Patents

Literature

343results about "Starch dervative coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

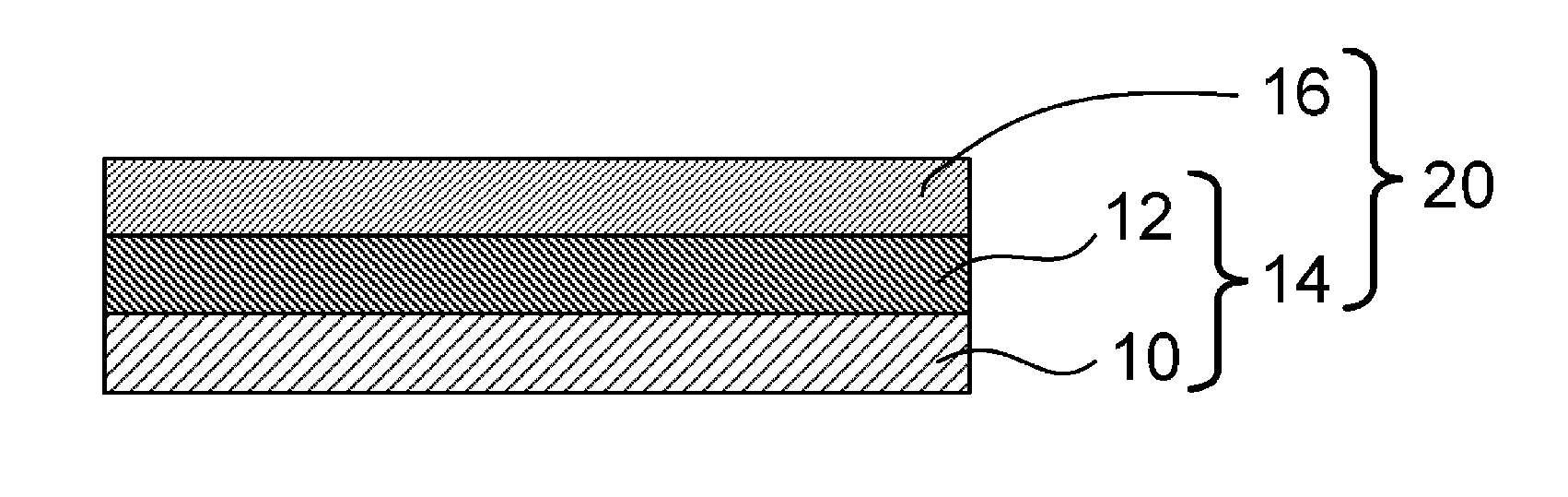

Hard coat film, polarizing plate, and image display

ActiveUS20090214871A1Deterioration in brittlenessHigh surface hardnessMaterial nanotechnologyStarch dervative coatingsOrganic solventPolyrotaxane

A hard coat film includes a transparent plastic film substrate; and a hard coat layer, wherein the hard coat layer is formed of a composition for forming a hard coat layer, the composition containing the following component (A), component (B), and an organic solvent:Component (A): a polyrotaxane,Component (B): a monomer having two or more ethylenically unsaturated groups.

