Dual-counterweight mechanical arm for conveniently grabbing workpiece

A technology for manipulators and workpieces, applied in the field of manipulators, can solve problems such as jamming, waste of human resources, manual spotting, etc., and achieve the effects of convenient and accurate alignment, improving work efficiency and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention can be explained in more detail with reference to the following examples; however, the present invention is not limited to the combination of these examples.

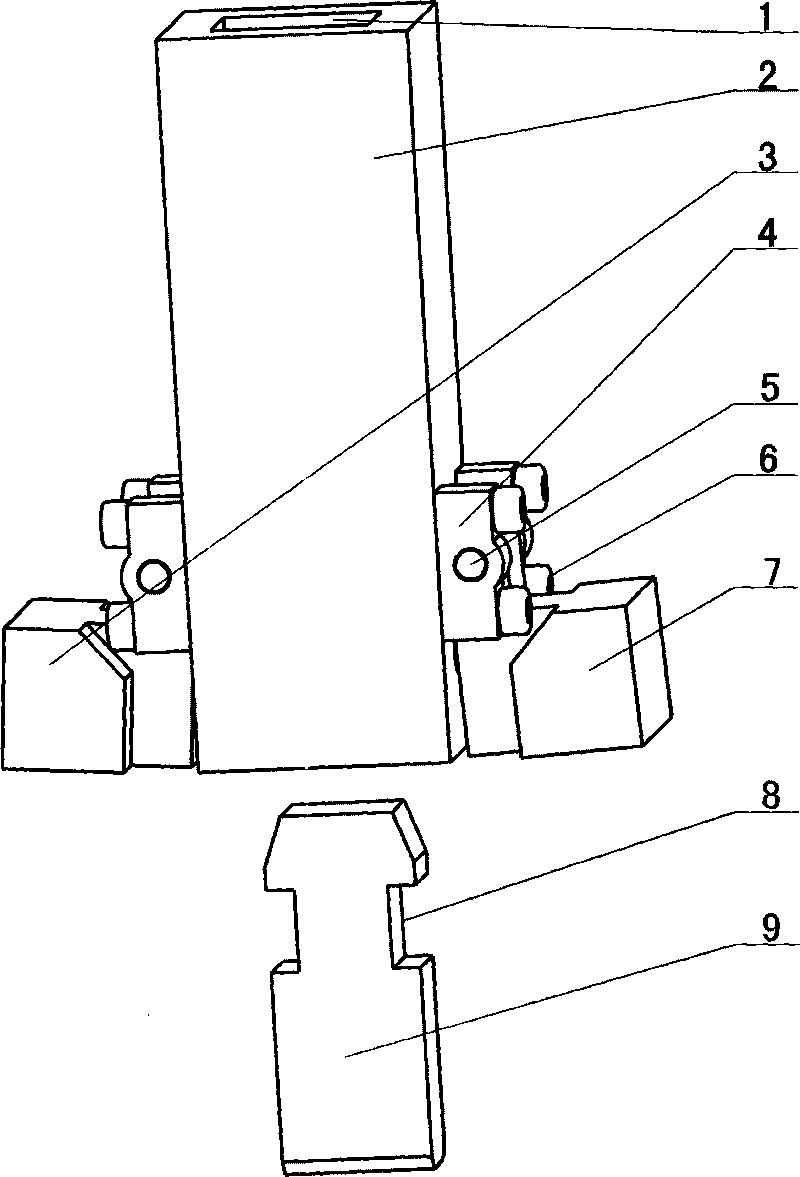

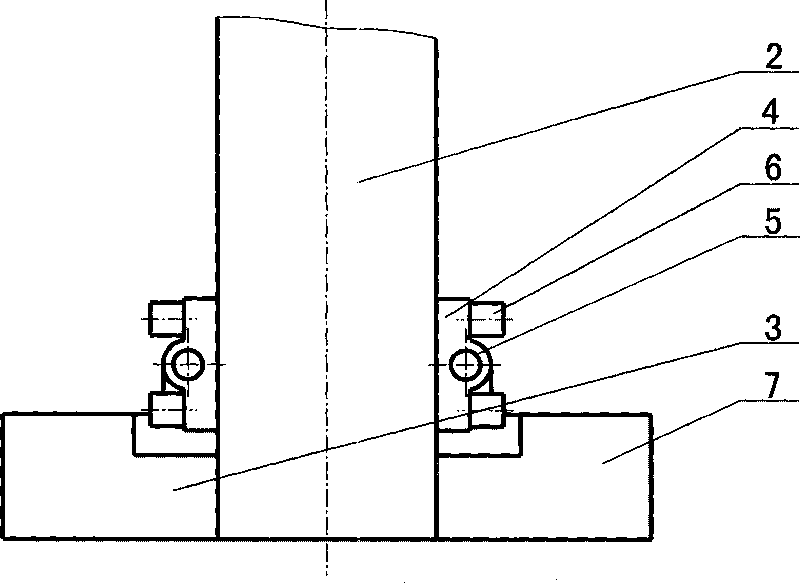

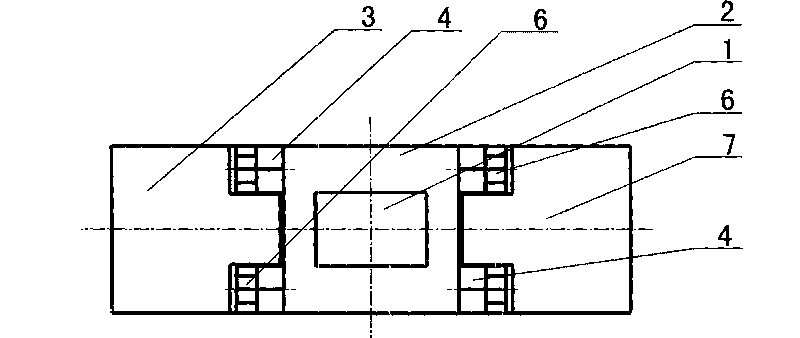

[0015] exist figure 1 , 2 , 3 middle; a double counterweight manipulator for grabbing workpieces conveniently, comprising: outer cover 2, manipulator clamping part A3, clamping part rotating pin fixing seat 4, pin shaft 5, screw 6, manipulator clamping part B7 and The workpiece 9; each side of the lower part of the jacket 2 is respectively provided with a pair of clamping member rotating pin fixing seats 4, and the clamping member rotating pin fixing seats 4 are fixed on the upper tongue-shaped clamping member at the lower part of the jacket 2 by screws 6 On both sides of the working hole of the protrusion 10, the pin shaft 5 arranged on the gripper B7 of the manipulator and the gripper A3 of the manipulator is fixedly arranged on both sides of the overcoat 2 by the rotating pin holder 4 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com