Patents

Literature

77results about How to "Strong fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bronzing pulp and preparation method thereof

ActiveCN103255646ARich styleRich wash fastnessTransfer printing processDyeing processWater basedSolvent

The invention discloses bronzing pulp. The bronzing pulp is prepared from the following raw materials in parts by weight: 60-80 parts of acrylic ester emulsion, 2-6 parts of deionized water, 3-10 parts of a solvent, 1-5 parts of a stabilizer, 10-20 parts of EVA (Ethylene-Vinyl Acetate) hot melt adhesive powder, 0.5-3 parts of silica, 0.2-0.5 part of a polyurethane defoaming agent, 0.1-0.5 part of a pH regulator, 0.1-0.2 part of a preservative, 0.3-1 part of an emulsion wetting agent and 0.4-2 parts of a thickener. The bronzing pulp has the beneficial effects that the bronzing pulp is water-based pulp, the raw materials are easy to obtain and environment-friendly, the production is convenient, the technology is mature, and substances harmful to the environment can not be produced; and the bronzing pulp is soft in handfeel, firm in fastness, outstanding in resistance to tension fracture and diversified in application mode, enriches the styles of textiles, and endows the textiles with the noble quality.

Owner:GUANGZHOU SHENGQIN IND

Sun-proof composite modified polypropylene pipe for power cable protection

InactiveCN103012956AImprove heat stabilityReduce dosageInsulated cablesInsulated conductorsElastomerPolyolefin

The invention relates to a sun-proof composite modified polypropylene pipe for power cable protection. The pipe comprises the following components in percentage by weight: 73 to 78 percent of PP (Propene Polymer), 10 to 15 percent of POE (Polyolefin Elastomer), 4.8 to 5.2 percent of nano calcium carbonate, 0.3 to 0.4 percent of nucleating agent, 0.2 to 0.25 percent of coupling agent and 0.5 to 1 percent of sun-proof lubricating composite functional master batch. Not only does the pipe have better low-temperature impact resistance, wherein impact energy in a falling weight impact test at a temperature of minus 5 DEG C is improved by over 2.5 times, the friction coefficient is reduced by 40 percent and the Vicat heat-resistance temperature is risen by 5 DEG C, but also sun-proof performance of the pipe is improved and the application range of the power pipe is enlarged.

Owner:ZHEJIANG HUAFENG NEW MATERIAL

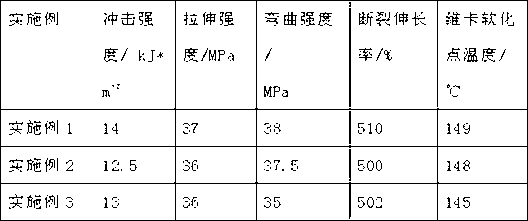

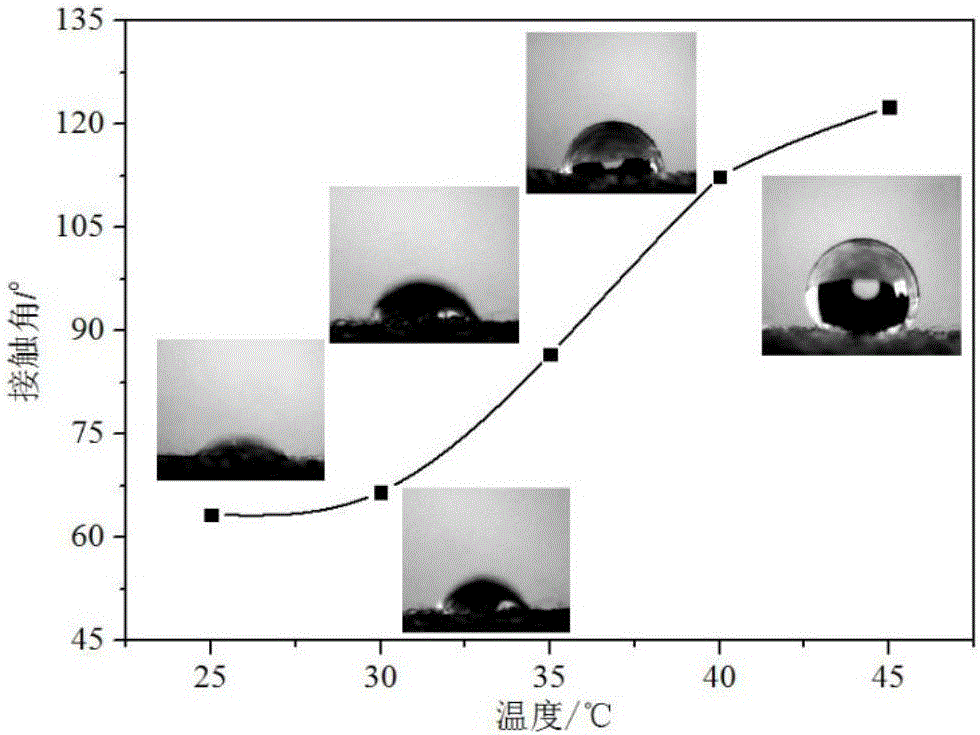

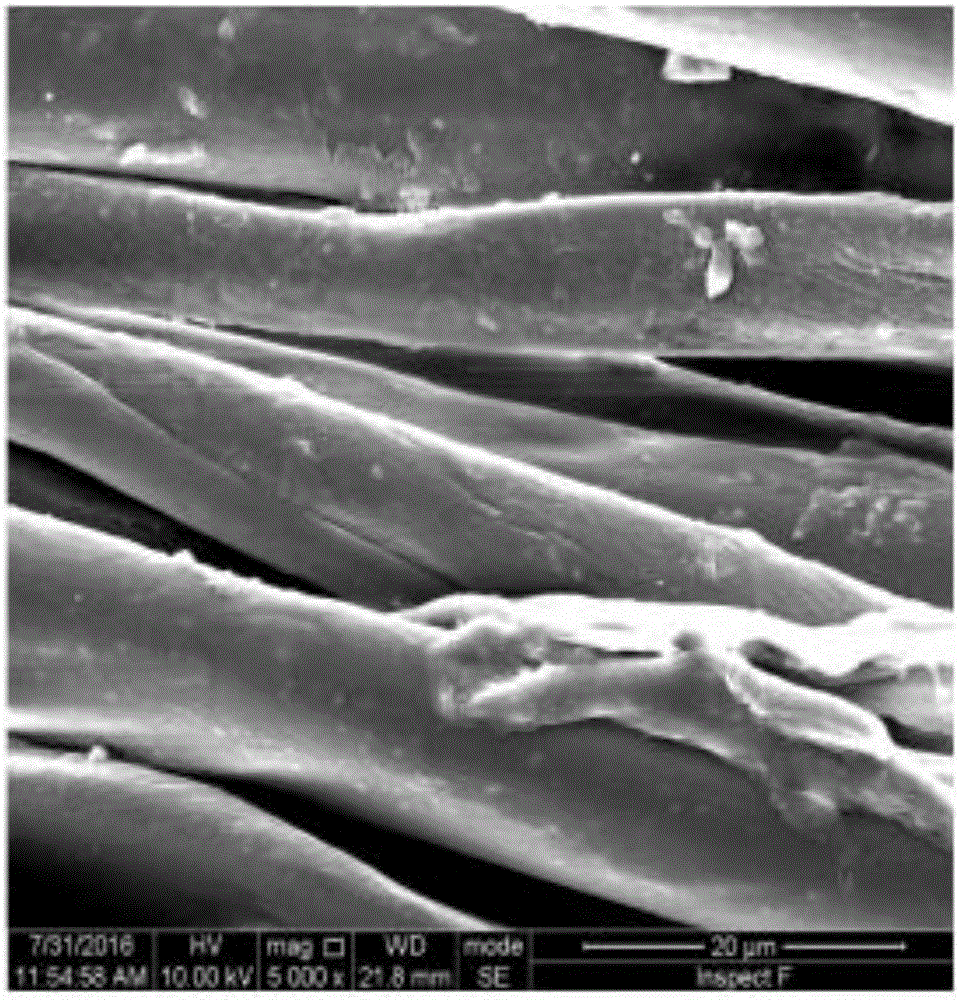

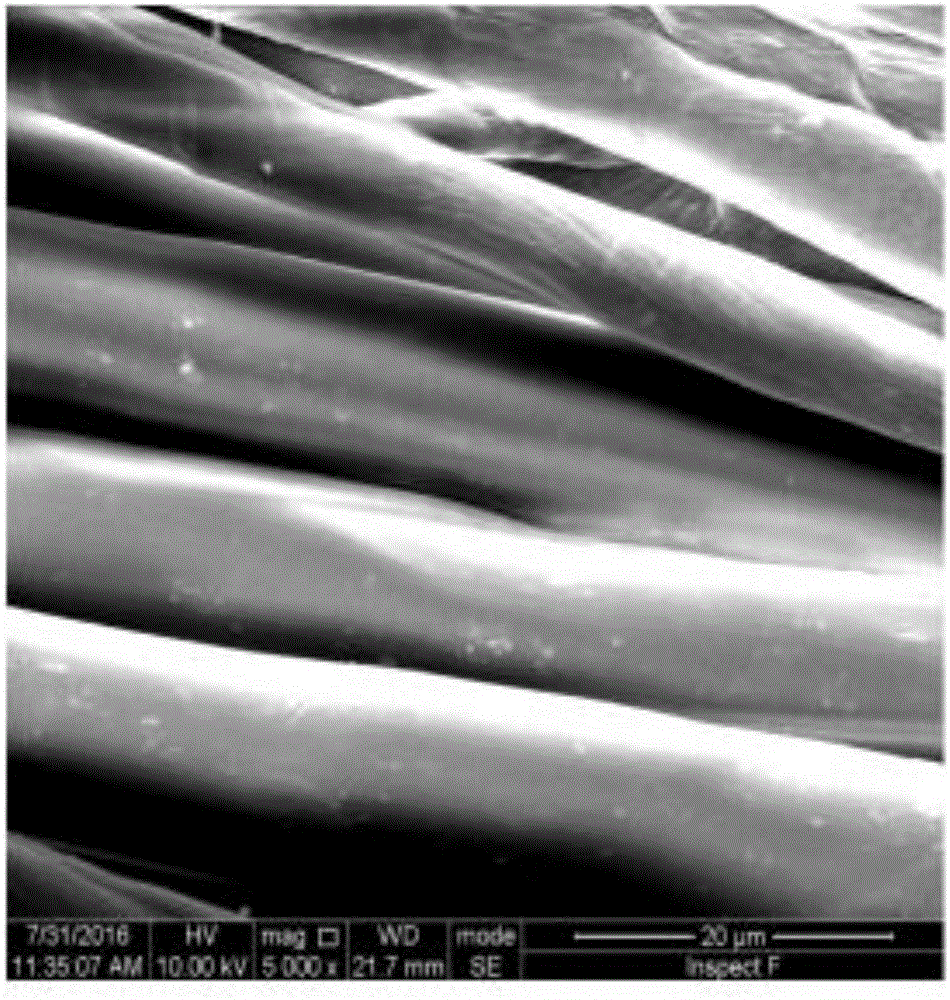

Temperature-sensitive waterproof moisture-permeable shell fabric and preparation method thereof

ActiveCN106498720AExcellent temperature sensitive performanceGood moisture permeabilityFibre typesHydrolysisMoisture

The invention provides temperature-sensitive waterproof moisture-permeable shell fabric and a preparation method thereof. The preparation method includes soaking base cloth in hydrochloric acid for hydrolysis, wherein the base cloth is shell fabric which can contain an amino and / or hydroxy structure after being hydrolyzed; soaking the hydrolyzed base cloth in a glutaric dialdehyde solution for pre-crosslinking reaction, and subjecting the pre-crosslinked base cloth to padding treatment in temperature-sensitive hydrogel so as to obtain crosslinked base cloth; applying the surface of the crosslinked base cloth with a coating agent and baking so as to obtain the temperature-sensitive waterproof moisture-permeable shell fabric. The temperature-sensitive waterproof moisture-permeable shell fabric has the advantages of good temperature-sensitive performance and waterproof moisture-permeable performance as well as excellent washability because of good bonding performance and high bonding firmness between the temperature-sensitive hydrogel and nylon fabric.

