Patents

Literature

47results about "Pectin coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bio-based binders for insulation and non-woven mats

ActiveUS20110086567A1Readily availableLow costStarch dervative coatingsStarch adhesivesFiberProcedure Agents

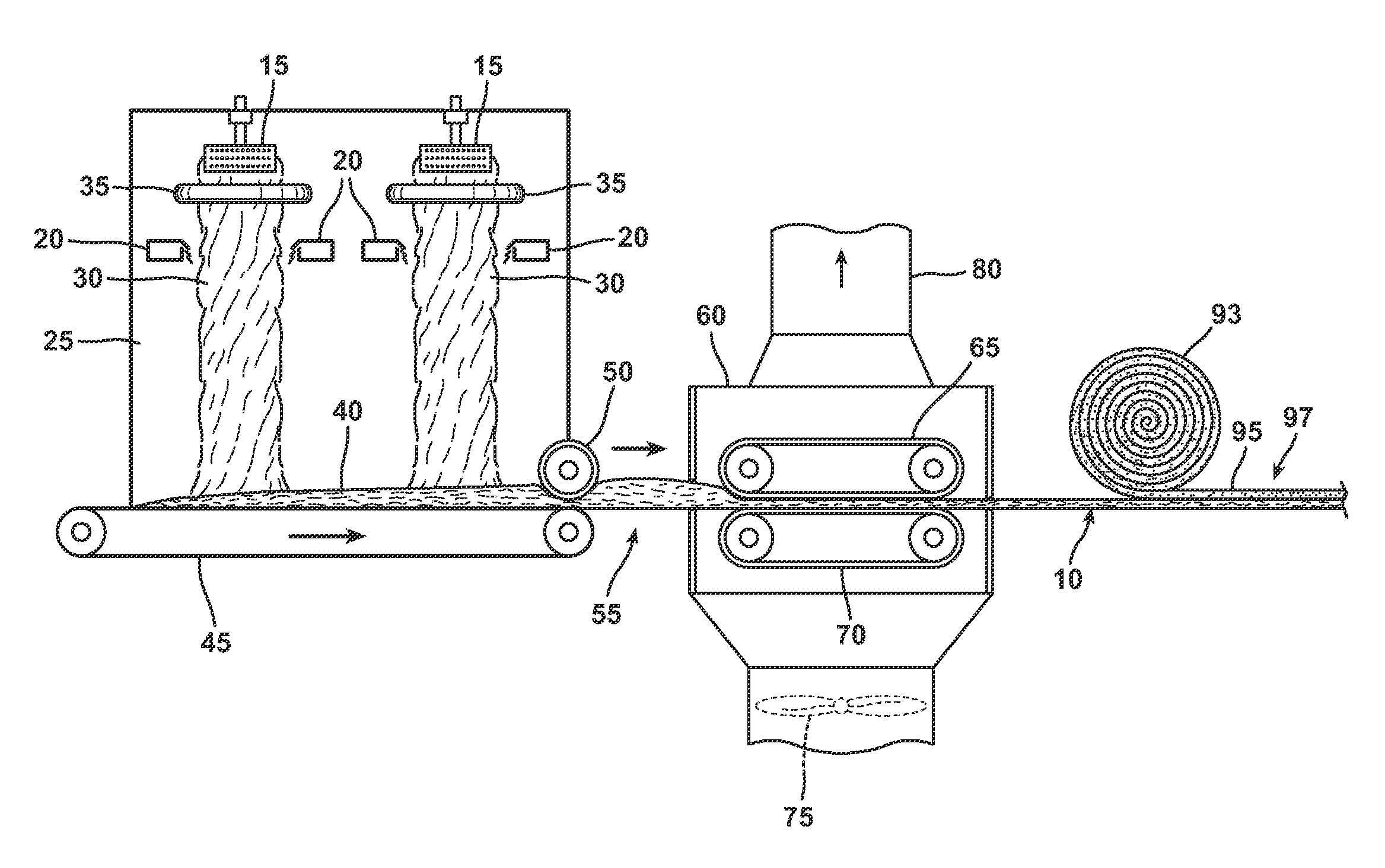

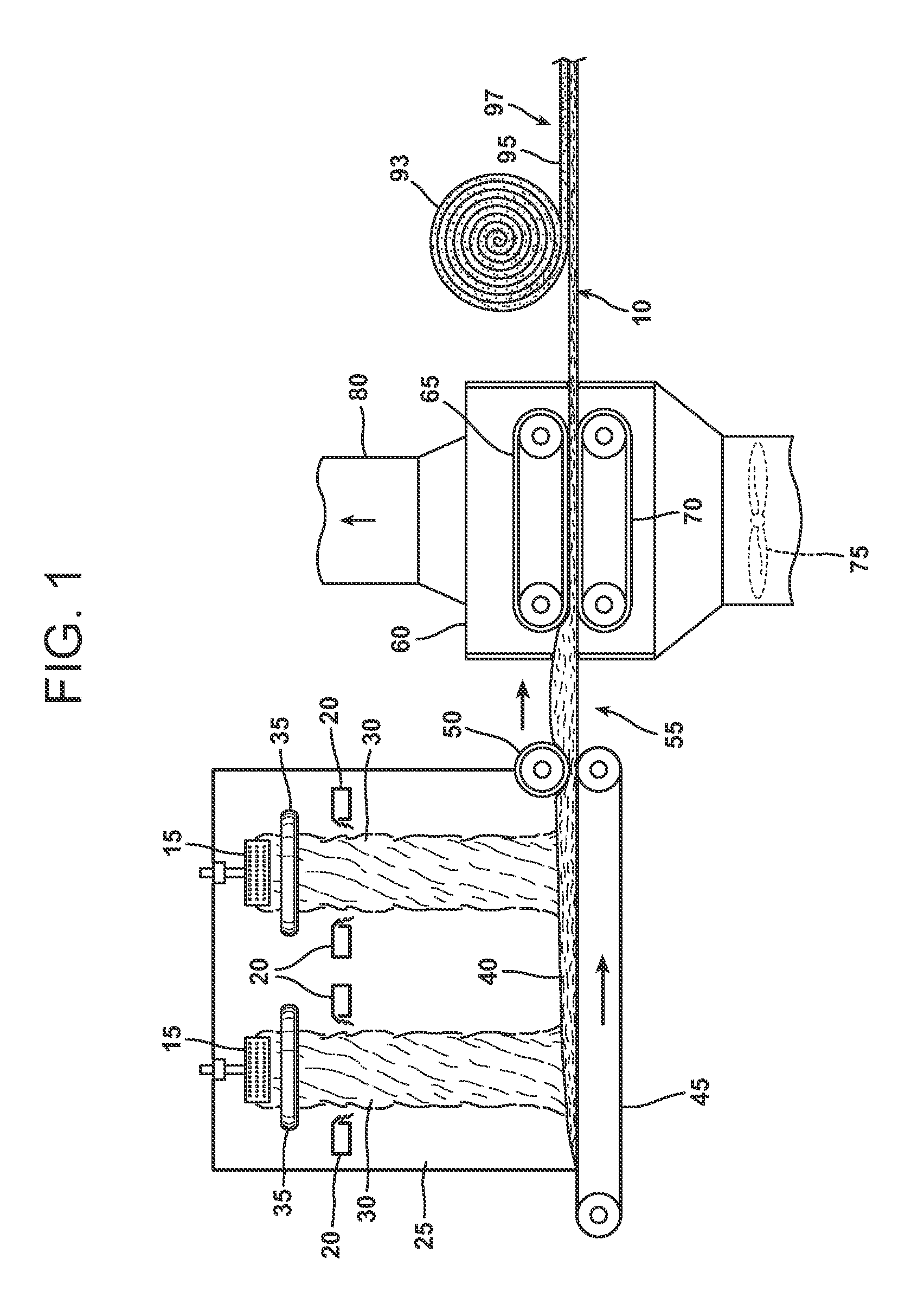

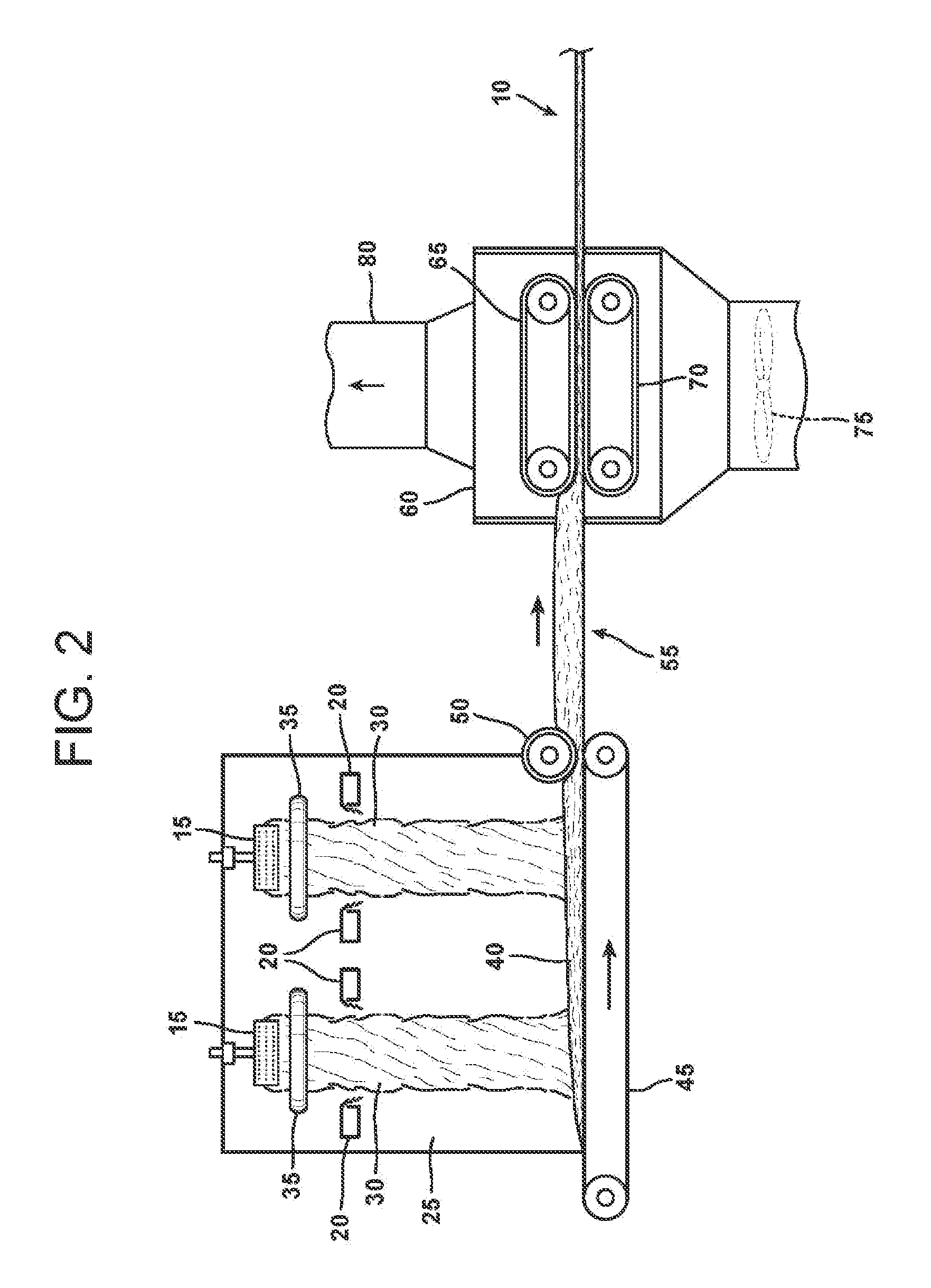

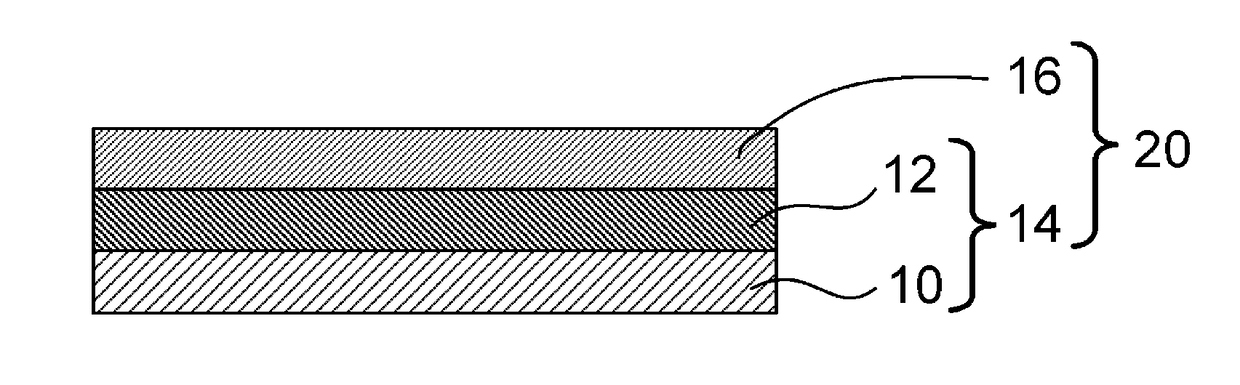

An aqueous binder composition is provided that includes a carbohydrate and a crosslinking agent. In exemplary embodiments, the carbohydrate-based binder composition may also include a catalyst, a coupling agent, a process aid, a crosslinking density enhancer, an extender, a moisture resistant agent, a dedusting oil, a colorant, a corrosion inhibitor, a surfactant, a pH adjuster, and combinations thereof. The carbohydrate may be natural in origin and derived from renewable resources. Additionally, the carbohydrate polymer may have a dextrose equivalent (DE) number from 2 to 20. In at least one exemplary embodiment, the carbohydrate is a water-soluble polysaccharide such as dextrin or maltodextrin and the crosslinking agent is citric acid. Advantageously, the carbohydrates have a low viscosity and cure at moderate temperatures. The environmentally friendly, formaldehyde-free binder may be used in the formation of insulation materials and non-woven chopped strand mats. A method of making fibrous insulation products is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

