Patents

Literature

61results about How to "Consistent pore size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

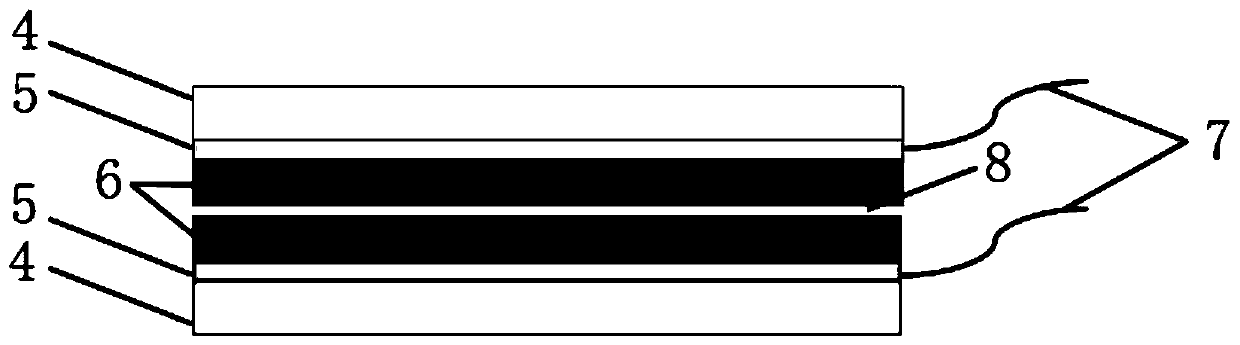

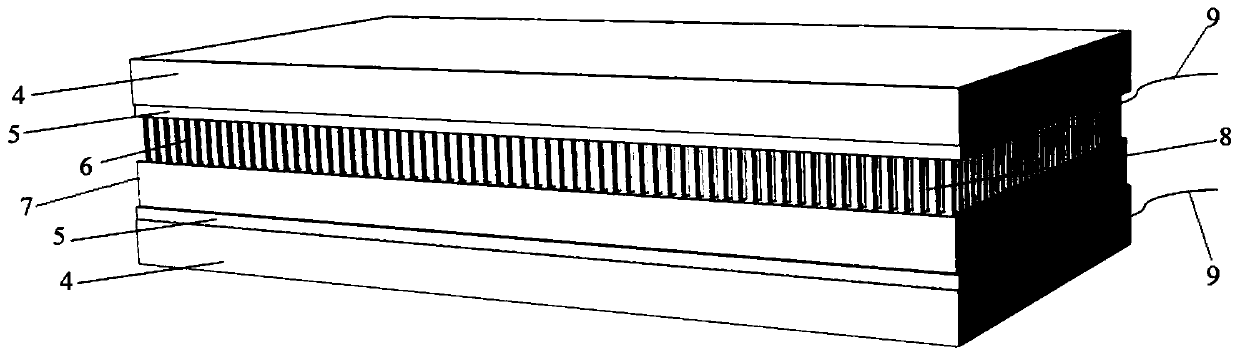

Flexible capacitive pressure sensor and preparation method thereof

ActiveCN109781311AHigh dielectric constantEasy to stretchForce measurementInteraction systemsHysteresis

The invention relates to the technical field of capacitive pressure sensors, in particular to a flexible capacitive pressure sensor and a preparation method thereof. The sensor comprises a top electrode, a bottom electrode, composite material dielectric layers and a wire, wherein the top electrode and the bottom electrode are each composed of a substrate of which the surface is provided with a conductive polymer layer; the wire extending to the outsides of the conductive polymer layers is embedded in the conductive polymer layers; the composite material dielectric layers are arranged on the surfaces of the conductive polymer layers on the top electrode and the bottom electrode; the flexible capacitive pressure sensor is formed by combining the surfaces, provided with composite material dielectric layers, of the top electrode and the bottom electrode in a face-to-face mode. The prepared high-performance flexible capacitive pressure sensor is high in sensitivity, small in hysteresis andgood in repeatability, the preparation cost is low, the method is simple, large-scale production can be achieved, and the sensor can be widely applied to the fields of a human-computer interaction system, a detection sensor system, medical health detection equipment and the like.

Owner:三三智能科技(日照)有限公司

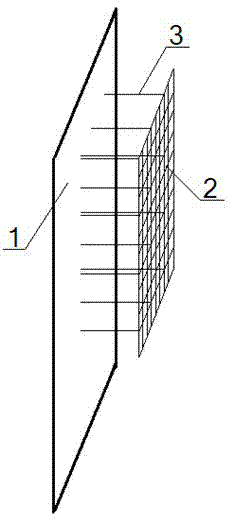

Transformation and construction method used for facing bare concrete of existing building outer wall

ActiveCN103470067AMeet the stiffness requirementsEasy to fixBuilding repairsForms/shuttering/falseworksRebarMaterials science

The invention discloses a transformation and construction method used for facing bare concrete of an existing building outer wall. The method comprises the steps of processing of a formwork, binding of reinforcing steel bars, installation of bare formwork, casting of the bare concrete, removal of the bare formwork, maintenance of the bare concrete, cutting of visible joints, blocking and repairing of split bolt holes and coating of protective paint. According to the method, a steel formwork of which the inner surface is attached to a stainless steel board servers as the bare formwork,, reinforcing steel bar meshes serve as structural bars, the self-compaction bare concrete serves as a bare concrete mixture, and the construction of a thin-type bare concrete faced wall is finished in the mode that many times of rolling over construction are conducted from the bottom to the top of the existing building outer wall. The method not only improves the appearance quality of the bare concrete, but also ensures close integration between the newly-cast bare concrete and the existing building outer wall.

Owner:WUDA JUCHENG STRUCTURE CO LTD

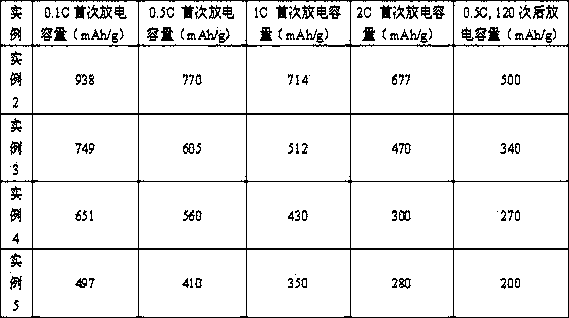

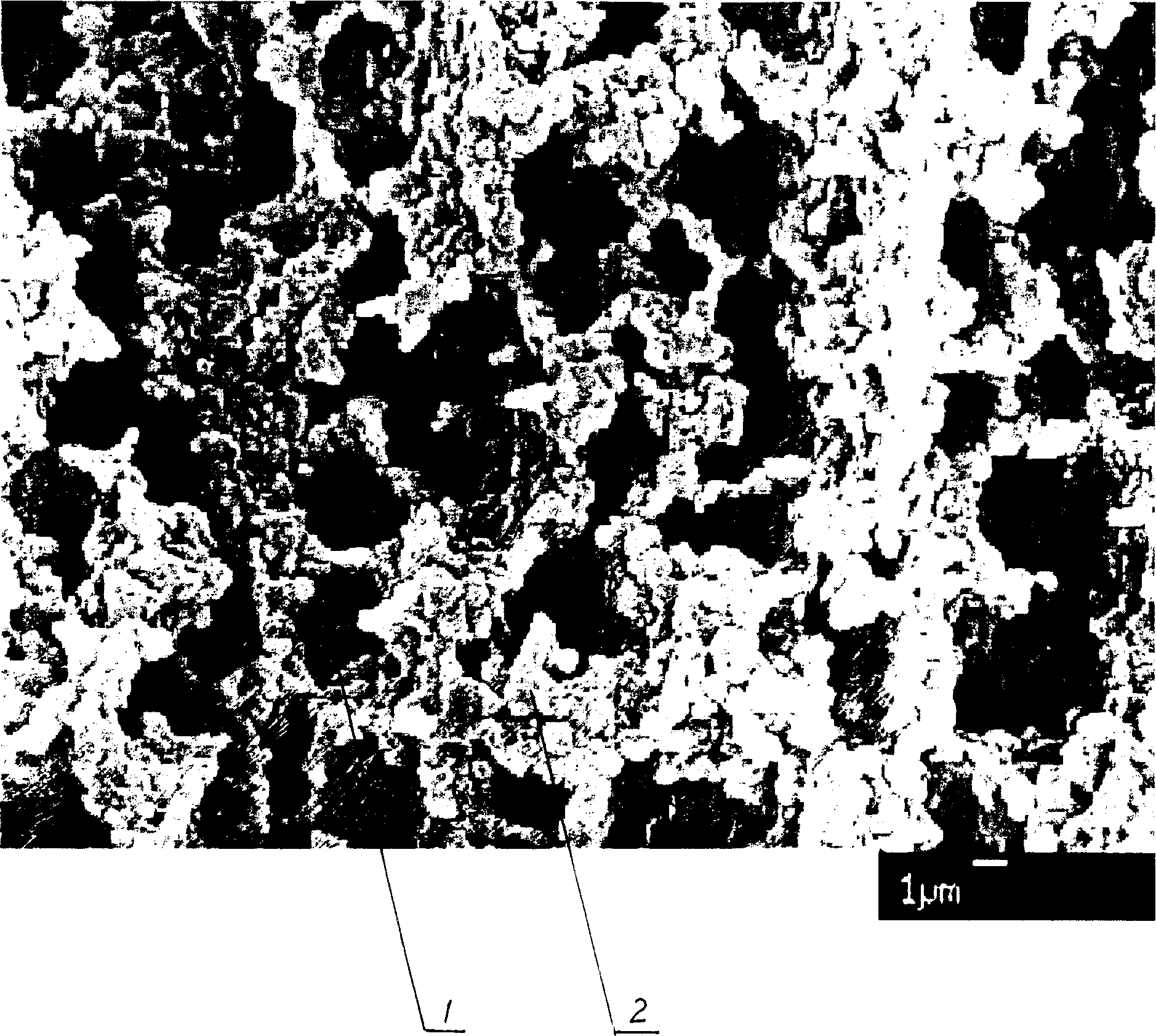

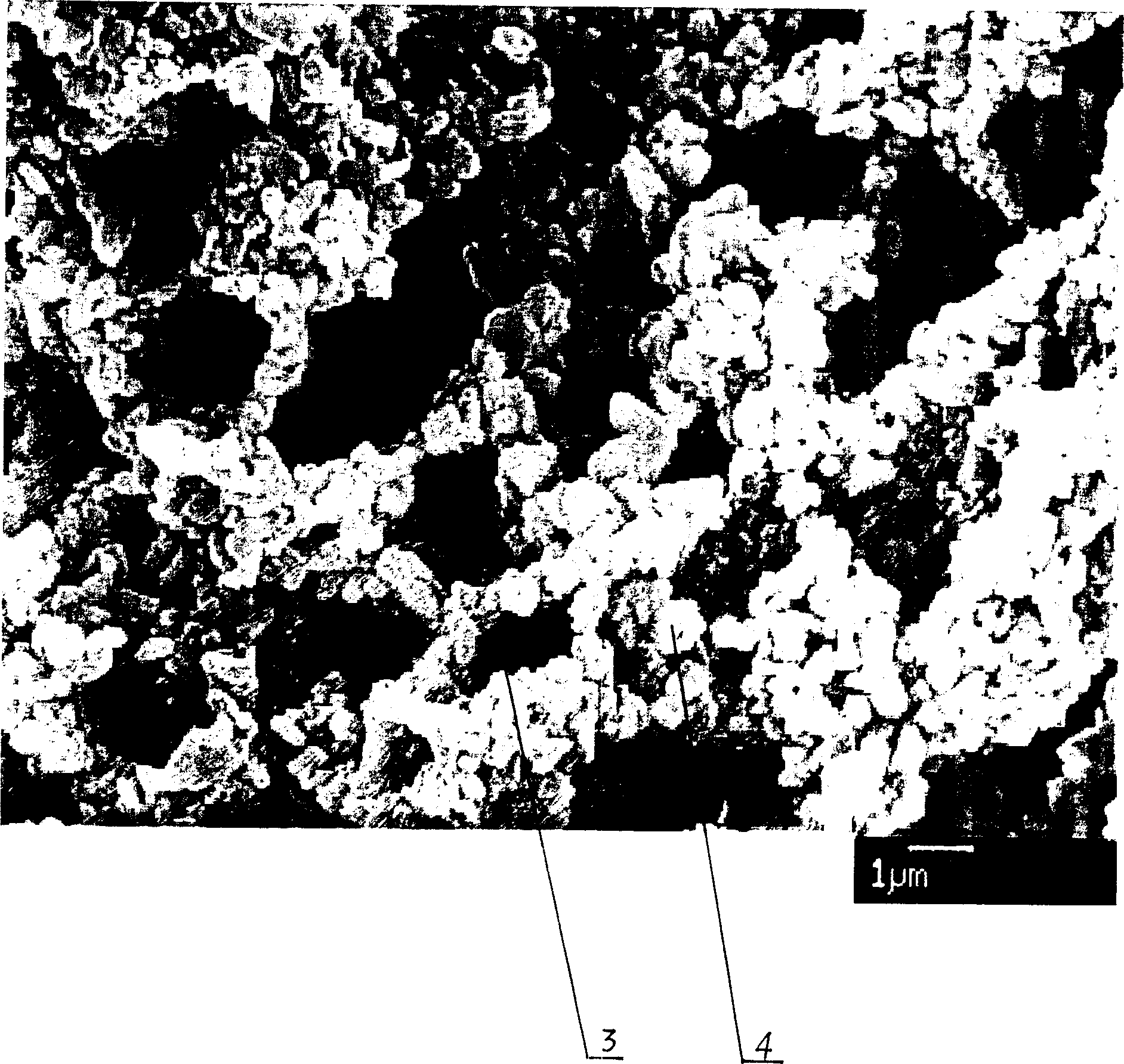

TiO2 coated sulfur/ordered mesoporous carbon composite cathode material and preparation method thereof

InactiveCN104269559ALower transmission impedanceImprove conductivityCell electrodesComposite cathodeHigh energy

The invention discloses a TiO2 coated sulfur / ordered mesoporous carbon composite cathode material and a preparation method thereof as well as the application thereof in a secondary aluminum battery. The cathode material consists of a sulfur active substance, ordered mesoporous carbon and TiO2 and is characterized in that the ordered mesoporous carbon has a highly-ordered three-dimensional pore structure, is provided with a conductive network and provides a large number of adhesion area for the active substance and a conductive channel; a TiO2 coating layer has a very effective shuttle effect of blocking polysulfide. The preparation method of the TiO2 coated sulfur / ordered mesoporous carbon composite cathode material comprises the following steps: compounding the ordered mesoporous carbon and sulfur and then TiO2 coating on an outer layer. The preparation method has the advantages of simple process, low cost, no toxic raw material used, environmental friendliness, high energy density and high sulfur utilization rate, and the rate performance and the cycle life of the secondary aluminum battery are greatly improved.

Owner:NANJING ZHONGCHU NEW ENERGY

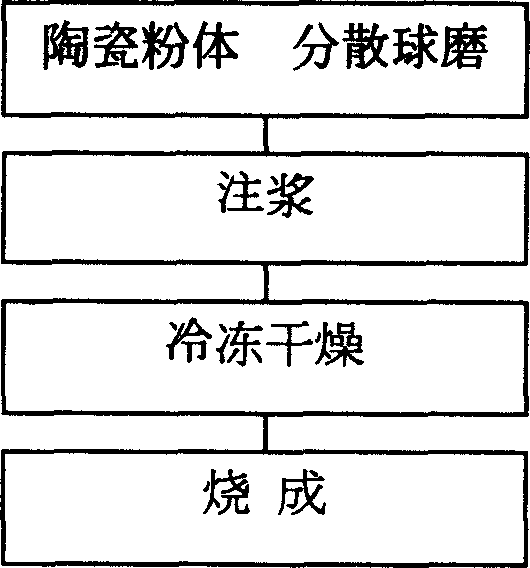

Method for preparing poruos material in micro-nano magnitude

The present invention relates to a preparation method of micrometer-nanometer porous material. Said preparation method includes the following steps: preparing ceramic pulp; using 5 wt%-90 wt% of ceramic powder body, 0.1 wt%-5 wt% of dispersing agent, 1 wt%-20 wt% of sintering additive, and 5 wt%-90 wt% of solvent, uniformly mixing distilled water and ground dispersing agent, then adding ceramic powder body and sintering additive, ball-grinding, and pouring the mixed ceramic pulp into mould, placing said mould into refrigerating tank, refrigerating and forming, mainly the frozen ceramic blank body into freeze-drying machine, freeze-drying, placing the dried ceramic blank body into sintering furnace, sintering so as to obtain the invented micrometer-nanometer porous ceramic material.