Owner:EASTERN LIAONING UNIV

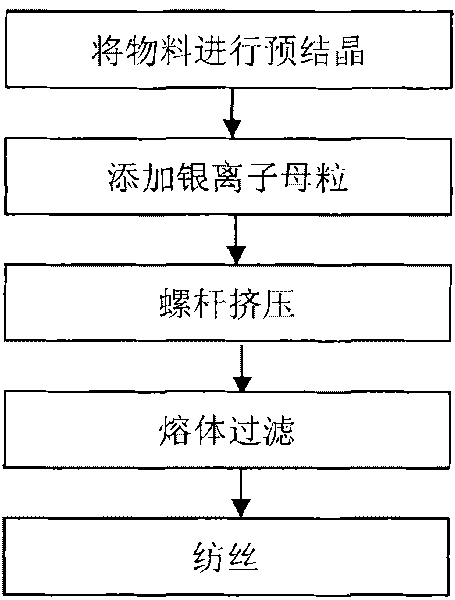

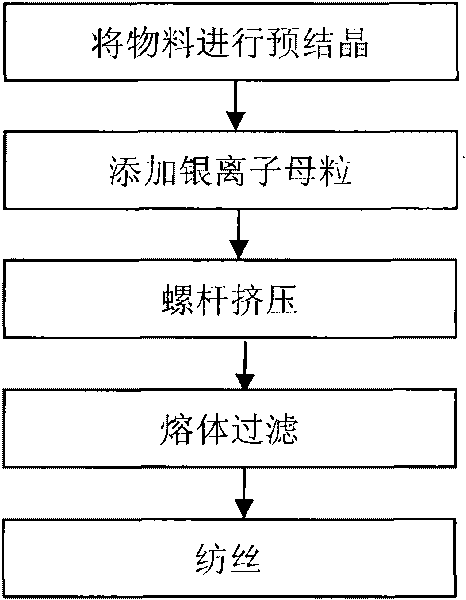

Preparation method of PBT silver-ion antibiotic moisture-absorption deodorization fibre

InactiveCN101760795AExcellent wear resistanceExcellent fiber crimpMelt spinning methodsFilament-forming treatmentFiberMoisture absorption

The invention discloses a preparation method of PBT silver-ion antibiotic moisture-absorption deodorization fibre, which comprises the following steps of: (1) crystallizing a material in advance, wherein the material is the mixture of a PBT slice and a silver-ion SHT antibiotic plastic master batch; concretely, crystallizing in advance by adopting dry hot air; (2) feeding the material in a screw type: firstly, drying the master batch by the hot air and then feeding the material obtained after mixing the master batch and the PBT slice into a screw extruder by a special master batch feeding machine which can measure the master batch; (3) filtering: filtering the mixture extruded by the extruder wherein the continuous production of spinning and the constancy of the pressure of the screw extruder are ensured during filtering; and (4) spinning: delivering the mixture from the filter to a spinning assembly, ejecting from a spinneret plate by the spinning assembly, and then coiling and forming. The fibre has favorable durability, dimensional stability and better elasticity, and the elasticity is free from the influence of the humidity.