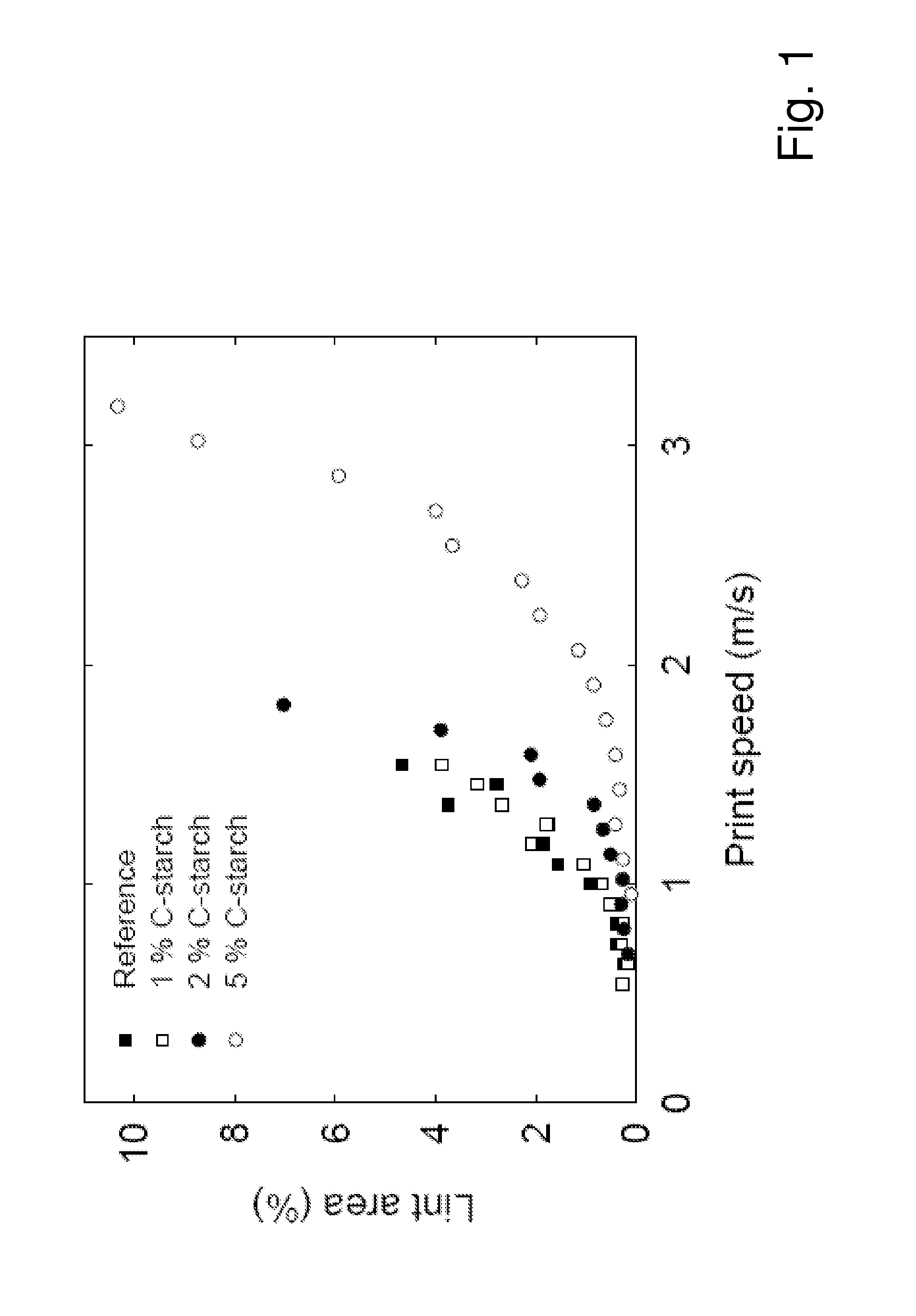

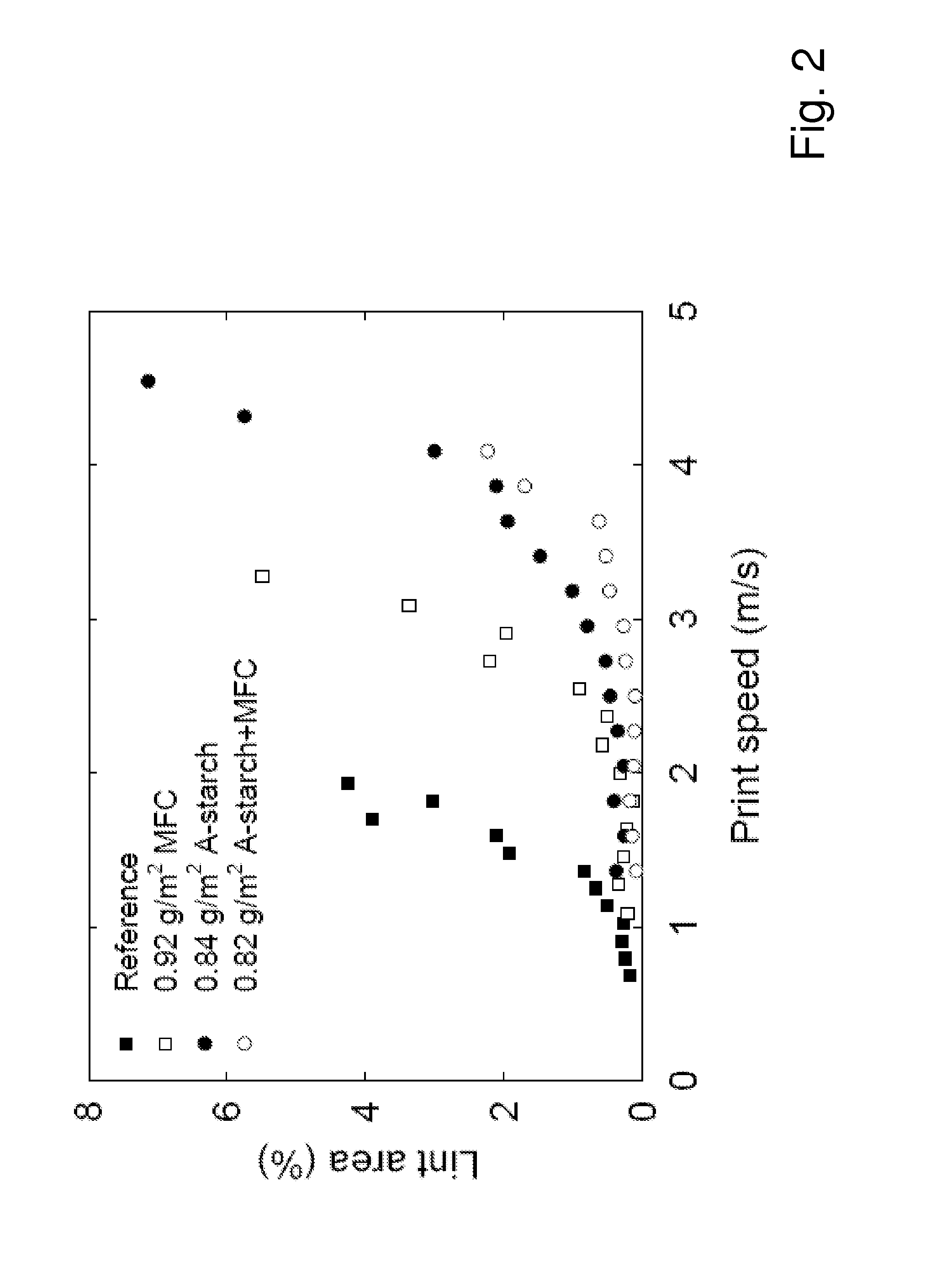

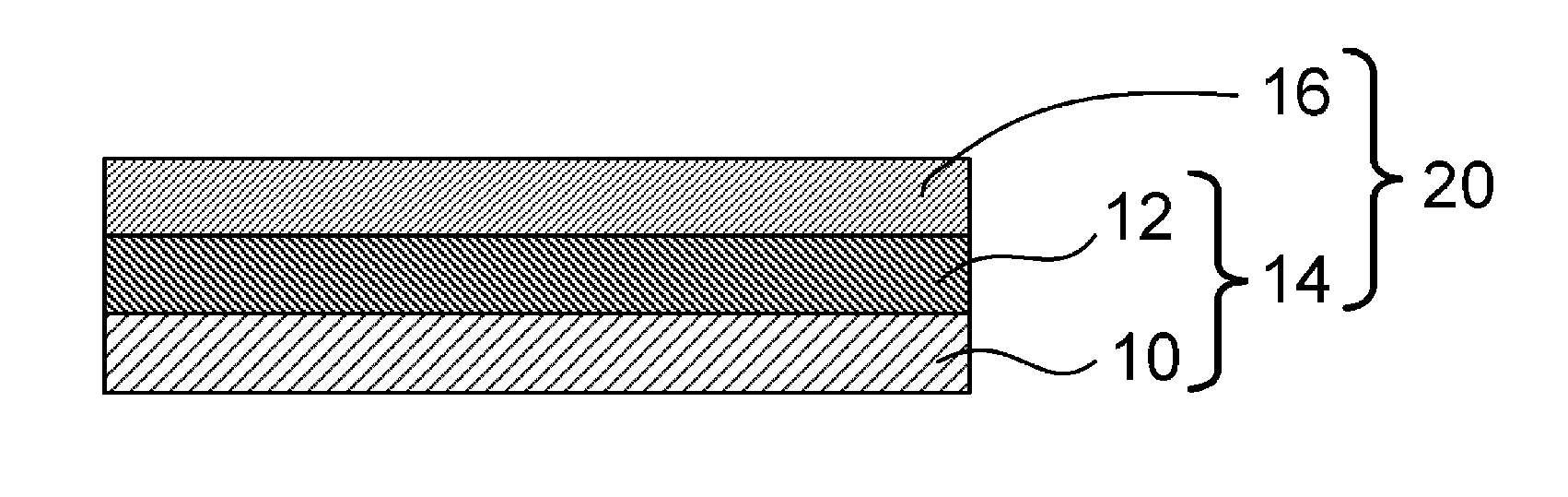

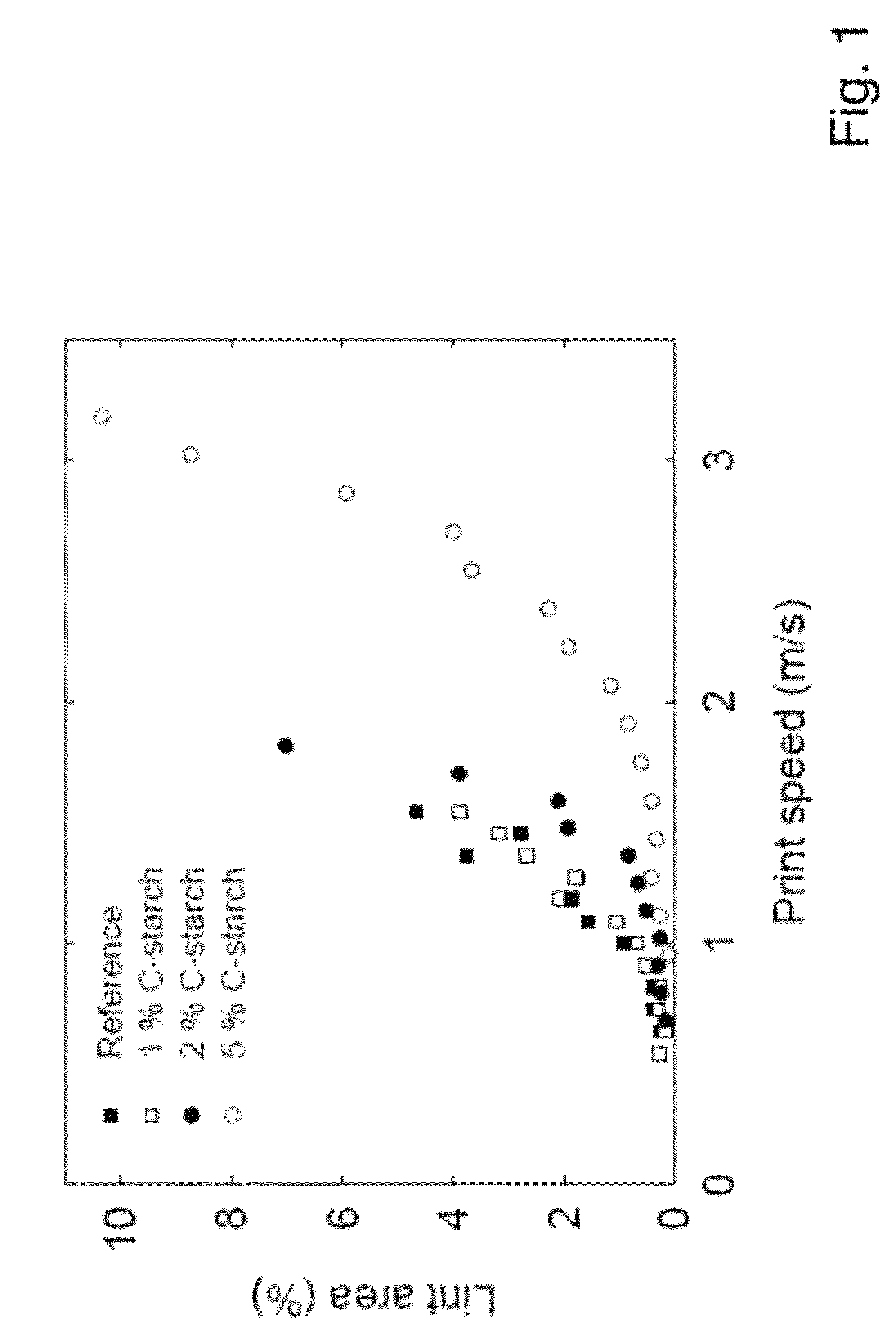

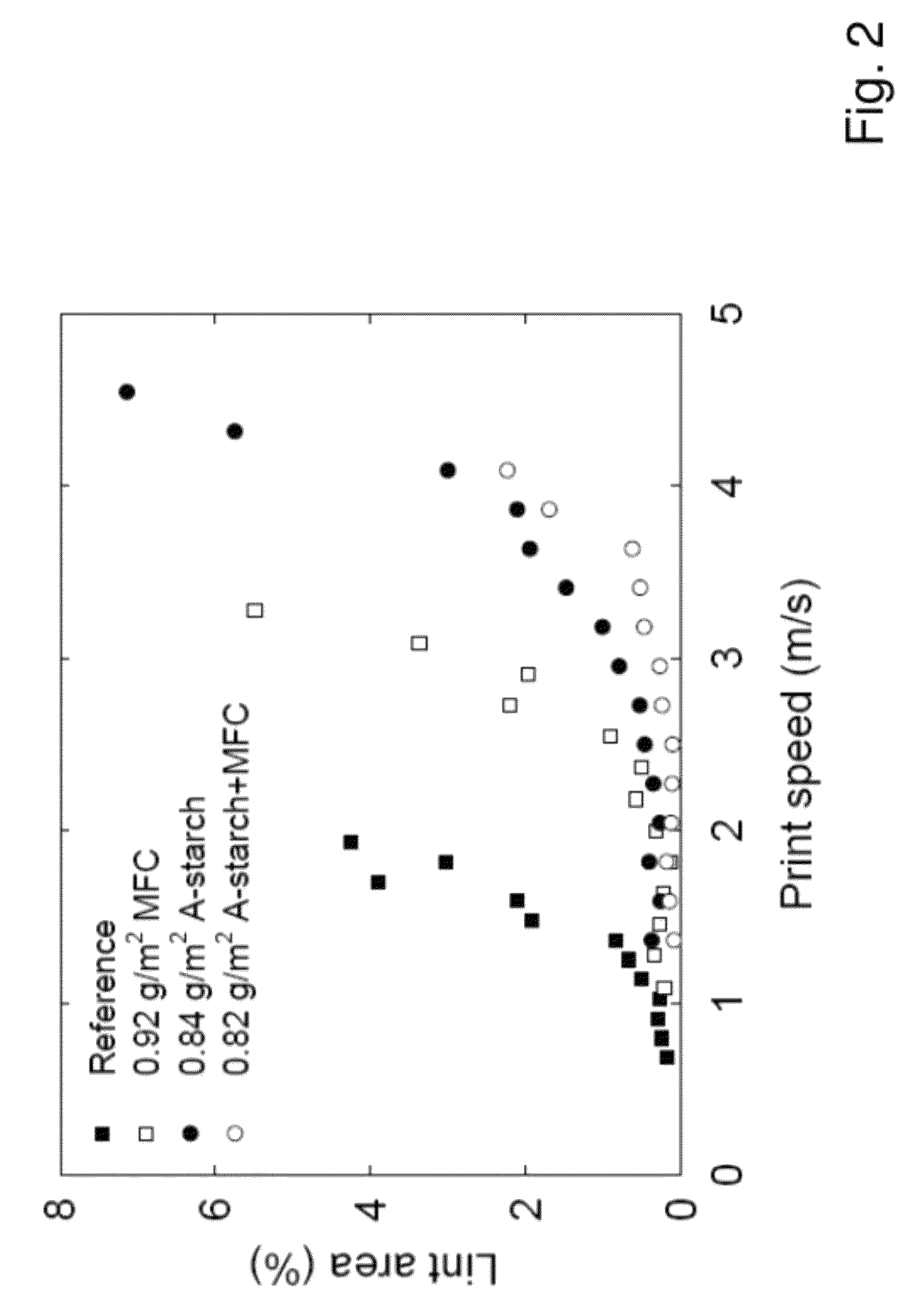

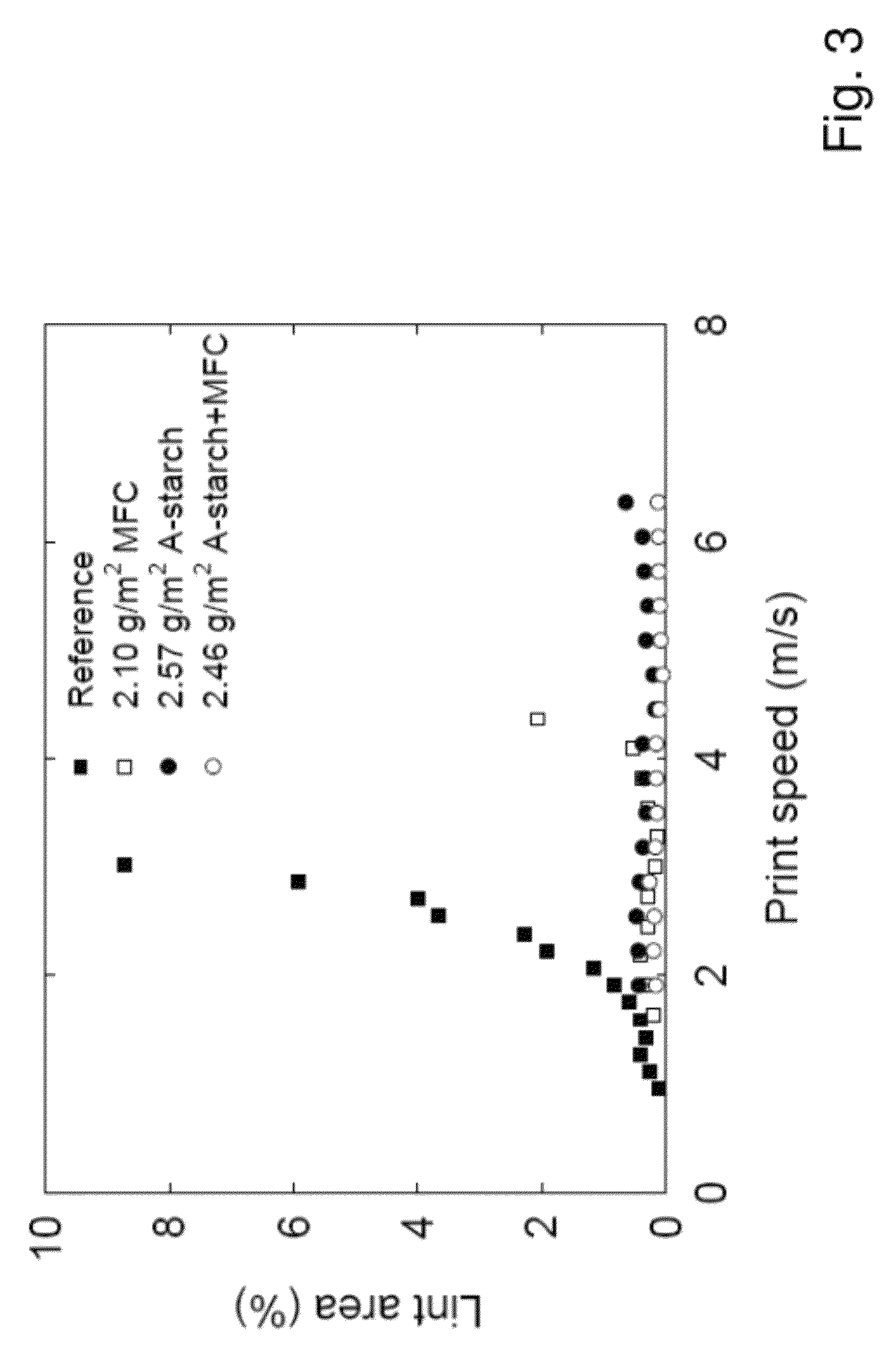

Composition for coating of printing paper

ActiveUS20110081554A1Reduced linting propensitySimple interfaceStarch dervative coatingsSpecial paperCelluloseColloid

The invention relates to compositions for coating of printing paper, said compositions comprising microfibrillated cellulose (MFC) and one or more polysaccharide hydrocolloids, and use of said compositions. Further, the invention relates to coated paper, comprising a first layer of polysaccharide hydrocolloid(s) and a second layer of MFC, and use of said paper. A method for reducing the linting and / or dusting of a paper is also disclosed.