Owner:FUJIFILM CORP

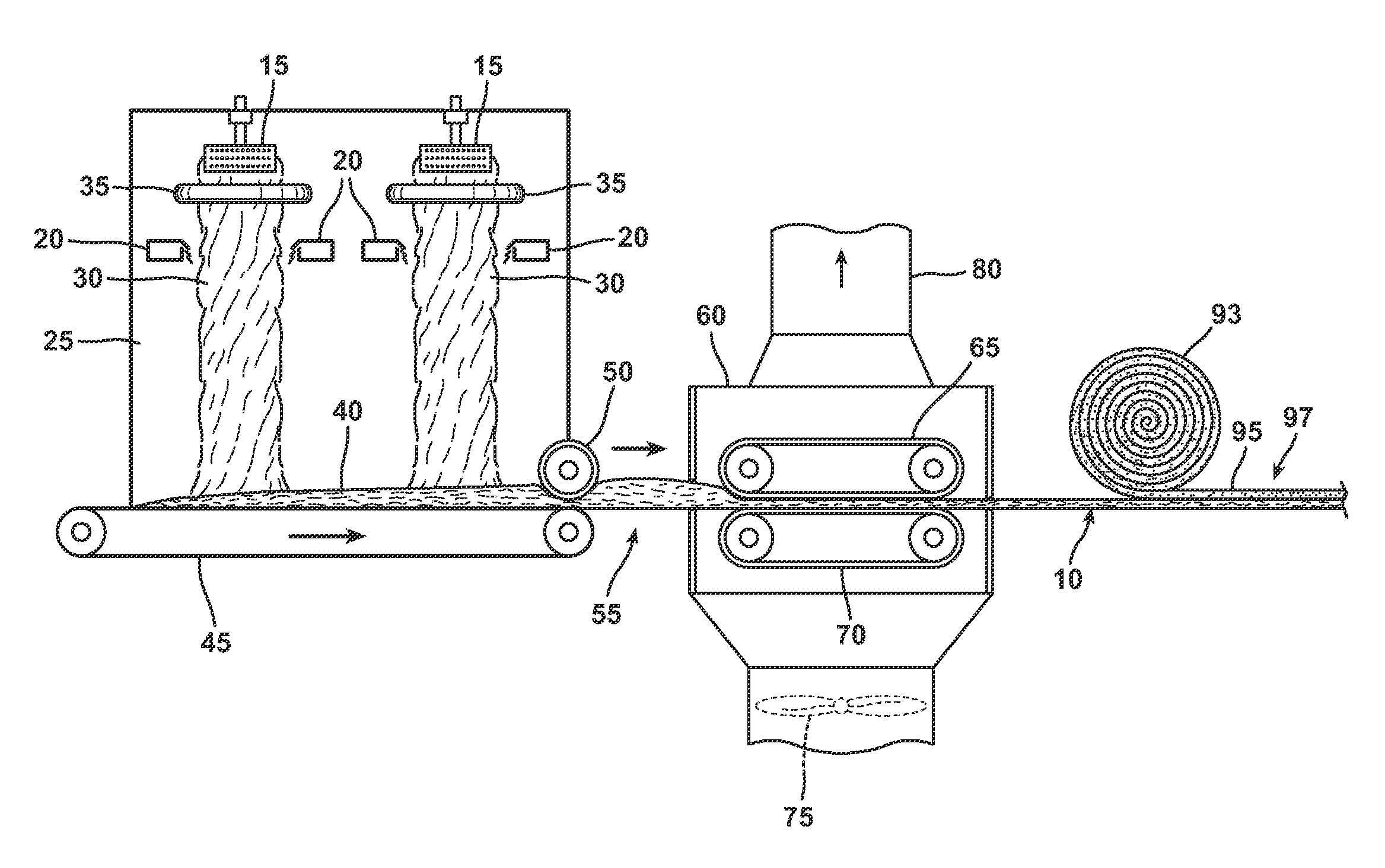

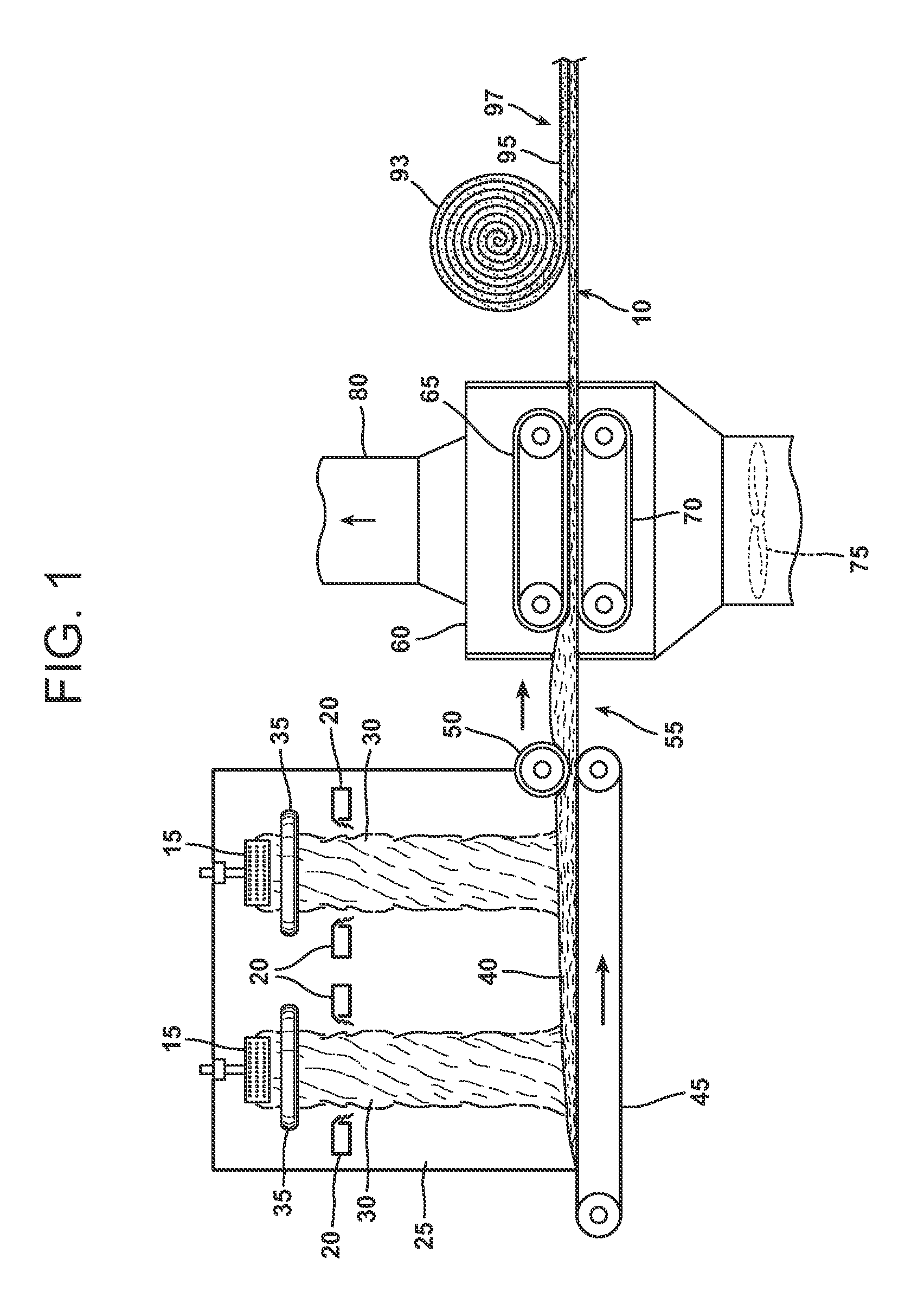

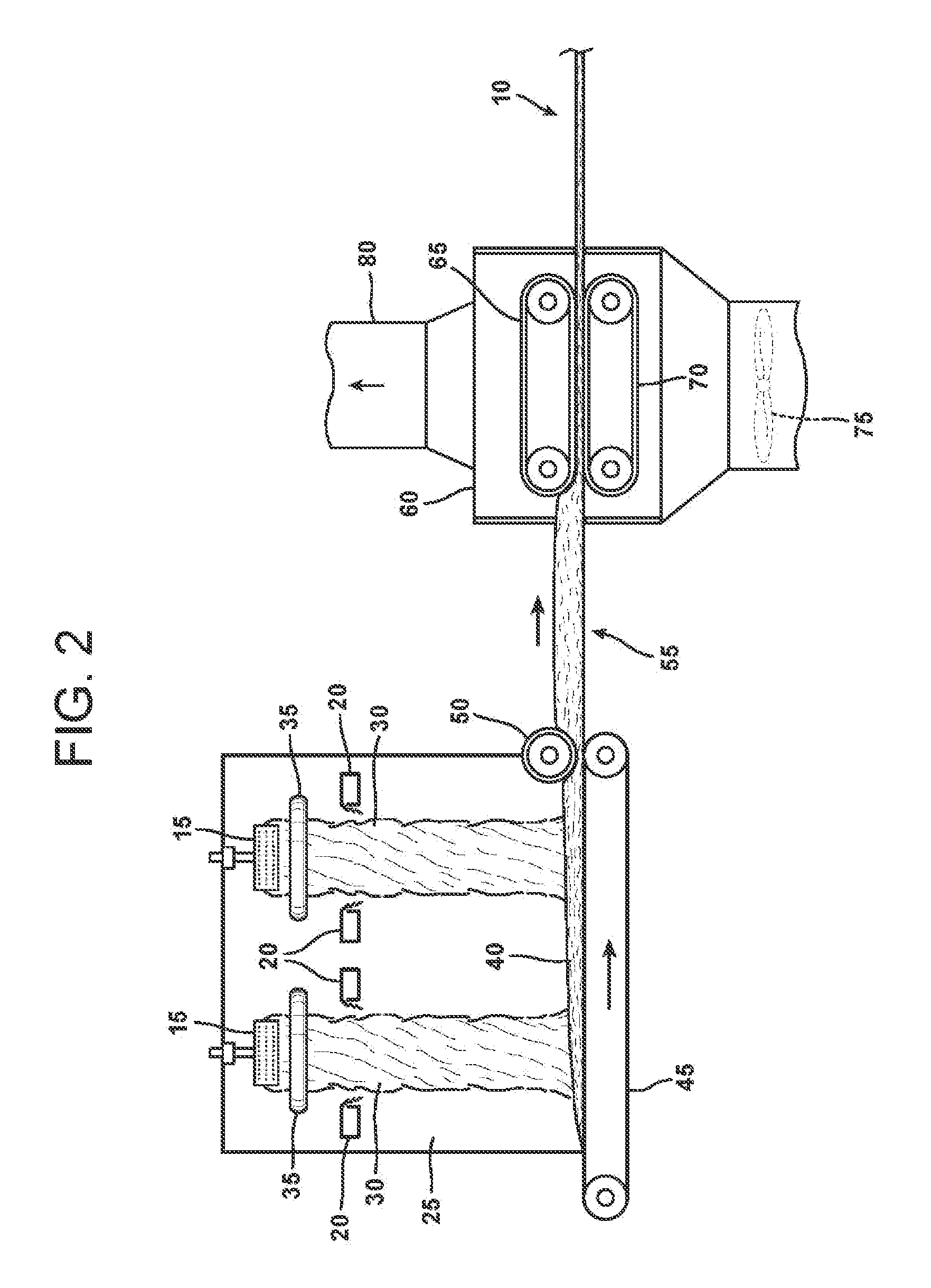

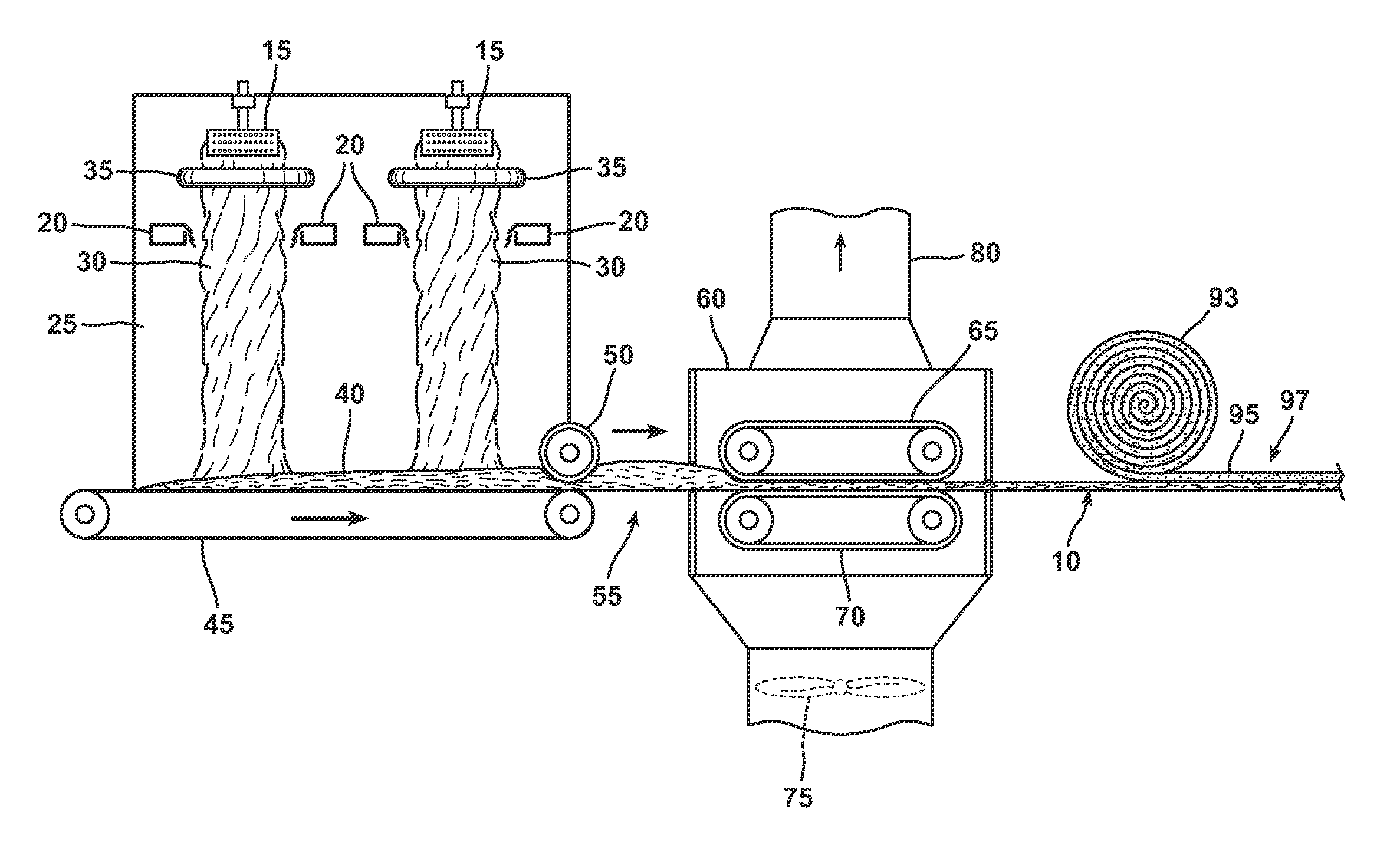

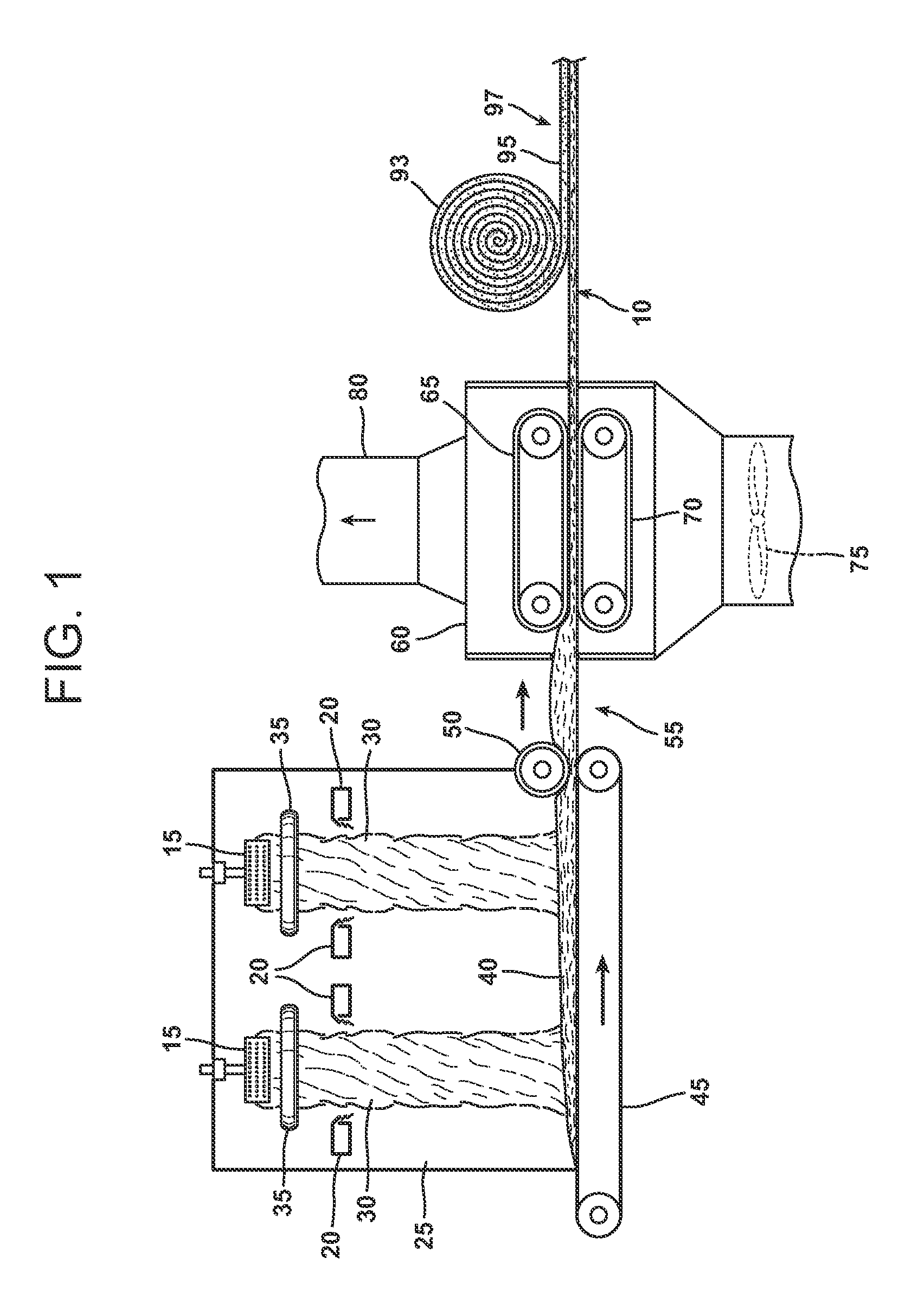

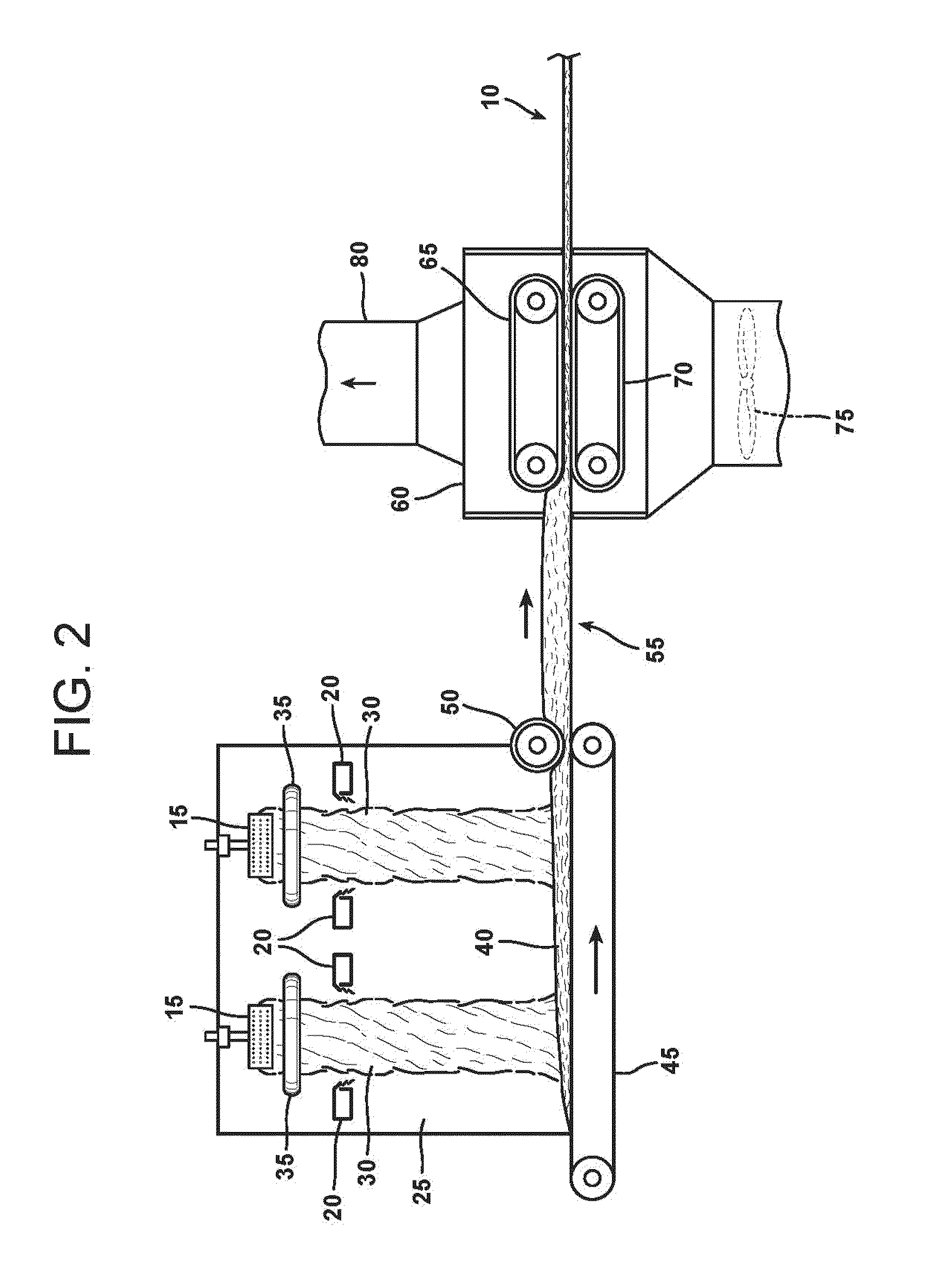

Bio-based binders for insulation and non-woven mats

ActiveUS20110086567A1Readily availableLow costStarch dervative coatingsStarch adhesivesFiberProcedure Agents

An aqueous binder composition is provided that includes a carbohydrate and a crosslinking agent. In exemplary embodiments, the carbohydrate-based binder composition may also include a catalyst, a coupling agent, a process aid, a crosslinking density enhancer, an extender, a moisture resistant agent, a dedusting oil, a colorant, a corrosion inhibitor, a surfactant, a pH adjuster, and combinations thereof. The carbohydrate may be natural in origin and derived from renewable resources. Additionally, the carbohydrate polymer may have a dextrose equivalent (DE) number from 2 to 20. In at least one exemplary embodiment, the carbohydrate is a water-soluble polysaccharide such as dextrin or maltodextrin and the crosslinking agent is citric acid. Advantageously, the carbohydrates have a low viscosity and cure at moderate temperatures. The environmentally friendly, formaldehyde-free binder may be used in the formation of insulation materials and non-woven chopped strand mats. A method of making fibrous insulation products is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Renewable binder for nonwoven materials

ActiveUS20080108741A1Improve adaptabilityLow viscosityStarch dervative coatingsNon-woven fabricsGlass fiberPolymer science

A formaldehyde-free curable aqueous composition comprising an adduct of (a) carbohydrate polymer and (b) a multi-functional crosslinking agent such as a polybasic acid may be used as a binder for non-woven products such as fiberglass insulation.

Owner:ARCLIN USA

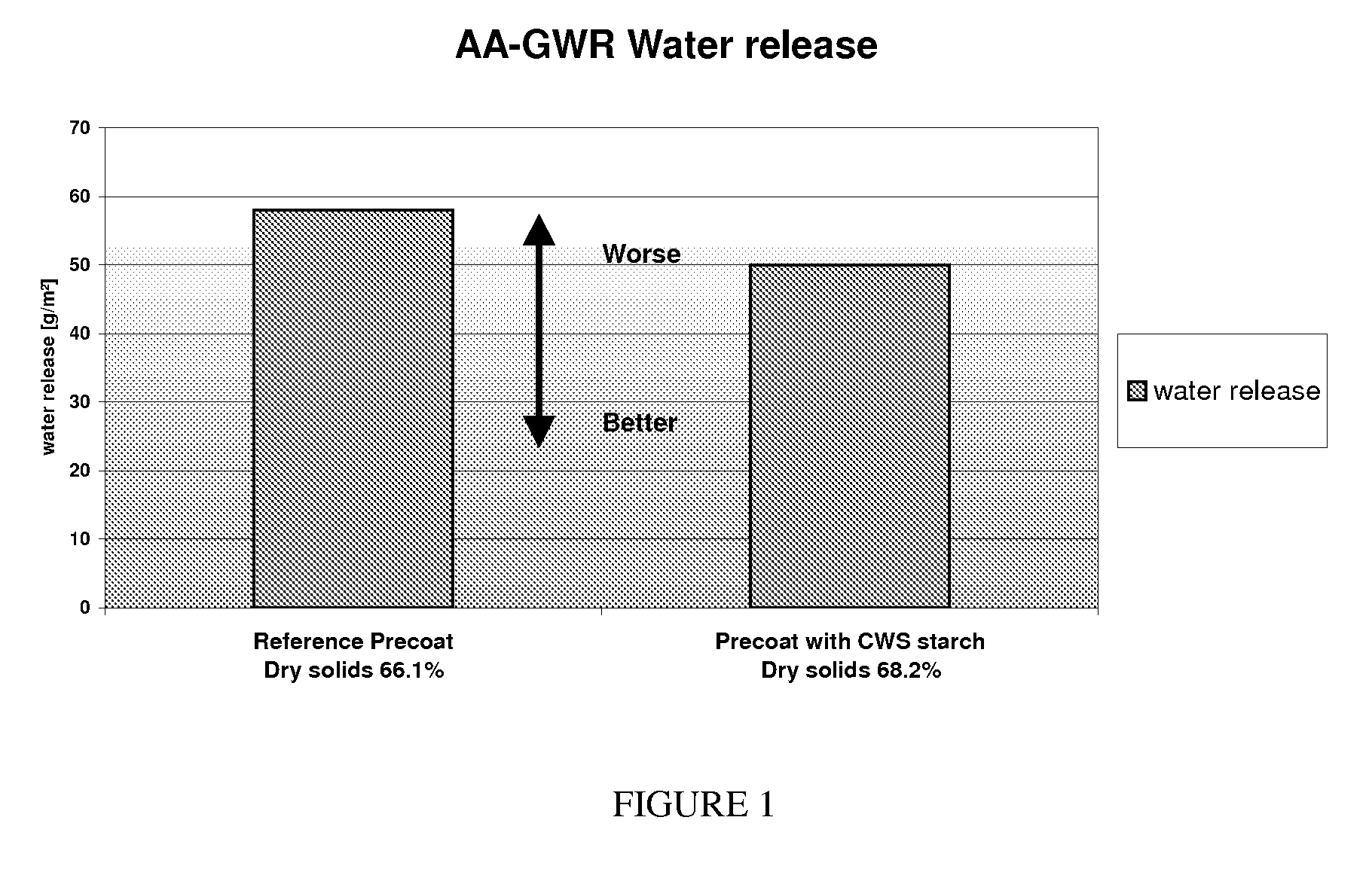

Coated substrate, a process for production of a coated substrate, a package and a dispersion coating

InactiveUS20130017349A1High strengthEasy to recycleMaterial nanotechnologyStarch dervative coatingsFiberCellulose

The present invention relates to a coated fiber based substrate comprising a dispersion coating wherein said dispersion coating comprises microfibrillated cellulose and colloidal particles of a polymer. The invention further relates to a package formed from said substrate, a dispersion coating and process for the production of mentioned substrate.

Owner:STORA ENSO OYJ

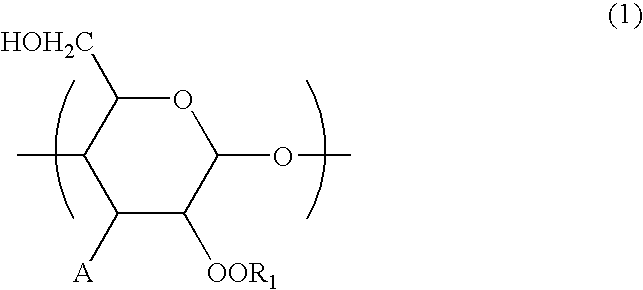

Curable starch composition, modified starch, preparation method and articles

InactiveUS20040152857A1Low water resistanceReduce biodegradationStarch dervative coatingsStarch adhesivesHydroxy groupAcid group

A curable starch composition comprising a mixture of a starch and a curing agent having a functional group complementally reactive with at least one hydroxyl group contained in a starch molecule; and a modified starch having at least one substituent selected from the group consisting of a hydrocarbon group, acid group, blocked isocyanate group, isocyanate group, oxidative polymerizable group, radical polymerizable unsaturated group and amide group in a starch molecule.

