Production method of nano-attapulgite composite catalyst for 3-methylpyridine preparation

A nano-attapulgite and composite catalyst technology, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of rare applications, low product purity, and difficult separation, and achieve reduction performance Excellent, good adsorption, good pore permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

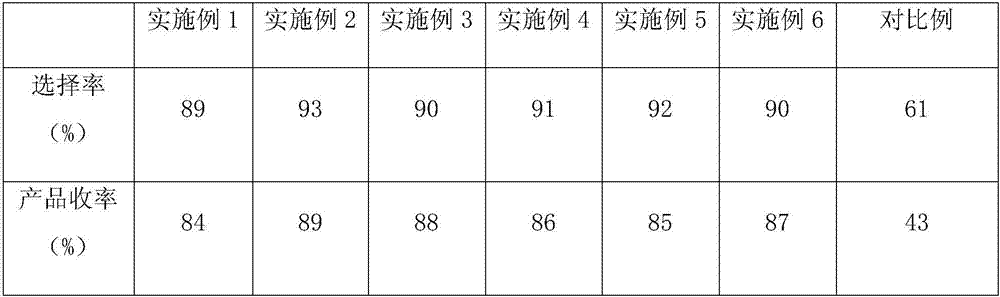

Examples

Embodiment 1

[0023] (1) Add nano-attapulgite raw ore into 1mol / L hydrochloric acid aqueous solution, separate and wash, then wash with 0.1mol / L silver nitrate solution until there is no chloride ion, then heat and boil with distilled water for 30min, and centrifugally wash to obtain acid-modified nano-attapulgite.

[0024] (2) Mix the acid-modified nano-attapulgite and zeolite molecular sieve with a mass ratio of 1:4, add 0.005g / mL aluminum hydroxide aqueous solution, mix well, dry and grind, and calcinate at 950°C 1h, to obtain nano-attapulgite composite carrier.

[0025] (3) The nano-attapulgite composite carrier is added to the silica sol with a particle size of 150-250nm, fully adsorbed, dried and ground to obtain a nano-attapulgite composite catalyst for the preparation of 3-picoline, wherein, The content of silica sol is 0.1 wt%, and the content of alumina is 20 wt%.

Embodiment 2

[0027] (1) Add nano-attapulgite raw ore into 1.5mol / L hydrochloric acid aqueous solution, separate and wash, then wash with 0.2mol / L silver nitrate solution until there is no chloride ion, then heat and boil with distilled water for 60min, and centrifugally wash to obtain acid modified Sexual nano attapulgite.

[0028] (2) Mix acid-modified nano-attapulgite and zeolite molecular sieve with a mass ratio of 1:10, add 0.01g / mL aluminum hydroxide aqueous solution, mix well, dry and grind, and calcinate at 1000°C 2h, the nano-attapulgite composite carrier was obtained.

[0029] (3) The nano-attapulgite composite carrier is added to the silica sol with a particle size of 150-250nm, fully adsorbed, dried and ground to obtain a nano-attapulgite composite catalyst for the preparation of 3-picoline, wherein, The content of silica sol was 1 wt%, and the content of alumina was 35 wt%.

Embodiment 3

[0031] (1) Add nano-attapulgite raw ore into 1.2mol / L hydrochloric acid aqueous solution, separate and wash, then wash with 0.15mol / L silver nitrate solution until there is no chloride ion, then heat and boil with distilled water for 40min, and centrifugally wash to obtain acid modified Sexual nano attapulgite.

[0032] (2) Mix the acid-modified nano-attapulgite and zeolite molecular sieve with a mass ratio of 1:5, add 0.007g / mL aluminum hydroxide aqueous solution, mix well, dry and grind, and calcinate at 970°C After 1.5 hours, the nano-attapulgite composite carrier was obtained.

[0033] (3) The nano-attapulgite composite carrier is added to the silica sol with a particle size of 150-250nm, fully adsorbed, dried and ground to obtain a nano-attapulgite composite catalyst for the preparation of 3-picoline, wherein, The content of silica sol is 0.5 wt%, and the content of alumina is 25 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com