High-shading-coefficient PC/GF (polycarbonate/glass fiber) composite material and preparation method thereof

A composite material, high shading technology, applied in the field of polymer materials, can solve the problems of not being able to give full play to the advantages of polycarbonate glass fiber composite materials, less research, etc., and achieve the effects of high strength, improved weather resistance, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

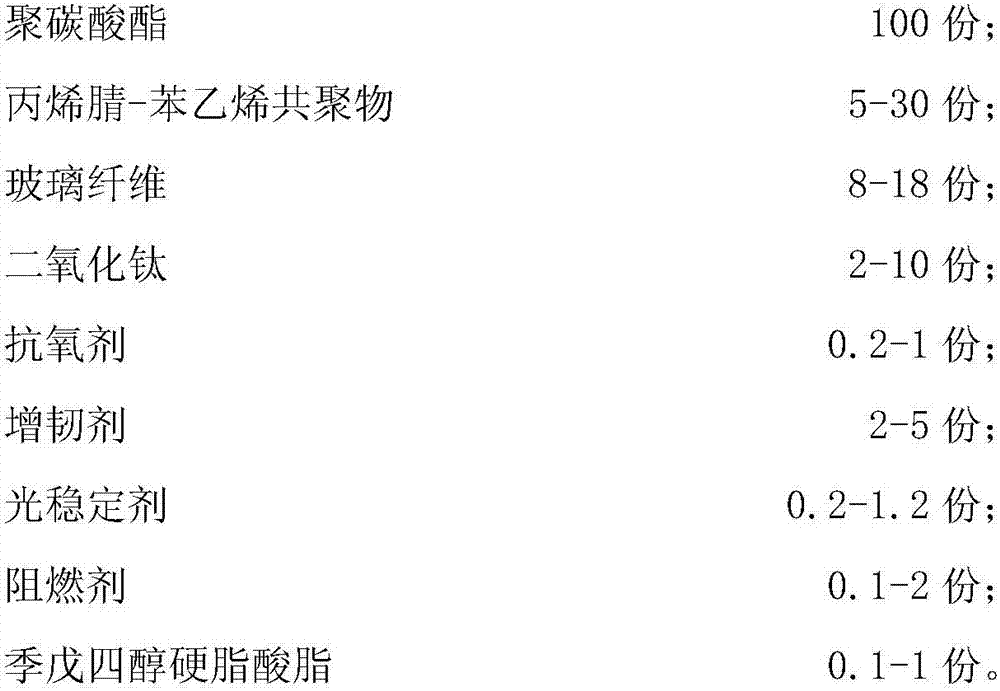

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Preparation of polycarbonate glass fiber composite material

[0025] 1) Weigh the required raw materials in proportion;

[0026] 2) Place the polycarbonate in an oven at 110°C for 24 hours, place the acrylonitrile-styrene copolymer in an oven at 80°C for 4 hours, place titanium dioxide in an oven at 110°C for 12 hours, and place glass fibers in an oven at 110°C for 12 hours. , After drying, place it in a vacuum sealing machine to seal for later use;

[0027] 3) Mix polycarbonate, acrylonitrile-styrene copolymer, antioxidant, toughening agent, light stabilizer, flame retardant, and pentaerythritol stearate in a high-speed mixer for 3-5 minutes, and then mix the glass fiber Add to the high-speed mixer and mix for 2 minutes; the rotation speed is 1150rpm;

[0028] 4) After being evenly mixed, it is sent to the twin-screw extruder, and melted and kneaded for at least 2min at a speed of 400rpm and a temperature of 240℃-290℃;

[0029] 5) After mixing, extrusion is cooled i...

Embodiment 2

[0046] Example 2: Performance test of composite materials

[0047] Product performance test, the results are shown in Table 2;

[0048] Table 2:

[0049] Material performance

unit

Recipe 1

Recipe 2

Recipe 3

Recipe 4

Recipe 5

Recipe 6

Tensile Strength

ISO527

Mpa

64

71

67

58

61

68

Elongation at break

ISO527

%

105

95

98

101

104

110

Bending strength

ISO178

Mpa

108

124

115

106

84

102

Notched impact strength

ISO179-2

Kj / m 2

28

42

38

34

28

62

Rockwell hardness

ISO2039-2

R-scale

108

124

126

122

98

122

1.0mm transmittance

GB / T2410

%

18

14

15

20

12

87

[0050] According to the mechanical performance test results shown in Table 1, it can be seen that the comprehensive mechanical properties of formula 2 or formula 3 are better. Compared with pure polycarbonate, the notched impact strength of the composite material is lower, because with the content of glass fiber and titanium dioxide Increase, its notched impact strength will be significantly reduced. Although the remaining mechanica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com