Patents

Literature

41results about "Pectin adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

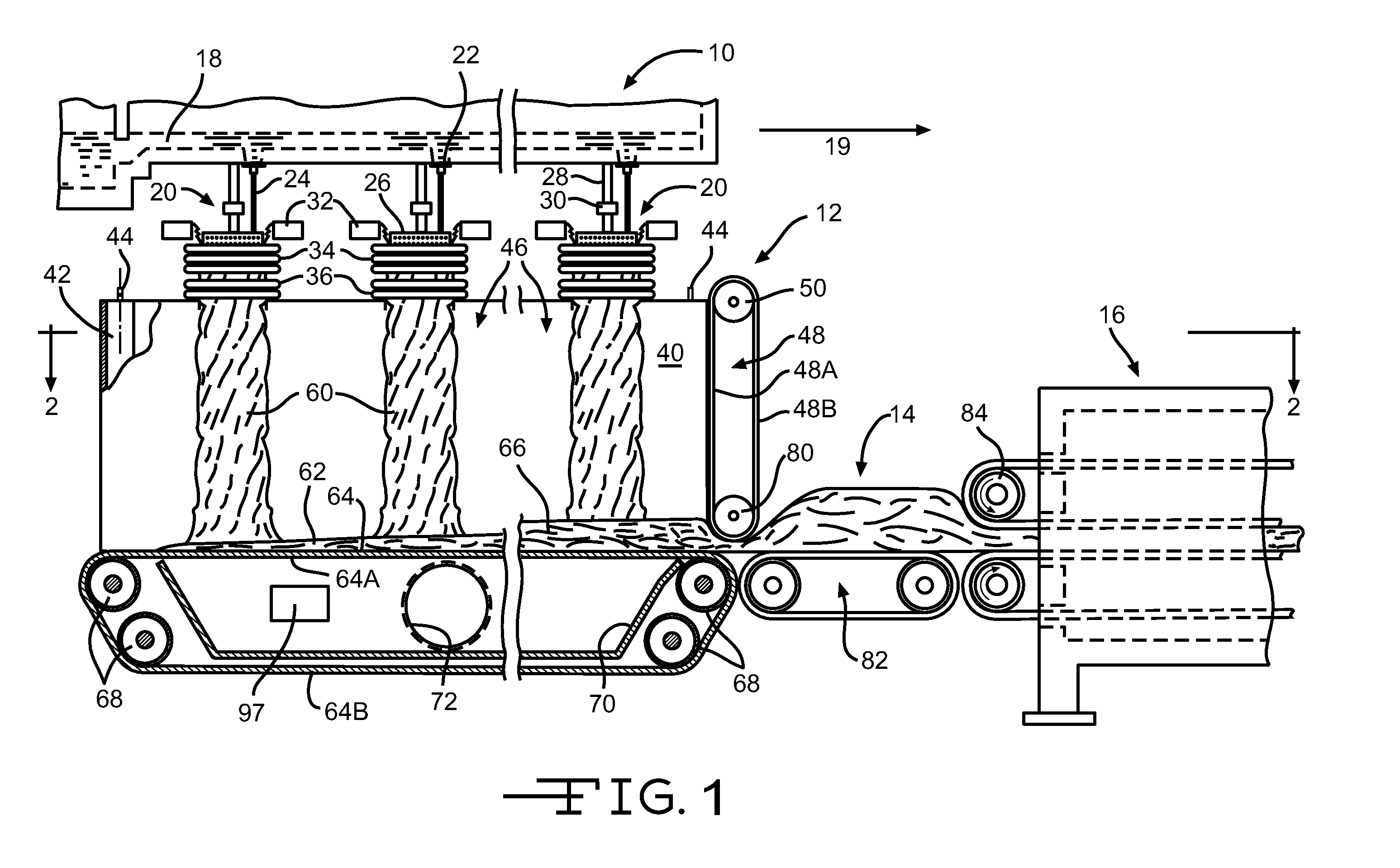

Bio-based binders for insulation and non-woven mats

ActiveUS20110086567A1Readily availableLow costStarch dervative coatingsStarch adhesivesFiberProcedure Agents

