Composite hydrogel, preparation method and application thereof

A composite hydrogel and gel water technology, which is applied in medical science, prosthesis, additive processing, etc., can solve the toxicity of chemical cross-linking agents, the instability of hyaluronic acid, and the inability to promote the complete healing of cartilage defects and the complete regeneration of cartilage and other problems, to achieve the effect of convenient operation, good application prospects, and good cartilage repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

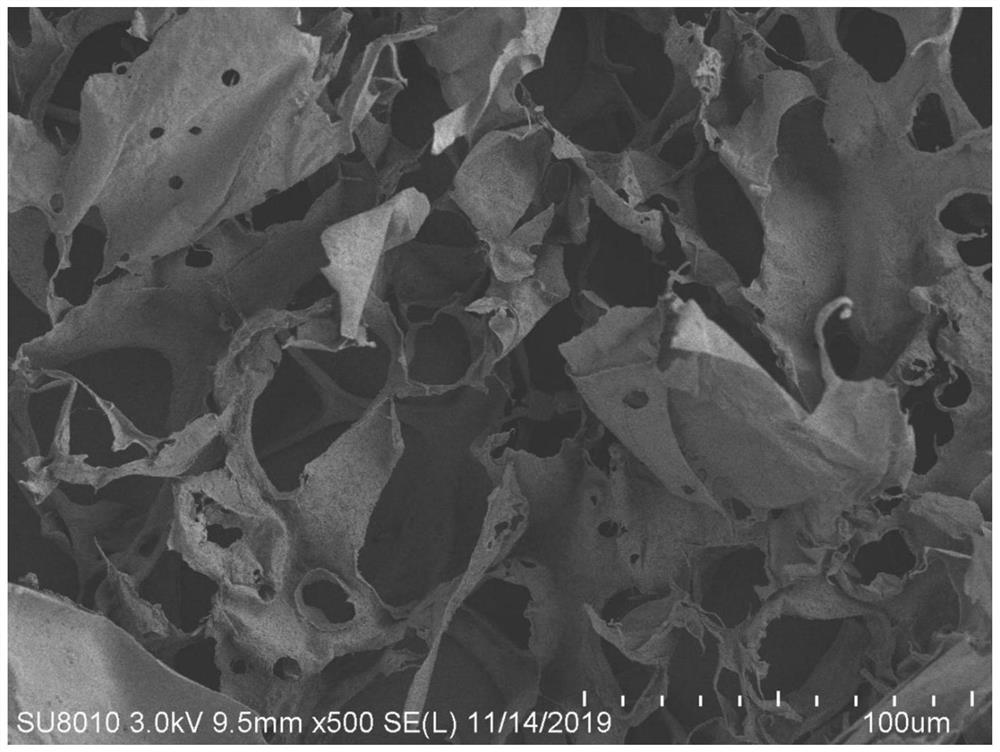

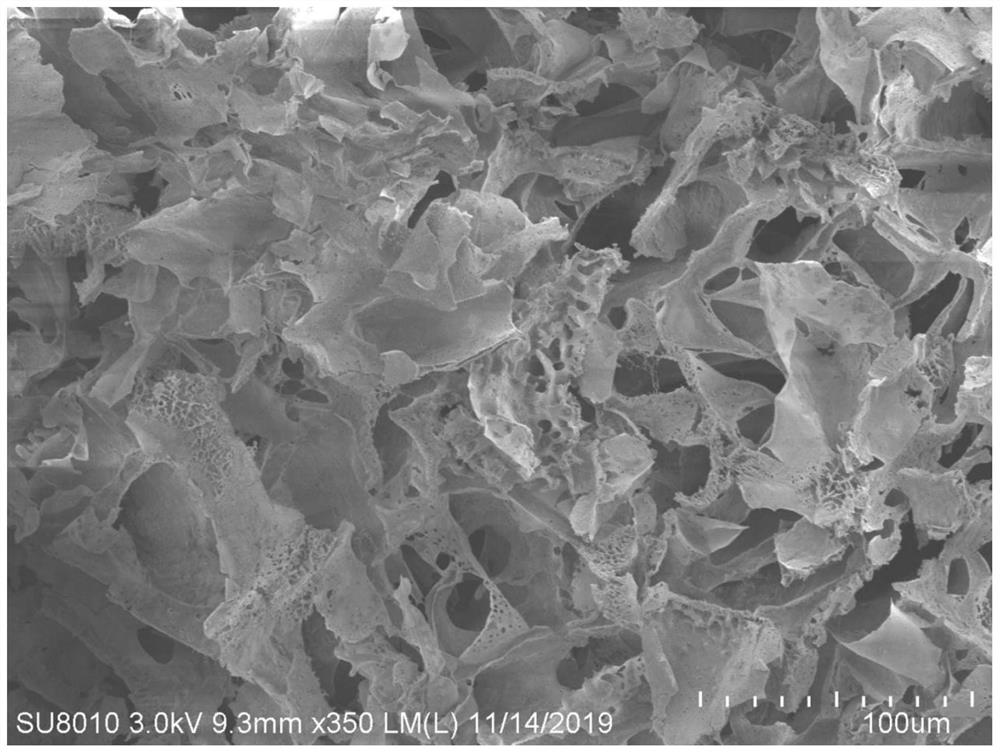

[0049] Weigh 11g of NaOH and 4g of urea into a beaker, add 85g of water to dissolve, and pre-cool to -18°C. Weigh 2g of chitin powder and disperse in it, place it in the freezer of the refrigerator to freeze, and stir it in time during the freezing process to ensure that the chitin is evenly dispersed. After 48 hours, it was taken out and thawed into a clear and translucent aqueous solution. Add 2.9g of 1,2-propylene oxide to 100g of 2% chitin solution at 2°C, raise the temperature to 5°C, react for 24h, then raise the temperature to 15°C, and react for 6h. The pH of the reaction system was adjusted to 7 with HCl to terminate the reaction. Dialyze and freeze-dry to obtain white spongy hydroxypropyl chitin, which is HPCH gel powder.

[0050] Accurately weigh 120.0mg of HPCH gel powder, put it into a 10mL small beaker, add 20mL deionized water into the beaker, stir magnetically for 10min to disperse evenly, and place it in a refrigerator at 8°C overnight. After HPCH is fully ...

Embodiment 2

[0052] The preparation method of the HPCH gel powder in this embodiment is the same as that in Example 1. Accurately weigh 120.0mg of HPCH gel powder, put it into a 10mL small beaker, add 20mL deionized water to the two beakers, stir magnetically for 10min to disperse evenly, and place it in a refrigerator at 8°C overnight. After HPCH is fully swollen, weigh 20 mg HA and add them to two beakers, stir evenly with a glass rod, submerge the bottom of the beakers into an ultrasonic cleaning machine, and ultrasonically mix for 30 minutes. At this time, HA / HPCH gel aqueous dispersions with a mass ratio of 1:6 were prepared. Pour the gel dispersion into a round glass dish, put it in a -20°C refrigerator stably, take it out after 6 hours, put it in a freeze dryer, freeze dry it for 12 hours, and get m(HA) / m(HPCH)=1:6 The gel powder of mass ratio is named as HA / HPCH-1. Accurately weigh 40.0mg of gel powder HA / HPCH-1 in a 5mL centrifuge tube, add 2mL of the above-prepared PBS into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com