Owner:曾宇平 +1

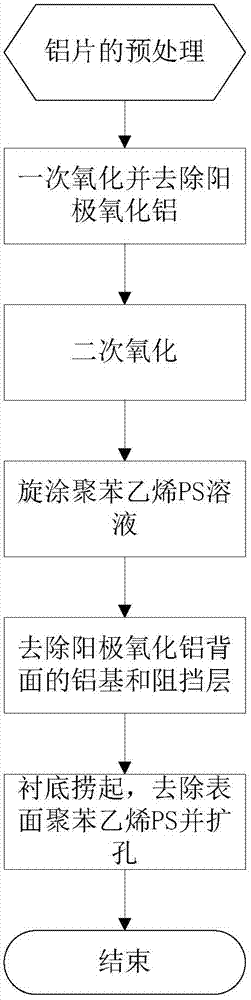

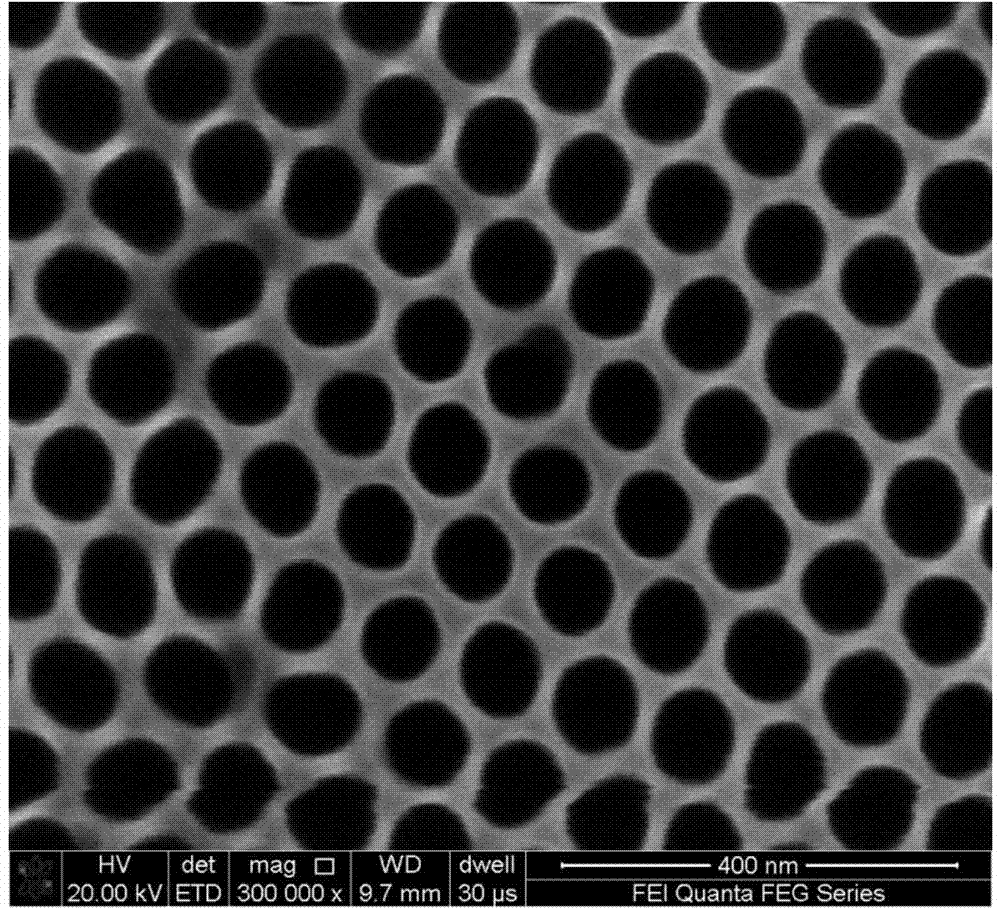

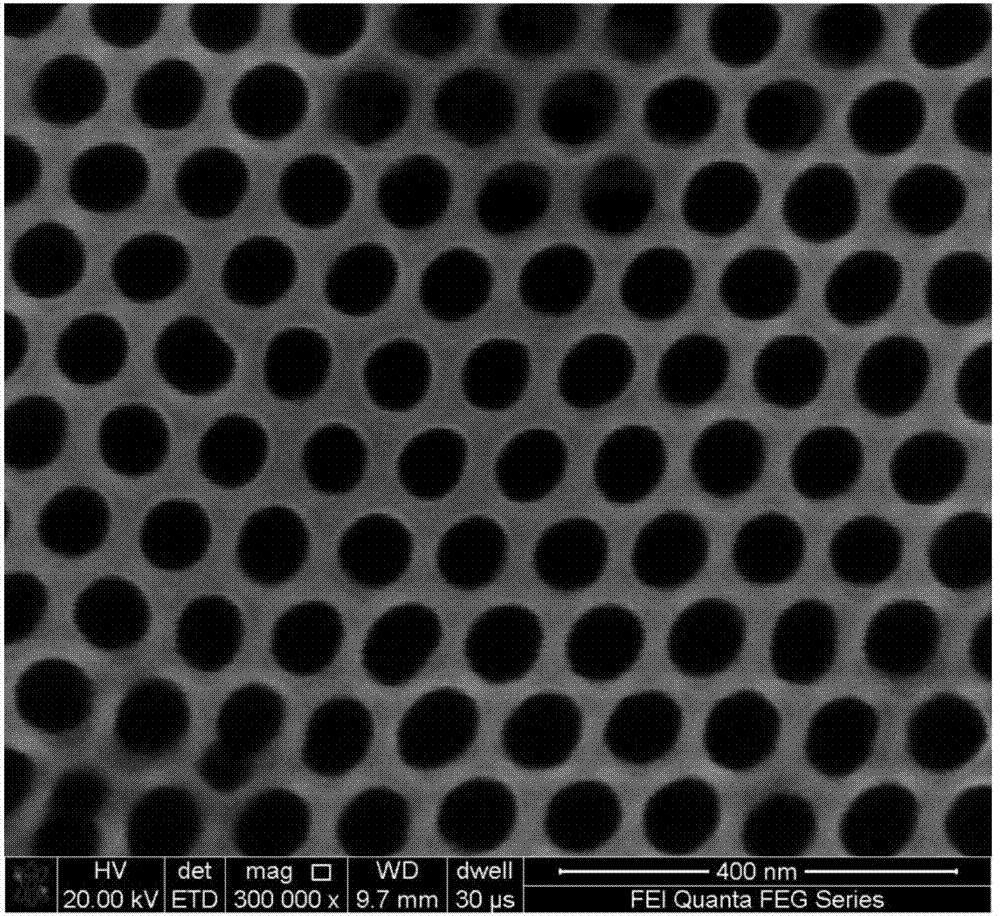

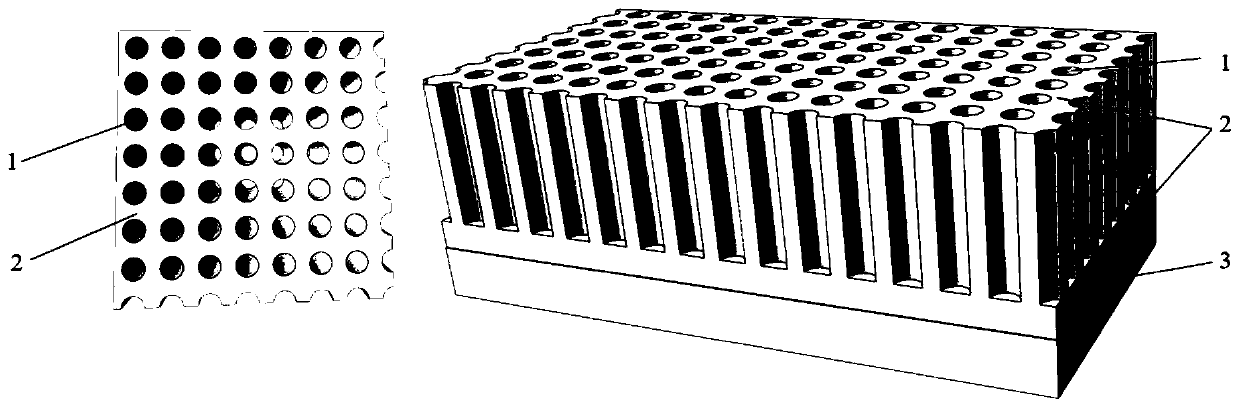

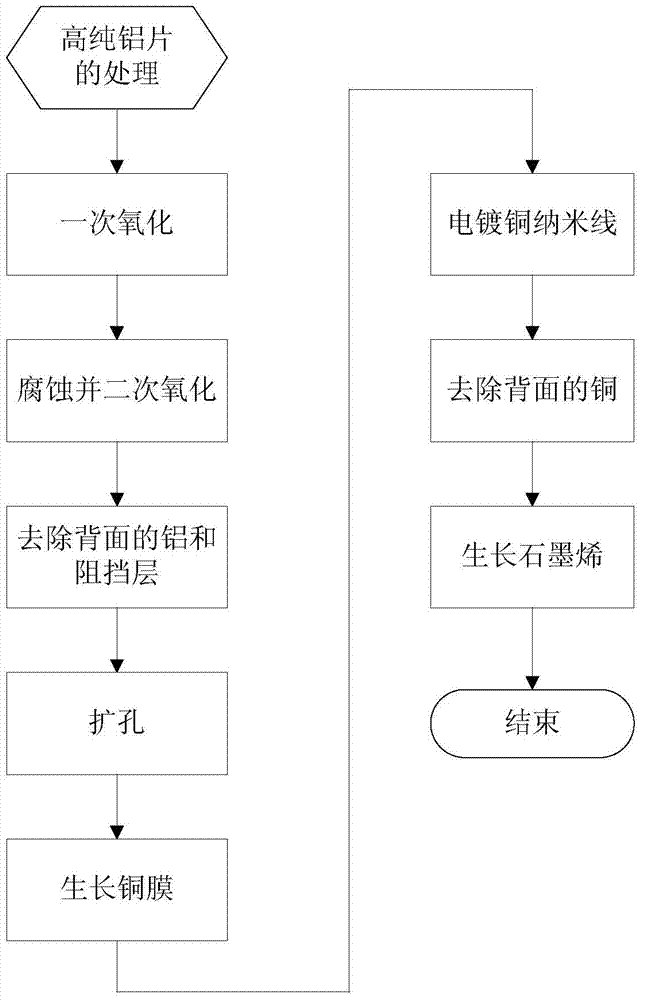

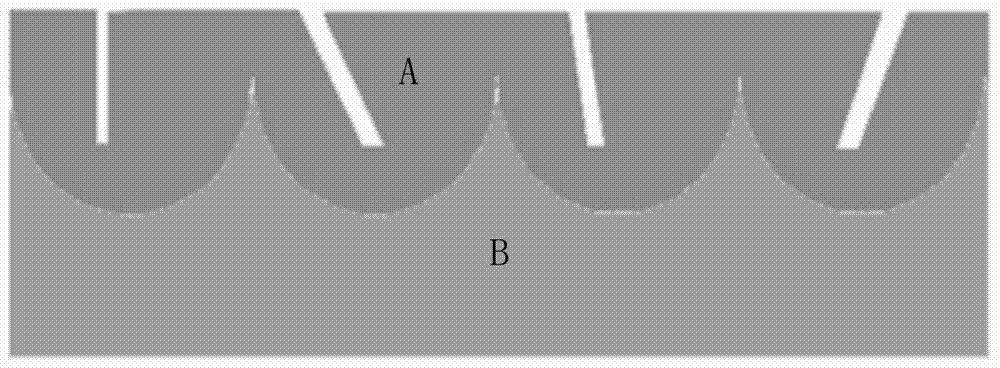

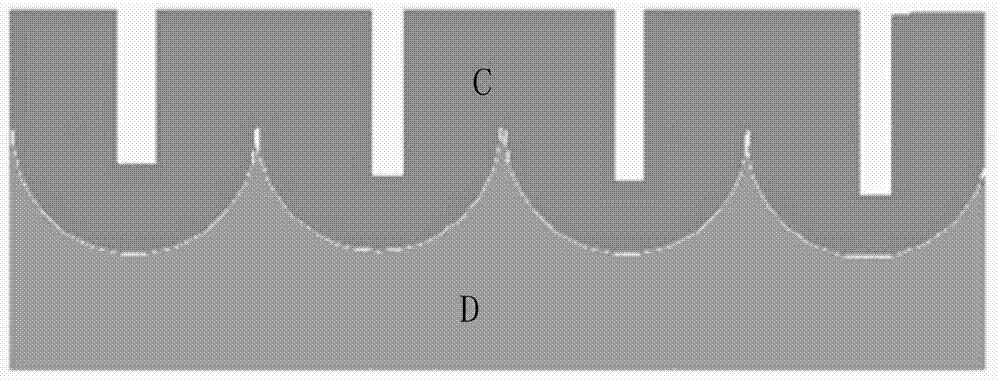

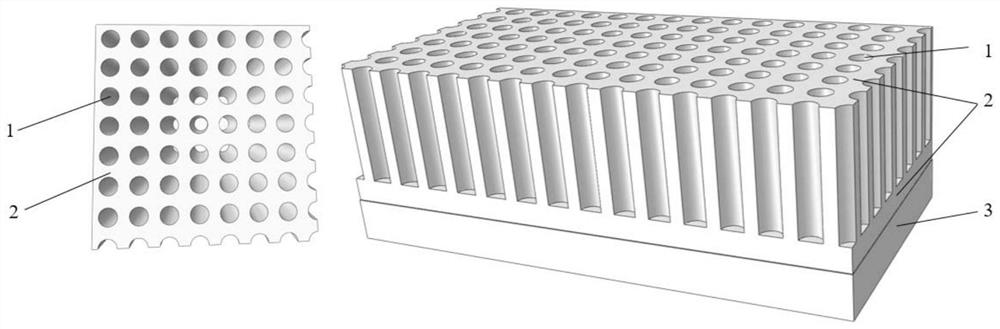

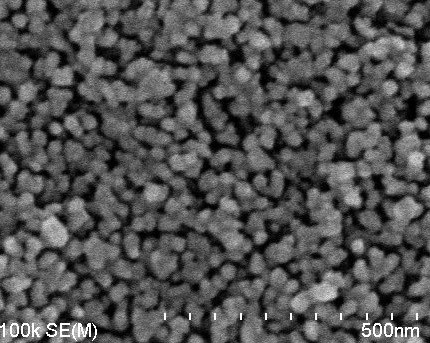

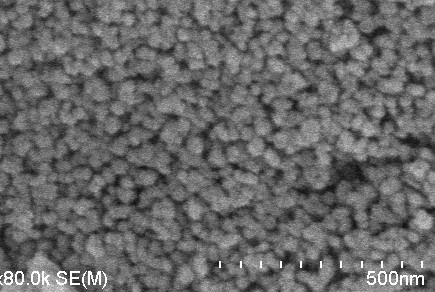

Method for preparing and transferring ultrathin perforated anode alumina template

InactiveCN104726920AEvenly distributedConsistent pore sizeSurface reaction electrolytic coatingMicrometerPolystyrene

The invention discloses a method and technique for preparing and transferring an ultrathin perforated anode alumina template and aims to mainly solve the problem that an existing anode alumina template cannot be used for directly preparing a mono-crystal nanometer point array. The method comprises the following steps: oxidizing an electrochemically-polished aluminum plate twice in an oxalic acid solution; oxidizing twice again, spin-coating polystyrene PS on the surface of anode alumina and removing an aluminum base and a barrier layer from the bottom surface of the anode alumina to obtain a perforated anode alumina template; finally transferring the template to a substrate of a subsequent required growth material; removing the spin-coated polystyrene PS from the surface by using chloroform to obtain a base plate of the perforated anode alumina template. The base plate of the perforated anode alumina template, obtained by the method disclosed by the invention, is uniformly distributed and uniform in hole diameter; the thickness of the template is nanometer grade; in comparison with the micrometer-grade thickness in the prior art, the thickness of the template prepared by the method disclosed by the invention can guarantee the adhesion between the template and the substrate, and the template can be used for preparing the mono-crystal nanometer point array.