Owner:INNVENTIA

Edible PGA coating composition

InactiveUS20050095272A1Low viscosityConfectioneryStarch adhesivesImmediate releaseBULK ACTIVE INGREDIENT

An edible, hardenable coating composition is disclosed which comprises high levels of low viscosity propylene glycol alginate and a surfactant, which may additionally contain a filler, a pigment, and optionally a small amount of a secondary film former and / or a strengthening polymer. The coating composition of the present invention may be applied to pharmaceutical and veterinary solid dosage forms, confectionery, seeds, animal feed, fertilizers, pesticide tablets, and foods and provides an elegant prompt release coating which does not retard the release of active ingredients from the coated substrate.

Owner:FMC CORP

Binder compositions with polyvalent phosphorus crosslinking agents

ActiveUS20130023174A1Readily availableLow costStarch dervative coatingsStarch adhesivesFiberProcedure Agents

An fibrous insulation product is provided that includes a binder comprising a polyol and a phosphorus crosslinking agent derived from a phosphonic or phosphoric acid, salt, ester or anhydride to form crosslinked phosphodiester linkages. The polyol is polyvalent, but may be monomeric or preferably polymeric; and may be synthetic or natural in origin. Carbohydrate polysaccharides are exemplary polyols, including water-soluble polysaccharides such as dextrin, maltodextrin, starch, modified starch, etc. Additionally, the carbohydrate polymer may have a dextrose equivalent (DE) number from 2 to 20. In exemplary embodiments, the binder may also include a catalyst, a coupling agent, a process aid, and other additives. The environmentally friendly, formaldehyde-free binder may be used in the formation of residential and commercial insulation materials and non-woven chopped strand mats. A method of making fibrous products is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Aqueous liquid composition, aqueous coating liquid, functional coating film and composite material

ActiveUS20150179357A1Sufficient viscosityImprove adhesionCosmetic preparationsStarch dervative coatingsWater basedPVA - Polyvinyl alcohol

Provided is an aqueous liquid composition including a water-based medium containing water, a polymer having at least one type of groups selected from hydroxyl groups and amino groups, and phosphonobutanetricarboxylic acid. The polymer is at least one polymer selected from the group consisting of a polysaccharide, polyamino acid, polyvinyl alcohol, polyallylamine, polyvinylamine, a polyamidine, a polyethylenimine, and their derivatives.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Edible PGA coating composition

InactiveUS6881449B2Low viscosityStarch adhesivesPretreated surfacesAdditive ingredientBULK ACTIVE INGREDIENT

An edible, hardenable coating composition is disclosed which comprises high levels of low viscosity propylene glycol alginate and a surfactant, which may additionally contain a filler, a pigment, and optionally a small amount of a secondary film former and / or a strengthening polymer. The coating composition of the present invention may be applied to pharmaceutical and veterinary solid dosage forms, confectionery, seeds, animal feed, fertilizers, pesticide tablets, and foods and provides an elegant prompt release coating which does not retard the release of active ingredients from the coated substrate.

Owner:FMC CORP

Nanometer Ag antimicrobial and preparation method thereof

InactiveCN102613243ABroad-spectrum antibacterialImprove permeabilityBiocideAntifouling/underwater paintsPlasticizerDistilled water

The invention discloses a nanometer Ag antimicrobial comprising nanometer Ag particle, a solubilizer, a water-soluble polymer, a plasticizer, a processing modifier, a solvent, a film-forming assistant, essence, pigment, distilled water or deionized water. The invention also disclosed a preparation method of the nanometer Ag antimicrobial. The preparation method comprises the steps of: adding the nanometer Ag particle into the distilled water or the deionized water, adding the solubilizer and the water-soluble polymer, and stirring to prepare a solution A; adding the plasticizer and the processing modifier (acrylate (ACR)) into the solvent, stirring, adding the film-forming assistant, and stirring to prepare a solution B; and adding the solution A into the solution B, adding the essence and the pigment, and stirring to obtain the nanometer Ag antimicrobial. The nanometer Ag antimicrobial disclosed by the invention has the advantages of strong adhesion on objects, good film forming property, good friction resistance and long-lasting antibacterial effect; and the preparation method has the advantages of simpleness and strong operability.

Owner:宋信宇

Seed coatings, coating compositions and methods for use

ActiveUS20180251654A1Promote seedling establishmentEasy to grow plantsBiocideCellulose coatingsPolyethylene oxidePotato starch

A seed or seedling is coated with underivatized guar, cationic hydroxypropyl guar, polyacrylamide, poly(methacrylic acid), poly(acrylic acid), polyacrylate, polyethylene glycol), polyethyleneoxide, poly(vinyl alcohol), polyglycerol, polytetrahydrofuran, polyamide, hydroxypropyl guar, carboxymethyl guar, carboxymethylhydroxypropyl guar, underivatized starch, cationic starch, corn starch, wheat starch, rice starch, potato starch, tapioca, waxy maize, sorghum, waxy sorghum, sago, dextrin, chitin, chitosan, xanthan gum, carageenan gum, gum karaya, gum arabic, pectin, cellulose, hydroxycellulose, hydroxyalkyl cellulose, hydroxyethyl cellulose, carboxymethylhydroxyethyl cellulose, or hydroxypropyl cellulose, the coated seed or seedling having a shelf-life at room temperature in ambient conditions in an unsealed container to at least two months.

Owner:RHODIA OPERATIONS SAS

Edible PGA coating composition

An edible, hardenable coating composition is disclosed which comprises high levels of low viscosity propylene glycol alginate and a surfactant, which may additionally contain a filler, a pigment and optionally a small amount of a secondary film former and / or a strengthening polymer. The coating composition of the present invention may be applied to pharmaceutical and veterinary solid dosage forms, confectionery, seeds, animal feed, fertilizers, pesticide tablets, and foods and provides an elegant prompt release coating which does not retard the release of active ingredients from the coated substrate.

Owner:FMC CORP

Modified biomaterial, uses thereof and modification methods

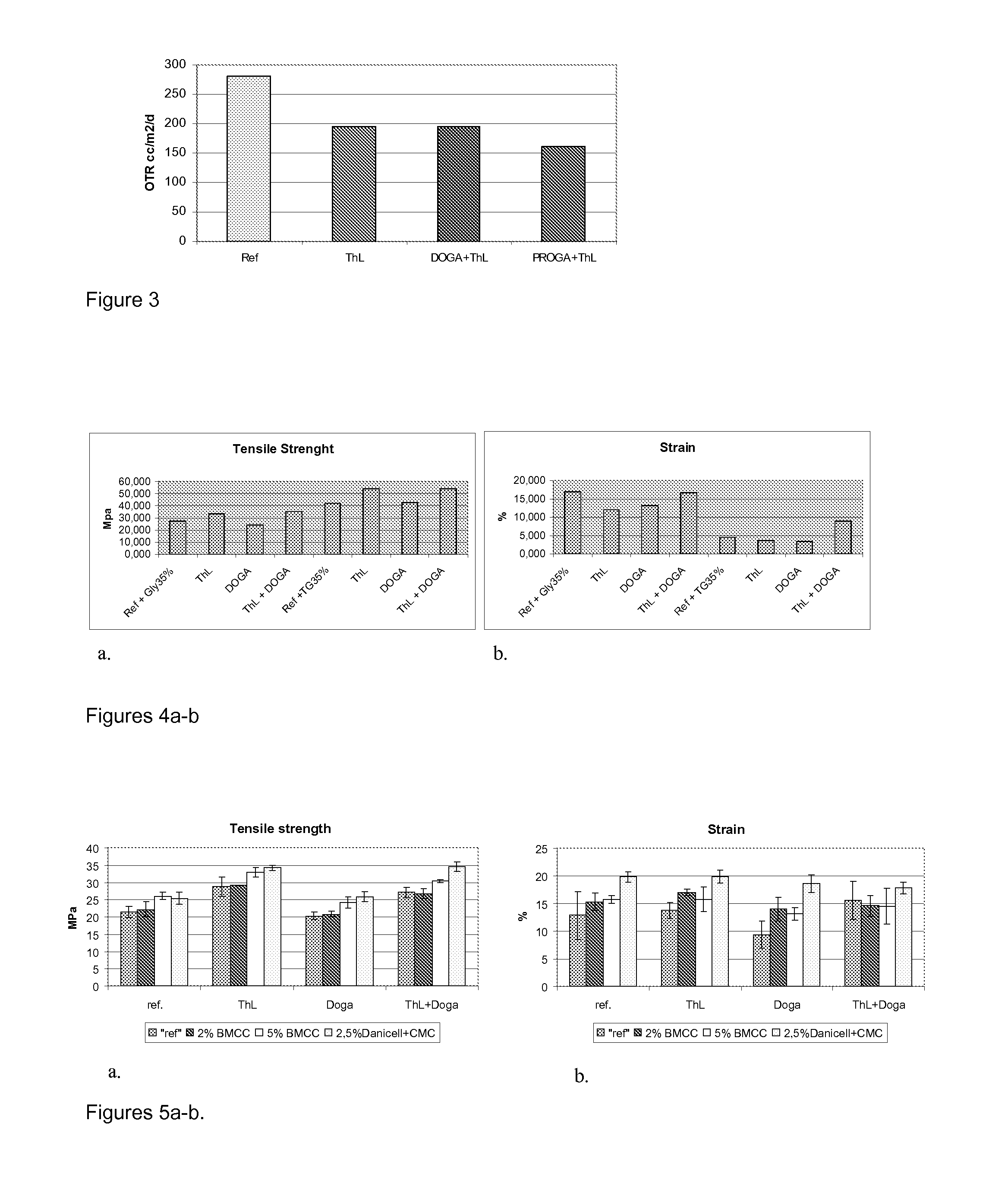

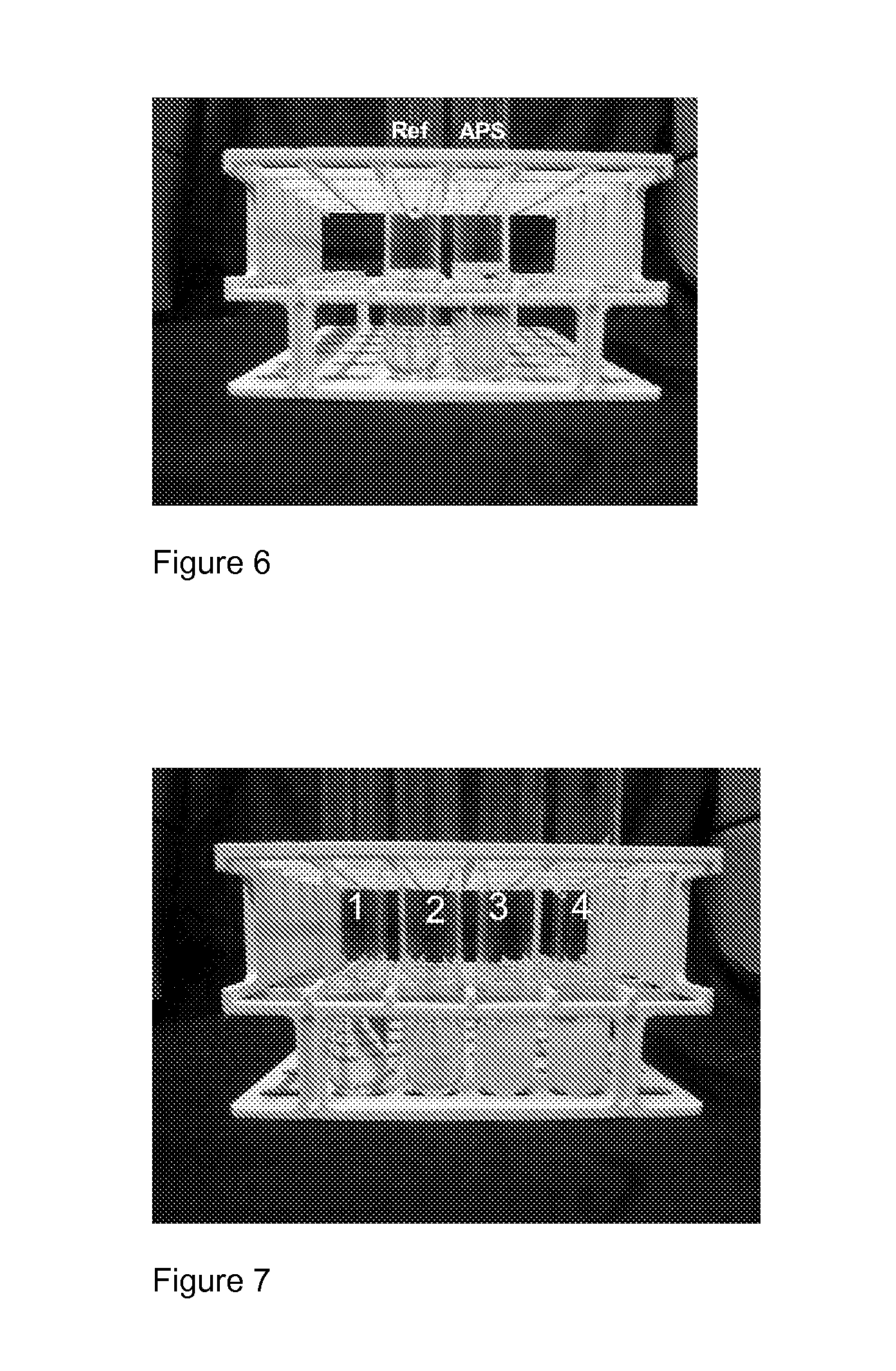

InactiveUS20120276596A1Improve barrier propertiesImprove mechanical propertiesPulp properties modificationMicroorganism/enzyme additionBiological materialsPolysaccharide

The present invention relates to the fields of biomass technology, and more precisely to applications of packaging, and coating products for food and cosmetics. The present invention relates to a method of modifying a polymeric polysaccharide matrix and to a method of coating a product to impart new properties to the product. The present invention further relates to a modified polymeric polysaccharide matrix, to a product being coated with a modified polymeric polysaccharide matrix and uses thereof.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

Stabilizing methods for coating seeds with biological materials

The present invention provides a method for coating seeds with biological materials such as bacteria, fungi (e.g., yeasts and molds), parasites, recombinant vectors, and viruses. The method comprises (a) applying a moistening liquid to seeds to moisten seeds, wherein the moistening liquid comprises a moistening polymer, and (b) coating the moistened seeds with an effective amount of a dry composition, wherein the dry composition comprises biological materials, one or more disaccharides, one or more oligosaccharides, one or more polysaccharides, one or more carboxylic acid salts, and one or more hydrolyzed proteins. The coated seeds may have an initial water activity (Aw) below 0.4, and the microorganisms on the coated seeds have initial viability of at least 5 logs of colony forming units per gram of seeds (CFU / g seed). Also provided are coated seeds.