Owner:KANSAI PAINT CO LTD

Coating compositions

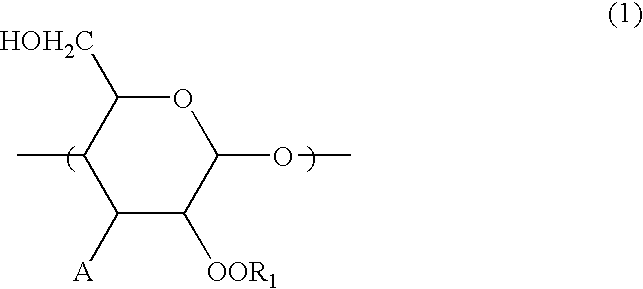

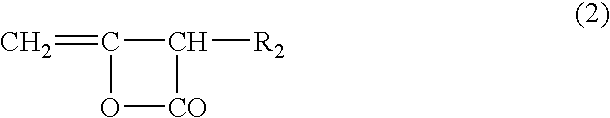

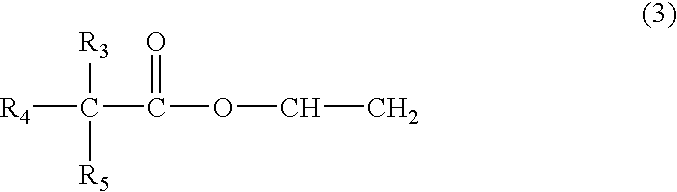

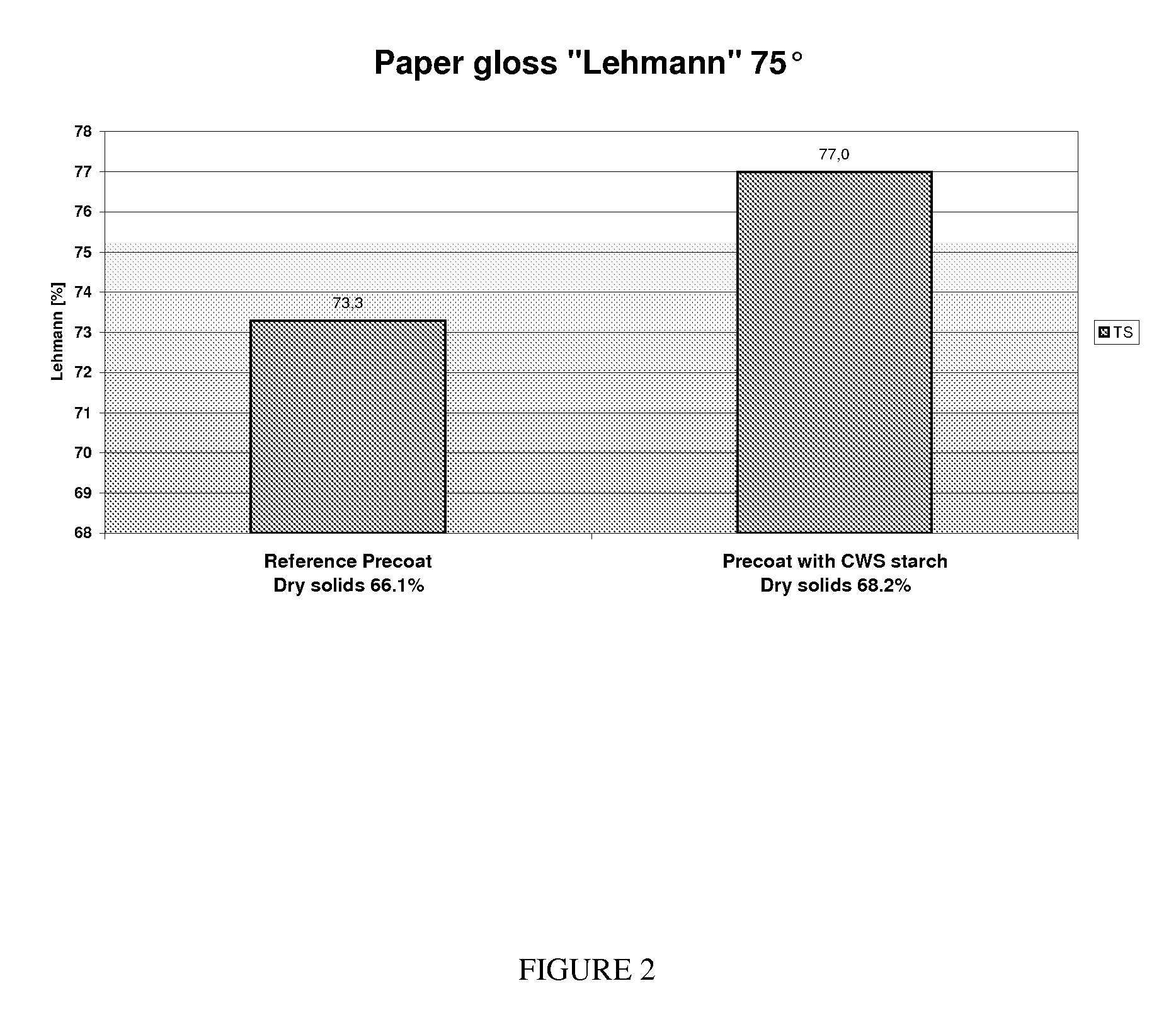

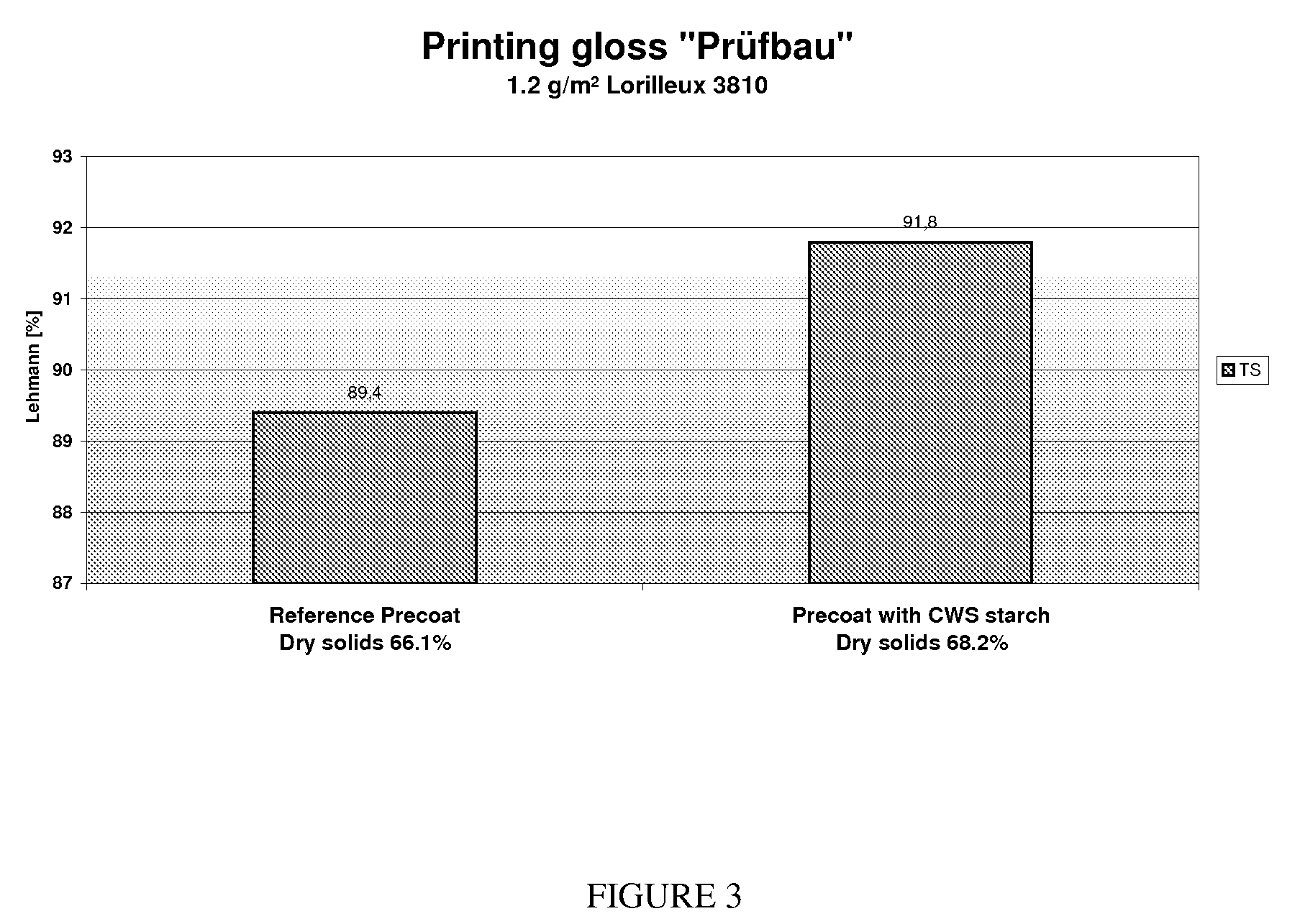

A coating composition comprising a starchy material, said material having:a number average molecular weight (Mn) of 3 500 to 20 000 Daltons,a granular structure before solubilisation,a solubility at pH 7 and 20° C. (S1) of 30-90%, anda solubility at pH 10 and 35° C. (S2) which is at least 10% greater than S1.

Owner:CARGILL INC

Manufacturing method of fabric for ink jet printing and ink jet printing method

This invention relates to a method of manufacturing a fabric for ink jet printing and to an ink jet printing method for imparting to the fabric a clear and sharp image free from ink oozing in ink jet printing. Specifically, it relates to a method of manufacturing a fabric for ink jet printing which is characterized in that an aqueous treatment solution having a water-insoluble solvent dispersed or emulsified in an aqueous polymer solution is imparted to the fabric and dried; and to an ink jet printing method characterized in that the ink jet printing is made with the ink jet printing fabric used and that after developing, the pretreatment agent is removed by washing the fabric.

Owner:TORAY IND INC

Bio-based binders for insulation and non-woven mats

ActiveUS8864893B2Low costReadily availableStarch dervative coatingsLiquid surface applicatorsFiberWater soluble polysaccharides

An aqueous binder composition is provided that includes a carbohydrate and a crosslinking agent. In exemplary embodiments, the carbohydrate-based binder composition may also include a catalyst, a coupling agent, a process aid, a crosslinking density enhancer, an extender, a moisture resistant agent, a dedusting oil, a colorant, a corrosion inhibitor, a surfactant, a pH adjuster, and combinations thereof. The carbohydrate may be natural in origin and derived from renewable resources. Additionally, the carbohydrate polymer may have a dextrose equivalent (DE) number from 2 to 20. In at least one exemplary embodiment, the carbohydrate is a water-soluble polysaccharide such as dextrin or maltodextrin and the crosslinking agent is citric acid. Advantageously, the carbohydrates have a low viscosity and cure at moderate temperatures. The environmentally friendly, formaldehyde-free binder may be used in the formation of insulation materials and non-woven chopped strand mats. A method of making fibrous insulation products is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Composition for coating of printing paper

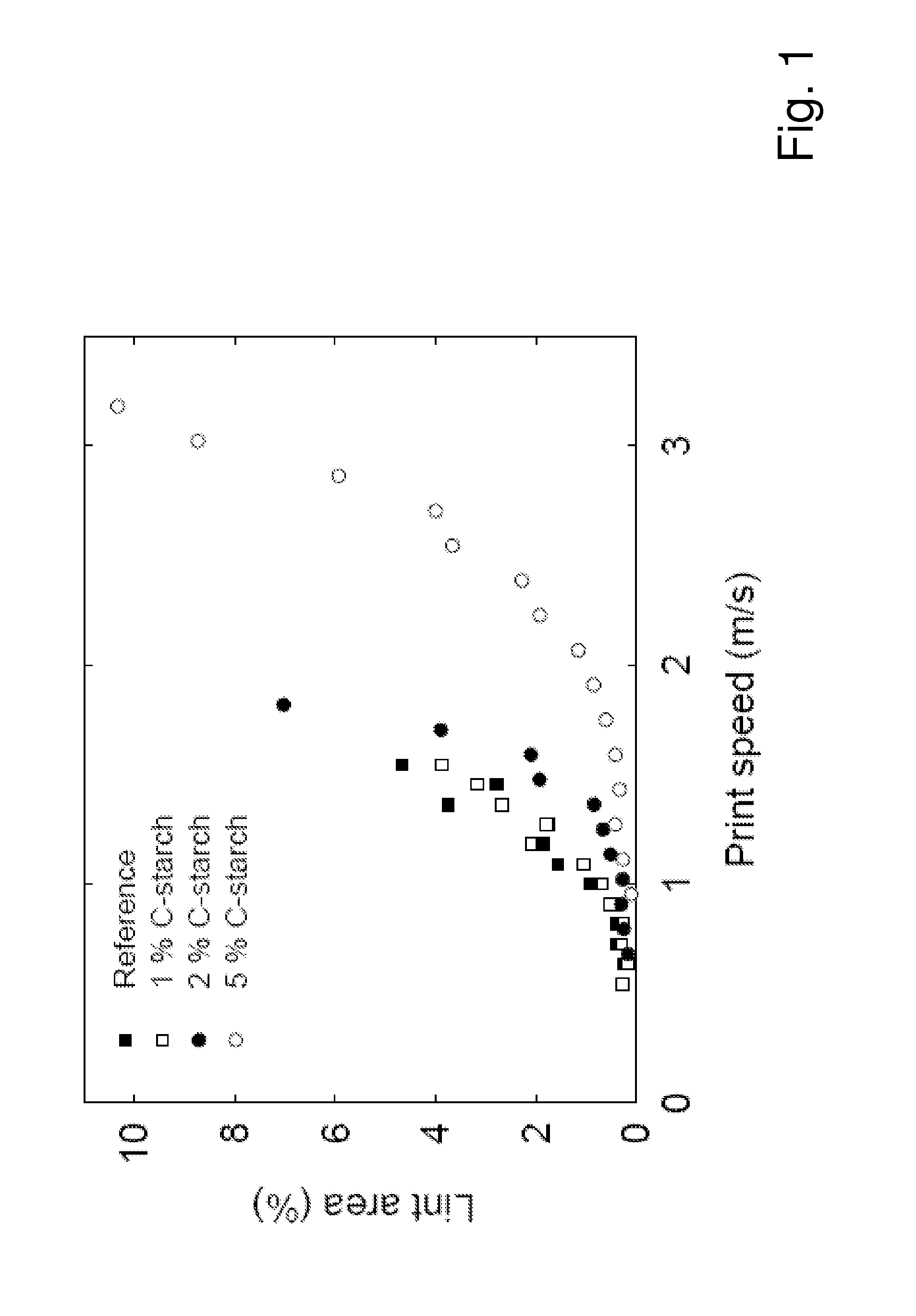

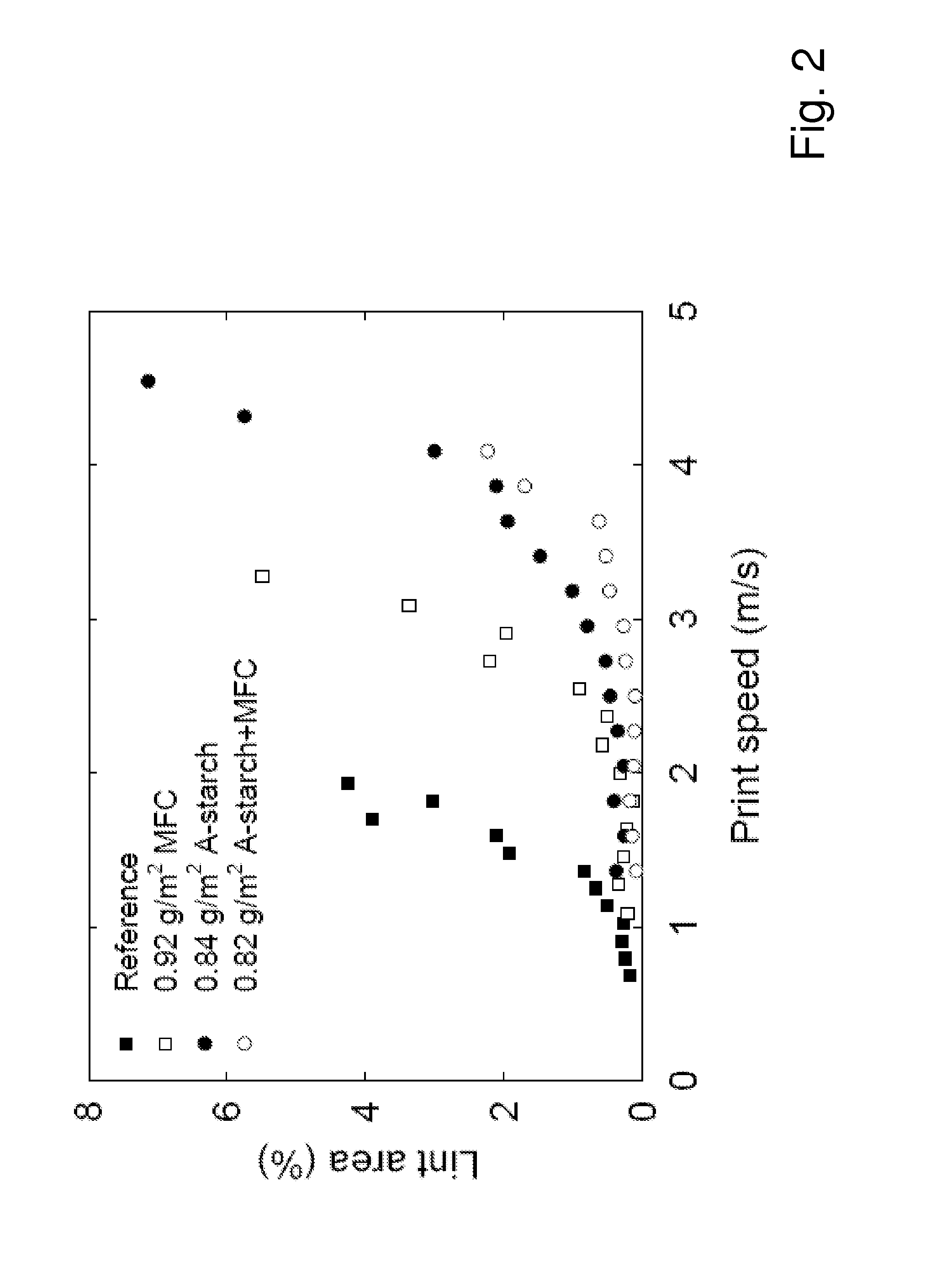

ActiveUS20110081554A1Reduced linting propensitySimple interfaceStarch dervative coatingsSpecial paperCelluloseColloid

The invention relates to compositions for coating of printing paper, said compositions comprising microfibrillated cellulose (MFC) and one or more polysaccharide hydrocolloids, and use of said compositions. Further, the invention relates to coated paper, comprising a first layer of polysaccharide hydrocolloid(s) and a second layer of MFC, and use of said paper. A method for reducing the linting and / or dusting of a paper is also disclosed.

Owner:INNVENTIA

Ink-jet recording material and preparation method thereof as well as method for preparing ink absorption layer coating liquid

ActiveCN102092209ALow priceIncrease polarityStarch dervative coatingsConjugated diene hydrocarbon coatingsPolymer scienceAdhesive

The invention provides an ink-jet recording material and a preparation method thereof as well as a method for preparing an ink absorption layer coating liquid, and relates to an ink-jet material and a preparation method thereof as well as a method for preparing an ink absorption layer coating liquid, so that the problems of poor ink absorption effect, nonuniform color distribution of printed images, unclear printed images and higher preparation cost of the existing ink-jet recording material can be solved. The ink-jet recording material is prepared from the ink-jet layer coating liquid which is prepared from PVC (polyvinyl chloride) serving as a base material, a 20-30% polyacrylic acid emulsion serving as a primer, an inorganic nano-pigment with the thickness of 10-100nm, a dispersing agent, acetic acid, deionized water and an adhesive aqueous solution. The prepared ink-jet recording material prepared through PVC material corona treatment, PVC substrate glue coating, drying, ink absorption layer coating and drying has the advantages that that the printed image is clear, the ink droplet does not diffuse, and the color is distributed uniformly; and the ink-jet recording material has excellent performances of color definition, color saturation, glossiness and the like. The raw material cost and the manufacture cost are low, so the ink-jet recording material is advantageous to industrial production, popularization and application.