Owner:XIDIAN UNIV

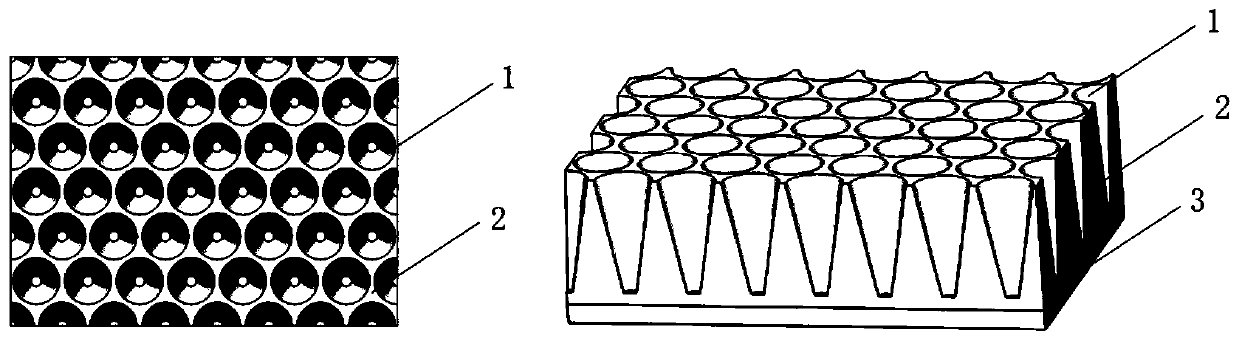

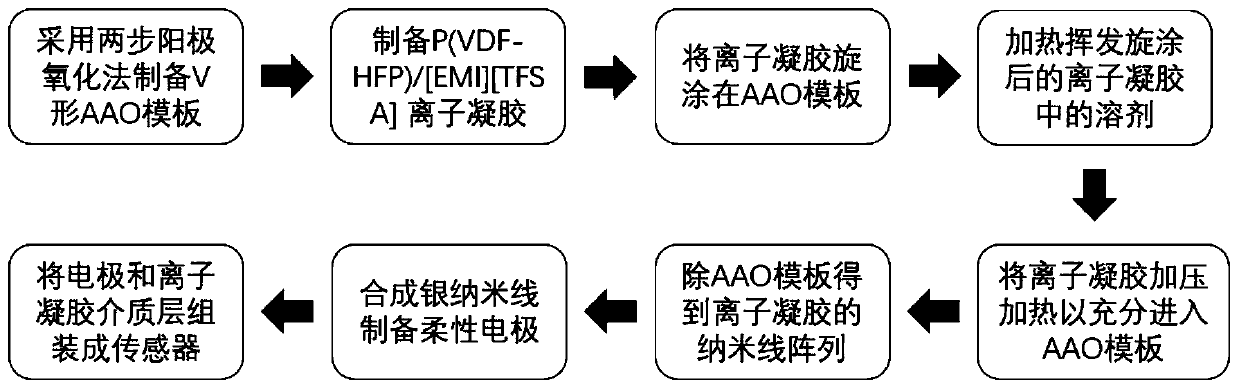

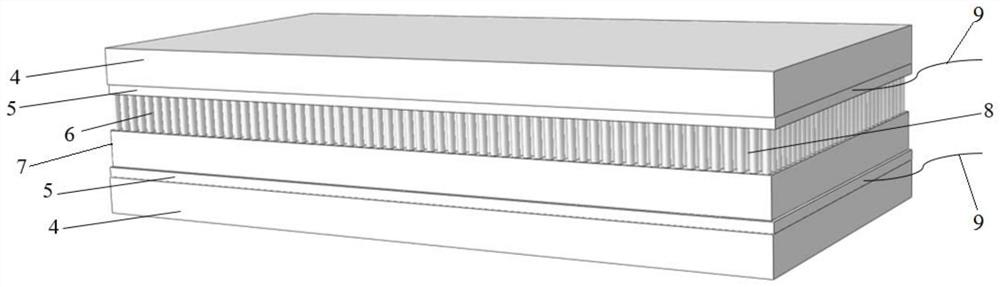

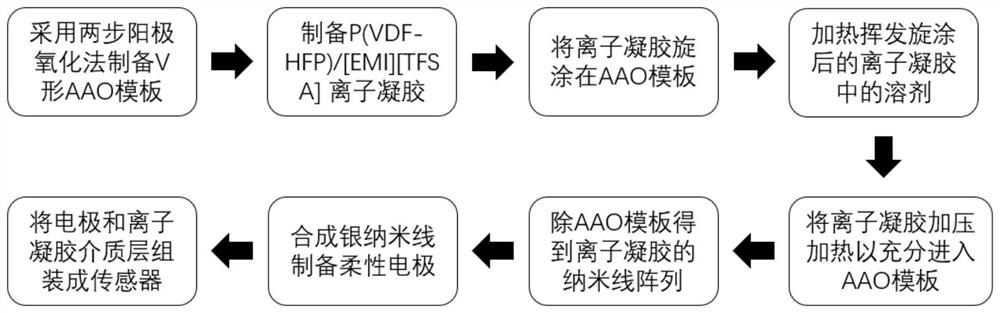

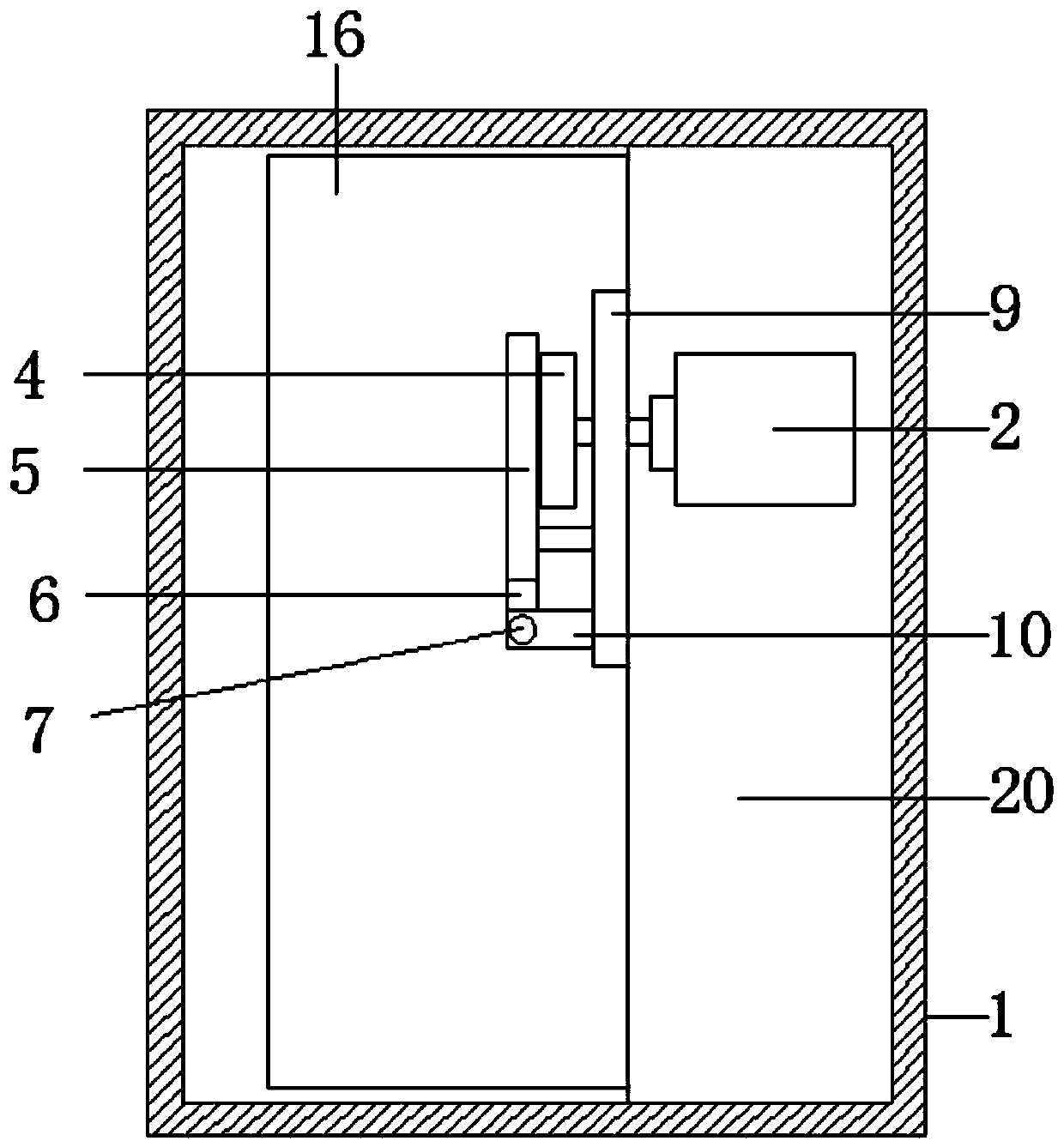

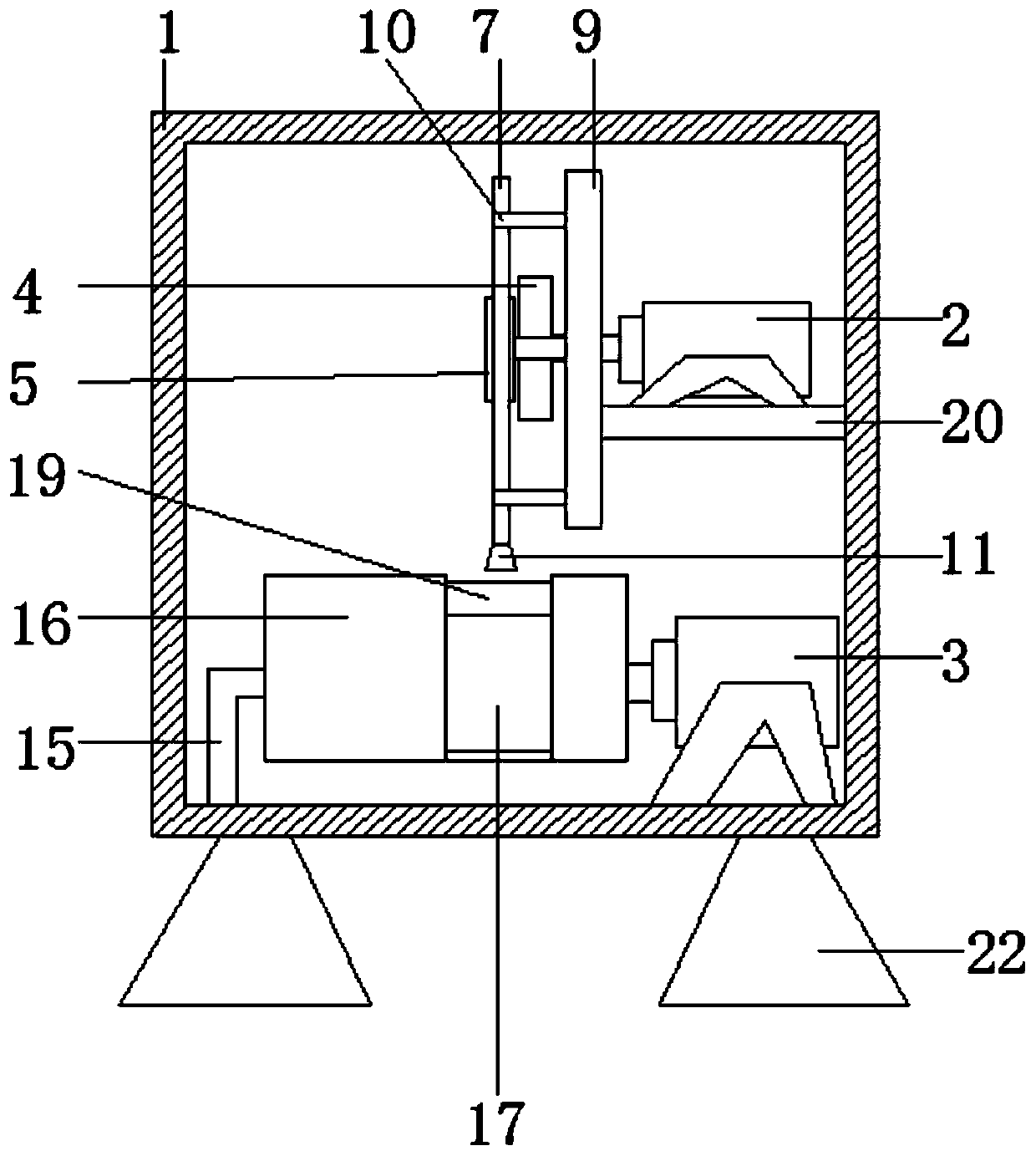

Capacitive pressure sensor and preparation method thereof

ActiveCN109781312AHigh sensitivityHigh dielectric constantForce measurementHysteresisCapacitive pressure sensor

The invention belongs to the technical field of capacitive pressure sensors, and particularly relates to a capacitive pressure sensor and a preparation method thereof. The sensor comprises electrodes,an ionic gel dielectric layer and wires, wherein the electrode is composed of a substrate of which the surface is provided with a silver nanowire layer; a wire extending to the outside of the silvernanowire layer is embedded in the silver nanowire layer; the ionic gel dielectric layer is arranged on the surfaces of the silver nanowire layers on the top electrode and the bottom electrode; the structure of the ionic gel dielectric layer is as follows: columnar ionic gel is distributed on the surface of a substrate layer; wherein the substrate layer in the ionic gel dielectric layer is arrangedon the silver nanowire layer of one electrode, and the silver nanowire layer of the other electrode is arranged on the columnar ionic gel in the ionic gel dielectric layer. The prepared sensor is high in sensitivity, small in hysteresis and good in repeatability, and can be widely applied to electronic skin, wearable products, implantation equipment and multifunctional sensor systems.

Owner:三三智能科技(日照)有限公司

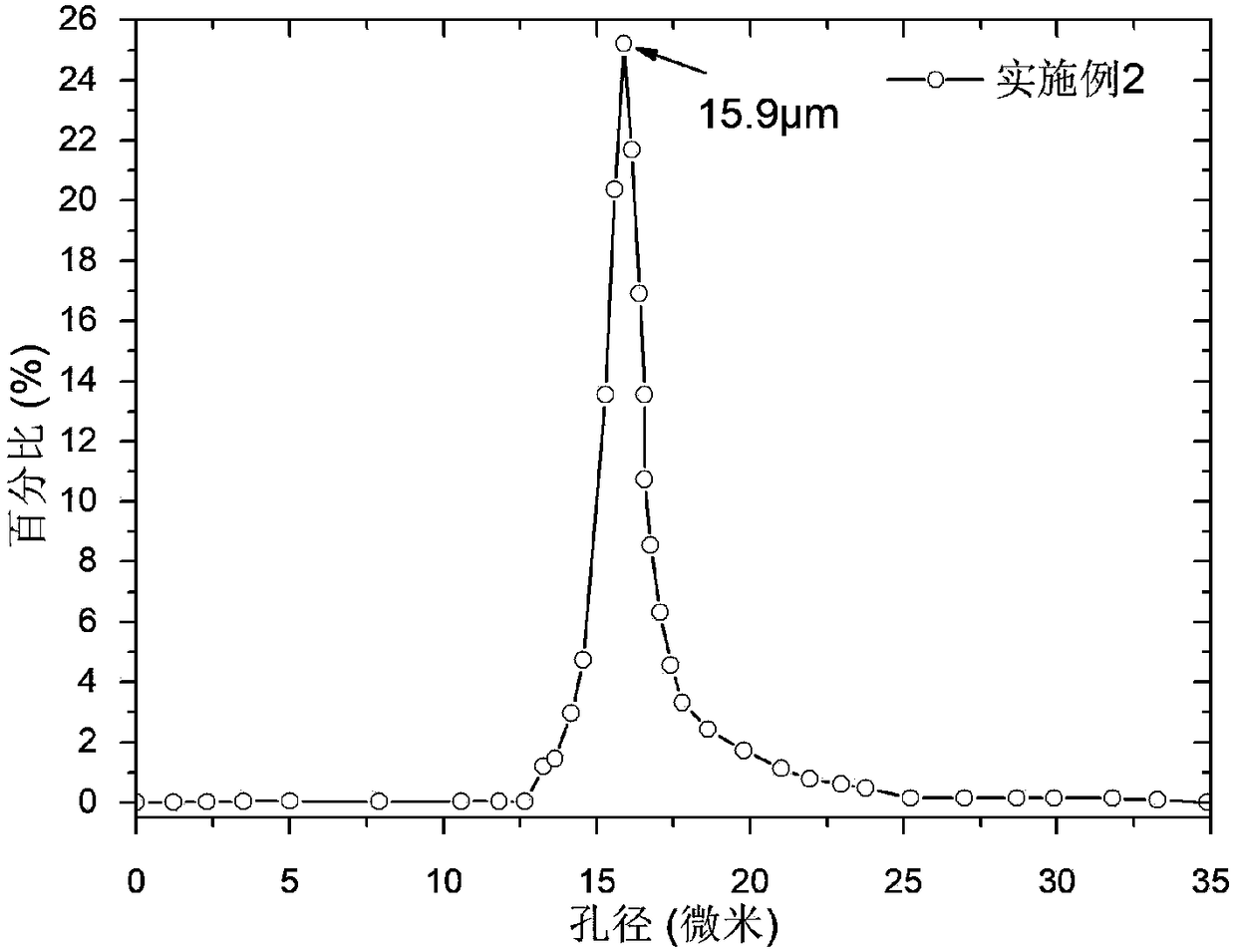

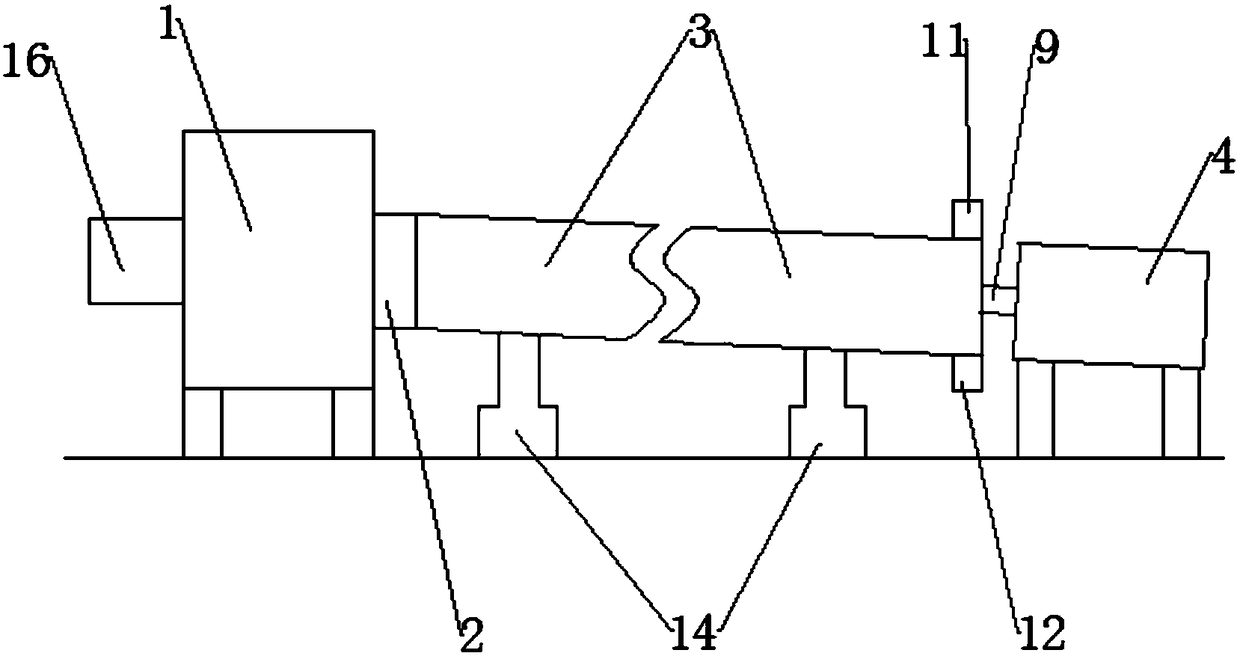

Technology for preparing micropore pipe through semi-molten continuous extrusion of high molecular powder

The invention relates to a technology for preparing a micropore pipe through semi-molten continuous extrusion of high molecular powder. The technology is characterized by comprising the following steps: (1) feeding solid powdered material in a screw extruding device through a hopper; (2) heating a barrel entering the screw extruding device, and performing initial compaction by a threaded rod at the same time so as to enable materials to be in a semi-molten state; (3) feeding the material in a handpiece for further compaction; (4) feeding the materials in a mould cavity of a neck mould of the screw extruding device to be tubular, determining inner and outer diameters under the effect of a vacuum cooling forming sleeve, and initially cooling; (5) cutting through a cutting device to obtain the micropore pipe. According to the technology, the high molecular powder is continuously extruded and formed when being in semi-molten state and the produced product does not need to be subjected to aftertreatment simultaneously when production of micropore pipes is realized, so that the production efficiency is greatly improved. According to the technology, a solvent is not used, and thus the micropore pipe is beneficial to environmental protection and health of operators.

