Bio-based binder systems

a technology of bio-based binder and binder plate, which is applied in the direction of pectin adhesives, adhesive types, coatings, etc., can solve the problems of unstable urea-extended resoles, ammonia is not a particularly desirable alternative, and throat and nose irritation of workers, so as to save time and money, low cost, and low loss of ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

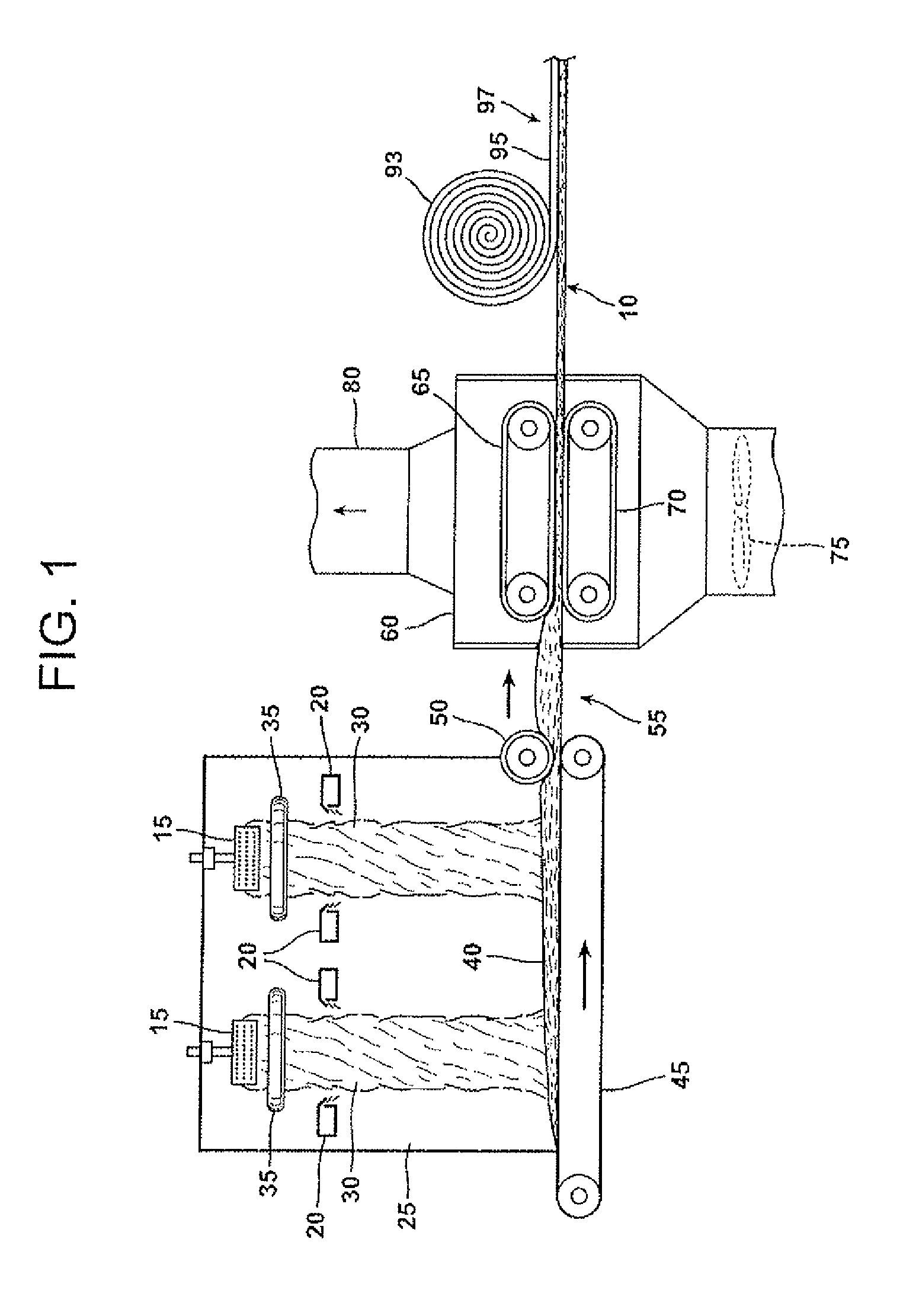

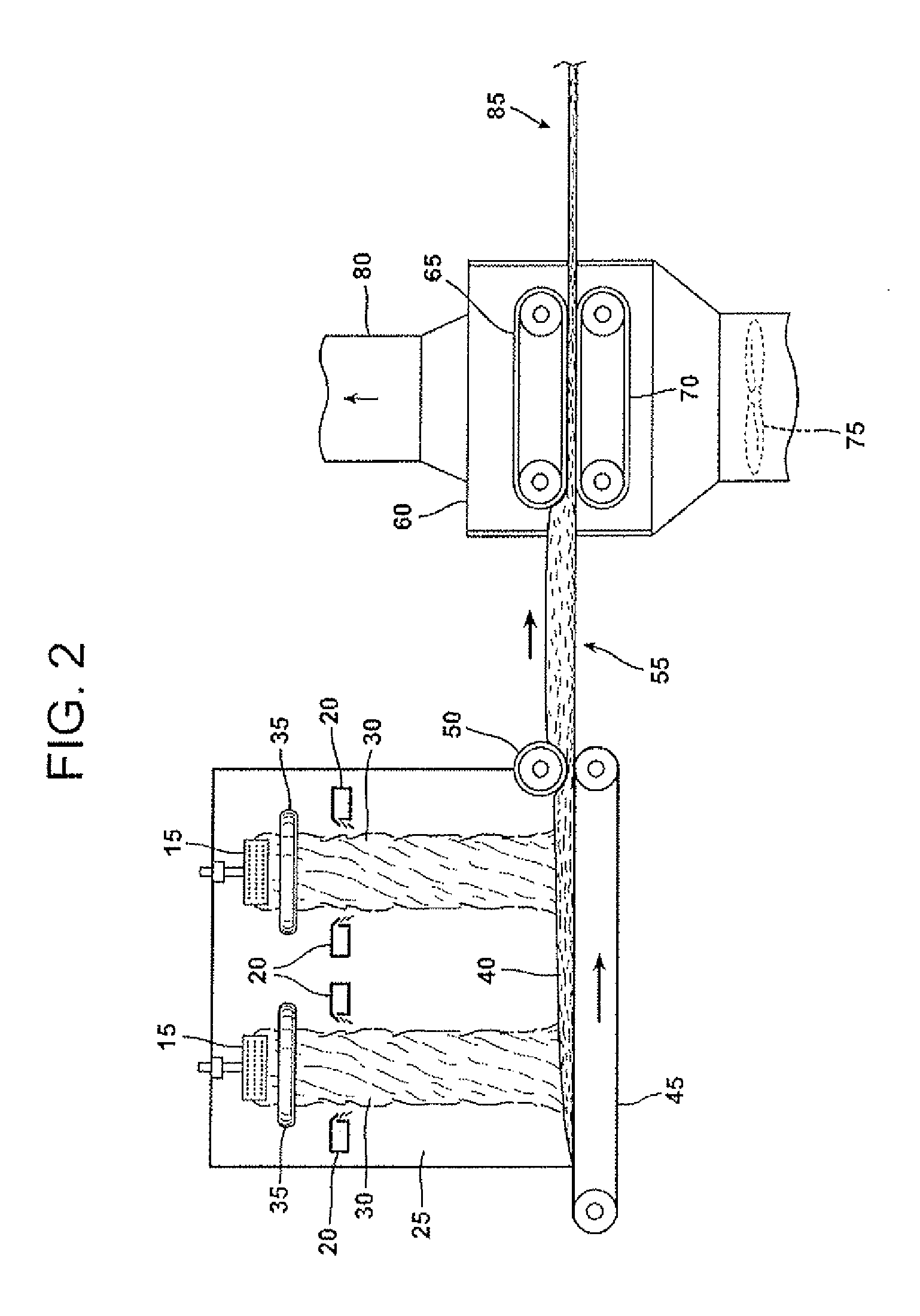

Image

Examples

example 1

Blowing Corn Stillage Oil

[0112]Into a 6000 gallon steel tank equipped with an air sparge distributor, positive displacement blower, regenerative thermal oxidizer(RTO) system, controlled heat source(whether it be external steam or hot oil jacket), and cooling coils, 45,000 pounds of corn stillage oil, similar to the corn stillage oil described in PCT Publication WO 2010 / 135637, published Nov. 25, 2010 (entitled “Blown Corn Stillage Oil”) is charged. Air is sparged through the oil as it is heated. The air is sparged through the oil at a rate that maximizes the rate while at the same time causes a relatively even distribution of air bubbles within the oil. The rate of sparging is set so the reactor remains under a slight vacuum which indicates the RTO system can remove VOCs adequately and safely as they are produced from the reaction. The speed with which viscosity increases is directly proportional to the rate at which air is being blown into the corn stillage oil, and indirectly prop...

example 1a

Blowing Corn Stillage Oil and Soybean Oil Blends

