Medical chemical-resistant transparent polycarbonate composition and preparation method thereof

A technology of polycarbonate and chemical resistance, which is applied in the field of medical chemical-resistant transparent polycarbonate composition and its preparation, can solve the problem that the quality management system cannot meet the requirements of medical device risk management, stress relief is not good, and cannot meet the requirements Dimensional requirements and other issues, to achieve the effect of retaining dimensional accuracy, improving dimensional accuracy and chemical resistance, and excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

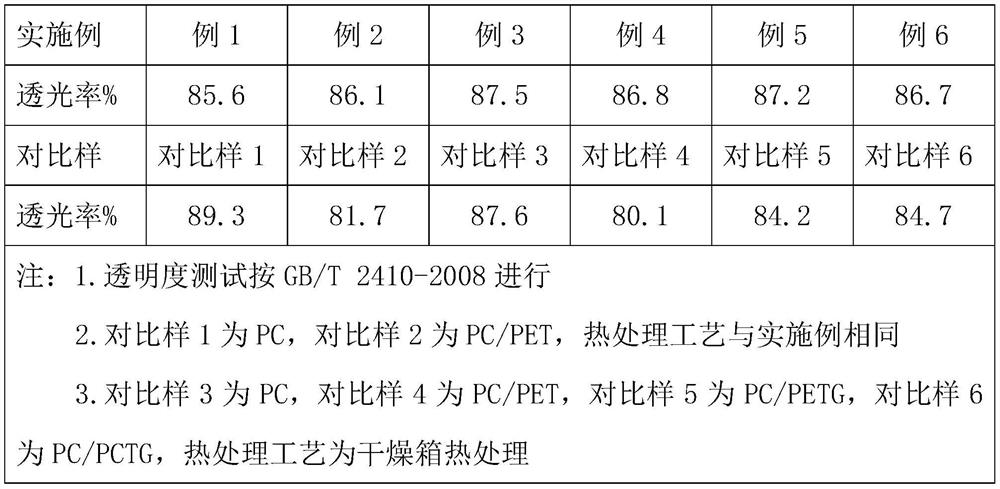

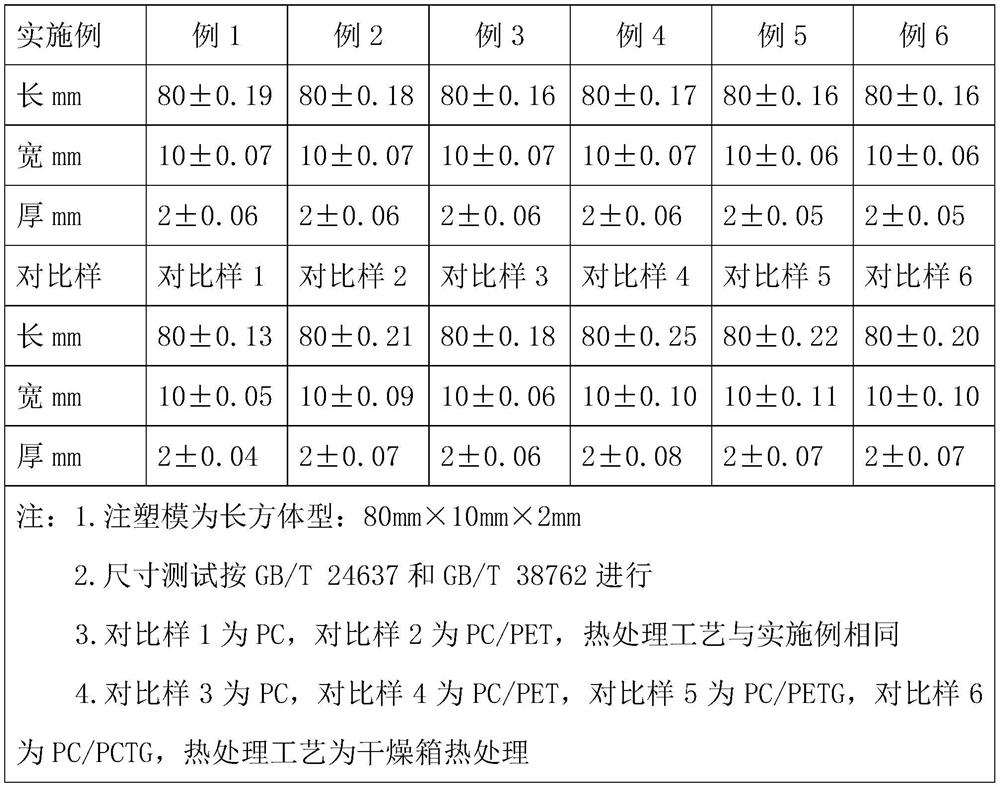

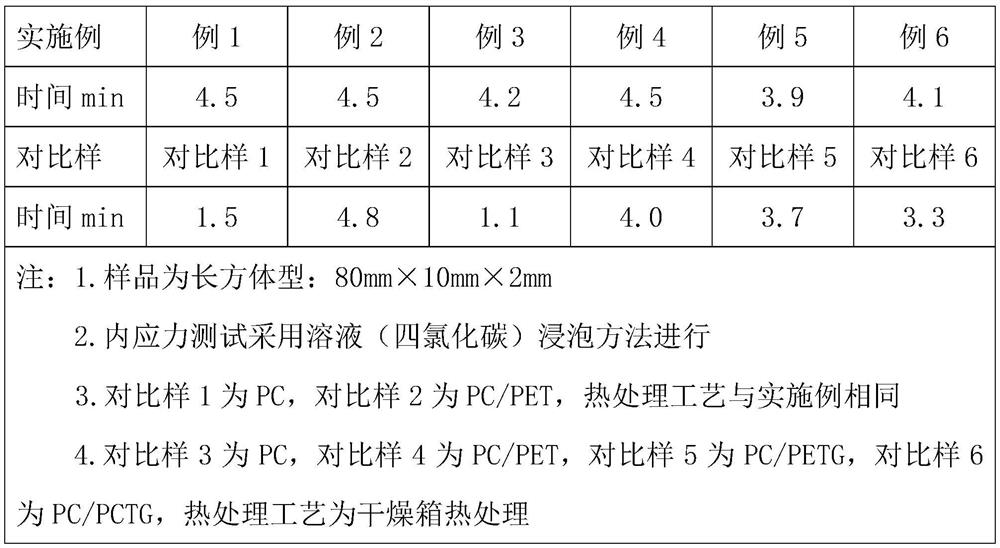

Examples

Embodiment 1

[0027] In the clean workshop, use a dehumidifier to dry each component separately: polycarbonate is dried at 120°C for 4 hours; PETG is dried at 100°C for 4 hours; styrene-acrylonitrile-glycidyl methacrylate ternary The copolymer was dried at 80°C for 4 hours, and the other components were dried at 80°C for 4 hours. According to the mass ratio, 100 kg of polycarbonate, 10 kg of PETG, and 0.5 kg of styrene-acrylonitrile-glycidyl methacrylate terpolymer were weighed for pre-mixing. A two-stage extruder combined with a parallel twin-screw extruder and a single-screw extruder is used for melt blending, a premix of polycarbonate, PETG, styrene-acrylonitrile-glycidyl methacrylate terpolymer It is added from the main feeding port of the twin-screw extruder, the blending temperature is 220-290° C., pelletized and dried under water to obtain pellets of the polycarbonate composition. The polycarbonate composition pellets are baked and injection molded into semi-finished products by inj...

Embodiment 2

