Turnover device of solar battery assembly

A technology of solar cells and flipping devices, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low automation integration, increased probability of machine breakage, and poor compatibility, so as to improve automation integration, avoid pollution and broken, The effect of short action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

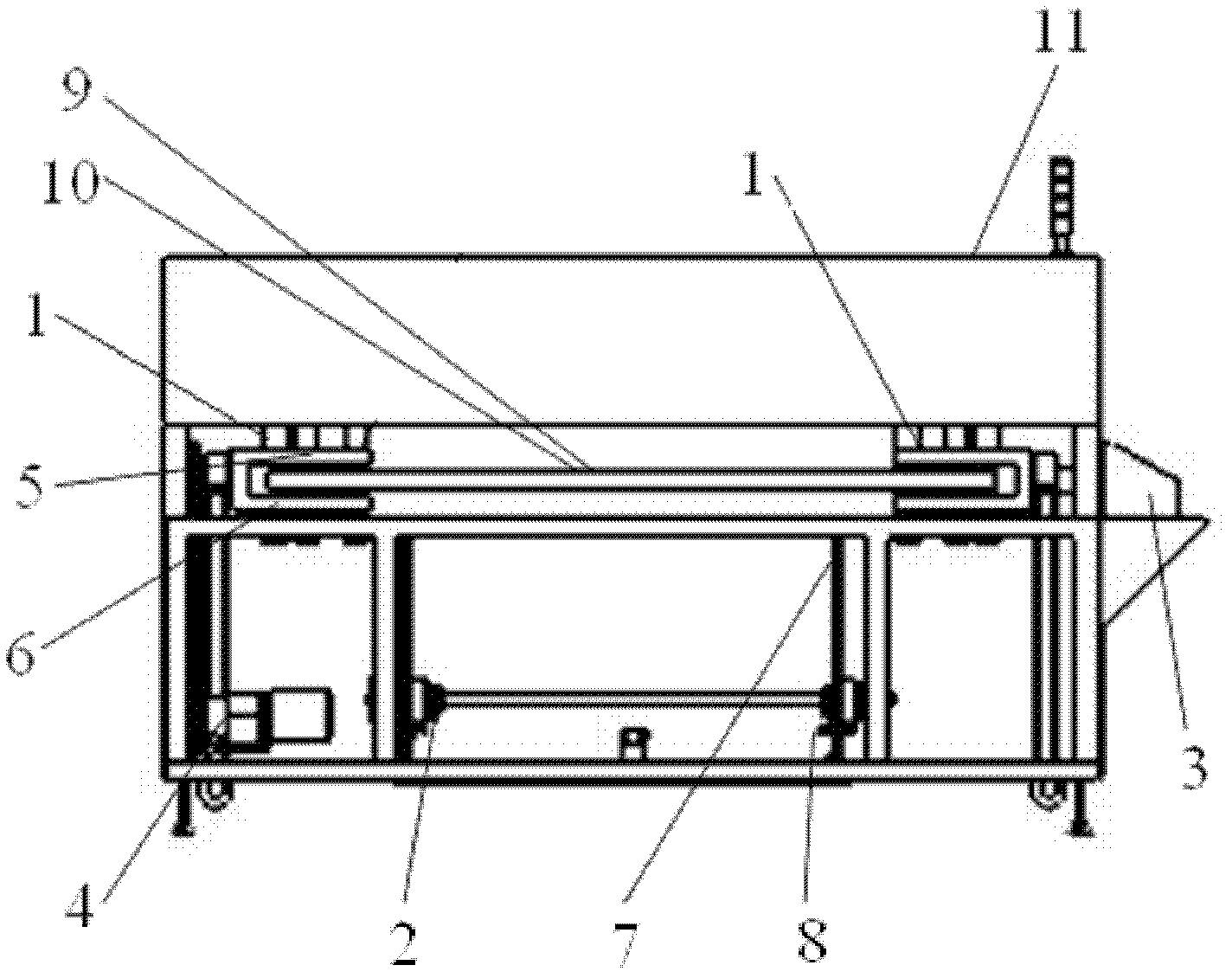

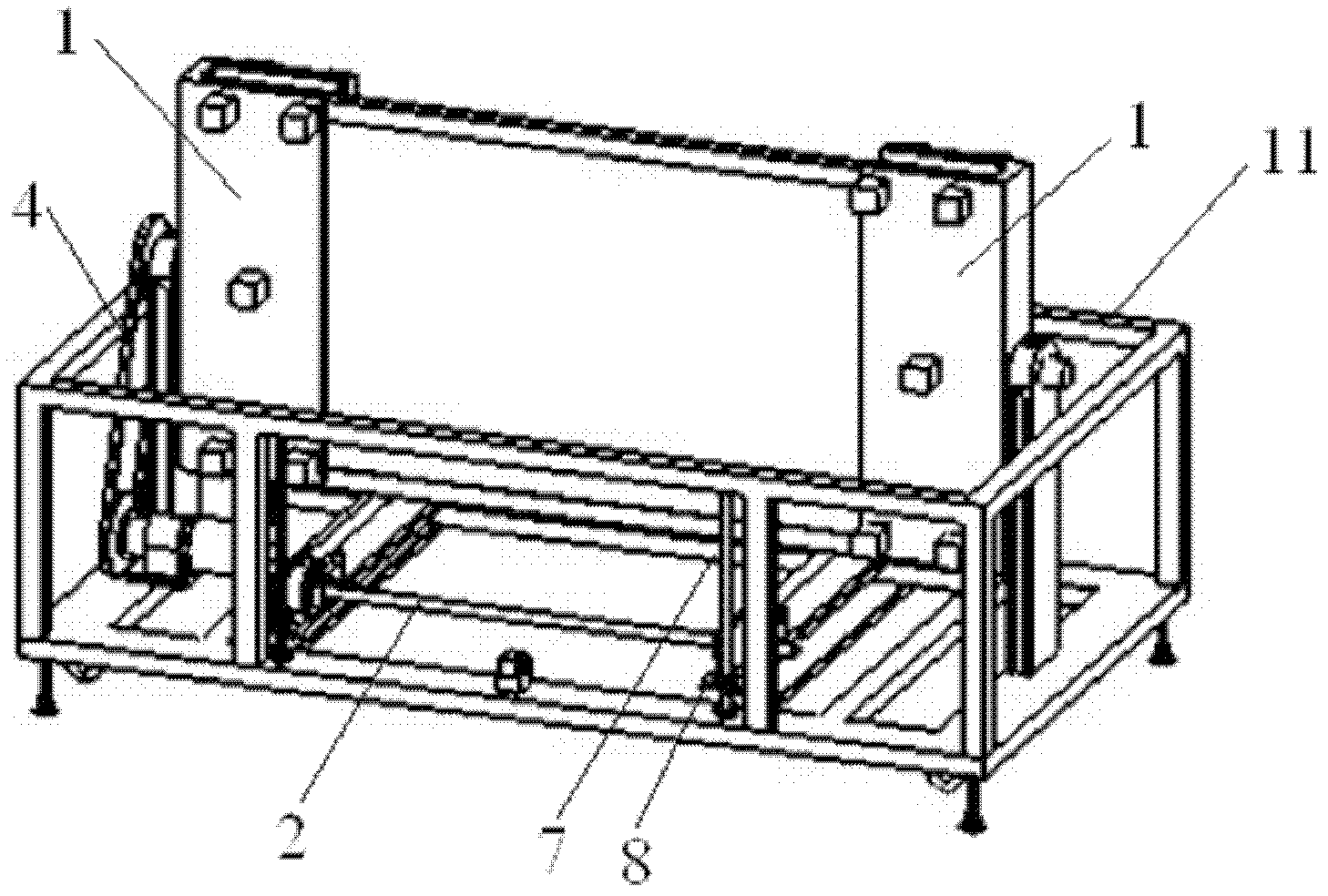

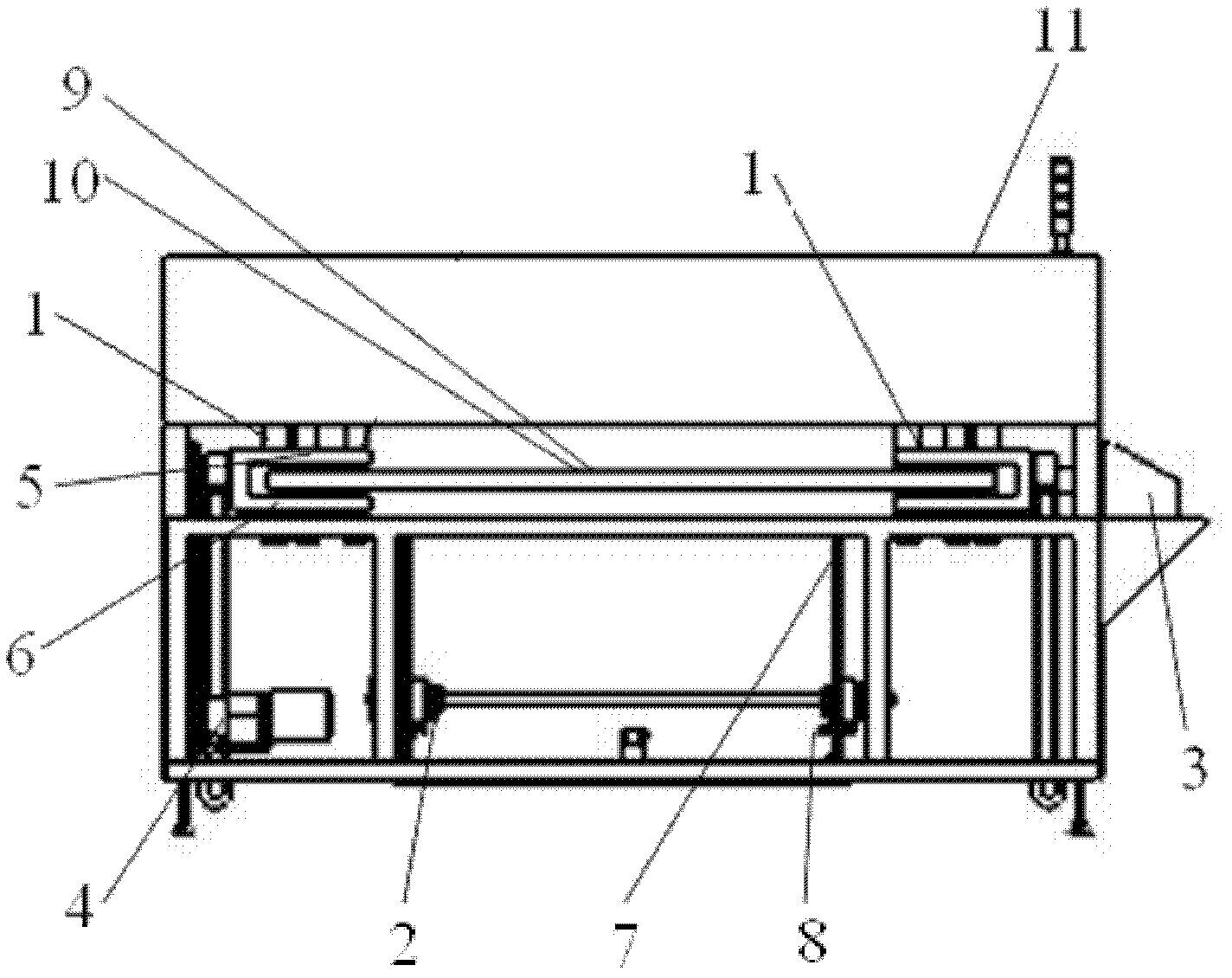

[0025] A flipping device for a solar cell module, the structure of which is as follows Figure 1~2 As shown, the overturning device includes a clamping overturning mechanism 1, a conveyor belt lifting mechanism 2, a control system 3, a sprocket drive mechanism 4, an upper limit position sensor 7, a lower limit position sensor 8, and a protective outer frame 11. The clamping overturning mechanism 1 is two Two semi-frame structures are respectively arranged on both sides of the device to form a holder for holding solar cell modules. A first clamping sensor 5 and a second clamping sensor 6 are installed on the inner side of the clamping turning mechanism 1 , and a first component judging sensor 9 and a second component judging sensor 10 are installed on the outer side. The sprocket drive mechanism 4 and the conveyor belt lifting mechanism 2 are located below the clamping and turning mechanism 1, and the sprocket driving mechanism 4 is connected with the sprocket wheel of the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com