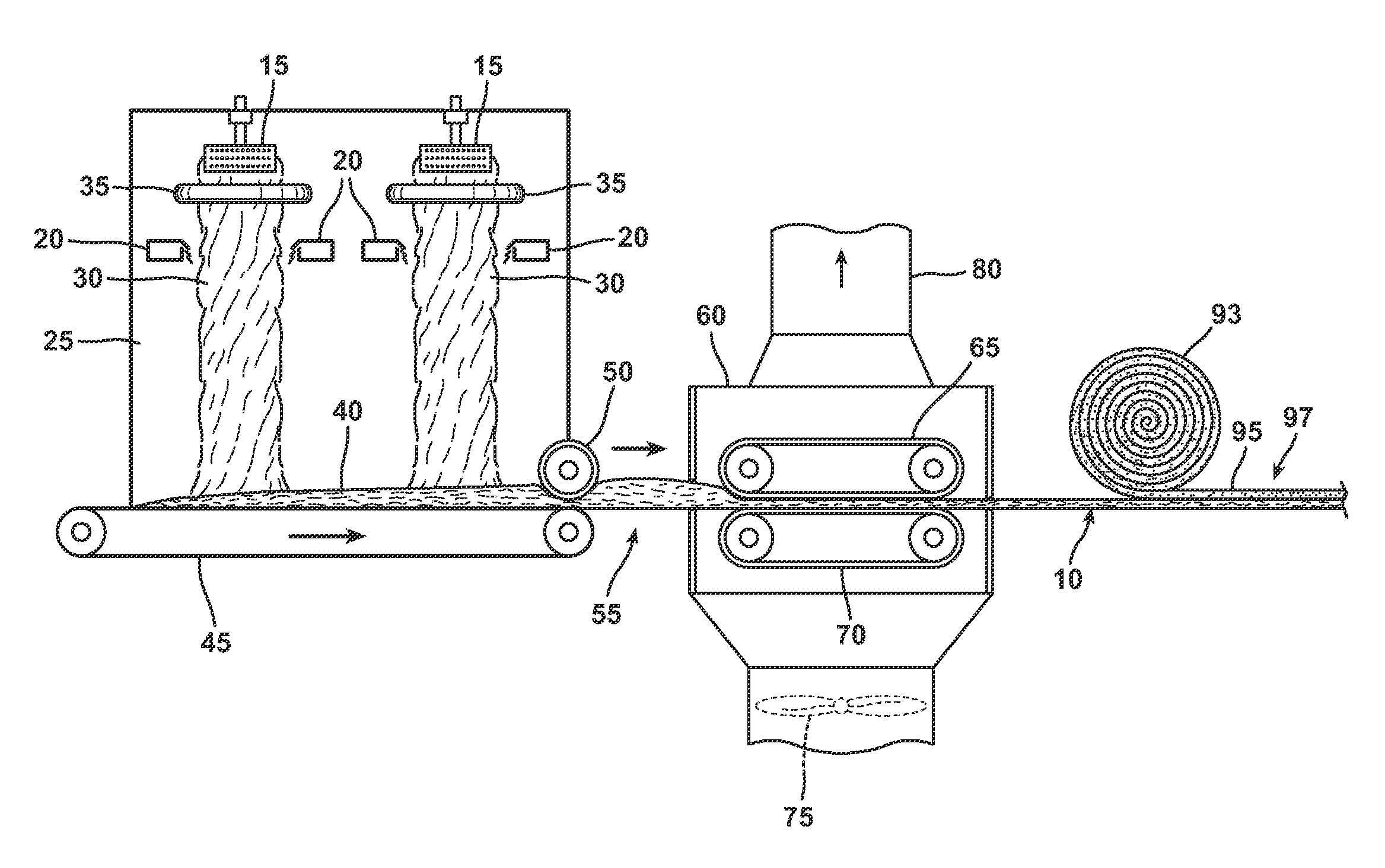

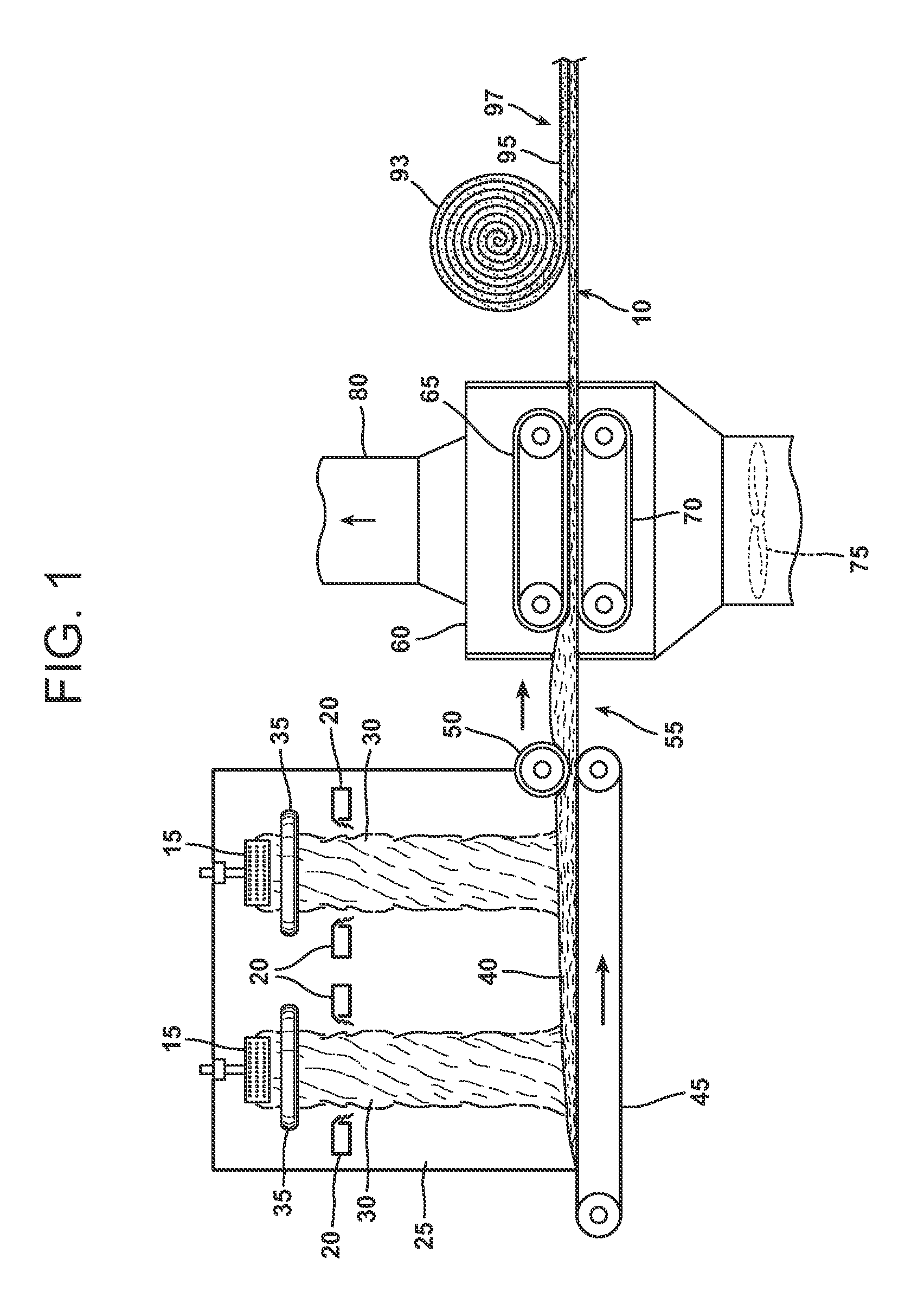

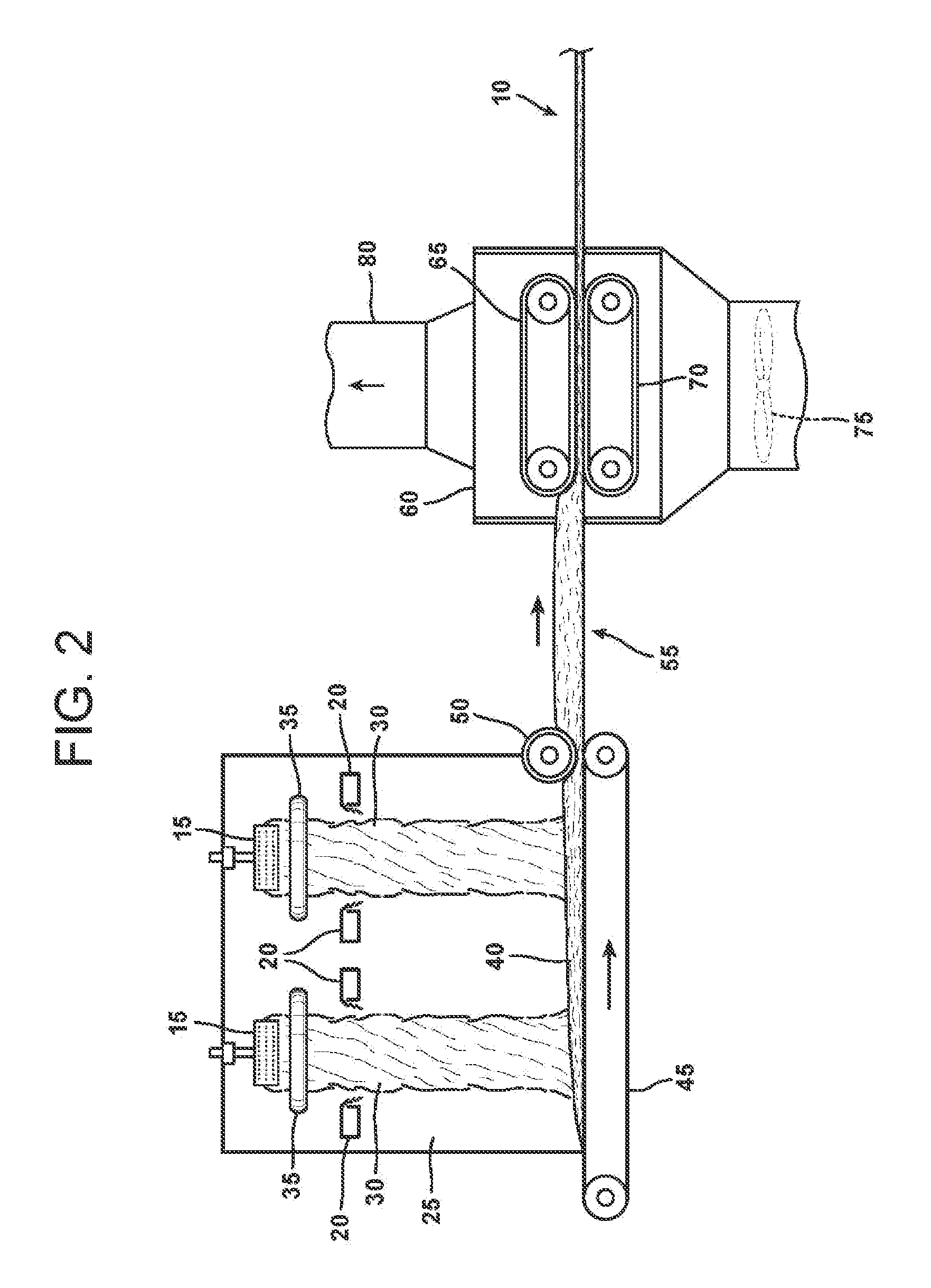

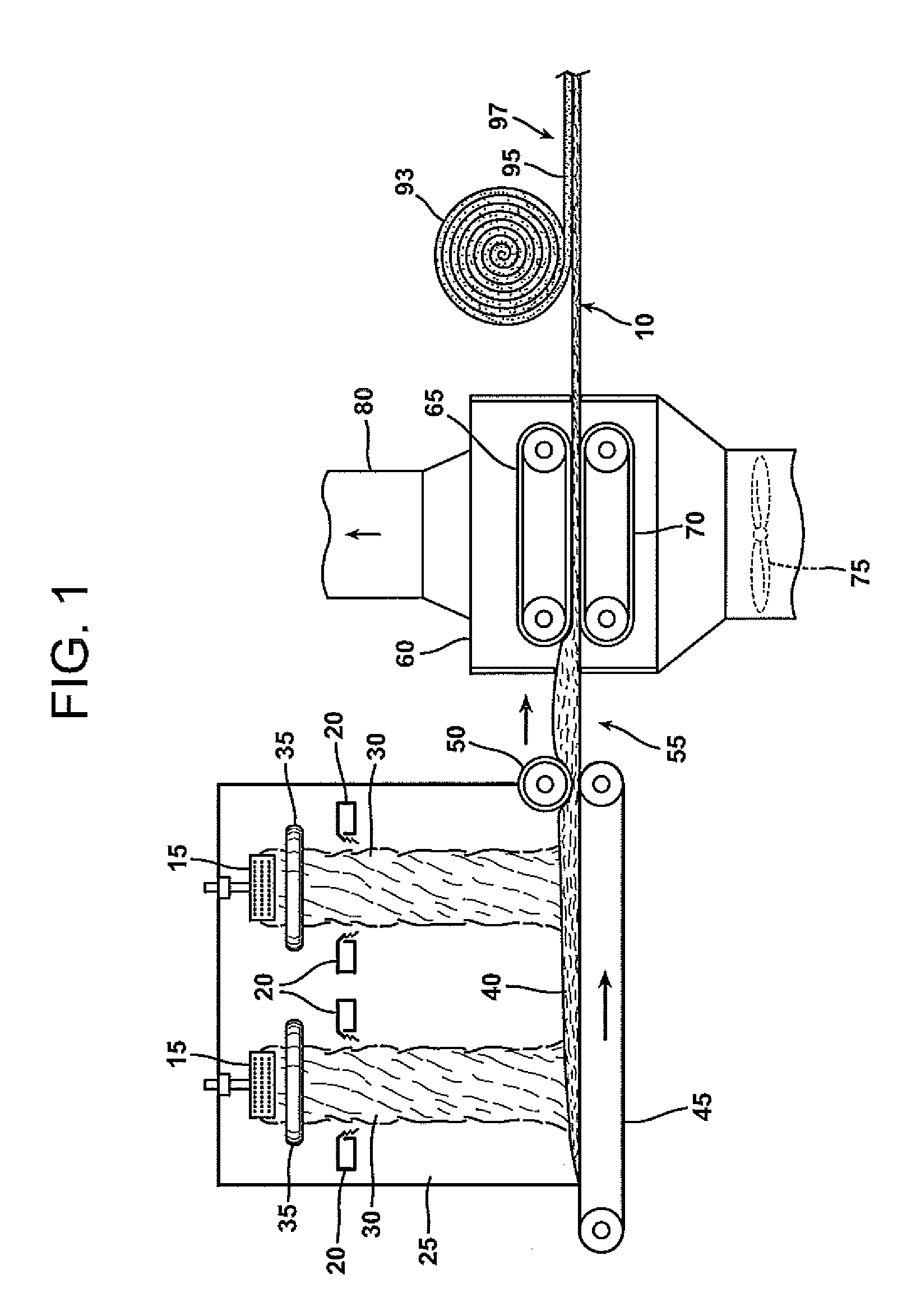

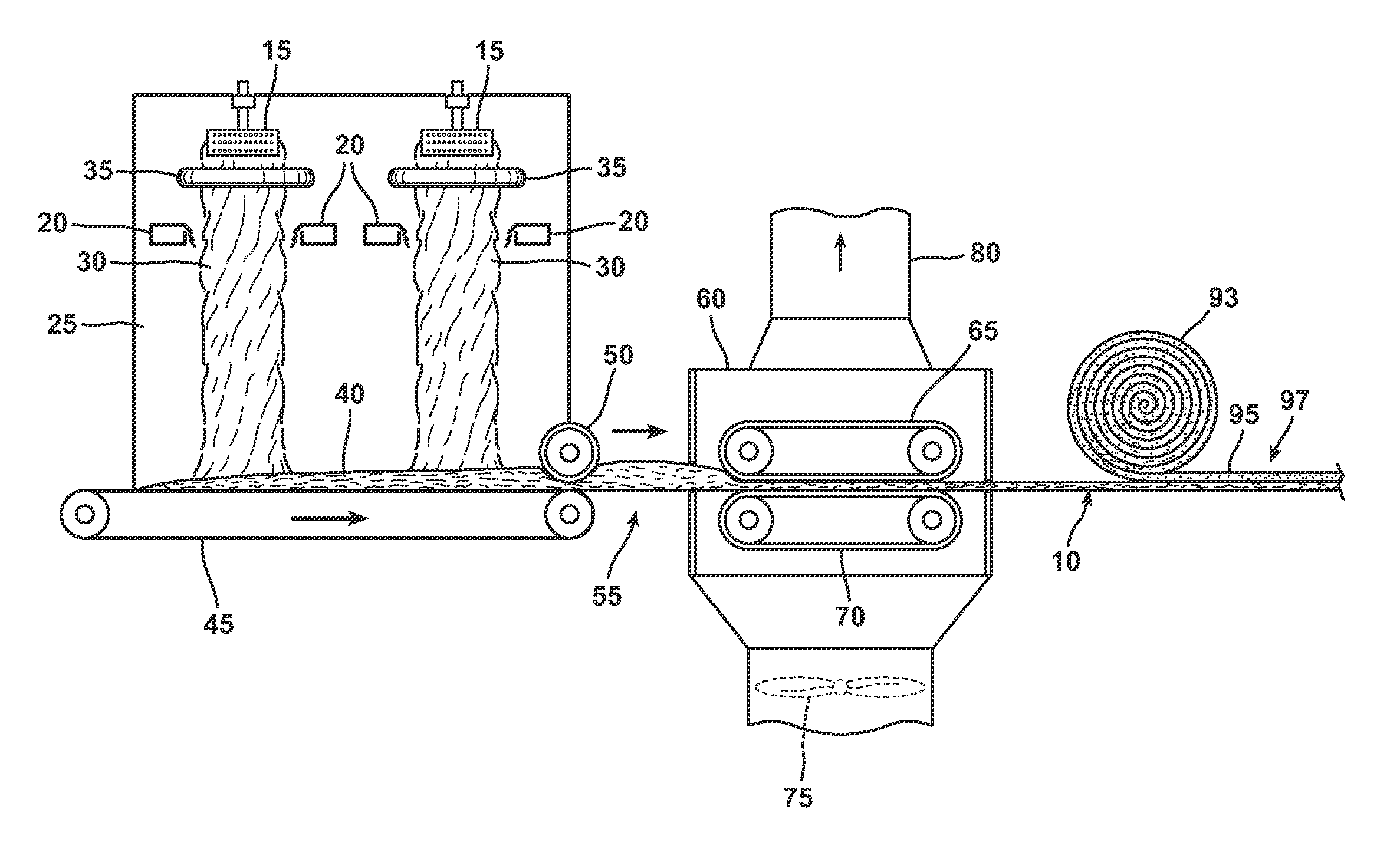

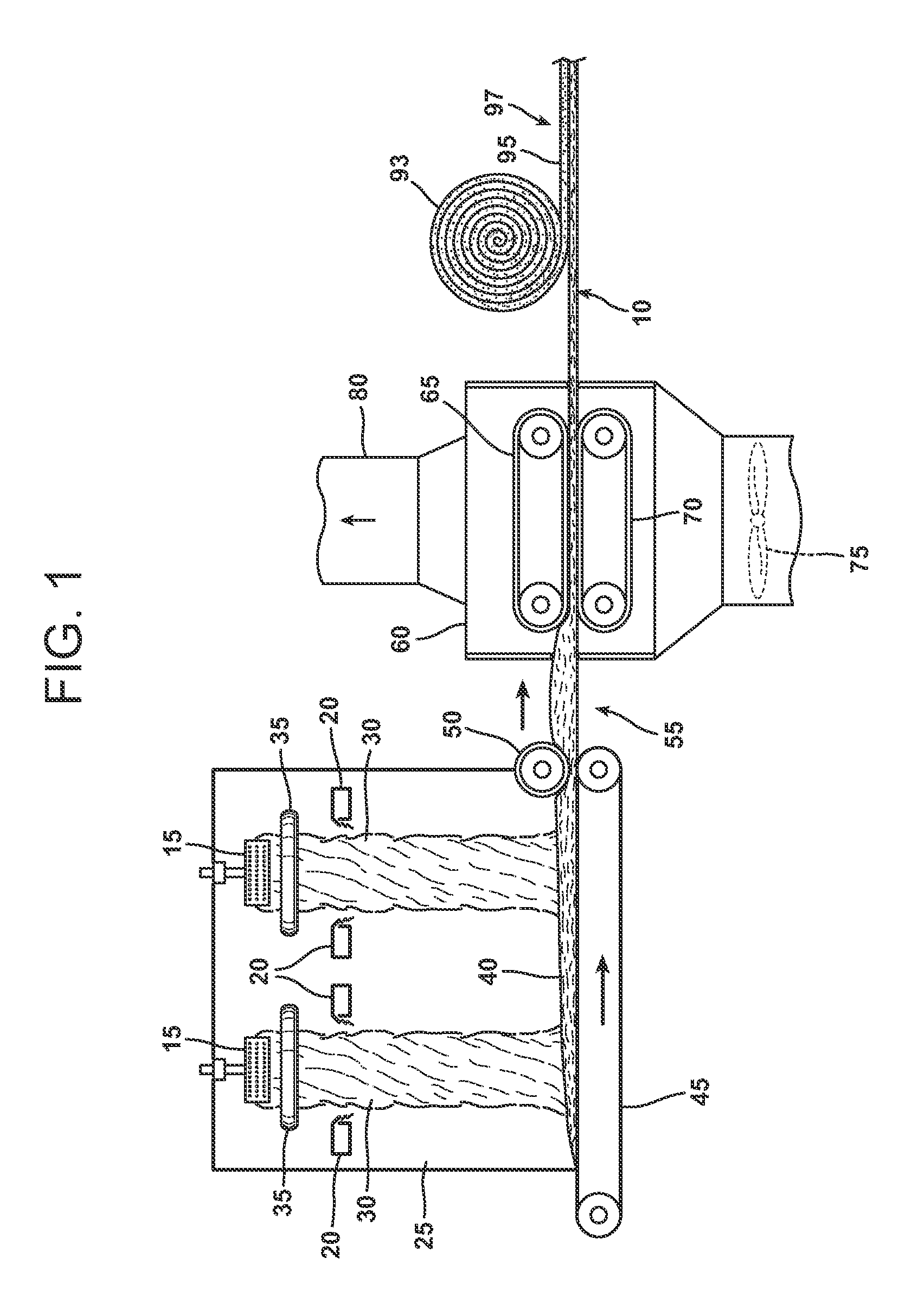

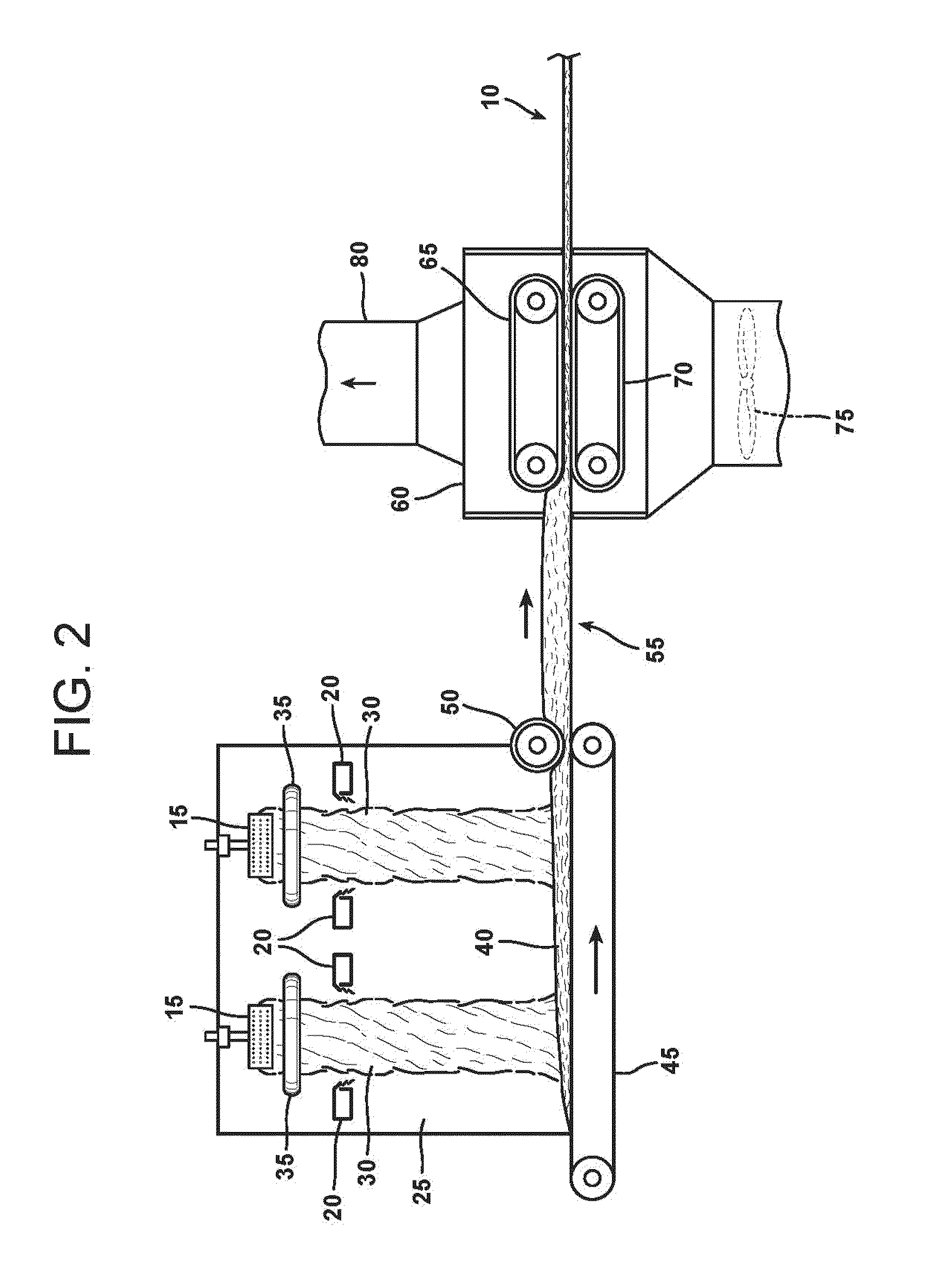

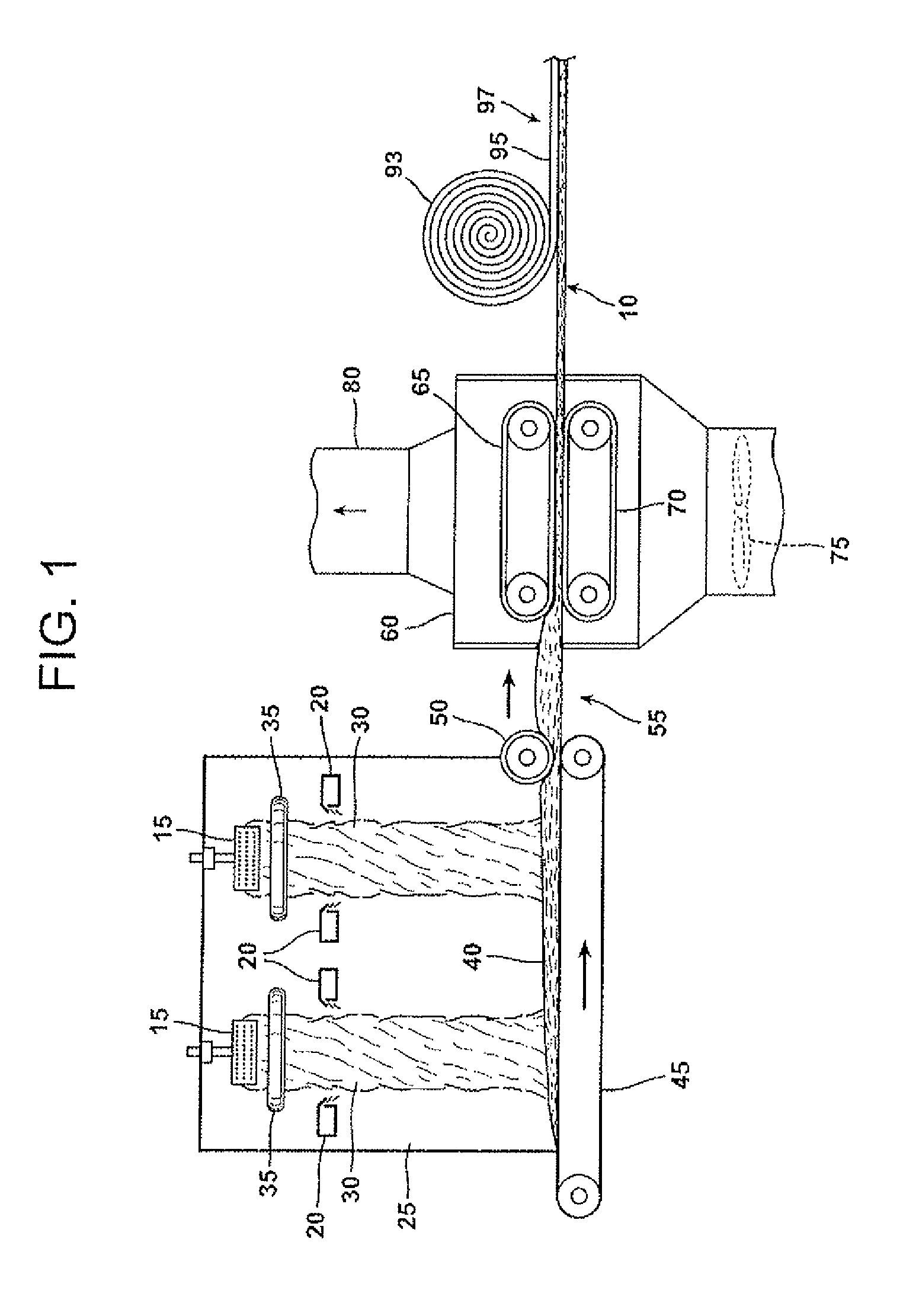

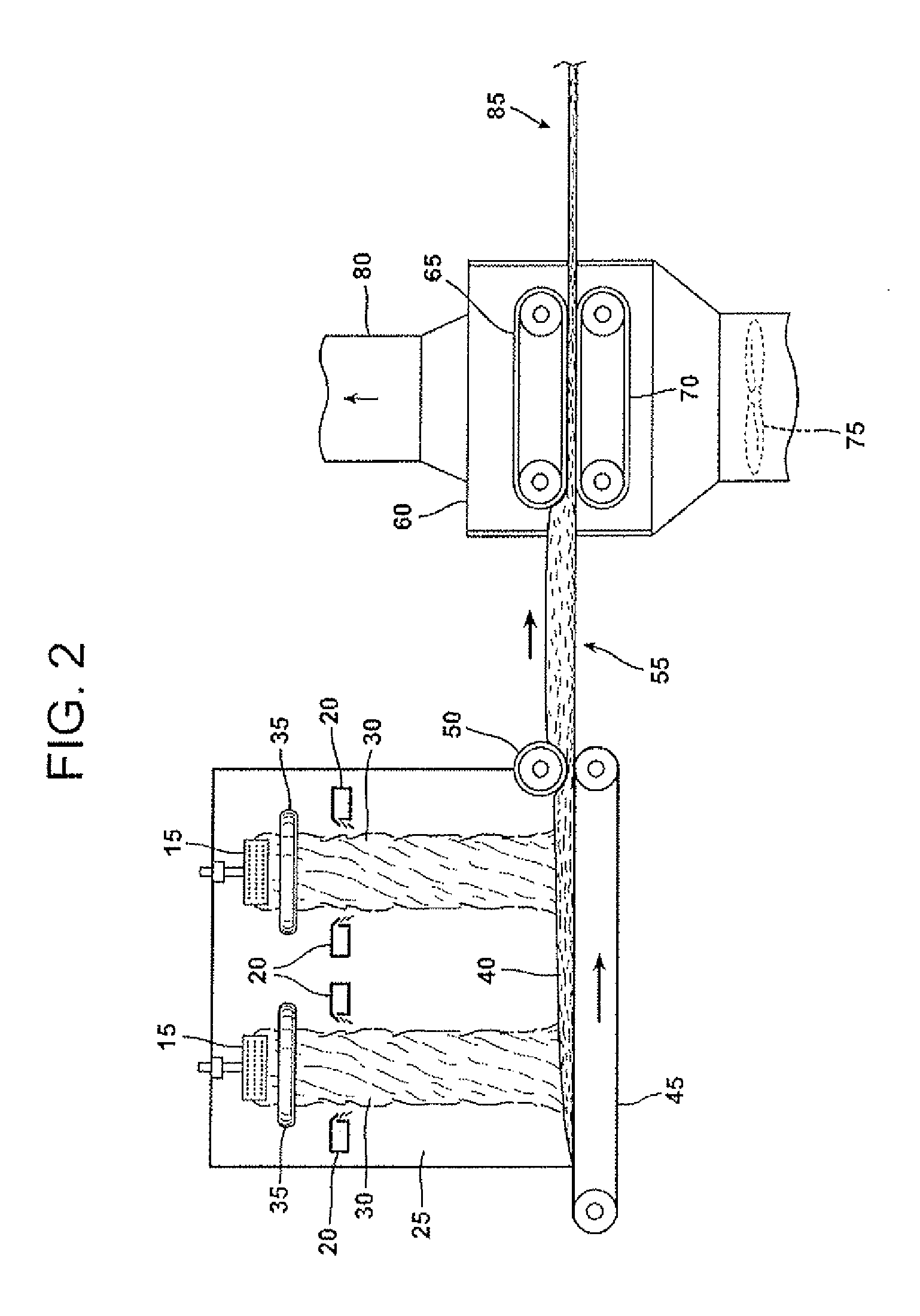

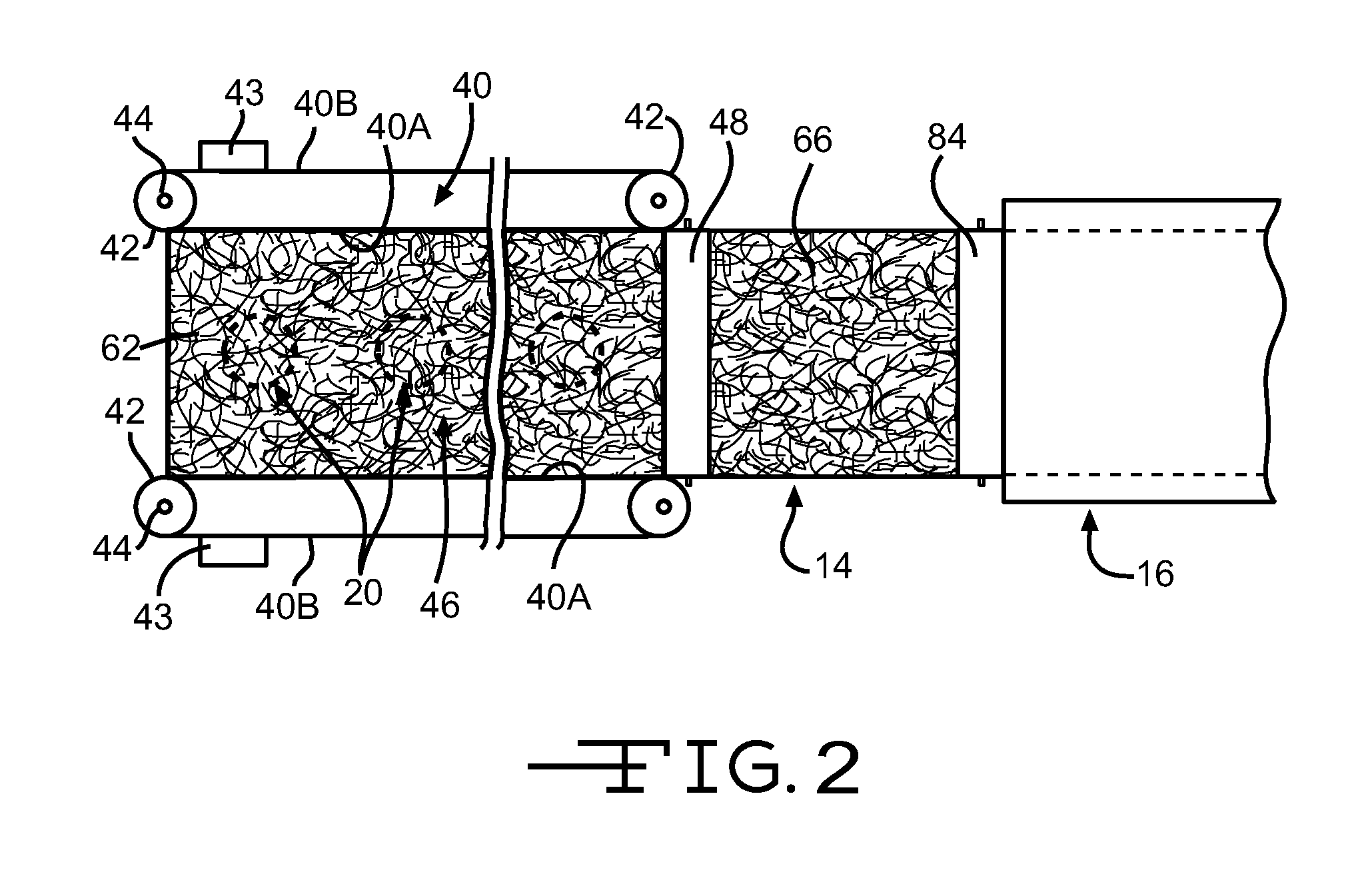

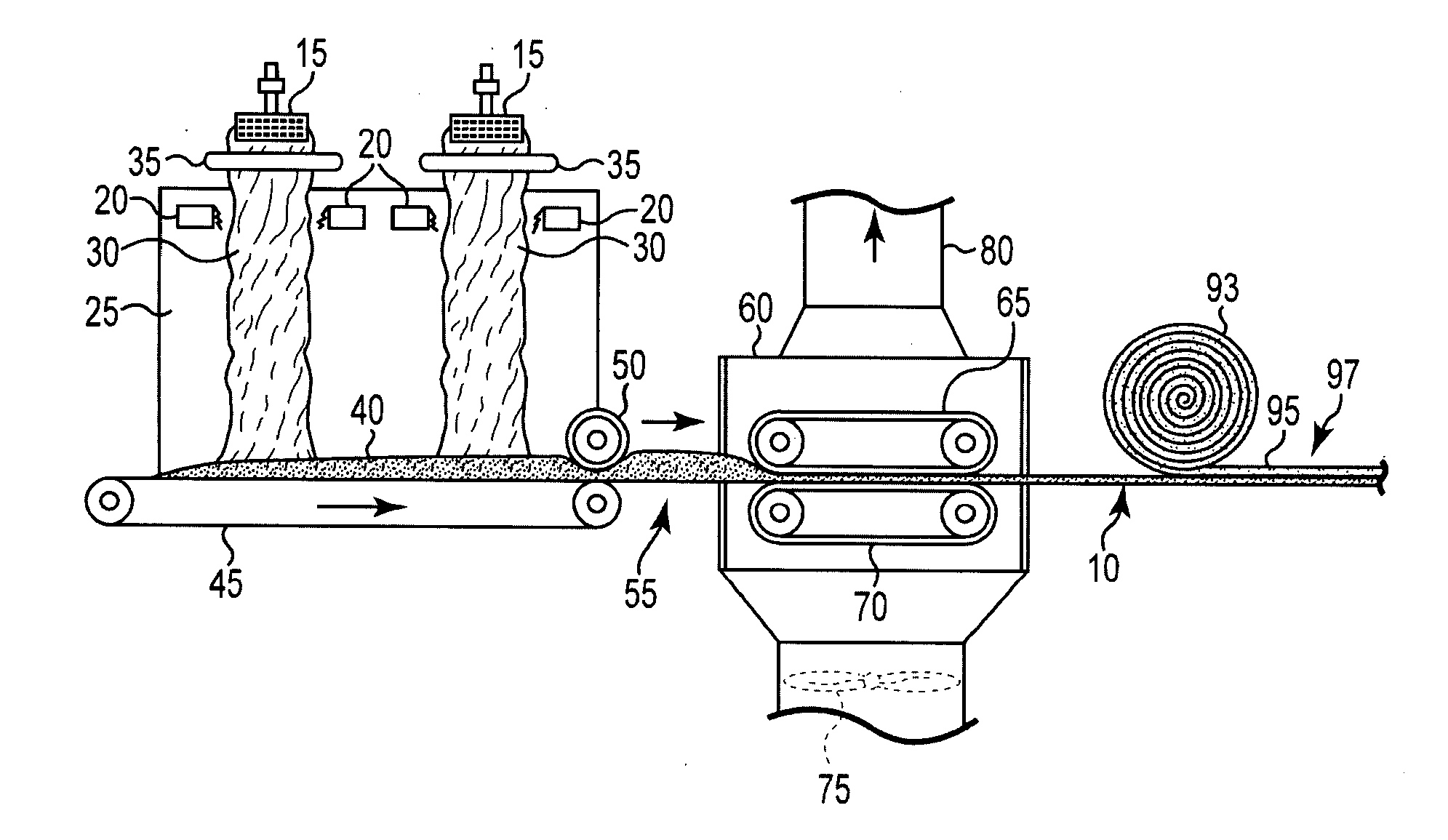

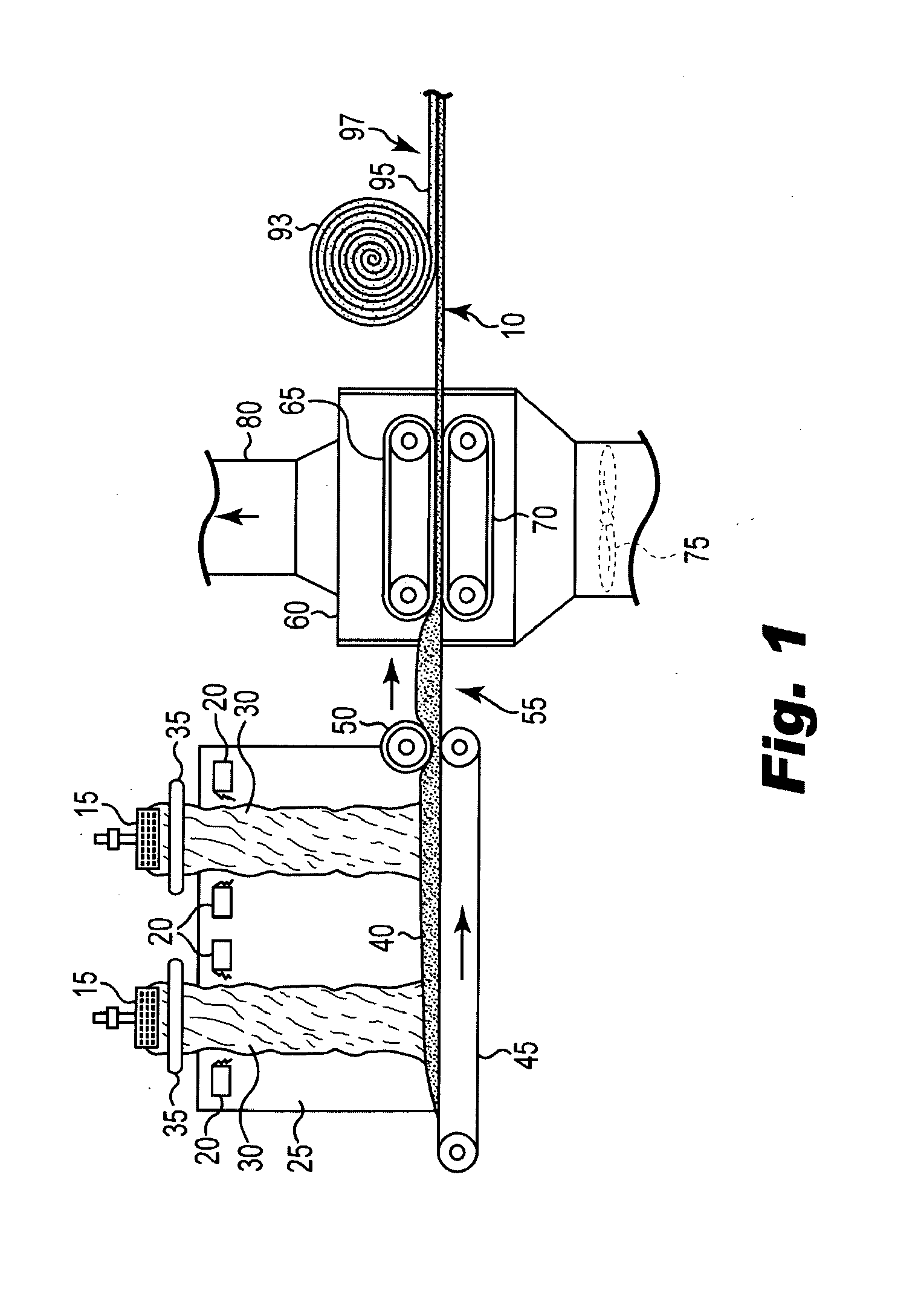

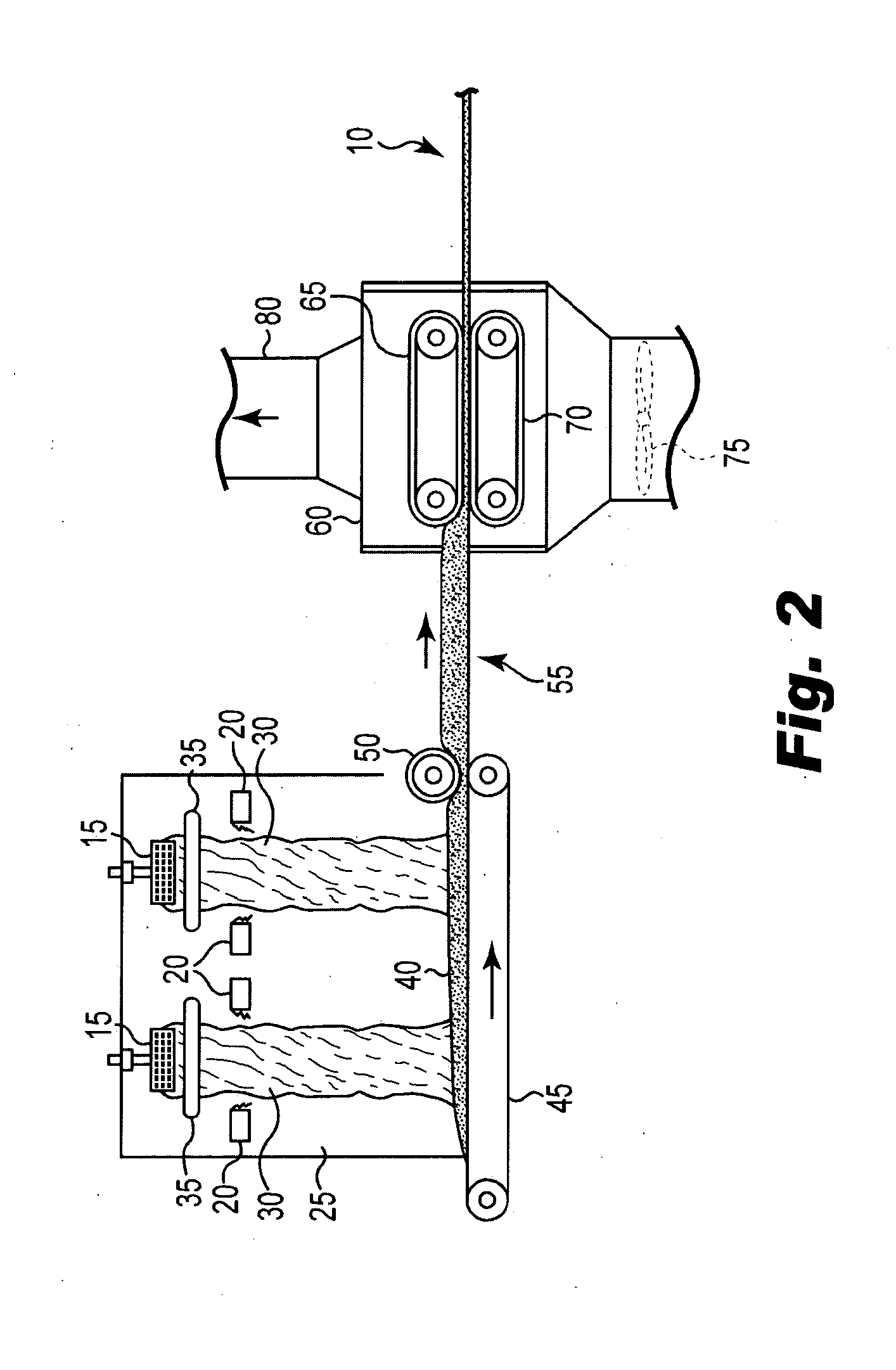

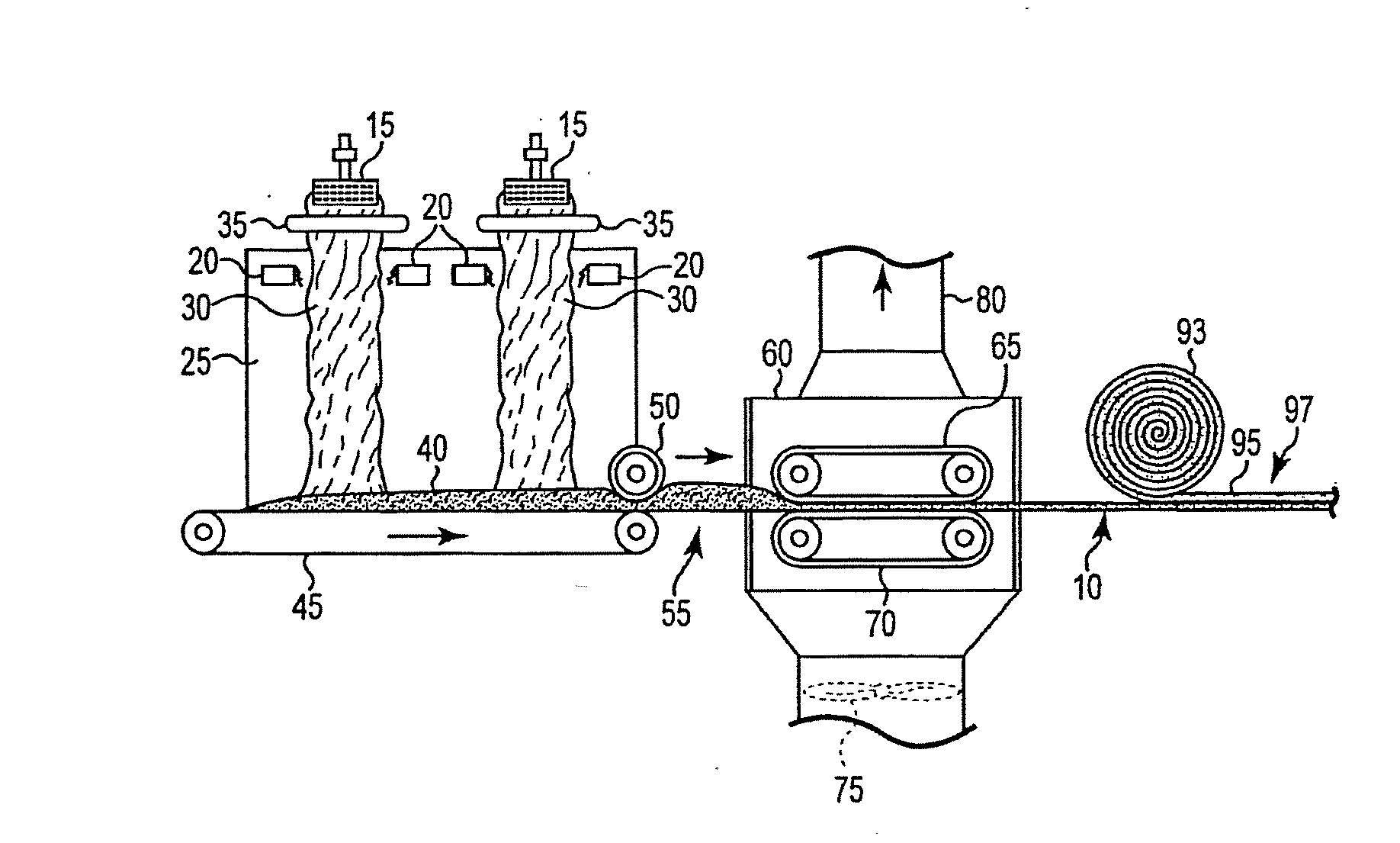

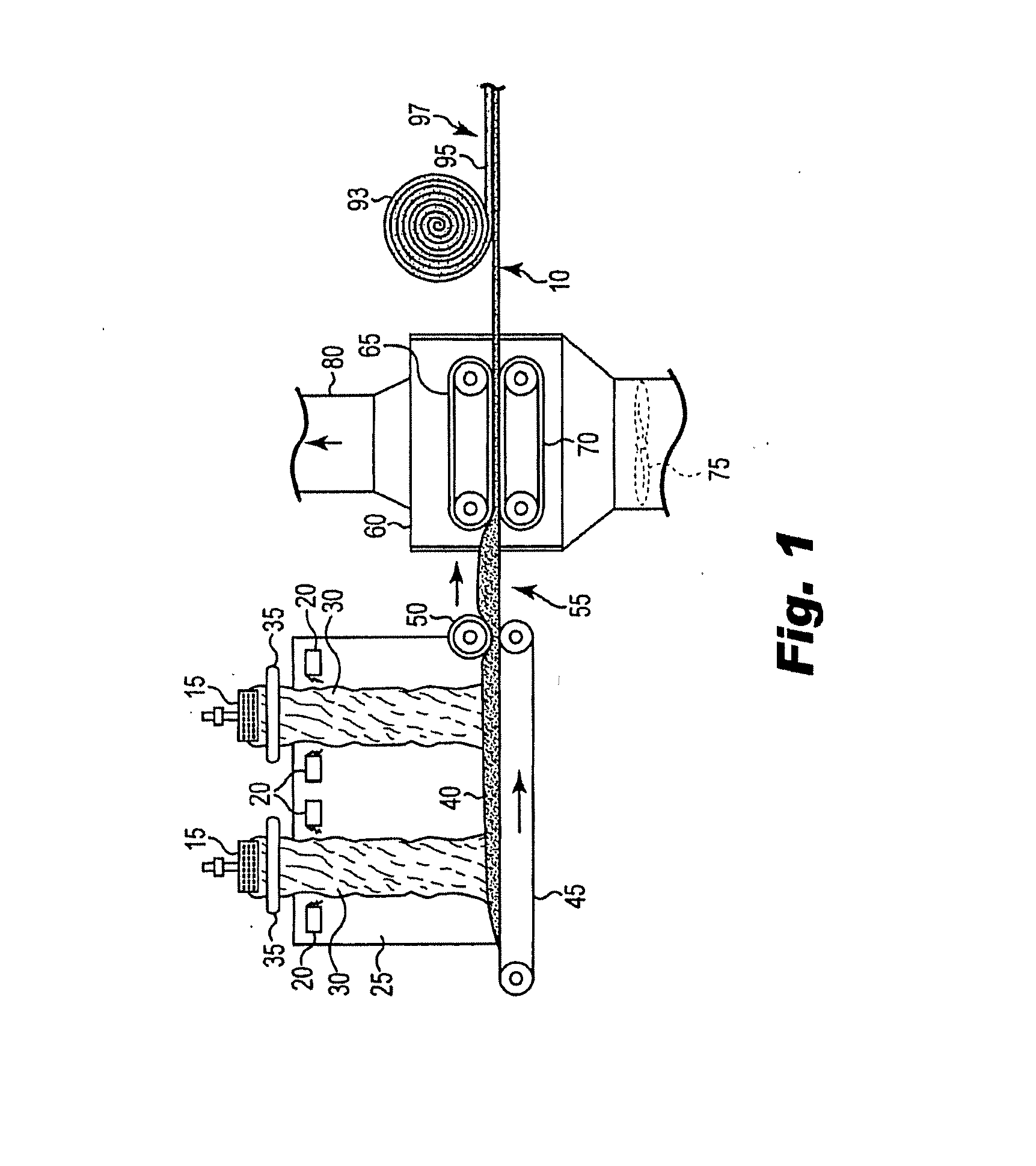

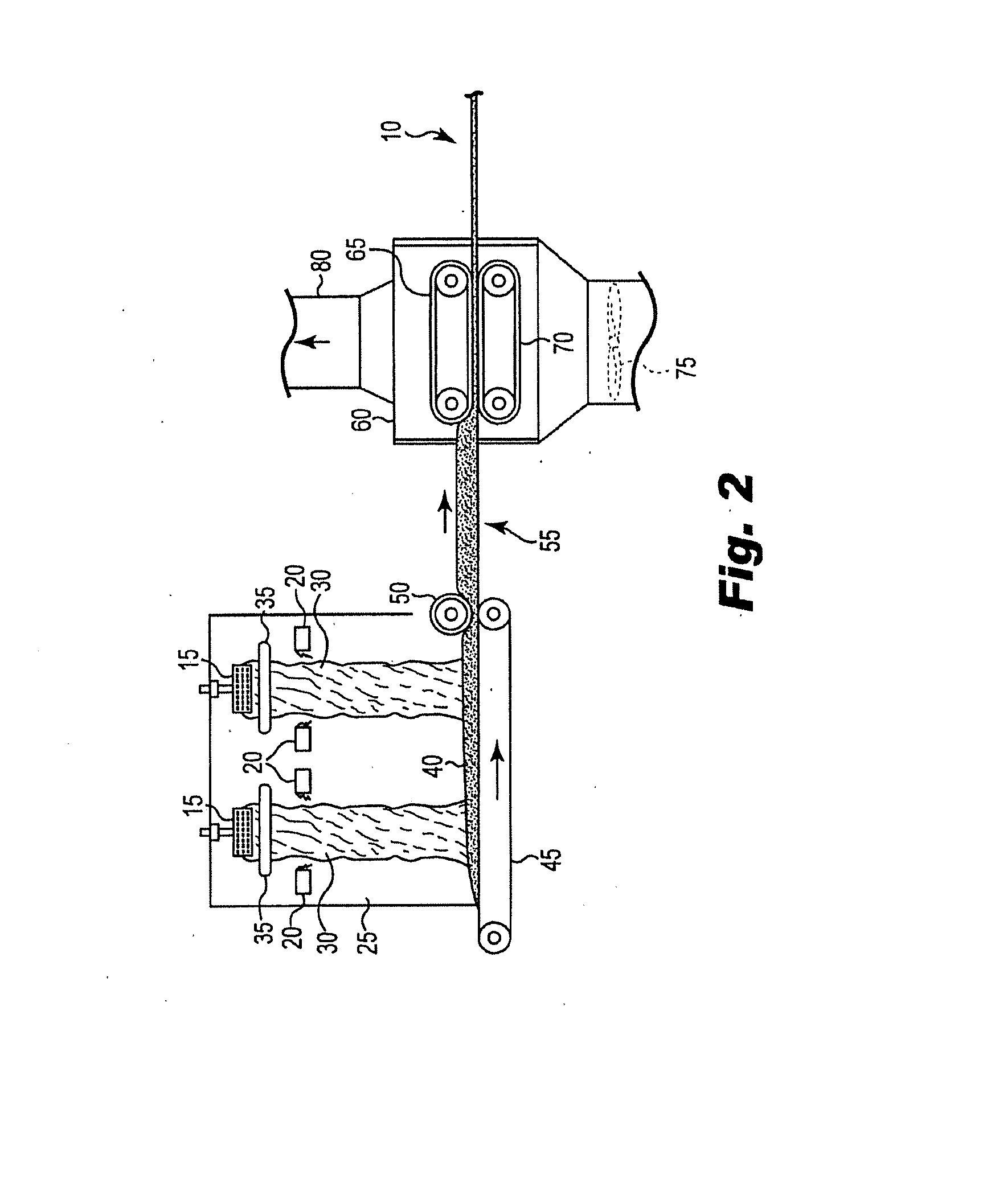

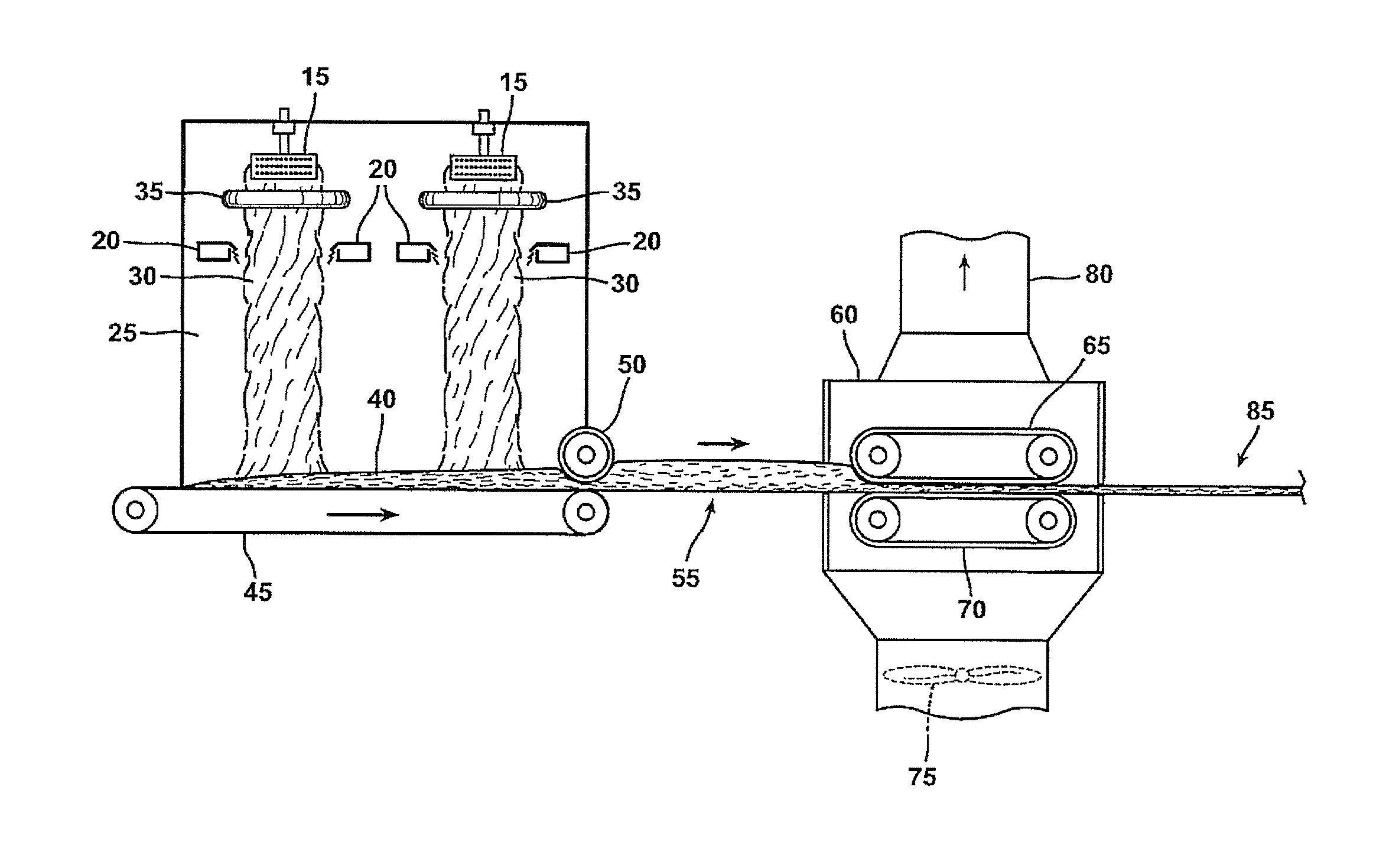

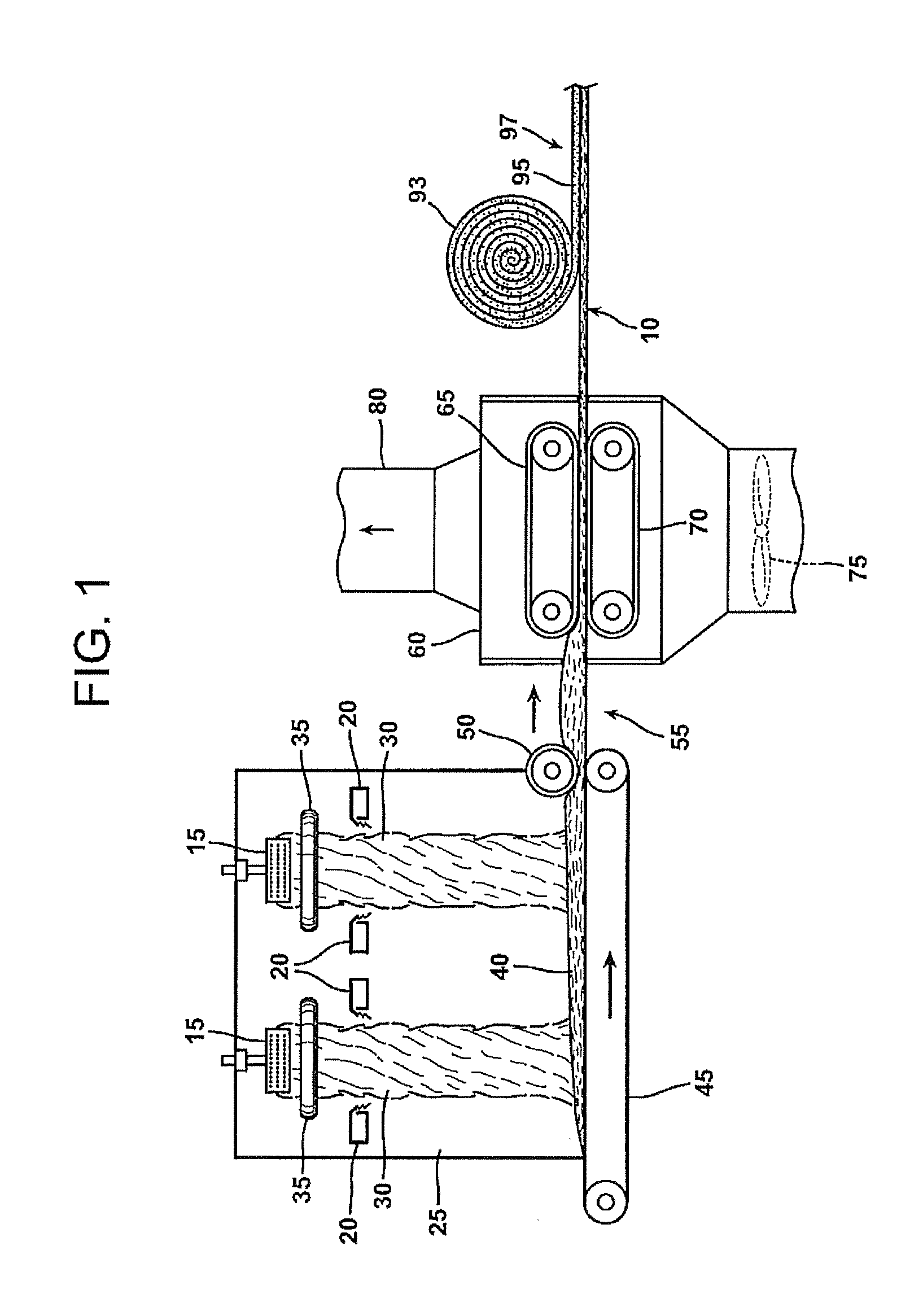

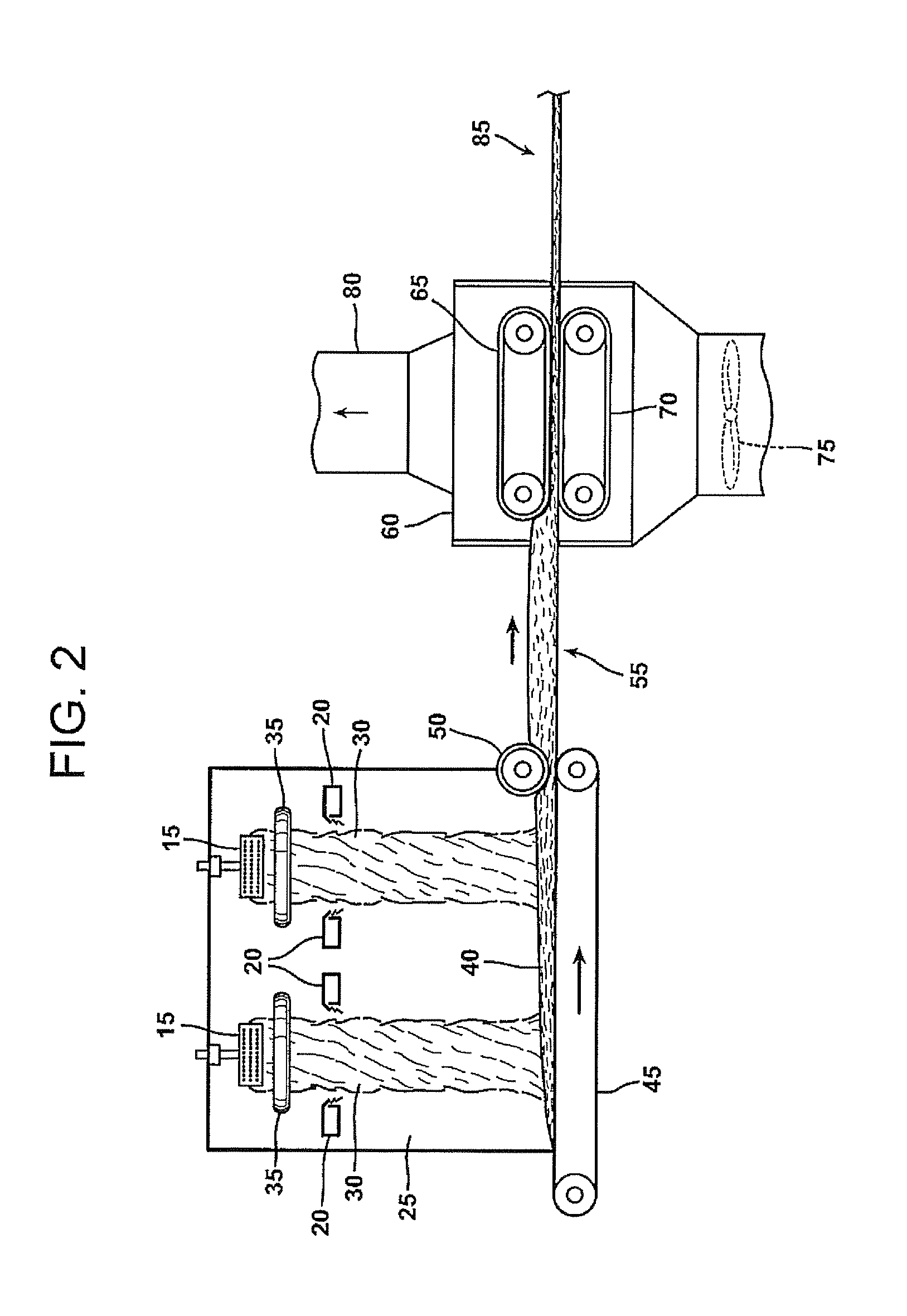

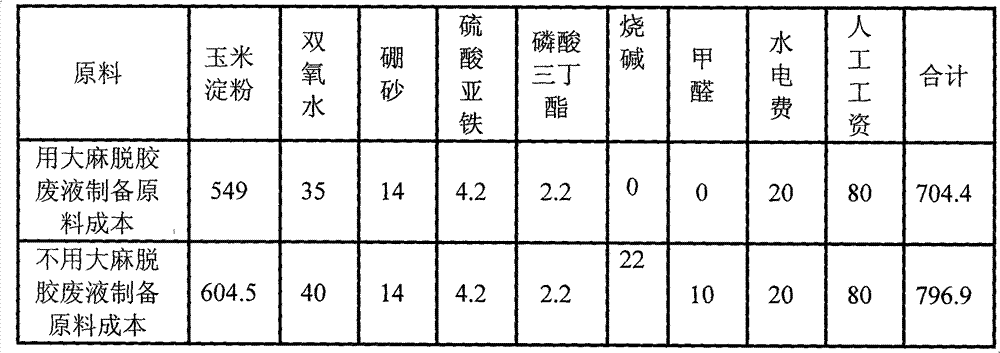

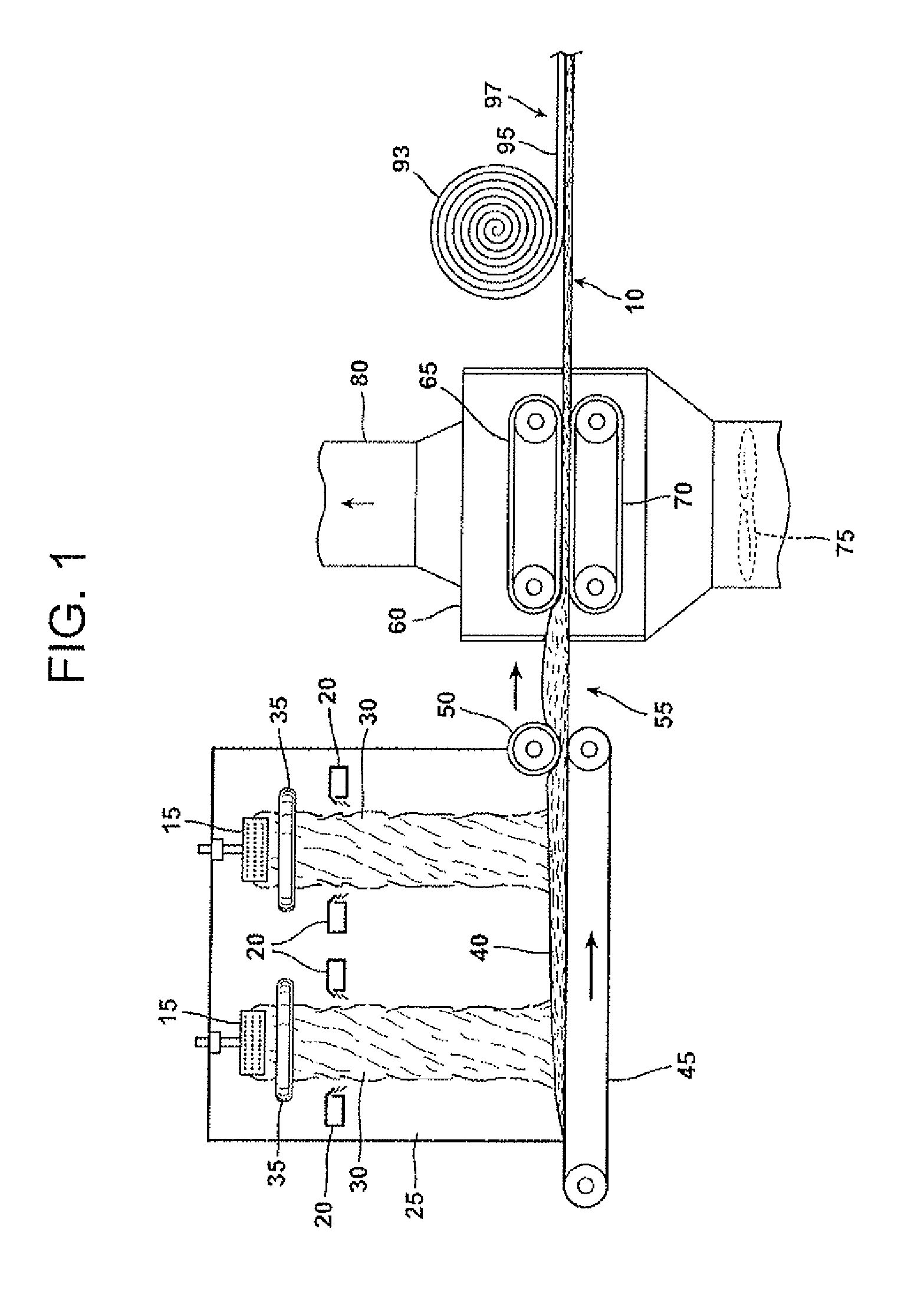

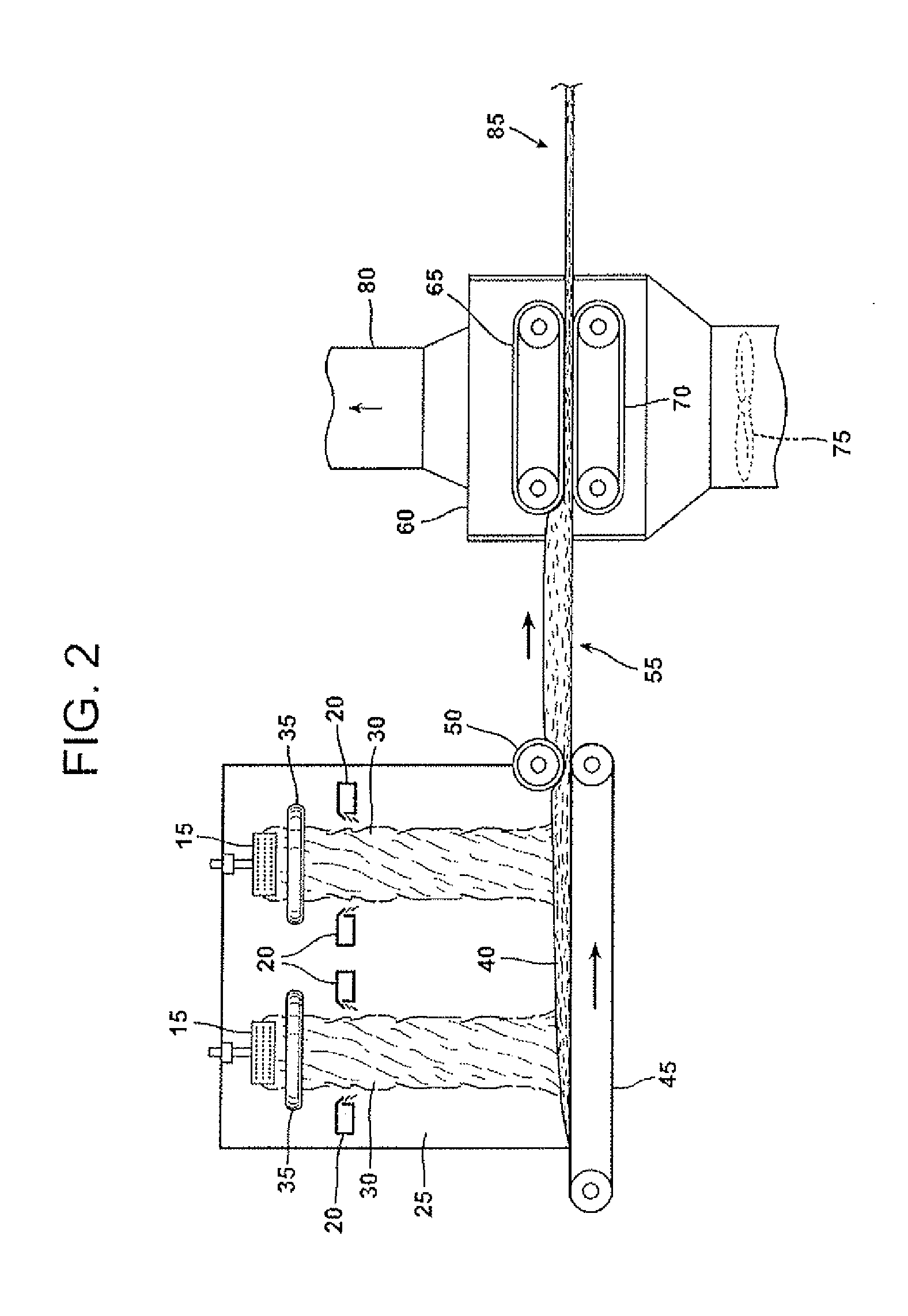

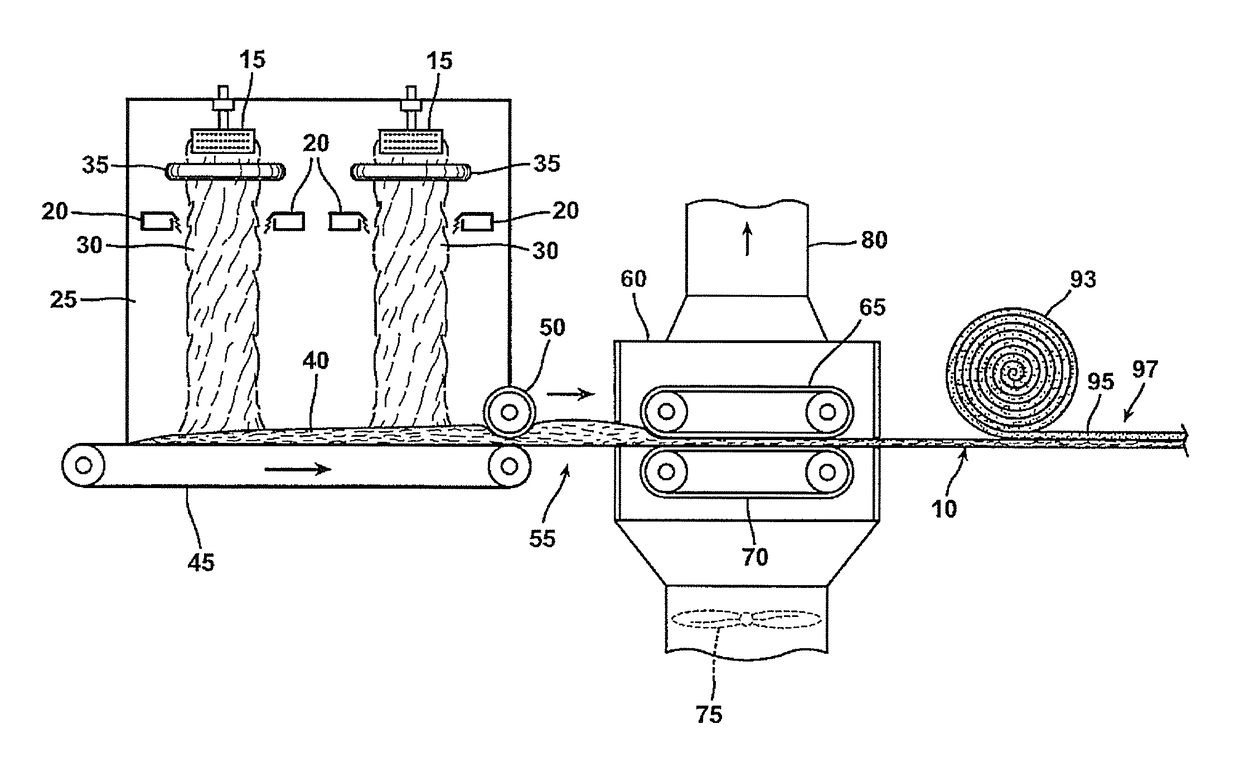

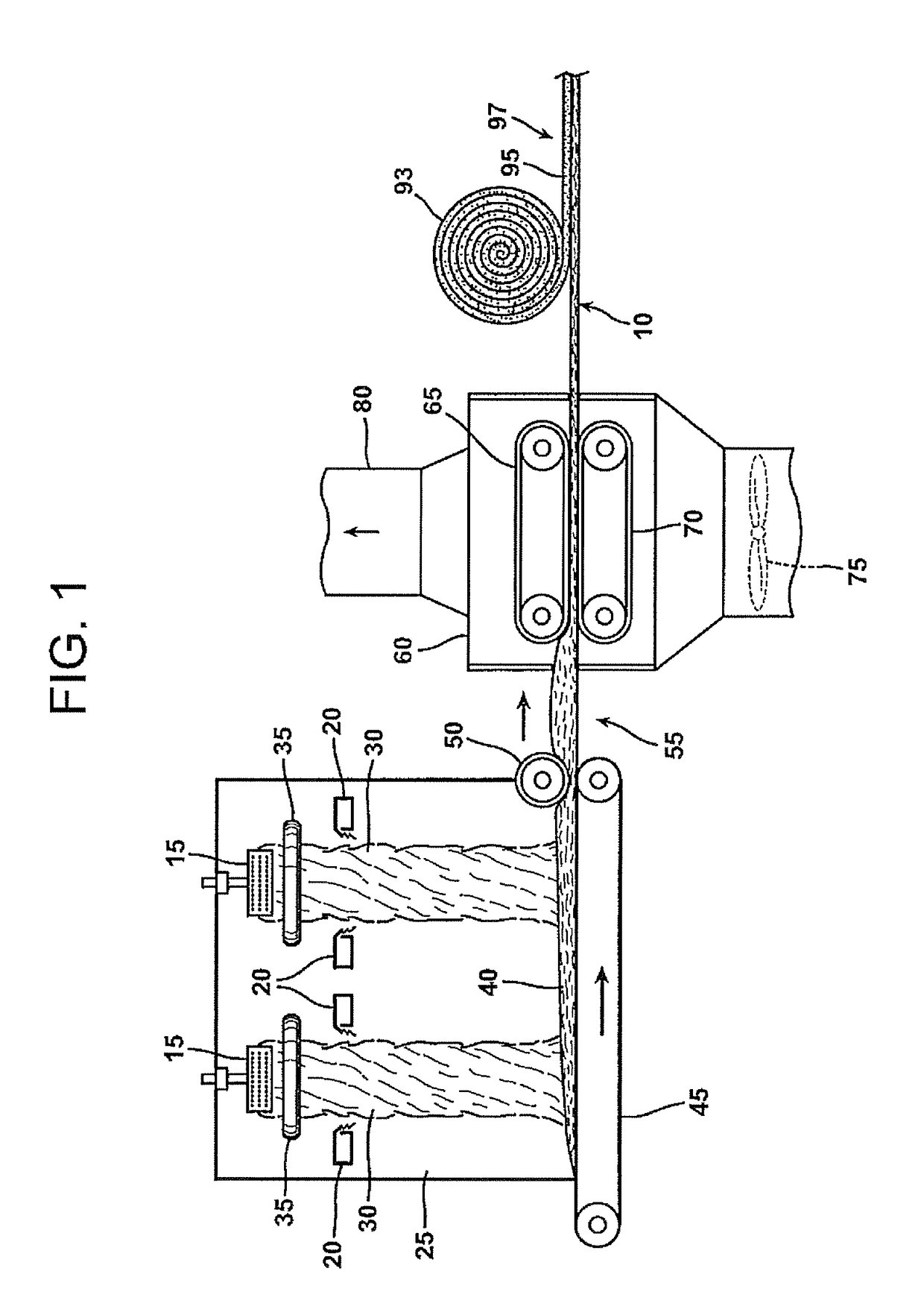

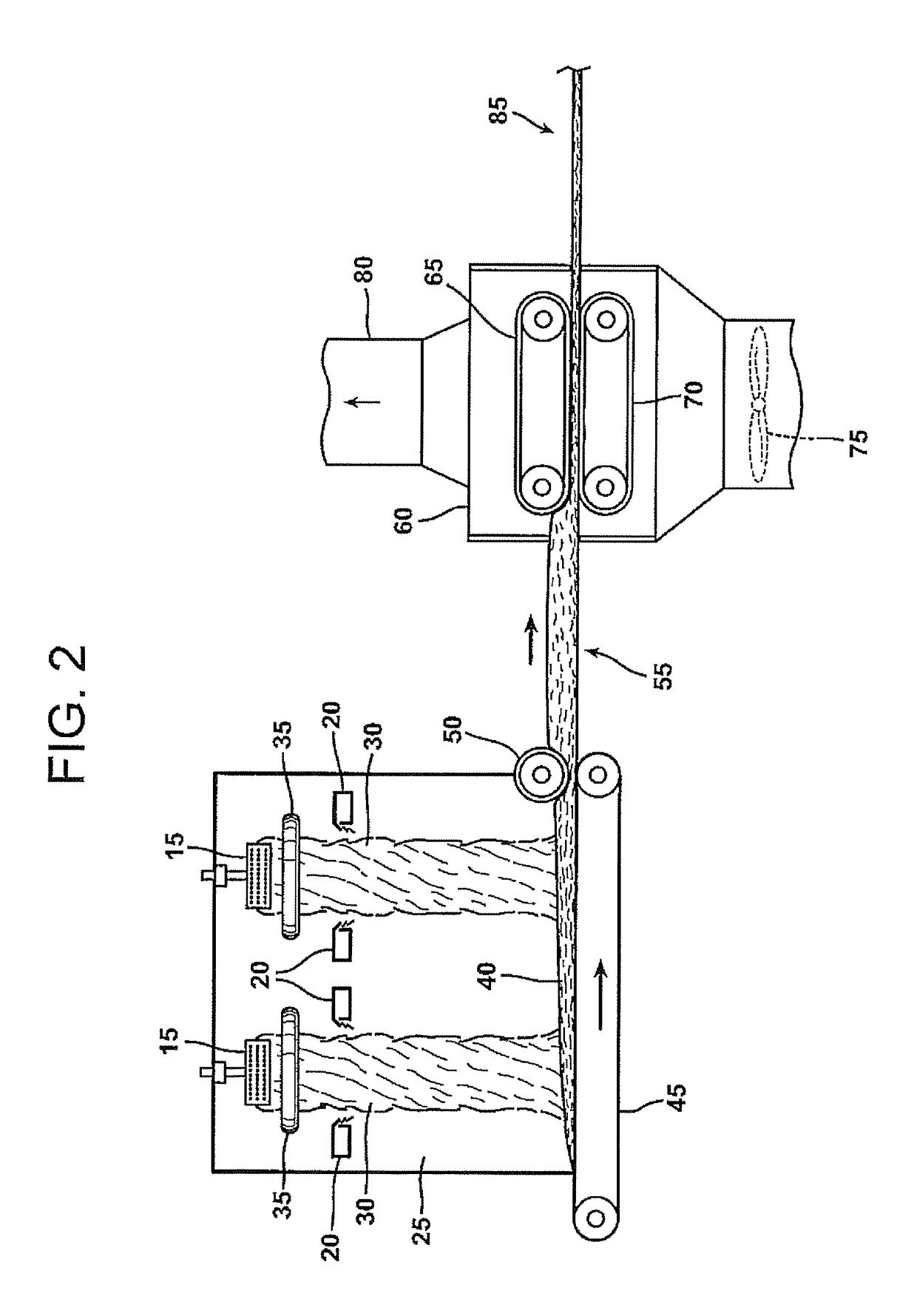

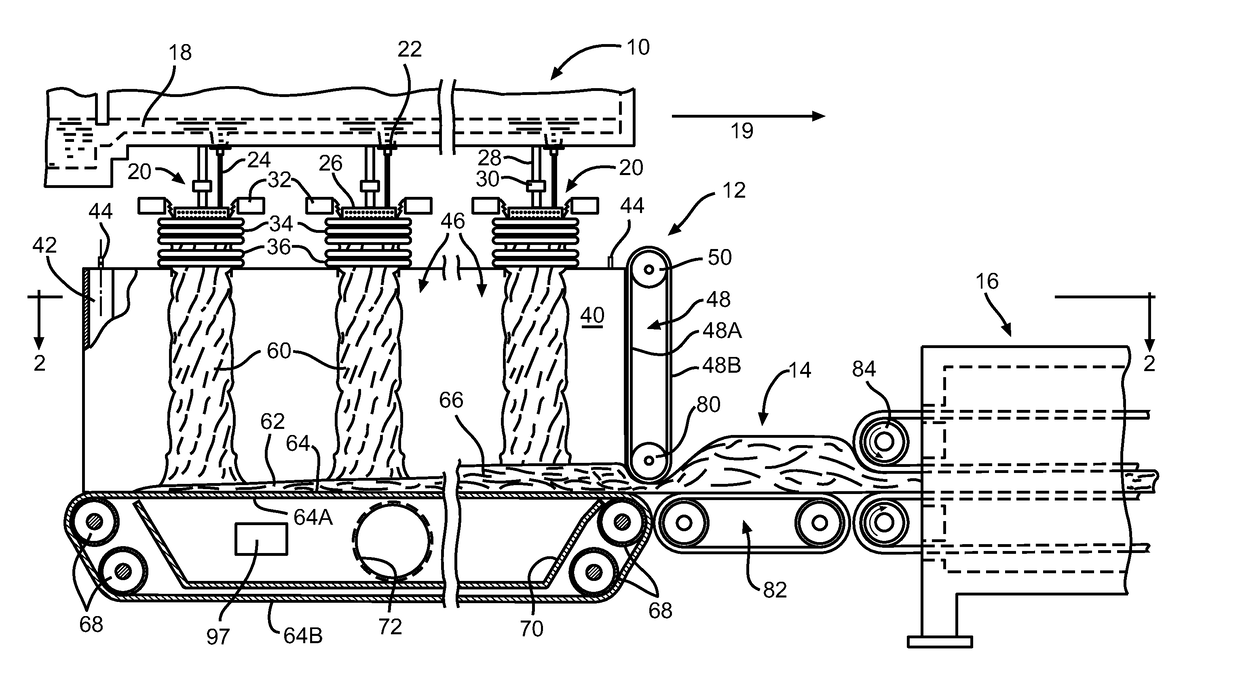

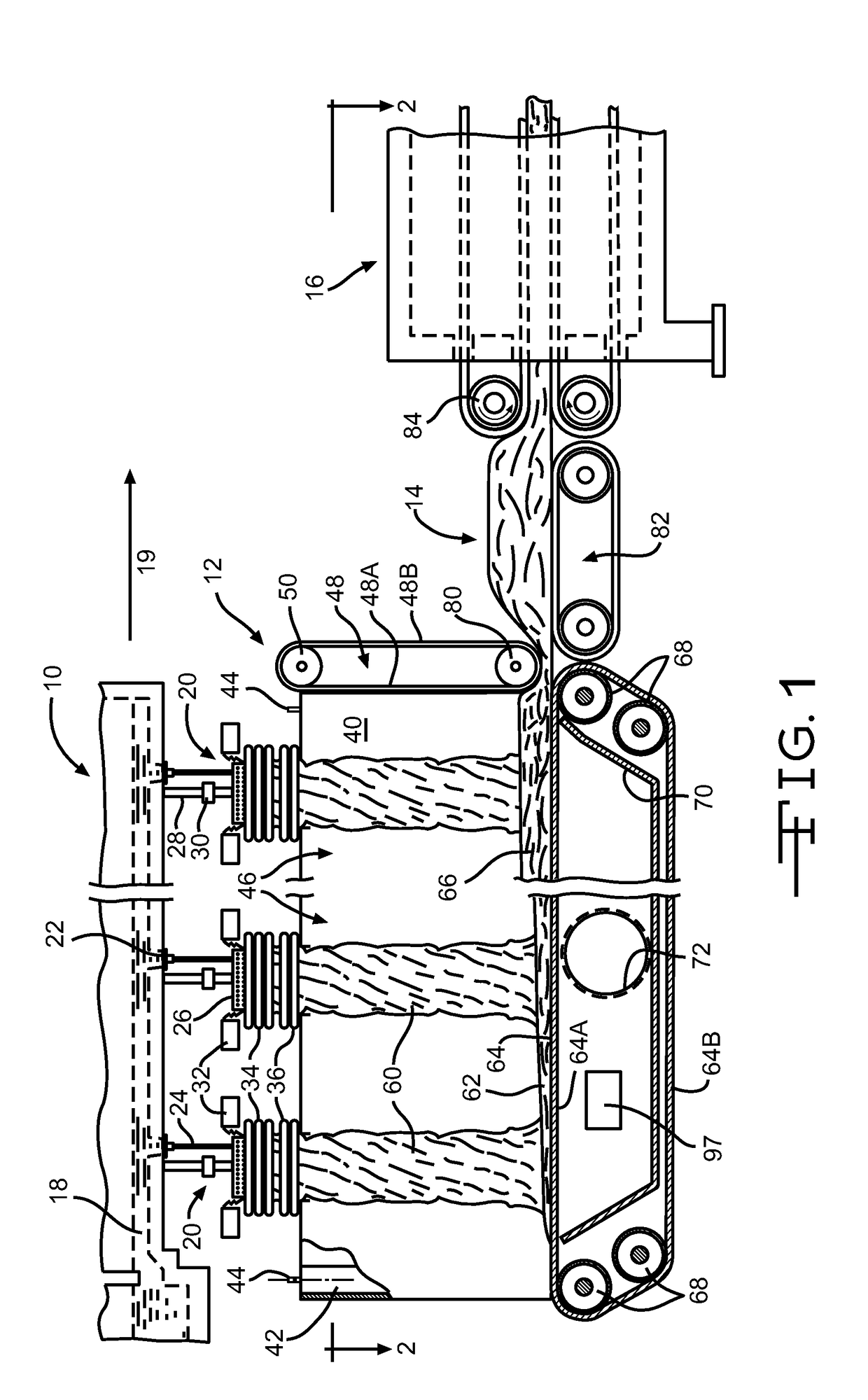

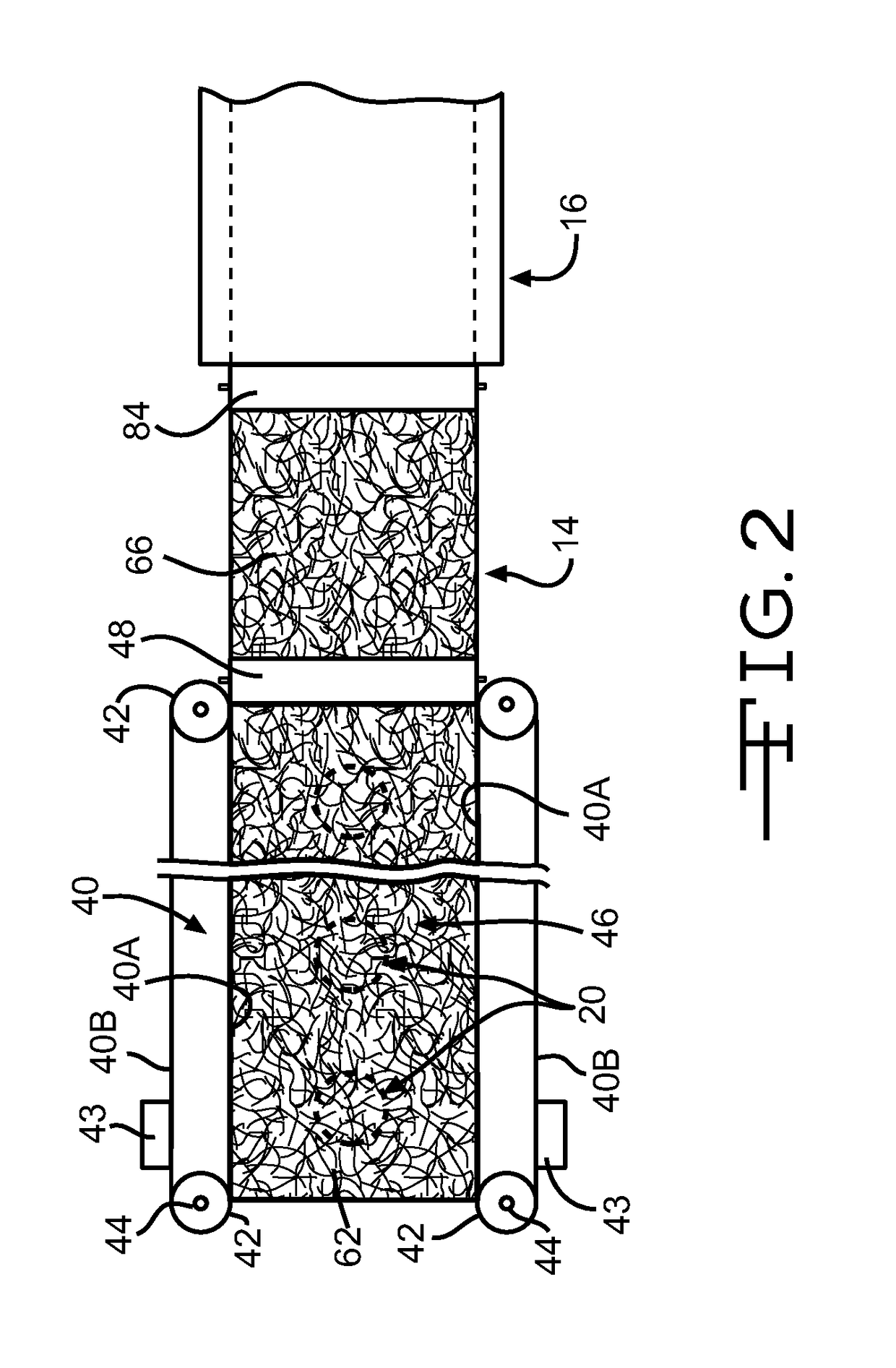

An aqueous binder composition is provided that includes a carbohydrate and a crosslinking agent. In exemplary embodiments, the carbohydrate-based binder composition may also include a catalyst, a coupling agent, a process aid, a crosslinking