Owner:ADVANCED BIONUTRITION CORP

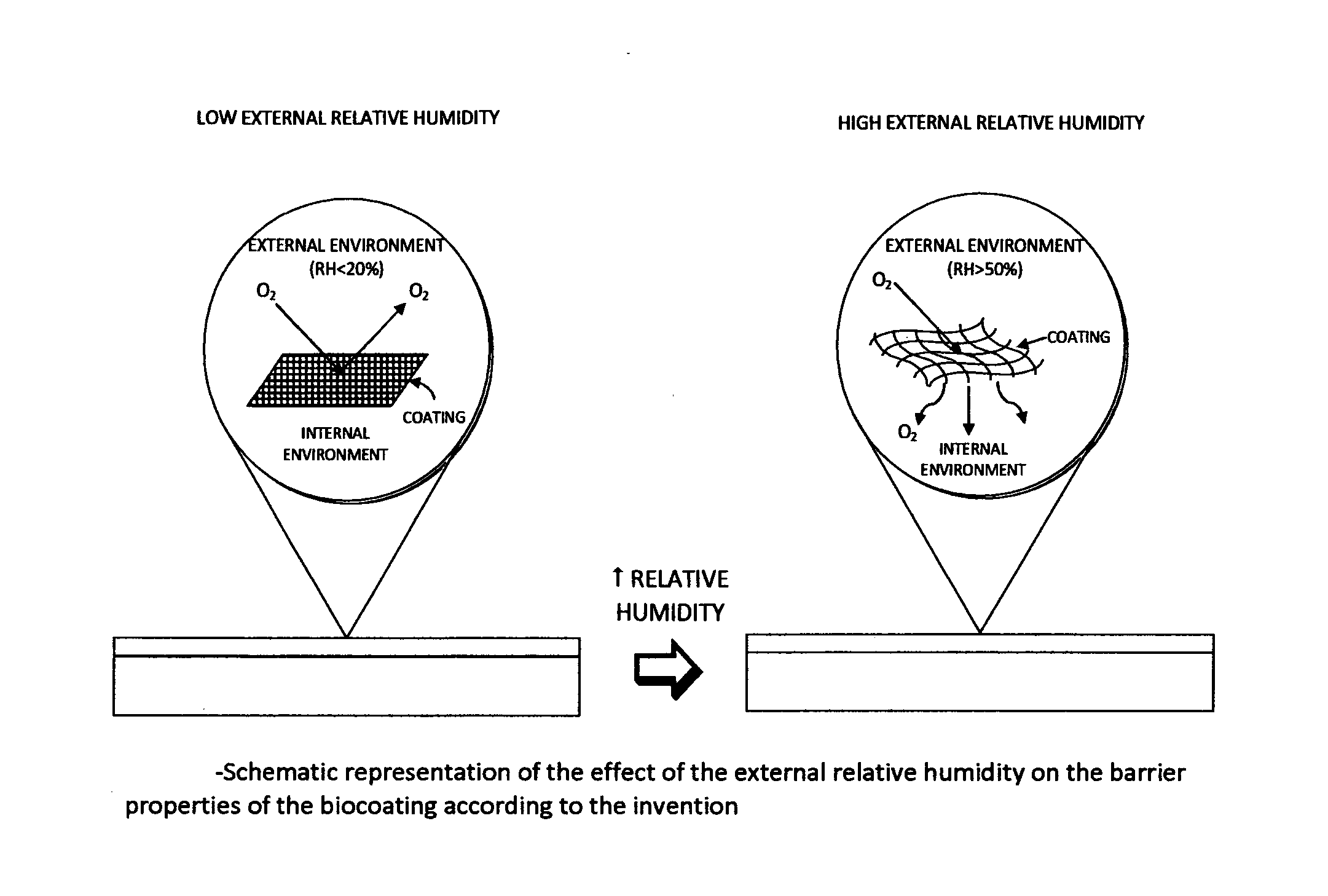

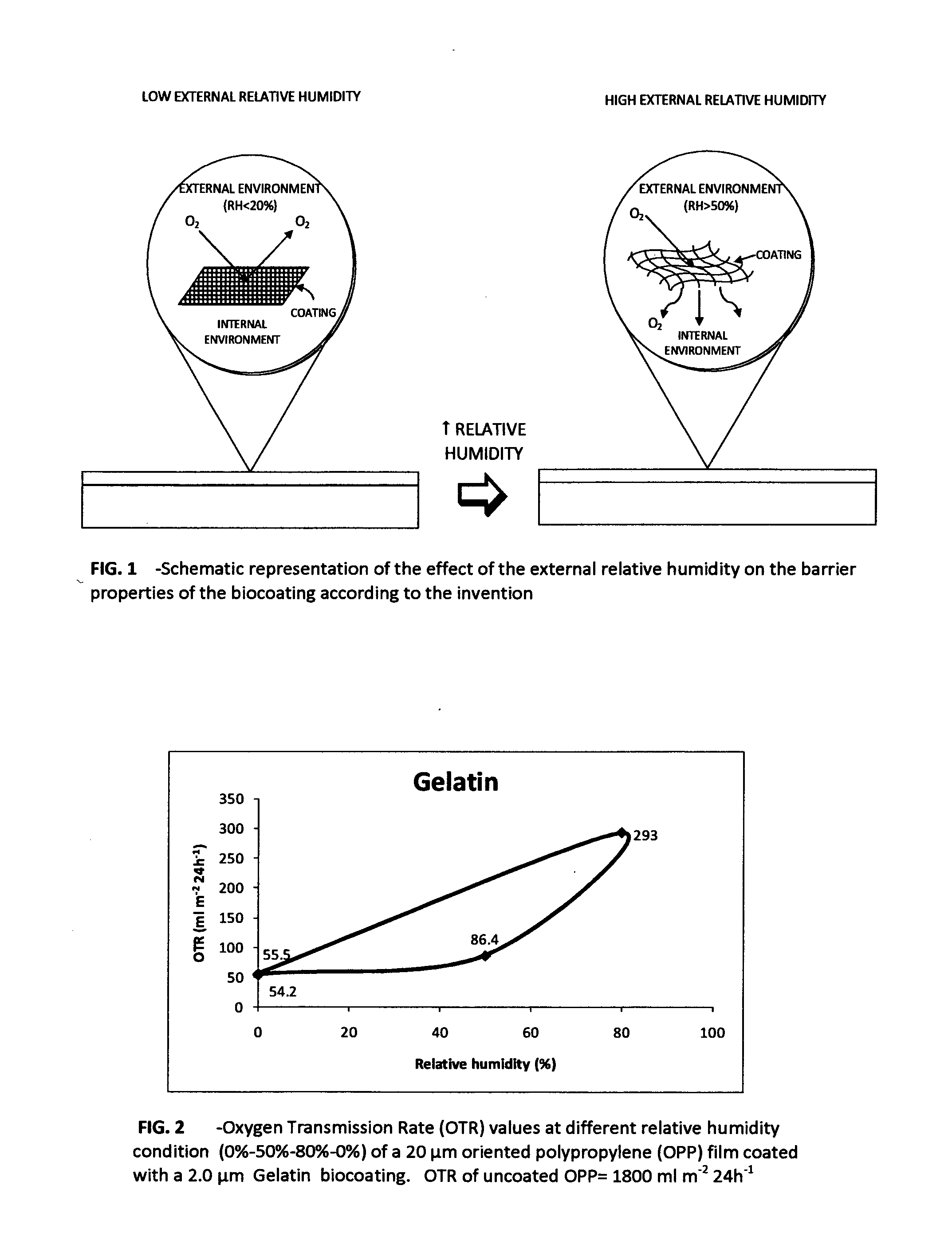

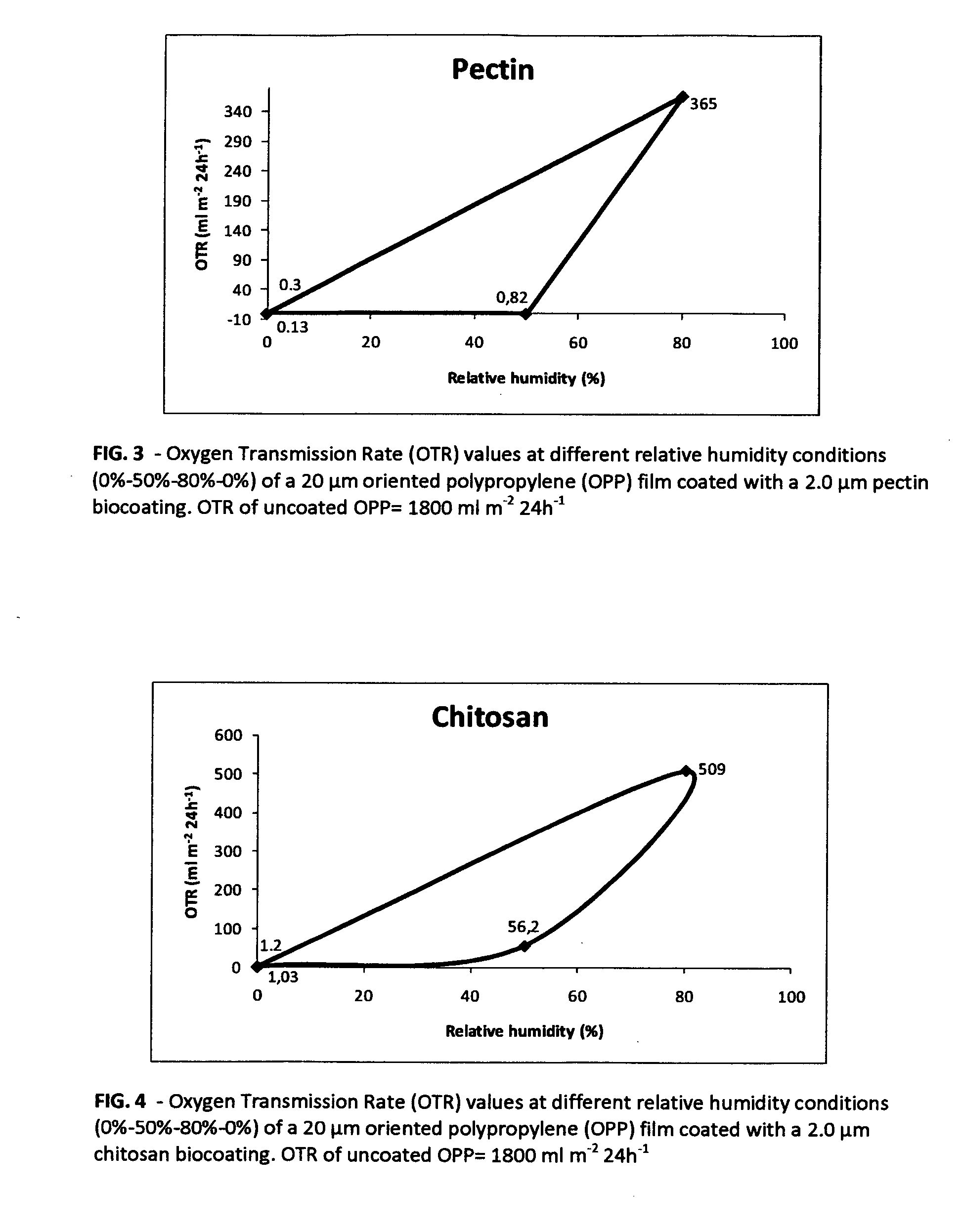

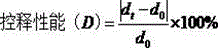

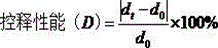

Coatings from natural macromolecules, with gas barrier properties tailored in situ, and related preparation method

InactiveUS20110283918A1Strong adhesionCosmetic preparationsPeptide/protein ingredientsBarrier effectGelatin

The invention concerns lake compositions based on natural macromolecules (gelatin, chitosan, pectine etc.) with possible additions of vinyl polymers, metal-alcoxides etc., characterized by a barrier effect modulated in situ, in particular as a function of the relative humidity in the exterior ambient.

Owner:MIRANTE

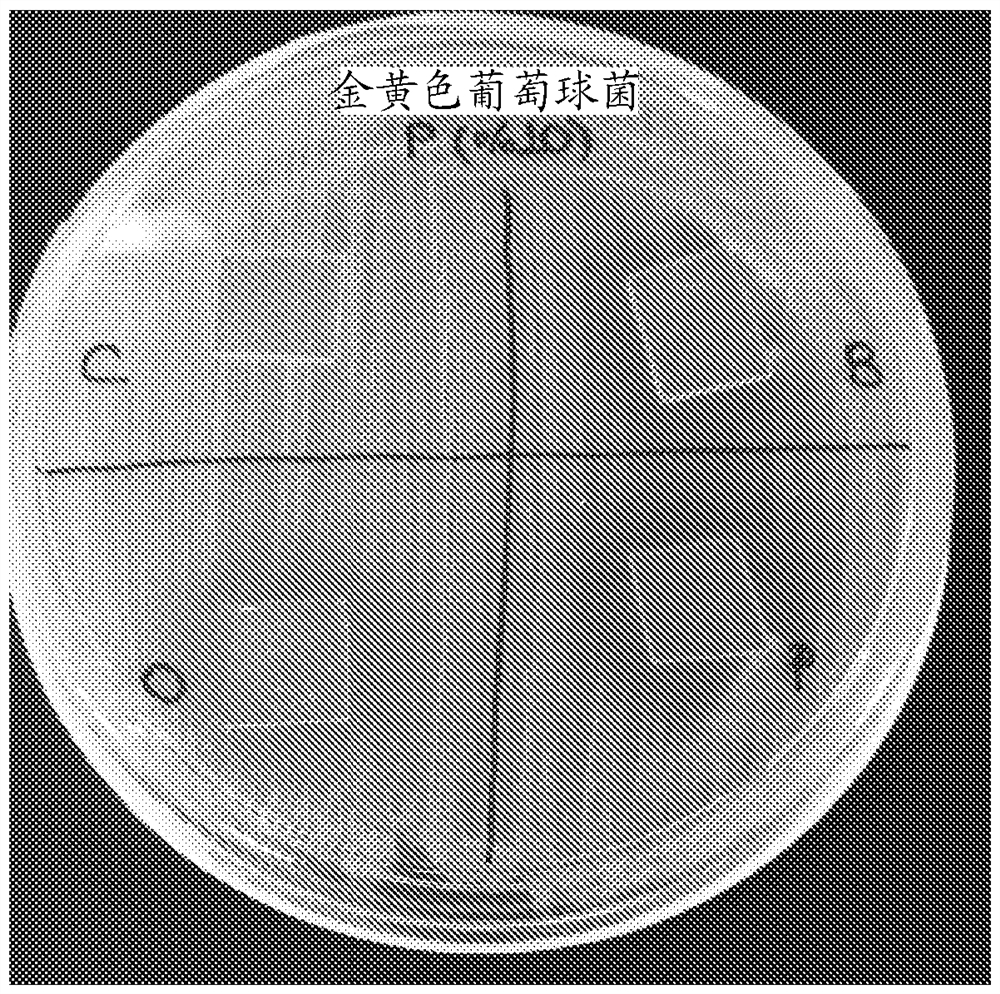

Controlled-release antibacterial edible composite film and preparation method thereof

ActiveCN106279744ASuit one's needsInhibit growthAntifouling/underwater paintsFood preservationSodium lactateComposite film

The invention discloses a controlled-release antibacterial edible composite film and a preparation method thereof. Soy isolate protein serves as a main substrate, glycerin, pectin, nisin, sodium lactate and the like are added according to a specific proportion, so that antibacterial activity and the mechanical performance of the film are improved, and coating is performed for three times by the aid of ultrasound-assisted technology to prepare a controlled-release edible antibacterial protein composite film. The antibacterial activity of the composite film can be effectively improved by nisin-sodium lactate bacteriostatic agents, and microbe development is prevented. Release of the bacteriostatic agents can be effectively controlled by a multilayer film structure prepared by controlled-release technology, and the antibacterial activity of the film is greatly enhanced. The antibacterial activity of the antibacterial composite film slightly changes within two months during storage period, the mechanical performance also slightly changes, the diameter of an antibacterial ring is decreased by 10-15%, tensile strength is reduced by 3-9%, water permeability is enhanced by 2-7%, oxygen permeability is enhanced by 4-5.5%, the color of the film is transparent and does not remarkably change, and the effective period of food quality is prolonged. The composite film is simple to operate, stable and reliable in product quality and suitable for industrial production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

