Paper surface sizing composition, sized paper, and method for sizing paper

a paper surface sizing and composition technology, applied in the field of paper surface sizing composition, can solve the problems of uncoated papers not having the properties desired in coated papers, uncoated papers often have significant increases in cost,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

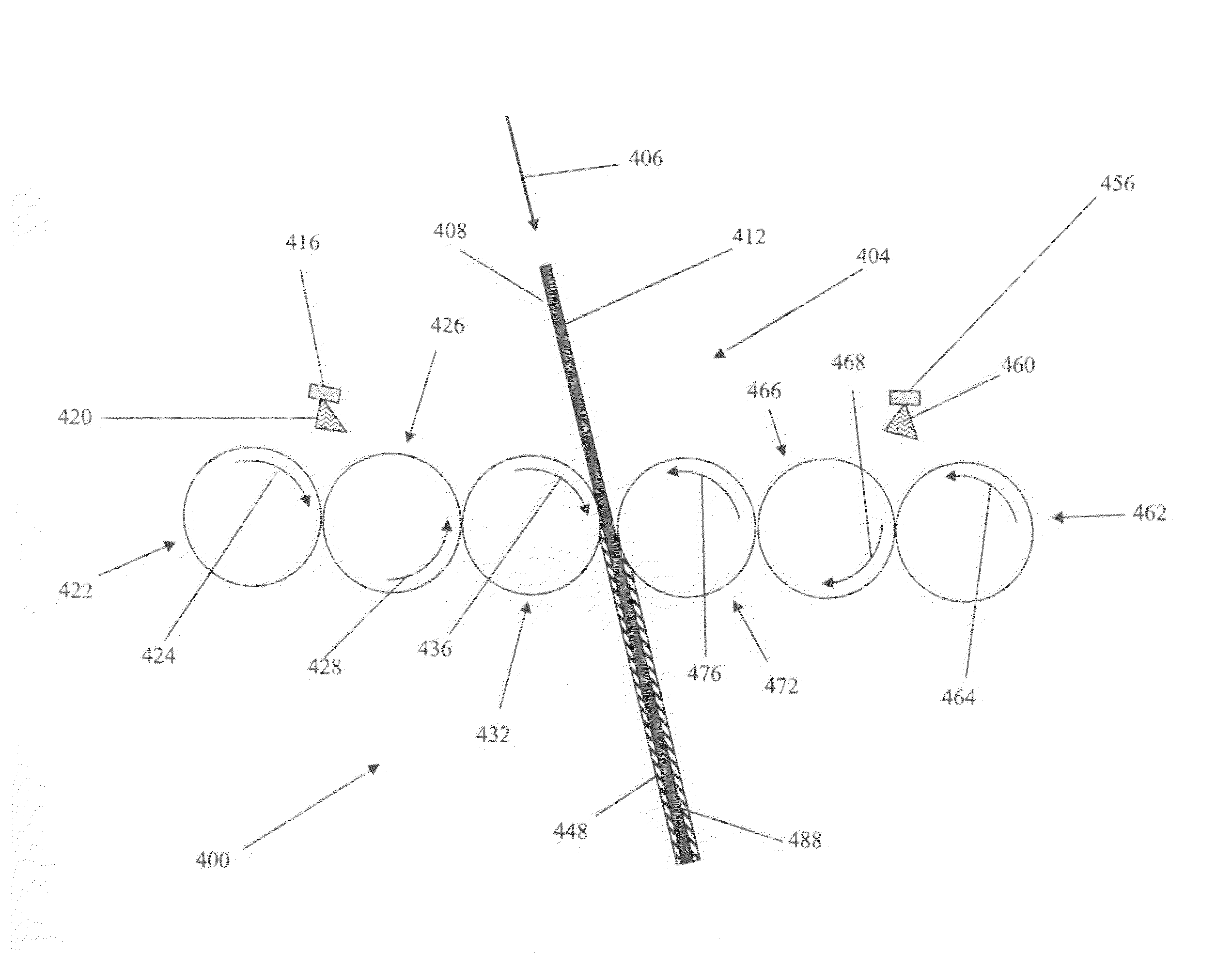

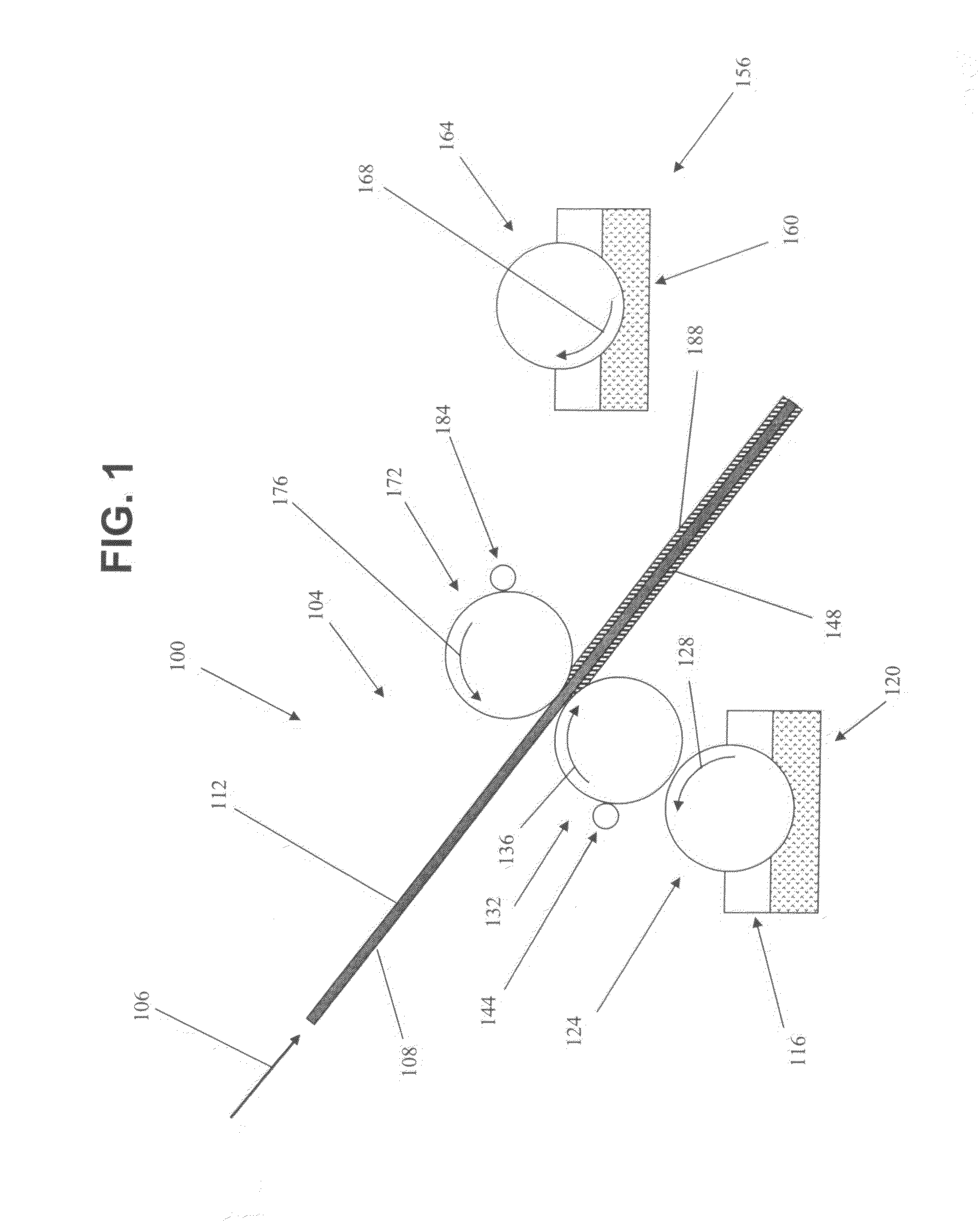

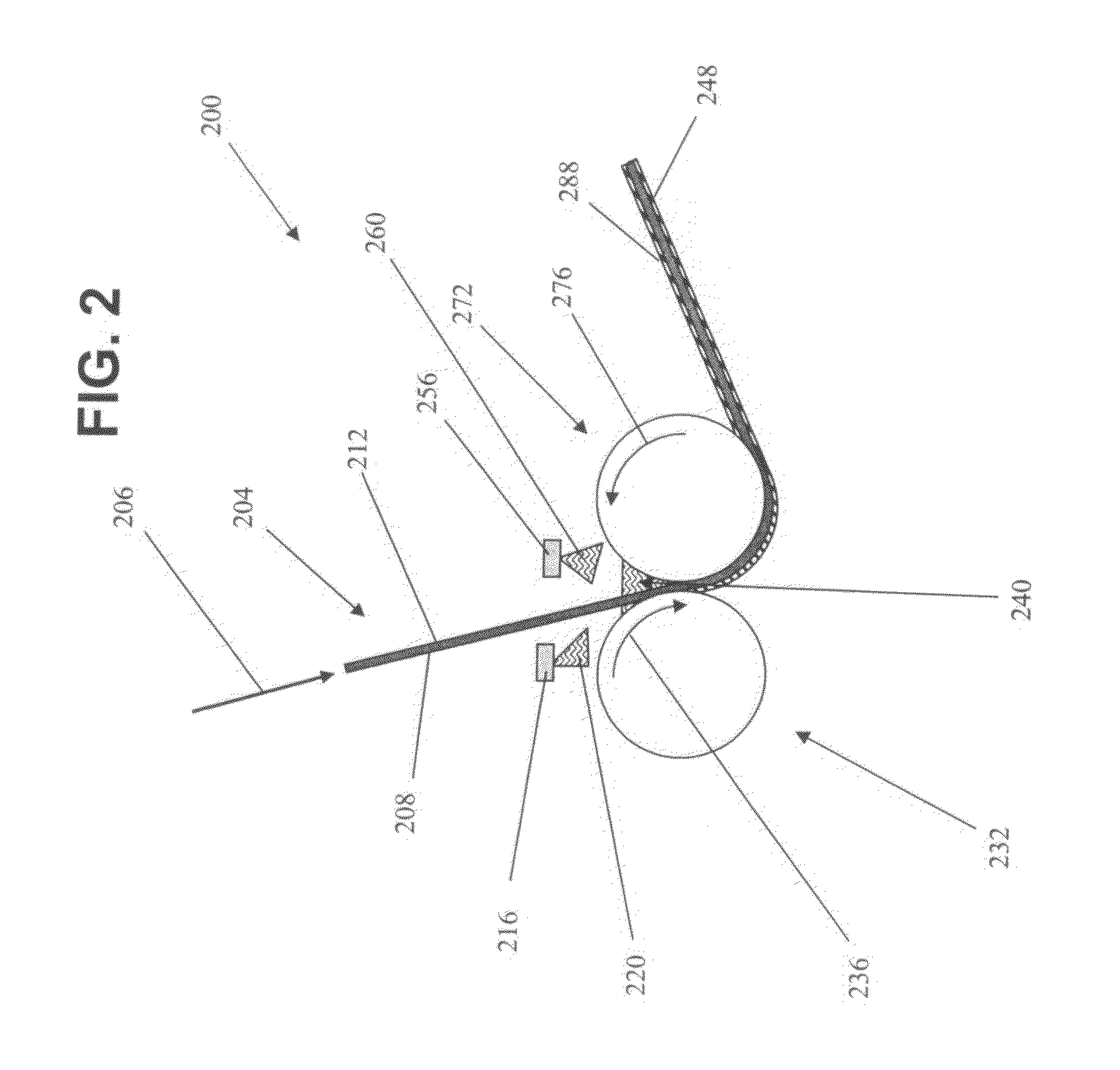

Image

Examples

example 1

[0154]A surface sizing composition is prepared according to the following formulation.

TABLE 1aSize press coating formulationsAragonite precipitated calcium carbonate(1)100 parts Starch60 partsVinyl acetate ethylene copolymer(2)10 partsSodium chloride30 partsLeucophor T-100(3)10 parts(1)Supplied by Mississippi Lime Company, Alton, Illinois, 62002(2)Supplied by Air Products and Chemicals, Inc, Allentown, PA 18195. Instead of vinyl acetate ethylene copolymer, a polyvinyl alcohol (PVOH) may be used.(3)Supplied by Clariant Corporation, Charlotte, NC 28205

