Blind in hollow glass

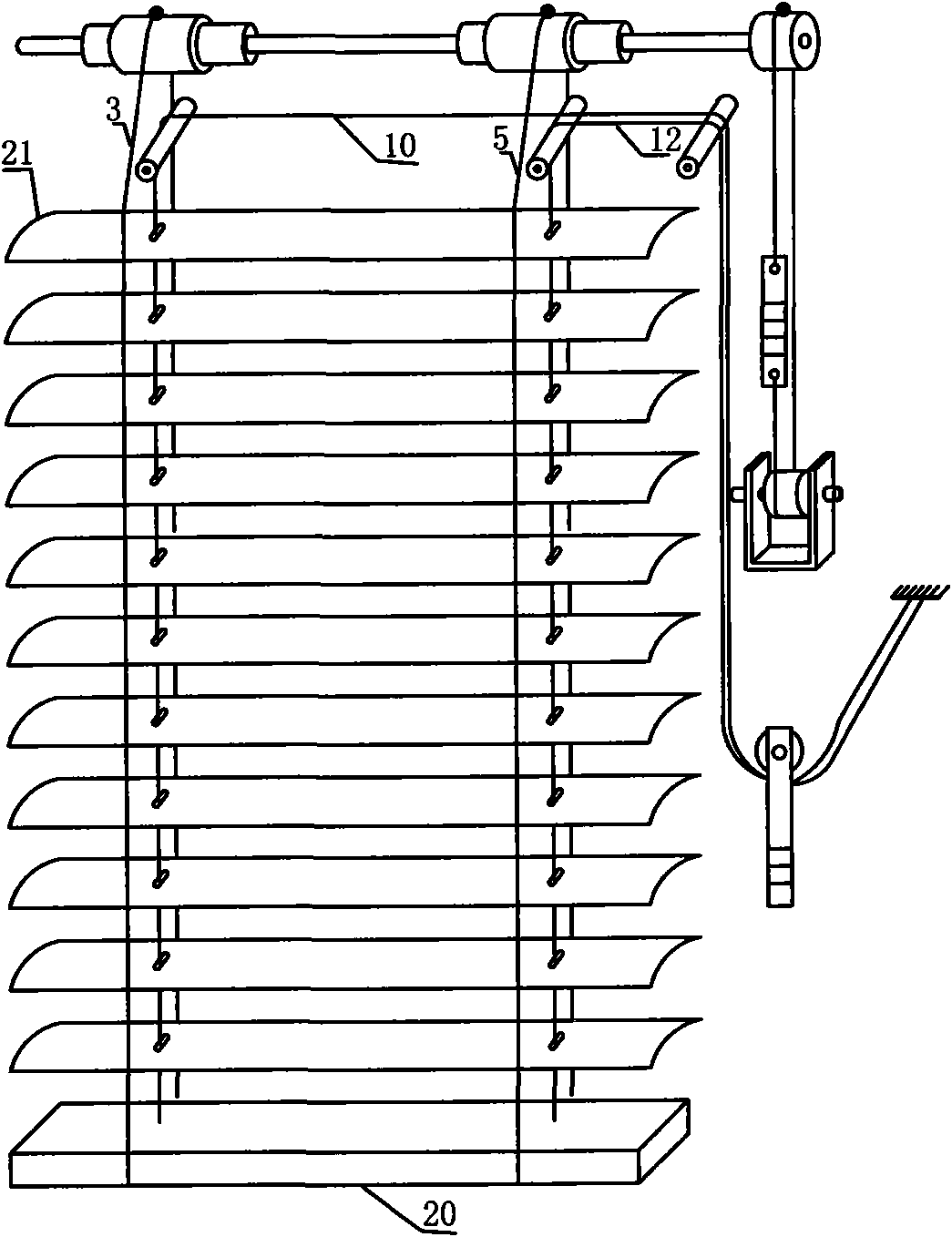

A louver and glass technology, applied in the field of louvers, can solve the problems of incomplete overturning of the counterweight bottom beam 20, poor shading performance, shading coefficient and thermal insulation performance of hollow louver glass, etc., and achieve good energy-saving performance, high shading performance, and turning over smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