Owner:HARBIN INST OF TECH

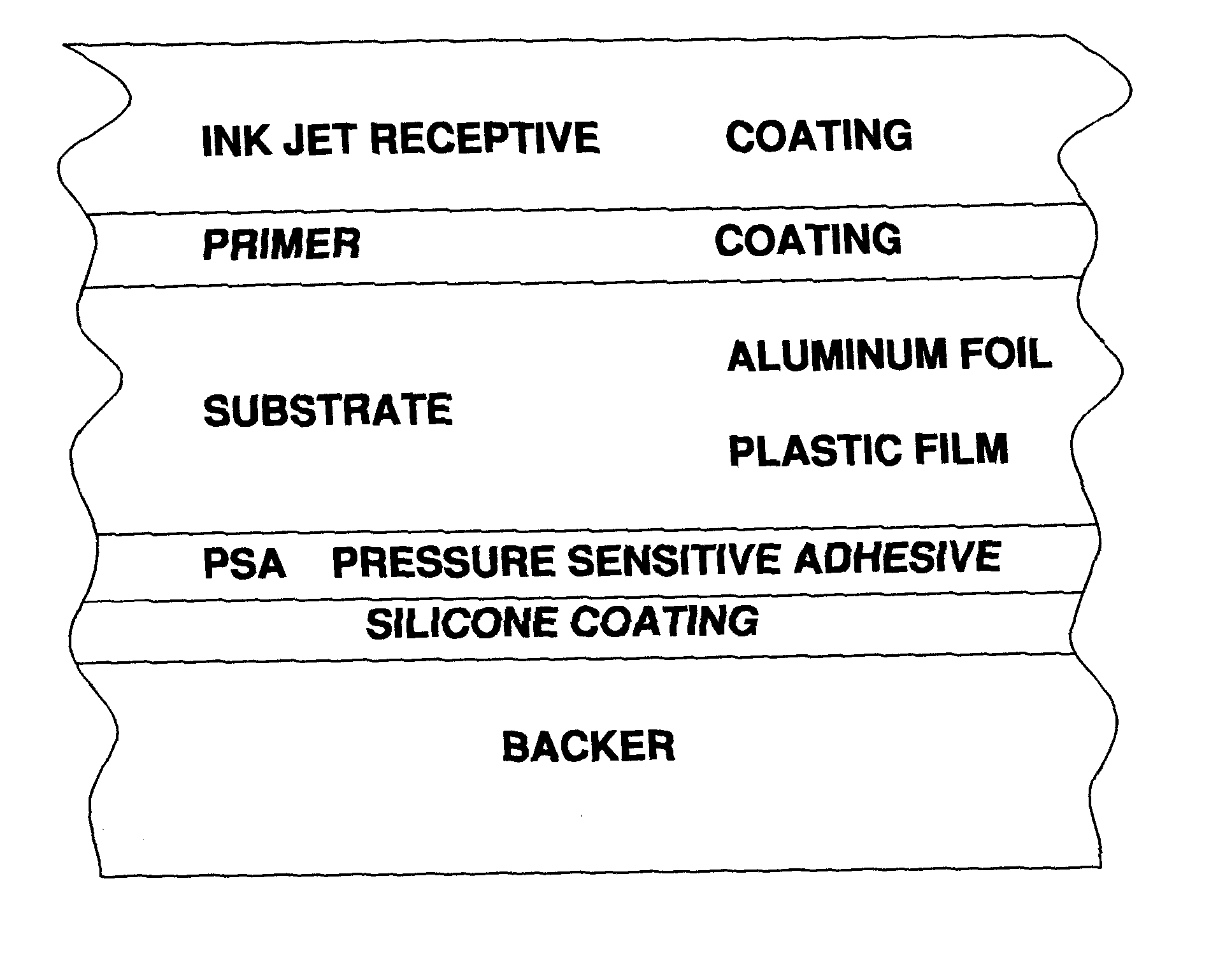

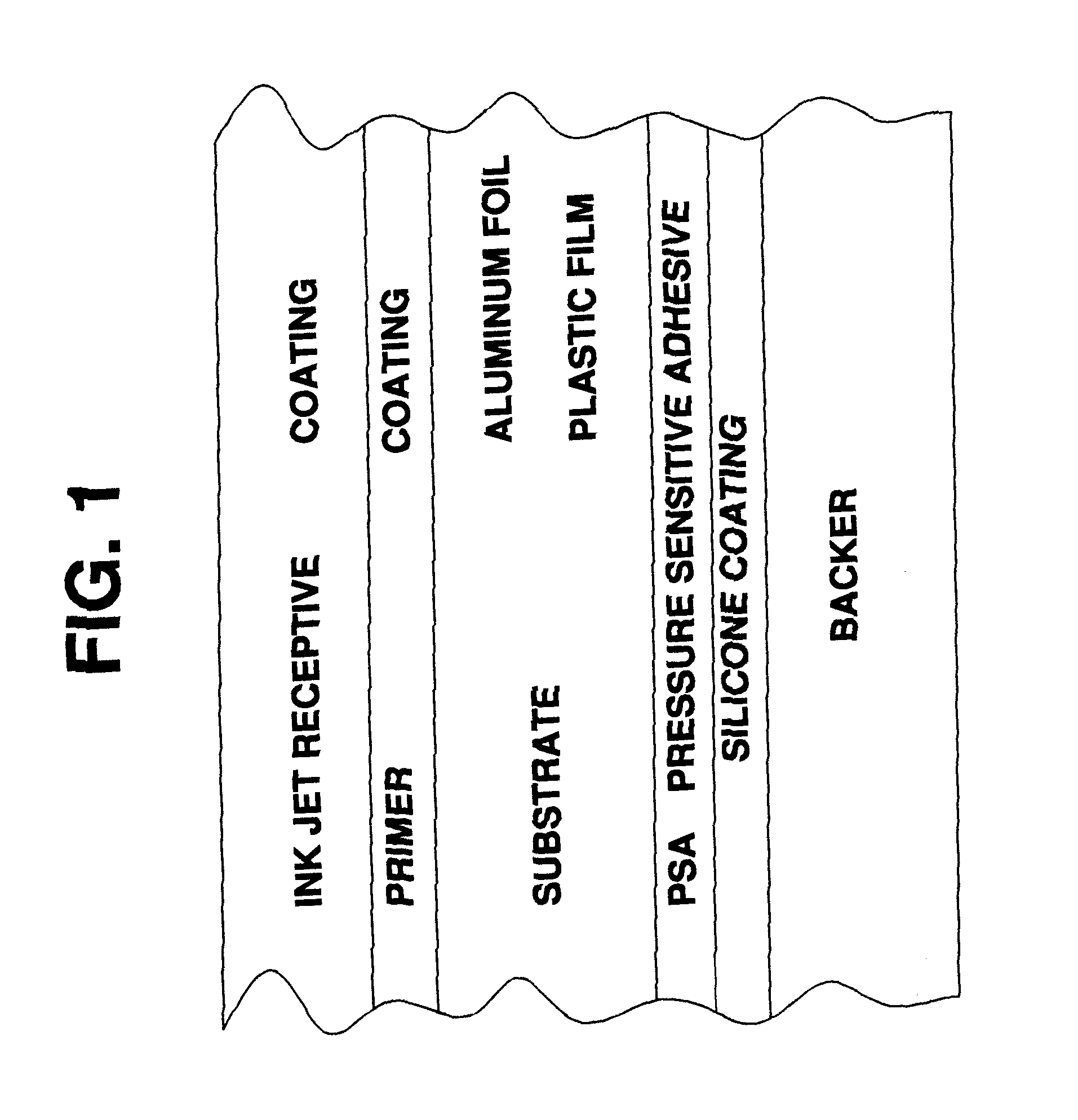

Pressure sensitive ink jet media for digital printing

InactiveUS6461422B1High acceptanceHigh resolutionCosmetic preparationsStarch dervative coatingsPorous substrateCoated surface

The problems of applying ink jet inks to various known coating surfaces so as to overcome smearing, poor resolution and attack by water etc., is overcome by the use of the new ink jet receptive media. The media comprises in combination: (1) a waterproof ink jet receptive coating, (2) a primer coating, (3) a non-porous substrate, (4) a pressure sensitive adhesive coating, (5) a silicone coating and (6) a backer layer. The receptive coating comprises the combination of: (1) binder, (2) charge control agent, (3) cross-linking agent, (4) adhesion enhancing agent and (5) dispersant. The absorption of the ink jet ink to the substrate is maximized, thus attracting and fixing the ink and providing a waterproofing effect.