Owner:YIZHENG XINGHAI CHEM FIBER

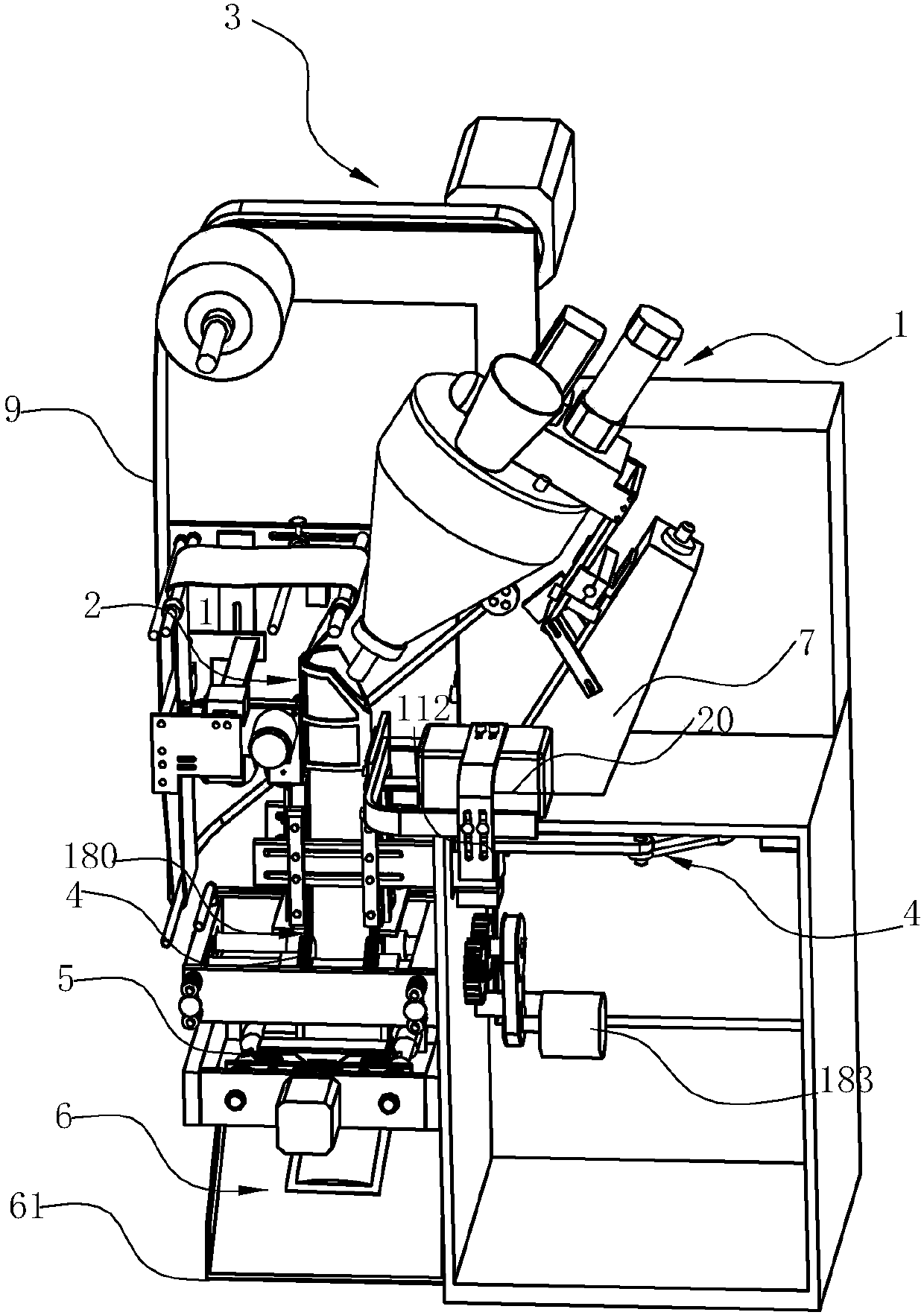

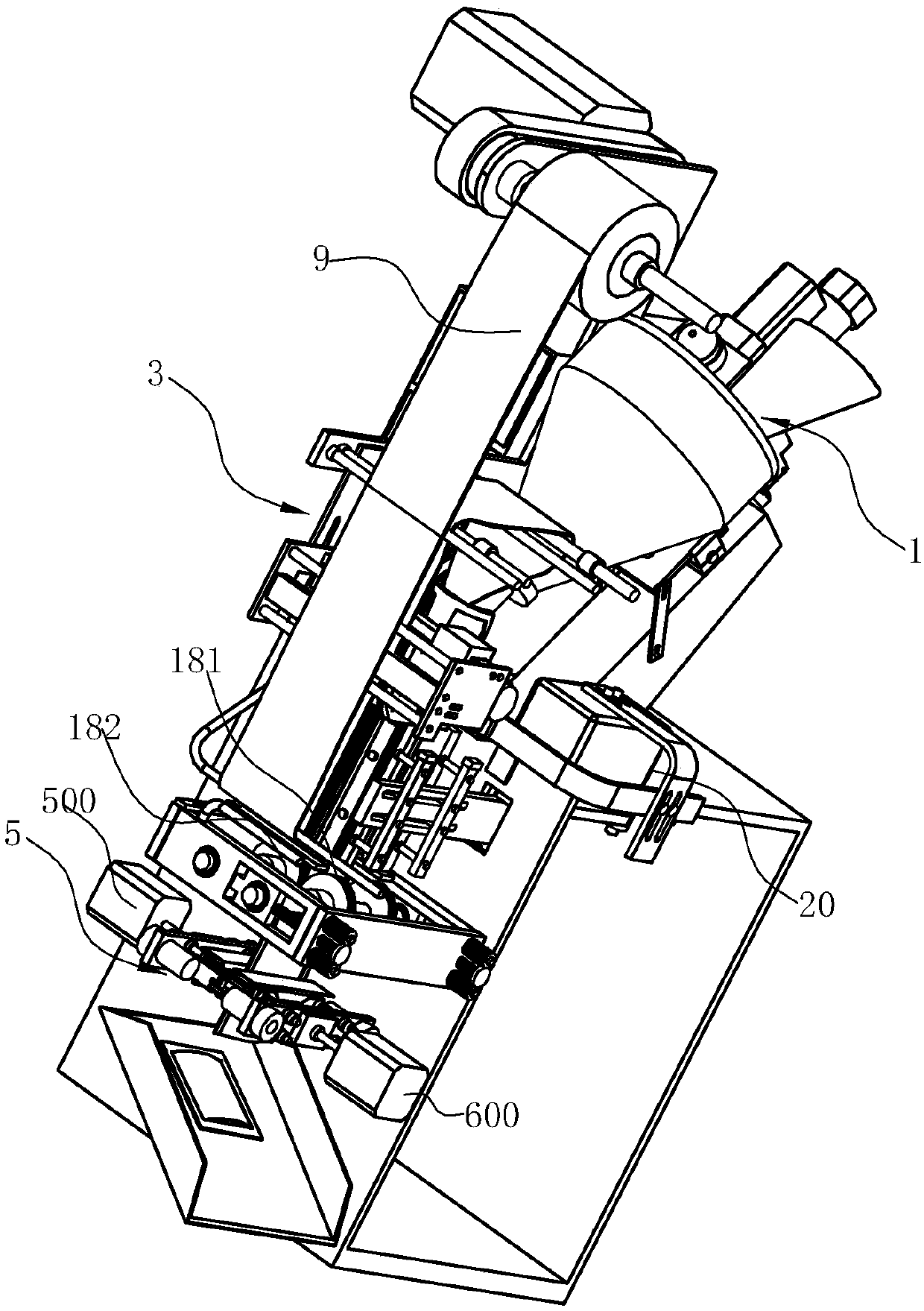

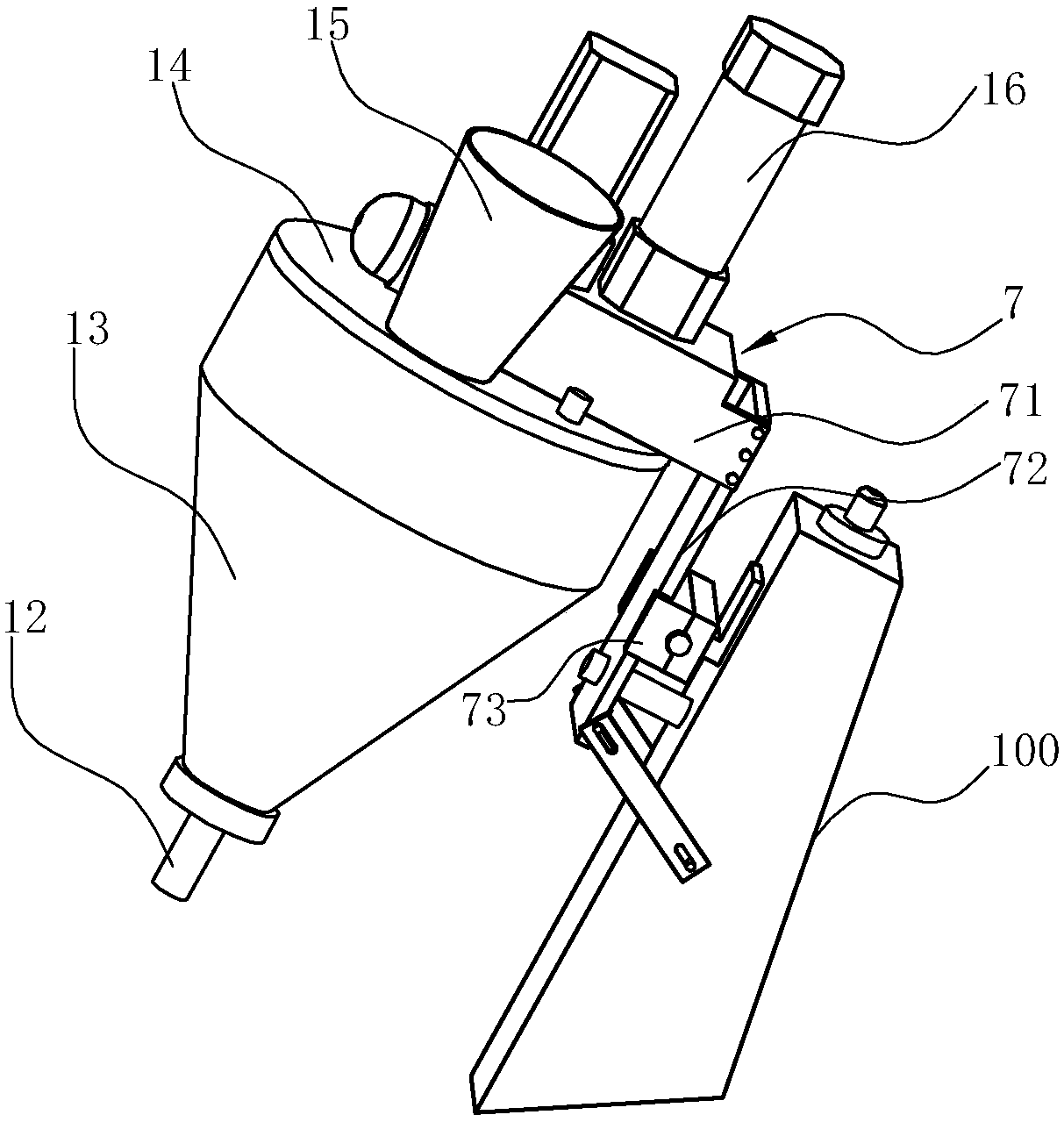

Dustproof packaging equipment

PendingCN108045643AImprove protectionImprove sealingWrapper twisting/gatheringAssembly lineEngineering

The invention relates to dustproof packaging equipment. The dustproof packaging equipment is characterized in that the dustproof packaging equipment comprises a feeding mechanism, a bag opening mechanism, a bag conveying mechanism, a side hot iron pressurizing mechanism, a hot iron cut-off mechanism and a discharging mechanism which are sequentially distributed to form an assembly line; the feeding mechanism is provided with a feeding inlet allowing particle materials to be input and a discharging outlet allowing the particle materials to be output; the bag opening mechanism is provided with an annular partition plate surrounding the outer periphery of a material guiding barrel; the bag conveying mechanism is used for conveying to-be-input packaging bag films to the bag opening mechanism;the side hot iron pressurizing mechanism is used for pressing the two side edges of an annular supporting bag; and the hot iron cut-off mechanism is used for forming an independent single packaging bag comprising the particle materials. Compared with the prior art, the dustproof packaging equipment has the advantages that the whole system is high in automation degree, lots of labor force is saved,packaging bag seals are good in leakproofness and high in firmness after packaging, dust, damp and pollution can be resisted, and the particle materials are appropriately protected.

Owner:HANGZHOU ANBANG AGRI BIOLOGICAL TECH

Preparation method for BOPET high-imitation metal wiredrawing VCM film

ActiveCN103692722ASave production costSave manufacturing costSynthetic resin layered productsMetal layered productsUltravioletBoPET

The invention discloses a preparation method for a BOPET (biaxially oriented polyester) high-imitation metal wiredrawing VCM film. The method includes: conducting surface wiredrawing treatment on one side of a transparent BOPET film; coating one surface without surface wiredrawing treatment by a polyurethane UV curable paint, carrying out UV photo-curing and heat curing, and performing natural cooling to obtain a surface hardened coating; coating the surface subjected to surface wiredrawing treatment with a model SC-400 pre-aluminizing prime coat to obtain a fastness enhanced coating; conducting vacuum aluminizing processing on the fastness enhanced coating to obtain a vacuum aluminized layer; and coating the aluminized surface of the vacuum aluminized layer with a model SC-500 topcoat, thus obtaining an antioxidant protective coating. Single-layer BOPET is adopted as a film main material, thus reducing the dosage of a raw material film, saving the production cost, prolonging the product life and improving the tolerance to various adverse conditions. The film obtained by the method has the visual effects of an imitated metal wire drawing board, thus realizing the purpose of high simulation of different material wiredrawing metal boards.

Owner:SHANGHAI RADIX VACUUM METALIZING

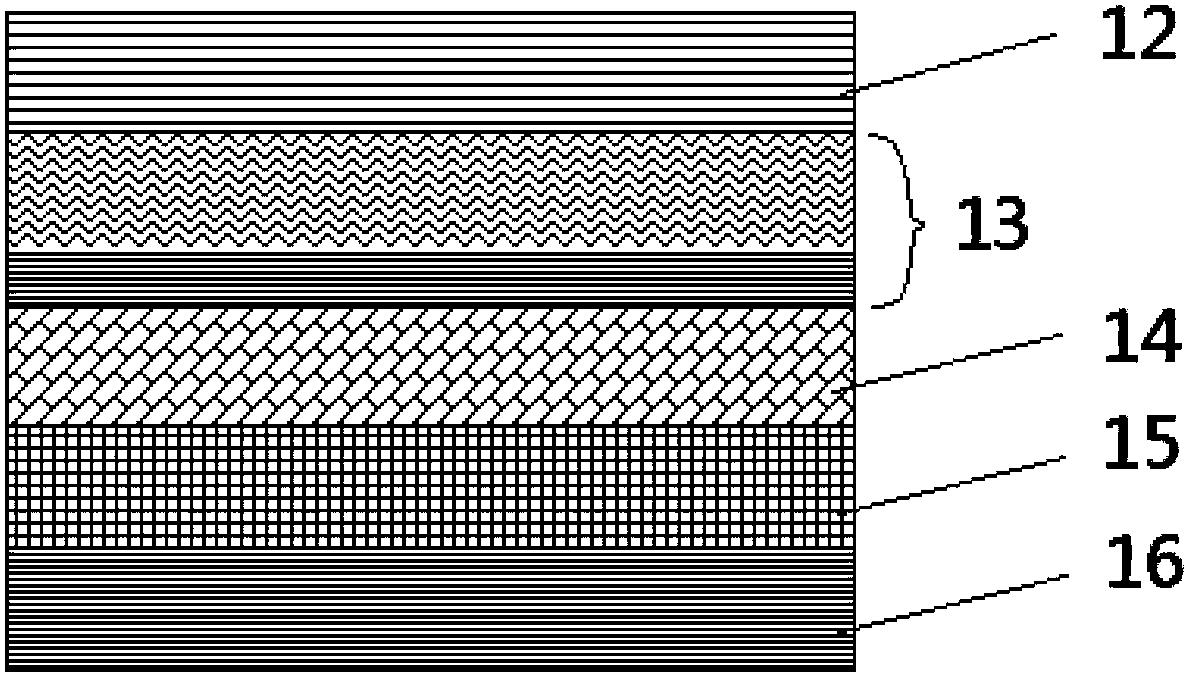

Double-side adhesion hard screen protection film, production method thereof and use method thereof

ActiveCN104057675AStrong fastnessNot easy to foamSynthetic resin layered productsLaminationTectorial membraneEngineering

The invention discloses a double-side adhesion hard screen protection film. The double-side adhesion hard screen protection film comprises a PET base material layer. An organosilicone bottom adhesive layer is arranged on one side surface of the PET base material layer, and an acrylic ester adhesive layer is arranged on the other side surface the PET base material layer. A release film layer is arranged on the surface of the acrylic ester adhesive layer. An organosilicone surface adhesive layer is arranged on the surface of the organosilicone bottom adhesive layer in a coating mode, and another release film layer is arranged on the organosilicone surface adhesive layer in an attaching mode. Due to the adoption of the structure and the method, the double-side adhesion hard screen protection film has the advantages that the adhesion strength is high, the light transmission performance is good, and the film has high fastness, will not bubble or be scratched easily and has compression resistance; bottom adhesives are additionally applied before applying organosilicone adhesives, and therefore the organosilicone adhesive layers and the PET base material layer can be bonded more firmly; the film is ultrathin and can exhaust air quickly and automatically in the adhering process, and adhesive residues will not remain when the protection film is replaced; the film is stable in performance.

