan 12. A drainage hole 16 is provided on the window frame 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com