Inorganic thermal insulation material for wall

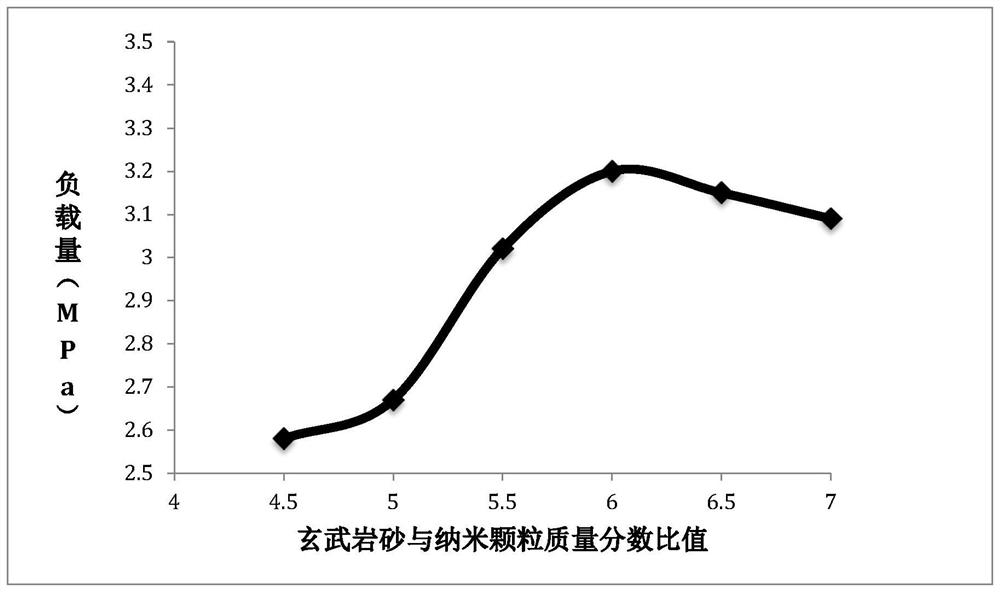

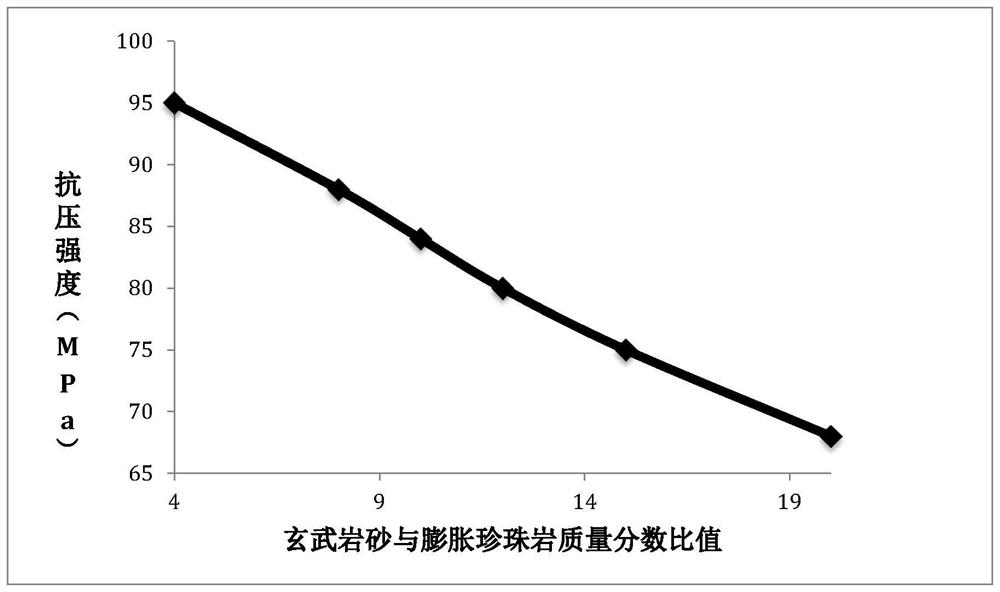

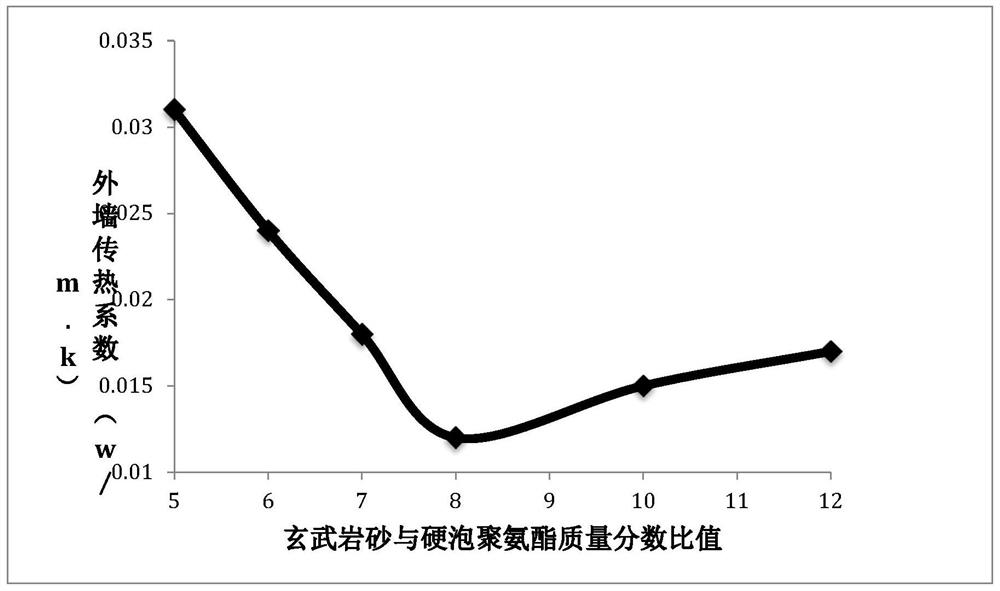

A thermal insulation and wall technology, which is applied in the application fields of inorganic wall thermal insulation materials and thermal insulation materials, can solve the problem that the K value of the heat transfer coefficient cannot meet the requirements of ultra-low energy consumption buildings, etc., and achieves the elimination of harmful chemical substances, The effect of increasing the load and surface area and reducing the K value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 Rock wool material preparation steps

[0048] (1) Take 60 parts of basalt sand, melt it at a high temperature above 1450°C, and then use a four-axis centrifuge to form fibers at high speed, and cool it to below 200°C for later use;

[0049] (2) Take 8 parts of binder, 5 parts of dustproof oil, and 10 parts of water repellent, spray them into the fibers after centrifugal cooling and stir them evenly;

[0050] (3) Take 8 parts of aluminum hydroxide, 10 parts of nanoparticles, 15 parts of expanded perlite, 7.5 parts of rigid polyurethane foam, 4 parts of polymer bonding mortar, 5 parts of thermal insulation mortar, 7 parts of polymer plastering anti-cracking mortar, water 10 parts, put into a blender and stir evenly for later use;

[0051] (4) Add the mortar mixture in step (3) to the fiber mixture in step (2) in batches and stir evenly, and put it into the mold after mixing;

[0052] (5) The formed rough plate is dried in an oven at 220°C for more than 4 ho...

Embodiment 2

[0054] Embodiment 2 Adhesive preparation steps