Owner:安徽格林开思茂光电科技股份有限公司

Bronzing pulp and preparation method thereof

ActiveCN103255646BRich styleRich wash fastnessTransfer printing processDyeing processWater basedSolvent

The invention discloses bronzing pulp. The bronzing pulp is prepared from the following raw materials in parts by weight: 60-80 parts of acrylic ester emulsion, 2-6 parts of deionized water, 3-10 parts of a solvent, 1-5 parts of a stabilizer, 10-20 parts of EVA (Ethylene-Vinyl Acetate) hot melt adhesive powder, 0.5-3 parts of silica, 0.2-0.5 part of a polyurethane defoaming agent, 0.1-0.5 part of a pH regulator, 0.1-0.2 part of a preservative, 0.3-1 part of an emulsion wetting agent and 0.4-2 parts of a thickener. The bronzing pulp has the beneficial effects that the bronzing pulp is water-based pulp, the raw materials are easy to obtain and environment-friendly, the production is convenient, the technology is mature, and substances harmful to the environment can not be produced; and the bronzing pulp is soft in handfeel, firm in fastness, outstanding in resistance to tension fracture and diversified in application mode, enriches the styles of textiles, and endows the textiles with the noble quality.

Owner:GUANGZHOU SHENGQIN IND

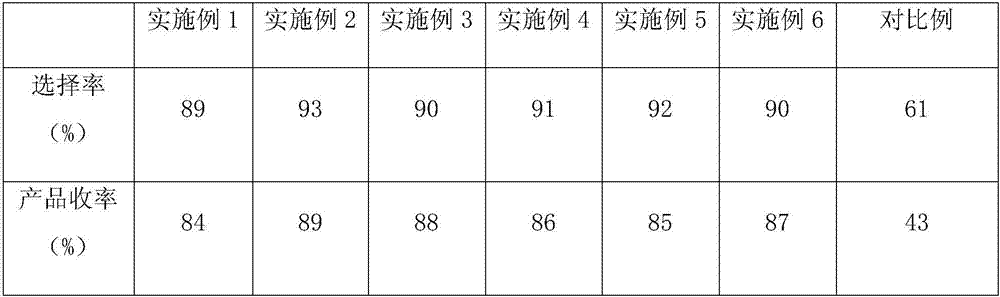

Production method of nano-attapulgite composite catalyst for 3-methylpyridine preparation

ActiveCN107983398AHighly selective adsorptionImprove permeabilityOrganic chemistryMolecular sieve catalystsMolecular sieveAluminium hydroxide

The invention provides a production method of a nano-attapulgite composite catalyst for 3-methylpyridine preparation. The method comprises following steps: nano-attapulgite raw ore is added to an aqueous hydrochloric acid solution for separating and washing, then a silver nitrate solution is utilized for washing, a mixed solution is heated and boiled by distilled water, centrifugal washing is performed, and acid modified nano-attapulgite is obtained; the acid modified nano-attapulgite is mixed uniformly with zeolite molecular sieves, a mixture is added to an aqueous aluminium hydroxide solution and mixed uniformly, a mixed solution is dried, ground and calcined at high temperature, and nano-attapulgite composite supports are obtained; the nano-attapulgite composite supports are added to silicon dioxide sol, sufficient adsorption, drying and grinding are performed, and the nano-attapulgite composite catalyst for the 3-methylpyridine preparation is obtained. According to the prepared catalyst, the zeolite molecular sieves and attapulgite are taken as the composite supports, and aluminium oxide and silicon dioxide are adsorbed into multi-stage support pores, so that catalyst is high in strength, low in cost and good in dispersibility and has good selectivity and high product yield in the 3-methylpyridine preparation.

Owner:上海磐石矿业有限公司

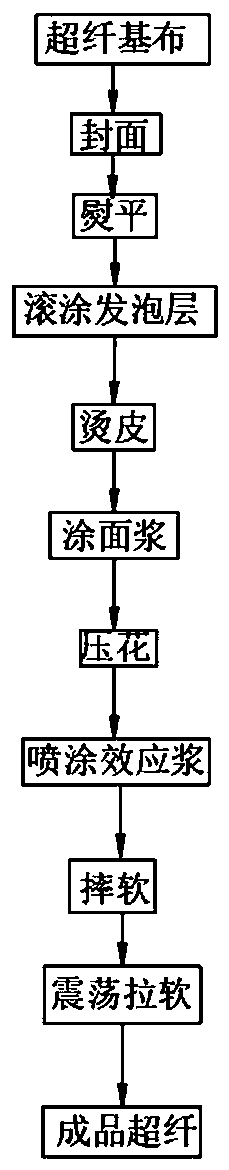

Water-based directly-coated microfiber sofa leather

InactiveCN110592956AOvercome body shape differencesOvercoming poor thickness uniformityTextiles and paperWater basedSpray coating

The invention belongs to the technical field of leather, and particularly discloses water-based directly-coated microfiber sofa leather, and a water-based directly-coated microfiber sofa leather production process. The water-based directly-coated microfiber sofa leather is prepared by preparing a microfiber base fabric and a cover, conducting ironing, roll-coating a foaming layer, conducting scalding, coating surface slurry, conducting embossing, spray-coating effect slurry, and conducting milling and oscillation staking to obtain the finished product (microfiber sofa leather). By means of microfiber gray cloth, the sofa leather has a microstructure similar to that of natural leather, overcomes the poor body form part and poor thickness uniformity of genuine leather, has super moisture absorption performance, and has the structure closer to that of genuine leather; in cooperation with the finishing of the genuine leather, the microfiber leather is more environmentally friendly, even has the texture of the genuine leather and has the unique moisture absorption performance and breathability, is higher in firmness and more durable in use, and even has performance on some aspects better than that of the genuine leather; in addition, the finishing process is close to the processing method of the genuine leather, and therefore the water-based directly-coated microfiber sofa leather has the appearance and the internal structure both close to those of the natural leather.

Owner:江苏优贝斯新材料科技有限公司

High-fastness and environment-friendly wood board processing process

InactiveCN104647485AStrong fastnessQuality improvementNon-macromolecular adhesive additivesLaminationPre treatmentPollution

The invention discloses a high-fastness and environment-friendly wood board processing process. The processing process is characterized by comprising the following steps: (1) pretreating a raw material; (2) manufacturing a wood core board; (3) preparing glue; (4) adhering and removing volatile: adhering a square material with the wood core board through the glue, performing forced cooling and ventilating. The processed wood board has high fastness and high quality and does not bend or deform easily, the content of free formaldehyde of a finished product is reduced through forced ventilation cooling, the wood board is environment-friendly and pollution-free, the finish and the flatness of the finished product are better, the manufacturing process is simple, the manufacturing cost is low, the production efficiency is high, the quality of the wood board product is greatly improved, and a consumer can buy secure wood boards.

Owner:QINGDAO RENJIE IND & TRADE

Car garment cloth containing poly ethylene (PE) and oxford fabric (polyester taffeta)

InactiveCN102535185AStrong fastnessNot easy to tearSynthetic resin layered productsRemovable external protective coveringsPolyesterSurface layer

The invention relates to a car garment cloth containing poly ethylene (PE) and oxford fabric (polyester taffeta); the surface layer of the car garment cloth is made of the PE; a layer arranged under the PE is made of the oxford fabric or polyester taffeta; and the PE is stuck with the oxford fabric or polyester taffeta in a compounding way without a medium. A car garment made from the car garment cloth has the functions of the common car garment, is strong in firmness so as to be not easily torn, and also has a waterproof function.