density enhancer, an extender, a moisture resistant agent, a dedusting oil, a colorant, a corrosion inhibitor, a surfactant, a pH adjuster, and combinations thereof. The carbohydrate may be natural in origin and derived from renewable resources. Additionally, the carbohydrate polymer may have a dextrose equivalent (DE) number from 2 to 20. In at least one exemplary embodiment, the carbohydrate is a water-soluble polysaccharide such as dextrin or maltodextrin and the crosslinking agent is citric acid. Advantageously, the carbohydrates have a low viscosity and cure at moderate temperatures. The environmentally friendly, formaldehyde-free binder may be used in the formation of insulation materials and non-woven chopped strand mats. A method of making fibrous insulation products is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Insulative products having bio-based binders

InactiveUS20110223364A1Readily availableLow costStarch adhesivesStarch derivtive adhesivesFiberWater soluble polysaccharides

Fibrous insulation products have an aqueous binder composition that includes a carbohydrate and a crosslinking agent. In exemplary embodiments, the carbohydrate-based binder composition may also include a catalyst, a coupling agent, a process aid, a crosslinking density enhancer, an extender, a moisture resistant agent, a dedusting oil, a colorant, a corrosion inhibitor, a surfactant, a pH adjuster, and combinations thereof. The carbohydrate may be natural in origin and derived from renewable resources. Additionally, the carbohydrate polymer may have a dextrose equivalent (DE) number from 2 to 20. In at least one exemplary embodiment, the carbohydrate is a water-soluble polysaccharide such as dextrin or maltodextrin and the crosslinking agent is citric acid. Advantageously, the carbohydrates have a low viscosity and cure at moderate temperatures. The environmentally friendly, formaldehyde-free binder may be used in the formation of insulation materials and non-woven chopped strand mats. A method of making fibrous insulation products is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Bio-based binders for insulation and non-woven mats

ActiveUS8864893B2Low costReadily availableStarch dervative coatingsLiquid surface applicatorsFiberWater soluble polysaccharides

An aqueous binder composition is provided that includes a carbohydrate and a crosslinking agent. In exemplary embodiments, the carbohydrate-based binder composition may also include a catalyst, a coupling agent, a process aid, a crosslinking density enhancer, an extender, a moisture resistant agent, a dedusting oil, a colorant, a corrosion inhibitor, a surfactant, a pH adjuster, and combinations thereof. The carbohydrate may be natural in origin and derived from renewable resources. Additionally, the carbohydrate polymer may