[0155]The surface sizing solution containing the above ingredients is made at 16% solids. The Brookfield viscosity is measured to be 40 cps using #2 spindle, 100 rpm at 150 degrees F. The surface size composition is applied to a 75-gsm rawstock using a rod metering size press coater. The target pickup is 5.4 gsm total for both sides of the paper. Calendering is done on a steel-to-steel lab calender at room temperature with a nip pressure...

example 2

[0162]The surface sizing compositions are prepared according to the following formulations.

TABLE 2aSize press coating formulationsExampleExampleExampleExampleExampleExampleChemicals2a2b2c2d2e2fGround Calcium50100100carbonate(1)Aragonite50100100precipitated calciumcarbonate(2)Oxidized starch1001001001006060Vinyl acetate ethylene1010copolymer(3)NaCl5.255.257766OBA(4)141419191919Target size press140140140140140140pickuplb / tonlb / tonlb / tonlb / tonlb / tonlb / tonSolids, actual20.120.020.220.120.220.2Brookfield @ 50 rpm1358883686464PH8.18.58.18.47.68.1temp152150150152150152(1)Supplied by Omya, Inc, Proctor, VT 05765(2)Supplied by Mississippi Lime Company, Alton, Illinois, 62002(3)Supplied by Air Products and Chemicals, Inc, Allentown, PA 18195(4)Supplied by Clariant Corporation, Charlotte, NC 28205