Owner:SUZHOU KAHO POLYMER TECH CO LTD +1

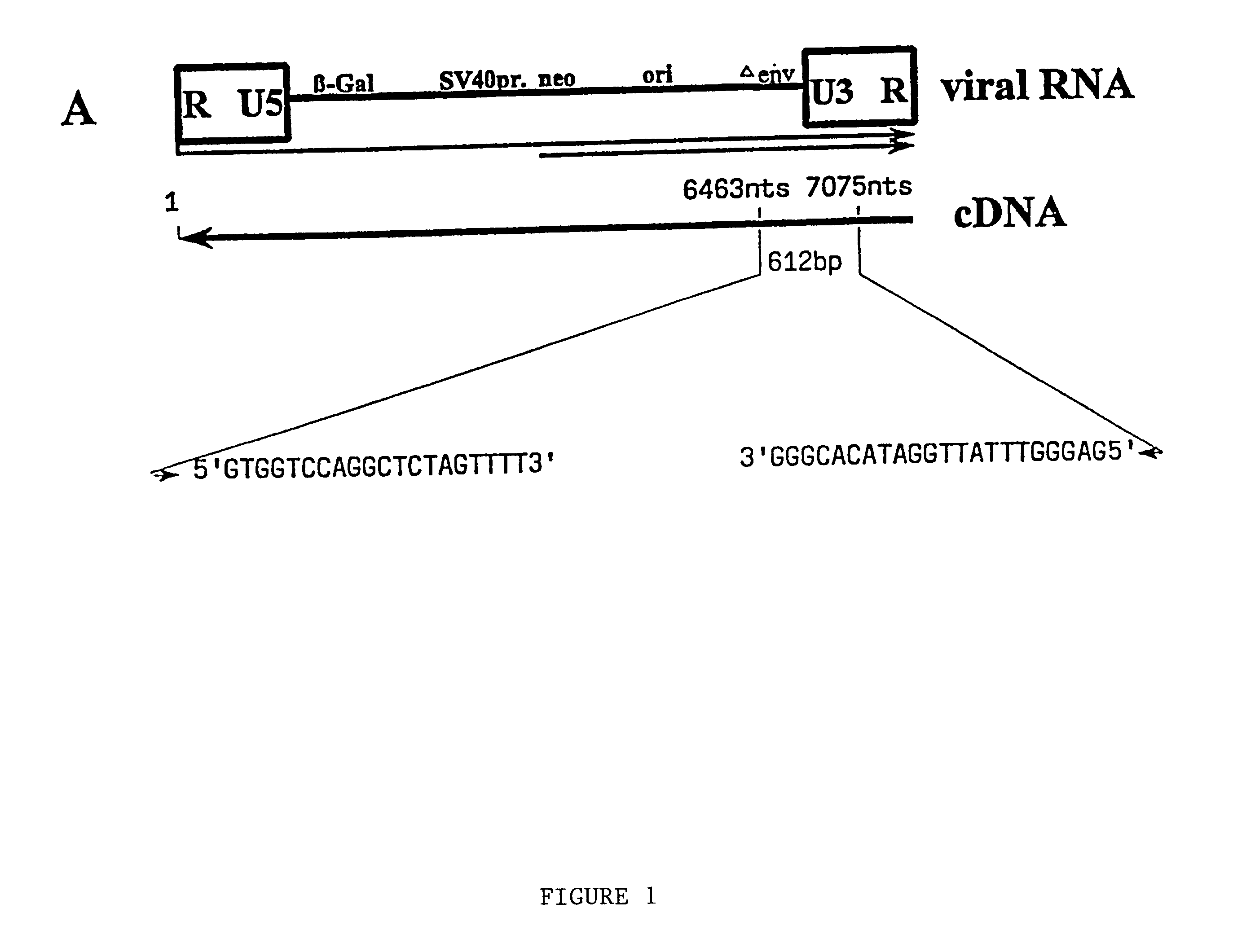

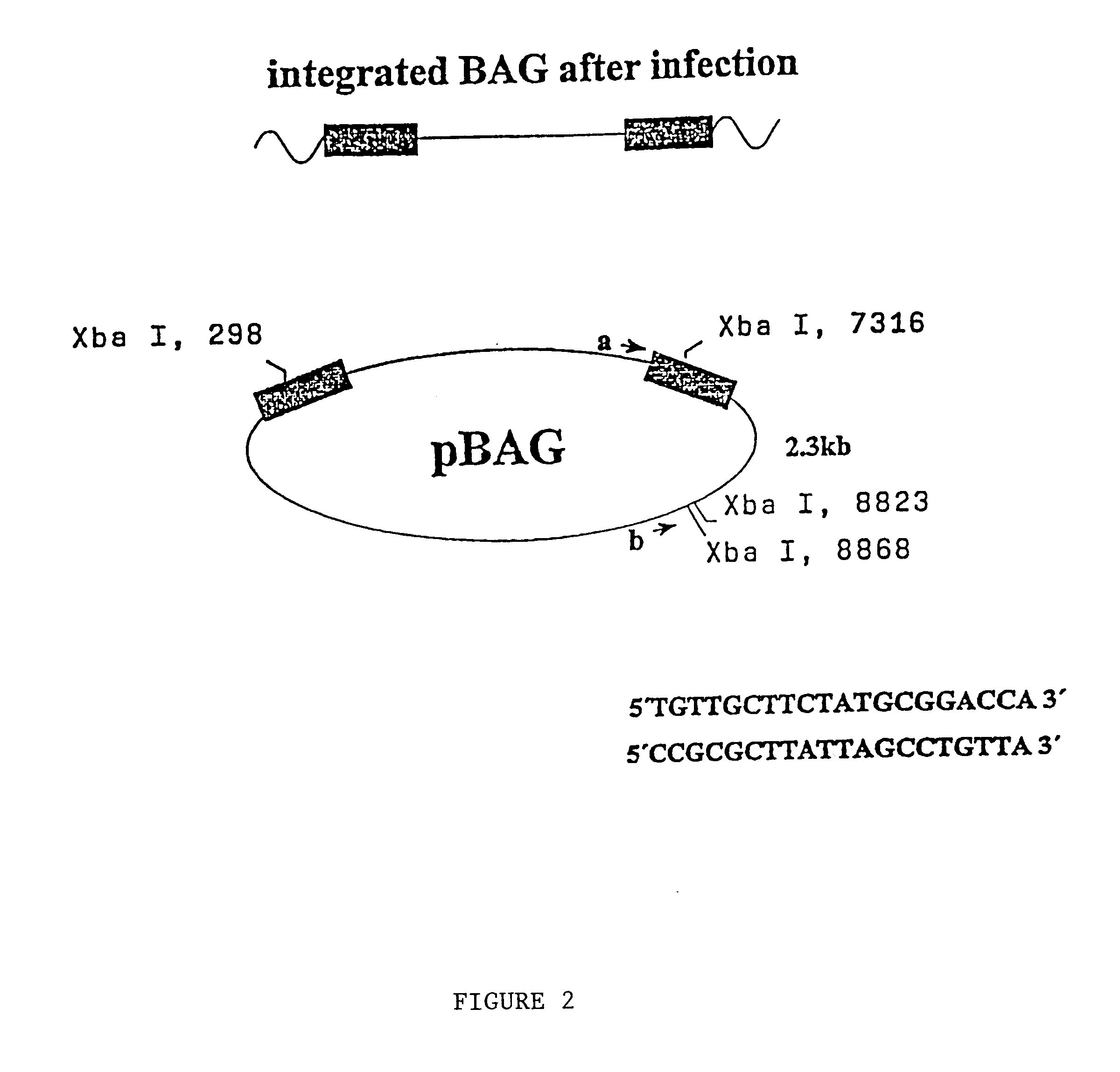

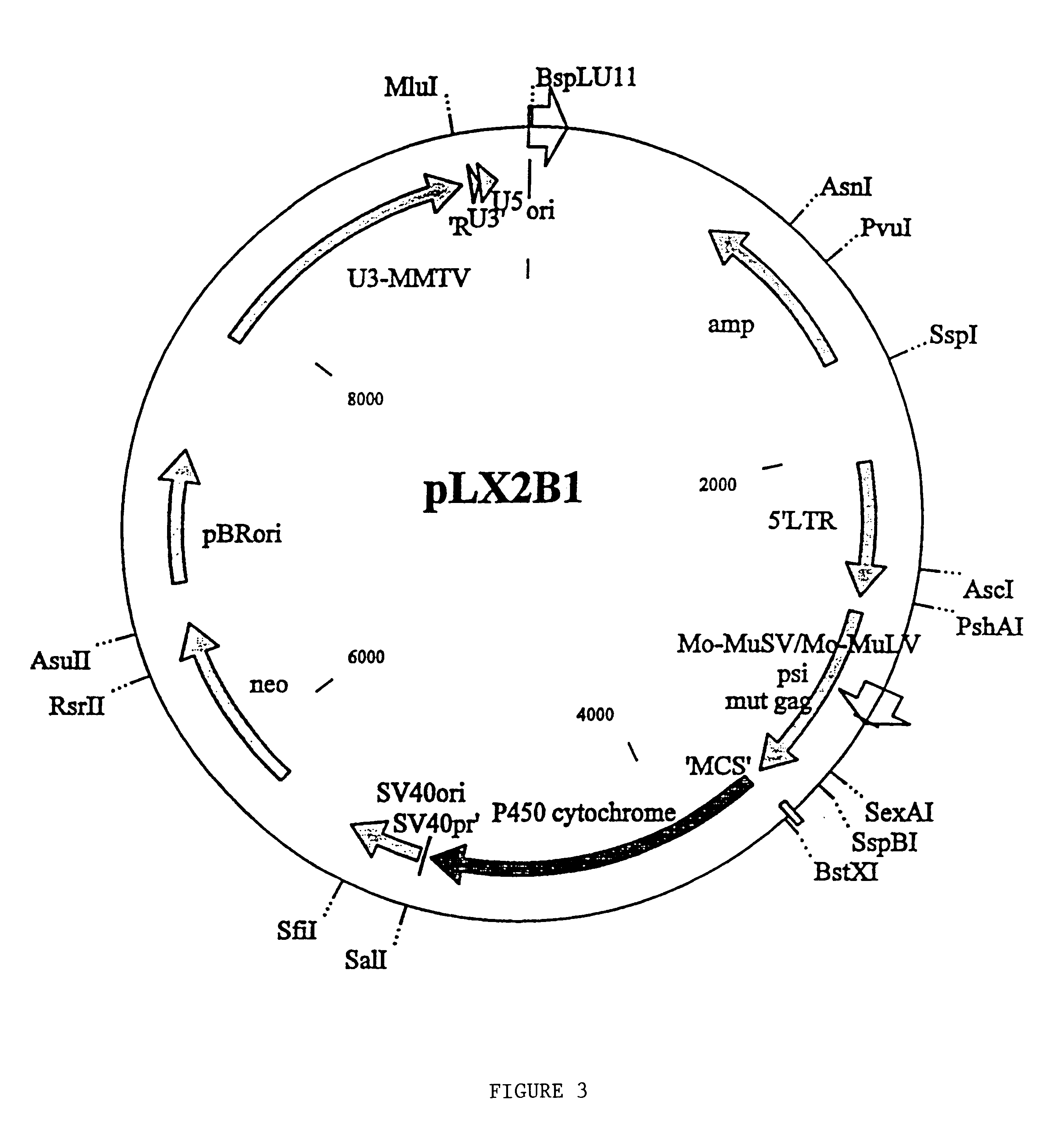

Encapsulated cells producing viral particles

InactiveUS6776985B1Excellent mechanical propertyImprove mechanical propertiesBiocideGenetic material ingredientsTarget organRetrovirus

The present invention relates to encapsulated cells producing viral particles, especially retroviral particles containing the genome of a retroviral vector carrying therapeutic genes, to methods for the preparation of such encapsulated cells, as well as to the use of such encapsulated cells for the delivery of genes, especially therapeutic genes, to target organs / cells.

Owner:BAVARIAN NORDIC AS +2

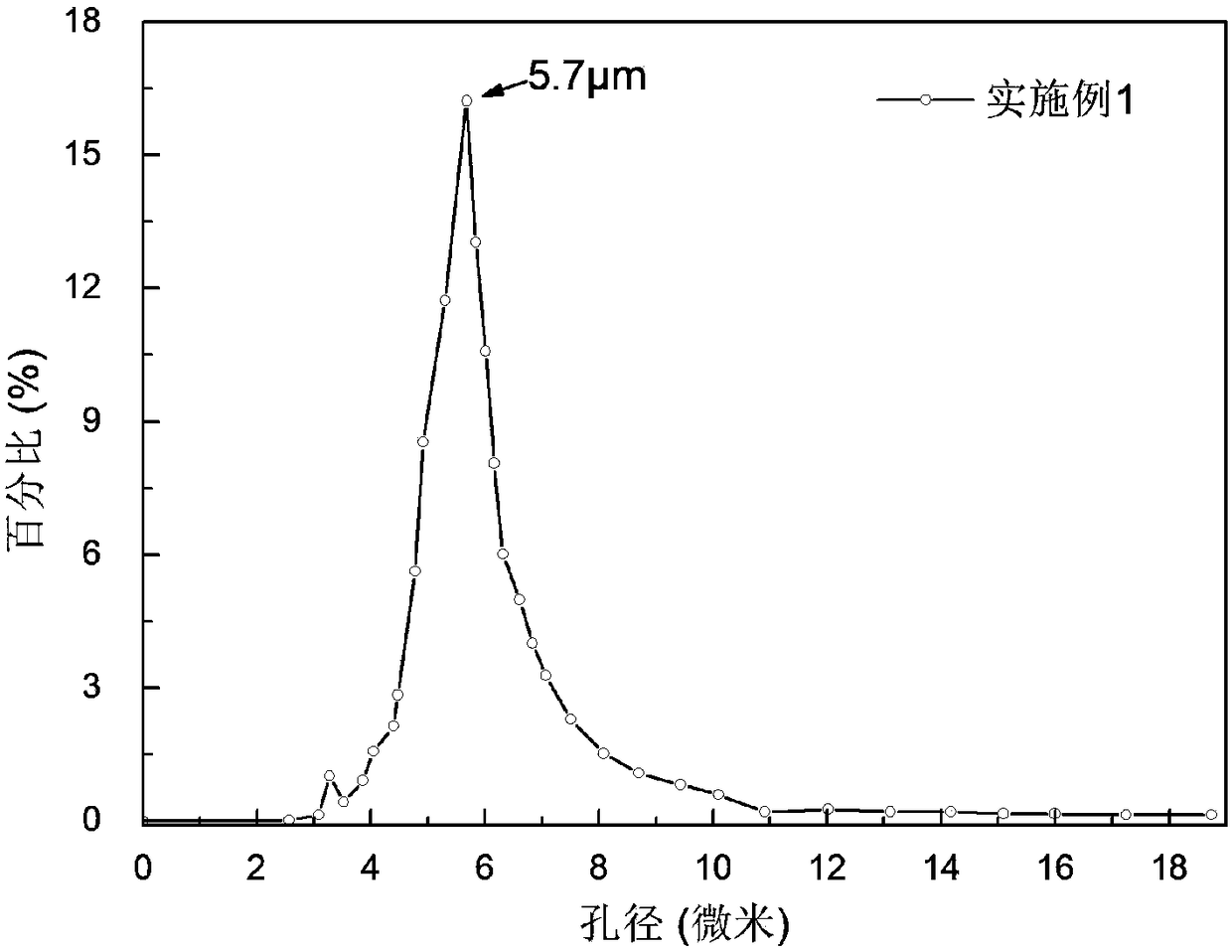

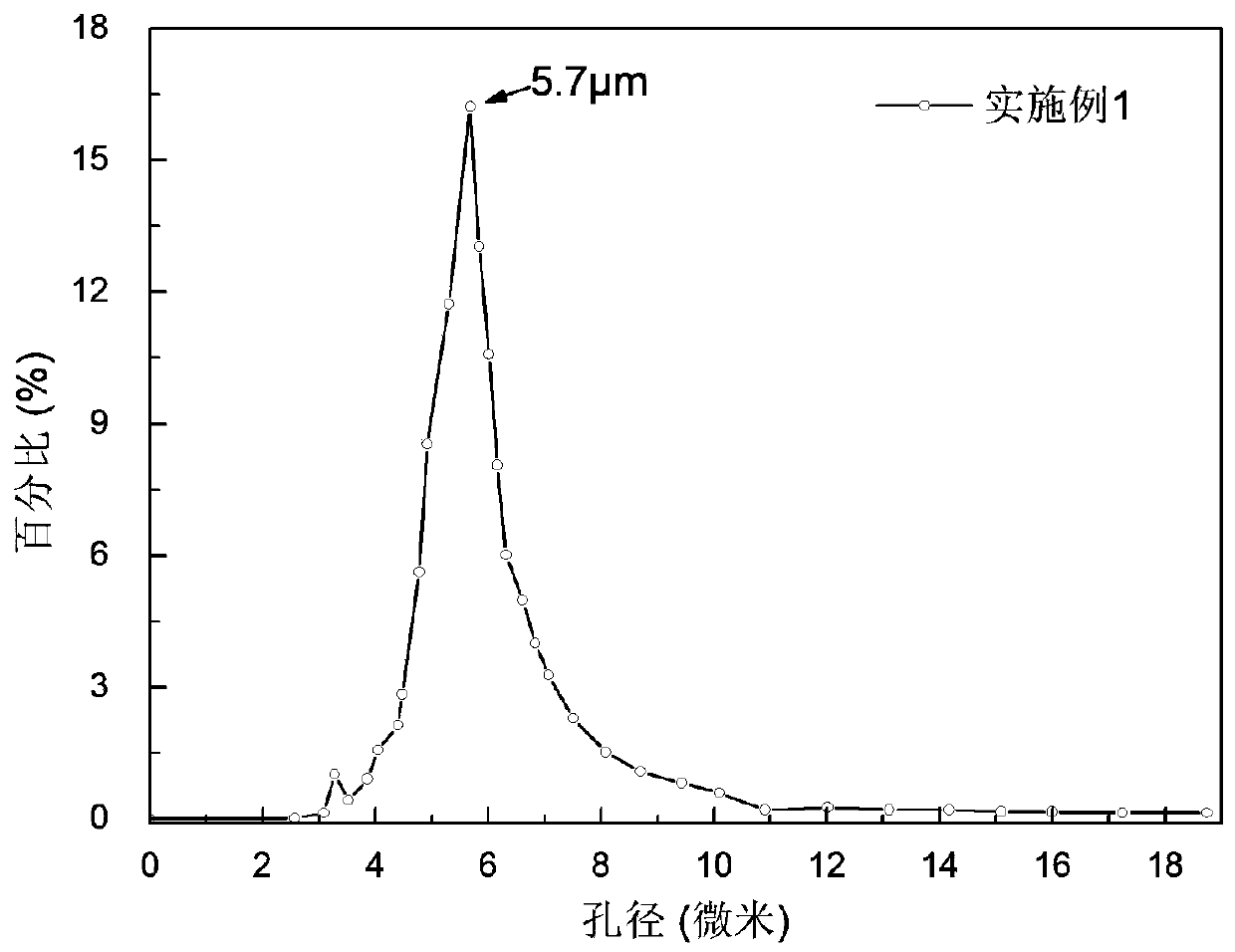

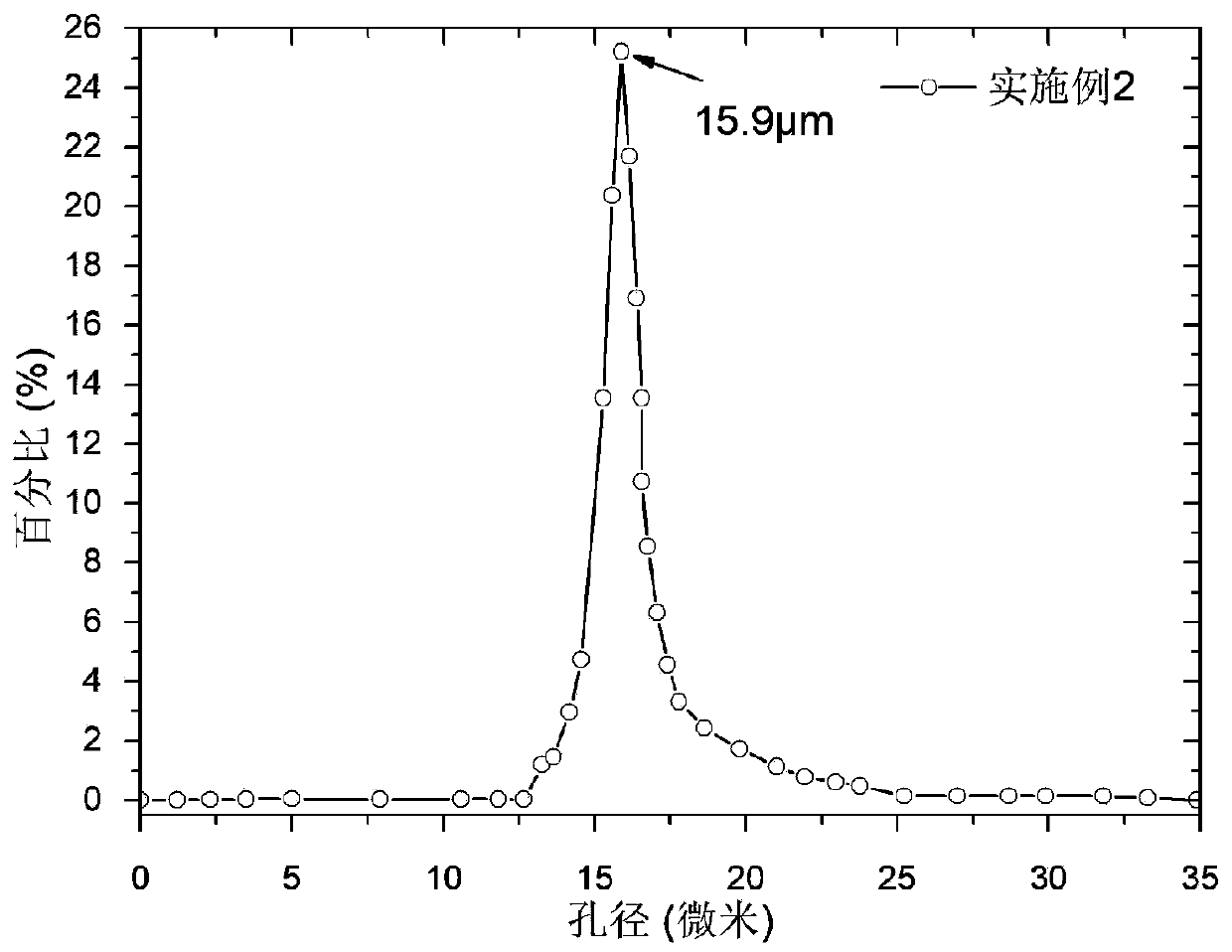

Method for preparing pore-size-controllable silicon carbide ceramic by means of three dimensional (3D) molding

ActiveCN108439987ANarrow pore size distributionAperture controlAdditive manufacturing apparatusCeramicwareSilicon dioxideTetrahydrofuran

The invention provides a method for preparing pore-size-controllable silicon carbide ceramic by means of three dimensional (3D) molding, belonging to the technical field of 3D printing. The method comprises the following steps: separately and uniformly coating two types of silicon carbide powder, having different particle sizes, with a mixture of polycarbosilane and silicon dioxide powder to obtain coarse, median and fine coated composite powder with three particle sizes, and mixing the obtained coarse, median and fine coated composite powder with three particle sizes according to a mass ratioof 100 to (0.2-1.6) to obtain printing powder; molding the printing powder by using a direct three-dimensional printing molding machine to obtain a ceramic green body, wherein ink used for the three-dimensional printing molding machine is a tetrahydrofuran solution of polycarbosilane having a mass concentration of 0.5-1.3%; sintering the ceramic green body obtained in the step (4) at a high temperature to obtain the pore-size-controllable silicon carbide ceramic. The method provided by the invention realizes the control of the pore size of the silicon carbide ceramic product by adjusting thecoarse powder median particle diameter D50.