Owner:杭州汇龙汽车用品有限公司

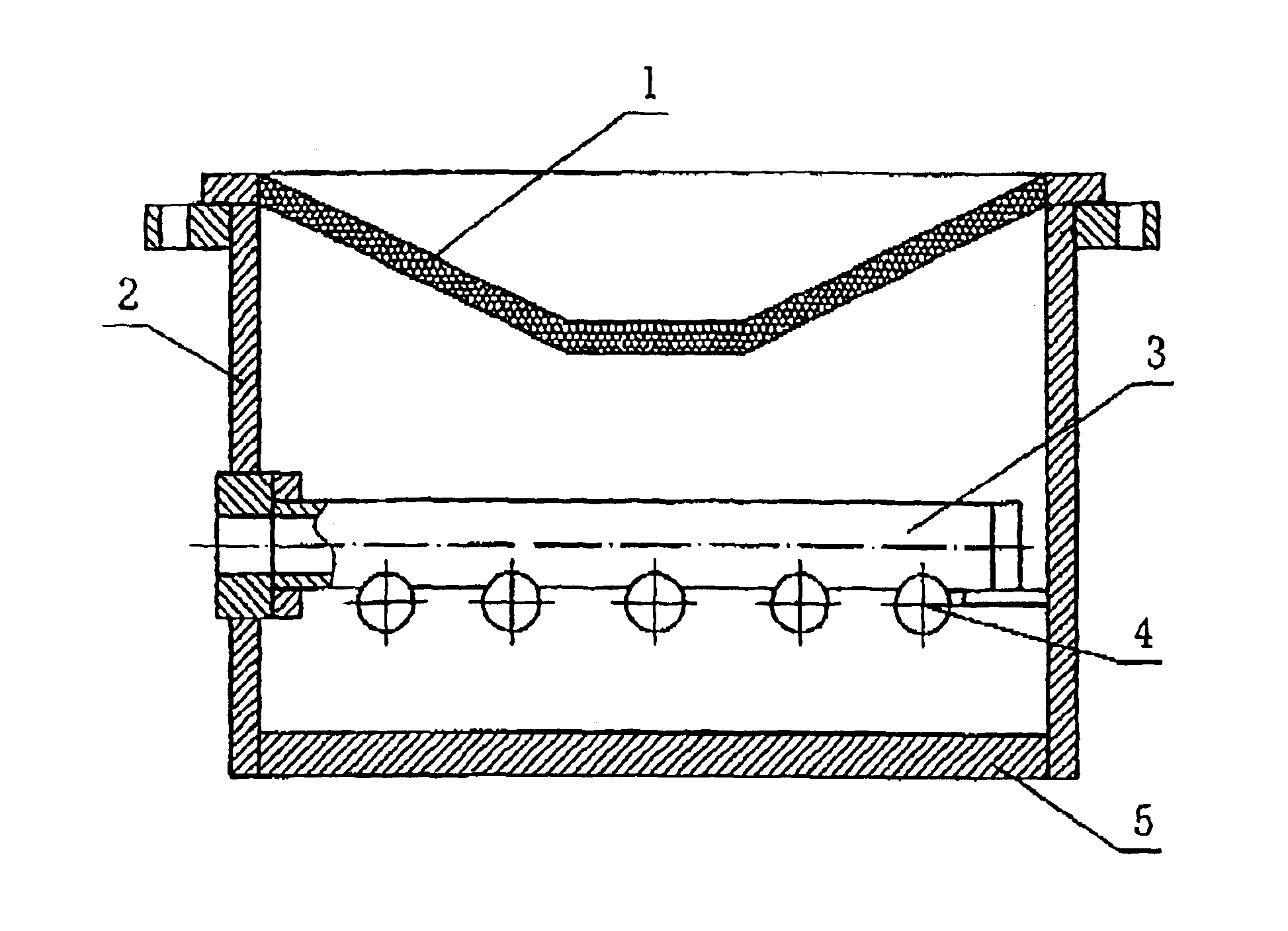

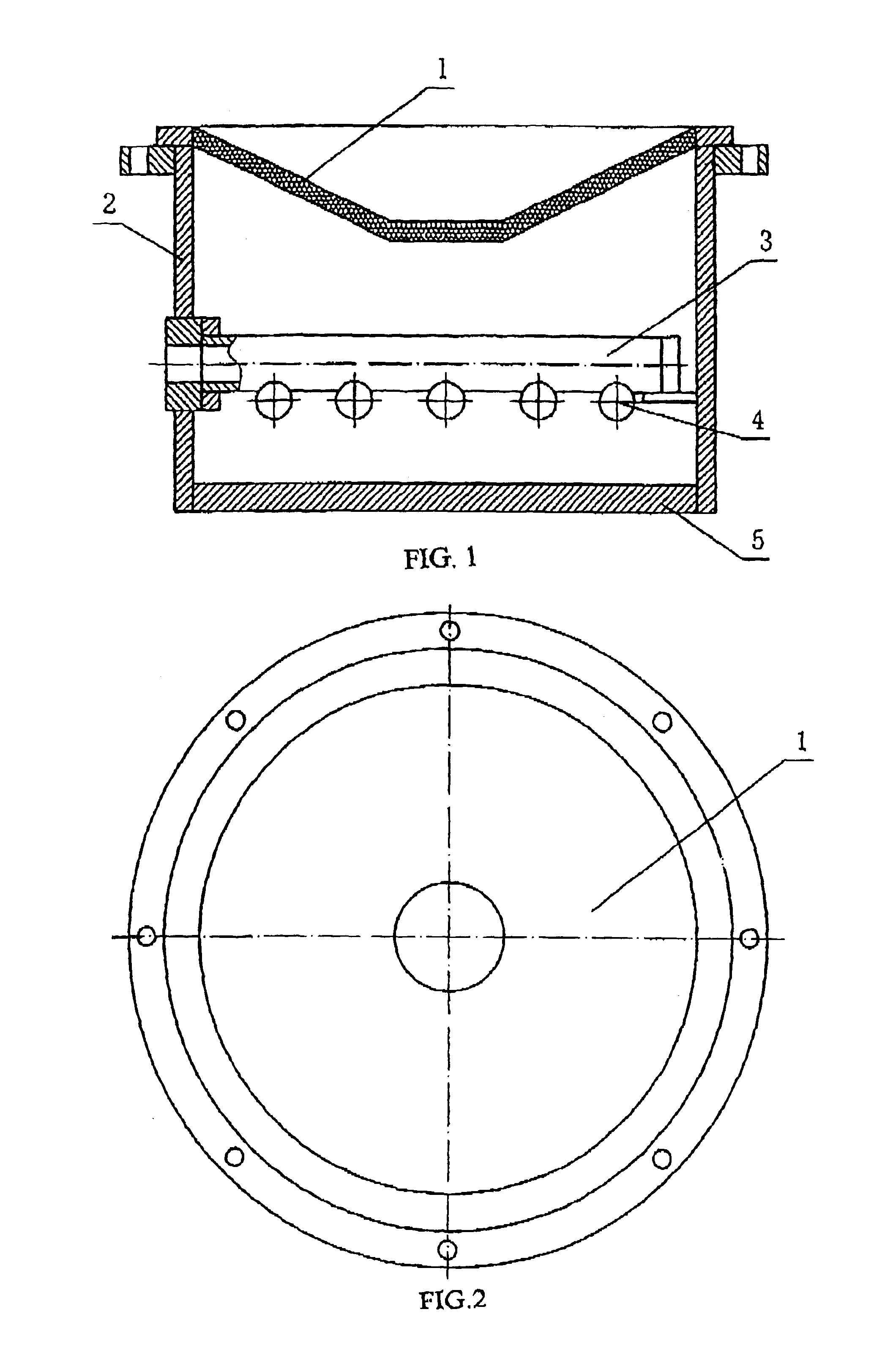

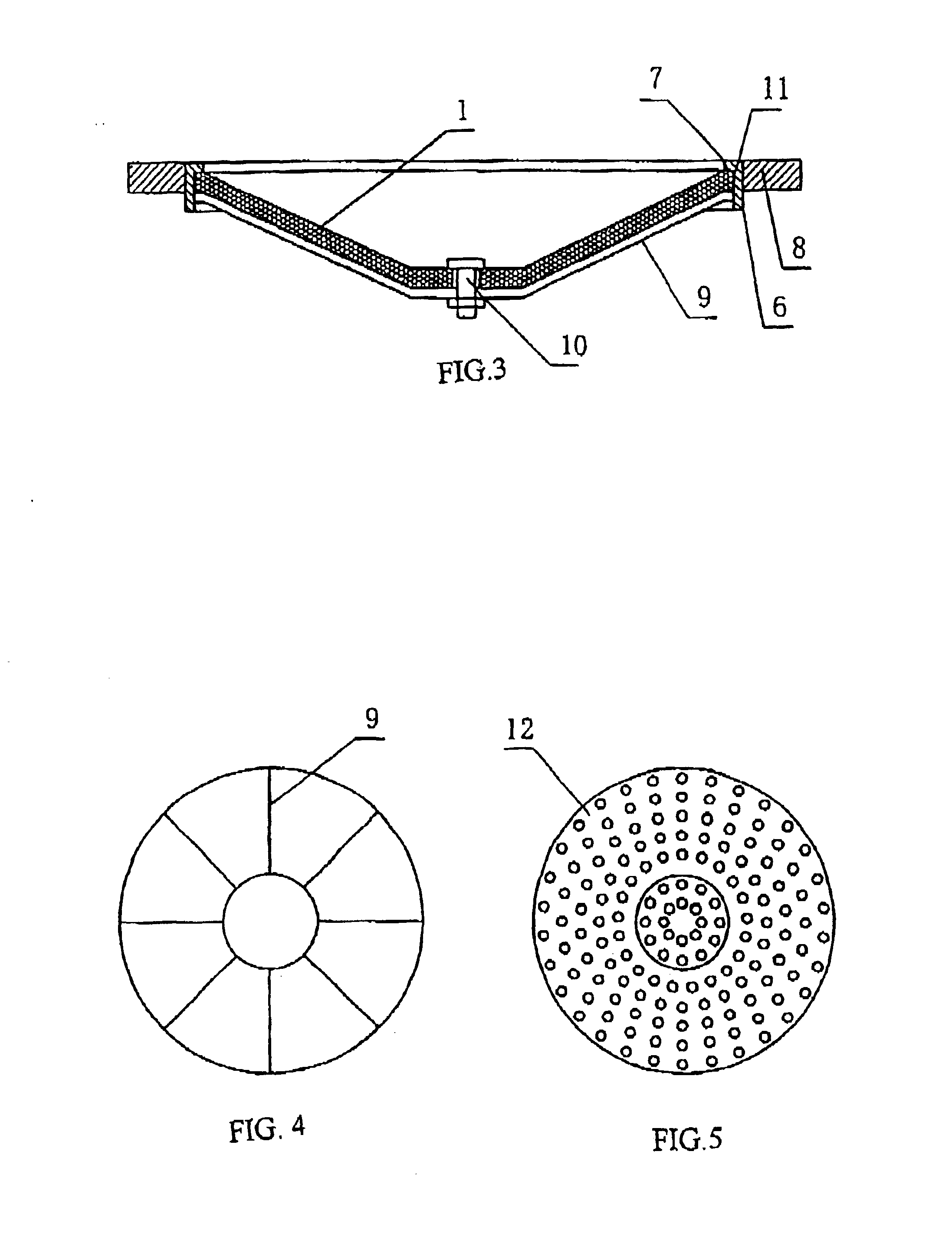

Frustum filter used for separation of cation and anion exchange resins

InactiveUS6892892B2Equally distributedHigh strengthOther chemical processesIon-exchanger regenerationMaximum diameterFiltration

A frustum filter used for separation of cation and anion exchange resins, which is used in condensate water polishing system or apparatus, wherein said frustum filter comprises a microporous filtering net body (1) which is formed by sintering a mixture of silicon carbide grains and a binder, said net body being provided with a plurality of micropores, the diameter of said micropores being in a range of 50-300 micron, said filtering net body (1) being shaped as an inverted truncated cone and its maximum diameter being in a range of 50-200 cm, the angle between a inner tapered face and a horizontal plane being in a range of 15°-30° and the thickness of said filtering net body being in a range of 2 cm-14 cm. Some reinforcing steel bars which have the property of high temperature resistance are embedded in said filtering net body(1) in advance. A steel ring (6) welded at the housing (2) is fixed on the external circumference of said filtering net body (1). This invention has the following advantages: it can distribute evenly water and has high strength; it can not be blocked easily and will not create dead zones when filtration; the product of the invention has high strength and cannot be deformed easily over the prior art; it also has the properties of strong acid fastness, strong alkali fastness, high temperature resistance, oxidation resistance.