[0029]In the clean workshop, use a dehumidifier to dry each component separately: polycarbonate is dried at 110°C for 4 hours; PETG is dried at 90°C for 4 hours; styrene-acrylonitrile-maleic anhydride terpolymer is dried at Dry at 80°C for 4 hours, and dry the other components at 80°C for 4 hours. According to the mass ratio, 100 kg of polycarbonate, 15 kg of PETG, and 1 kg of styrene-acrylonitrile-maleic anhydride terpolymer were weighed for pre-mixing, and 0.1 kg of antioxidant was weighed for pre-mixing. A two-stage extruder combined with a parallel twin-screw extruder and a single-screw extruder is used for melt blending, and the premixed material of polycarbonate, PETG, and styrene-acrylonitrile-maleic anhydride terpolymer is obtained from the twin-screw extruder. The main feeding port of the extruder and the antioxidant premix are respectively added from the side feeding port of the twin-screw extruder, the blending temperature is 220-290°C, and after underwater pelletiz...

Embodiment 3

[0031] In the clean workshop, use a dehumidifier to dry each component separately: polycarbonate is dried at 120°C for 4 hours; PCTG is dried at 100°C for 4 hours; styrene-acrylonitrile-glycidyl methacrylate ternary The copolymer was dried at 80°C for 4 hours, and the other components were dried at 80°C for 4 hours. According to the mass ratio, 100 kg of polycarbonate, 10 kg of PCTG, and 0.5 kg of styrene-acrylonitrile-glycidyl methacrylate terpolymer were weighed for pre-mixing. The premix of polycarbonate, PCTG, styrene-acrylonitrile-glycidyl methacrylate terpolymer is melt-blended using a two-stage extruder combined with a parallel twin-screw extruder and a single-screw extruder It is added from the main feeding port of the twin-screw extruder, the blending temperature is 220-290° C., pelletized and dried under water to obtain pellets of the polycarbonate composition. The polycarbonate composition pellets are baked and injection molded into semi-finished products by inject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com