Automatic loading device for horizontal electric upsetting machine

A technology of automatic feeding and electric upsetting machine, which is applied in the direction of operating devices, forging/pressing/hammer devices, metal processing equipment, etc., can solve the problems of excessive labor, narrow scope of application, complex structure, etc., and achieve less working space, The effect of simple mechanism and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

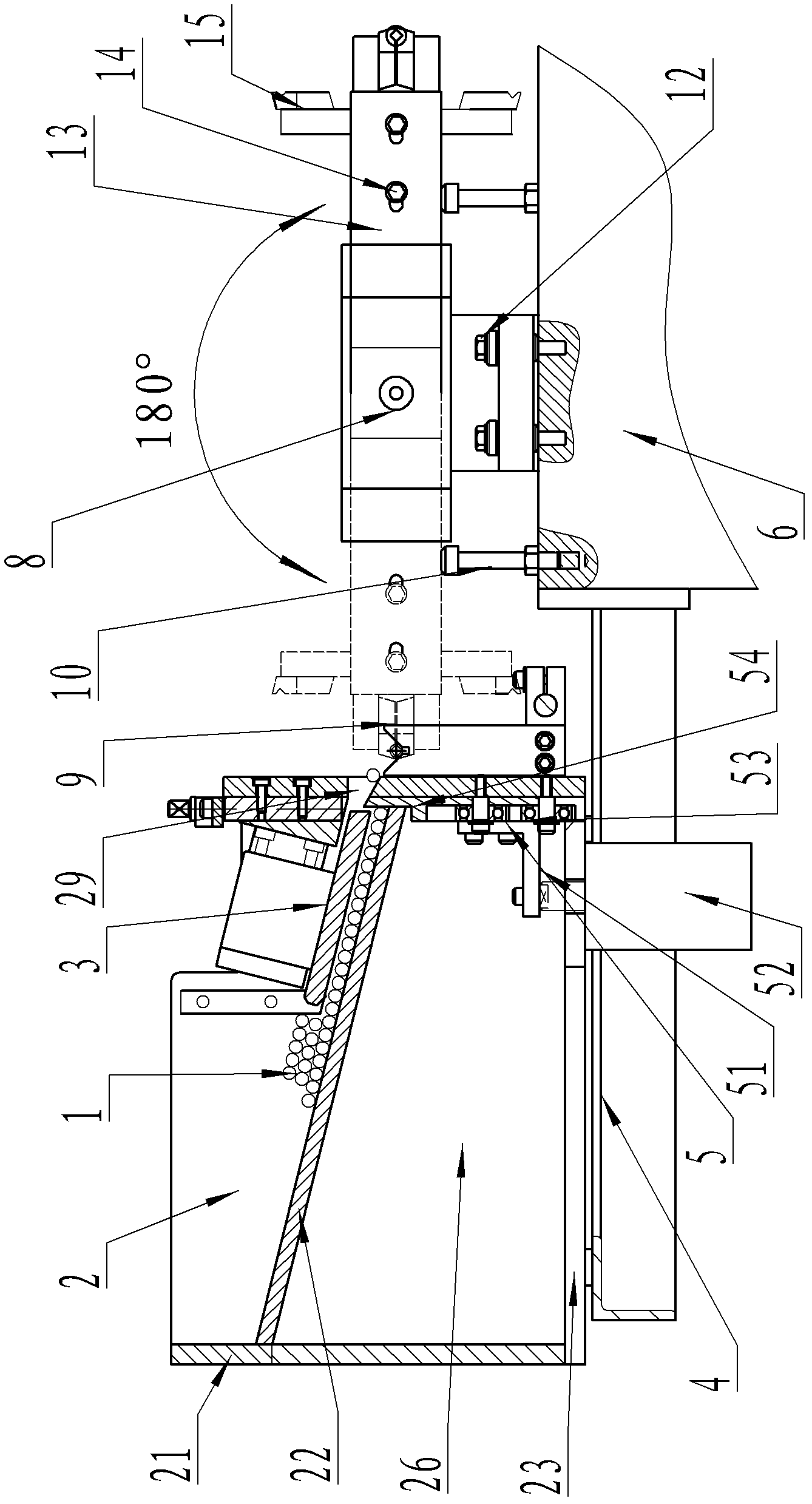

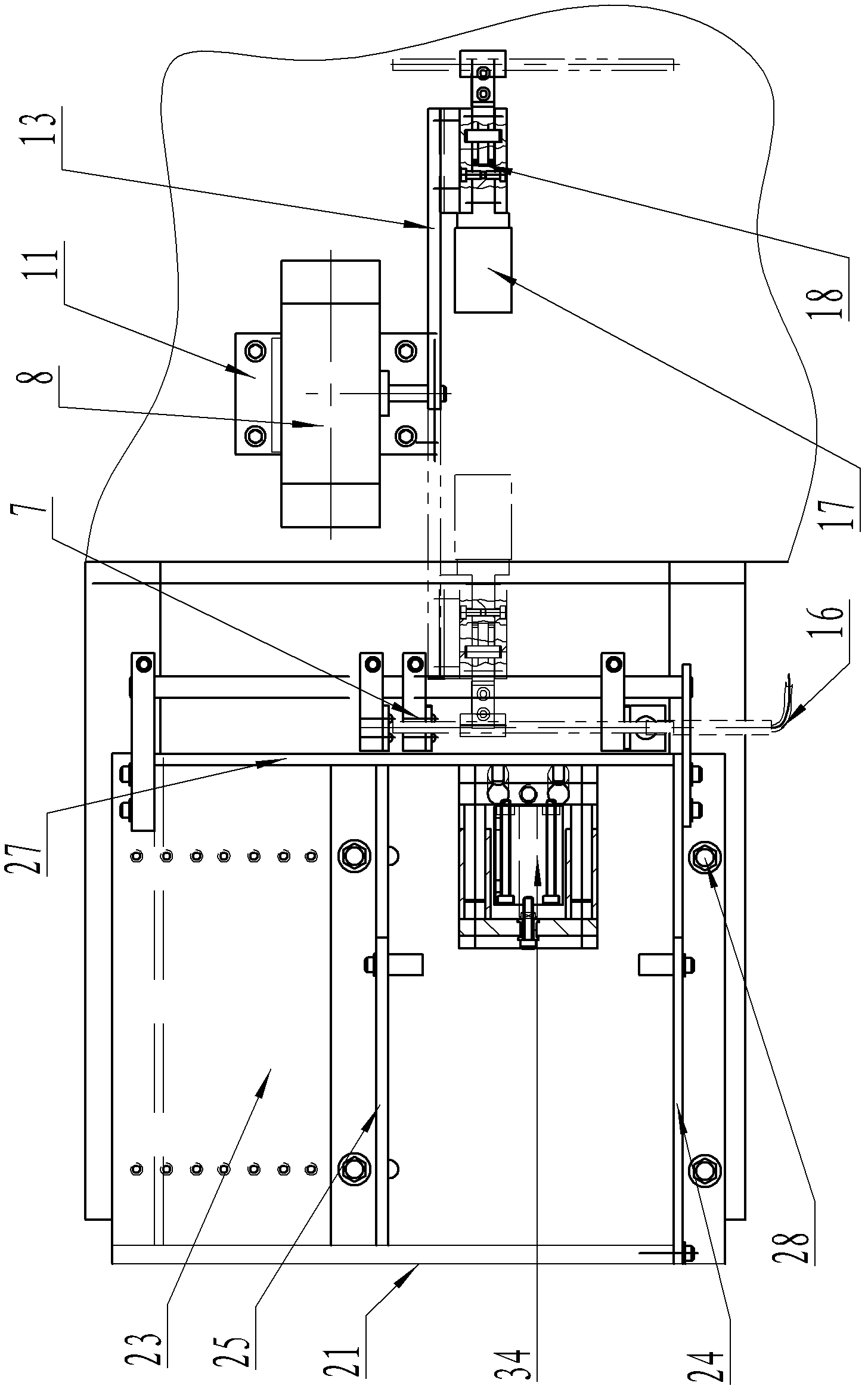

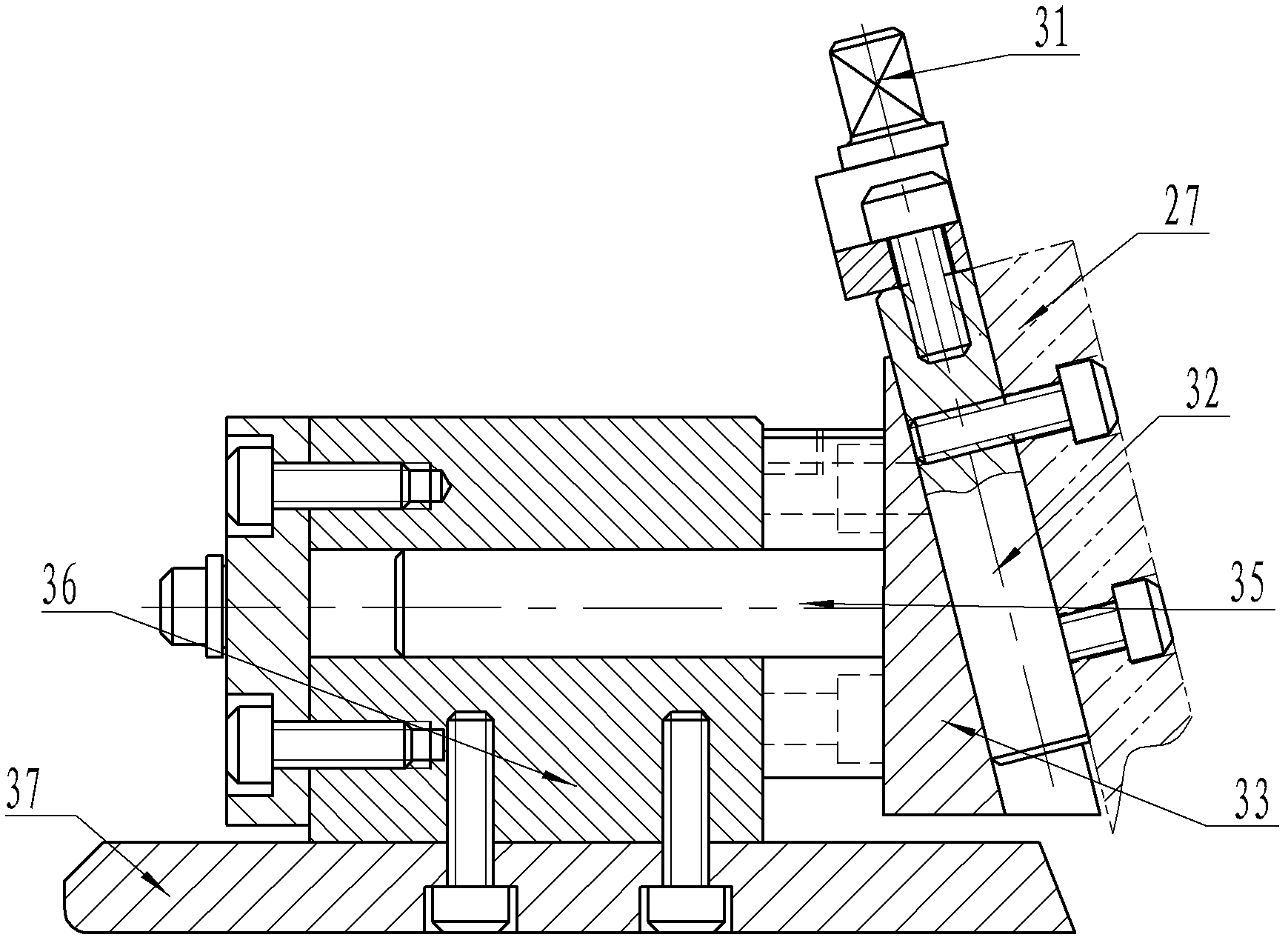

[0024] Embodiment 1, an automatic feeding device for a horizontal electric upsetting machine, is characterized in that: a material box 2 installed on the frame 4, a material receiving mechanism 7 fixed on the material box below the outlet of the material box It is composed of a feeding mechanism with a mechanical claw 9 that is driven by a rotary cylinder 8 and can rotate 180 degrees and is installed on the panel 6 of the electric upsetting machine.

[0025] An inclined upper plate 22 for placing bars is provided in the feed box, and a supporting steel plate 54 is provided on the inner side of the feed box front plate 27 below the feed box outlet 29,