have a dextrose equivalent (DE) number from 2 to 20. In at least one exemplary embodiment, the carbohydrate is a water-soluble polysaccharide such as dextrin or maltodextrin and the crosslinking agent is citric acid. Advantageously, the carbohydrates have a low viscosity and cure at moderate temperatures. The environmentally friendly, formaldehyde-free binder may be used in the formation of insulation materials and non-woven chopped strand mats. A method of making fibrous insulation products is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Bio-based binder systems

InactiveUS20140083328A1Low costReadily availableOil/fat/wax adhesivesStarch adhesivesGlass fiberMaterials science

An environmentally friendly, bio-based binder system that is useful for the formation of fiberglass insulation, the system includes: A) an aqueous curable binder composition, which includes a carbohydrate and a crosslinking agent; and B) a dedust composition, which includes a blown, stripped plant-based oil and optionally at least one emulsifying agent. The bio-based binder system is typically heated to form a cured binder system.

Owner:CARGILL INC

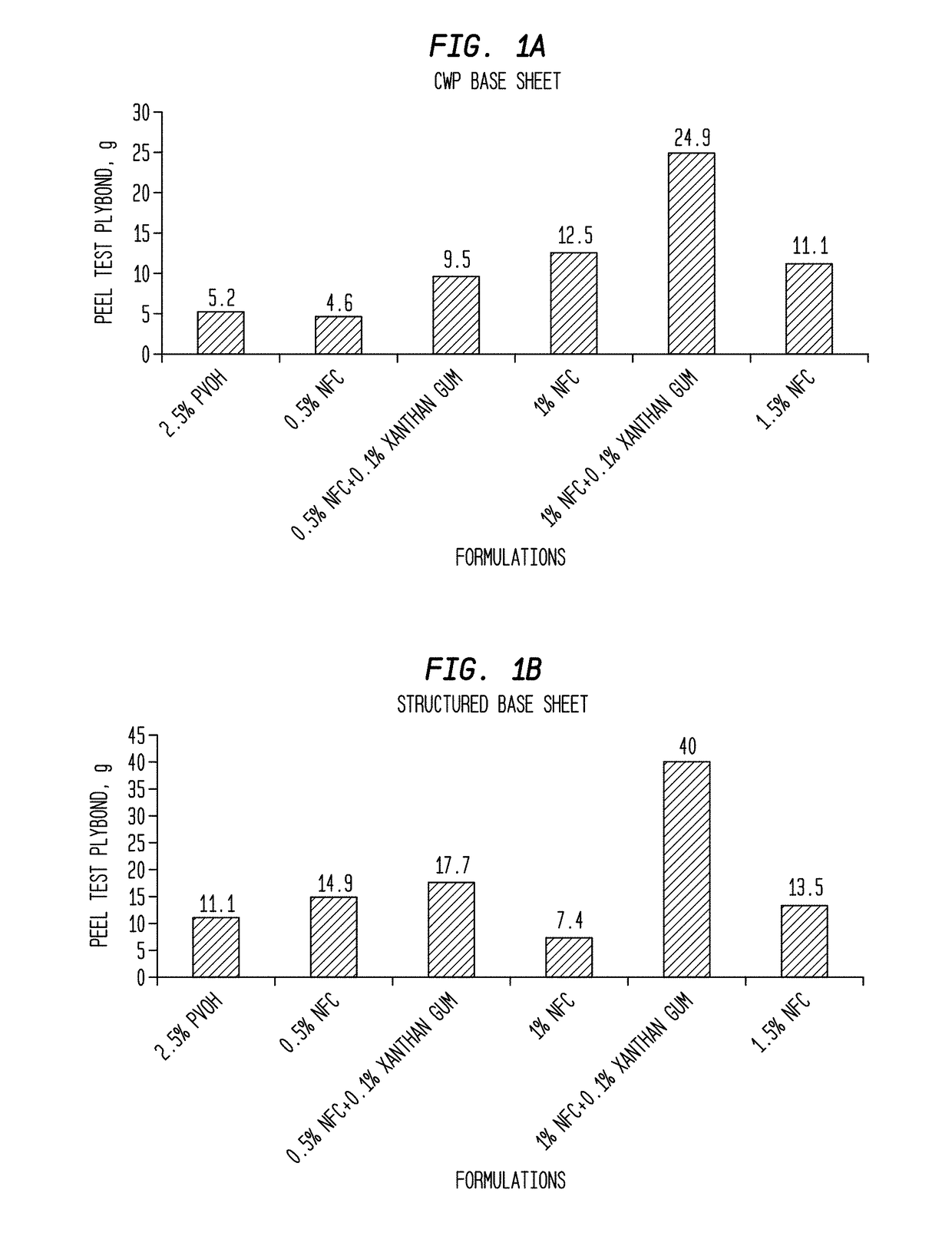

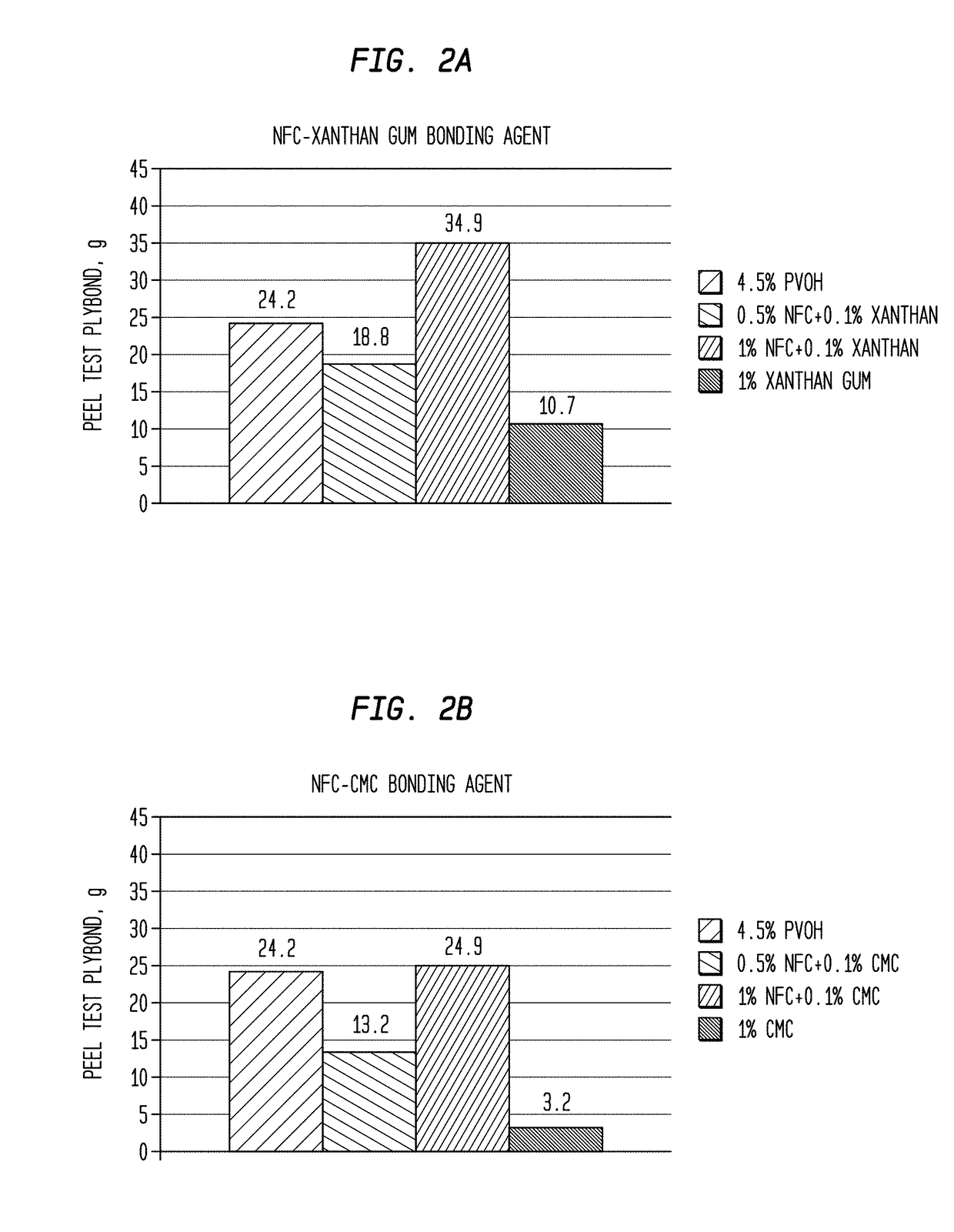

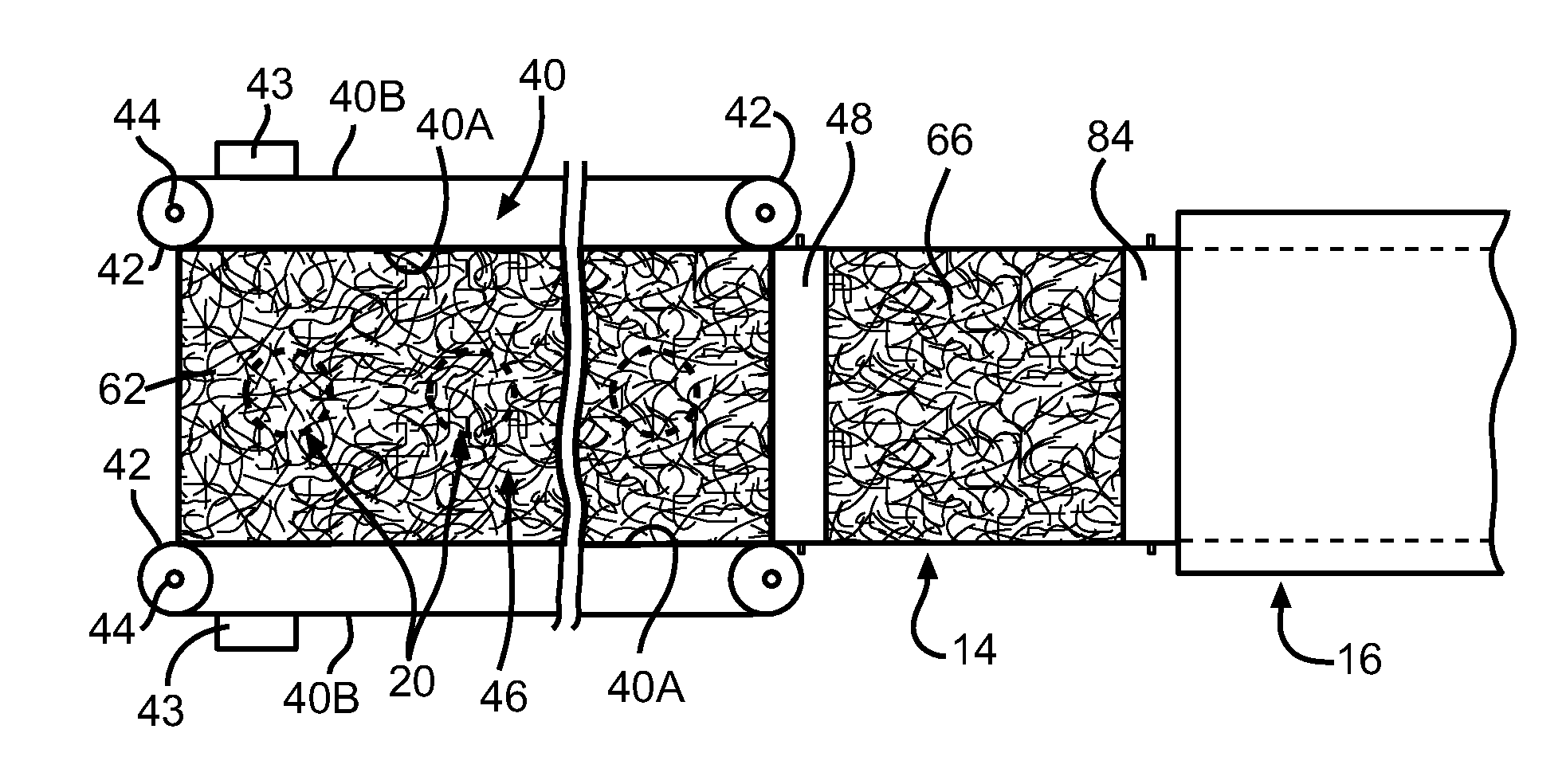

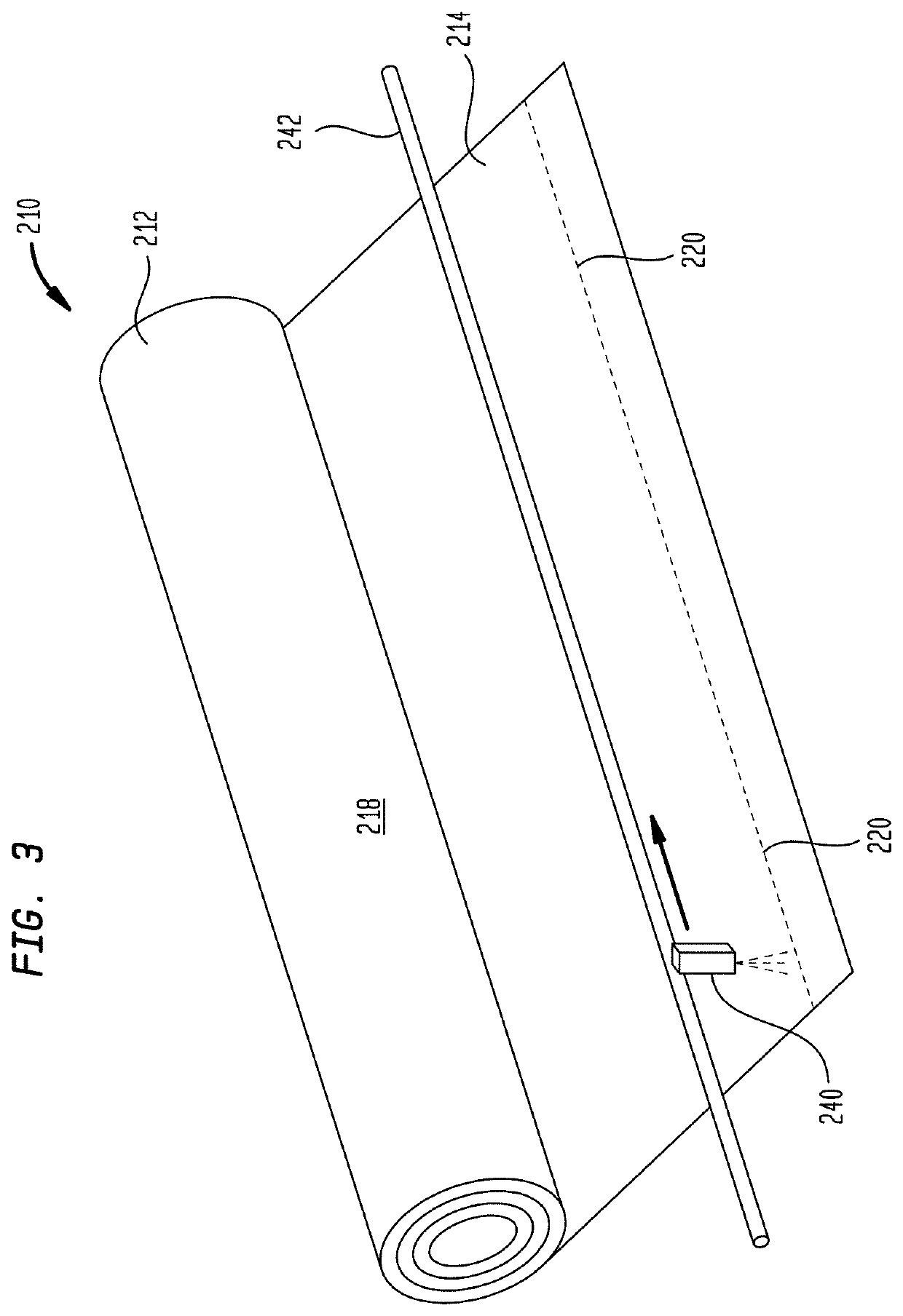

Nanofibrillated Cellulose Ply Bonding Agent Or Adhesive and Multi-Ply Absorbent Sheet Made Therewith