[0055] (1) Take 20 parts of red algae, add double 4% sodium hydroxide solution to soak for 2.5 hours, and heat to 100°C, stir while heating, and adjust the pH to neutral with water after 2.5 hours;

[0056] (2) Take 60 parts of corn starch, add an equal amount of 35% sodium hydroxide solution and 30% hydrogen peroxide solution to it, heat to 65°C, and react for 1.5 hours. After the reaction, the cassava flour is prepared with water to make the pH neutral;

[0057] (3) Put the treated red algae slurry and cornstarch into a blender, add 30-35 parts of water, heat while stirring, heat to 65°C and keep it for 3 hours, adjust the pH to 6.8±0.1 with acetic acid , and filtered to obtain a clear glue solution.

[0058] The experimental results showed that when the mass ratio of red algae and corn starch was 1:3, the viscosity was the largest.

Embodiment 3

[0059] Example 3 Preparation steps of polymer bonded mortar

[0060] (1) Take 0.028 parts of disperse latex powder and 0.005 part of methyl cellulose ether respectively, divide the disperse latex powder into 4 parts evenly, then stir 0.005 part of methyl cellulose ether with one part of disperse latex powder evenly, and then Stir well with the other three parts of dispersed latex powder for later use;

[0061] (2) Take 1 part of cement and 1.5 parts of medium sand and mix them evenly for later use;

[0062] (3) Evenly divide the mixture of cement and medium sand into 10 parts, and then pour one part into the mixer for stirring. During the stirring process, spray the mixture of dispersed latex powder and methyl cellulose ether into it, and make it mix with the mixer. The mixture of cement and medium sand is mixed evenly;

[0063] (4) Then add another 9 parts of the mixture of cement and medium sand to the mixer in turn, and the amount added each time should not exceed 1 / 5 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com