[0163]The pigmented size press formulations are applied to an unsurface sized 75 gsm base paper using a rod metering size press. The target coat weight or pick up is 5-6 gsm. Calendering is done on a ...

example 3

[0165]The surface sizing compositions are prepared according to the following formulations.

TABLE 3aSize press coating formulationsExampleExampleExampleExampleExampleExampleExampleChemicals3a3b3c3d3e3f3gGround calcium100carbonate(1)Aragonite precipitated100100100100100calcium carbonate(2)Starch10010010060606060Vinyl acetate102020ethylene copolymer(3)Modified carboxylated20styrene butadienecopolymer(4)Carboxylated styrene20butadiene copolymer(5)NaCl4777777Fluorescence Optical60606060606060Brightener(6)Solids %20202020202020Brookfield @ 50 rpm115486434364130pH7.88.38.18.07.78.08.1Temp, F.150150149151148151150Target size140140140140140140140press pickuplb / tonlb / tonlb / tonlb / tonlb / tonlb / tonlb / ton(1)Supplied by Omya, Inc, Proctor, VT 05765(2)Supplied by Mississippi Lime Company, Alton, Illinois, 62002(3)Supplied by Air Products and Chemicals, Inc, Allentown, PA 18195. Instead of vinyl acetate ethylene copolymer, a polyvinyl alcohol (PVOH) may be used.(4)Supplied by RhomNova, Akron, Ohio 44...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com