Owner:W C BRADLEY ZEBCO HLDG INC D B A ZEBCO

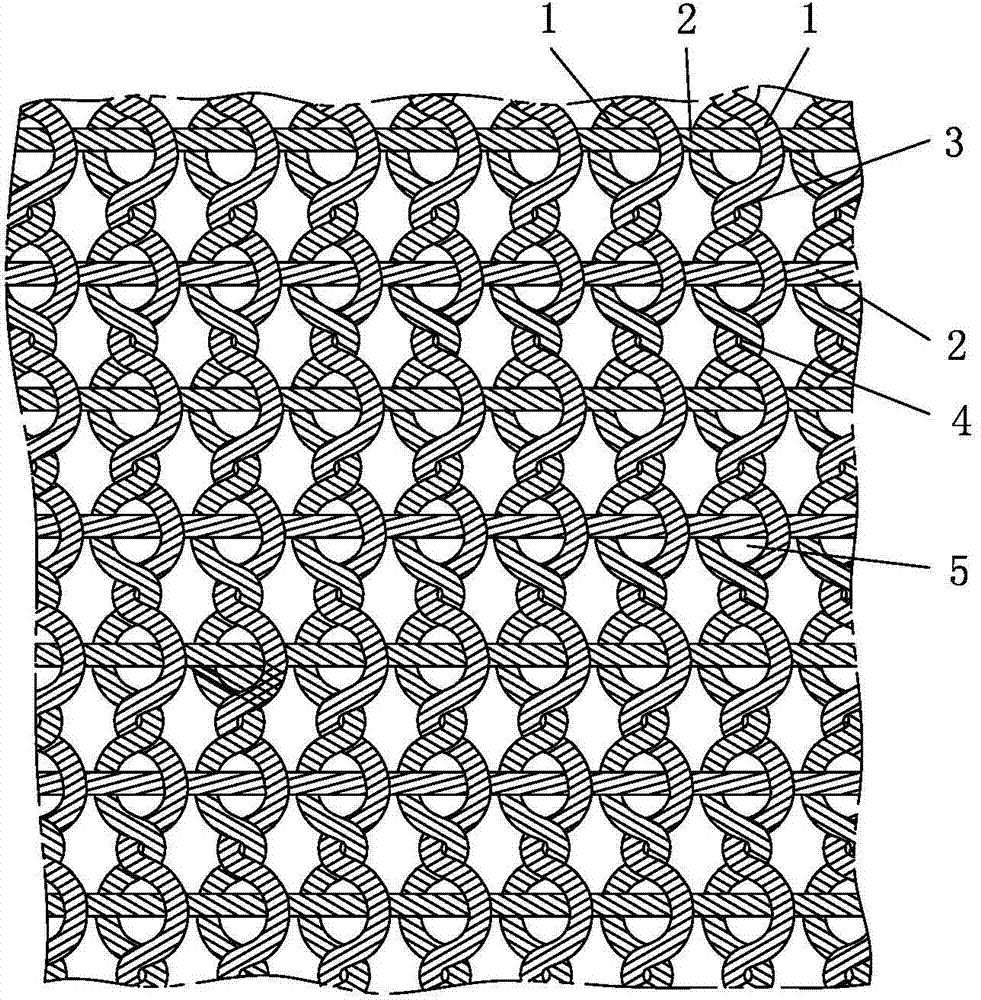

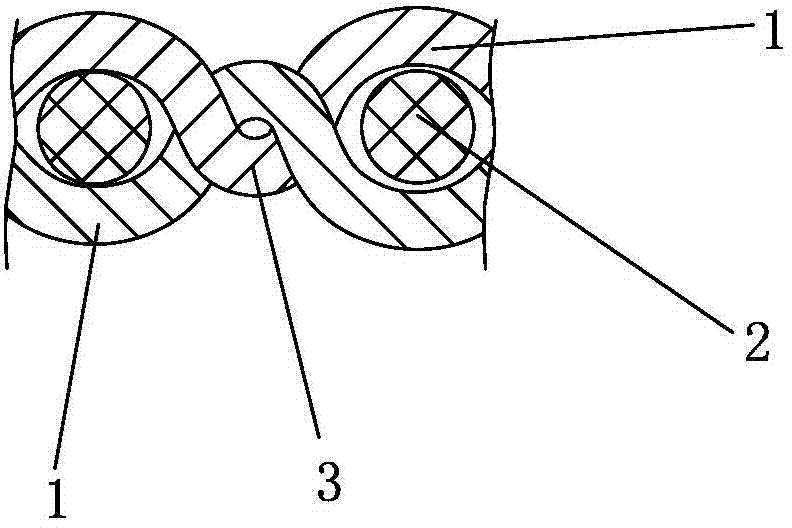

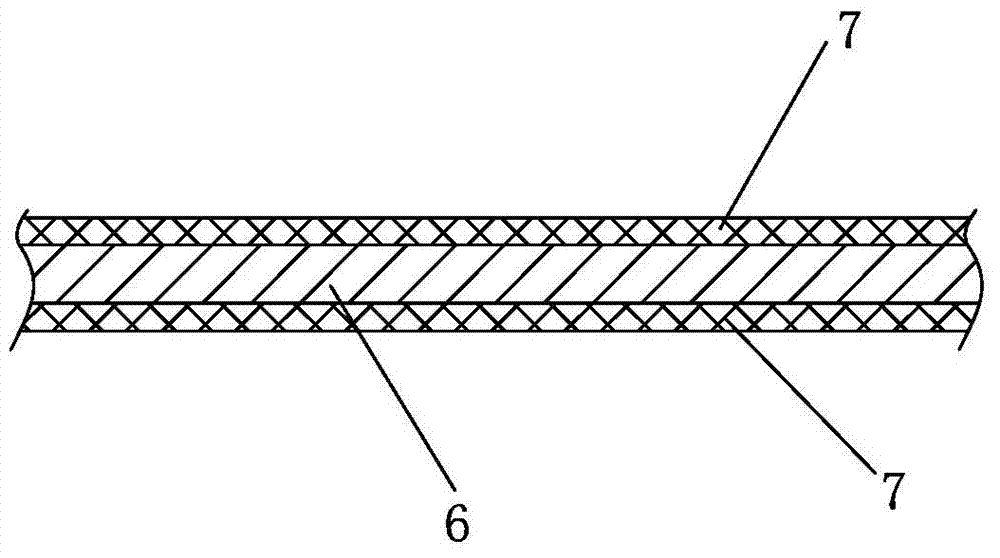

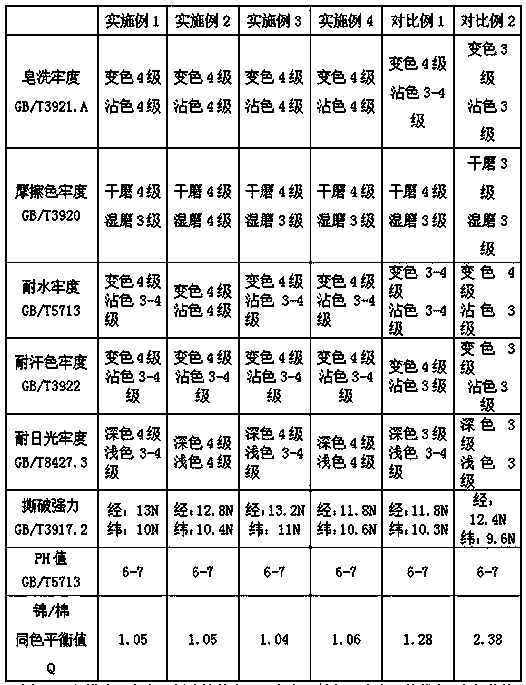

Warp and weft forwards and backwards entwisted interwoven impregnated core fabric for conveyor belt

InactiveCN103806163AAvoid deformationStrong fastnessWoven fabricsRubber layered productsPulp and paper industryConveyor belt

The invention belongs to the technical field of textiles and particularly relates to warp and weft forwards and backwards entwisted interwoven impregnated core fabric for a conveyor belt. The white body fabric is formed by interweaving warp and weft. The weft and the warp are respectively composed of forwards entwisted yarn formed by twisting at least two strands of raw material yarn and backwards entwisted yarn formed by twisting at least two strands of the raw material yarn. The two strands of the warp form a group and the two strands of the warp of each group are used for forming forwards entwisted knots and backwards entwisted knots in the warp direction, wherein the forwards entwisted knots and the backwards entwisted knots are arranged at intervals. The weft is compactly arranged at the corresponding forwards entwisted knots and the corresponding backwards entwisted knots or in closed loops which are formed by the backwards entwisted knots, the forwards entwisted knots and the two strands of the warp. The outer surface of the white body fabric is provided with at least one glue layer which is formed through impregnation. The raw material yarn is chinlon filament yarn or polyester filament yarn. The warp is interwoven to fix the weft, the woven core fabric is not prone to deformation, the service life is long, off tracking is avoided in long-distance conveying with the manufactured conveyor belt, the glue layer and the rubber are stuck and off tracking is avoided. The service life of the conveyor belt is prolonged.

Owner:ZHEJIANG GUOLI TECH

Dye for terylene fabric embossing and manufacturing technique thereof

The invention discloses a dye for terylene fabric embossing, which is prepared by the following components by weight percentage: 80% to 90% disperse red BLSF, 0.5% to 2% 3B red, and 8% to 18% diffusat MF. The invention also provides a manufacturing technique of the dye. The invention has the advantages of stable color tone, bright color, firmness, high dye uptake, environment friendliness, and safety.

Owner:韩耀君

Preparation method for spinning flame retardation polyester filament using flask return

InactiveCN107299399AImprove flame retardant performanceImprove securityFlame-proof filament manufactureFilament forming substance formingPolyesterHigh intensity

The invention discloses a preparation method for spinning flame retardation polyester filament using flask return, and the method comprises the steps of 1 pre-crystallizing material, namely polyester flask return by using dry hot-air; 2 feeding the material in screw type, and feeding the polyester flask return to a screw extruder through a pipeline after drying; 3 adding quantitative flame retardation master batch, namely drying the flame retardation master batch to remove moisture, and then adding quantitative dry flame retardation master batch in a screw feed inlet; 4 filtering, namely tackifying melts in a reaction vessel when the melts are squeezed by a extruder and then refiltering the melts, and guaranteeing continuous spinning and constant melting pressure; and 5 spinning, putting a mixture from a filter in a spinning assembly, and spraying the mixture from a spinneret through the spinning assembly; side blowing for cooling; oiling and then winding for formation. The filament strip prepared by the invention has good flame resistance, high security, high intensity, good endurance and stable size.