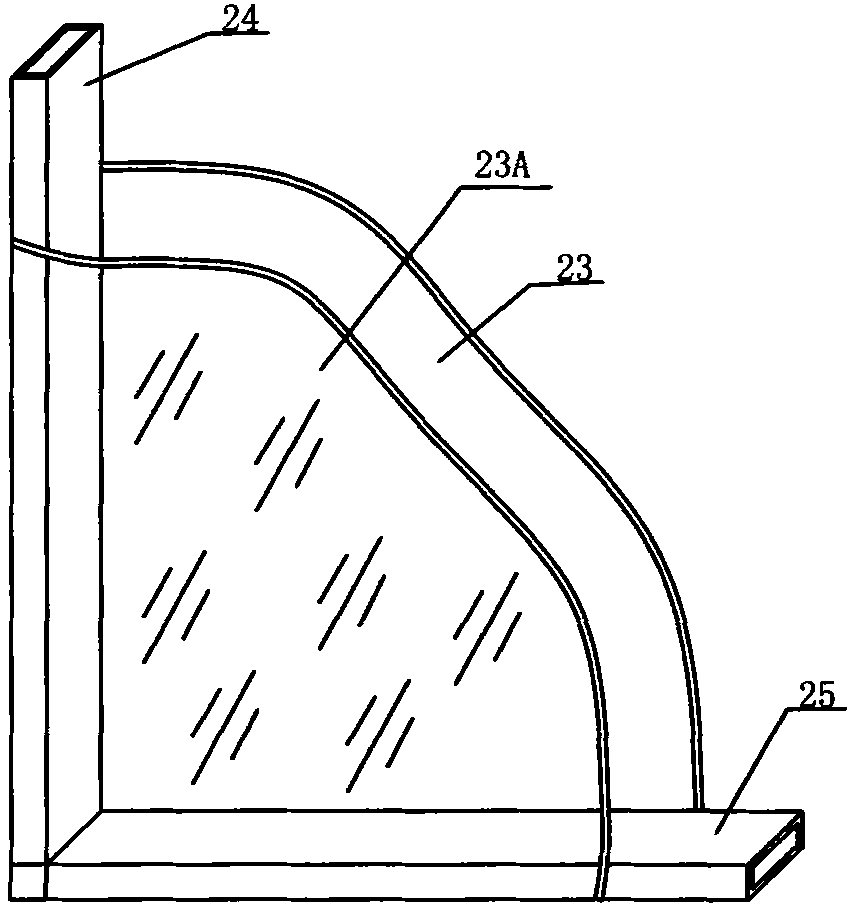

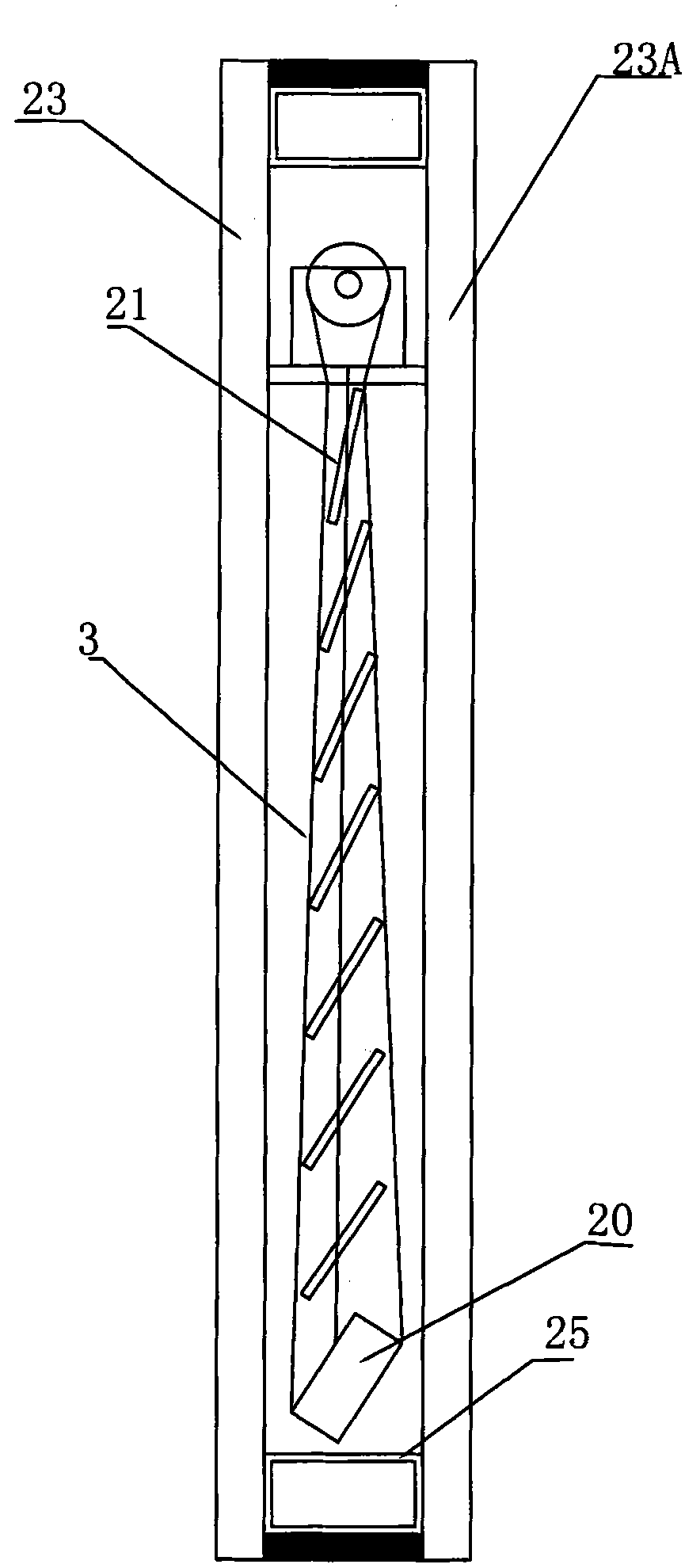

[0020] Figure 2A It is a schematic diagram of the structure of an embodiment of the present invention, and only shows the part of the blinds in the hollow glass. The figure shows the blinds installed in the hollow glass in the space enclosed by the outdoor side glass 23, the indoor side glass 23A and the frame 24. The structure of outdoor side glass 23, indoor side glass 23A and frame 24 see Figure 1A The present invention does not change these structures. See again Figure 2A The upper and lower long shafts 1 of the shutter body are respectively fixed on the frame 24, and each long shaft 1 is provided with a set of coaxial friction wheels 2, 4. The steering ropes 3 and 5 are connected to each other head and tail respectively, and are respectively wound on the upper and lower friction wheels 2, 4 and fixed, and are fixed to the two long sides of each blade 21 at the front and rear to form two closed rope sets. . The upper and lower steering wheels 6 are respectively arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com