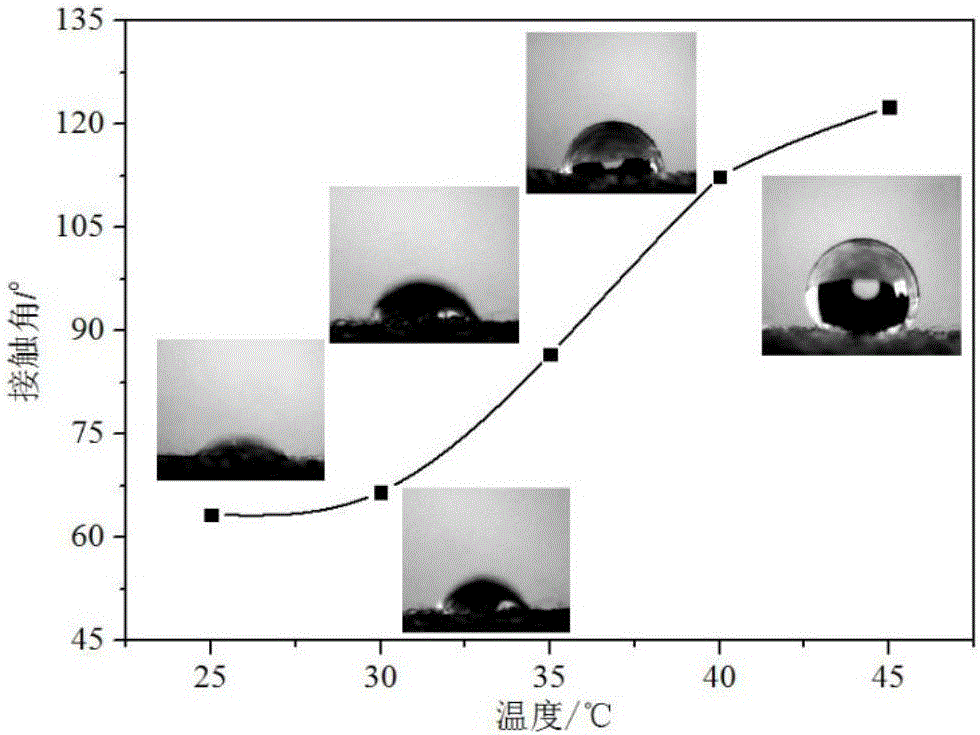

Temperature-sensitive waterproof moisture-permeable shell fabric and preparation method thereof

A waterproof and moisture-permeable, temperature-sensitive hydrogel technology, applied in the direction of fiber type, textile and papermaking, fiber processing, etc., can solve the problems of poor fastness and easy detachment of PNCS microgels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a temperature-sensitive waterproof and moisture-permeable fabric, comprising the following steps:

[0031] (1) Soak the base cloth in hydrochloric acid to carry out hydrolysis treatment, the base cloth is a fabric that can be hydrolyzed to obtain amino and / or hydroxyl structures;

[0032] (2) Soak the hydrolyzed base cloth obtained in the step (1) in a glutaraldehyde solution to carry out a pre-crosslinking reaction, and then perform a padding treatment on the obtained pre-crosslinked base cloth in a temperature-sensitive hydrogel to obtain a cross-linked fabric;

[0033] (3) Coating the coating agent on the surface of the cross-linked base cloth obtained in the step (2) and then baking to obtain a temperature-sensitive waterproof and moisture-permeable fabric.