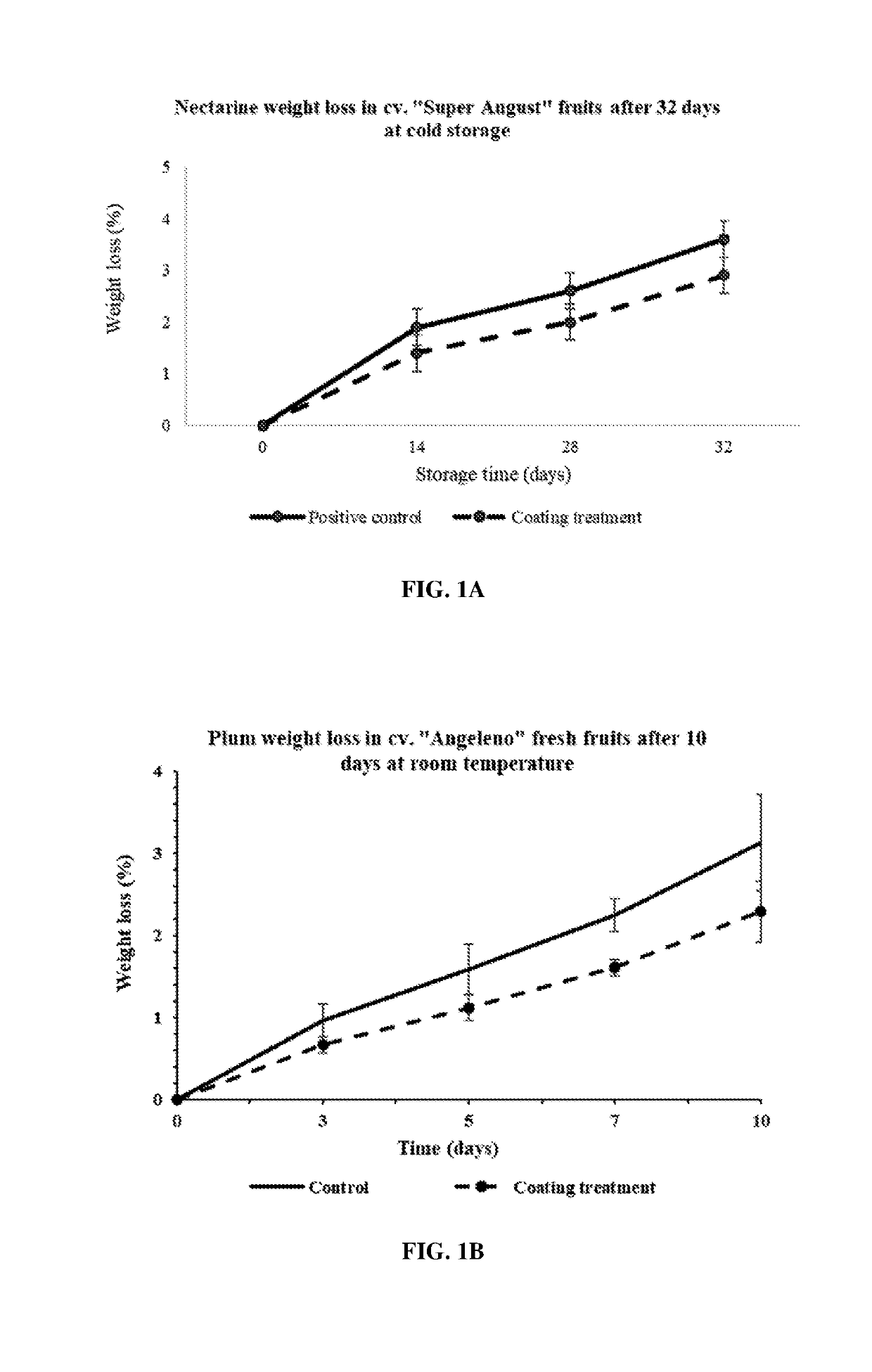

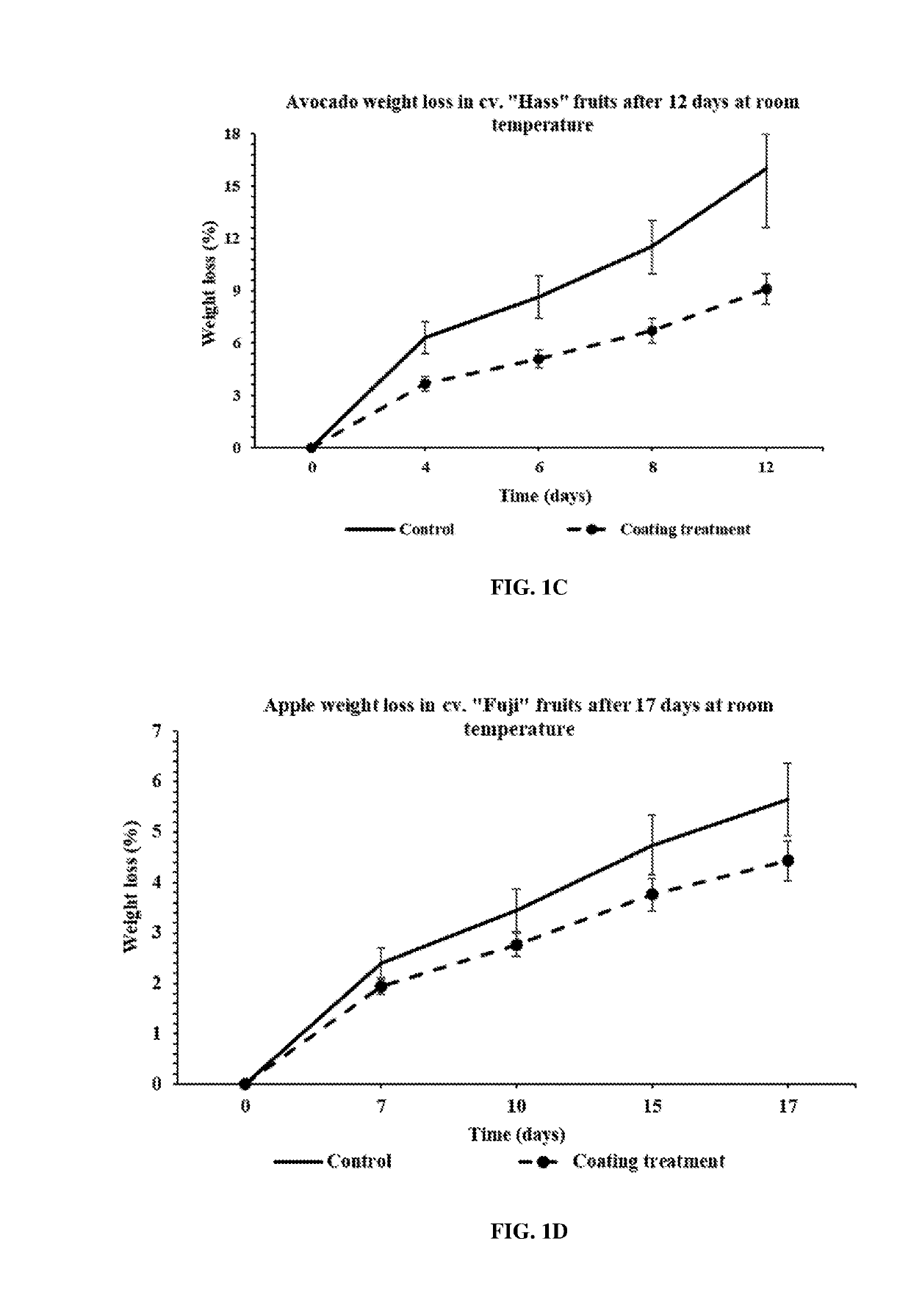

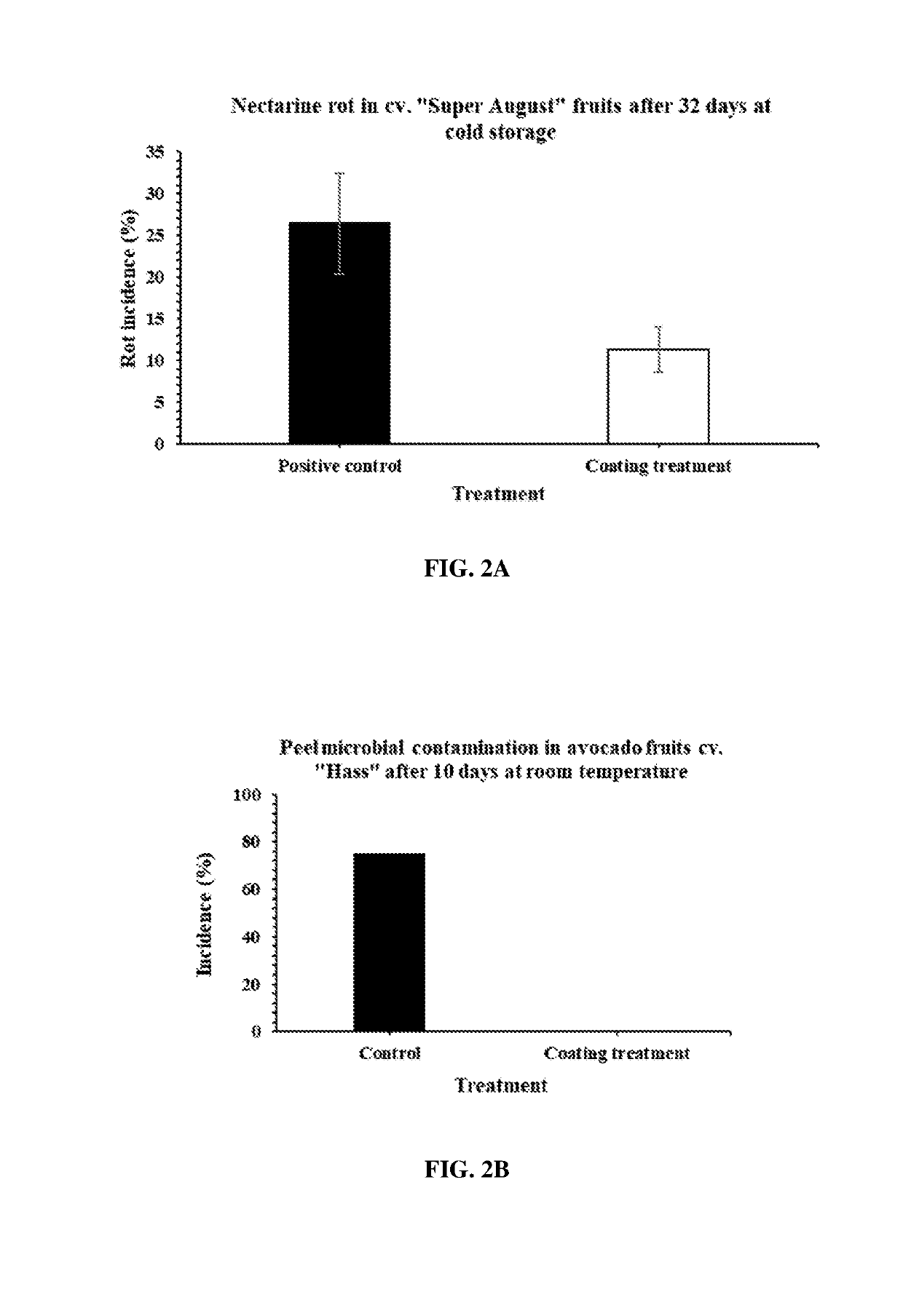

Coating compositions and methods of use thereof

InactiveUS20190281844A1Extended shelf lifeReduce dehydrationBiocideDead plant preservationChemistryCoating

Owner:POLYNATURAL HLDG SPA

Composition for coating of printing paper

ActiveUS8241756B2Reduction tendencyMinimize agglomerationStarch dervative coatingsSpecial paperCellulosePolysaccharide

The invention relates to compositions for coating of printing paper, said compositions comprising microfibrillated cellulose (MFC) and one or more polysaccharide hydrocolloids, and use of said compositions. Further, the invention relates to coated paper, comprising a first layer of polysaccharide hydrocolloid(s) and a second layer of MFC, and use of said paper. A method for reducing the linting and / or dusting of a paper is also disclosed.

Owner:INNVENTIA

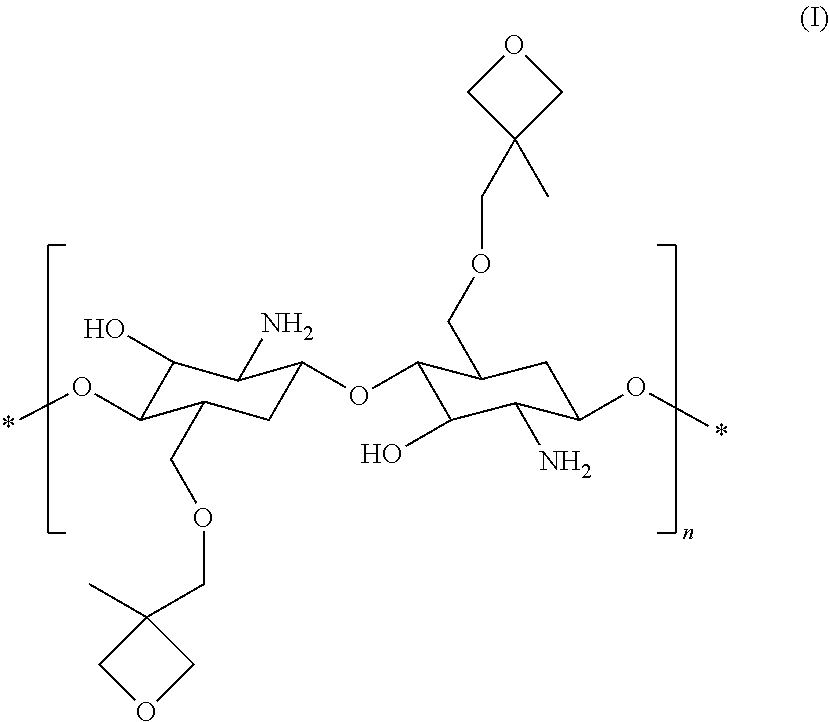

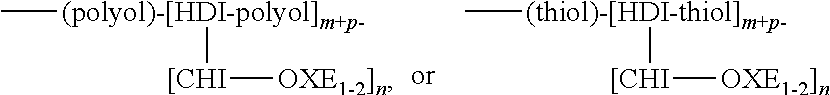

Cosmetic Formulation Incorporating a UV-Triggered Self-Healing Material

A cosmetic composition for treating hair, nails and skin, including the lips, is provided, which composition comprises a UV activated self-repair film forming material, for example, a polymer, such as a polyurethane polymer, containing a polysaccharide substituted with a UV active oxetane, or a metallo-supramolecular film-former capable of reforming polymeric like chains via metal ligand complexation.

Owner:AVON PROD INC

Seed coatings, coating compositions and methods for use

ActiveUS10745578B2Promote plant growthImprove adhesionBiocideCellulose coatingsPolymer sciencePotato starch

A seed or seedling is coated with underivatized guar, cationic hydroxypropyl guar, polyacrylamide, poly(methacrylic acid), poly(acrylic acid), polyacrylate, polyethylene glycol), polyethyleneoxide, poly(vinyl alcohol), polyglycerol, polytetrahydrofuran, polyamide, hydroxypropyl guar, carboxymethyl guar, carboxymethylhydroxypropyl guar, underivatized starch, cationic starch, corn starch, wheat starch, rice starch, potato starch, tapioca, waxy maize, sorghum, waxy sorghum, sago, dextrin, chitin, chitosan, xanthan gum, carageenan gum, gum karaya, gum arabic, pectin, cellulose, hydroxycellulose, hydroxyalkyl cellulose, hydroxyethyl cellulose, carboxymethylhydroxyethyl cellulose, or hydroxypropyl cellulose, the coated seed or seedling having a shelf-life at room temperature in ambient conditions in an unsealed container to at least two months.

Owner:SPECIALTY OPERATIONS FRANCE

Non-covalently bonding anti-microbial nanoparticles for water soluble wood treatment

Embodiments described herein include capped nanoparticles having a nanoparticle core and at least one capping agent including a biochemical constituent of wood or a woody plant or a derivative thereof functionally associated to the nanoparticle core. Some embodiments provide for wood products and wood treatment compositions including such capped nanoparticles, and methods for preparing and using such capped nanoparticles to produce treated wood or treated wood products.

Owner:EMPIRE TECH DEV LLC

Oxygen barrier film, food packaging material comprising same, and method for producing oxygen barrier film

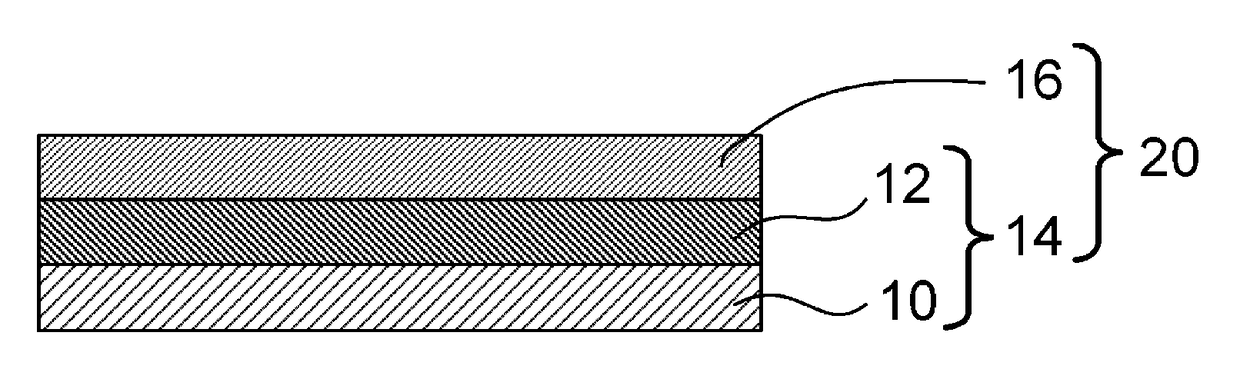

PendingUS20220153938A1Improve adhesionEasy to manufactureWrappersNon-macromolecular adhesive additivesPolymer scienceFood packaging

Disclosed are an oxygen barrier film, a food wrapper including the same, and a method of preparing the oxygen barrier film. The oxygen barrier film may include: a base layer; and an organic / inorganic hybrid layer located on the base layer and including a natural hydrogel and a silane coupling agent.

