Thermosensitive graphite oxide composite aquagel and preparation method thereof

A technology of composite hydrogel and oxide stone, which is applied in the field of polymer materials, can solve the problems of less temperature-sensitive hydrogel and complicated composite hydrogel methods, and achieve the goal of accelerating the dispersion of solids, simple methods, and reduced difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

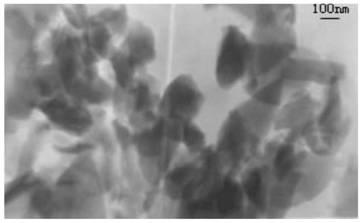

Image

Examples

Embodiment 1

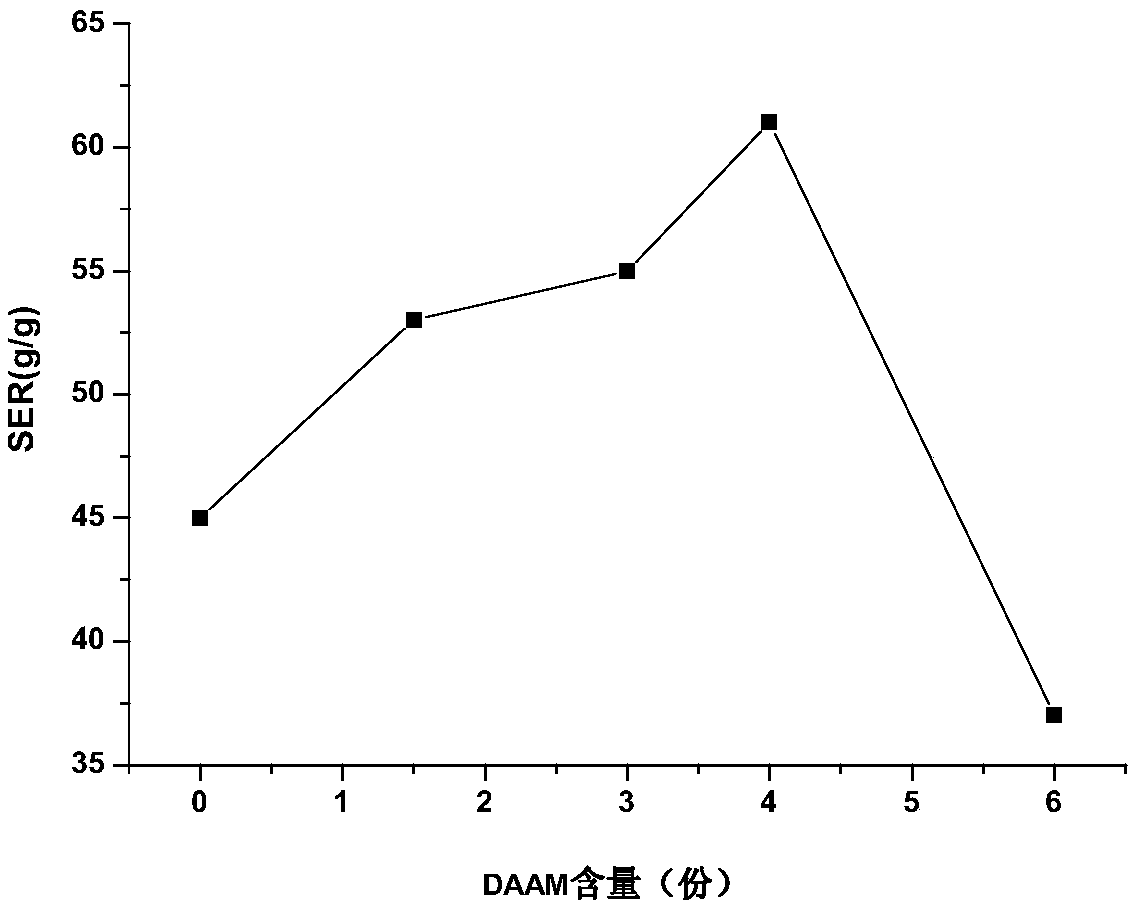

[0026] (1) a kind of thermosensitive graphite oxide composite hydrogel and preparation method thereof according to claim 1, the composite hydrogel preparation process is: other conditions are as described in claim 1, get 0.7g graphite oxide, ultrasonic Disperse according to the corresponding shortest duration described in claim 1, add respectively DAAM by graphite oxide DAAM mass ratio 0, 1:1.5, 1:3, 1:4, 1:6 ratio, add monomer gross mass 0.3% Joint agent to prepare graphite oxide composite hydrogel.