Owner:MAINTOP TECH DEV CO LTD

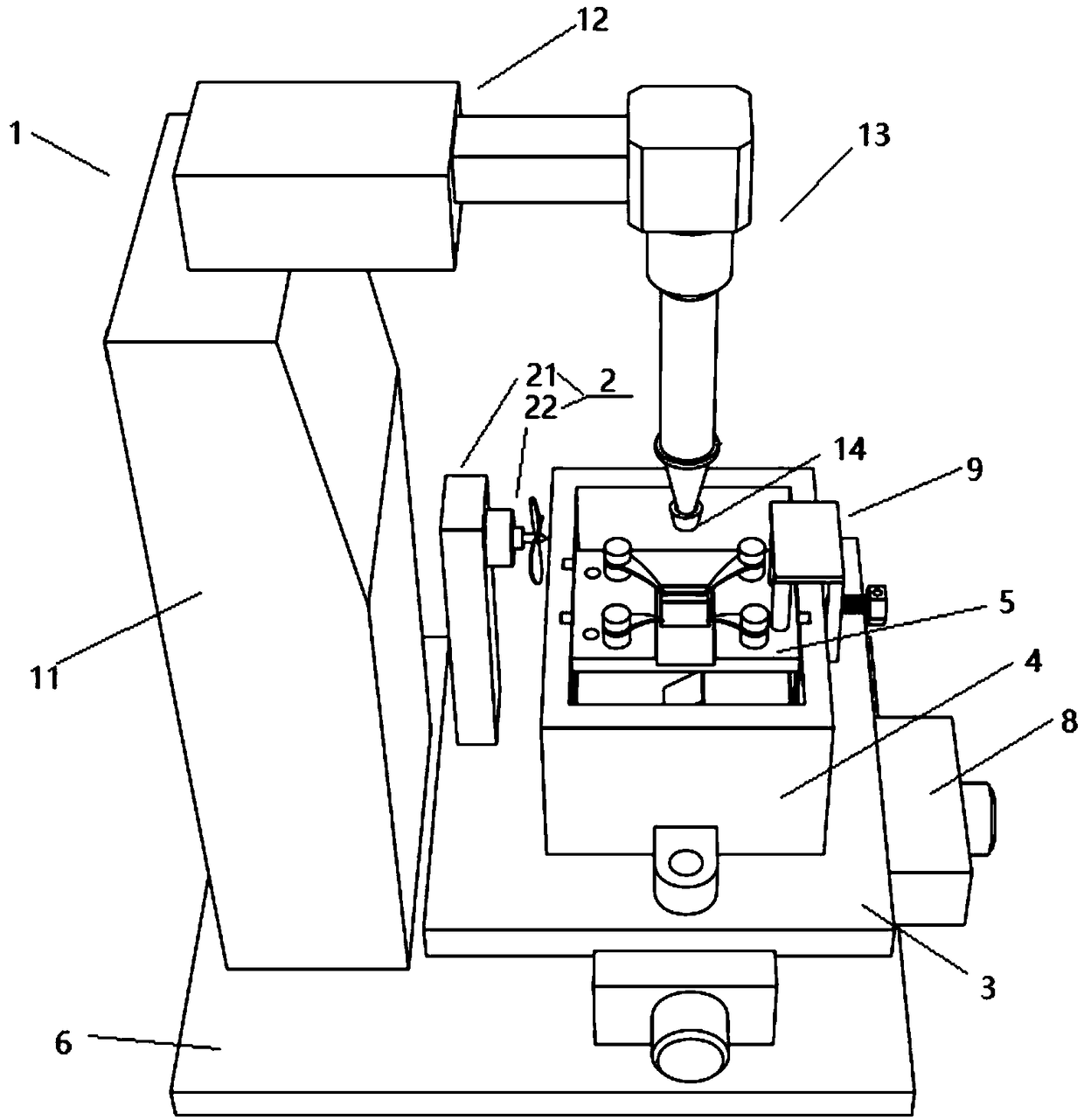

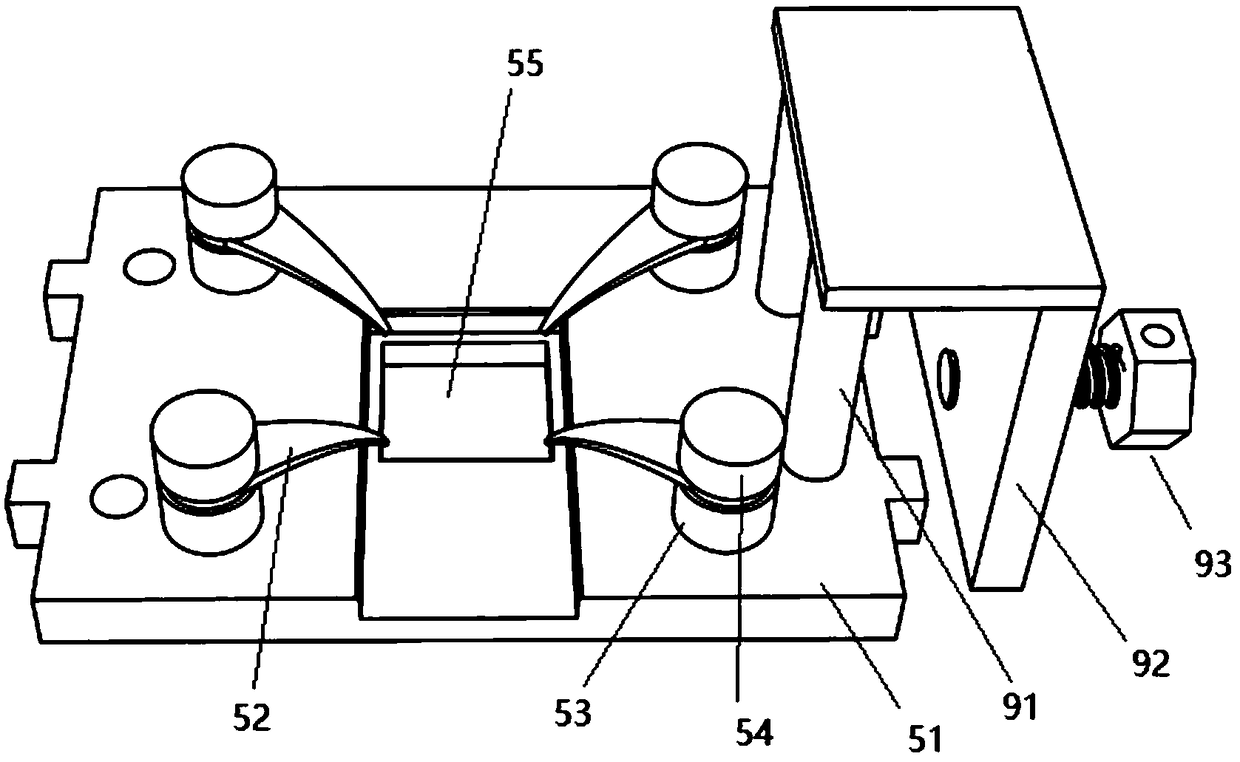

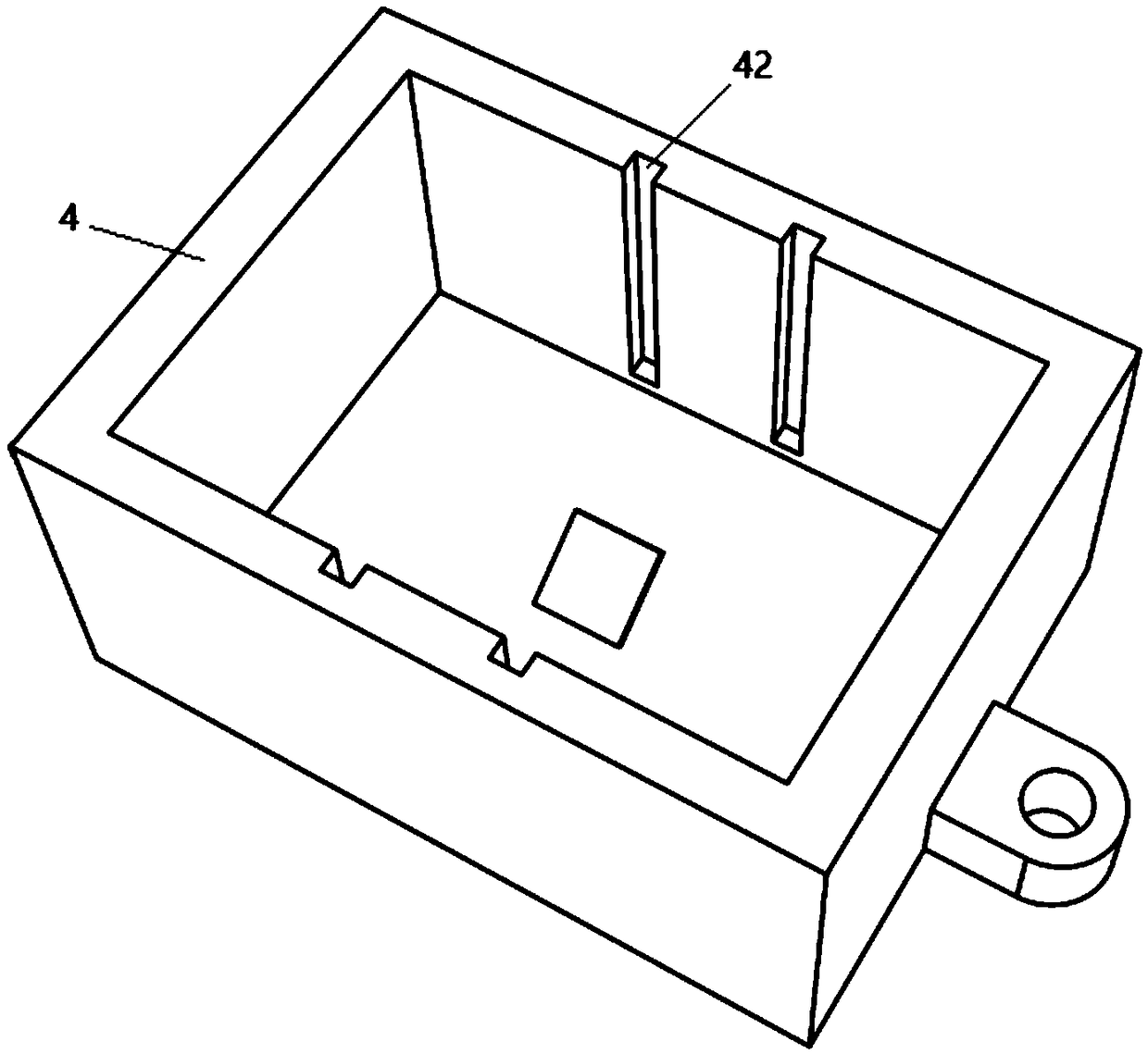

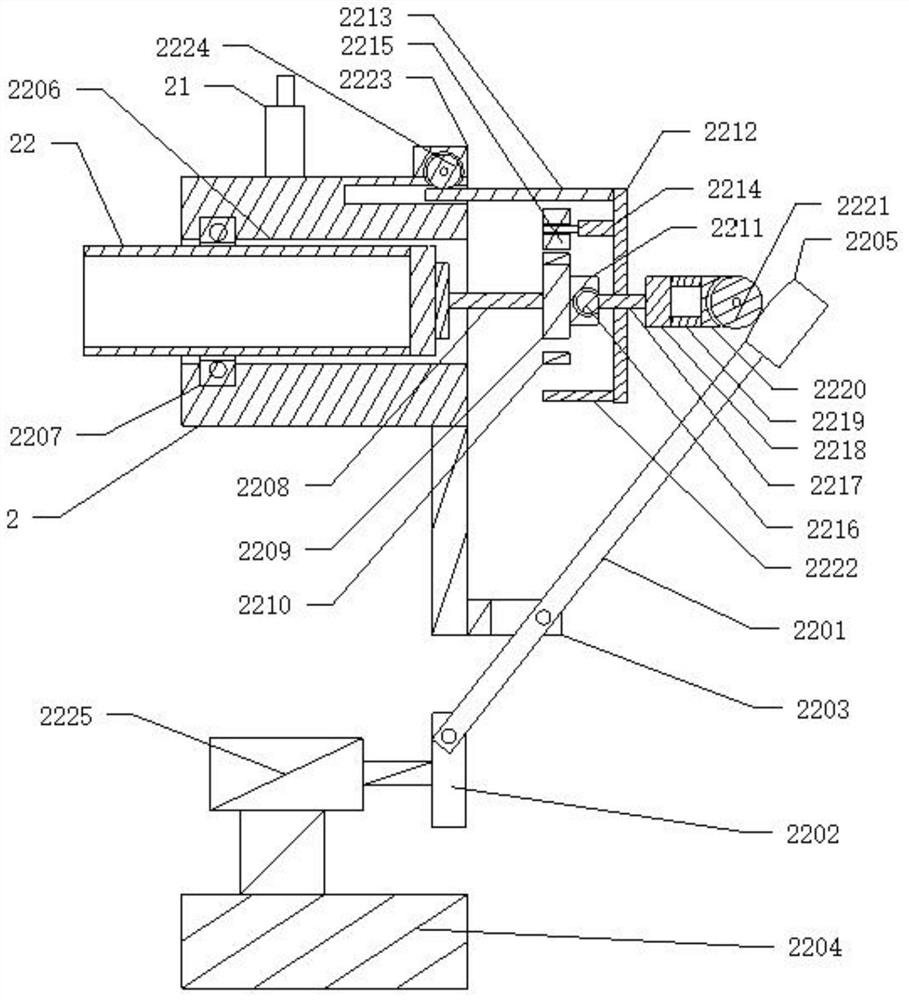

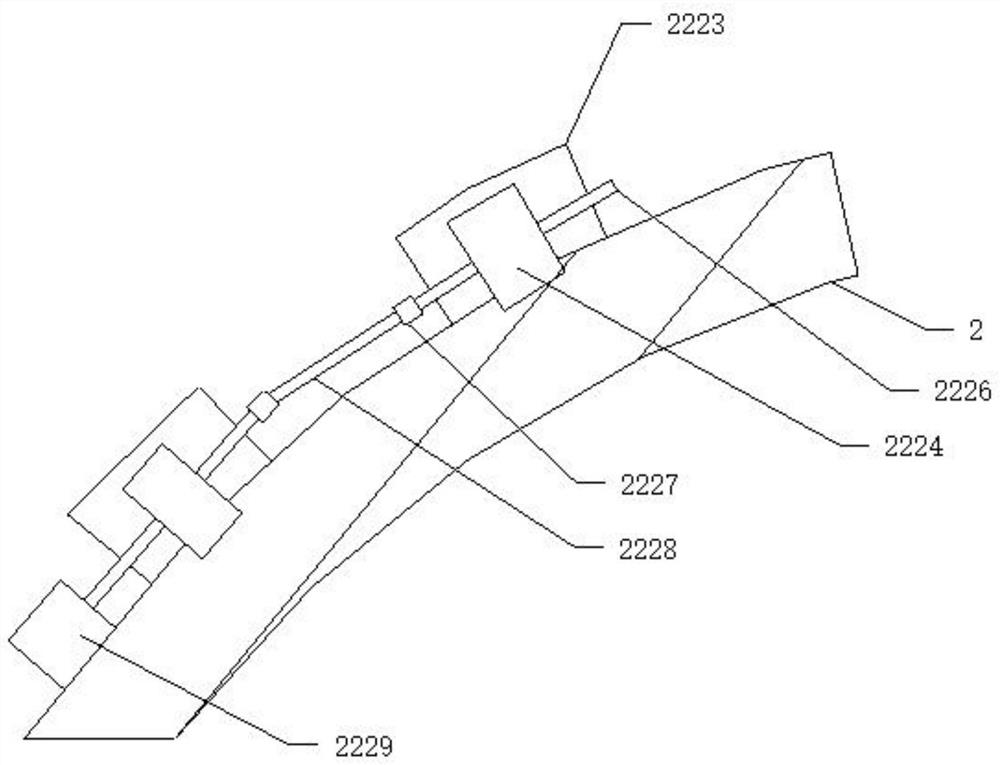

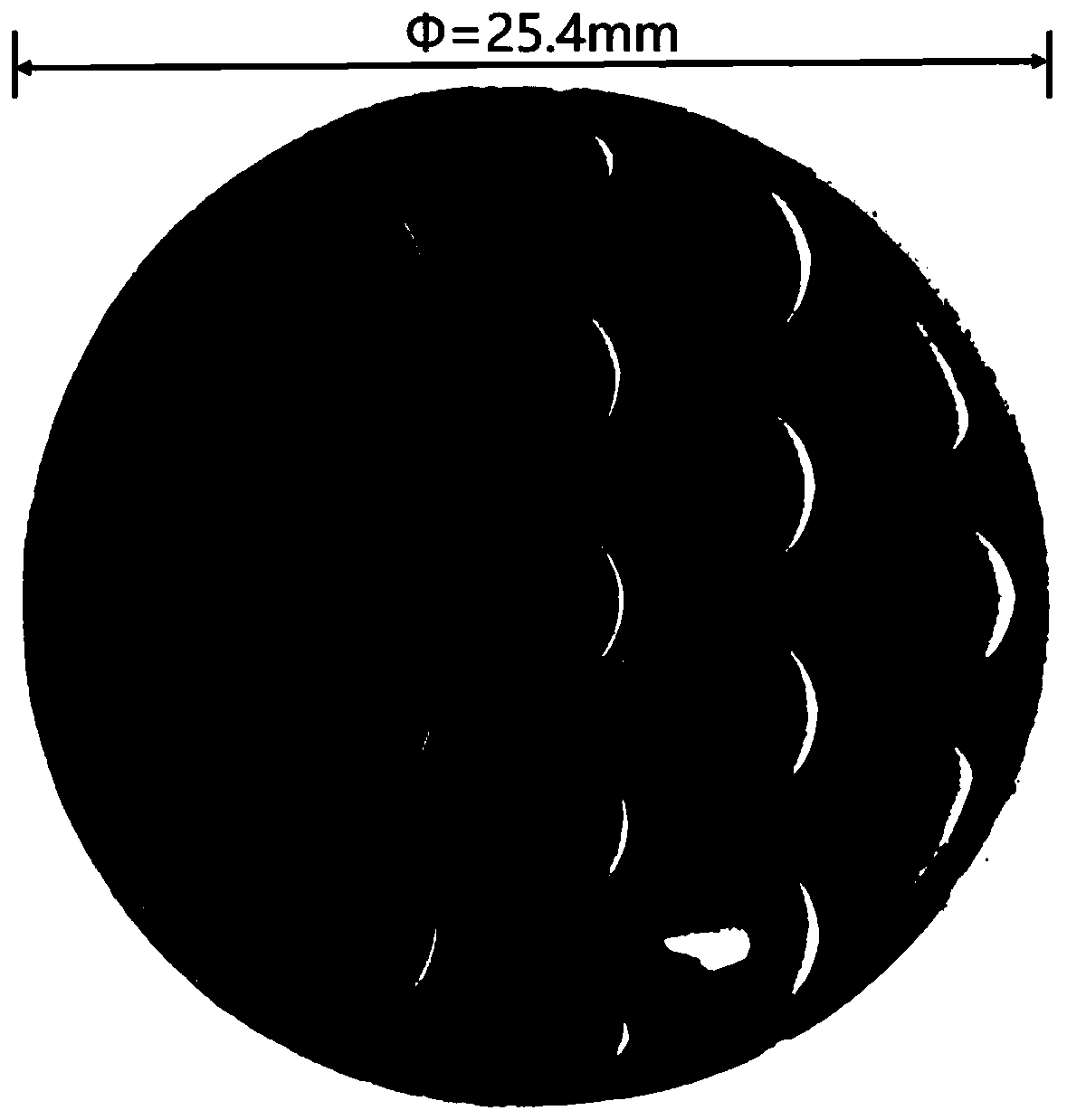

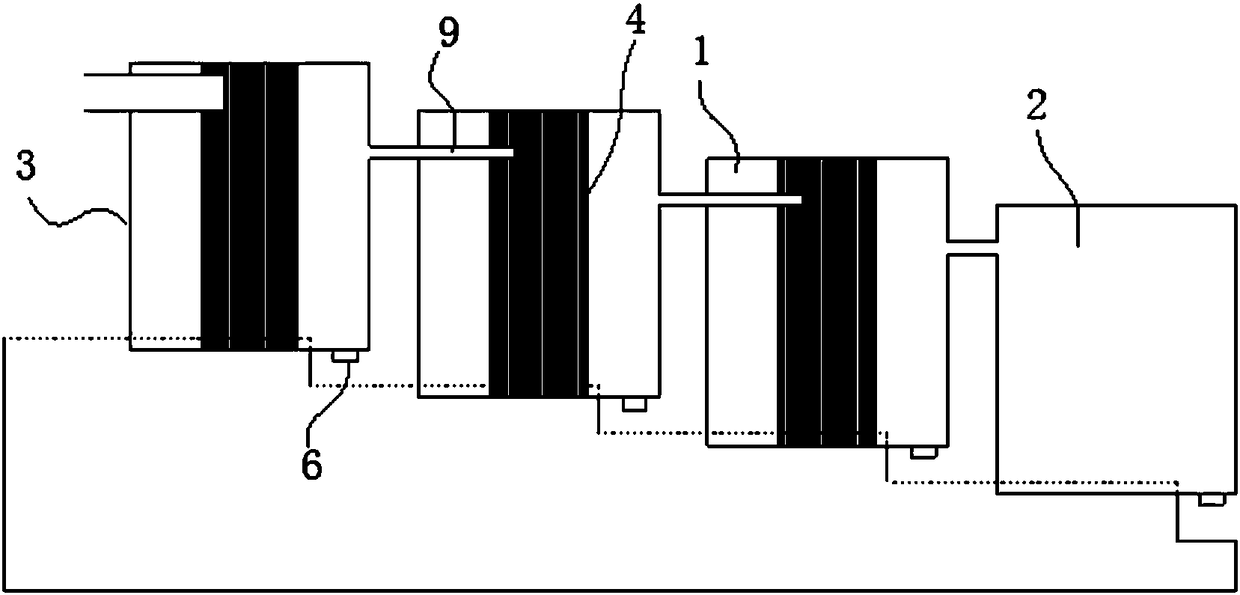

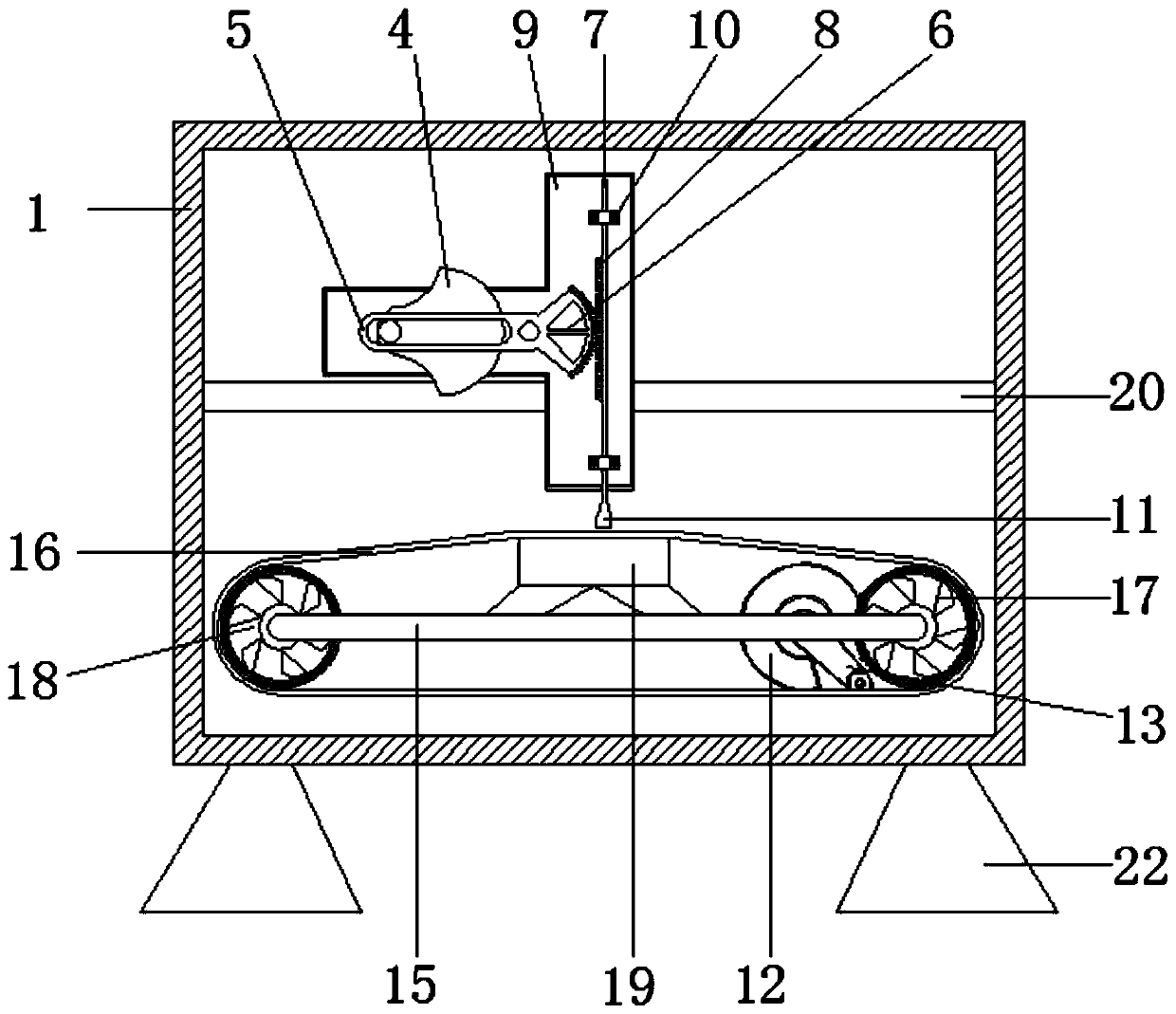

Auxiliary laser repeating punching method and device for ceramics based on static solution

The invention discloses an auxiliary laser repeating punching method for ceramics based on a static solution. The method comprises the steps that a fixing workpiece is soaked in a cooling solution ofa solution groove, the defocus amount of a laser to the to-be-processed workpiece is adjusted to 0, then a mist removal device and a laser emitter are started for primary punching, after primary punching, the defocus amount of the laser is adjusted to a negative value, secondary punching is conducted, and after secondary punching, the to-be-processed workpiece is taken out for cleaning. The invention further a laser repeating punching device. The device comprises a laser system, a mist removal fan, a machine tool working table, the solution groove, a workpiece clamp, a machine tool base and areflection mirror. According to the method and device, through the cooking and flushing effect of the static cooling solution and a laser repeating punching mode, processing cracks are reduced, the hole taper is lowered, the hole roundness is improved, and the effect of slag attachment and a recasting layer is reduced. Therefore, the punching quality is improved, the device is suitable for being transformed on the basis of existing equipment, simple in structure, easy to implement and low in cost, and the implementation method is simple.

Owner:GUANGXI UNIV

Large-area graphene preparing method based on high-density ordered copper nanowire catalyst

ActiveCN104726846AEvenly distributedConsistent pore sizeSurface reaction electrolytic coatingChemical vapor deposition coatingHigh densityCopper foil

The invention discloses a large-area graphene preparing method based on a high-density ordered copper nanowire catalyst, mainly aiming at solving the problem that graphene cannot be prepared from a copper foil in a large area at present. The preparing method comprises the following implementing steps: preparing a through-hole anodic aluminum oxide template by virtue of a method of secondary oxidation; depositing a layer of copper film on one surface of the through-hole anodic aluminum oxide template, using the copper film as an electrode, and preparing a high-density ordered copper nanowire in required size in the through-hole anodic aluminum oxide template; and finally catalyzing by taking the high-density ordered copper nanowire as a catalyst so as to promote the growth of graphene in a large area. Compared with graphene growing from existing copper foil catalyst, the graphene disclosed by the invention has the advantages of larger area and better quality, and the graphene is applicable to the manufacturing of semiconductor devices.

Owner:XIDIAN UNIV

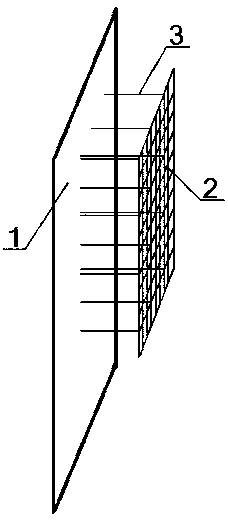

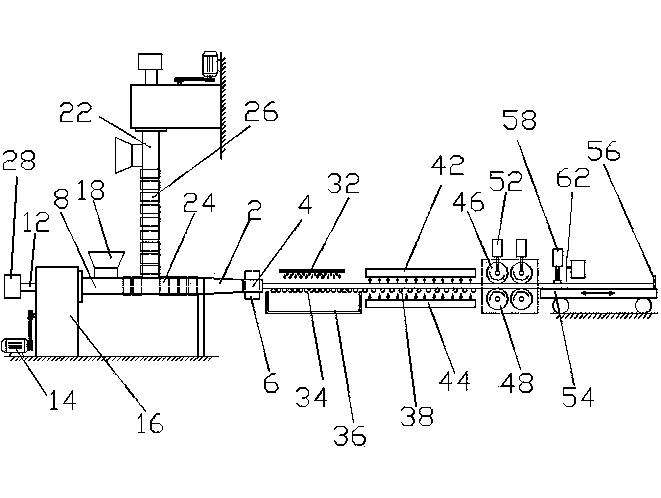

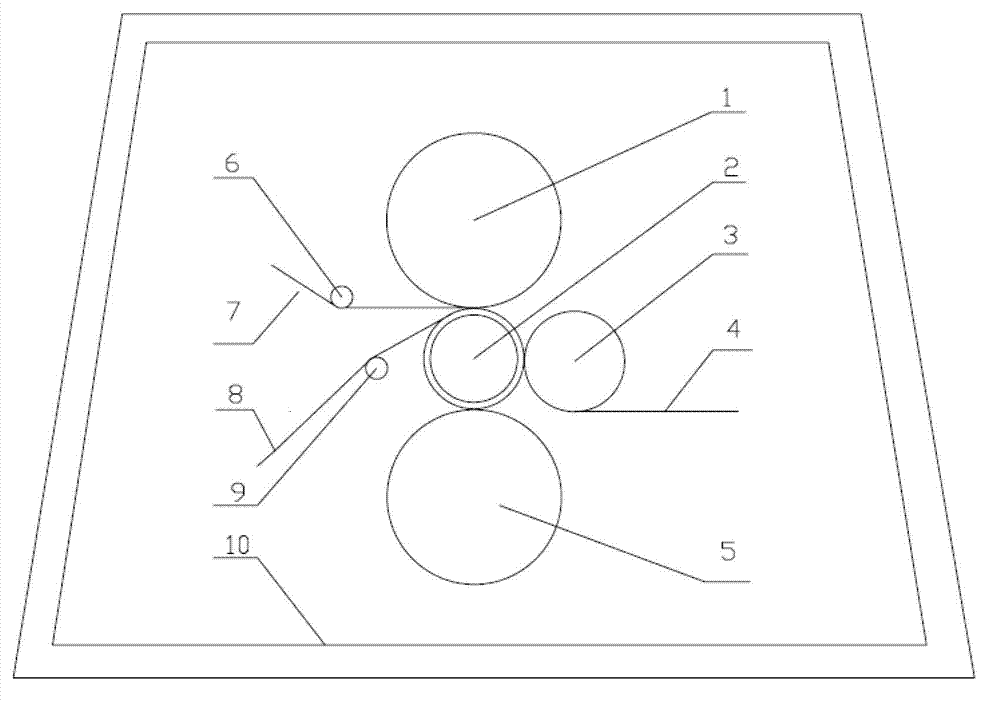

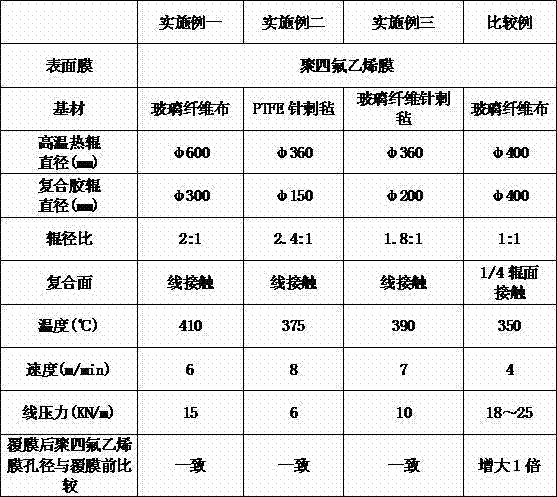

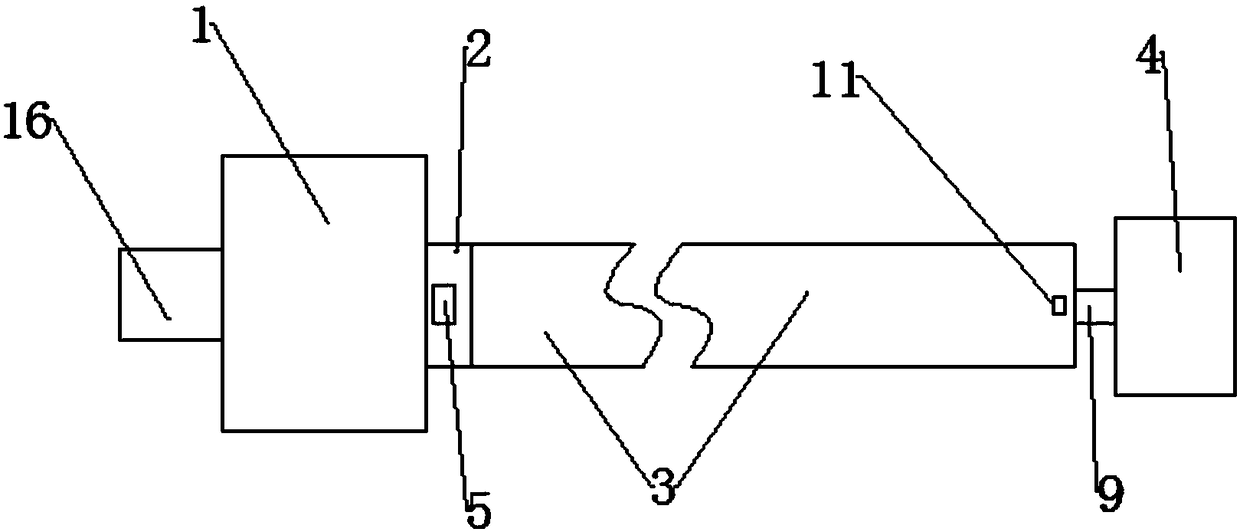

Hot melt laminating device and method of membrane filter material

ActiveCN103085429AAvoid damageConsistent pore sizeLaminationLamination apparatusDiameter ratioCooling effect