[0026] The rotary cylinder of the feeding mechanism is installed on the panel of the electric upsetting machine through the adjustable cylinder seat plate 11, the output shaft of the rotary cylinder is equipped with a rocker arm 13, and the rocker arm adjustment bolt 14 is used to fix the mechanical claw adjustment arm on the roc...

Embodiment 2

[0027] Embodiment 2, an automatic feeding device for a horizontal electric upsetting machine, is characterized in that: a material box 2 installed on the frame 4, a material receiving mechanism 7 fixed on the material box below the outlet of the material box It is composed of a feeding mechanism with a mechanical claw 9 that is driven by a rotary cylinder 8 and can rotate 180 degrees and is installed on the panel 6 of the electric upsetting machine.

[0028] An inclined upper plate 22 for placing bars is provided in the feed box, and a supporting steel plate 54 is provided on the inner side of the feed box front plate 27 below the feed box outlet 29,

[0029] The rotary cylinder of the feeding mechanism is installed on the panel of the electric upsetting machine through the adjustable cylinder seat plate 11, the output shaft of the rotary cylinder is equipped with a rocker arm 13, and the rocker arm adjustment bolt 14 is used to fix the mechanical claw adjustment arm on the roc...

Embodiment 3

[0032] Embodiment 3, an automatic feeding device for a horizontal electric upsetting machine, is characterized in that: the material box 2 installed on the frame 4 is located below the material box outlet and fixed on the material box 7 It is composed of a feeding mechanism with a mechanical claw 9 that is driven by a rotary cylinder 8 and can rotate 180 degrees and is installed on the panel 6 of the electric upsetting machine.

[0033]An inclined upper plate 22 for placing bars is provided in the feed box, and a supporting steel plate 54 is provided on the inner side of the feed box front plate 27 below the feed box outlet 29,

[0034] The rotating cylinder of the feeding mechanism is installed on the panel of the electric upsetting machine through the cylinder seat plate 11, the output shaft of the rotating cylinder is equipped with a rocker arm 13, and the adjusting arm adjusting bolt 14 is used to fix the mechanical claw adjusting arm 18 on the rocking arm. Arm front end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com