[0027] (2) Determination of water absorption: test according to GBT8810-2005; it is characterized in that the equilibrium swelling rate is calculated according to the following formula:

[0028]

[0029] In the formula:

[0030] m i —mass of composite hydrogel after long-term water absorption and saturation, g;

[0031] M——the mass of dry gel after drying in an oven, g.

Embodiment 2

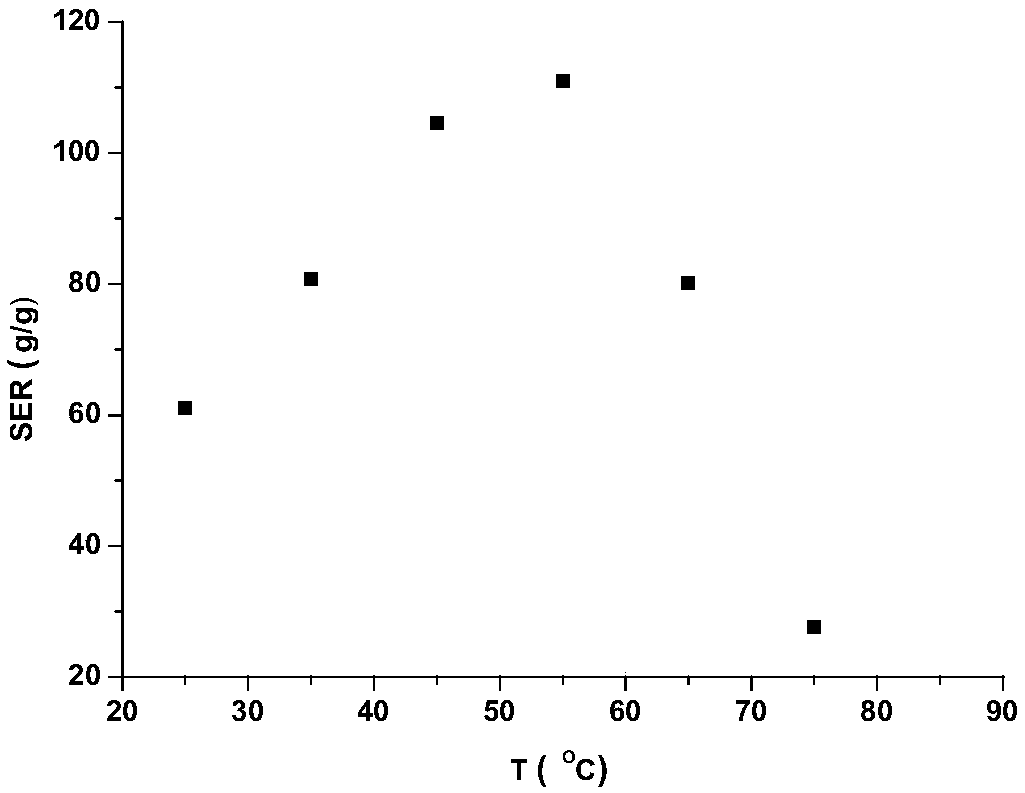

[0033] Temperature sensitivity test: take the same amount of composite hydrogel (graphite oxide DAAM mass ratio 1:4, ultrasonic dispersion according to the corresponding shortest time as described in claim 1, prepared by 0.3% cross-linking agent for total monomer mass), soak in The temperatures were 25°C, 35°C, 45°C, 55°C, 65°C, and 75°C in deionized water. After reaching the swelling equilibrium, test the equilibrium swelling rate under the above temperature conditions.

Embodiment 3

[0035] Other conditions are as described in claim 1, get 0.7g graphite oxide, DAAM is added according to 4 times of graphite oxide mass, ultrasonic dispersion is according to claim 1 corresponding shortest duration, crosslinking agent consumption is respectively 1.0 of the total mass of the monomer %, 0.7%, 0.5%, 0.3%, and 0.2% prepared composite hydrogels, respectively, to measure their equilibrium swelling rates at 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com