The invention discloses a hot melt laminating device and hot melt laminating method of a membrane filter material. A high-temperature hot roller, a composite glue roller and a cooling roller are sequentially arranged in the vertical direction from top to bottom; a gap adjusting device is arranged between the high-temperature hot roller and the composite glue roller; and a stripping roller is tightly abutted against the cloth outlet side of the composite glue roller. A polytetrafluoroethylene membrane and a base material are synchronously input between the high-temperature hot roller and the composite glue roller in a hot melt laminating process, and are stripped by the stripping roller and rolled after a hot press forming process. The roller diameters of the high-temperature hot roller and the cooling roller are the same, and the diameters of the high-temperature hot roller and the cooling roller are phi 360-600mm; the roller diameters of the composite glue roller and the stripping roller are the same, the diameters of the composite glue roller and the stripping roller are phi 150-300mm, and a diameter ratio of the composite glue roller and the stripping roller is in a range of 1.8-2.4. The hot melt laminating device is reasonable in structure; the composite glue roller has good cooling effect and long service life; the service life is up to 8-12 months; and the composite glue roller has convenience in replacement and maintenance. The polytetrafluoroethylene membrane filter material produced by the invention ensures the physical properties and the chemical properties of the polytetrafluoroethylene membrane, and has small damage on the polytetrafluoroethylene membrane; the prepared membrane filter material and the used polytetrafluoroethylene membrane have the same pore size; and the filter efficiency of the membrane filter material is improved.

Owner:ANHUI JINHON GREENISM TECH

Method for preparing zirconia ceramic ultrafiltration membrane

ActiveCN110270230ANarrow distributionGood pore size consistencyUltrafiltrationPolyvinyl alcoholUltrafiltration

The invention discloses a method for preparing a zirconia ceramic ultrafiltration membrane. The method is characterized by comprising the following steps: preparing a zirconia sol by using a sol-gel method; uniformly mixing the zirconia sol with a certain amount of water as well as one or more of polyethylene glycol, polyvinyl alcohol, methylcellulose and glycerinum so as to obtain a film coating liquid; impregnating the film coating liquid onto the surface of a ceramic filtering membrane substrate; and drying the substrate after the coating, further soaking the dried substrate into a nitric acid solution of which the pH value is 1-3 in a high-temperature reaction kettle, and carrying out a hydrothermal reaction at 180-220 DEG C, so as to obtain a ceramic ultrafiltration membrane with a uniform aperture of 10-20nm.

Owner:翁志龙

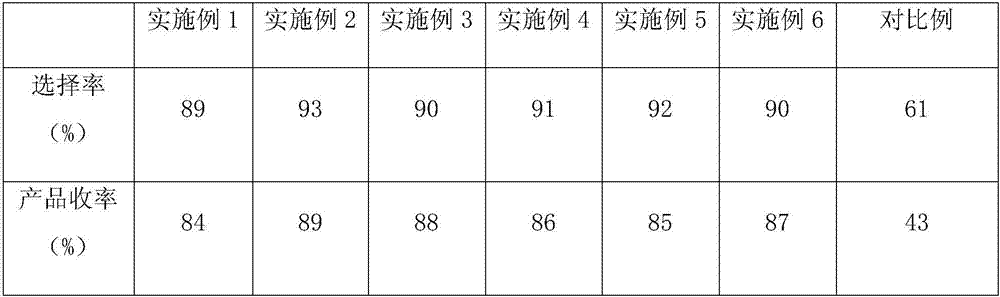

Production method of nano-attapulgite composite catalyst for 3-methylpyridine preparation

ActiveCN107983398AHighly selective adsorptionImprove permeabilityOrganic chemistryMolecular sieve catalystsMolecular sieveAluminium hydroxide

The invention provides a production method of a nano-attapulgite composite catalyst for 3-methylpyridine preparation. The method comprises following steps: nano-attapulgite raw ore is added to an aqueous hydrochloric acid solution for separating and washing, then a silver nitrate solution is utilized for washing, a mixed solution is heated and boiled by distilled water, centrifugal washing is performed, and acid modified nano-attapulgite is obtained; the acid modified nano-attapulgite is mixed uniformly with zeolite molecular sieves, a mixture is added to an aqueous aluminium hydroxide solution and mixed uniformly, a mixed solution is dried, ground and calcined at high temperature, and nano-attapulgite composite supports are obtained; the nano-attapulgite composite supports are added to silicon dioxide sol, sufficient adsorption, drying and grinding are performed, and the nano-attapulgite composite catalyst for the 3-methylpyridine preparation is obtained. According to the prepared catalyst, the zeolite molecular sieves and attapulgite are taken as the composite supports, and aluminium oxide and silicon dioxide are adsorbed into multi-stage support pores, so that catalyst is high in strength, low in cost and good in dispersibility and has good selectivity and high product yield in the 3-methylpyridine preparation.