Owner:CHARTPAK

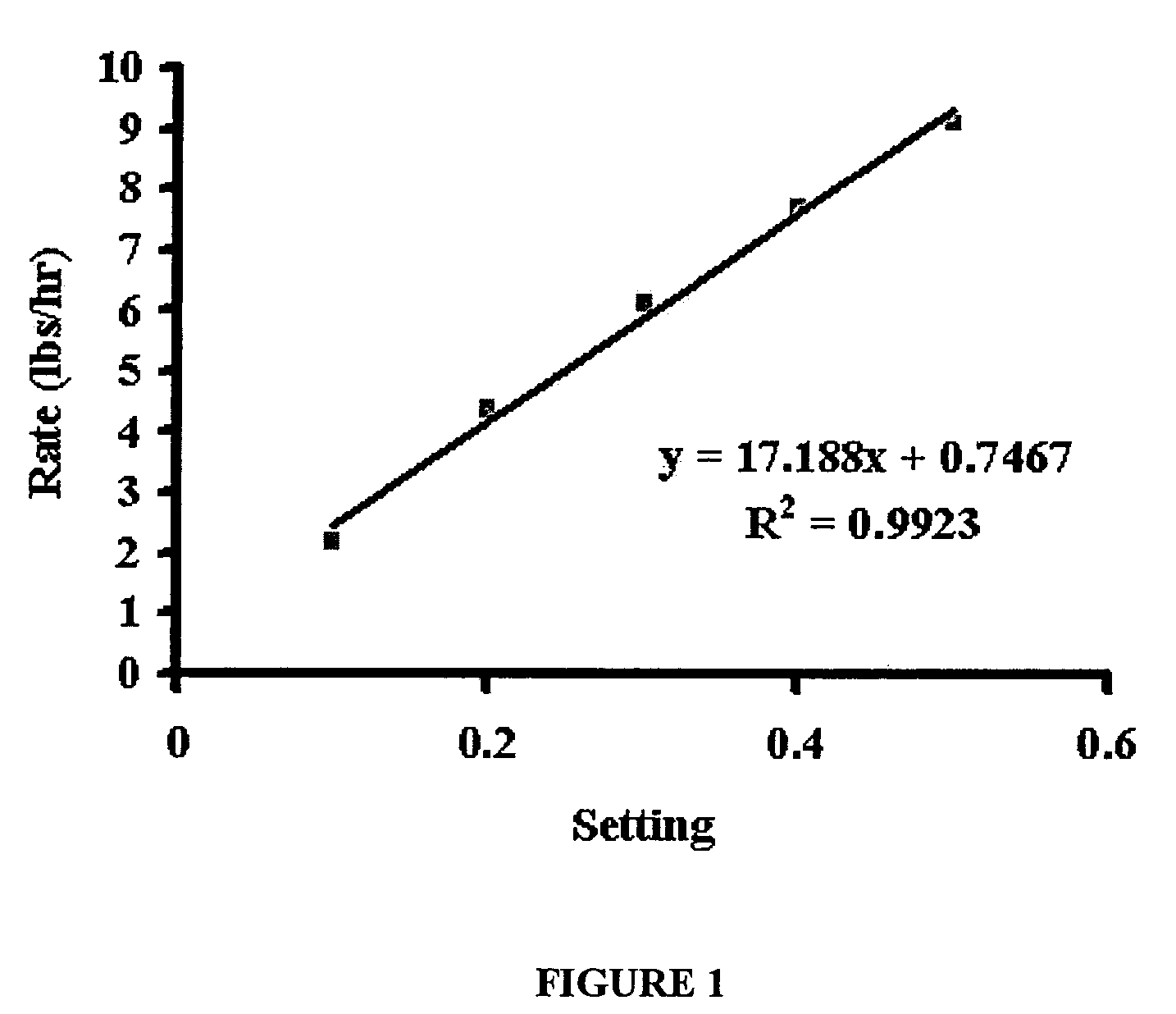

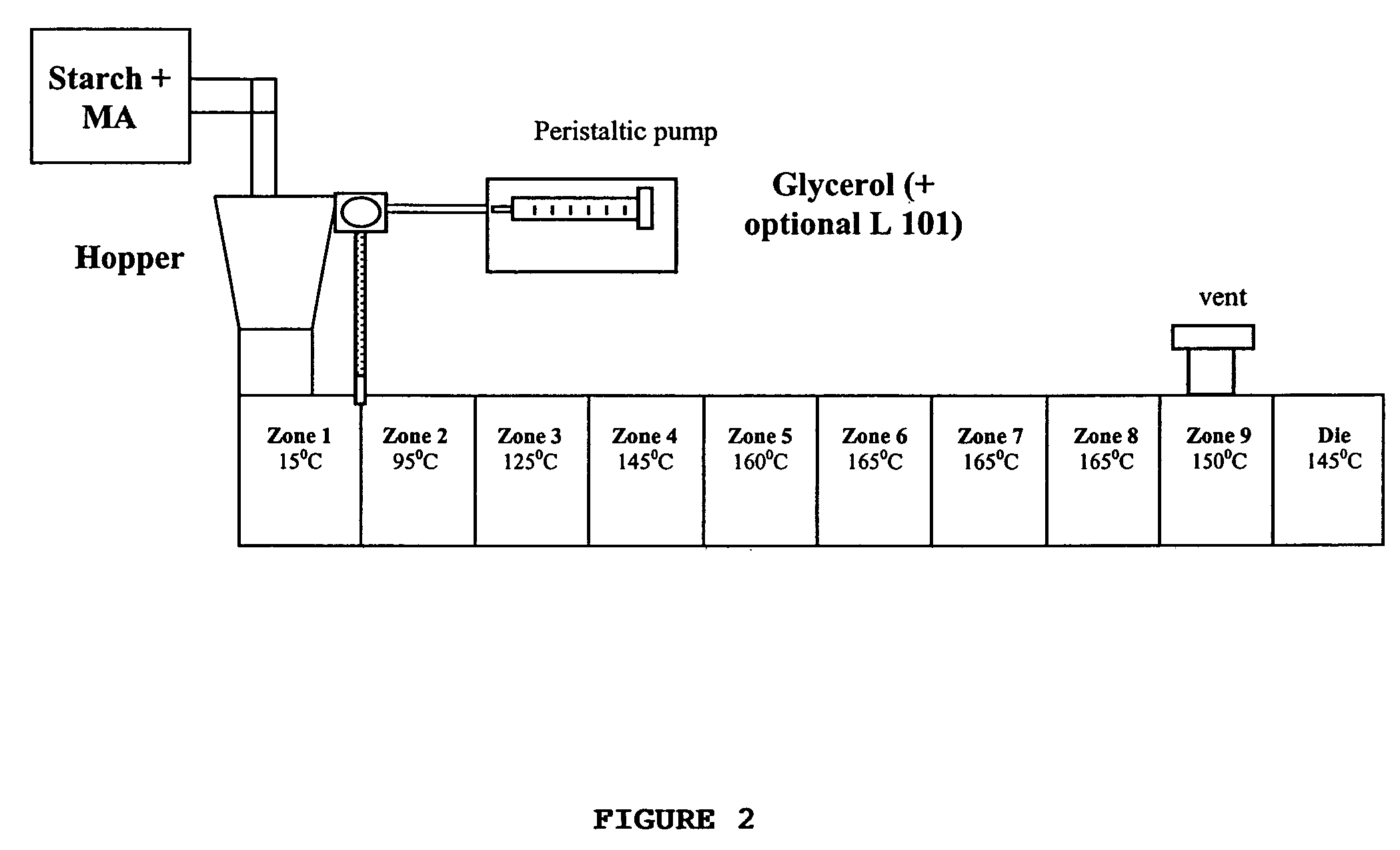

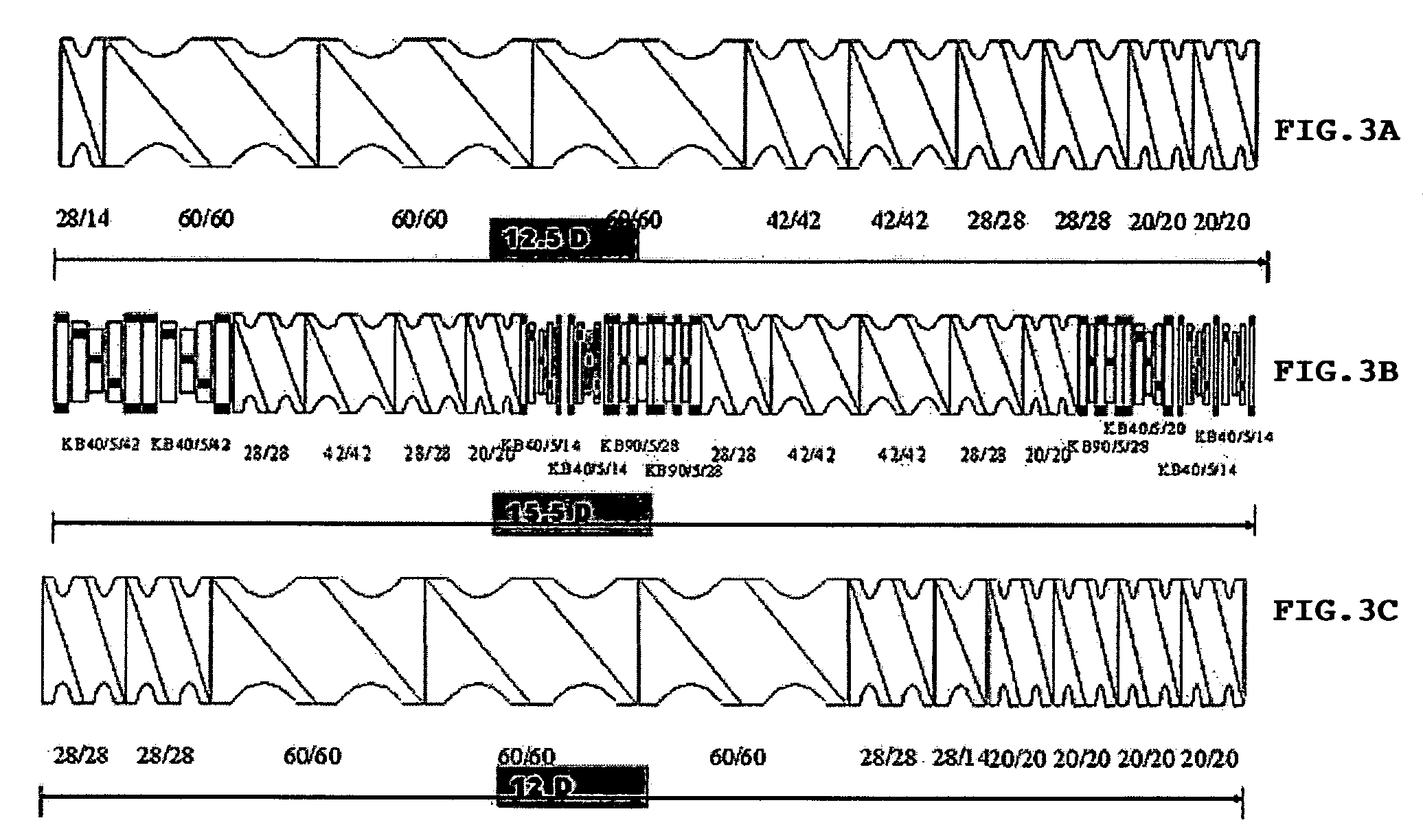

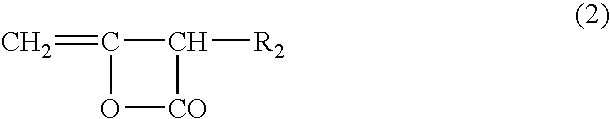

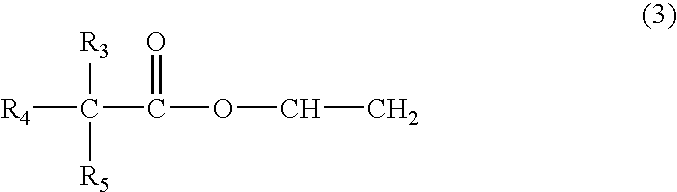

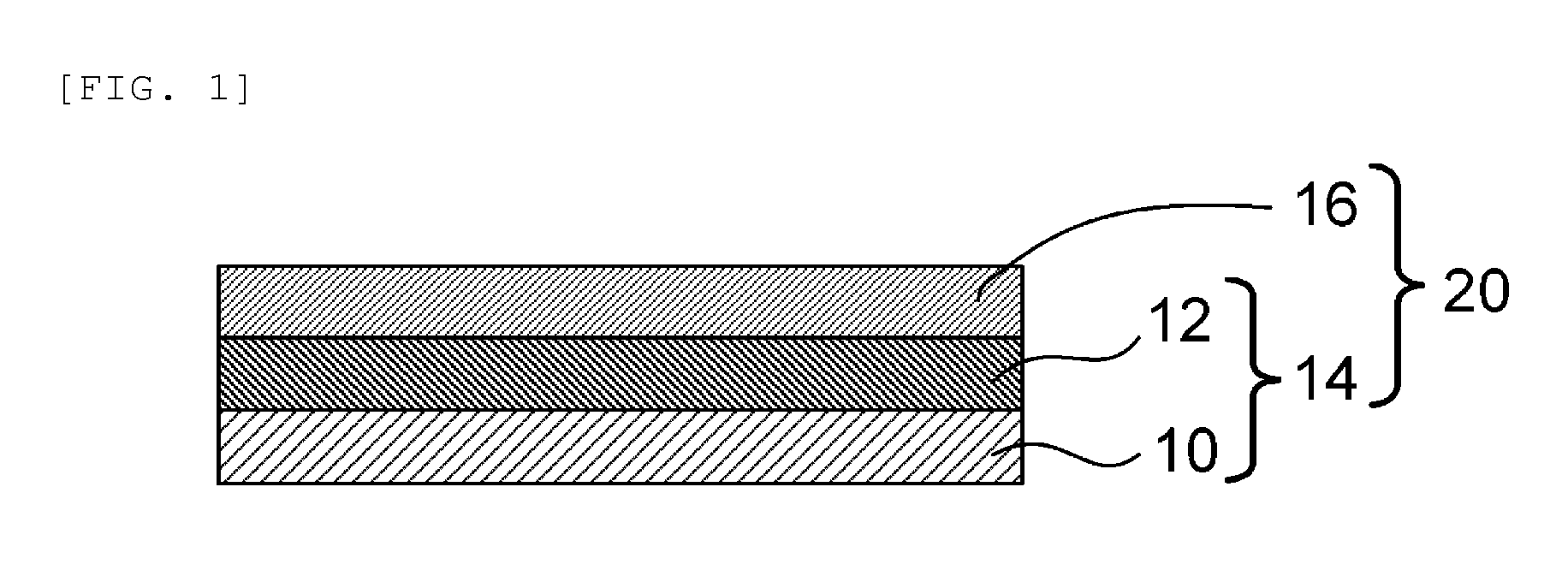

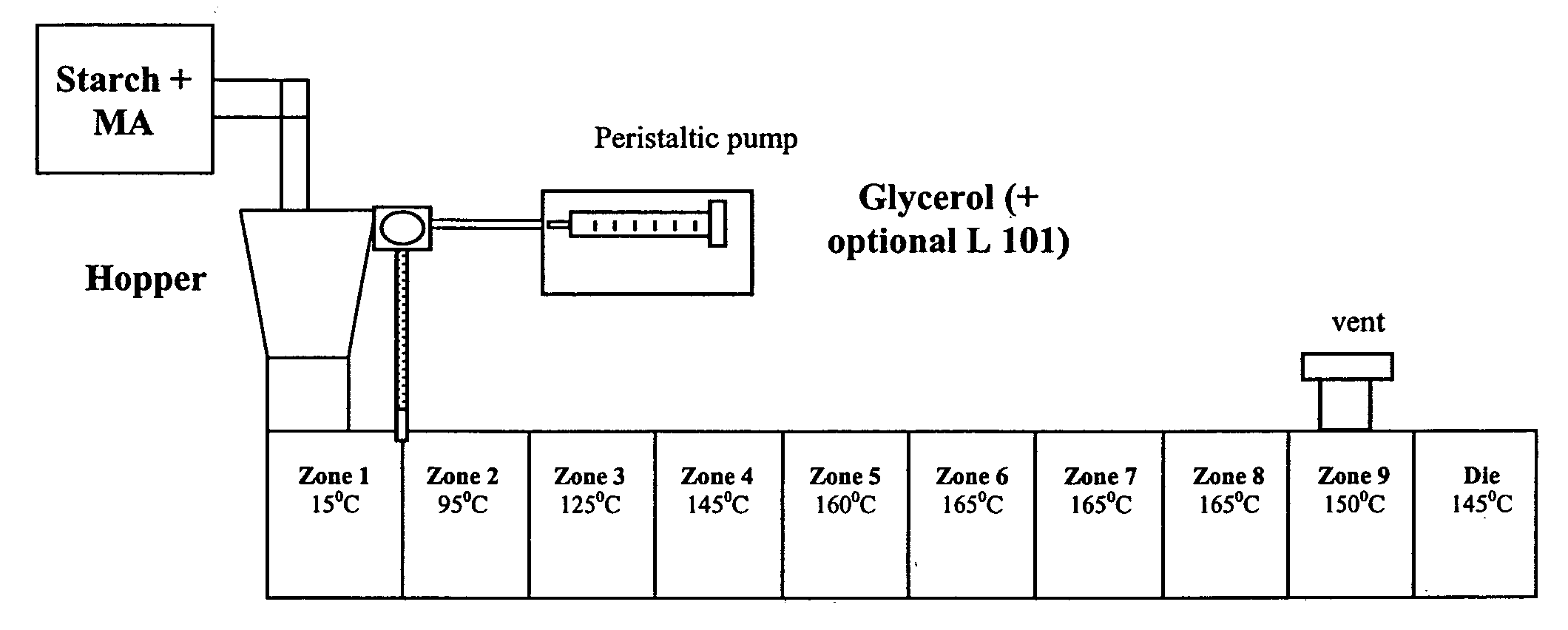

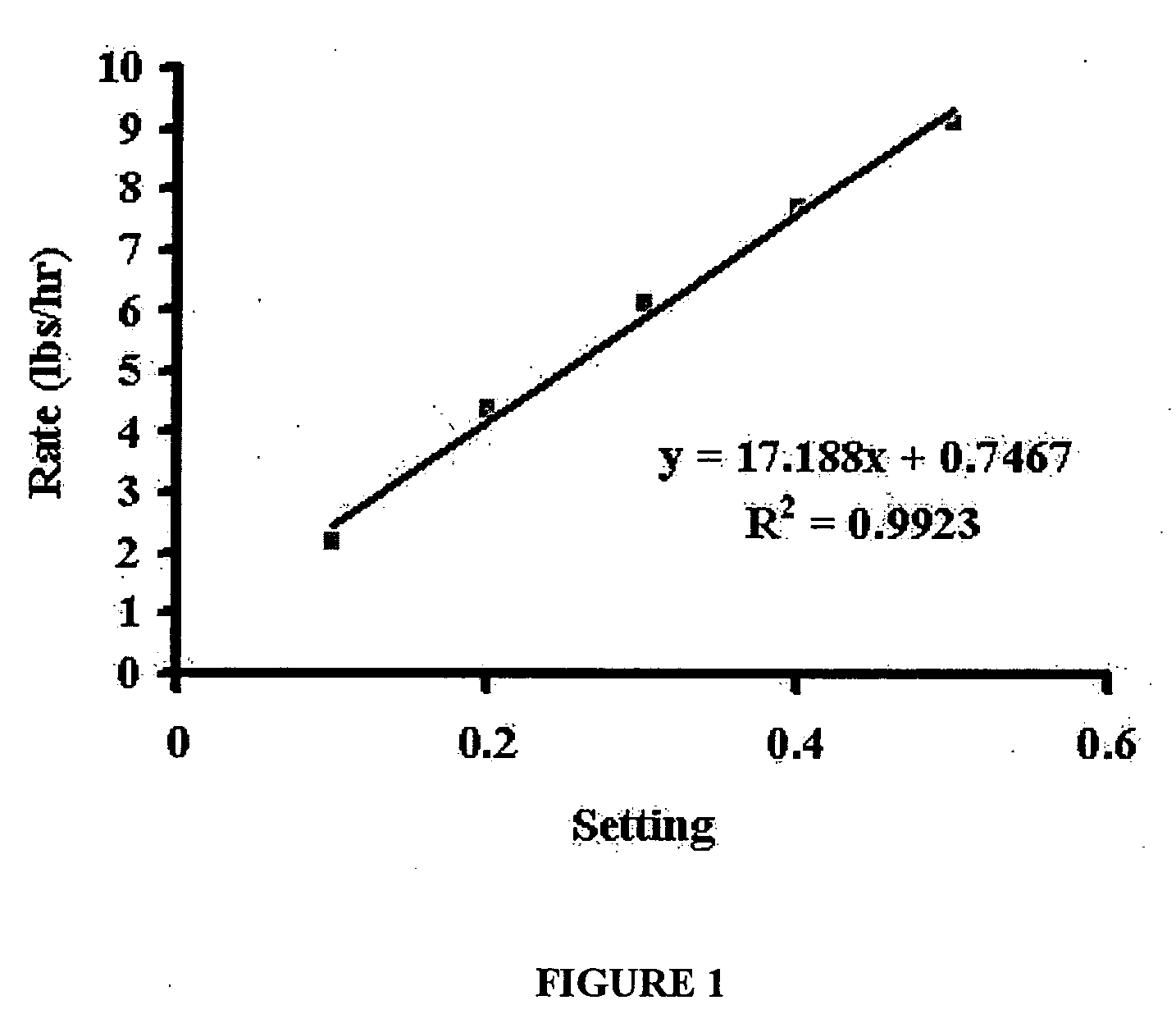

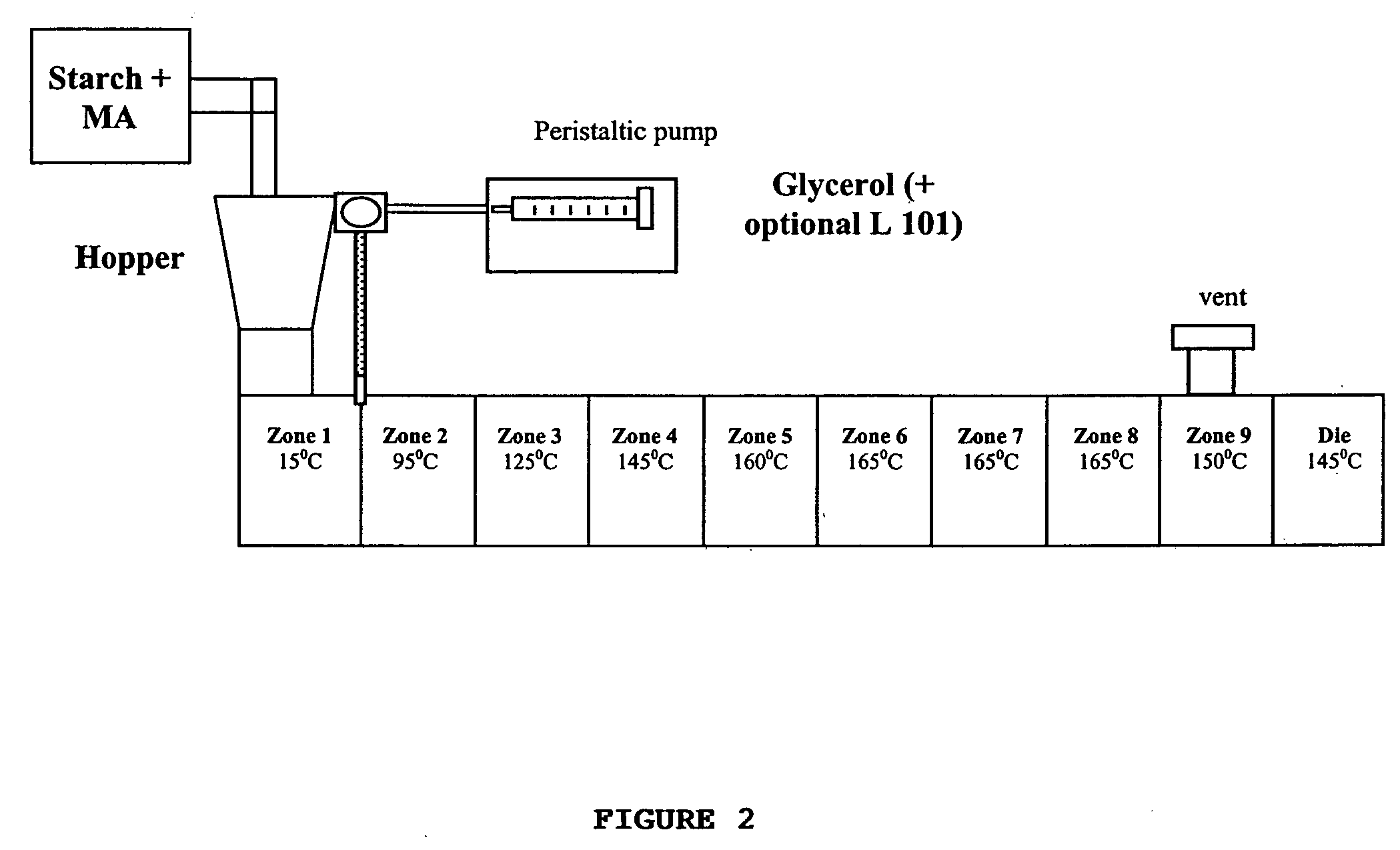

Chemically modified plasticized starch compositions by extrusion processing

ActiveUS7153354B2Improved propertyEconomical and reproducibleStarch dervative coatingsAmylose/amylopectin derivative coatingsPlasticizerViscosity

A chemically modified plasticized starch (CMPS) is prepared by reacting starch with an organic dibasic acid or an anhydride of the acid in the presence of a plasticizer using optional free radical initiators, and optionally with the incorporation of nano clays in the reactive extrusion process. The starch is thermoplastic and has a lower viscosity than the traditional thermoplastic starch. The CMPS is useful in preparing starch polymer compositions which are at least partially biodegradable.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Curable starch composition, modified starch, preparation method and articles

InactiveUS20070275258A1Good property in water resistance and corrosion resistance and weather resistance and durabilityStarch dervative coatingsStarch adhesivesHydroxy groupAcid group

A curable starch composition comprising a mixture of a starch and a curing agent having a functional group complementally reactive with at least one hydroxyl group contained in a starch molecule; and a modified starch having at least one substituent selected from the group consisting of a hydrocarbon group, acid group, blocked isocyanate group, isocyanate group, oxidative polymerizable group, radical polymerizable unsaturated group and amide group in a starch molecule.

Owner:KANSAI PAINT CO LTD

Water-based slurry composition, electrode plate for electricity storage device, and electricity storage device

ActiveUS20120156562A1Sufficient viscosityGood dispersionStarch dervative coatingsElectrolytic capacitorsWater basedSlurry

A water-based slurry composition contains (1) a water-based medium containing at least water as a polar solvent, (2) at least one polymer selected from cellulose derivatives, alginic acid derivatives, starch derivatives, chitin derivatives, chitosan derivatives, polyallylamine and polyvinylamine, (3) a hydrophobic filler, and (4) a polybasic acid or a derivative thereof. The composition has a water content of 30 mass % or higher. An electrode plate for an electricity storage device, and the electricity storage device are also disclosed.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

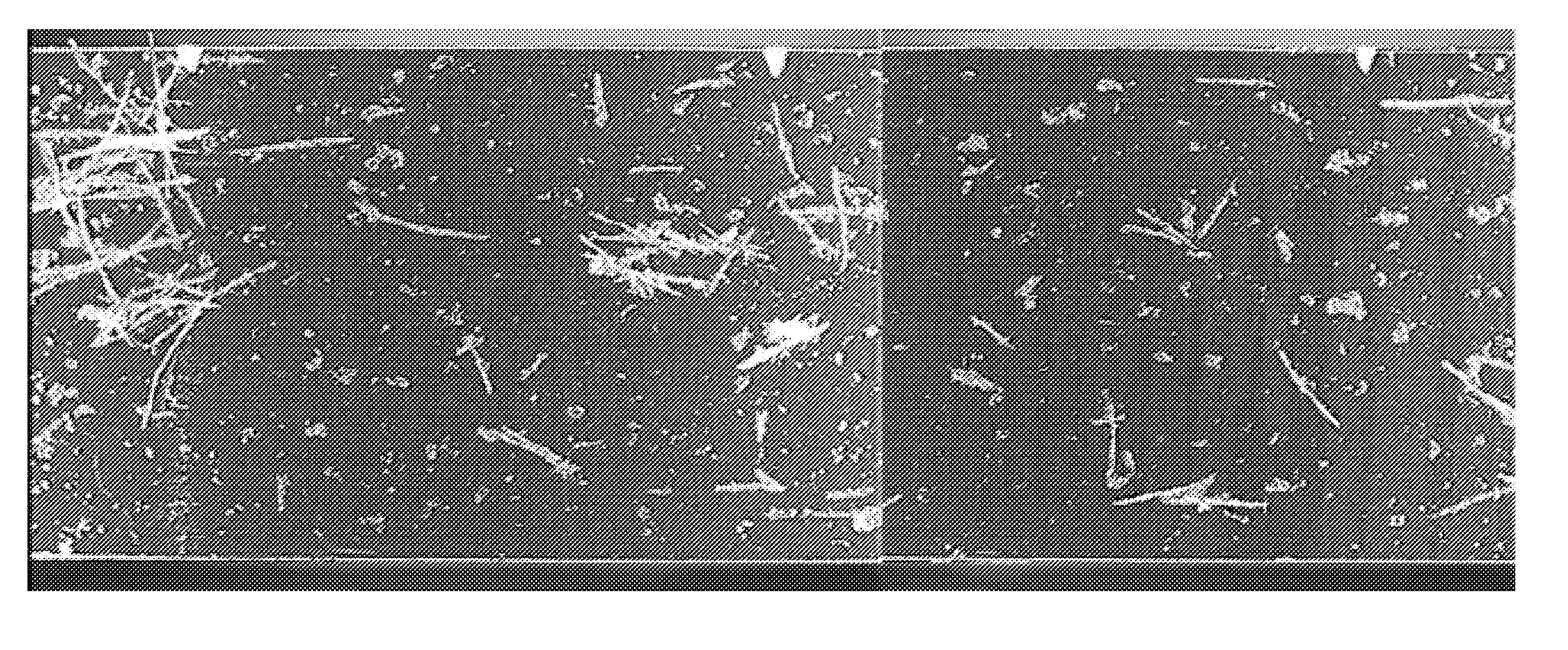

Non-thermoplastic starch fibers and starch composition for making same

InactiveUS7025821B2Starch dervative coatingsAmylose/amylopectin derivative coatingsFiberThermoplastic

Non-thermoplastic starch fibers having no melting point and having apparent peak wet tensile stress greater than about 0.2 MegaPascals (MPa). The fibers can be manufactured from a composition comprising a modified starch and a cross-linking agent. The composition can have a shear viscosity from about 1 Pascal·Seconds to about 80 Pascal·Seconds and an apparent extensional viscosity in the range of from about 150 Pascal·Seconds to about 13,000 Pascal·Seconds. The composition can comprise from about 50% to about 75% by weight of a modified starch; from about 0.1% to about 10% by weight of an aldehyde cross-linking agent; and from about 25% to about 50% by weight of water. Prior to cross-linking, the modified starch can have a weight average molecular weight greater than about 100,000 g / mol.