Owner:EVERCHEMTECH

Advanced thin protective films

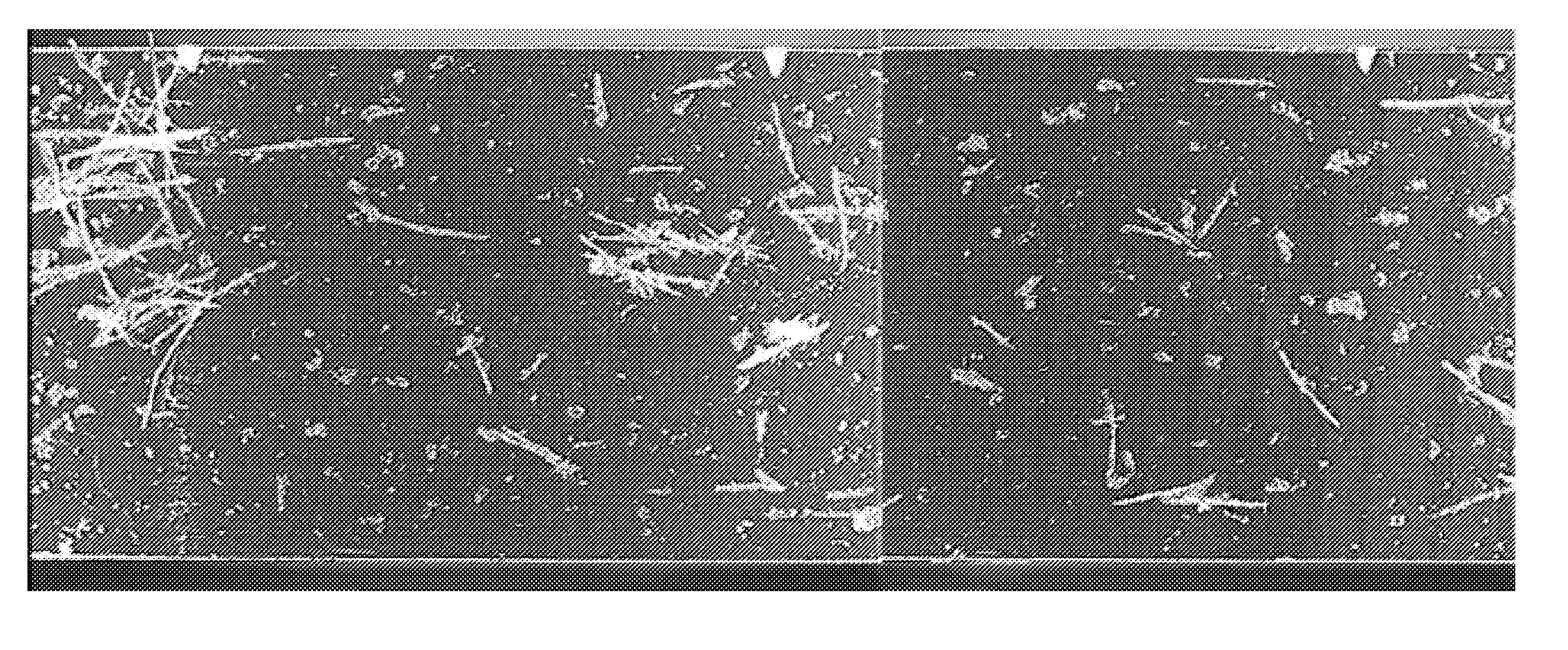

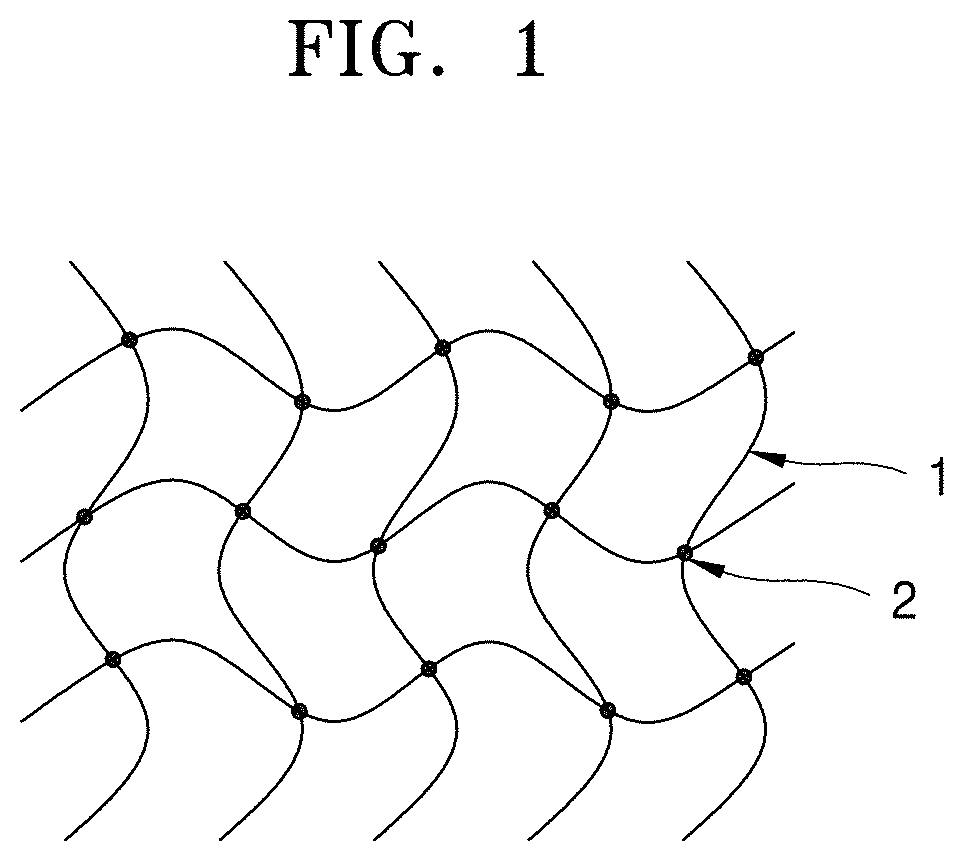

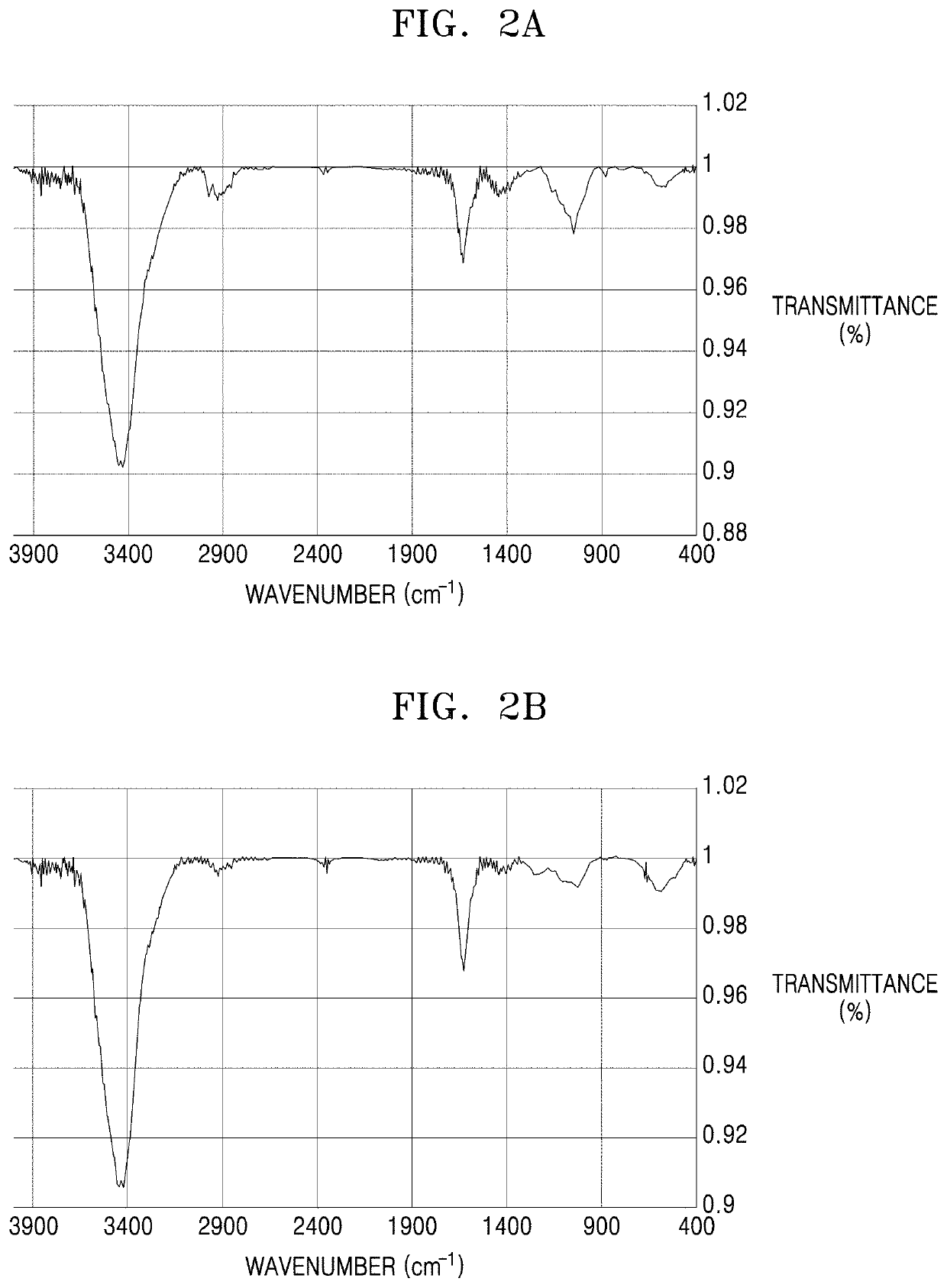

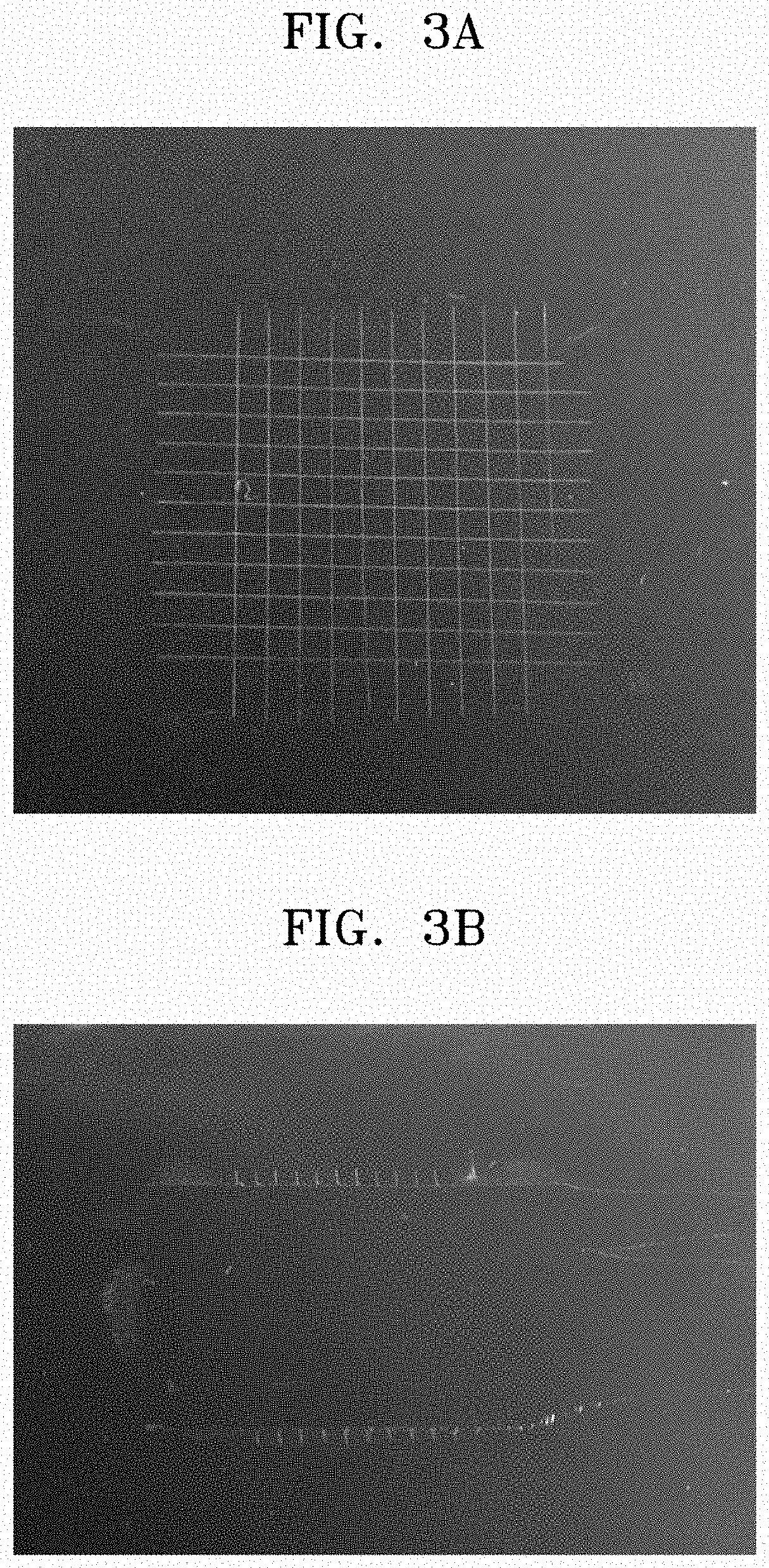

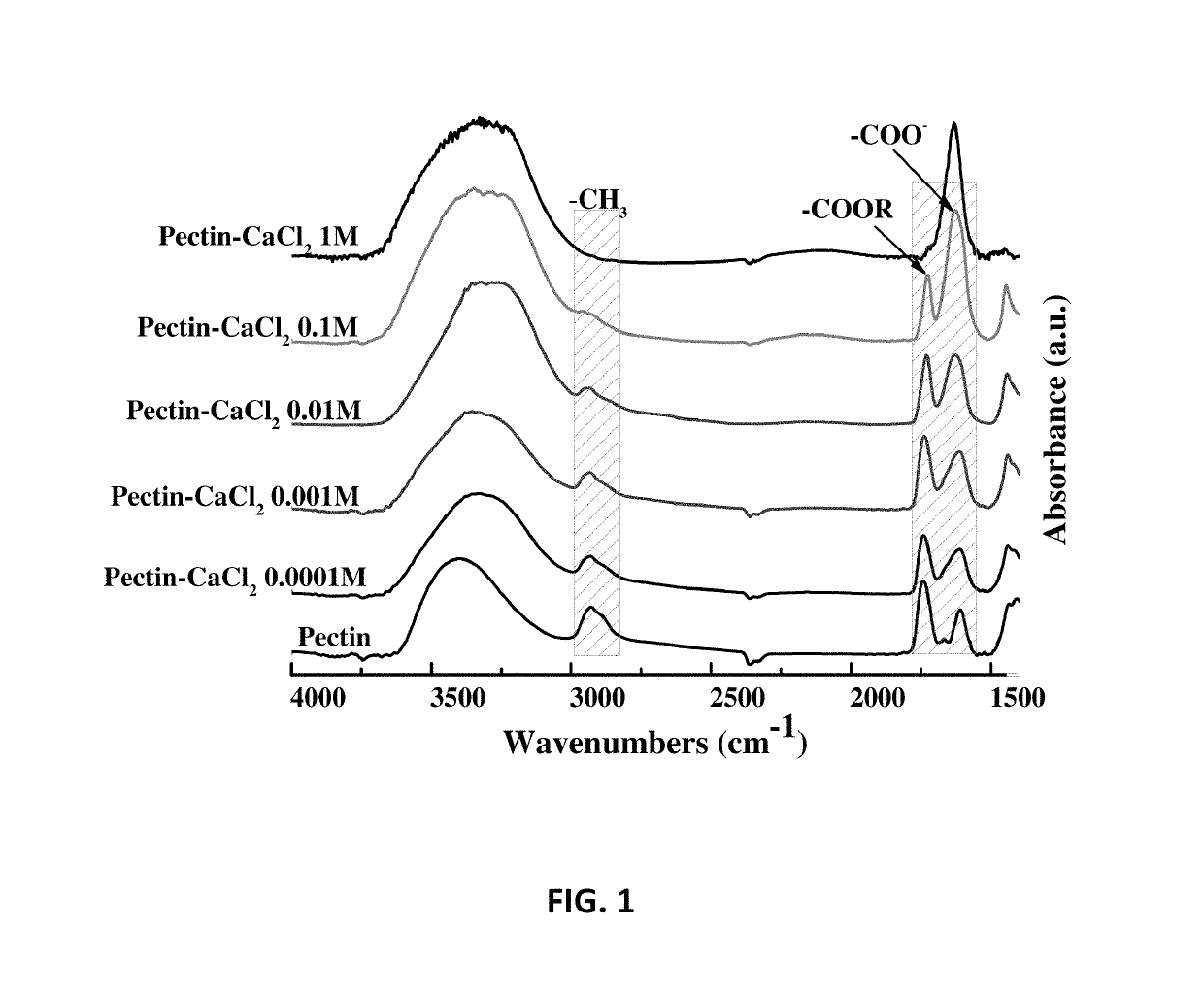

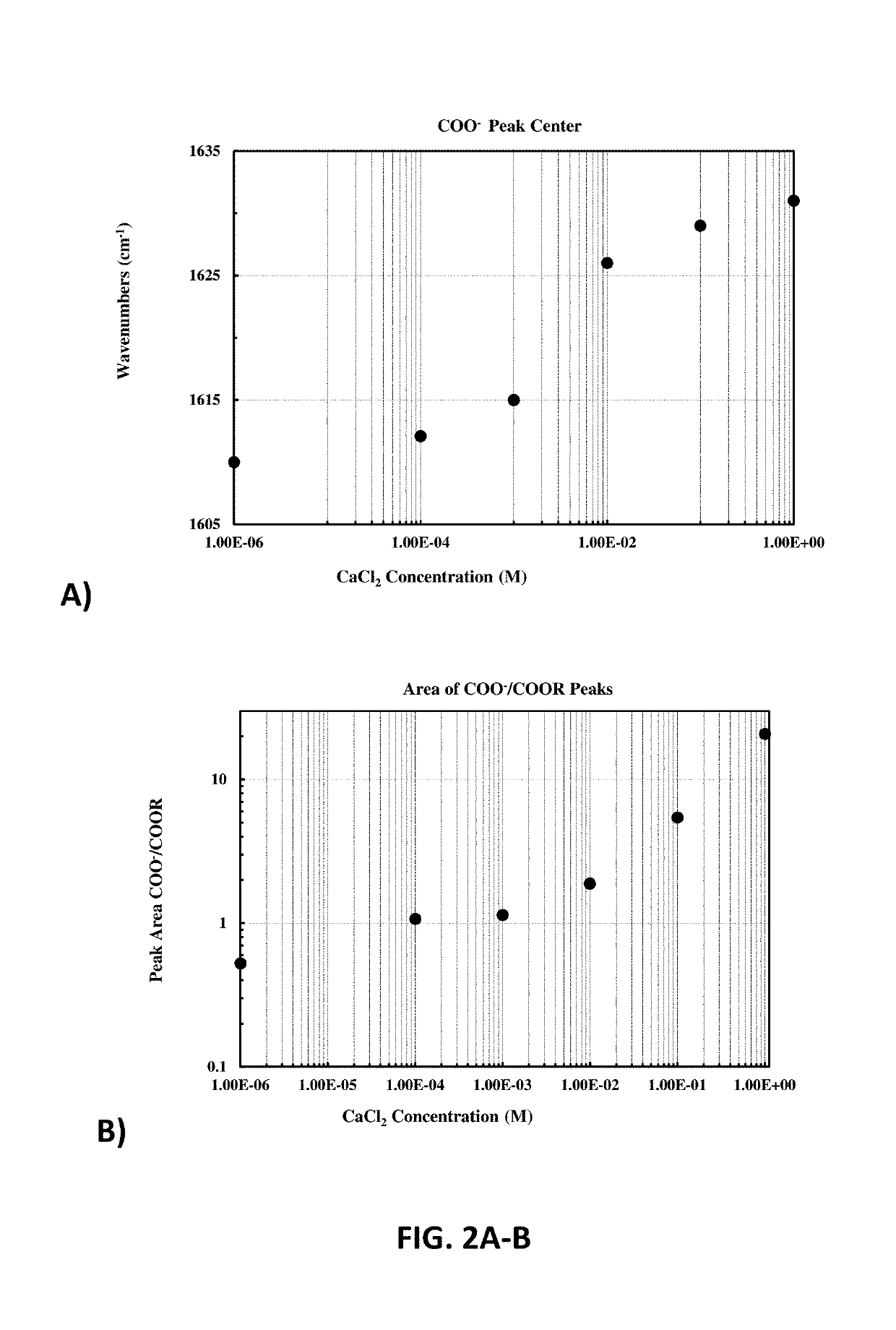

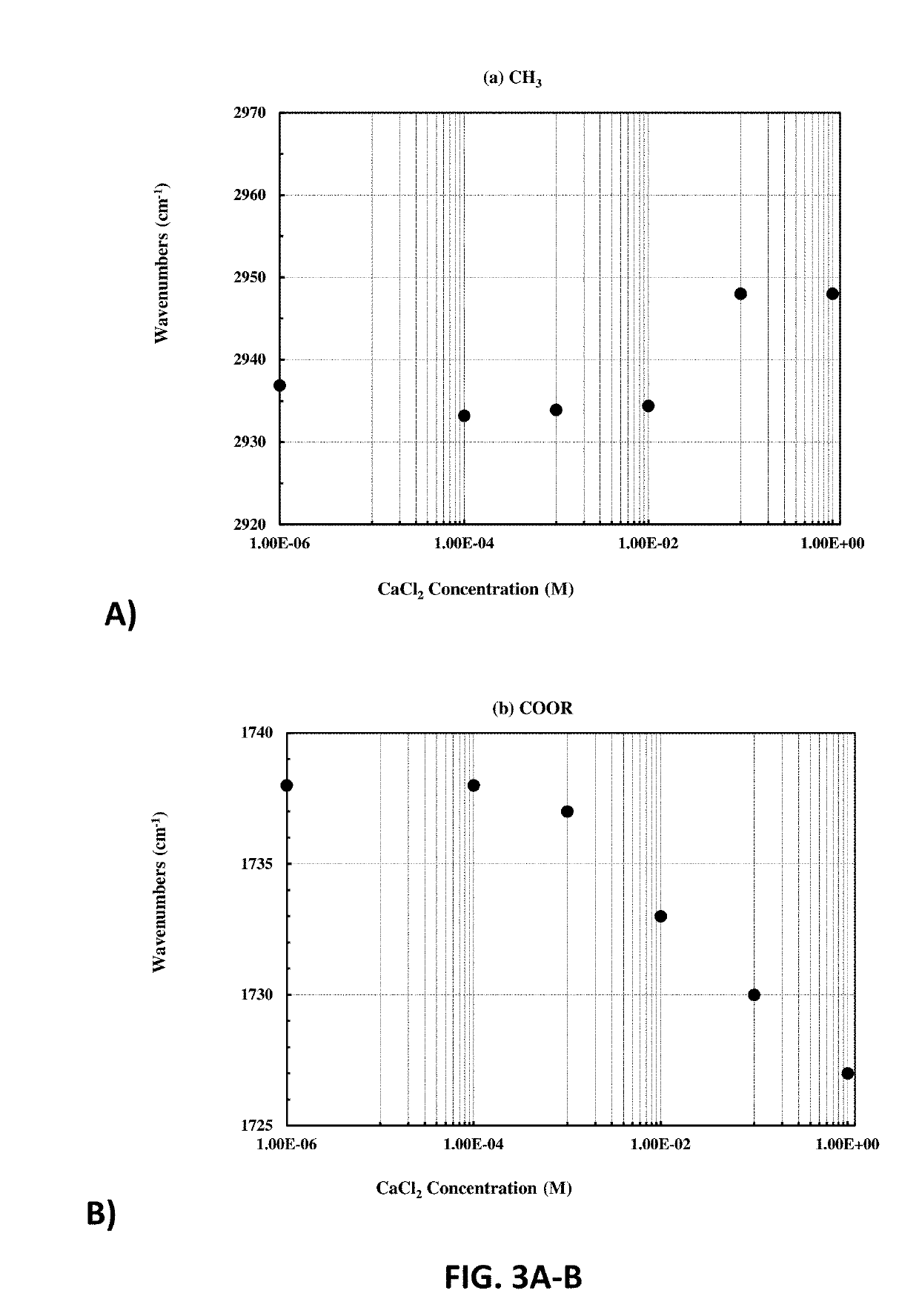

Thin film coatings and methods of manufacture thereof are presented. Ultra-thin coatings of cross-linked high-methoxyl pectin polysaccharides were fabricated by spin-casting solutions of citrus pectin followed by cross-linking upon exposure to solutions of calcium chloride (CaCl2) in ethanol. By adjusting temperature, degree of cross-linking, and pH of the surroundings, the pectin coatings can be carefully tuned for a desired response.

Owner:UNIV OF SOUTH FLORIDA

Aqueous composition for preparing hard capsule, preparation method therefor, hard capsule, and method for recycling hard capsule scraps

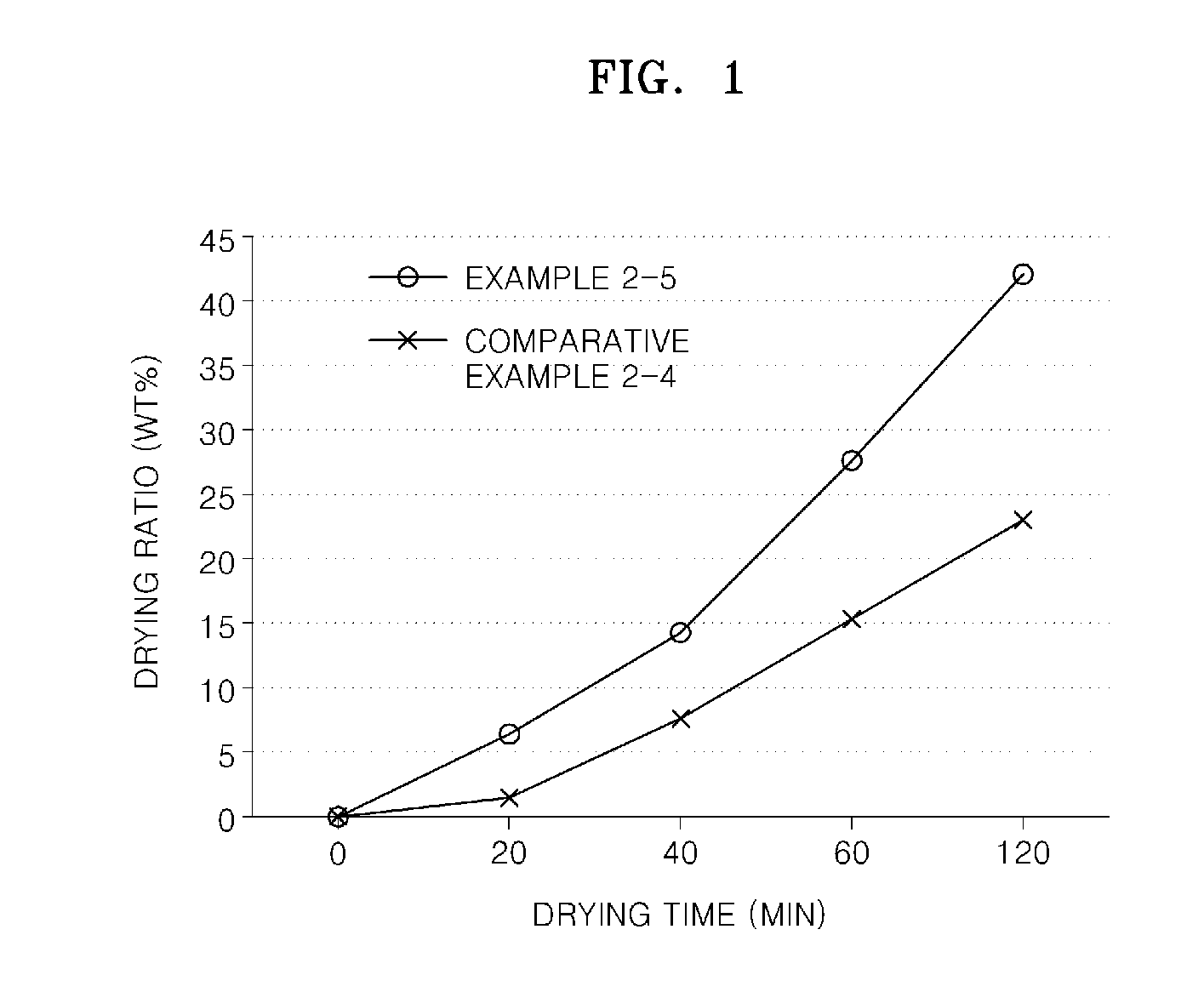

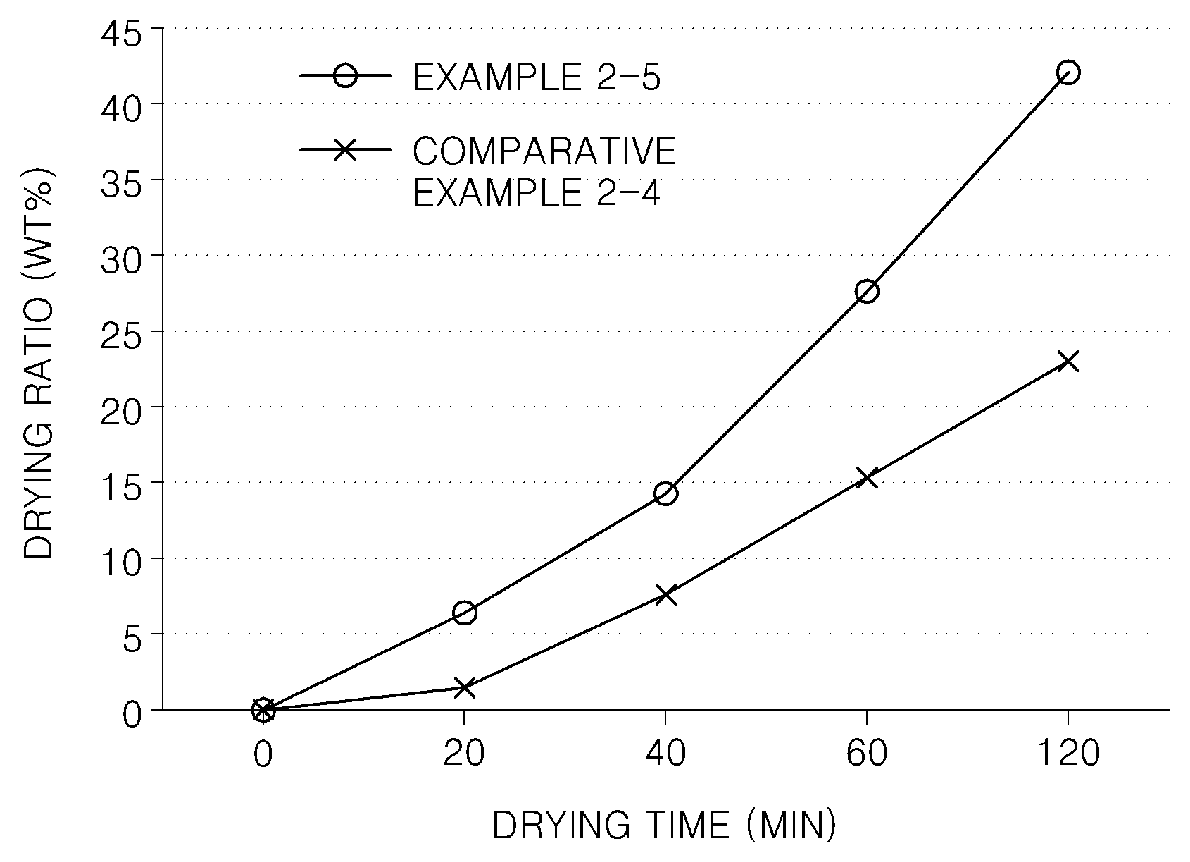

ActiveUS20150197655A1Reduce preparation timeDry in timePlastic recyclingPretreated surfacesCelluloseAlcohol

Disclosed are an aqueous composition for preparing a hard capsule, a preparation method therefor, a hard capsule, and a method for recycling hard capsule scraps. The disclosed aqueous composition for preparing a hard capsule comprises a water-soluble cellulose ether, an alcohol, and water. In addition, the method for recycling hard capsule scraps comprises the step of dissolving hard capsule scraps comprising a water-soluble cellulose ether into a mixture solution comprising water and an alcohol so as to prepare an aqueous composition for preparing a recycled hard capsule.