Owner:上海磐石矿业有限公司

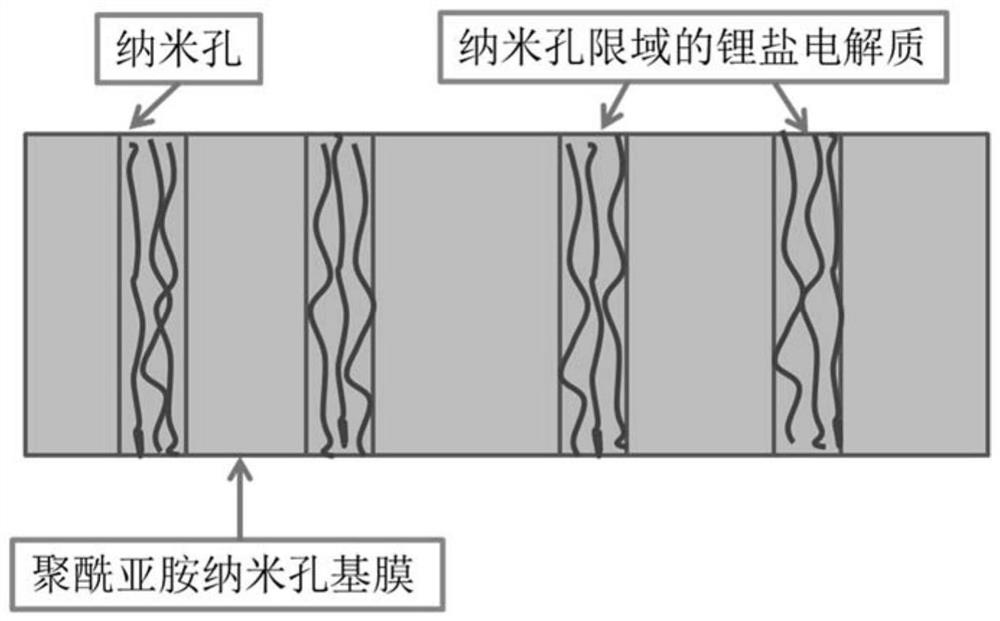

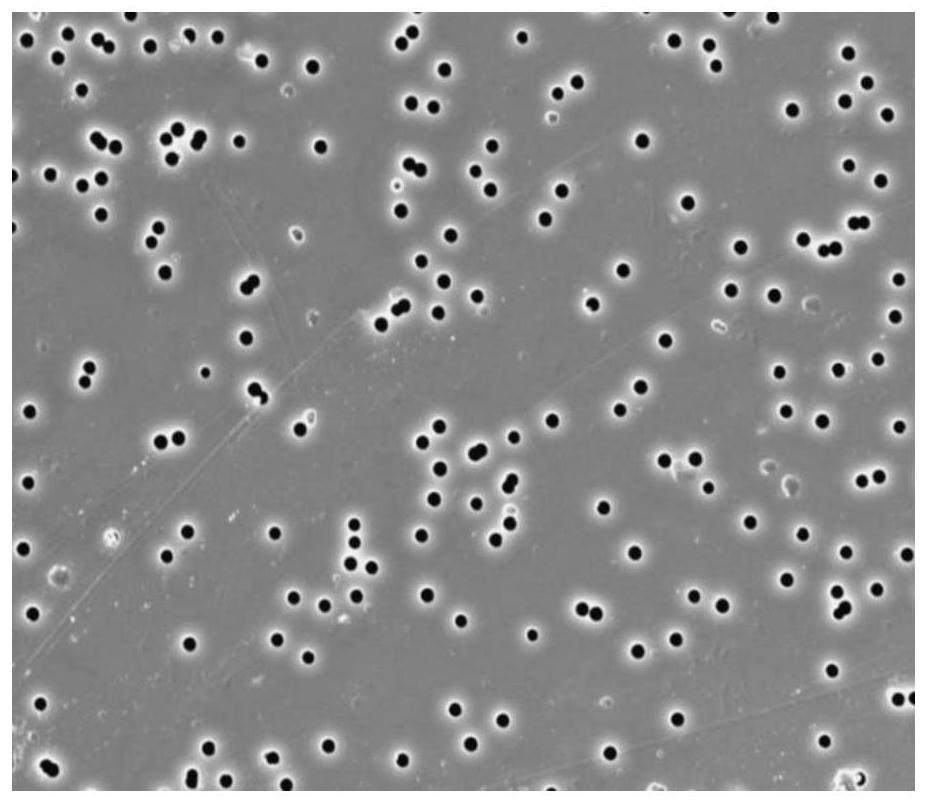

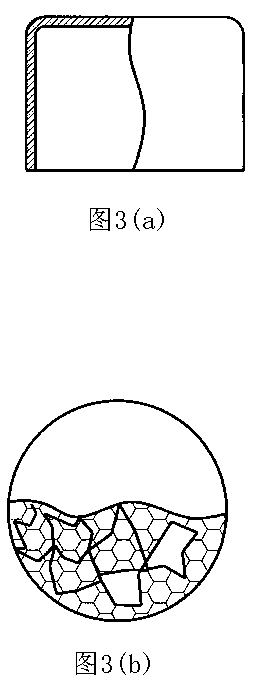

Nuclear pore film-based solid electrolyte film and preparation method thereof

ActiveCN112421184AImprove securityImprove battery performanceLi-accumulatorsCell component detailsSolid state electrolyteLithium metal

The invention discloses a nuclear pore film-based solid electrolyte film and a preparation method thereof. A polyimide heavy ion track etching porous film is used as a base film, polyimide can resisthigh temperature of 400 DEG C, can stably work within the temperature range of -200 to 300 DEG C, has extremely low contractibility, and has excellent mechanical properties and insulativity. Due to the excellent performance of the polyimide film, the high mechanical property and thermal stability of the prepared electrolyte diaphragm are ensured. The film (nuclear pore film) prepared by the heavyion track etching technology has the advantages of consistent pore diameter, controllable size and convenient and adjustable pore density. The polymer chain electrolyte is filled in the nanopores of the polyimide heavy ion track etching film, and the spatial confinement effect of the directionally arranged nanopores enables the polymer chain to extend along the direction of the nanopores, so thatthe glass transition temperature of the polymer is reduced, and the lithium ion conductivity of the polymer electrolyte is improved; therefore, the all-solid-state lithium ion battery or the lithium metal battery has excellent safety performance and battery performance.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Gas detection probe using multi-phase catalyst alloy and far infrared ceramic filter and capable of performing back flushing washing and rapid calibration

ActiveCN105277591AUniform concentrationSensitivity unchangedMaterial analysis by electric/magnetic meansAlkanePorous ceramics

The invention relates to a gas detection probe using a multi-phase catalyst alloy and a far infrared ceramic filter and capable of performing back flushing washing and rapid calibration, and belongs to the field of safety protection, wherein the gas detection probe is suitable for catalytic combustion, semiconductor type gas sensors. According to the present invention, the filtering capacity is unaffected by humidity, the absorption rate on the detected gas is low, and the service life is long; the n-shaped porous polytetrafluoroethylene core shell, the internal porous multi-phase catalyst alloy, the internal negative ions and the internal far infrared ceramic catalyst assembly are the core components of the gas detection probe; the n-shaped porous polytetrafluoroethylene core shell has water repellency and provides non-invasion on most solvents, and the porous ceramic catalyst assembly provides irreversible adsorption and high reaction activity on sulfur-silicon-based gas while does not provide reaction activity on hydrogen, alkane gases and carbon monoxide gas, and does not adsorb, such that the sulfur-silicon-based interference gas can be efficiently filtered out; and with the standard gas input and the gas washing back flushing pipe component, the great convenience is provided for the gas sensor calibration and the back flushing washing, and the benefits are provided for the prolonging of the service life.

Owner:HARBIN AISHENG INTELLIGENT TECH DEVCO

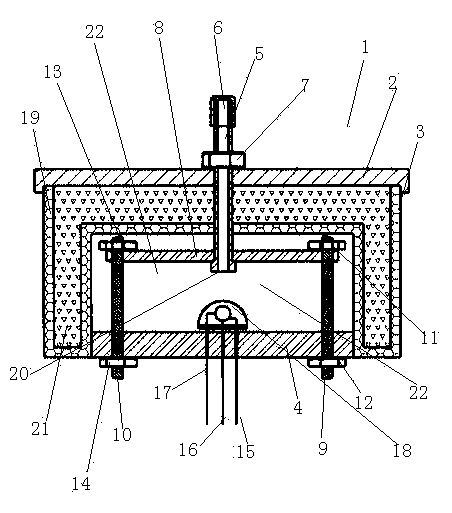

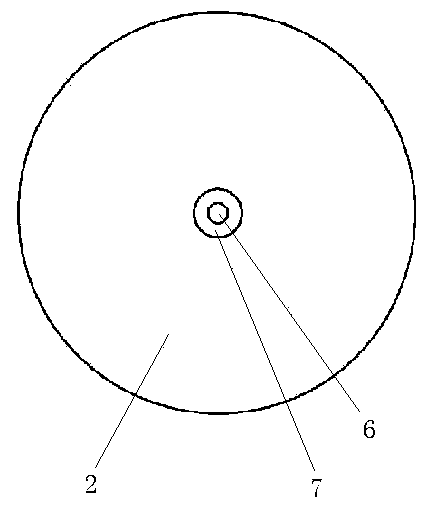

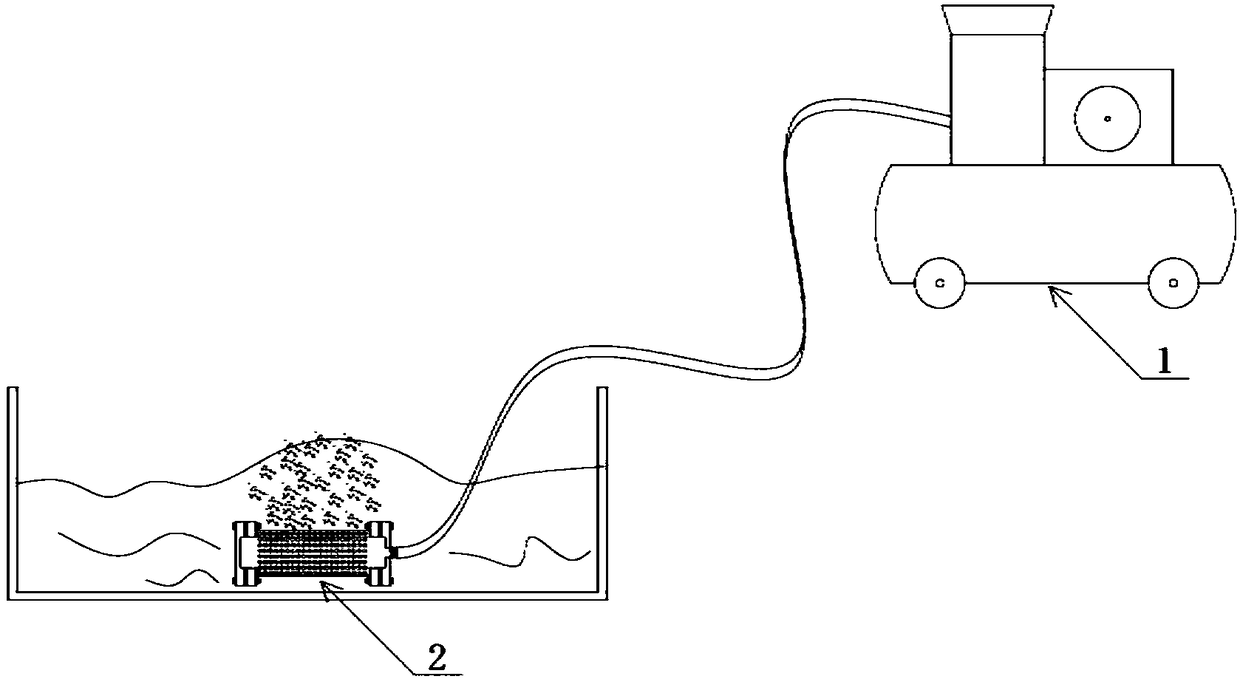

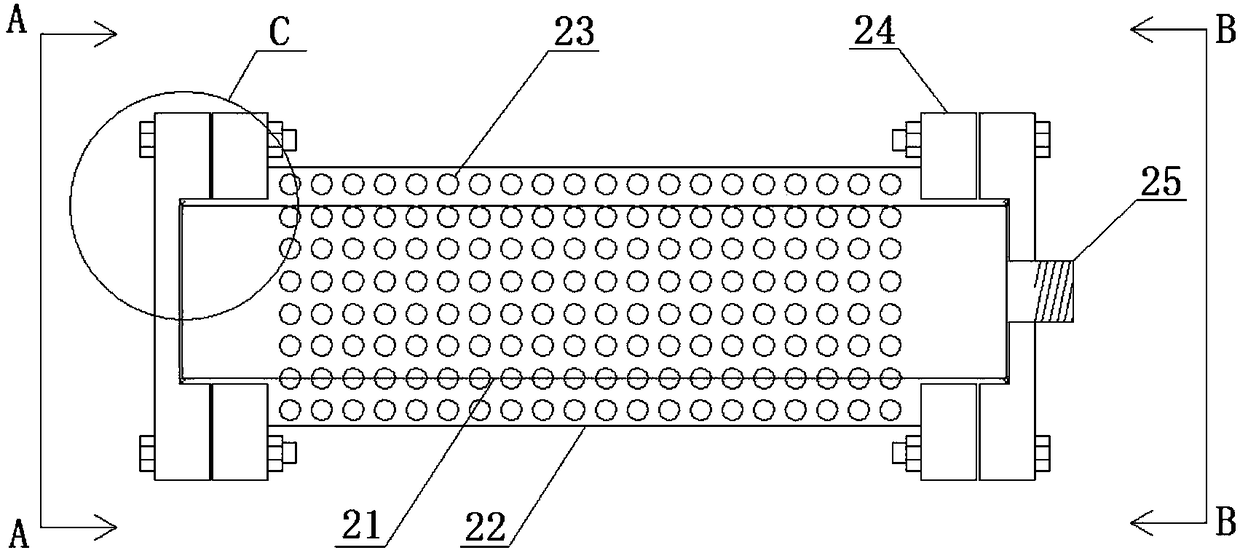

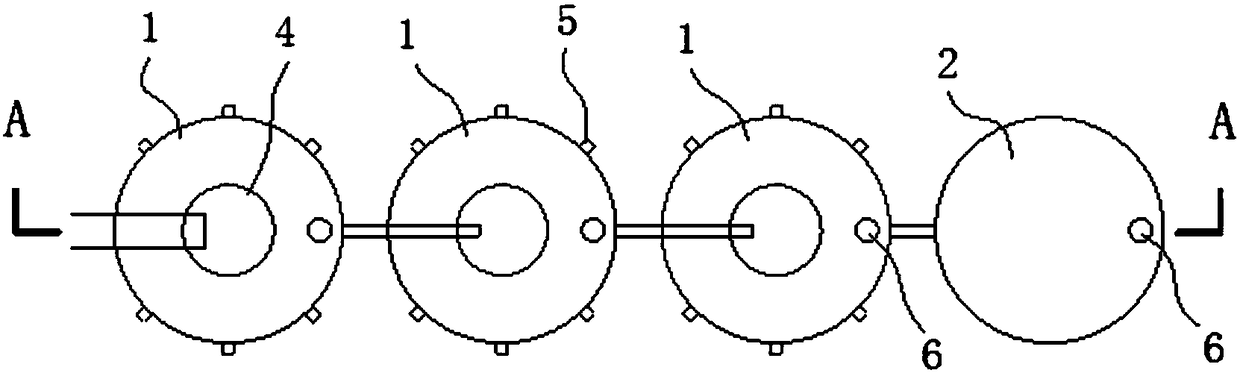

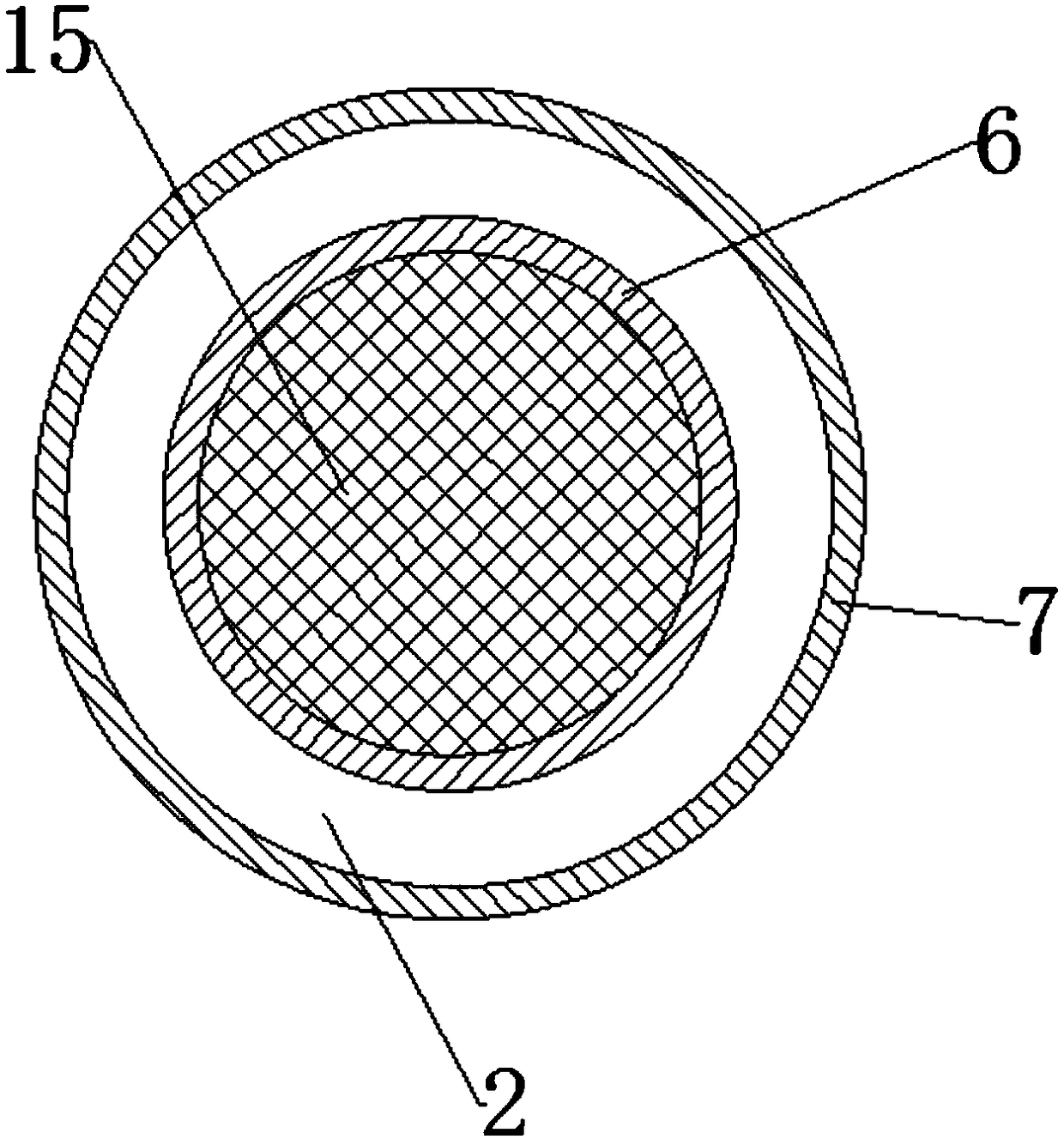

Bubble generating device with tubular membrane

InactiveCN108383253ATo overcome the difference in pore size, easy to blockSolve easy blockageMixing methodsTransportation and packagingEngineeringAir compressor

The invention discloses a bubble generating device with tubular membrane. The device comprises an air compressor and an air distribution head connected with the air compressor, wherein the air distribution head comprises a tubular membrane and a protection sleeve sleeving outside the tubular membrane circular holes are uniformly formed in the protection sleeve, and two ends of the protection sleeve are respectively fixedly connected with the tubular membrane through flanges; and an air inlet end of the tubular membrane is connected with the air compressor through an outer threaded joint. According to the device, the tubular membrane is used as the air distribution head of the bubble generating device, so that the device has the advantages of being not easy to block, easy release of air bubbles, low energy consumption, high safety, reliable operation, etc.