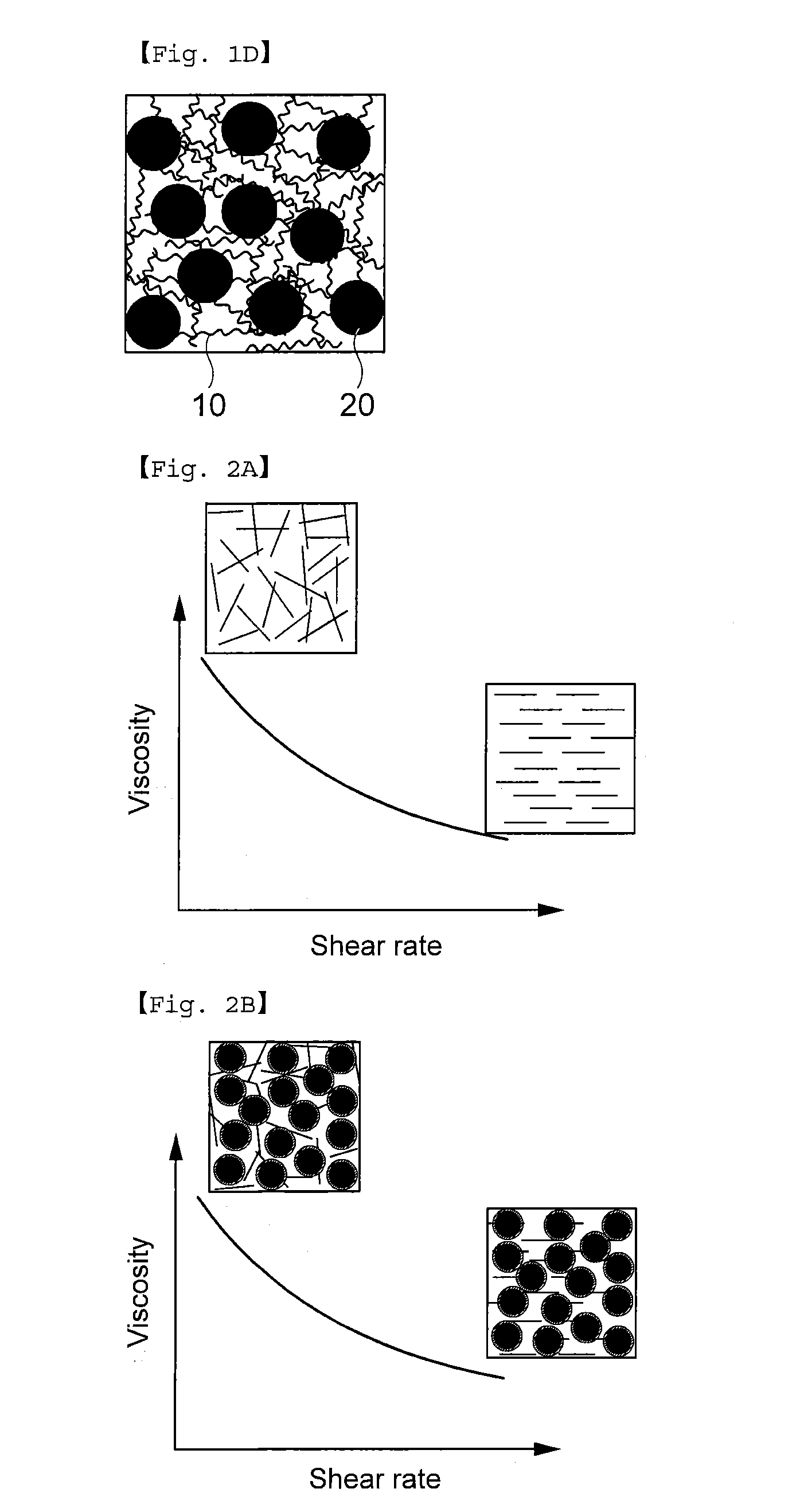

ActiveUS20170204567A1More surface areaHigh viscosityAdhesive processesFilm/foil adhesivesPolymer sciencePolyol

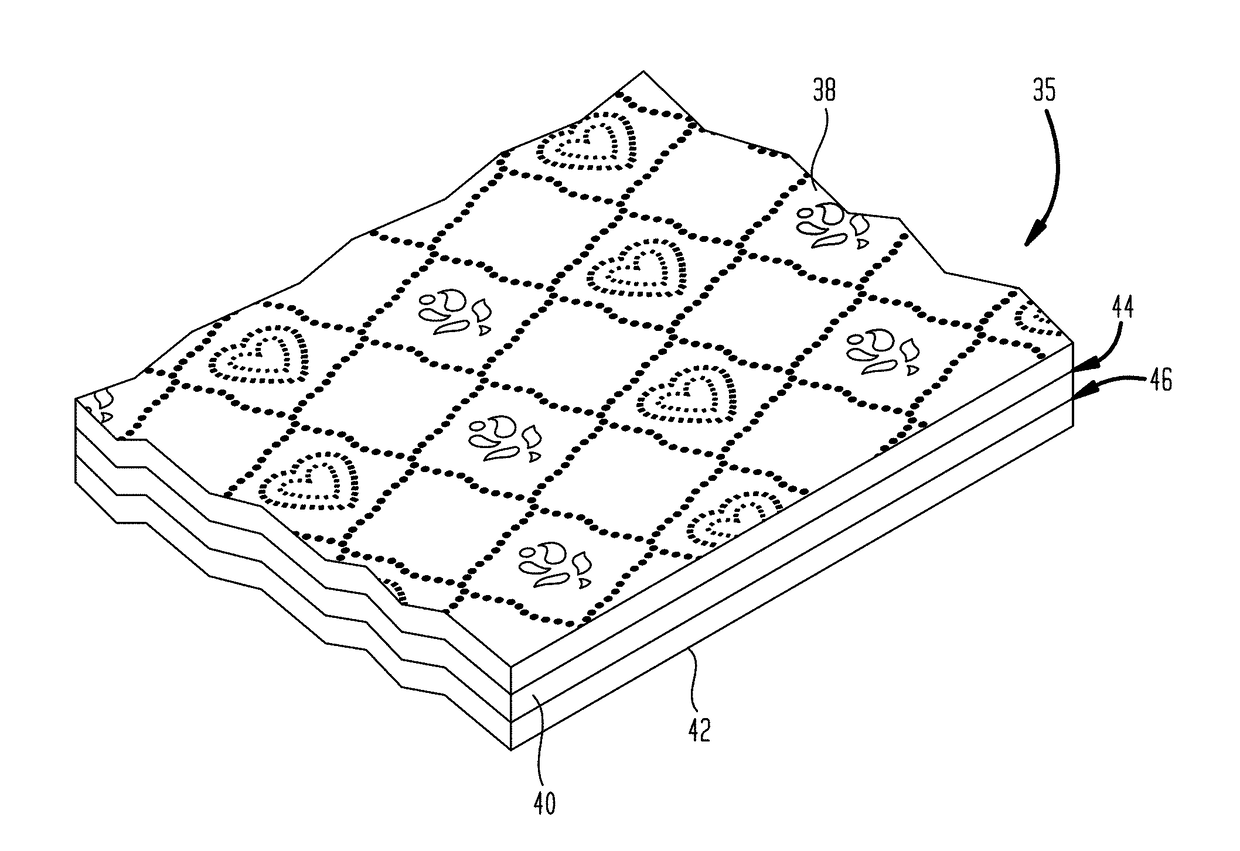

A ply-bonding agent or adhesive composition characterized by a viscosity and a surface tension for the manufacture of paper tissue and paper towel, includes: (a) water; (b) nanofibrillated cellulose; and (c) one or more modifiers effective to modify either or both of (i) the viscosity of the composition or (ii) the surface tension of the composition, wherein the one or more additional modifiers are selected from the group consisting of components (iii), (iv), (v), (vi), (vii) or (viii), wherein: (iii) is PVOH and a viscosity modifier; (iv) is a viscosity modifier; (v) is a viscosity modifier and a surface tension modifier other than PVOH; (vi) is a water-soluble cellulose derivative; (vii) is a water soluble polyol; and (viii) is a surface tension modifier other than PVOH. The compositions are particularly useful for ply-bonding multi-ply absorbent sheet when the plies are treated with debonder.

Owner:GPCP IP HLDG LLC

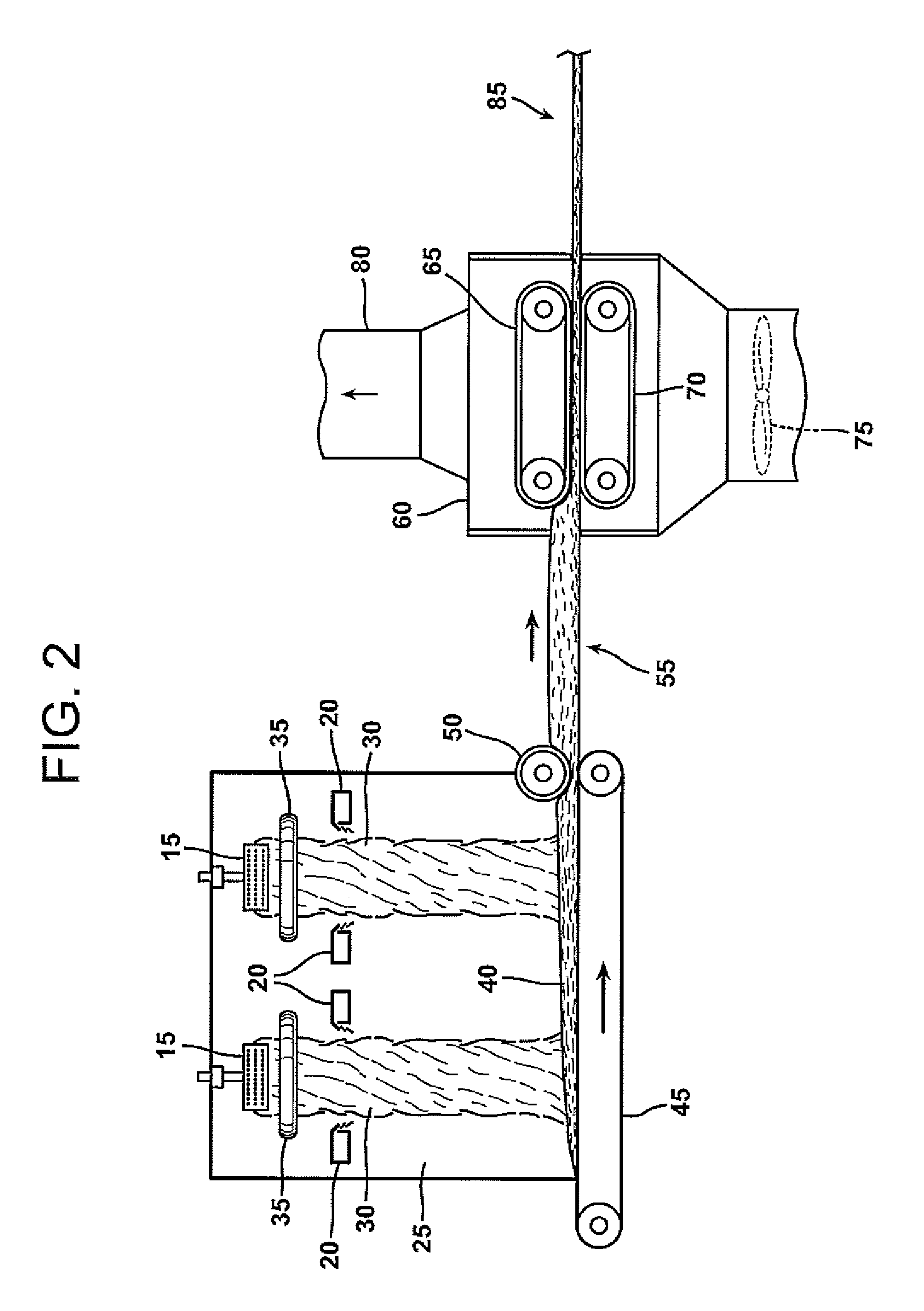

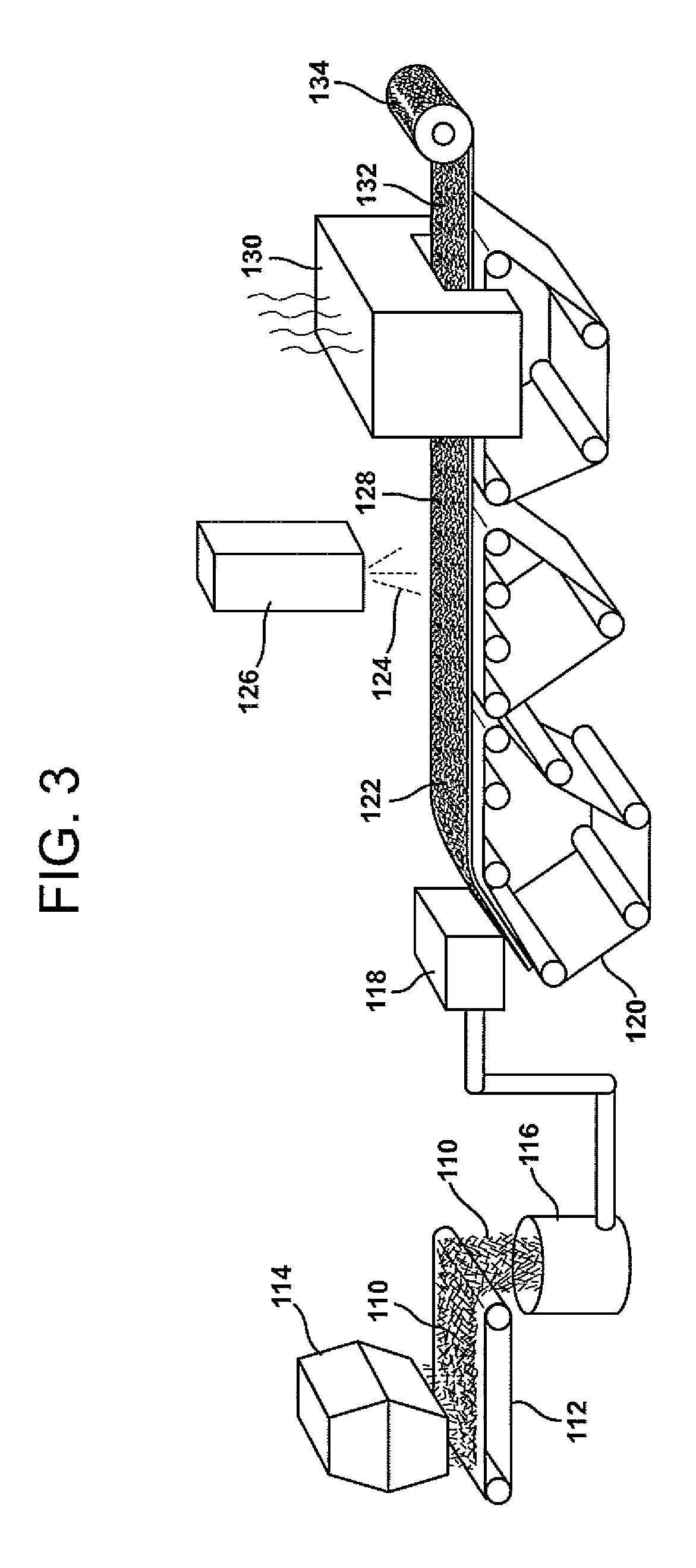

Biocides for bio-based binders, fibrous insulation products and wash water systems

Biocides for bio-based binder compositions are disclosed. Bio-based binders include those having a nutrient source such as carbohydrate, protein or fat, which can serve as an energy source for organisms to grow in areas that contact binder. Principal areas that contact bio-based binder in a fiberglass insulation manufacturing process include the raw ingredients, the binder chemicals, the prepared binder dispersions, the forming hood and related equipment, the final insulation product and, importantly, the cleaning systems and washwater arising from cleaning the manufacturing equipment and / or forming the product. Frequently the washwater is stored until re-cycled for re-use. Storage may take place in tanks, towers, vats and even outdoor reservoirs, all of which may harbor the growth of unwanted organisms, for which a biocide is desirable.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Bio-based binders including carbohydrates and a pre-reacted product of an alcohol or polyol and a monomeric or polymeric polycarboxylic acid

InactiveUS20140038485A1Speed crosslinking reactionLow viscosityFibre treatmentStarch adhesivesPolyolAlcohol

An environmentally friendly, formaldehyde-free, aqueous binder composition that includes a carbohydrate, a crosslinking agent, and a pre-reacted product of an alcohol or polyol and monomeric or polymeric polycarboxylic acid or polyglycerol is provided. The pre-reacted product may include glycerol and esters of citric acid such a monoglyceryl citrate, diglyceryl citrate, and triglyceryl citrate as well as other higher molecular weight citric acid-based esters. The inclusion of the pre-reacted product in the binder composition helps to speed the crosslinking reaction, induces faster water evaporation, decreases the viscosity of the binder, helps to reduce the amount of water needed for application of the binder, decreases tackiness, and helps to achieve a maximum vertical expansion of the insulation pack in the transfer zone. The binder composition may be used in the formation of insulation materials and non-woven chopped strand mats.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC +1

Bio-based binders including carbohydrates and a pre-reacted product of an alcohol or polyol and a monomeric or polymeric polycarboxylic acid

ActiveUS20150152244A1Low viscositySpeed the crosslinking reactionFibre treatmentStarch adhesivesEvaporationGlycerol

An environmentally friendly, formaldehyde-free, aqueous binder composition that includes a carbohydrate, a crosslinking agent, and a pre-reacted product of an alcohol or polyol and monomeric or polymeric polycarboxylic acid or polyglycerol is provided. The pre-reacted product may include glycerol and esters of citric acid such a monoglyceryl citrate, diglyceryl citrate, and triglyceryl citrate as well as other higher molecular weight citric acid-based esters. The inclusion of the pre-reacted product in the binder composition helps to speed the crosslinking reaction, induces faster water evaporation, decreases the viscosity of the binder, helps to reduce the amount of water needed for application of the binder, decreases tackiness, and helps to achieve a maximum vertical expansion of the insulation pack in the transfer zone. The binder composition may be used in the formation of insulation materials and non-woven chopped strand mats.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Insulative products having bio-based binders

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC +1

Method for preparing bond for corrugated board by using potato residue as raw material

ActiveCN101643633AReduce pollutionImprove water resistanceMechanical working/deformationNon-macromolecular adhesive additivesPotato starchHigh pressure

The invention discloses a method for preparing bond for corrugated boards by using potato residue as the raw material, which belongs to the technical field of preparing bonds. In the method, a bond with good performance and low cost for a corrugated board is obtained by using waste potato residue used for producing potato starch industrially as the main raw material, using superfine pulverizationby a colloid wet grinding method and the physical modification means of high-pressure steam treatment, combining oxidation modification treatment and adding a series of assistant agents. The main bonding properties of the prepared bond for the corrugated board are similar to those of a starch-based bond; the prepared bond conforms to the requirement of producing the corrugated board and can be widely applied to the production, the bonding and the like of the corrugated board; in addition, because the waste potato residue is used as the main raw material, the production cost is obviously reduced and the environmental pollution is effectively reduced.