Owner:仪征市仲兴环保科技有限公司

One-bath dyeing process of brocade cotton fabric

The invention relates to one-bath dyeing process of brocade cotton fabric. The process comprises the following steps: putting the brocade cotton fabric subjected to cold-dwell desizing treatment intoa dye vat, wherein a bath ratio is 1 to (5-10), adding Anoky NC type reactive dye, and sequentially adding anhydrous sodium sulphate and an alkaline agent after the reactive dye is uniformly dissolved, slowly heating up to 98-100 DEG C and carrying out heat preservation for 50-60min, then cooling and draining, sequentially washing and soaping, then washing again, and discharging the fabric. The reactive dye used in the process contains a quaternary ammonium pyridine formic acid active group, and the pH value of a dyeing bath gradually changes from alkalinity to acidity as the rise of temperature, and the dye-uptake of the dye changes along with the change of the pH; when being alkaline, the dye bath reacts with a hydroxyl group in cotton fibers, so that a covalent bond with a firm structure is formed, and cotton dyeing is further realized; when being gradually turned to be acid, the dye bath reacts with an amino group in chinlon, so that a covalent bond with a firm structure is formed,and chinlon dyeing is further realized; therefore, the brocade cotton fabric is not only good in color and cloth surface effect, but also has the fastness which is in line with customer requirements.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

Sewing cloth containing oxford fabric and hot air cotton (acupuncture cotton)

InactiveCN102529195AStrong fastnessNot easy to tearLaminationLamination apparatusAdhesiveAcupuncture

The invention discloses sewing cloth containing an oxford fabric and hot air cotton (acupuncture cotton). The oxford fabric serves as an upper layer of the sewing cloth; the lower layer of the oxford fabric is provided with hot air cotton or acupuncture cotton; and the oxford fabric is bonded with the hot air cotton or acupuncture cotton through an adhesive. The sewing cloth made of the material has the functions of general sewing cloth, has high firmness, is prevented from being torn easily, and can be used for preserving heat, insulting heat and preventing surface paint of a vehicle from being scratched.

Owner:杭州汇龙汽车用品有限公司

Dye for polyester fabric and production process of dye

The invention discloses a dye for polyester fabric and a production process of the dye. The dye is prepared from the following raw materials in percent by weight: 70%-90% of disperse violet SE-BL; 0.2%-2% of disperse red 3B and 8%-28% of dispersing agent MF. The dye disclosed by the invention has the characteristics of stable color and light, bright color, high dyeing rate, strong fastness, good washing fastness, environmental friendliness and safety.

Owner:浙江山川科技股份有限公司

Method for softening and dyeing soybean straw

InactiveCN108748560AHigh strengthMake up for the defect of easy breakageRadiation/waves wood treatmentWood treatment detailsPetalAlkyl polyglycoside

The invention belongs to the technical field of straw dyeing treatment, and particularly relates to a method for softening and dyeing soybean straw. The method specifically comprises the following steps that (1) the soybean straw is immersed in a magnesium sulfate solution for heat preservation and immersing, then is taken out after the solution drains and until no water drops falls, the soybean straw is put into a freezing room for freezing treatment and then is taken out, and then the soybean straw is subjected to constant-temperature steam treatment and then is taken out, and the soybean straw is dried until the moisture content is 7-9%; (2) the soybean straw is immersed in a coloring agent for immersing and then is taken out after the coloring agent drains and until no water drops falls, and the soybean straw is put into an electric field for electric field treatment, wherein the coloring agent is prepared from the following raw materials of fresh cockscomb petals, carrots, fresh celery leaves, fresh ryegrass, natural phenol polyoxyethylene ether, alkyl polyglucoside, grifola polysaccharide, lycium barbarum polysaccharide and water; and (3) the soybean straw is dried until themoisture content is 15-17%. According to the method, the breaking strength of the soybean straw is greatly enhanced after softening and dyeing treatment, the color is bright, uniform and glossy, discoloring and color fading are avoided, and extremely high color fastness to washing and color fastness to rubbing are achieved.

Owner:阜南县明强柳编工艺品有限公司

Fabric used for door curtain

InactiveCN105082679ASoft and slipperyPure colorSynthetic resin layered productsWoven fabricsYarnStructural engineering

The invention discloses a fabric used for a door curtain. The fabric comprises a fabric main body. The innovative points of the invention are as follows: the fabric main body is formed by braiding of warp and weft; a transparent layer is sewed on the upper surface of the fabric main body; rib stitches are uniformly arranged on the transparent layer; warp is an acrylic fiber filament with a fineness of 70 D and weft is a terylene textured yarn with fineness of 68 D; and a plurality of rows of net structures are arranged on the fabric main body. The fabric used for the door curtain touches soft and smooth and has a pure color and high fastness; the surface of the fabric presents a feeling of plumpness and fineness; and since the plurality of rows of heart-like or elliptic net structures are arranged on the fabric main body of the fabric, when the door curtain is put down and a door is opened, wind enters a room through splits, which enables ventilation to be realized while allowing the door curtain not to flutter with wind, and a part of light rays enters the room through the splits, which enables indoor illumination needs to be met.

Owner:JIANGSU JUWEI NEW MATERIALS

A kind of bronzing paste for textile fabric transfer printing

ActiveCN104746360BSoft touchStrong fastnessTransfer printing processDyeing processWater basedCrack resistance

The invention relates to gold stamping slurry for transfer printing of textile fabrics. The gold stamping slurry comprises the following components: polyvinyl chloride emulsion, diisooctyl phthalate, trixylyl phosphate, 1:2 type metal complex dyes, chlorinated paraffin, deionized water, methylisobutylketone, bright laser powder, barium stearate, hot melt adhesive powder, silicon dioxide, an antifoaming agent, a pH regulator, an ultraviolet absorbent, an emulsion wetting agent, modified amino organosilicon and ester gum. The gold stamping slurry has the beneficial effects that the slurry refers to water-based slurry, the raw materials are readily available, the slurry is environmentally friendly and convenient to prepare, and substances harmful to the environment are not produced; according to addition of the chlorinated paraffin, the gold stamping size is soft in handfeel; according to addition of the barium stearate, the gold stamping slurry is high in fastness, high in solvent resistance and transparency and outstanding in cracking resistance, the application modes are diversified, and the styles of the textiles are enriched; and moreover, the gold stamping textiles are endowed with excellent washing fastness and bright appearance, and high quality of the textiles is reflected.

Owner:JIANGMEN CAIGE ENVIRONMENTAL PROTECTION TECH IND

Dye for polyester textures and production process thereof

The invention discloses a dye for polyester textures and a production process thereof. The dye is prepared from the following raw materials in percentage by weight: 20% to 30% of dispersing brilliant red F-3BS, 10% to 20% of dispersing red FB, and 50% to 70% of dispersing agent MF. The dye has the advantages that the color and the light are stable, the color is bright, the dyeing rate is high, the fastness is high, the washable effect is high, and the environment-friendly effect and safety are realized.

Owner:浙江山川科技股份有限公司

Dispersing agent for dyeing of polyester fabrics and production process thereof

The invention discloses a dispersing agent for the dyeing of polyester fabrics and a production process thereof. The dispersing agent for the dyeing of the polyester fabrics is prepared from the following components in percentage by weight: 20 to 30 percent of disperse blue 2BLN, 0.01 to 0.05 percent of disperse turquoise blue S / GL, 30 to 40 percent of disperse blue SE / 5R, 0.004 to 0.008 percent of disperse yellow 8GFF and 30 to 40 percent of dispersing agent MF. The dispersing agent for the dyeing of the polyester fabrics and the production process thereof have the characteristics of stable chromatic light, bright color, high fastness, high dyeing rate, environmental friendliness and safety.

Owner:浙江山川科技股份有限公司

Automobile cover cloth containing aluminum foil and oxford fabric (polyester taffeta)

InactiveCN102555350AStrong fastnessAvoid scratchingLaminationLamination apparatusPolyesterEngineering

The invention discloses an automobile cover cloth containing an aluminum foil and an oxford fabric (polyester taffeta). The upper layer of the automobile cover cloth is the aluminum foil; the oxford fabric or polyester taffeta is arranged on the lower layer of the aluminum foil; and the aluminum foil is adhered with the oxford fabric or polyester taffeta by glue. An automobile cover made by the cloth has a function of the common automobile cover, has high firmness, is difficult to tear away, and can preserve and insulate heat and prevent the paint on the surface of an automobile from being scratched.

Owner:杭州汇龙汽车用品有限公司

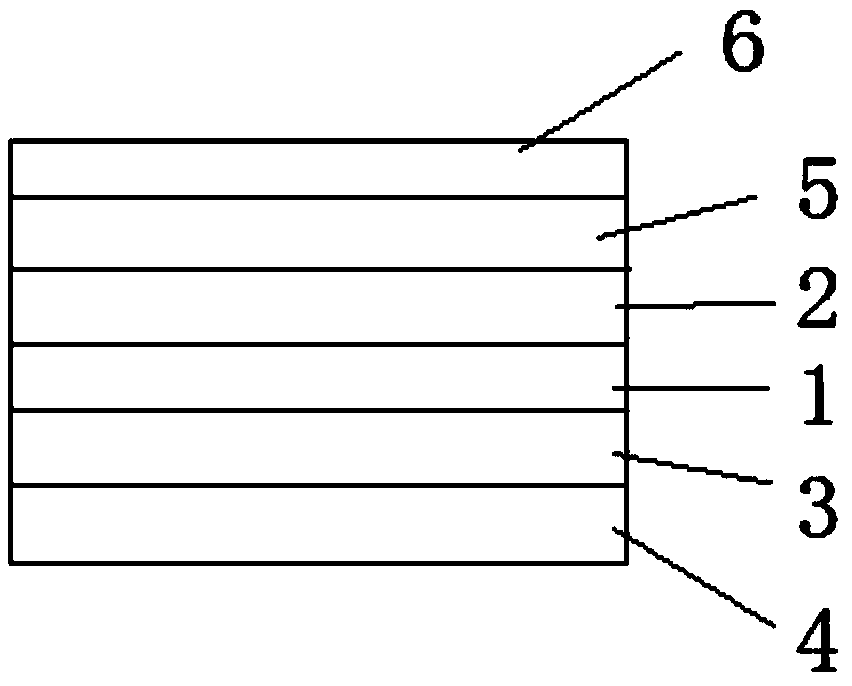

Aluminum alloy plate with woodgrained paper

InactiveCN107060251AStrong fastnessIntegrity guaranteedCovering/liningsSynthetic resin layered productsSurface layerAlloy

The invention discloses an aluminum alloy plate with wood-grain paper, which comprises a surface layer (1) and a bottom layer (2), wherein the surface layer (1) is a wood-grain paper layer, and the bottom layer (2) is a non-woven fabric layer. A bonding layer (3) is provided between the surface layer (1) and the bottom layer (2), and the surface layer (1) and the bottom layer (2) are connected through the bonding layer (3) to form a composite paper layer, and the composite paper layer and The decorative aluminum plate (4) is connected, and a reinforcing plate surface (5) is provided between the composite paper layer and the decorative aluminum plate (4). The invention makes the fastness of the decorative aluminum alloy plate stronger and tougher, and the surface tension increases.