Owner:LOTTE FINE CHEM CO LTD

Heat-resistant polysaccharide protein composite film and preparation method thereof

InactiveCN104893431AImprove tensile propertiesHigh transparencyStarch dervative coatingsStarch coatingsComposite filmWheat starch

The invention discloses a heat-resistant polysaccharide-protein composite film and a preparation method thereof. The heat-resistant polysaccharide-protein composite film is composed of the following components in parts by mass: 10-20 parts of corn starch, 3-8 parts of whey protein, 5-15 parts of wheat starch, 3-6 parts of ACETEM, 1-2 parts of erythritol, 3-7 parts of acetate starch, 2-5 parts of acetyl glyceride, 3-7 parts of pectin, 4-10 parts of agar, 2-5 parts of d-dihydrocarvone, 1-3 parts of malic acid, 1-5 parts of glutamic acid, 1-3 parts of Quillaia saponaria saponin, 1-4 parts of lecithin and 2-6 parts of emulsifier. By using the polysaccharide-protein composite as the film-forming matrix, the prepared polysaccharide-protein composite film has the advantages of favorable stretchability and high transparency, is especially suitable to be coated on fried food, and can obviously lower the free fatty acid content in the food, reduce browning and lower the oil consumption, so that the fried food tastes crisp and delicate.

