Thermo-sensitive hydrogel and preparation method thereof

A temperature-sensitive hydrogel and temperature-sensitive monomer technology, applied in the field of polymer material synthesis, can solve the problems of high energy consumption and high cost of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a temperature-sensitive hydrogel, comprising the following steps: irradiating a temperature-sensitive monomer and a crosslinking agent in a solvent by ultraviolet light in the presence of a photoinitiator to perform a polymerization reaction , to obtain thermosensitive hydrogel; the photoinitiator has a photobleaching effect; the crosslinking agent is a substance with two functionalities.

[0025] Aiming at the technical status of the temperature-sensitive hydrogel preparation method, the present invention adopts the rapid, efficient and controllable polymerization method to prepare the temperature-sensitive hydrogel according to the principle of photofront polymerization, which can improve the temperature-sensitive hydrogel preparation. High efficiency, reducing the cost required for preparation.

[0026] In the embodiment of the present invention, a certain proportion of temperature-sensitive monomers, cross-linking agents...

Embodiment 1

[0040] Example 1: Preparation of Thermosensitive Hydrogel by Photofront Polymerization

[0041] Recipe ratio:

[0042] Monomer NIPAM, accounting for 56% of the total mass, 5.6g;

[0043] Crosslinking agent MBA, accounting for 1.5% of the total mass, 0.15g;

[0044] Photoinitiator TPO, accounting for 3.5% of the total mass, 0.35g;

[0045] Solvent DMSO, accounting for 39% of the total mass, 3.9g.

[0046] The preparation process is as follows:

[0047] (1) Mix 5.6g NIPAM, 0.15g MBA, 0.35g photoinitiator TPO and 3.9g DMSO, and perform ultrasonic vibration for 20min in a dark environment;

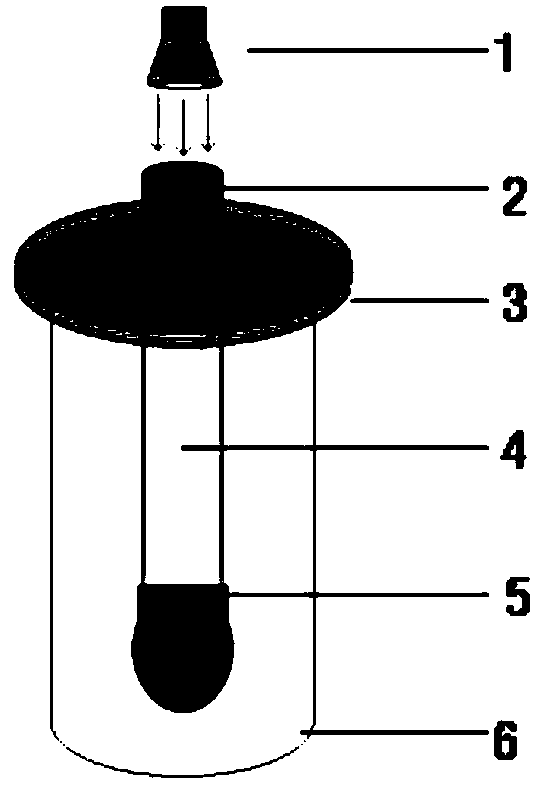

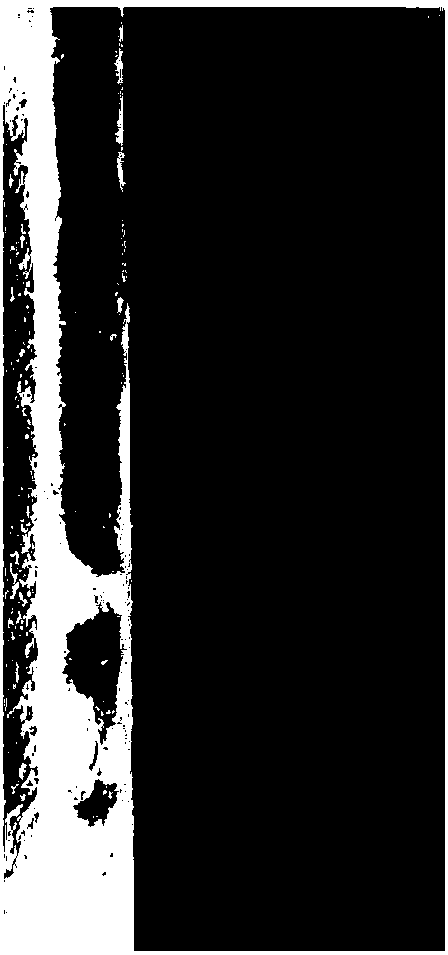

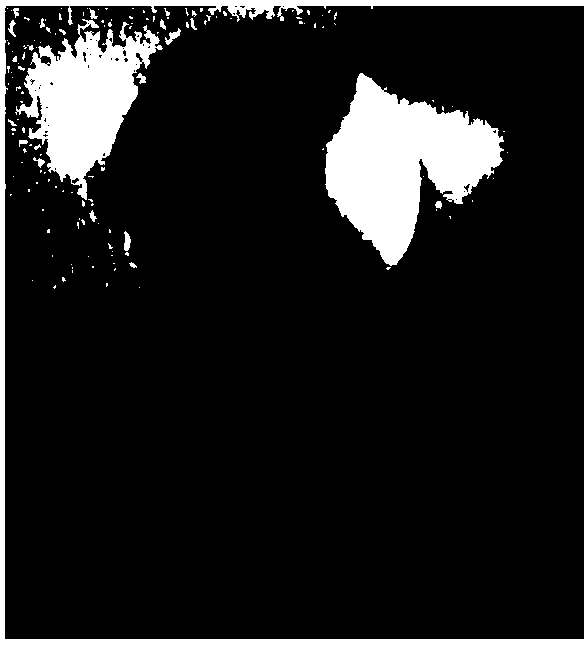

[0048] (2) Pour the mixed solution obtained in step (1) into figure 1 The reactor of the shown reaction device (a hollow glass tube with a rubber cap at one end, the size is an inner diameter of 8mm, and a length of 100mm), was left for 10 minutes, and the air bubbles in the glass tube were removed, and then it was placed under an ultraviolet light irradiation machine for 20 minutes. The...

Embodiment 2

[0072] Example 2: Preparation of Thermosensitive Hydrogel by Photofront Polymerization

[0073] Recipe ratio:

[0074] NIPAM, accounting for 56% of the total mass, 5.6g;

[0075] MBA, 1.5% of the total mass, 0.15g;

[0076] Photoinitiator 819, accounting for 3.5% of the total mass, 0.35g;

[0077] DMSO, accounting for 39% of the total mass, 3.9g.

[0078] The preparation process is as follows:

[0079] (1) Mix 5.6g NIPAM, 0.15g MBA, 0.35g photoinitiator 819 and 3.9g DMSO, and perform ultrasonic vibration for 20min in a dark environment;

[0080](2) Pour the mixed solution obtained in step (1) into a special reactor (same as Example 1) at a room temperature of 25°C and under the condition of avoiding light, and let it stand for 10 minutes to remove the air bubbles in the glass tube, and then put it Illuminate for 20 minutes under the ultraviolet light irradiation machine, and the light intensity is controlled at 5.0mW / cm 2 ;

[0081] (3) After the light is finished, take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com