Owner:PROCTER & GAMBLE CO

Non-thermoplastic starch fibers and starch composition for making same

InactiveUS20050076809A1Starch dervative coatingsAmylose/amylopectin derivative coatingsThermoplasticFiber

Non-thermoplastic starch fibers having no melting point and having apparent peak wet tensile stress greater than about 0.2 MegaPascals (MPa). The fibers can be manufactured from a composition comprising a modified starch and a cross-linking agent. The composition can have a shear viscosity from about 1 Pascal.Seconds to about 80 Pascal.Seconds and an apparent extensional viscosity in the range of from about 150 Pascal.Seconds to about 13,000 Pascal.Seconds. The composition can comprise from about 50% to about 75% by weight of a modified starch; from about 0.1% to about 10% by weight of an aldehyde cross-linking agent; and from about 25% to about 50% by weight of water. Prior to cross-linking, the modified starch can have a weight average molecular weight greater than about 100,000 g / mol.

Owner:THE PROCTER & GAMBLE COMPANY

Renewable binder for nonwoven materials

ActiveUS7893154B2Low viscosityImprove adaptabilityStarch dervative coatingsNon-woven fabricsGlass fiberAdduct

A formaldehyde-free curable aqueous composition comprising an adduct of (a) carbohydrate polymer and (b) a multi-functional crosslinking agent such as a polybasic acid may be used as a binder for non-woven products such as fiberglass insulation.

Owner:ARCLIN USA

Paper surface sizing composition, sized paper, and method for sizing paper

InactiveUS20080173420A1Natural cellulose pulp/paperStarch dervative coatingsPulp and paper industryDrying time

Embodiments of the present invention provide a paper surface sizing composition, a paper web coated on one or more sides or surfaces with a paper surface sizing composition, and a method for treating one or more sides of the paper web with a paper surface sizing composition to impart benefits relating to one or more of the following properties: (1) brightness; (2) opacity; (3) paper smoothness; (4) print quality; (5) optionally ink dry time (e.g., for ink jet printing where the sizing composition has option); and (6) optionally minimizing or eliminating edge welding (e.g., for paper webs used in, for example, form printing).

Owner:INT PAPER CO

Starch film and method for manufacturing starch foam

A biodegradable starch film is provided. The biodegradable starch film includes a starch which is cross-linked by means of a cross-linking agent. The cross-linking agent comprises glycidyl methacrylate 2,3-epoxypropyl methacrylate (GMA), octenyl succinyl anhydride (OSA), or dodecyl succinic anhydride (DDSA) or combinations thereof. The cross-linking agent is 1 to 10 weight parts based on the starch of 100 weight parts. Furthermore, a method for manufacturing starch foam is also provided.

Owner:IND TECH RES INST

Binder compositions with polyvalent phosphorus crosslinking agents

ActiveUS20130023174A1Readily availableLow costStarch dervative coatingsStarch adhesivesFiberProcedure Agents

An fibrous insulation product is provided that includes a binder comprising a polyol and a phosphorus crosslinking agent derived from a phosphonic or phosphoric acid, salt, ester or anhydride to form crosslinked phosphodiester linkages. The polyol is polyvalent, but may be monomeric or preferably polymeric; and may be synthetic or natural in origin. Carbohydrate polysaccharides are exemplary polyols, including water-soluble polysaccharides such as dextrin, maltodextrin, starch, modified starch, etc. Additionally, the carbohydrate polymer may have a dextrose equivalent (DE) number from 2 to 20. In exemplary embodiments, the binder may also include a catalyst, a coupling agent, a process aid, and other additives. The environmentally friendly, formaldehyde-free binder may be used in the formation of residential and commercial insulation materials and non-woven chopped strand mats. A method of making fibrous products is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

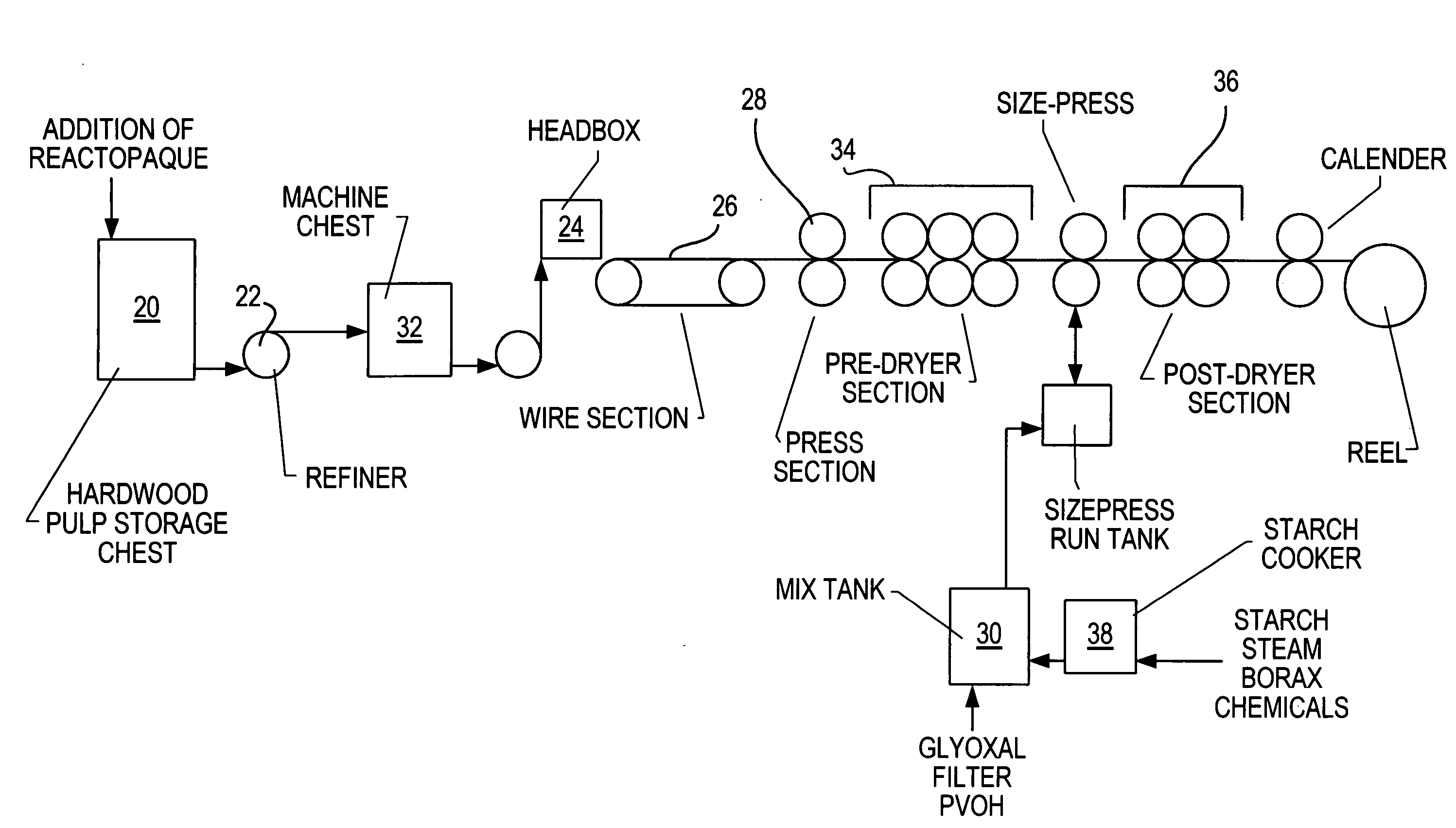

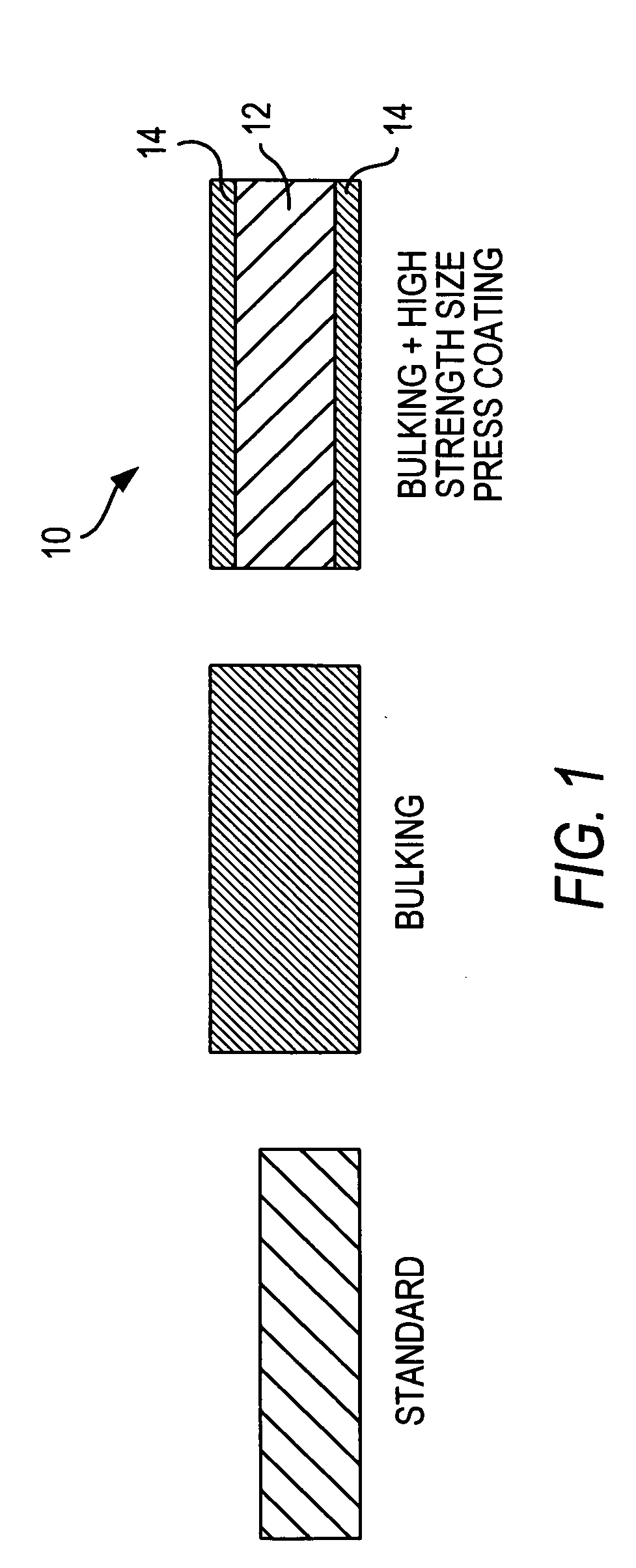

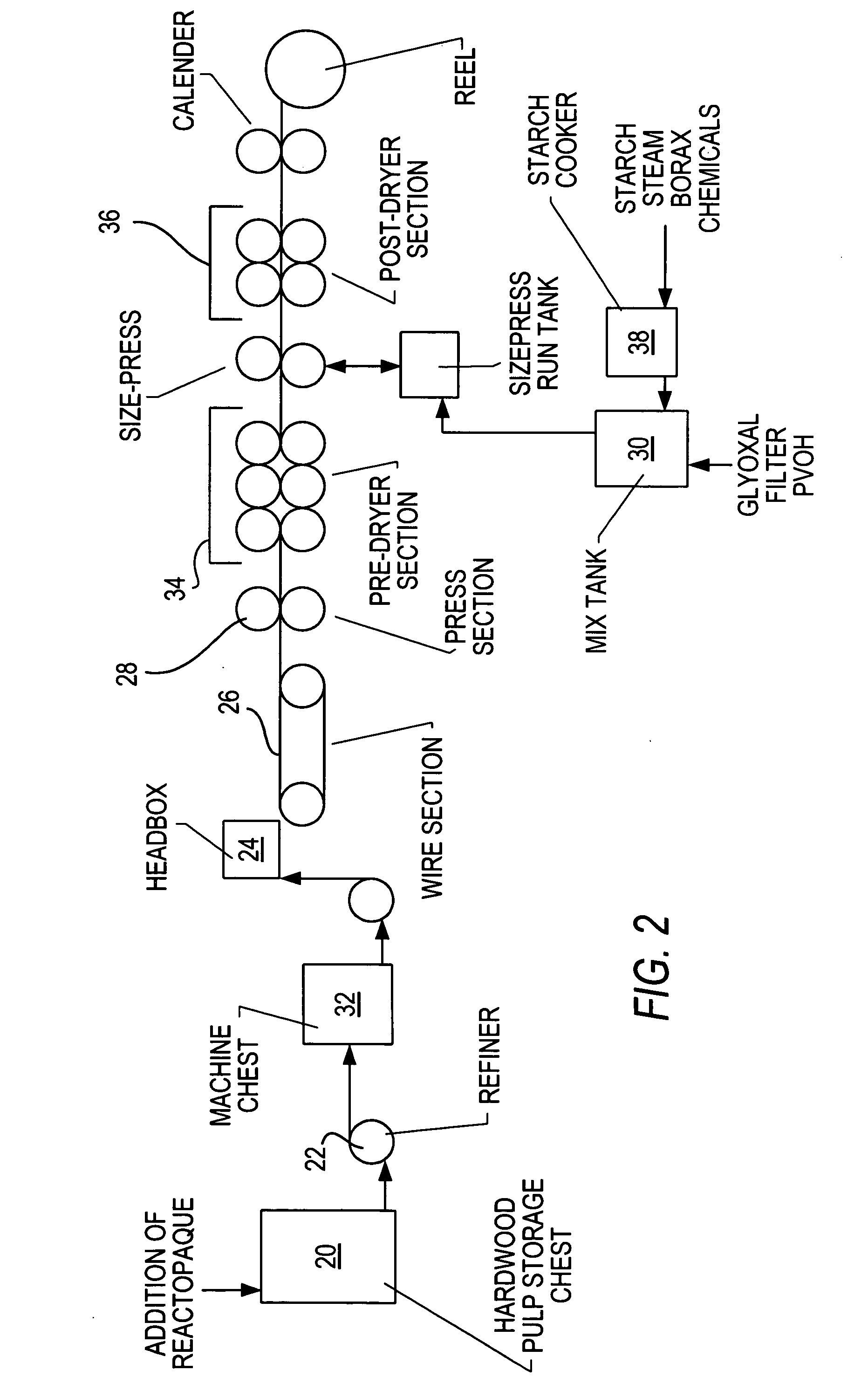

Paper with improved stiffness and bulk and method for making same

InactiveUS20090020247A1Improve bulkIncrease stiffnessSpecial paperWater-repelling agents additionCellulosePulp and paper industry

The invention provides a three layered reprographic paper having improved strength, stiffness and curl resistance properties, and a method for making same. The paper has a central core layer made largely of cellulose and bulked with a bulking agent such as a diamide salt. A starch-based metered size press coating is pressed on both sides of the core layer, wherein the starch has a high solid content. The coating forms a three layered paper having an I-beam arrangement with high strength outer layers surrounding a low density core.

Owner:INT PAPER CO

Aqueous coating liquid for an electrode plate, electrode plate for an electrical storage device, method for manufacturing an electrode plate for an electrical storage device, and electrical storage device

ActiveUS20120148917A1Improve adhesionEasy to optimizeStarch dervative coatingsCell electrodesWater basedPolyvinyl alcohol

A water-based coating formulation for an electrode plate of an electricity storage device, said water-based coating formulation being adapted to form a coating film layer on the electrode plate, contains at least one resin binder having a saponification degree of 40% or higher and selected from unmodified and modified polyvinyl alcohols and unmodified and modified ethylene-vinyl alcohol copolymers, a conductive material, and a specific polybasic acid or its acid anhydride in a water-based medium containing water as a polar solvent. Per parts by mass of the conductive material (2), the resin binder is from 0.1 to 3 parts by mass and the polybasic acid or the like is from 0.01 to 6 parts by mass. The coating formulation has a solids content of from 0.02 mass % to 40 mass %.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Tape joint compounds with CMC thickener system

ActiveUS20050056187A1Limited solubilityEasy to useStarch dervative coatingsCovering/liningsJoint compoundPhysical therapy

CMC with CMDS greater than or equal to 0.76, optionally with a non-ionic co-thickener or a CMC with CMDS less than 0.75 is used as both the rheology modifier and partial clay substitute in tape joint compounds. This significant reduction of clay level is sufficient to eliminate most of the negative characteristics of clay in joint compound.

Owner:HERCULES LLC

Methods of making and using a superabsorbent polymer product including a bioactive, growth-promoting additive

ActiveUS7423090B2Promote growthImprove usabilityBiocideStarch dervative coatingsSuperabsorbent polymerGrowth promoting

A method of and a product formed by entrapping a bioactive, growth-promoting additive in a starch matrix to form a starch-based, superabsorbent polymer product for use in agricultural applications involves (1) graft polymerizing a monomer and a starch to form a starch graft copolymer including a starch matrix; (2) isolating the starch graft copolymer; (3) forming particles of starch graft copolymer; and (4) adding a bioactive, growth-promoting additive such that at least some of the bioactive, growth-promoting additive is entrapped by the starch matrix. Following placement of the starch-based SAP including a bioactive, growth-promoting additive in proximity to a plant, root, seed, or seedling, growth of the plant, root, seed, or seedling is promoted because availability of beneficial nutrients is increased.

Owner:UPL MAURITIUS LTD

Aqueous liquid composition, aqueous coating liquid, functional coating film and composite material

ActiveUS20150179357A1Sufficient viscosityImprove adhesionCosmetic preparationsStarch dervative coatingsWater basedPVA - Polyvinyl alcohol

Provided is an aqueous liquid composition including a water-based medium containing water, a polymer having at least one type of groups selected from hydroxyl groups and amino groups, and phosphonobutanetricarboxylic acid. The polymer is at least one polymer selected from the group consisting of a polysaccharide, polyamino acid, polyvinyl alcohol, polyallylamine, polyvinylamine, a polyamidine, a polyethylenimine, and their derivatives.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Biopolymer compositions and products thereof

This invention relates to biopolymer-based compositions and biopolymer-based formed bodies such as film, sheet, capsule, casing or coating-film or spray thereof. In another embodiment, the invention relates to a process for producing a biopolymer-based starting material and biopolymer-based formed bodies such as cited above, for the manufacture of pharmaceutical, veterinary, food for cosmetic products.