[0113]Into a 6000 gallon steel tank equipped with an air sparge distributor, positive displacement blower, regenerative thermal oxidizer(RTO) system, controlled heat source(whether it be external steam or hot oil jacket), and cooling coils, 45,000 pounds of corn stillage oil and soybean oil blend, as indicated in Table 4 is charged. The corn stillage oil is similar to the corn stillage oil described in PCT Publication WO 2010 / 135637, published Nov. 25, 2010. The soybean oil is refined, bleached, and deodorized (RBD) soybean oil having an acid value of less than 0.5 mg KOH / gram. Air is sparged through the oil blend as it is heated to the temperature indicated in Table 4. The air is sparged through the oil blend at a rate that maximizes the rate while at the same time causes a relatively even distribution of air bubbles within the oil. The rate of sparging is set so the reactor remains under a slight vacuum which indicates the RTO system...

example 2

Stripping Blown Corn Stillage Oil

[0116]Into a 6000 gallon stainless steel reactor equipped with a mechanical agitator, a nitrogen sparge distributor, vacuum pump, regenerative thermal oxidizer(RTO) system, controlled heat source(hot oil jacket), and cooling coils, 45,000 pounds of blown corn stillage oil from Example 1, as indicated in Table 5, is charged. Nitrogen is sparged at about 5-10 CFM through the oil as it is heated to about 235° C. to 245° C. Once the oil reaches the desired temperature, shut off nitrogen sparge and apply full vacuum to the reactor (preferred pressure of 20 torr or less). The oil within the reactor is tested periodically to determine the viscosity at 40° C., flash point, and the acid value of the oil. When the oil reaches acid value of from 7-9 mg KOH / gram, break the vacuum to atmospheric pressure. Add desired amount of USP grade glycerol (which has lower than 0.3 weight percent impurities and less than or equal to 10 PPM Chloride ion (Cl−)) to the oil in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com