Cleaning device in indirect air cooling tower

A technology for cleaning devices and air cooling towers, which is applied to cleaning heat transfer devices, flushing, lighting and heating equipment, etc. It can solve the problems of long cleaning cycle, high work intensity, and heavy structure, so as to improve cleaning quality and efficiency, and increase power generation Efficiency, the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

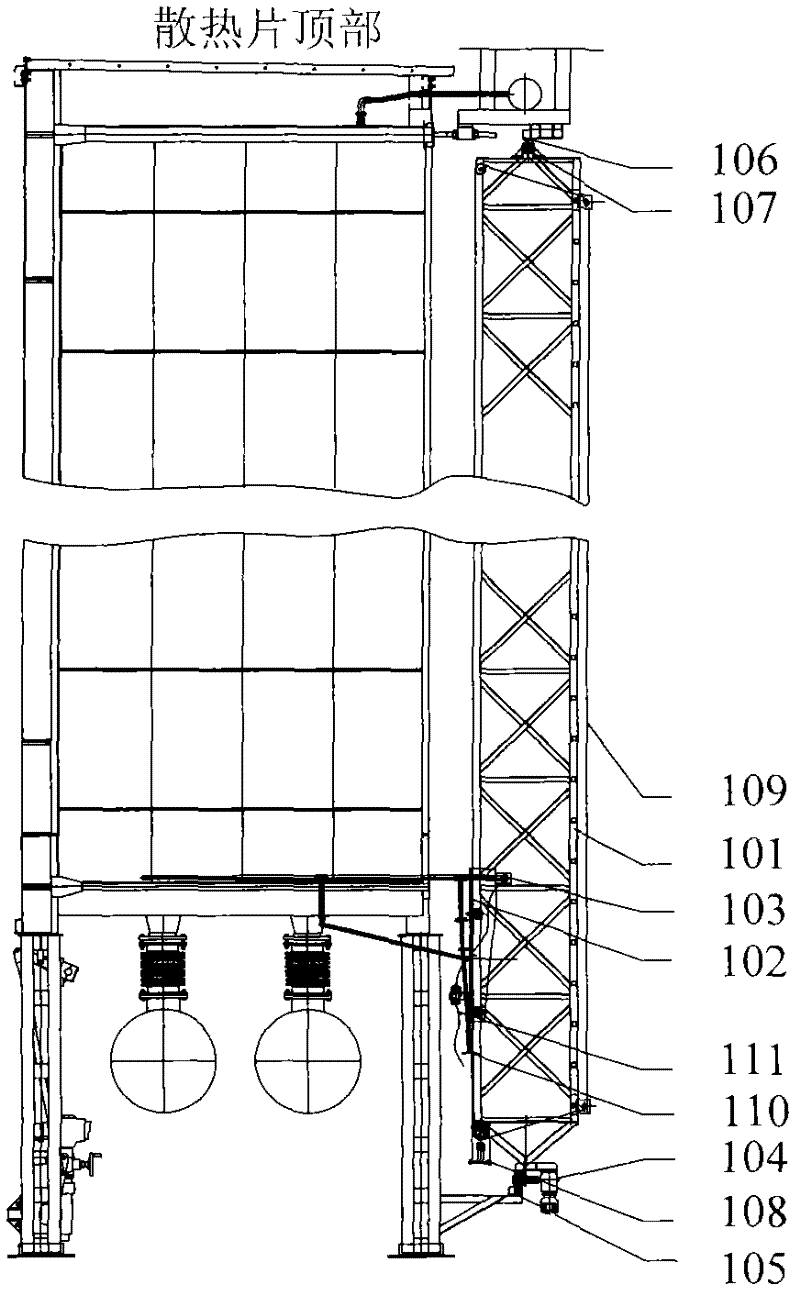

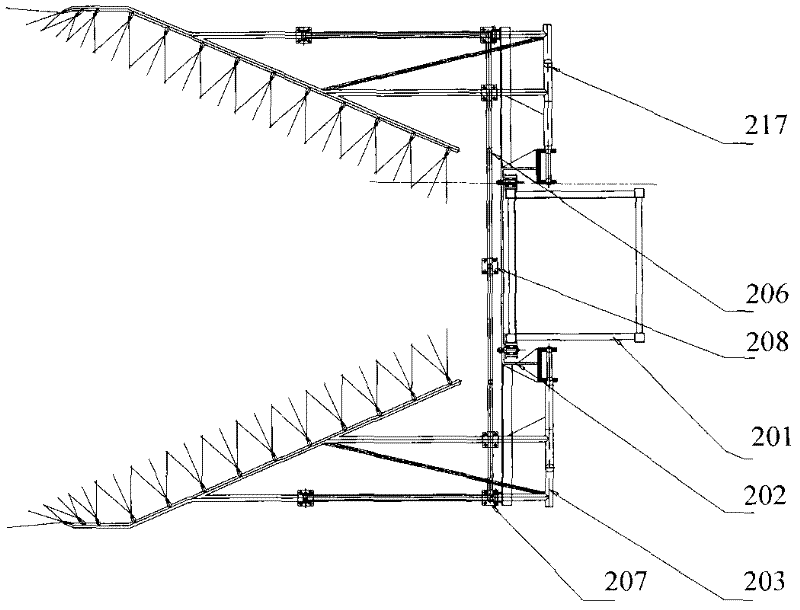

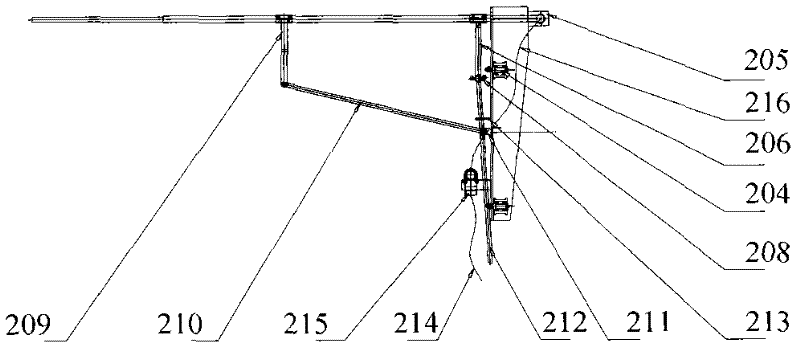

[0046] figure 1 It is a schematic diagram of the overall structure of the cleaning device in the indirect air-cooling tower of the present invention. As shown in the figure, the cleaning device in the indirect air-cooling tower of this embodiment includes a cleaning ladder 101, a transverse traveling mechanism, a nozzle tray 103, a longitudinal traveling mechanism and a cleaning pipe road. Among them, the horizontal walking mechanism is self-driven by the lower rail; the longitudinal walking mechanism includes a walking trolley 102 and a lifting drive 108, the nozzle frame 103 is fixed on the walking trolley 102, and the walking trolley 102 moves up and down on the cleaning ladder 101 through the lifting drive 108. Self-propelled; the nozzle tray 103 is arranged in a surrounding triangle, and it extends into the triangular unit formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com