Owner:PFIZER INC

Chemically modified plasticized starch compositions by extrusion processing

ActiveUS20060107945A1Low viscosityEasy to processStarch dervative coatingsAmylose/amylopectin derivative coatingsPlasticizerViscosity

A chemically modified plasticized starch (CMPS) is prepared by reacting starch with an organic dibasic acid or an anhydride of the acid in the presence of a plasticizer using optional free radical initiators, and optionally with the incorporation of nano clays in the reactive extrusion process. The starch is thermoplastic and has a lower viscosity than the traditional thermoplastic starch. The CMPS is useful in preparing starch polymer compositions which are at least partially biodegradable.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Energy-saving paint resistant to high temperature and high infrared radiation and preparation method thereof

ActiveCN105860612ASimple compositionEasy to prepareStarch dervative coatingsChemical industryMicro nanoRadiance

The invention relates to an energy-saving paint resistant to high temperature and high infrared radiation. The energy-saving paint resistant to high temperature and high infrared radiation is characterized by being prepared from, by weight, 40-100 parts of a radiation agent, 150-320 parts of filler and 72-180 parts of a binder. The radiation agent and the filler are weighed according to a proportion and premixed, then the mixture and the binder are subjected to high-shear mixing and dispersing, then micro-nano grinding and dispersing are carried out, and the energy-saving paint resistant to high temperature and high infrared radiation is obtained. The infrared radiance of the paint is kept within 0.85-0.95 at high temperature, and thus the paint can be widely applied to various kilns and can effectively improve the heat efficiency of kilns.

Owner:ANHUI HUAGUANG PHOTOELECTRIC MATERIAL TECH GRP CO LTD +2

Additives for water-resistant gypsum products

ActiveUS7473713B2Provides water resistanceFireproof paintsStarch dervative coatingsWater resistantPhenol

Emulsions are provided which are useful in imparting water-resistance to gypsum products. In one embodiment, the emulsions comprise at least one wax, an alkyl phenol, a salt of polynaphthalenesulfonic acid, and a complexed starch. Emulsions of this embodiment may be added to hot, even boiling, water without the emulsion separating or curdling. The emulsions of the present invention are stable for extended periods of time when stored at room temperature and do not require the addition of a bactericide. The emulsions of the present invention are pourable liquids at room temperature.