Owner:SUZHOU BEC BIOLOGICAL TECH

Aqueous liquid composition, aqueous coating liquid, functional coating film and composite material

ActiveUS9959985B2Sufficient viscosityImprove adhesionStarch dervative coatingsElectrolytic capacitorsWater basedPVA - Polyvinyl alcohol

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

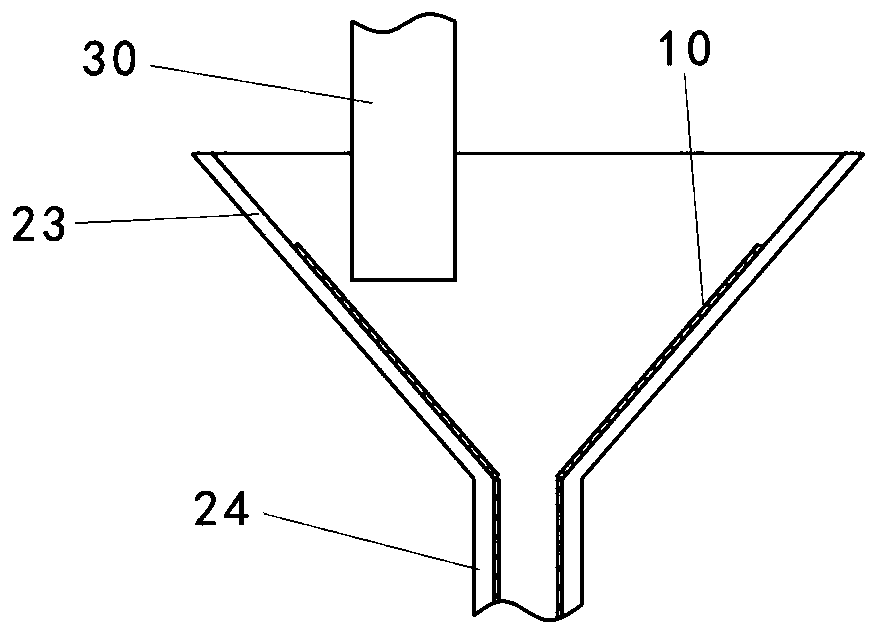

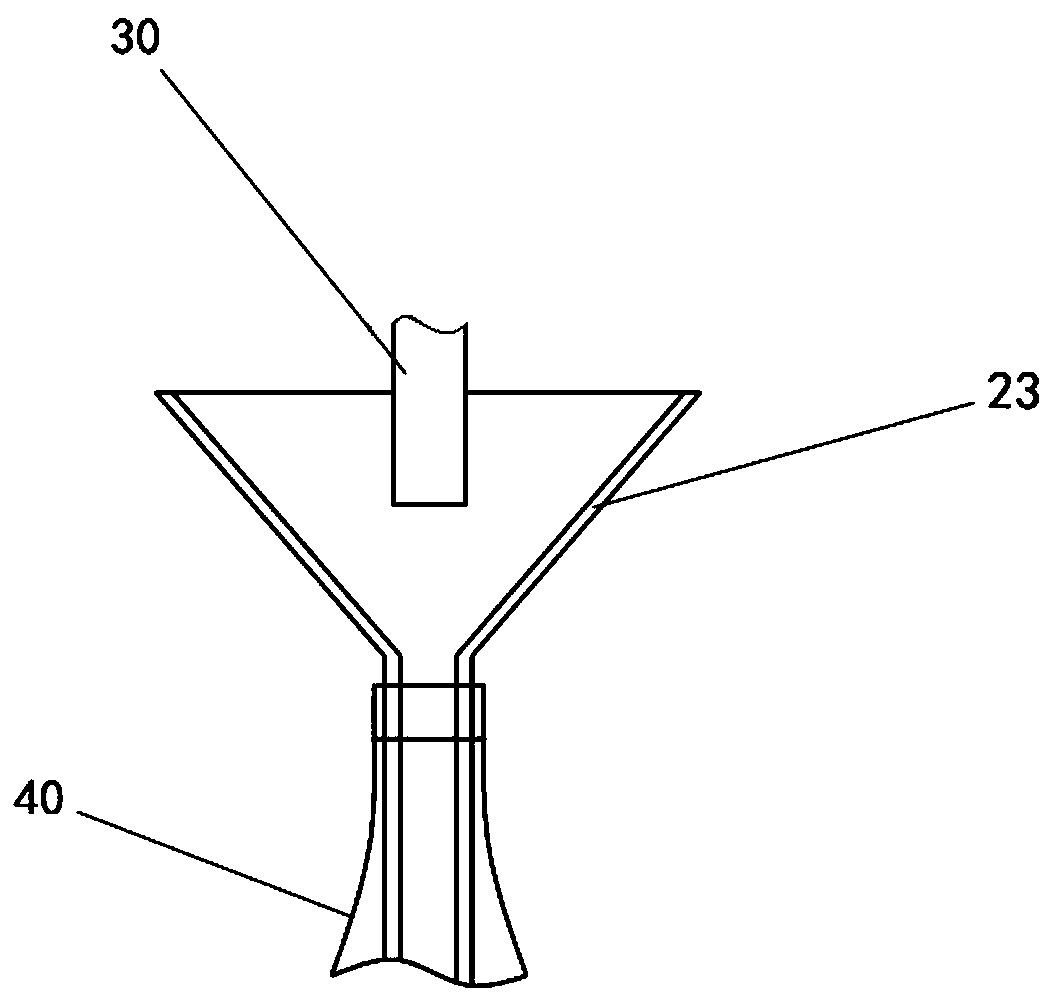

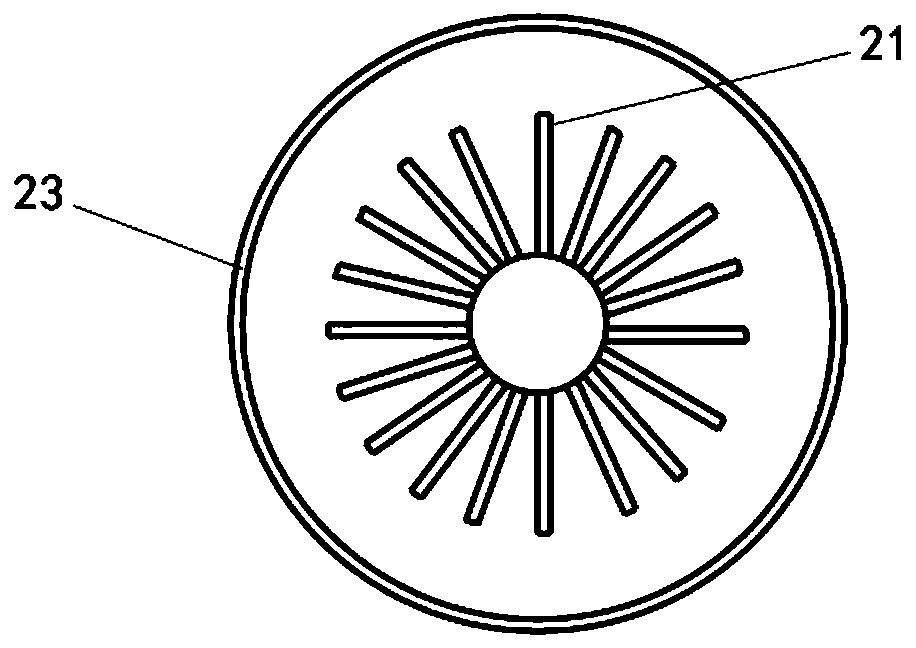

A kind of filling method of bird's nest bottle with small bottle mouth and natural filling auxiliary agent thereof

ActiveCN107129725BSolve the problem that it is not easy to pass through the mouth of the bird's nest bottleReduce cutting processLiquid fillingAntifouling/underwater paintsEngineeringBottle

The invention provides a small-opening bird's nest bottle filling method and a natural filling auxiliary agent. The small-opening bird's nest bottle natural filling auxiliary agent takes a natural filling auxiliary agent prepared from lotus leaf powder, aloe vera gel, pectin, konjac glucomannan and seaweed gel as an auxiliary lubricating agent, the surface of a funnel is coated with the natural filling auxiliary agent, filling is performed, so that the auxiliary agent solves the problem that bird's nests do not easily pass an opening of a small-opening bird's nest bottle as the diameter of the opening is small, vibration or cutting of the bird's nests is decreased, filling efficiency is improved, original strips of the bird's nests are kept, and loss of nutrient components is reduced. According to the small-opening bird's nest bottle filling method, filling time of the bird's nests is saved, and filling efficiency is improved.

Owner:燕之初健康美(厦门)食品有限公司

Green coating for wooden toy for children and production method

InactiveCN109705731AGuaranteed healthy growthImprove securityAntifouling/underwater paintsPaints with biocidesFood gradeCopper

The invention discloses a green coating for a wooden toy for children and a production method. According to the invention, sodium copper chlorophyllin is adopted; the green coating is composed of thefollowing components by weight: 1 part to 2 parts of the sodium copper chlorophyllin, 5 parts to 10 parts of edible gelatin, 2 parts to 5 parts of low-ester pectin, 0.5 part to 2 parts of food-grade sodium chloride, 1 part to 10 parts of food-grade calcium carbonate and 100 parts of water, wherein 1 part to 2 parts of the sodium copper chlorophyllin, 2 parts to 5 parts of the low-ester pectin, 0.5part to 2 parts of the food-grade sodium chloride and the water constitute a color paste group, and 5 parts to 10 parts of the edible gelatin, 1 part to 10 parts of the food-grade calcium carbonate and the water constitute a film-forming promotion group; and the color paste group and the film-forming promotion group are completely mixed when in use. By adoption of the production method provided by the invention, the green coating for the wooden toy for the children is obtained and has extremely high safety; after the green coating is coated onto a wooden toy for the children, even if a childbites the wooden toy during playing, the green coating does not bring health hazards to a biter, so healthy growth of the children is guaranteed; meanwhile, after the green coating is coated onto thewooden toy, a bright color is guaranteed, and the wooden toy can be more sanitary and safer.

Owner:杨佳意

Aqueous composition for preparing hard capsule, preparation method therefor, hard capsule, and method for recycling hard capsule scraps

ActiveUS11312878B2Reduce preparation timeDry in timePlastic recyclingCapsule deliveryCelluloseAlcohol

Disclosed are an aqueous composition for preparing a hard capsule, a preparation method therefor, a hard capsule, and a method for recycling hard capsule scraps. The disclosed aqueous composition for preparing a hard capsule comprises a water-soluble cellulose ether, an alcohol, and water. In addition, the method for recycling hard capsule scraps comprises the step of dissolving hard capsule scraps comprising a water-soluble cellulose ether into a mixture solution comprising water and an alcohol so as to prepare an aqueous composition for preparing a recycled hard capsule.

Owner:LOTTE FINE CHEM CO LTD

Blue coating for wooden toy for children and production method

InactiveCN109705732AGuaranteed healthy growthGuaranteed to be brightAntifouling/underwater paintsPaints with biocidesFood gradeGelatin

The invention discloses a blue coating for a wooden toy for children and a production method. According to the invention, a brilliant blue pigment is adopted; the blue coating is composed of the following components by weight: 1 part to 2 parts of the brilliant blue pigment, 5 parts to 10 parts of edible gelatin, 2 parts to 5 parts of low-ester pectin, 0.5 part to 2 parts of food-grade sodium chloride, 1 part to 10 parts of food-grade calcium carbonate and 100 parts of water, wherein 1 part to 2 parts of the brilliant blue pigment, 2 parts to 5 parts of the low-ester pectin, 0.5 part to 2 parts of the food-grade sodium chloride and the water constitute a color paste group, and 5 parts to 10 parts of the edible gelatin, 1 part to 10 parts of the food-grade calcium carbonate and the water constitute a film-forming promotion group; and the color paste group and the film-forming promotion group are completely mixed when in use. By adoption of the production method provided by the invention, the blue coating for the wooden toy for the children is obtained and has extremely high safety; after the green coating is coated onto a wooden toy for the children, even if a child bites the woodentoy during playing, the green coating does not bring health hazards to a biter, so healthy growth of the children is guaranteed; meanwhile, after the green coating is coated onto the wooden toy, a bright color is guaranteed, and the wooden toy can be more sanitary and safer.

Owner:杨佳意

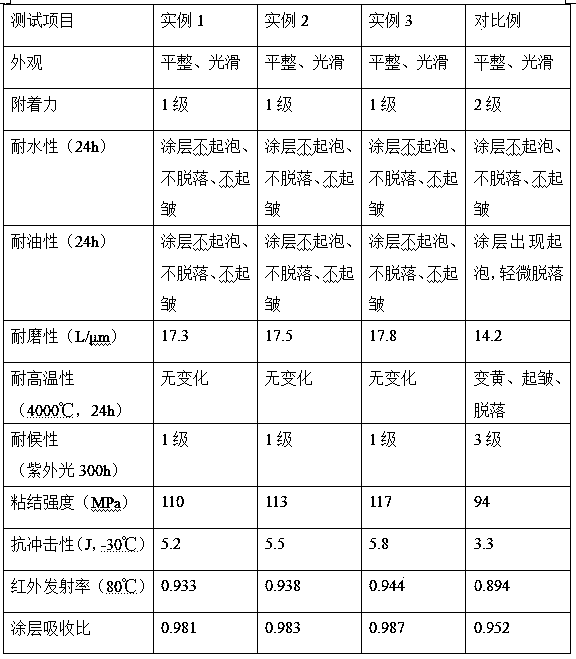

Preparation method of high-temperature-resistant waterproof solar heat-absorbing coating

InactiveCN108841254AImprove high temperature resistanceImprove structural compactnessFireproof paintsRadiation-absorbing paintsTemperature resistanceHigh heat

The invention relates to a preparation method of a high-temperature-resistant waterproof solar heat-absorbing coating and belongs to the technical field of solar heat absorption. The preparation method disclosed by the invention comprises the following steps: performing enzymolysis by taking orange peel as a raw material, and mixing with heat resistant starch to prepare an enzymolysis product; preparing mixed emulsion from organo-siloxane modified acrylate, preparing a nanometer titania crystal by taking tetrabutyl titanate as a raw material and by virtue of a sol-gel method, and finally mixing and grinding the enzymolysis product, the mixed emulsion, the nanometer titania and other aids, thereby obtaining the high-temperature-resistant waterproof solar heat-absorbing coating. According tothe method disclosed by the invention, modified pectin is prepared by utilizing the orange peel, and can form covalent bonds and other chemical bonding force with ester-based molecular chains in theheat-absorbing coating, so that the adhesion property of the solar heat-absorbing coating is improved. The high-temperature amylase is capable of improving the high temperature resistance of the solarheat-absorbing coating, the added titania nanometer material is capable of further improving the high temperature resistance of the solar heat-absorbing coating, and the coating has wide prospects.

Owner:FOSHAN TENGLI NEW ENERGY TECH CO LTD

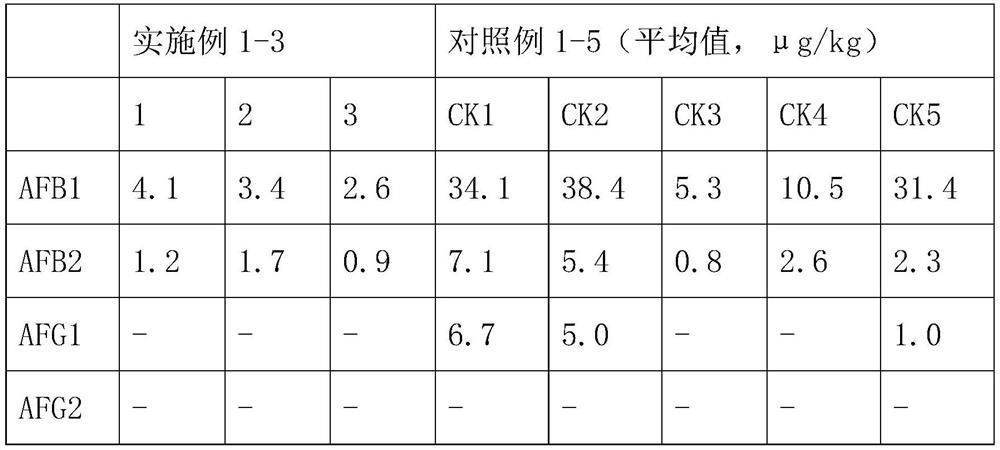

Novel aspergillus flavus infection-resistant green plant polysaccharide coating for peanuts and application method thereof

InactiveCN112272991ANo pollution in the processStop pollutionAntifouling/underwater paintsPaints with biocidesBiotechnologyPectic polysaccharide

The invention discloses a novel aspergillus flavus infection-resistant green plant polysaccharide coating for peanuts, and belongs to the technical field of peanut processing and production. The novelaspergillus flavus infection-resistant green plant polysaccharide coating comprises an agent A, an agent B and an agent C. The main component required by the coating is from waste apple pomace in theapple juicing industry, the cost is low, no pollution is caused, pectic polysaccharide is used as the main component, a physical sealing mode is mainly adopted, aspergillus flavus is prevented from polluting the peanuts, and compared with other existing technologies, the coating is green and safe, and other antibacterial and insect-resistant substances can be added according to needs.

Owner:QINGDAO ACAD OF AGRI SCI

Antimicrobial coatings based on pectin or gelatin

The present invention relates to gelatin or pectin based antimicrobial surface coating materials. In the present invention, the boron compound is mixed with gelatin or pectin and a surface coating material in the form of a film is obtained. The coating material can be used in all hygienic packaging industries, especially in the food industry. The present invention enables the packaging to be antifungal, anticandida and antibacterial.

Owner:YEDITEPE UNIVSI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com