Owner:王兆进

Special glue for rubber sole

InactiveCN105440978AImprove adhesionStrong fastnessNon-macromolecular adhesive additivesAdhesive processes with adhesive heatingPolymer scienceLatex rubber

The invention relates to the field of glue for shoemaking, especially to a special glue for a rubber sole. The special glue comprises, by mass, 15 to 20 parts of pectin, 18 to 23 parts of latex, 2 to 5 parts of compound resin, 1 to 2 parts of ethylene, 0.2 to 0.4 part of oxidation water, 0.3 to 0.6 part of a water repellent, 1 to 1.5 parts of an anti-oxidant and 20 to 30 parts of water. The special glue for the rubber sole has strong bonding strength; and in particular, when applied to the rubber sole, the special glue has strong fastness, is hard to age and oxidize after bonding, and has long usage time and stable performance.

Owner:TONGXIANG YIYUAN SHOES

Coloring agent used for dyeing and printing polyester cotton and pure cotton fabric and production process thereof

The invention discloses a coloring agent used for dyeing and printing polyester cotton and a pure cotton fabric and a production process thereof. The coloring agent is prepared from the following raw materials in parts by weight: 0.018-0.08 part of disperse blue 2BLN, 0.1-0.3 part of disperse violet HFRL, and 90-100 parts of brightener CPS-D. The coloring agent disclosed by the invention has the advantages of stable color tone, bright color, high dyeing rate, high fastness, good washing-resisting effect, environmental protection and safety.

Owner:浙江山川科技股份有限公司

Cloth for automobile garment

InactiveCN102320167APrevent infiltrationNot scratchedRemovable external protective coveringsMetal layered productsPolyesterSurface layer

The invention discloses cloth for an automobile garment. A surface layer of the cloth is made of polyester taffeta; a bottom layer of the cloth is made of acupuncture cotton, hot air cotton, PP (Polypropylene) cotton or spunlaced cotton; the surface layer is seamlessly compounded and bonded with the bottom layer through glue; silver is uniformly coated on the surface of the polyester taffeta on the surface layer of the cloth; and after the silver is coated, a water-resistant layer and a coating are sequentially and uniformly coated on the surface of the polyester taffeta. The automobile garment made of the material can achieve functions of a general automobile garment, has high firmness and cannot be torn off at the same time; and in addition, the automobile garment can be used for preventing automobile paint from being scratched and playing roles of preserving heat, insulating and resisting water and coldness.

Owner:陈统奎

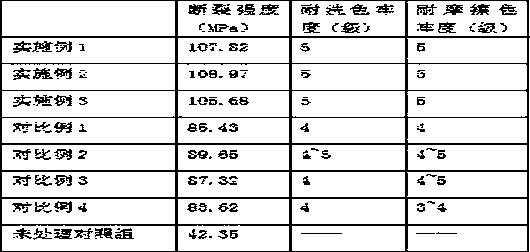

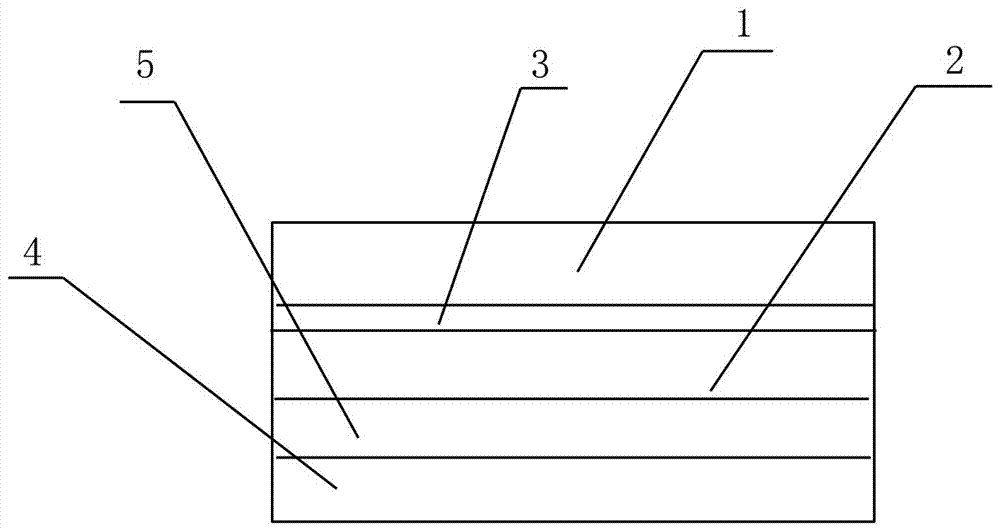

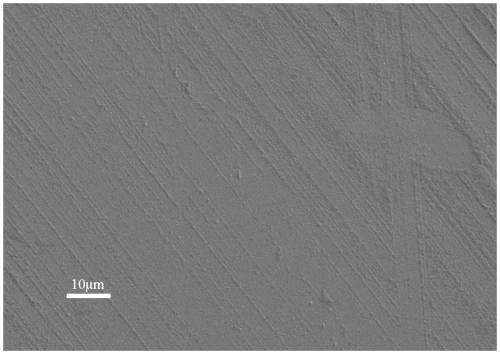

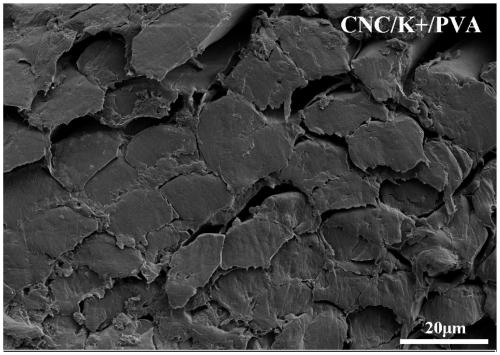

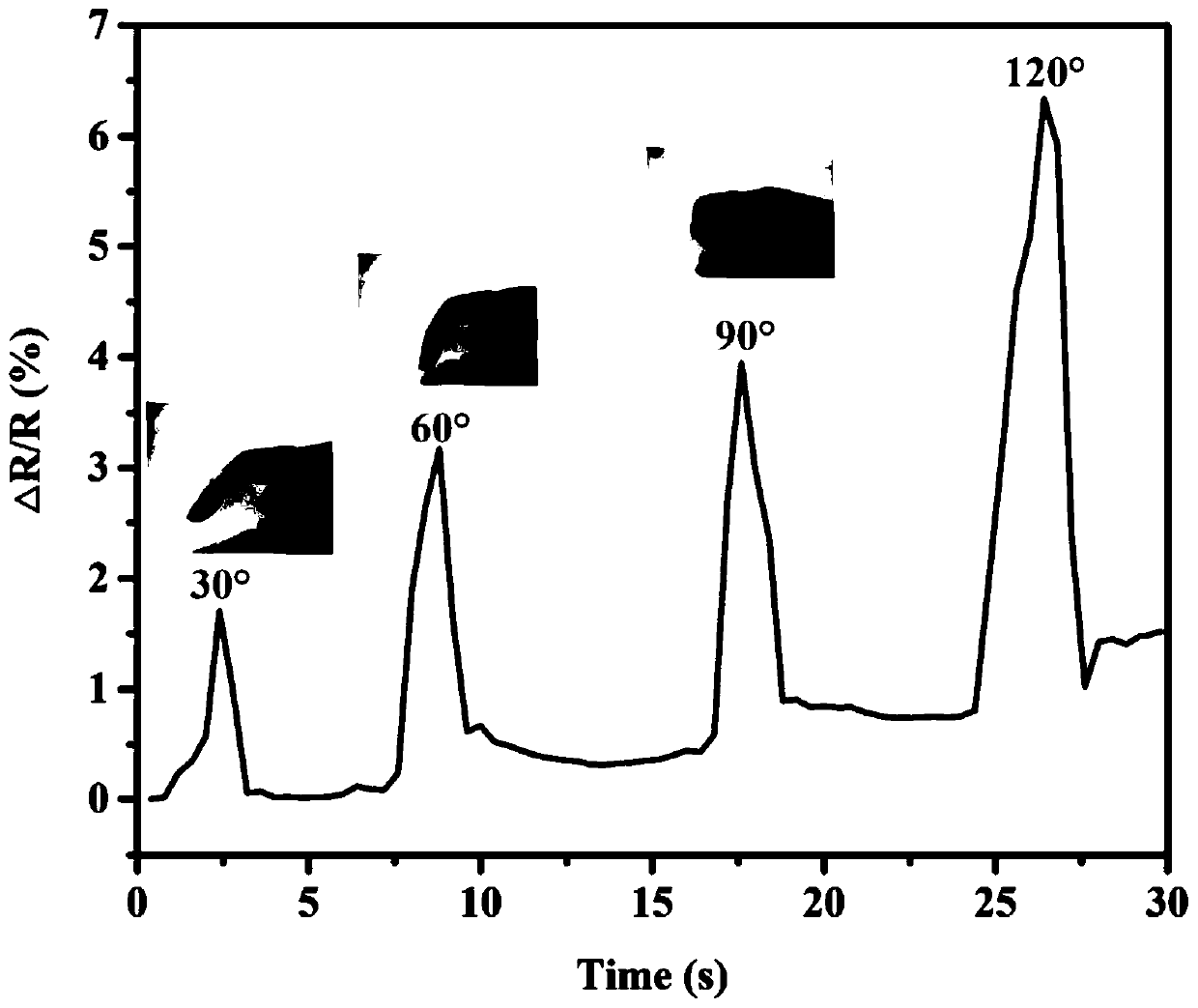

Preparation method of flexible high-strength textile-based conductive composite material

InactiveCN111101377ALarge specific surface areaEasy to prepareVegetal fibresWoven fabricPolyvinyl alcohol

The invention provides a preparation method of a flexible high-strength textile-based conductive composite material. According to key points of the method, a cellulose nanocrystal (CNC) is used as a template, a conductive monomer is added in a low-temperature acid state, then persulfate is slowly added dropwise, a conductive polymer / CNC hybrid material is generated through in-situ oxidative polymerization, a metal salt solution is added dropwise, then a polyvinyl alcohol (PVA) solution is added, the mixture is stirred uniformly and poured into a culture dish where a textile fabric is spread, and the conductive composite material is obtained after natural air-drying. The material has both biocompatibility and the conductivity of the conductive polymer and also has self-healing performance and excellent mechanical properties and wearability of a textile matrix; and moreover, the material has excellent sensing performance and can perform human exercise monitoring, thereby having broad application prospects in the fields of strain sensors, intelligent robot sensing skin, flexible wearable electronic equipment and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com