Owner:HEXION INC

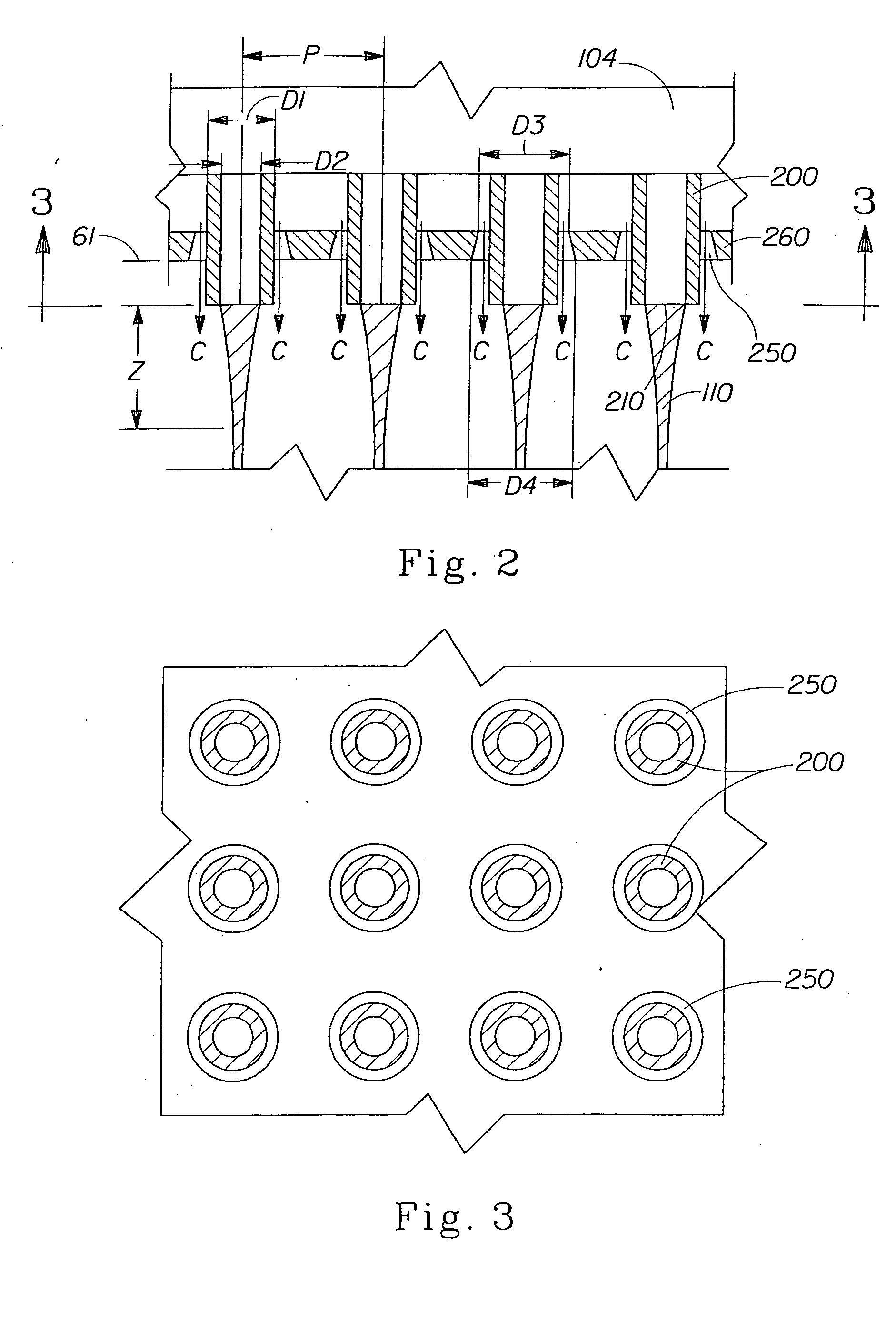

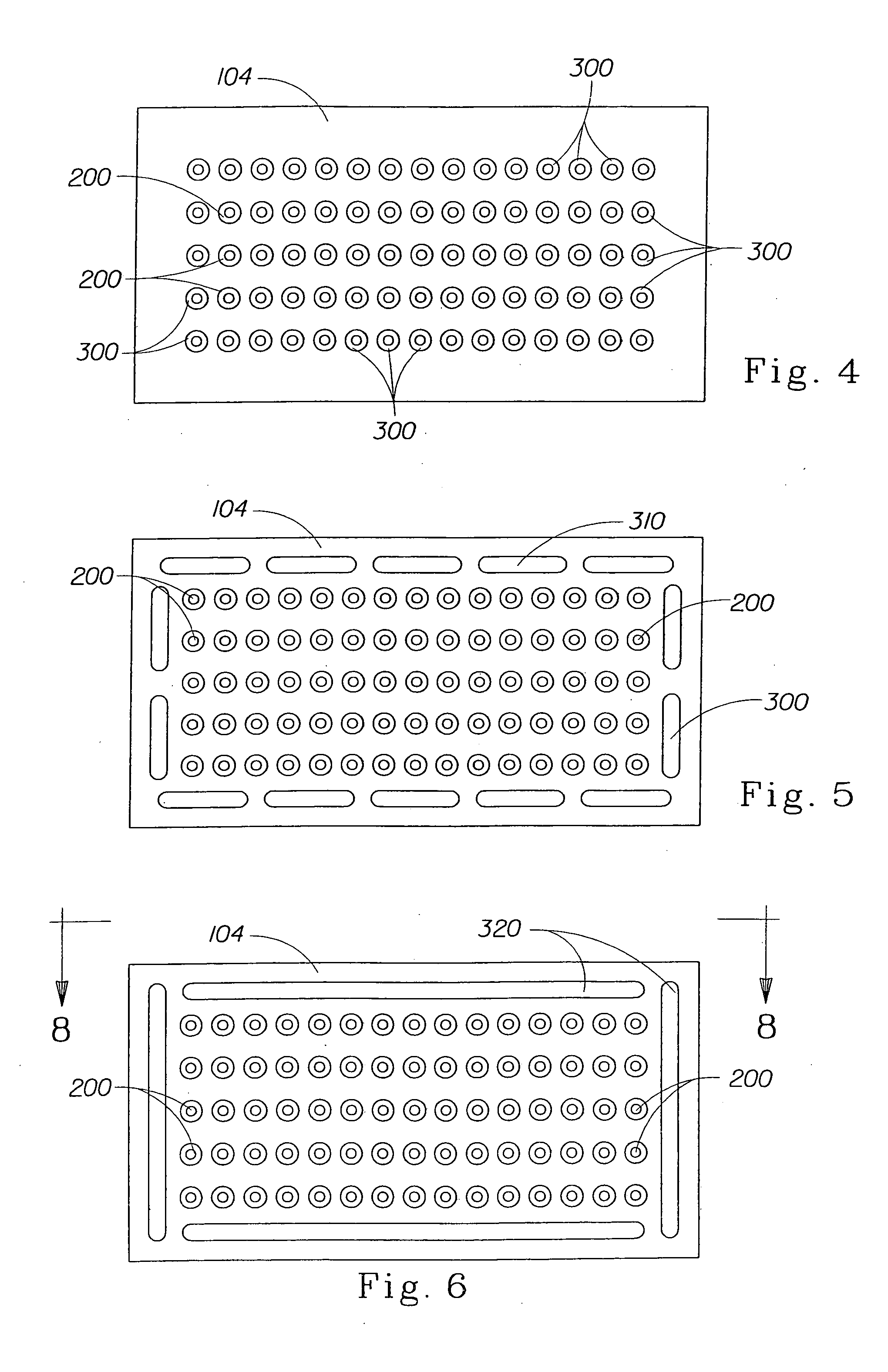

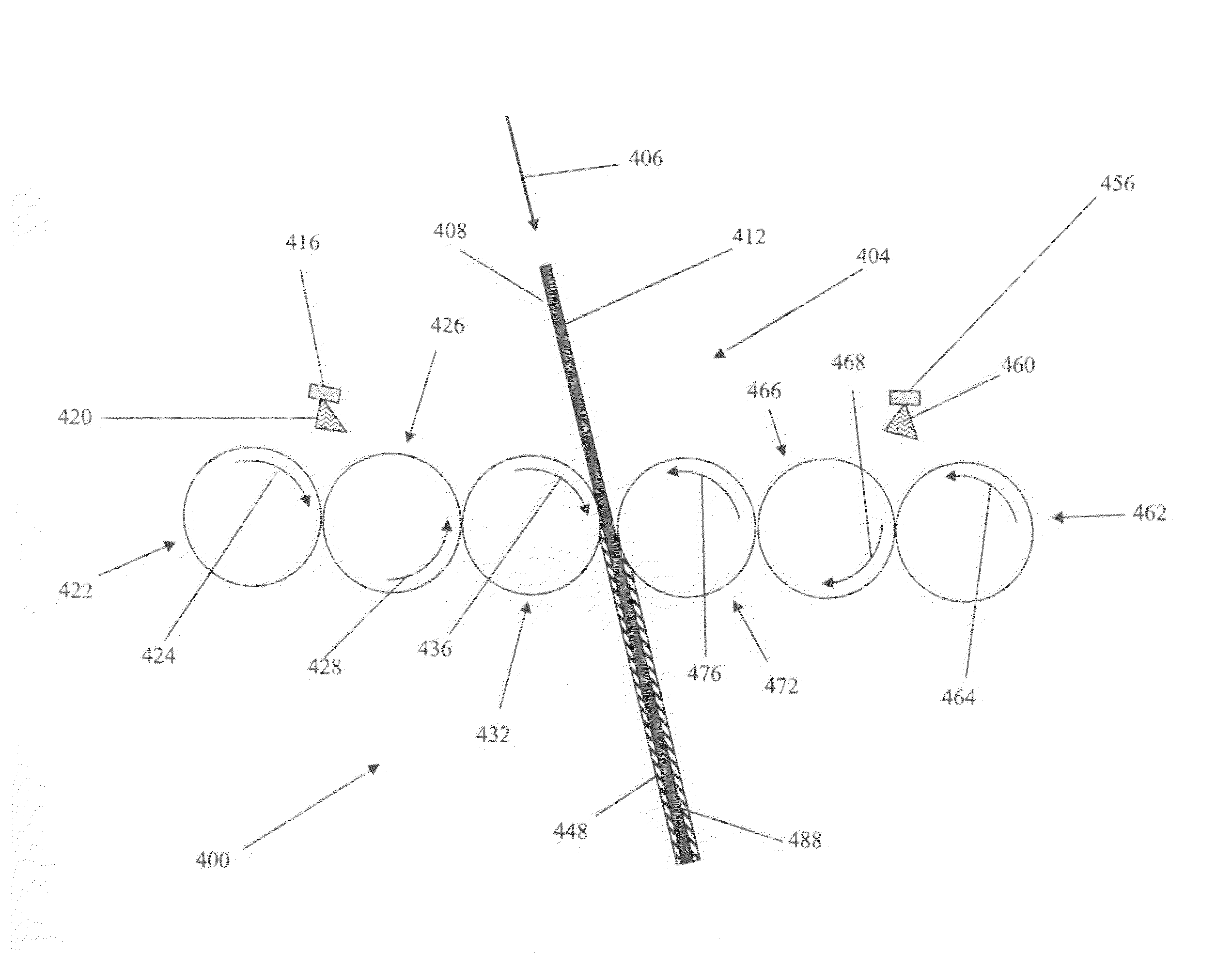

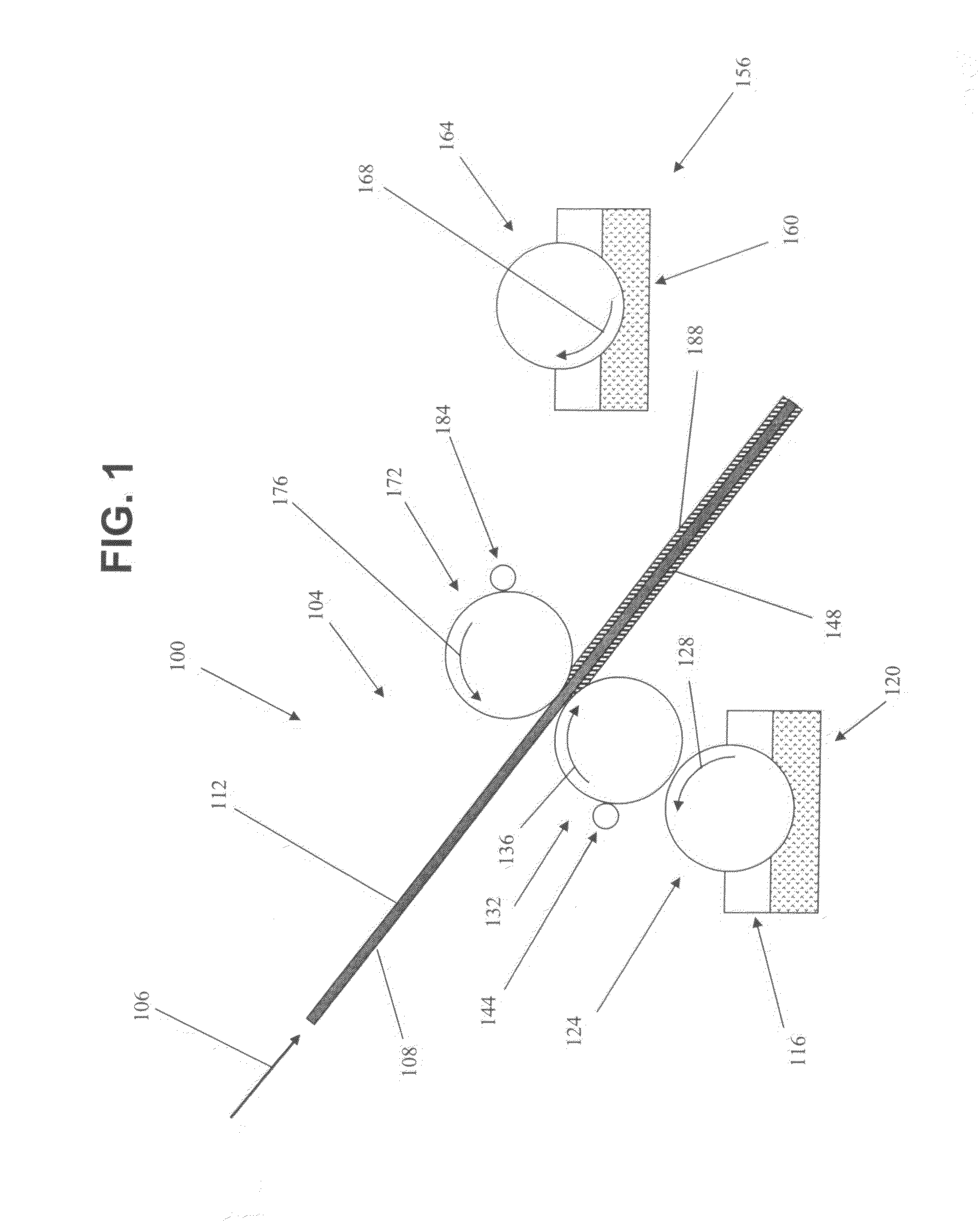

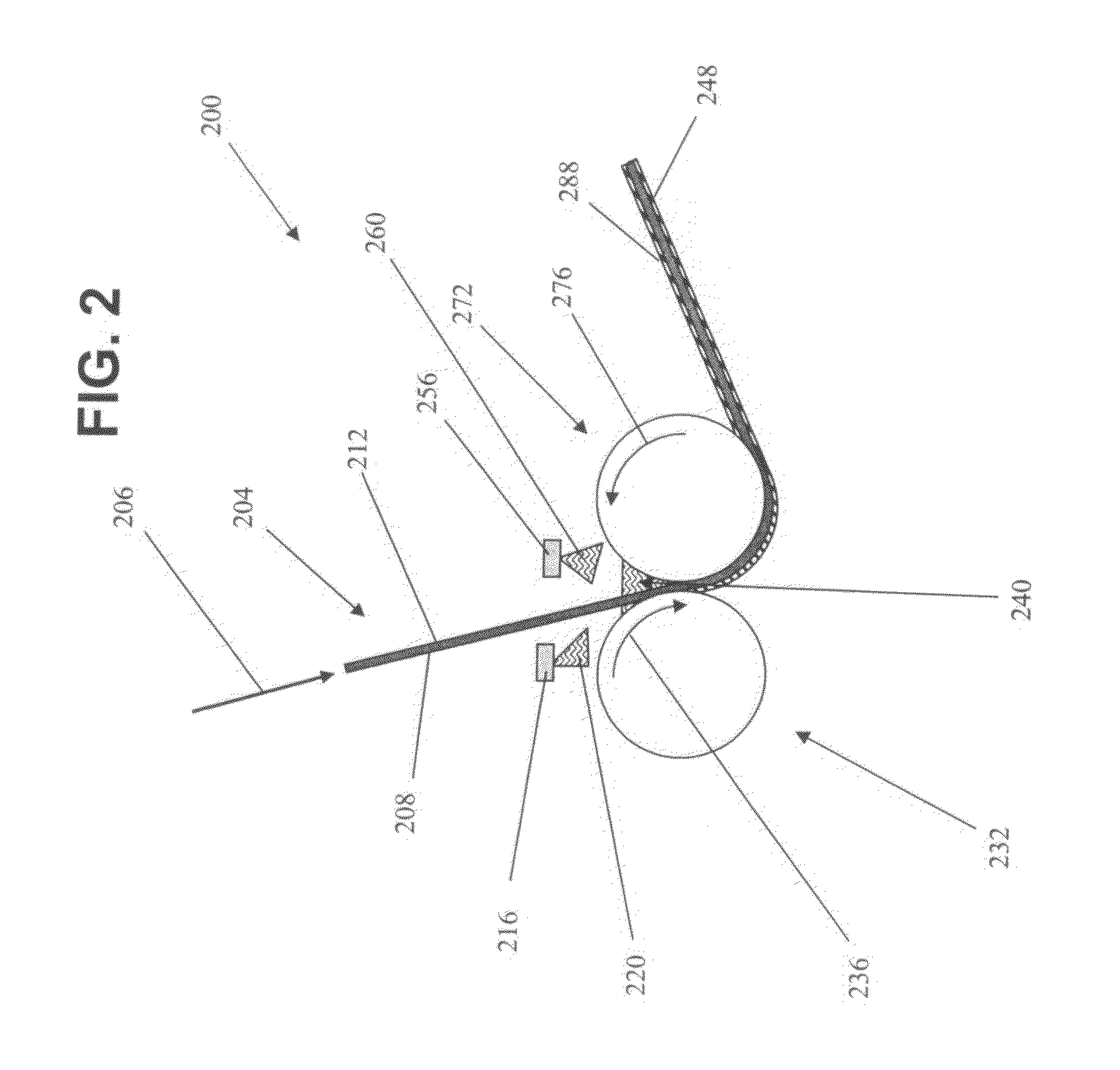

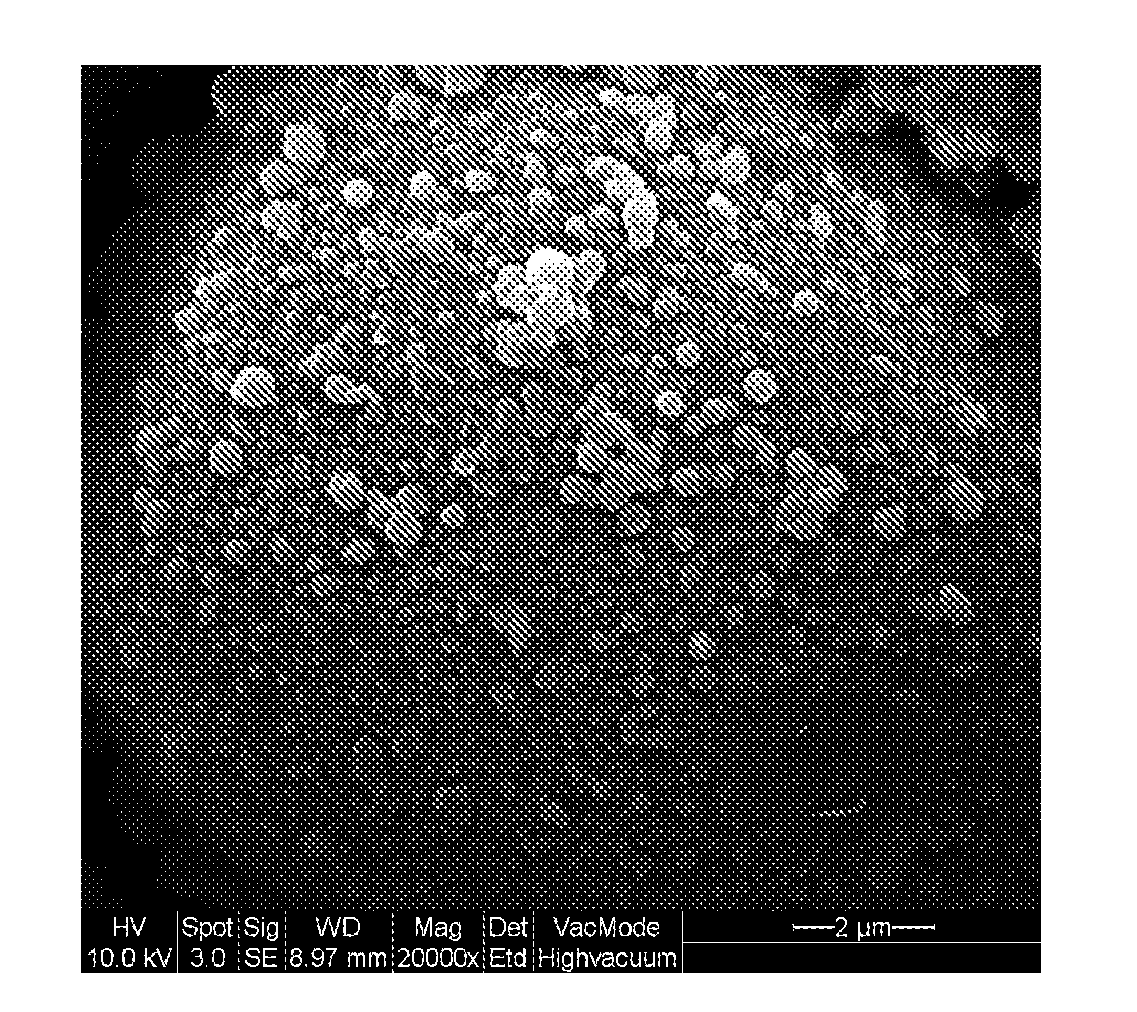

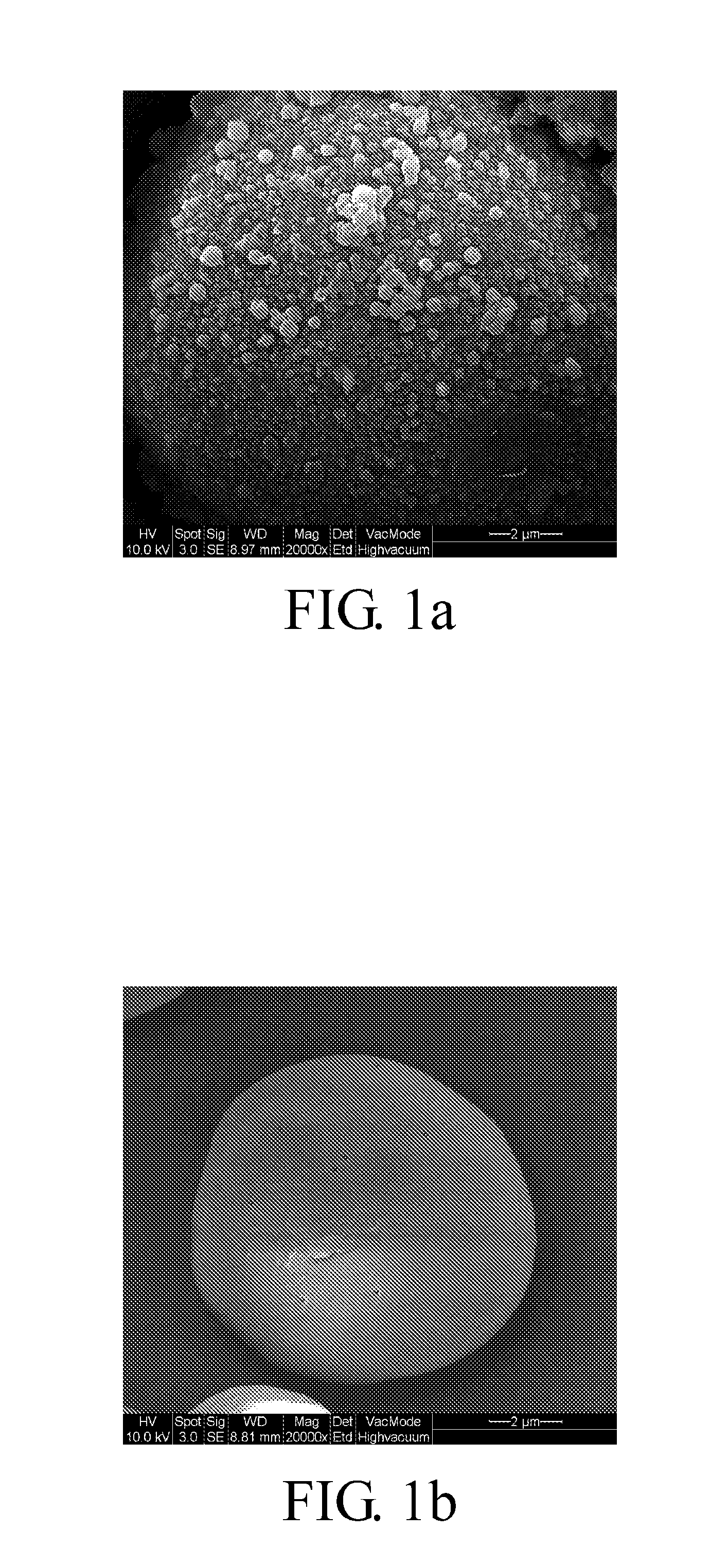

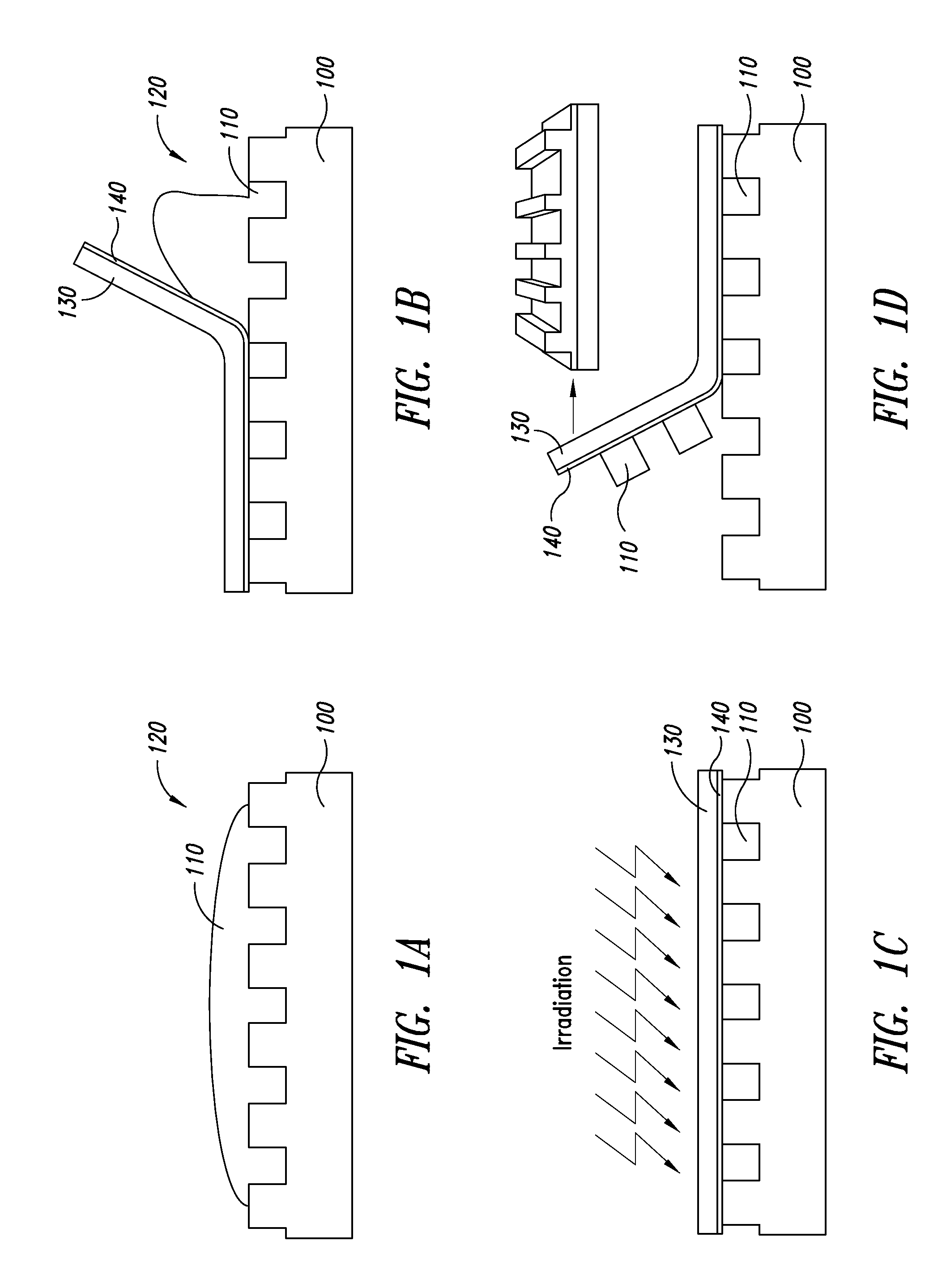

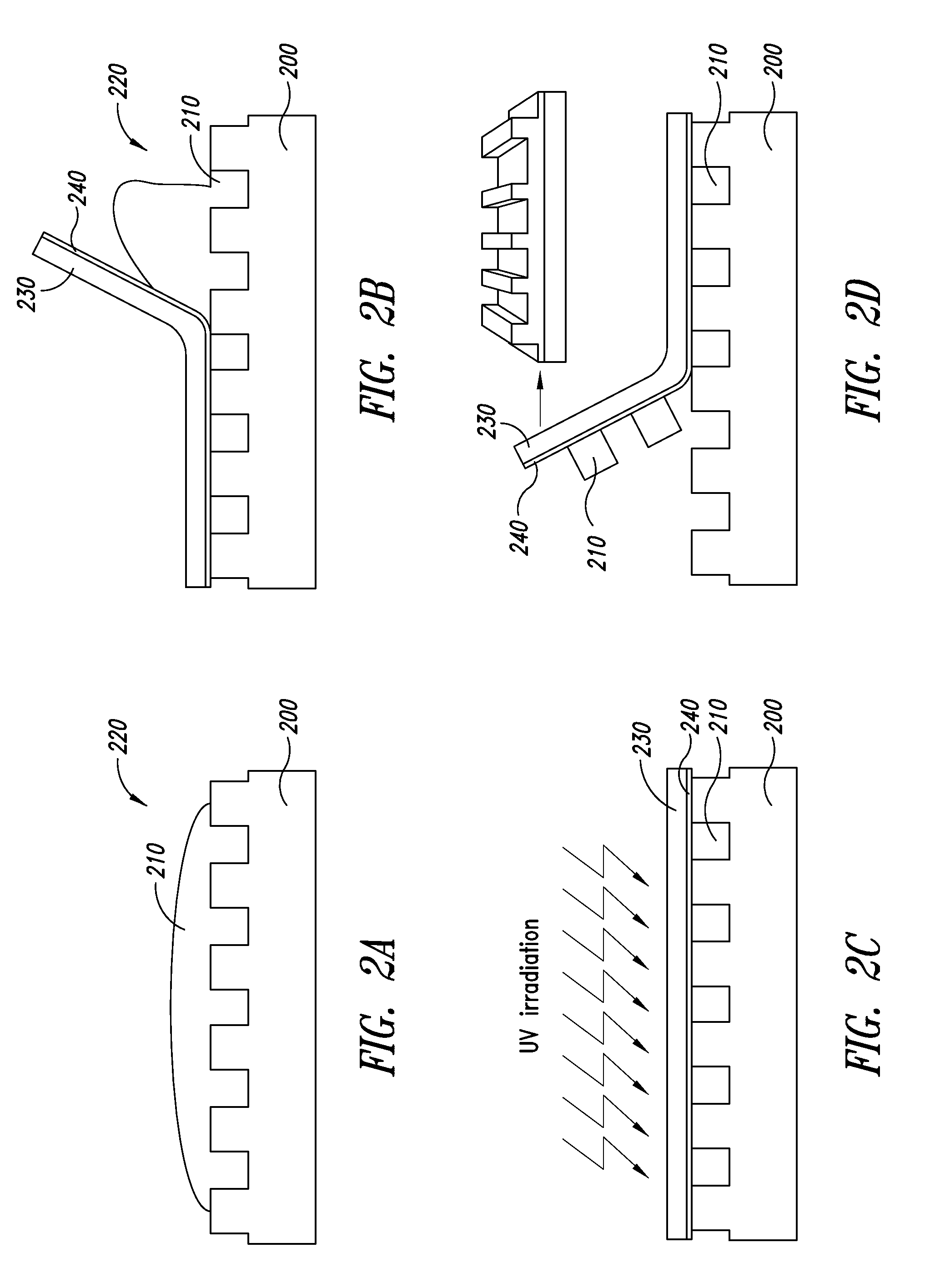

Method of manufacturing micro patterned device and device obtained by the method

The present invention refers to a method of manufacturing a micro patterned device. The method can comprise or consist of applying a light curable epoxy resin to a mold to obtain a curable resin filled mold. In a further step a polymeric film or an epoxy resin-coated glass is applied over the curable resin filled mold. Subsequently, the curable resin filled mold to which the polymeric film or the epoxy resin-coated glass is applied is irradiated to cure the resin. In another aspect the present invention refers to a micro patterned device obtained by a method described herein.

Owner:NANYANG TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com