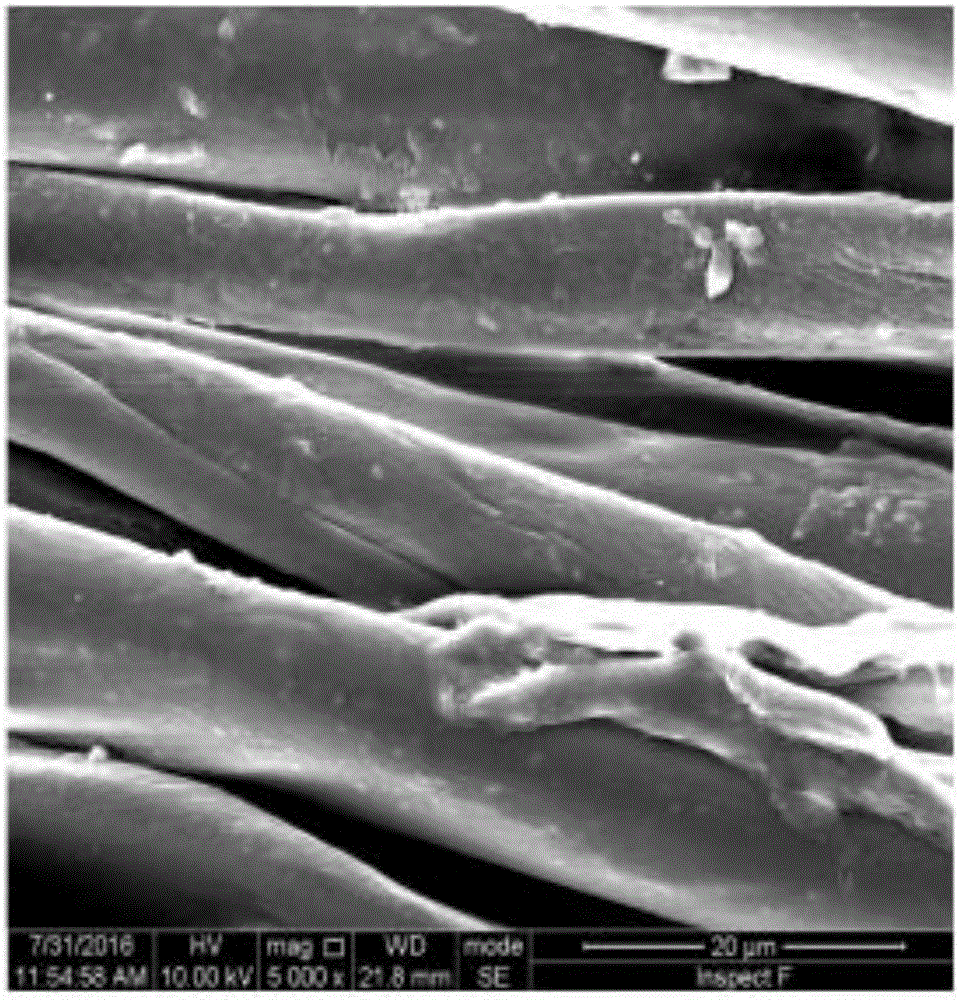

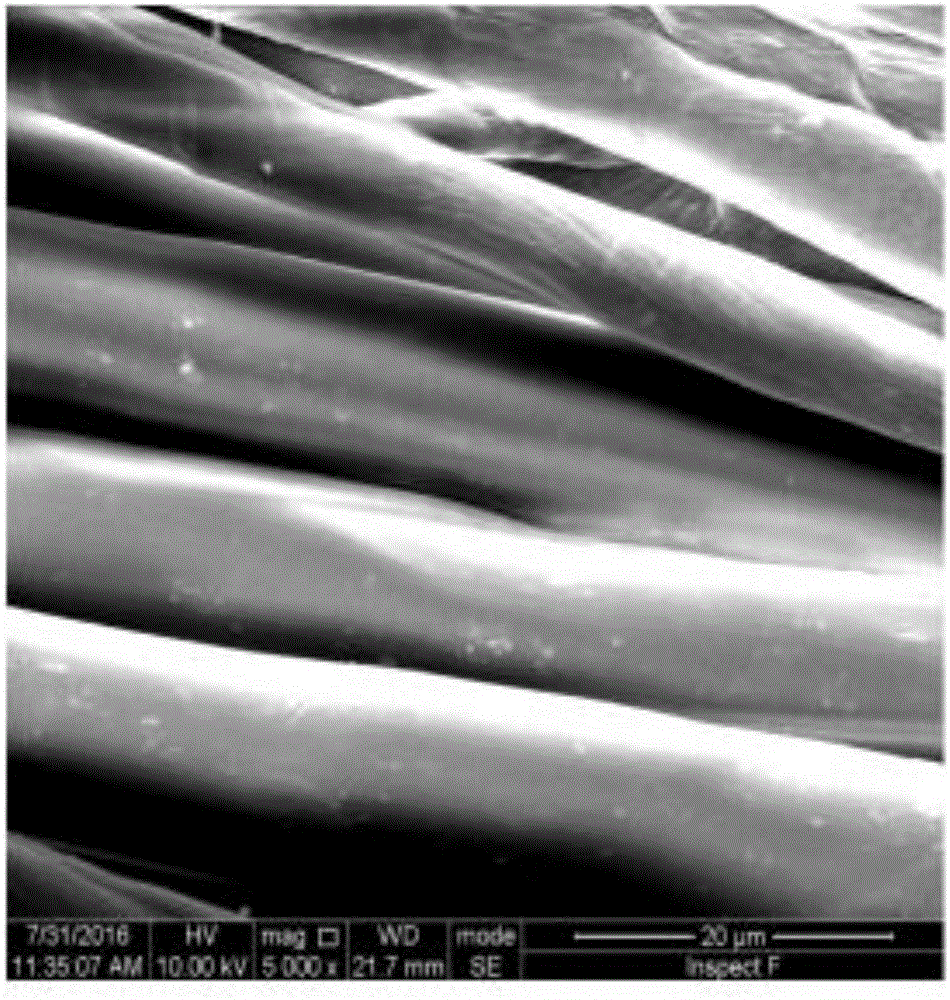

[0034] In the present invention, the base cloth is soaked in hydrochloric acid for hydrolysis treatment, and the base cloth is a fabric containing amino and / or hyd...

Embodiment 1

[0069] Soak 70D×70D, 260T, 2 / 2 twill nylon fabric in 0.5mol / L hydrochloric acid, and perform hydrolysis treatment for 30 minutes to obtain hydrolyzed base fabric;

[0070] In terms of parts by mass, 15 parts of chitosan, 20 parts of N-isopropylacrylamide, and 1 part of N, N-methylenebisacrylamide were dissolved with 2 parts of acetic acid at room temperature; It is 1 part of 10% N, N, N, N-tetramethylethylenediamine solution and 1 part of ammonium persulfate, stirred at 800r / min for 5min, then filled into a three-necked round bottom flask, and carried out free radical polymerization at room temperature under the protection of nitrogen 24h, obtain thermosensitive hydrogel;

[0071] Soak the hydrolyzed base cloth in a glutaraldehyde solution with a mass percentage of 5%, perform a pre-crosslinking reaction for 30 minutes, and then dip the obtained pre-crosslinked base cloth in the temperature-sensitive hydrogel for two dips and two rolls, wherein the rolling pressure 1kgf / cm 2...

Embodiment 2

[0075] Soak 70D×70D, 260T, 2 / 2 twill nylon fabric in 0.4mol / L hydrochloric acid, and perform hydrolysis treatment for 40min to obtain hydrolyzed base fabric;

[0076] In terms of parts by mass, 25 parts of chitosan, 40 parts of N-isopropylacrylamide, 1.5 parts of N, N-methylenebisacrylamide were dissolved with 4 parts of acetic acid at room temperature; It is 2 parts of 8% N, N, N, N-tetramethylethylenediamine solution and 1.5 parts of ammonium persulfate, stirred at 900r / min for 5min, then filled into a three-neck round bottom flask, and carried out free radical polymerization at room temperature under the protection of nitrogen 30h, obtain thermosensitive hydrogel;

[0077] Soak the hydrolyzed base fabric in a glutaraldehyde solution with a mass percentage of 4%, perform a pre-crosslinking reaction for 40 minutes, and then dip the obtained pre-crosslinked base fabric in the temperature-sensitive hydrogel for two dips and two rolls, wherein the rolling pressure 2kgf / cm 2 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com