Owner:JIANGNAN UNIV

Adhesive

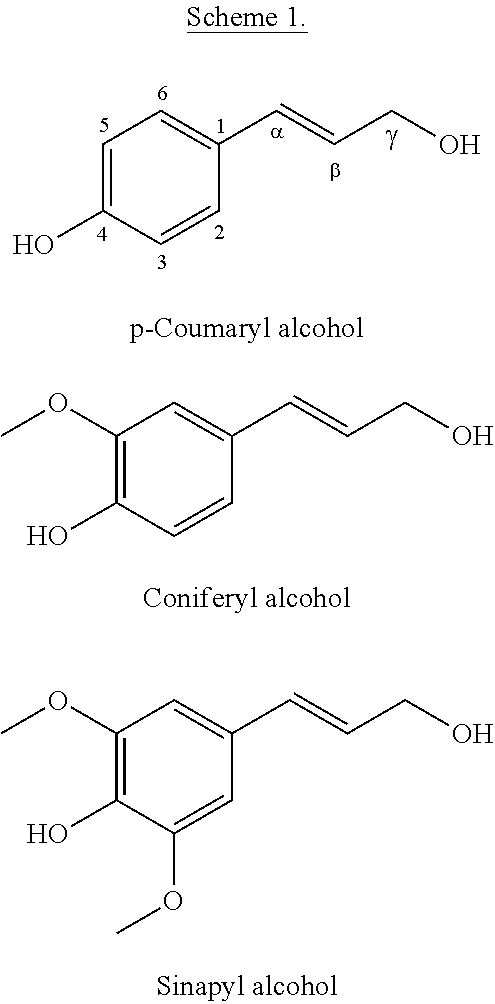

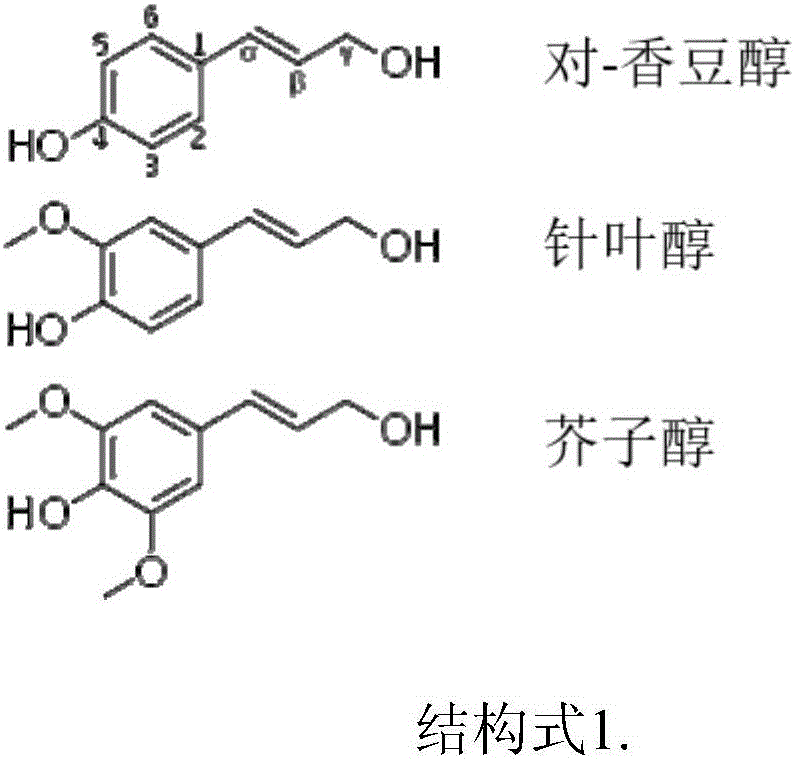

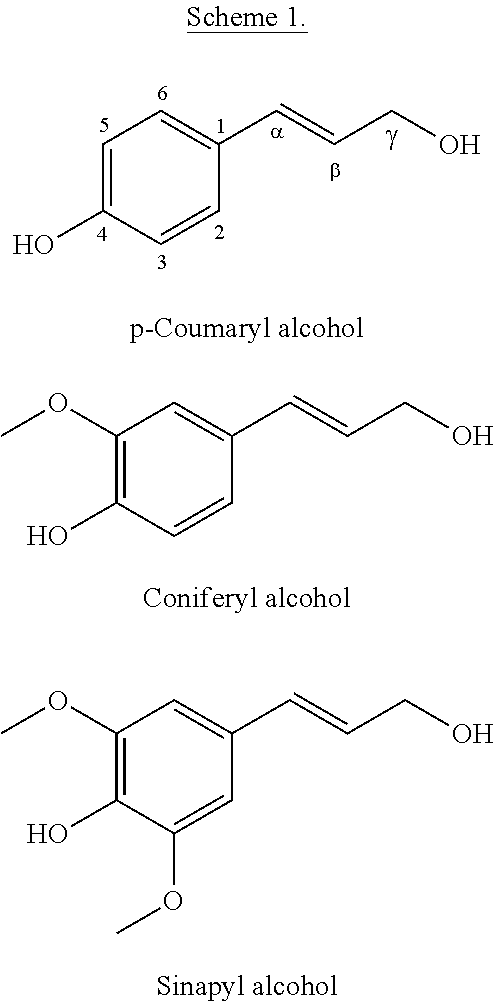

ActiveUS20160333240A1Promote denaturisationPromote solubilisationAgar-agar adhesivesStarch adhesivesLignanPolyphenol

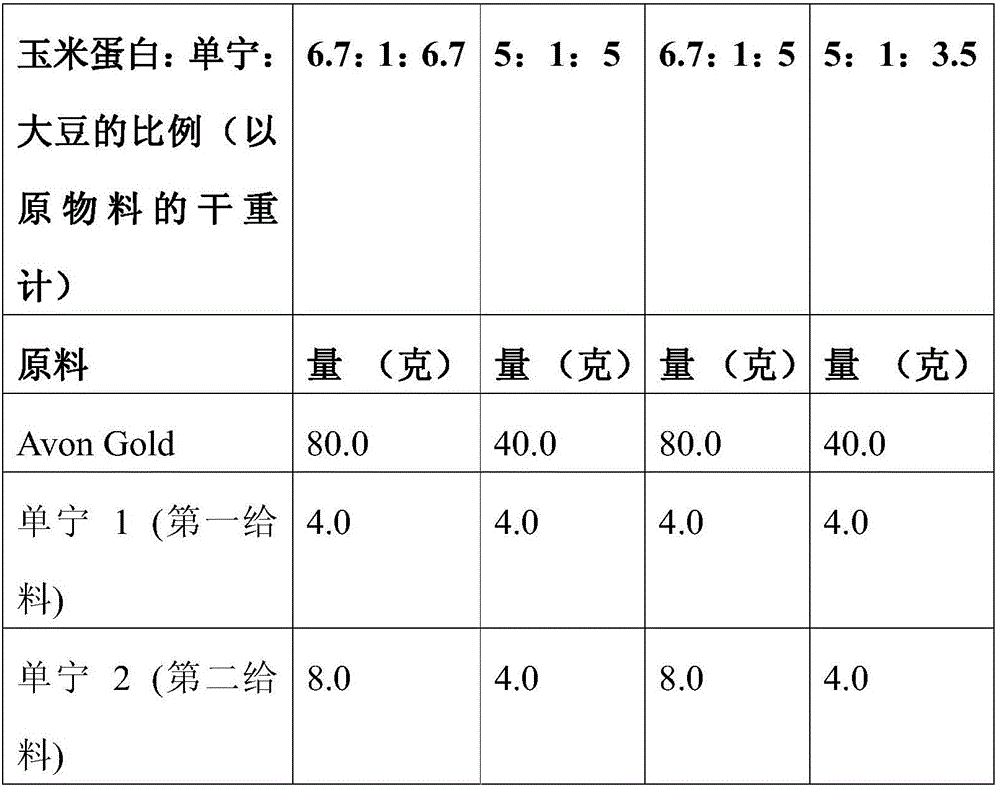

An aqueous adhesive composition and a process for preparing such compositions are disclosed. The composition comprises macromolecular complex comprising (A) a first component comprising (i) a framework element and (ii) a polyphenol, and (B) second component comprising a polypeptide, oligopeptide, amino acid, or polyamine. The framework element comprises (a) a polypeptide, oligopeptide, amino acid, or polyamine, (b) a polysaccharide, oligosaccharide, or monosaccharide, or a saccharide conjugate, or (c) a lignin, a lignan or a lignin conjugate. The polyphenol comprises a tannin, a tannic acid, a flavonoid, or a poly-resorcinol. An adhesive precursor composition comprising the first component is also disclosed.

Owner:NEW ZEALAND FOREST RES INST

Adhesive

An aqueous adhesive composition and a process for preparing such compositions are disclosed. The composition comprises macromolecular complex comprising (A) a first component comprising (i) a framework element and (ii) a polyphenol, and (B) second component comprising a polypeptide, oligopeptide, amino acid, or polyamine. The 5 framework element comprises (a) a polypeptide, oligopeptide, amino acid, or polyamine, (b) a polysaccharide, oligosaccharide, or monosaccharide, or a saccharide conjugate, or (c) a lignin, a lignan or a lignin conjugate. The polyphenol comprises a tannin, a tannic acid, a flavonoid, or a poly-resorcinol. An adhesive precursor composition comprising the first component is also disclosed.

Owner:NEW ZEALAND FOREST RES INST

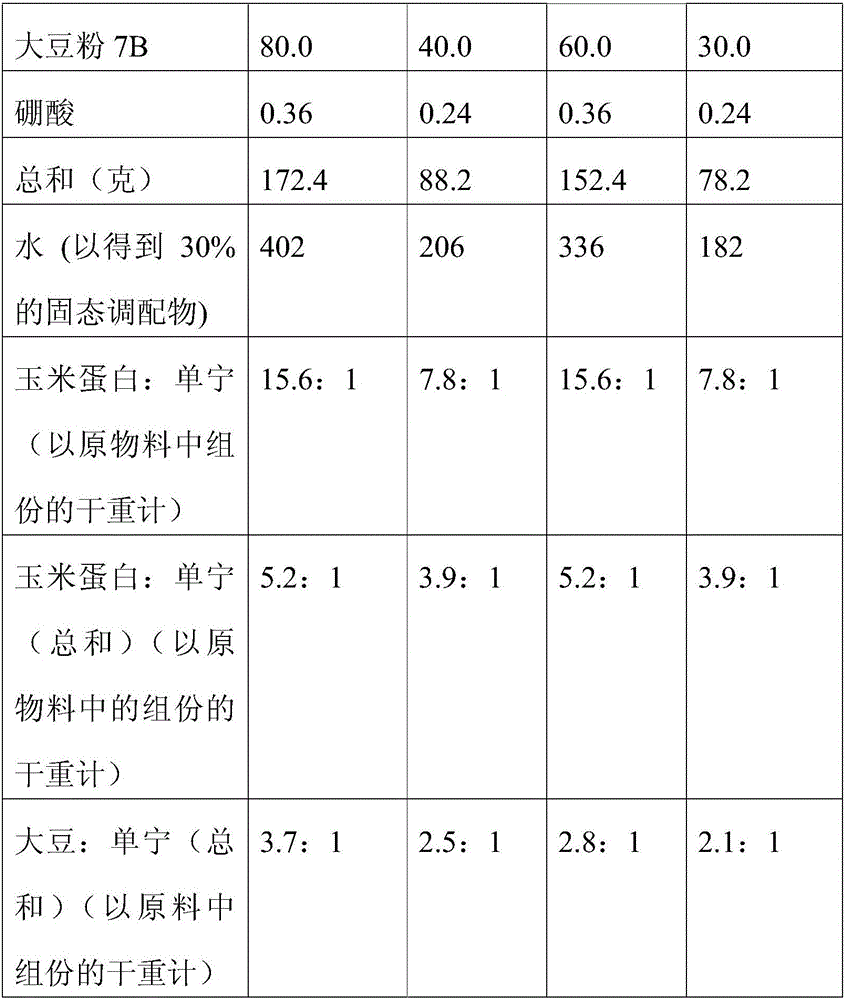

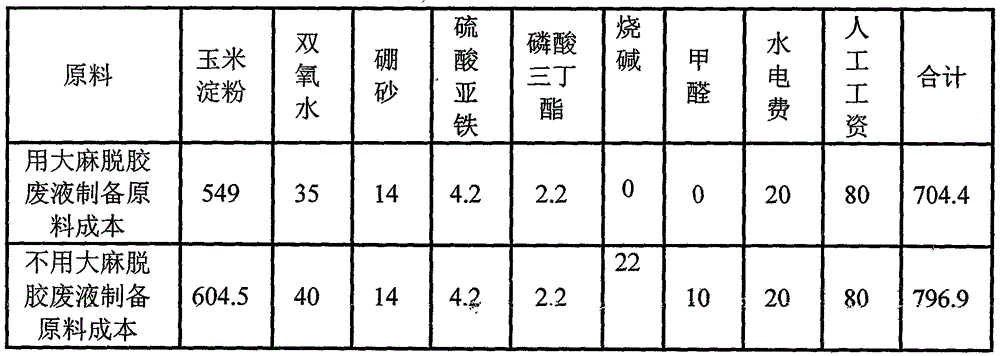

Preparation method of corn starch adhesive through cannabis degummed waste liquor

InactiveCN103360984AReduce manufacturing costSolve pollutionNon-macromolecular adhesive additivesStarch derivtive adhesivesSocial benefitsCannabis

The invention discloses a preparation method of corn starch adhesive through cannabis degummed waste liquor, which comprises the following steps: a, the preparation of carrier starch, b, the preparation of main starch, and c, the preparation of the corn starch adhesive. Corn starch is dissolved in warm water at 40 plus or minus 2 DEG C, and then catalyst FeSO4 is added. Cannabis degummed waste liquor is added till the pH value is 11.0 to 11.2, H2O2 is slowly added, and reaction is performed for 120min. Residual degummed waste liquor is added and stirred. Borax is dissolved in warm water at 40 plus or minus 2 DEG C, and then corn starch is added and uniformly mixed, and a small amount of tributyl phosphate is added, so as to perform defoaming. The carrier starch is added into the main starch while being stirred, stirring is performed for 30min, heat preservation is for 30min at 40 plus or minus 2 DEG C, and then a finished product is obtained after cooling. For producing 1 ton of adhesive, 166 Kg of corn starch, 260 Kg of degummed waste liquor, 0.22 Kg of FeSO4, 8.88 Kg of 30 percent H2O2, 2.33 Kg of borax, and 0.11 Kg of tributyl phosphate are required. The method is simple in processes and easy for industrialization, reduces the pollution of the cannabis degummed waste liquor, reduces the environmental management cost, simultaneously reduces the preparation cost of the corn starch adhesive, and increases the economic efficiency of enterprises and social benefit.

Owner:WEST ANHUI UNIV +3

Bio-based binder systems

ActiveUS20170022398A1Low costReadily availableOil/fat/wax adhesivesStarch adhesivesPolymer scienceCross linker

An environmentally friendly, bio-based binder system that is useful for the formation of fiberglass insulation, the system includes: A) an aqueous curable binder composition, which includes a carbohydrate and a crosslinking agent; and B) a dedust composition, which includes a blown, stripped plant-based oil and optionally at least one emulsifying agent. The bio-based binder system is typically heated to form a cured binder system.

Owner:CARGILL INC

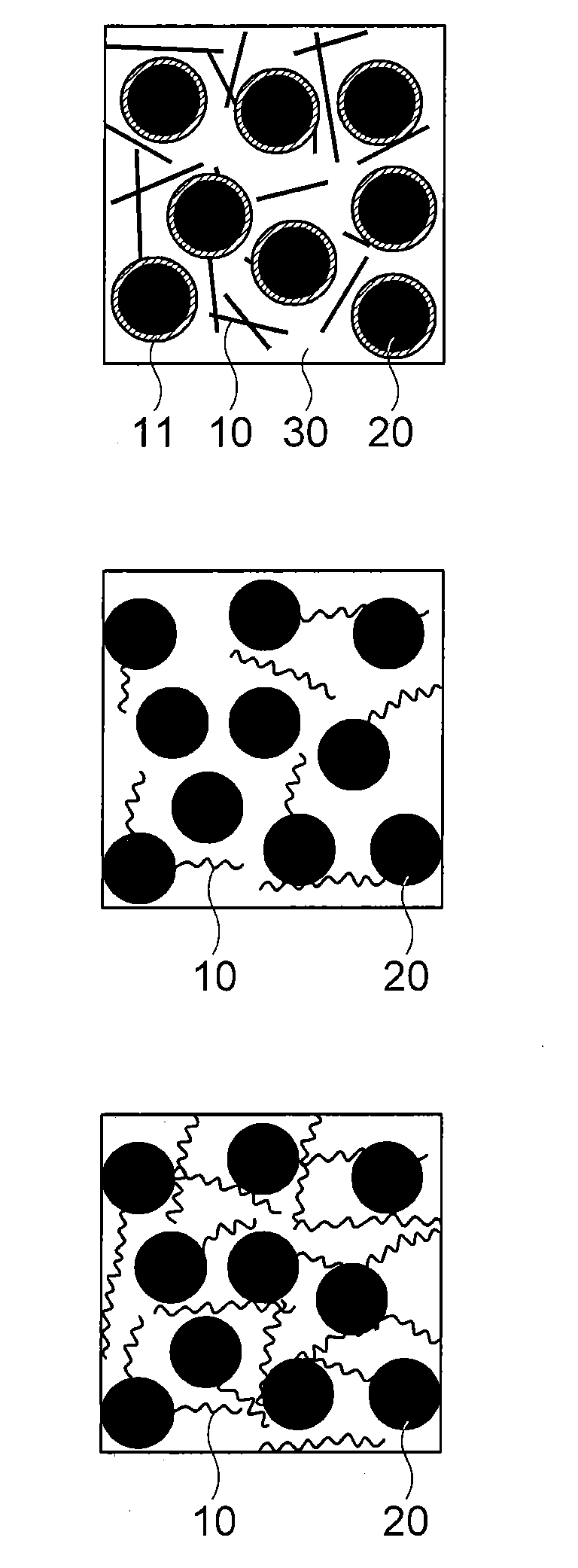

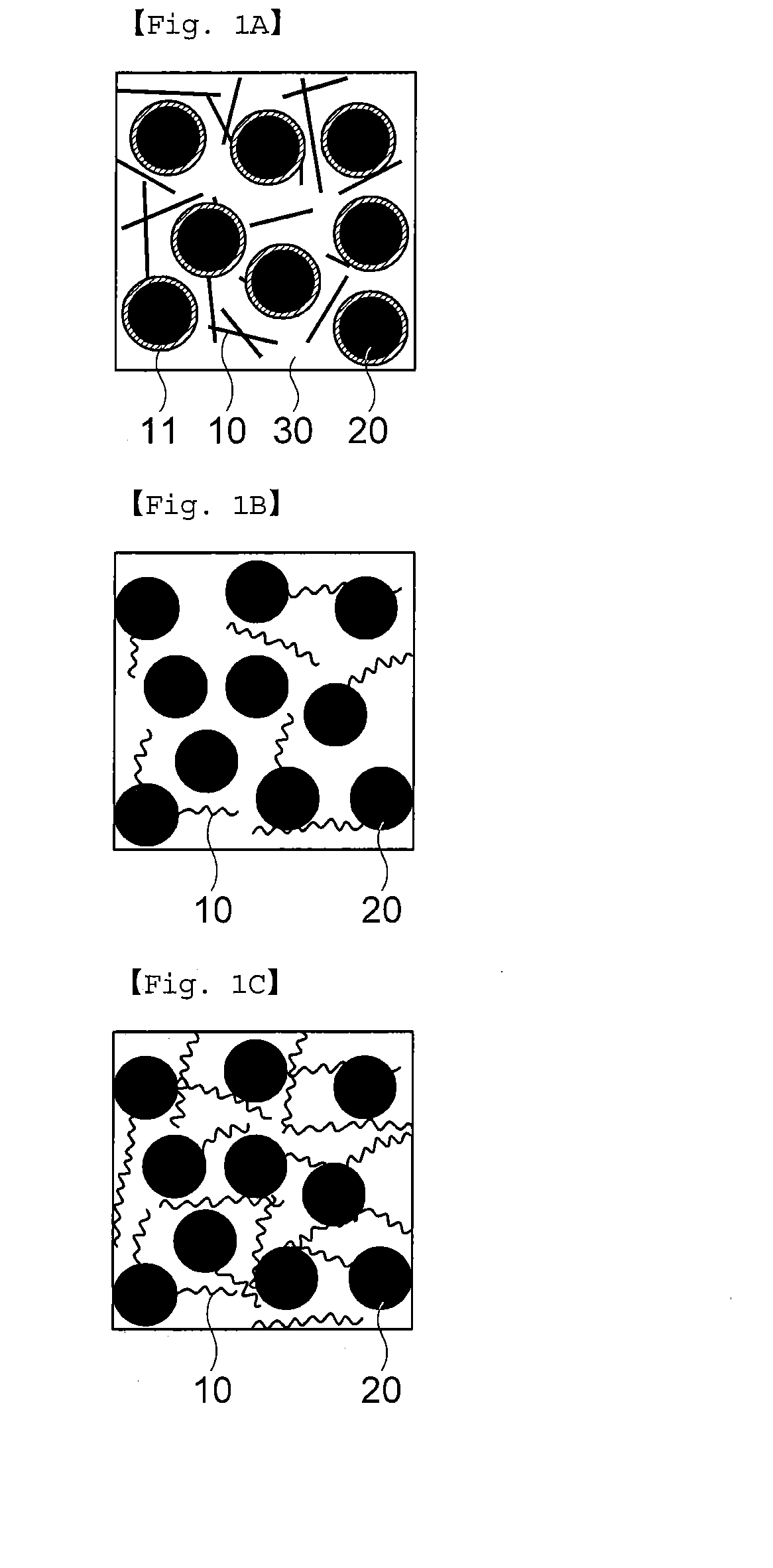

Binder composition for manufacturing electrode of energy storage device and method for manufacturing electrode of energy storage device

InactiveUS20120313051A1Sufficient binding forceSufficient forceElectrode manufacturing processesNon-macromolecular adhesive additivesBinding forceEnergy storage

Disclosed herein are a binder composition for manufacturing an electrode of an energy storage device and a method for manufacturing an electrode of an energy storage device. The binder composition includes galactomannan as a major component and may exhibit sufficient binding force with a considerably small amount, as compared to binders in the related art. When the binder composition disclosed herein is used to manufacture an energy storage device having the same weight as that manufactured using the binder in the related art, the energy storage device may contain a greater amount of active material, compared to the binder in the related art. Consequently, beneficial effects such as improvement in an energy density as well as eco-friendly characteristics may be rendered.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

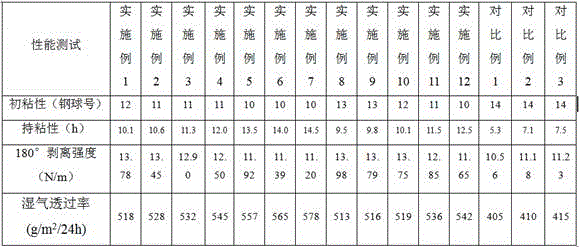

Medical adhesive and preparation method thereof

InactiveCN104479583AImprove performanceFast curingNon-macromolecular adhesive additivesCellulose adhesivesCellulosePolyvinyl alcohol

The invention relates to a medical adhesive and a preparation method thereof, and belongs to field of adhesives. The medical adhesive comprises the following components in parts by weight: 10-18 parts of pectin, 10-25 parts of hydroxypropyl methyl cellulose, 2-8 parts of lignin, 6-10 parts of polyvinyl alcohol, 4-12 parts of an ethylene / vinyl acetate copolymer, 2-5 parts of methyl hydroxyethyl cellulose, 1-3 parts of castor oil, 2-4 parts of an acetic acid, and 10-18 parts of ethanol. The medical adhesive disclosed by the invention has good performances, and has a fast curing speed, so that the curing time is short; the medical adhesive disclosed by the invention is high in adhesive strength, and long in stabilizing time; and the preparation method disclosed by the invention is simple and practicable, and suitable for wide-range popularization and application.

Owner:SUZHOU BEC BIOLOGICAL TECH

Insulative products having bio-based binders

Fibrous insulation products have an aqueous binder composition that includes a carbohydrate and a crosslinking agent. In exemplary embodiments, the carbohydrate-based binder composition may also include a catalyst, a coupling agent, a process aid, a crosslinking density enhancer, an extender, a moisture resistant agent, a deducting oil, a colorant, a corrosion inhibitor, a surfactant, a pH adjuster, and combinations thereof. The carbohydrate may be natural in origin and derived from renewable resources. Additionally, the carbohydrate polymer may have a dextrose equivalent (DE) number from 2 to 20. In at least one exemplary embodiment, the carbohydrate is a water-soluble polysaccharide such as dextrin or maltodextrin and the crosslinking agent is citric acid. Advantageously, the carbohydrates have a low viscosity and cure at moderate temperatures. The environmentally friendly, formaldehyde-free binder may be used in the formation of insulation materials and non-woven chopped strand mats. A method of making fibrous insulation products is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC +1

Biocides for bio-based binders, fibrous insulation products and wash water systems

Biocides for bio-based binder compositions are disclosed. Bio-based binders include those having a nutrient source such as carbohydrate, protein or fat, which can serve as an energy source for organisms to grow in areas that contact binder. Principal areas that contact bio-based binder in a fiberglass insulation manufacturing process include the raw ingredients, the binder chemicals, the prepared binder dispersions, the forming hood and related equipment, the final insulation product and, importantly, the cleaning systems and washwater arising from cleaning the manufacturing equipment and / or forming the product. Frequently the washwater is stored until re-cycled for re-use. Storage may take place in tanks, towers, vats and even outdoor reservoirs, all of which may harbor the growth of unwanted organisms, for which a biocide is desirable.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

High-strength glue

InactiveCN103540290AStrong stickinessNon-macromolecular adhesive additivesProtein adhesivesMaterials scienceSkin irritation

The invention provides a high-strength glue, which belongs to the technical field of a novel material. The glue is composed of 15% of bone glue, 15% of pectin, 15% of latex, 5% of a viscidity enhancer, 5% of an emulsifier, 3% of formaldehyde, 2% of fragrance and 40% of water through mixing. The glue has the advantages of being environment-friendly and healthy, the glue does not cause skin irritation, and the viscidity is extremely high.

Owner:封仕燕

Exercise bandage adhesive and preparation method thereof

ActiveCN105567140AGood bioadhesionMoisture wickingNon-macromolecular adhesive additivesCyclodextrin adhesivesAdhesiveIrritation

The invention discloses an exercise bandage adhesive and a preparation method thereof. The exercise bandage adhesive is composed of SBS, tackifier, HO-SBS, cyclodextrin poly-aldehyde, plant polysaccharide, naphthenic oil and anti-oxidant. An exercise bandage made of the exercise bandage adhesive has a good biological sticking property on skin, moisture can be absorbed well, sweat can be released well, pain cannot be caused when the exercise bandage is bonded to and torn away from the skin, no residual adhesive is left, and no irritation is generated to the skin.

