Laminated glass and manufacturing method thereof

A laminated glass and glass technology, applied in chemical instruments and methods, glass/slag layered products, lamination, etc., can solve the problems of laminated glass safety and no energy-saving effect, so as to save energy, realize heat transfer coefficient, and ensure safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

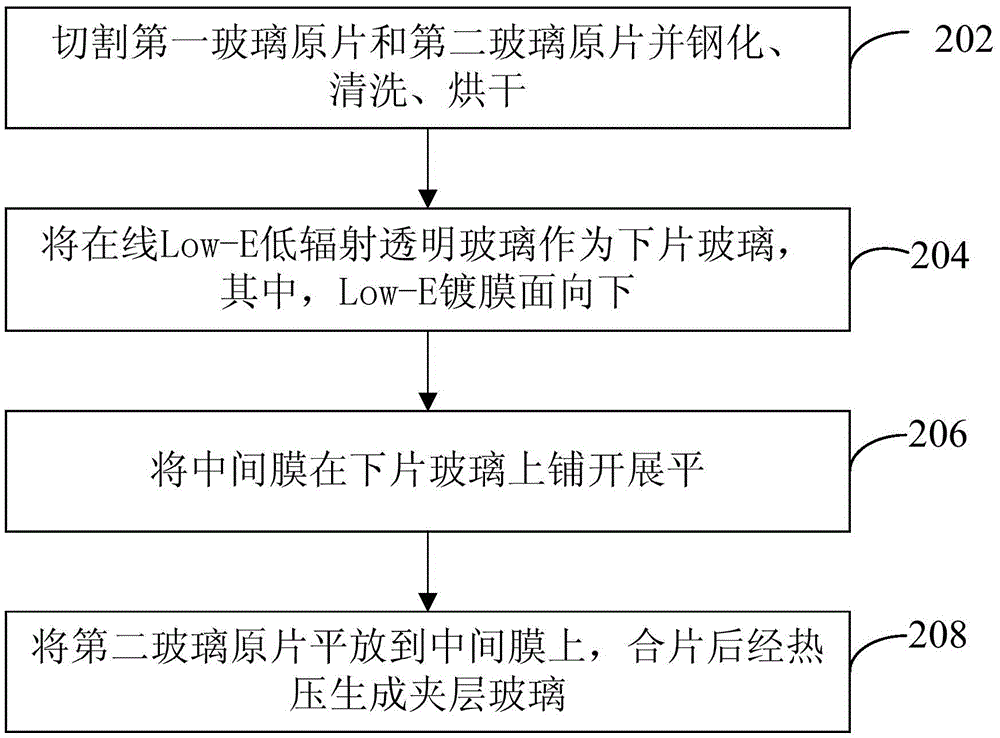

[0020] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

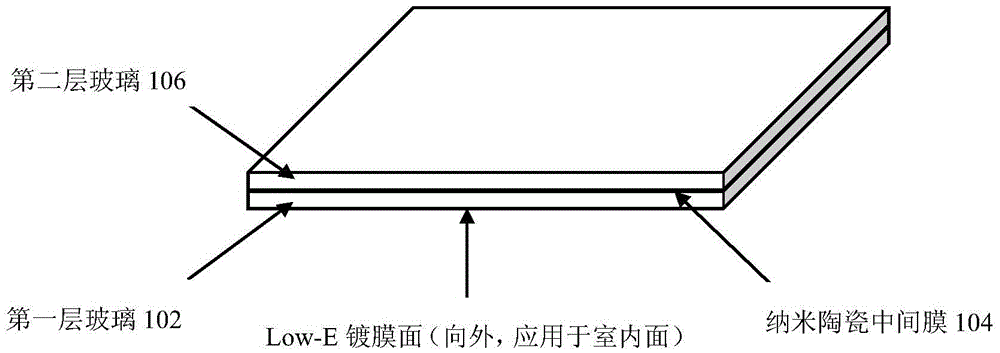

[0021] figure 1 A structural schematic diagram of a laminated glass according to an embodiment of the present invention is shown, as figure 1 As shown, the laminated glass of the present invention includes: a first layer of glass 102, a second layer of glass 106, and an interlayer film 104 between the two layers of glass.

[0022] Wherein, the first layer of glass 102 is online Low-E low-emission transparent glass, the second layer of glass 106 is ordinary transparent glass or toughened glass, and the intermediate film 104 is a modified PVB film doped with tungsten oxide nano-ceramic material. Among them, the modified PVB film mixed with tungsten oxide nano-ceramic material has the effect of blocking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com