Owner:RUGAO JIAHAO HOT MELT ADHESIVE

Adhesive

ActiveUS10696882B2Improve water resistanceProvides water resistanceAgar-agar adhesivesStarch adhesivesPolymer scienceLignan

Owner:NEW ZEALAND FOREST RES INST

Special glue for rubber sole

InactiveCN105440978AImprove adhesionStrong fastnessNon-macromolecular adhesive additivesAdhesive processes with adhesive heatingPolymer scienceLatex rubber

The invention relates to the field of glue for shoemaking, especially to a special glue for a rubber sole. The special glue comprises, by mass, 15 to 20 parts of pectin, 18 to 23 parts of latex, 2 to 5 parts of compound resin, 1 to 2 parts of ethylene, 0.2 to 0.4 part of oxidation water, 0.3 to 0.6 part of a water repellent, 1 to 1.5 parts of an anti-oxidant and 20 to 30 parts of water. The special glue for the rubber sole has strong bonding strength; and in particular, when applied to the rubber sole, the special glue has strong fastness, is hard to age and oxidize after bonding, and has long usage time and stable performance.

Owner:TONGXIANG YIYUAN SHOES

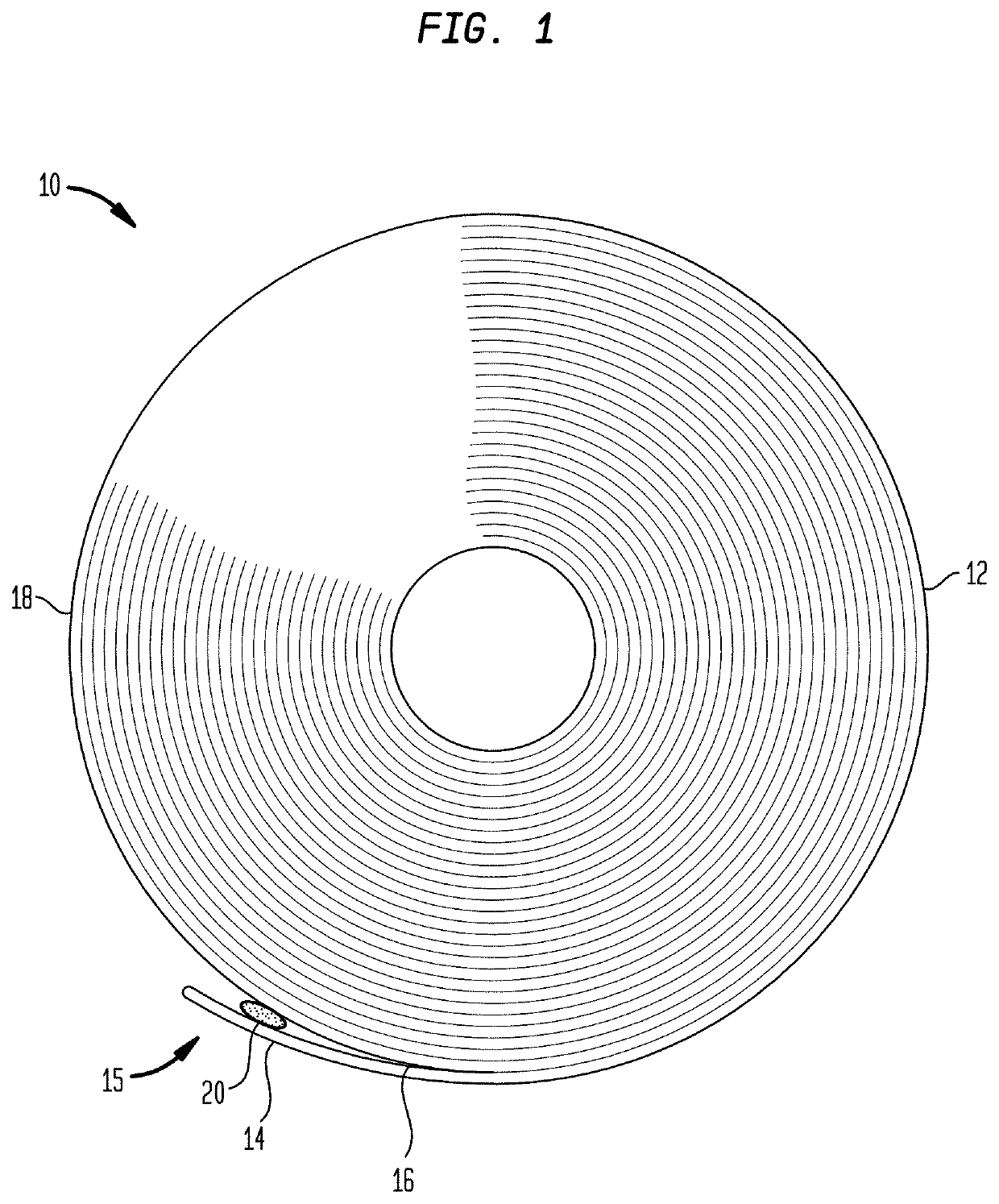

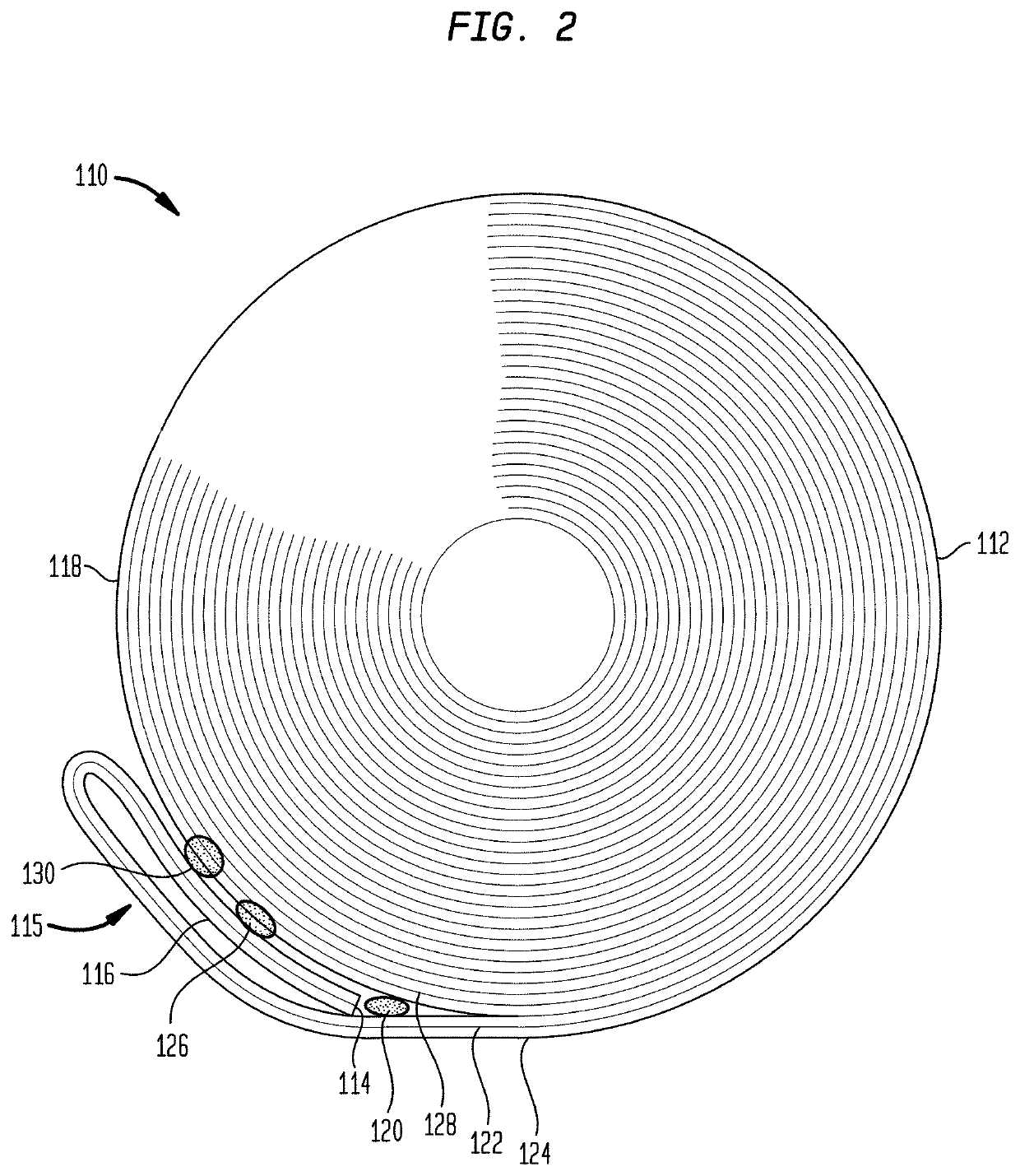

Absorbent Sheet Tail-Sealed with Nanofibrillated Cellulose-containing Tail-Seal Adhesives

PendingUS20200332470A1Improve the level ofHigh bonding strengthAdhesive processesFilm/foil adhesivesPolymer sciencePolyol

An aqueous NFC containing tail-seal adhesive includes:(a) water;(b) nanofibrillated cellulose; and(c) one or more of: (i) a water-soluble cellulose derivative; or (ii) a water soluble polyol; or (iii) a viscosity modifier other than a water soluble cellulose derivative.

Owner:GPCP IP HLDG LLC

Technique for preparing wheat gluten adhesives

InactiveCN101358123BSimple processLow requirements for production equipmentProtein adhesivesGlue/gelatin preparationBiotechnologyAdhesive

The present invention relates to a technique for preparing a wheat gluten protein adhesive, which belongs to the technical field of the production of plant protein adhesives. Citric acid solution is poured into the aqueous solution of wheat gluten protein to produce dispersed solution; then, water-soluble colloidal solution is poured into the dispersed solution to modify the protein in the dispersed solution, so that modified solution is produced; the modified solution is kept sill for one night, so that the wheat gluten protein adhesive is prepared. The technique has the advantages of simpleprocess flow, low requirement on production equipment, ample and easily obtained materials, low production cost, excellent product performance, etc. Particularly, the wheat gluten protein adhesive issuitably used as additive for food bonding, cardboard bonding and glass wool.

Owner:EAST CHINA NORMAL UNIV

Use of bonding resin

The present invention relates to the use of a bonding resin prepared by providing an aqueous solution comprising at least one biobased product selected from tannin, starch, soy protein, glycerol, chitin, pectin, dextrose or other carbohydrates, or a mixture thereof and mixing the aqueous solution with one or more of certain crosslinkers such as ethers, and optionally one or more additives. The bonding resin is used in the manufacture of laminates, mineral wool insulation or wood products, such as engineered wood products, such as plywood, oriented strandboard (OSB), laminated veneer lumber (LVL), medium density fiberboards (MDF), high density fiberboards (HDF) or particle boards. Preferably, the bonding resin does not comprise lignin.

Owner:STORA ENSO OYJ

Technique for preparing wheat gluten adhesives

InactiveCN101358123ANo releaseImprove performanceProtein adhesivesGlue/gelatin preparationCardboardAdhesive

The present invention relates to a technique for preparing a wheat gluten protein adhesive, which belongs to the technical field of the production of plant protein adhesives. Citric acid solution is poured into the aqueous solution of wheat gluten protein to produce dispersed solution; then, water-soluble colloidal solution is poured into the dispersed solution to modify the protein in the dispersed solution, so that modified solution is produced; the modified solution is kept sill for one night, so that the wheat gluten protein adhesive is prepared. The technique has the advantages of simple process flow, low requirement on production equipment, ample and easily obtained materials, low production cost, excellent product performance, etc. Particularly, the wheat gluten protein adhesive is suitably used as additive for food bonding, cardboard bonding and glass wool.

Owner:EAST CHINA NORMAL UNIV

Absorbent sheet tail-sealed with nanofibrillated cellulose-containing tail-seal adhesives

ActiveUS10774476B2Improve the level ofHigh bonding strengthAdhesive processesFilm/foil adhesivesPolymer sciencePolyol

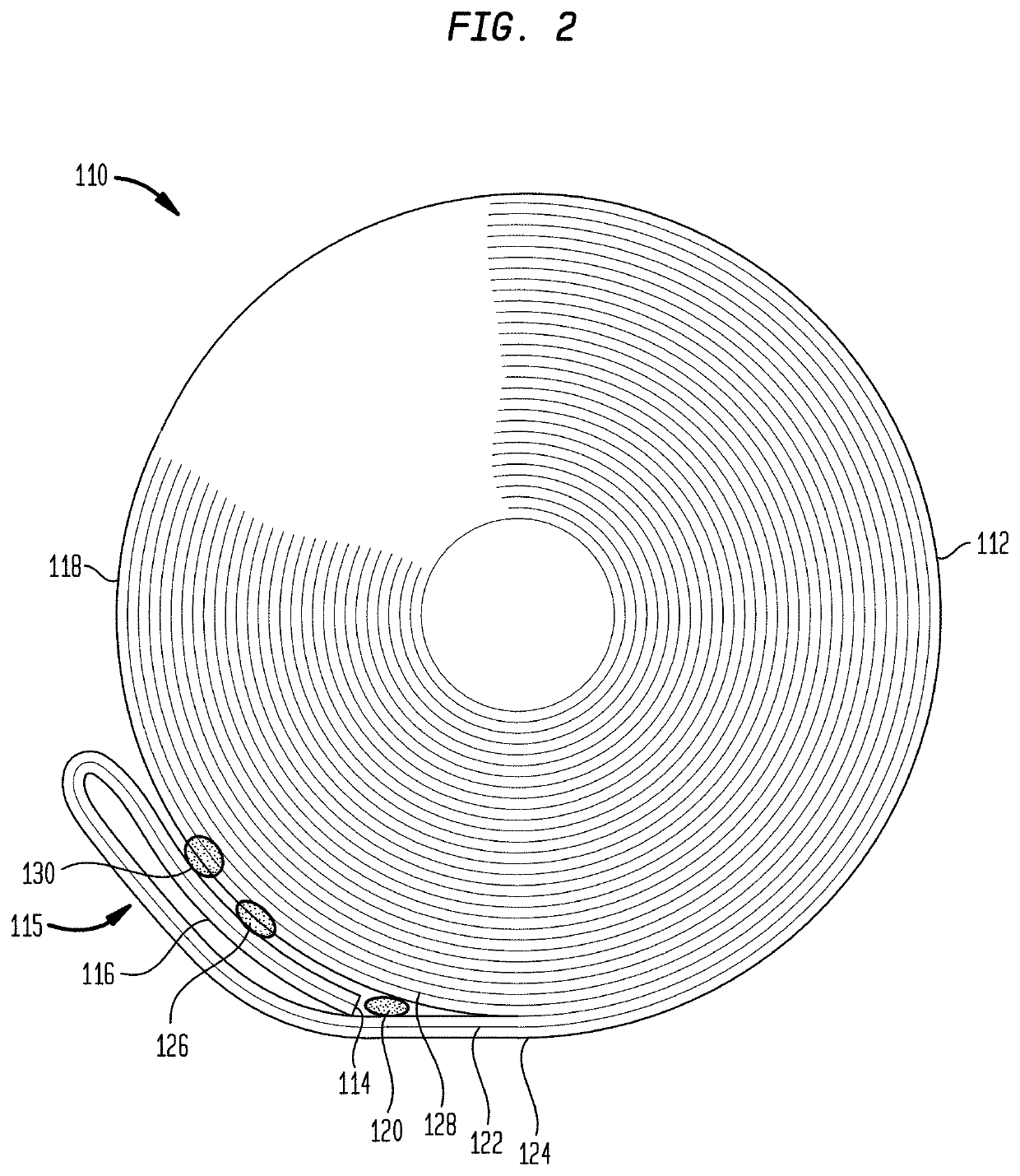

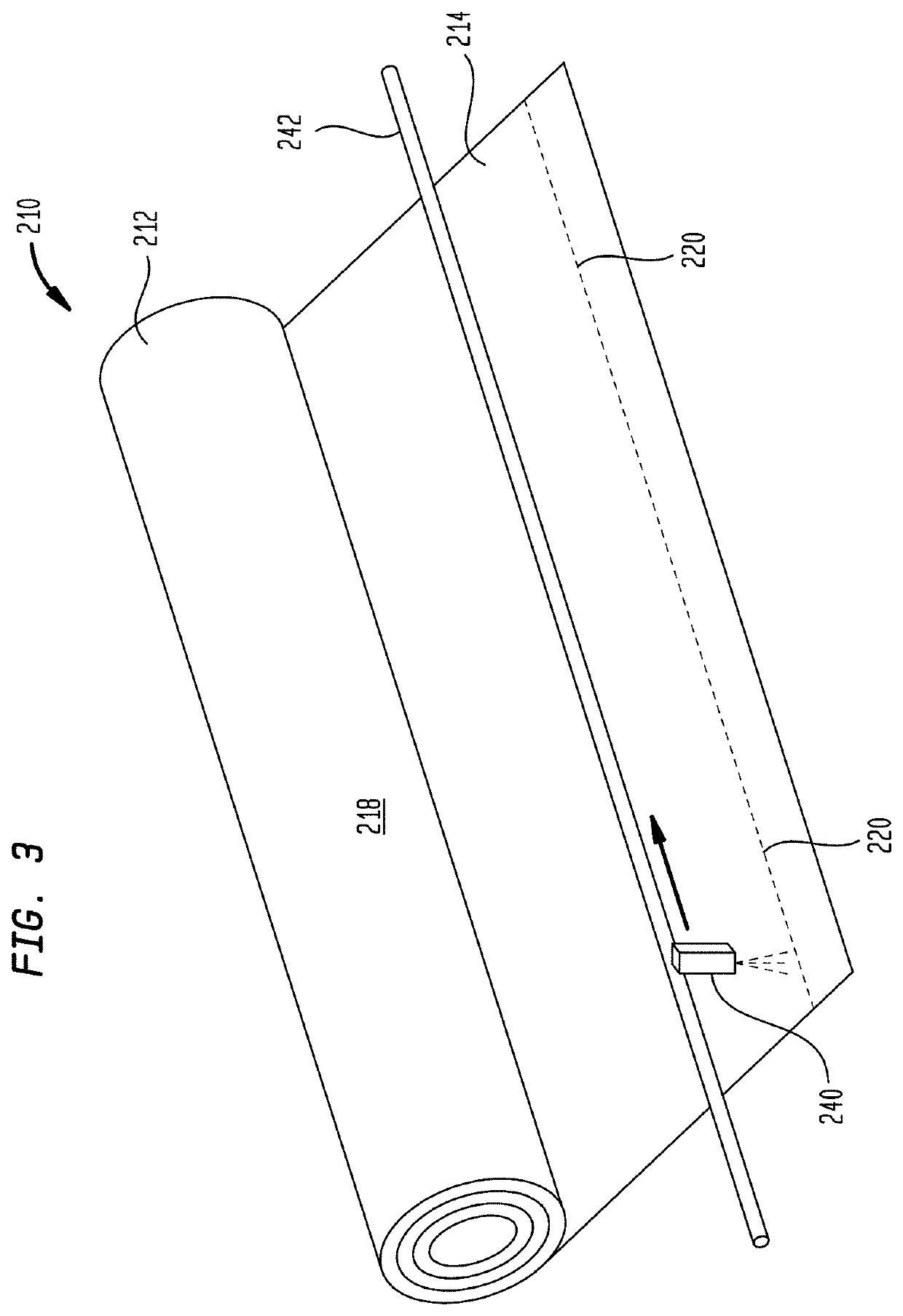

A roll of absorbent sheet tail-sealed with an NFC containing aqueous tail-seal adhesive includes an NFC containing aqueous tail-seal adhesive interposed between a tail of the roll of absorbent sheet and an underlying convolution of the roll adhering the tail to the underlying convolution to form the tail-seal. The NFC containing tail-seal adhesive comprises nanofibrillated cellulose and one or more additional components selected from the group consisting of components (i), (ii), (iii), (iv) and (v) wherein (i) is a water-soluble cellulose derivative; (ii) is a water soluble polyol; (iii) is a viscosity modifier other than a water soluble cellulose derivative; (iv) is PVOH; and (v) is PVOH and a viscosity modifier. The NFC containing tail-seal adhesive optionally includes a surface tension modifier other than PVOH.

Owner:GPCP IP HLDG LLC

Aqueous binders for granular and/or fibrous substrates

This invention relates to an aqueous binder composition containing a) at least one polymer P and b) at least one saccharide compound S, such that an amount of the saccharide compound S is ≧10 and ≦400 parts by weight per 100 parts by weight of polymer P, wherein an amount of an additional formaldehyde-containing binder is ≦50 parts by weight per 100 parts by weight of the summed overall amounts of the polymer P and the saccharide compound S. This invention also relates to a process for producing a shaped articles from granular and / or fibrous substrates where an aqueous binder composition of the present invention is applied to the granular and / or fibrous substrate, the granular and / or fibrous substrate thus treated is optionally shaped and then the granular and / or fibrous substrate thus obtained is thermally treated. This invention also relates to shaped articles obtained by a process of the present invention.

Owner:BASF SE

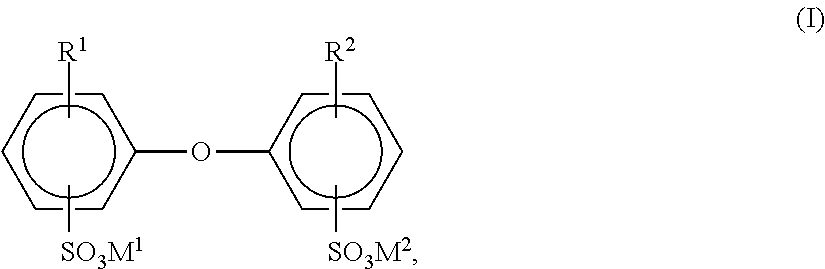

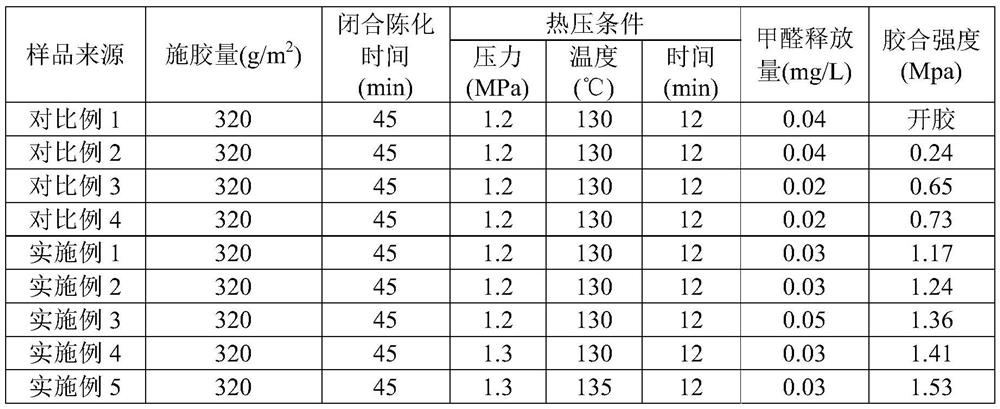

A kind of all bio-based adhesive and its preparation method and application

ActiveCN111100581BImprove reaction efficiencyGood adhesivenessMacromolecular adhesive additivesCellulose adhesivesPolymer scienceAdhesive

The invention relates to the field of adhesives, in particular to a full-bio-based adhesive and a preparation method and application thereof. The method comprises the following steps: preparation of demethylated nano-lignin: carrying out nanocrystallization treatment on the demethylated nano-lignin; preparation of oxidized nanocellulose; and preparation of the full-bio-based adhesive: carrying outa pre-crosslinking polymerization reaction on the demethylated nano-lignin suspension, the oxidized nanocellulose suspension and pectin to obtain the full-bio-based adhesive. According to the full-bio-based adhesive and the preparation method thereof provided by the invention, lignin is subjected to demethylation and nanocrystallization treatment, and cellulose is also subjected to nanocrystallization and oxidation treatment. In this way, the reaction efficiency of covalent bonds generated between lignin and cellulose is remarkably improved, the crosslinking degree is improved, the adhesion to a plate is good, and the bonding strength is high. By full-bio-based preparation, the release amount of harmful gases of the obtained adhesive is low, and the reutilization value of the whole plywood is improved through the main components of lignin and cellulose plywood sheets.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com