Owner:天津博迈科海洋工程有限公司

Foamed closed-cell aluminum foam and preparation technique thereof

The invention provides foamed closed-cell aluminum foam and a preparation technique thereof.The preparation technique comprises: heating powdered titanium hydride (TiH2) 30 micrometers in particle size with a baking oven at a gradient speed of increase of 100 DEG C per hour, and holding the temperature raised to 500 DEG C for 5 hours; heating pure aluminum or aluminum alloy with an aluminum melting furnace to 680 DEG C for melting, adding 4% by weight of alumina powder, stirring for 100-120 S so that molten aluminum thickens, and cooling the thickened molten aluminum to 610 DEG C and holding the temperature for use; adding 2% by weight of pre-treated titanium hydride (TiH2) into the molten aluminum to be used, and stirring for 55 S; adding suitable thickened molten aluminum added with a foaming agent into a forming mold, heating in a heating furnace to 680 DEG C, holding the temperature until full foaming, naturally cooling, and opening the mold to obtain the formed closed-cell aluminum foam product.

Owner:贾维 +1

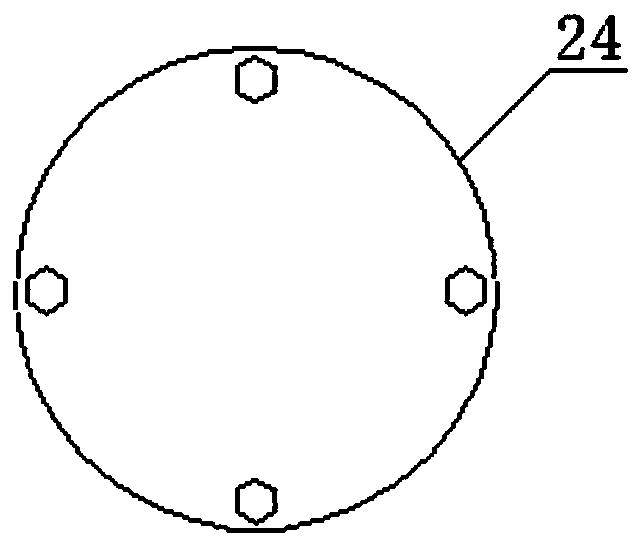

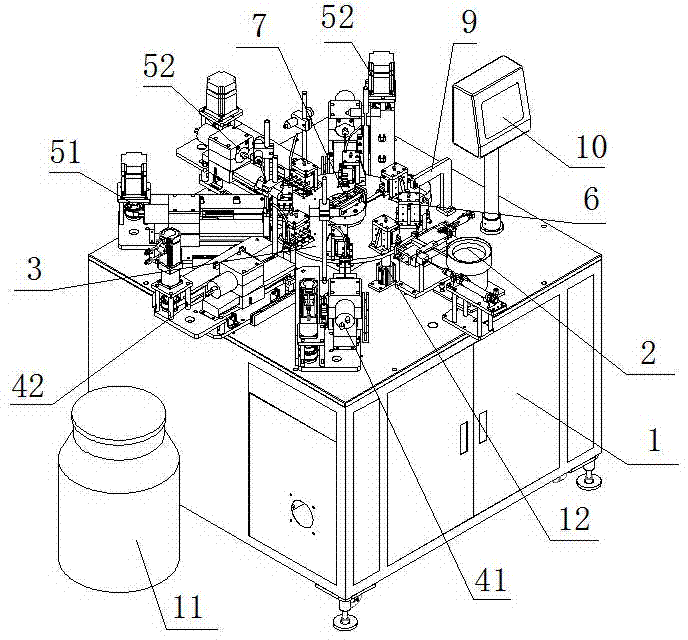

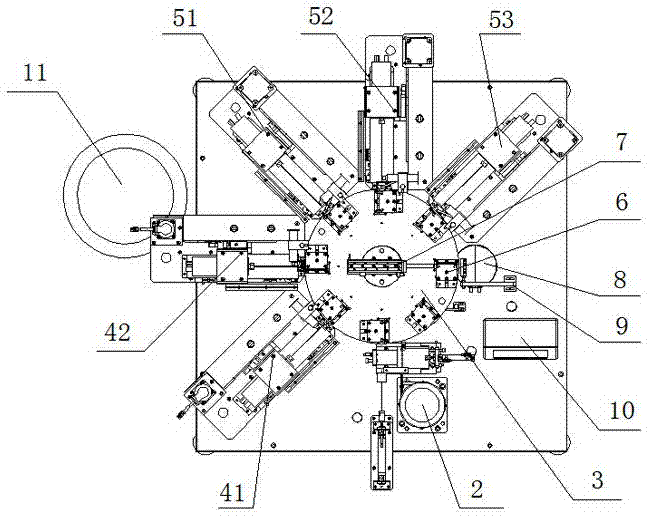

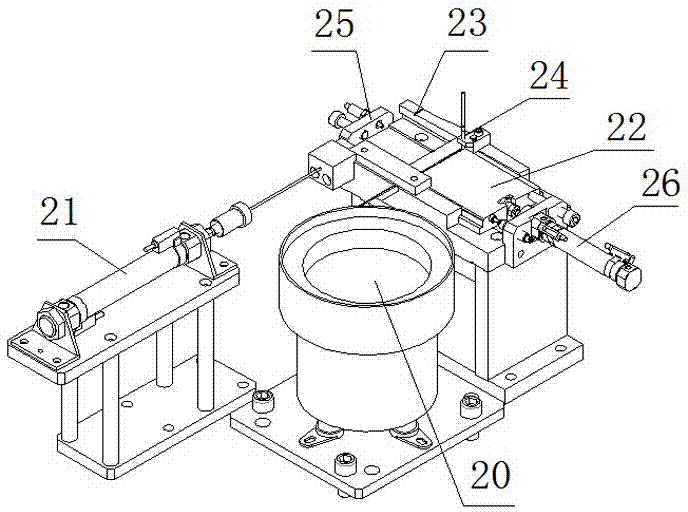

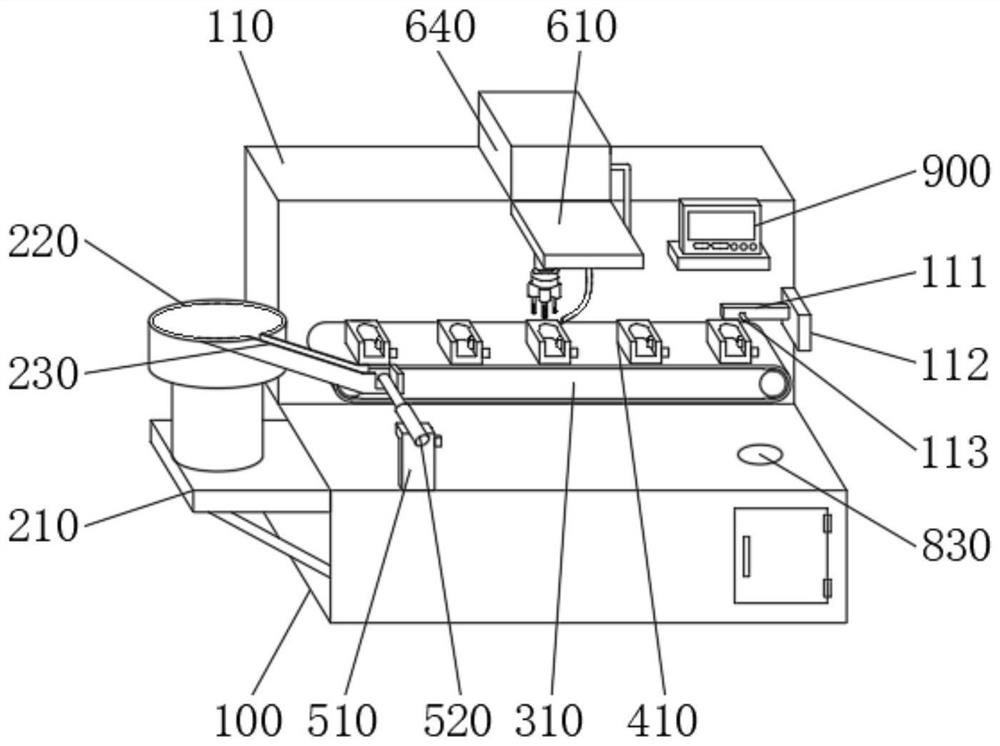

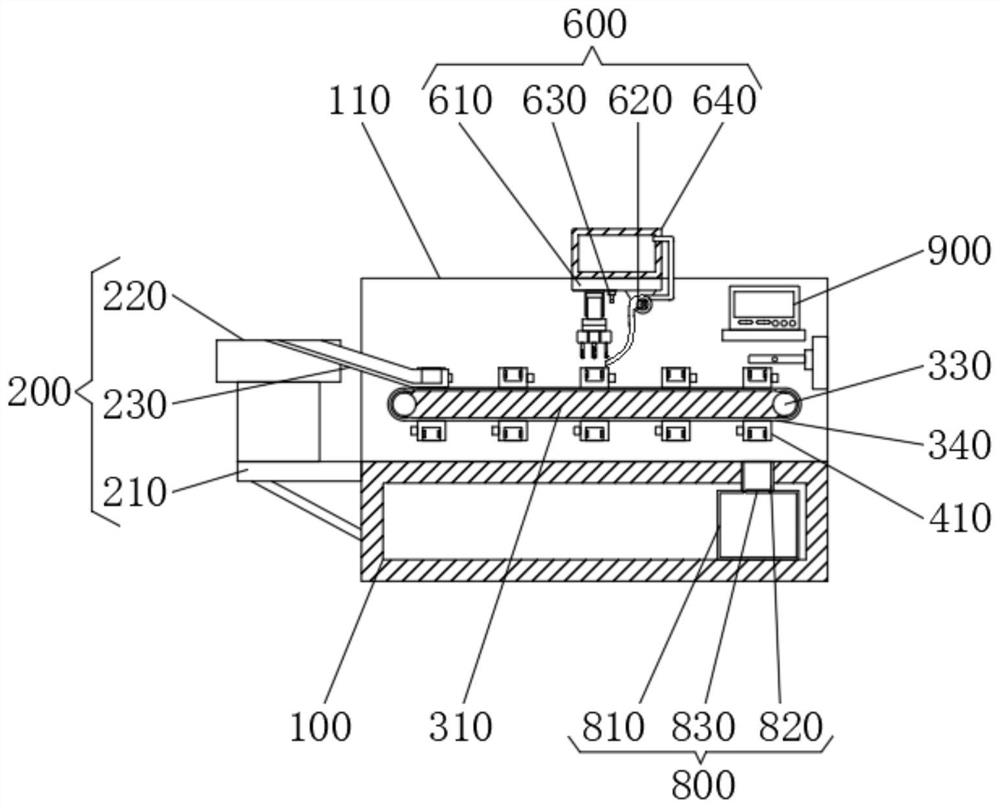

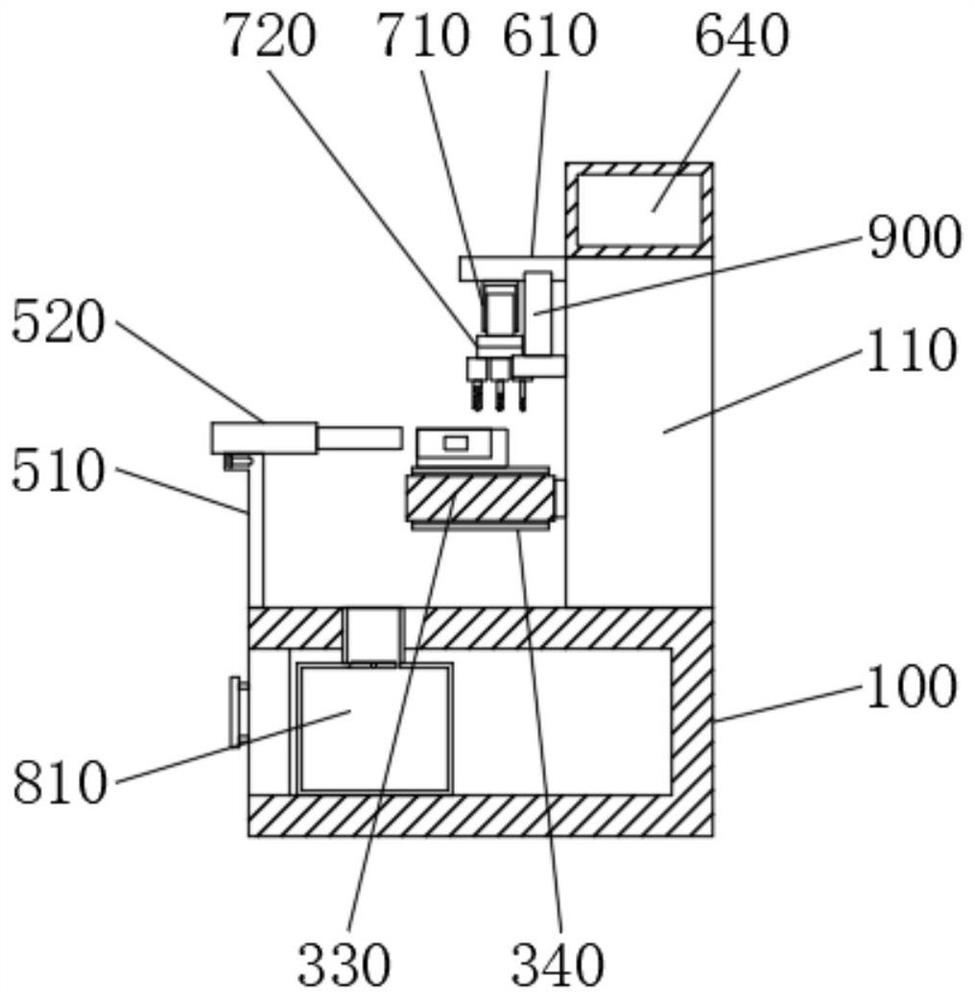

Ceramic grinding hole expanding machine

The invention provides a ceramic grinding hole expanding machine. The machine comprises a stand, a ceramic feeding mechanism, a jig turning plate mechanism, a first drilling mechanism, a second drilling mechanism, a first hole expanding mechanism, a second hole expanding mechanism, a third hole expanding mechanism, a ceramic jig mechanism, a ceramic blanking mechanism, a ceramic recovering mechanism, a ceramic blowing-off mechanism, a control system, a cooling barrel and a jig separating power mechanism. The machine is applicable to drilling, hole expanding, accurate positioning and processing of fine ceramic, so as to achieve consistent aperture and straight through holes; the minimum diameter of an expandable inner hole is 0.6mm, and the maximum diameter is up to 10mm; the length of the expandable inner hole is 4 to 30mm; in addition, accurate positioning and full automatic and accurate feeding can be achieved; qualified products and unqualified products can be fully automatically sieved and can accurately blanked and individually recovered; therefore, the intelligence operation degree is high, the working efficiency is high, the processing time is saved, the yield of products is high, the effect is good, the cost is small, the use is simple, convenient and fast, and the demand of fine industry development can be met.

Owner:DONGGUAN JINGKE AUTOMATION TECH

Automatic punching device for cylindrical neodymium iron boron

InactiveCN112935321AProcessing saves time and effortImprove work efficiencyFeeding apparatusMetal working apparatusPunchingStructural engineering

The invention discloses an automatic punching device for cylindrical neodymium iron boron and belongs to the technical field of neodymium iron boron machining. The automatic punching device comprises an operation table, a feeding mechanism, a conveying mechanism, a fixing mechanism, a pushing mechanism, a cleaning mechanism, a punching mechanism, a collecting mechanism and a control device, wherein the feeding mechanism is fixedly connected to the left side wall of the operation table through bolts, the conveying mechanism is arranged above the operation table, the fixing mechanism is fixedly connected to the periphery of the outer side wall of the conveying mechanism through bolts, and the pushing mechanism is fixedly connected to the front side of the left side of the top of the operation table through bolts. For the automatic punching device for the cylindrical neodymium iron boron, by replacing manual punching with automatic punching, more time and more labor can be saved during neodymium iron boron machining, and the working efficiency is improved at the same time; and the punching process is completely automatic, so that the yield is increased while the qualified rate is increased, chips produced during punching are prevented from being scattered at will, damages to the machine are avoided, and the production and machining cost is reduced while the economic loss is avoided.

Owner:安徽新科磁业有限公司

Automatic digging mechanism of intelligent construction tunneling machine

The invention discloses an automatic digging mechanism of an intelligent construction tunneling machine. The automatic digging mechanism comprises a first tunneling mechanism and a second tunneling mechanism, wherein the first tunneling mechanism is arranged on the second tunneling mechanism, a ring of synchronously telescopic and rotating first drill bits are arranged on the first tunneling mechanism, a first top pressing shaft is arranged at an end of each first drill bit, a first chain wheel is arranged at the end of each first top pressing shaft, a ring of synchronously telescopic and rotating second drill bits are arranged on the second tunneling mechanism, a fourth top pressing shaft is arranged at the end of each second drill bit, and a second chain disc is arranged at the end of each fourth top pressing shaft. The first drill bits and the second drill bits drill holes on a wall, so that the hole size on the wall can be unified, the problem of different hole sizes caused by manual drilling can be avoided, and the digging efficiency is improved greatly.

Owner:同炎数智科技(重庆)有限公司

A 3D forming method for preparing silicon carbide ceramics with controllable pore size

ActiveCN108439987BNarrow pore size distributionAperture controlAdditive manufacturing apparatusCeramicwareCarbide siliconMolding machine

The invention provides a method for preparing pore-size-controllable silicon carbide ceramic by means of three dimensional (3D) molding, belonging to the technical field of 3D printing. The method comprises the following steps: separately and uniformly coating two types of silicon carbide powder, having different particle sizes, with a mixture of polycarbosilane and silicon dioxide powder to obtain coarse, median and fine coated composite powder with three particle sizes, and mixing the obtained coarse, median and fine coated composite powder with three particle sizes according to a mass ratioof 100 to (0.2-1.6) to obtain printing powder; molding the printing powder by using a direct three-dimensional printing molding machine to obtain a ceramic green body, wherein ink used for the three-dimensional printing molding machine is a tetrahydrofuran solution of polycarbosilane having a mass concentration of 0.5-1.3%; sintering the ceramic green body obtained in the step (4) at a high temperature to obtain the pore-size-controllable silicon carbide ceramic. The method provided by the invention realizes the control of the pore size of the silicon carbide ceramic product by adjusting thecoarse powder median particle diameter D50.

Owner:MAINTOP TECH DEV CO LTD

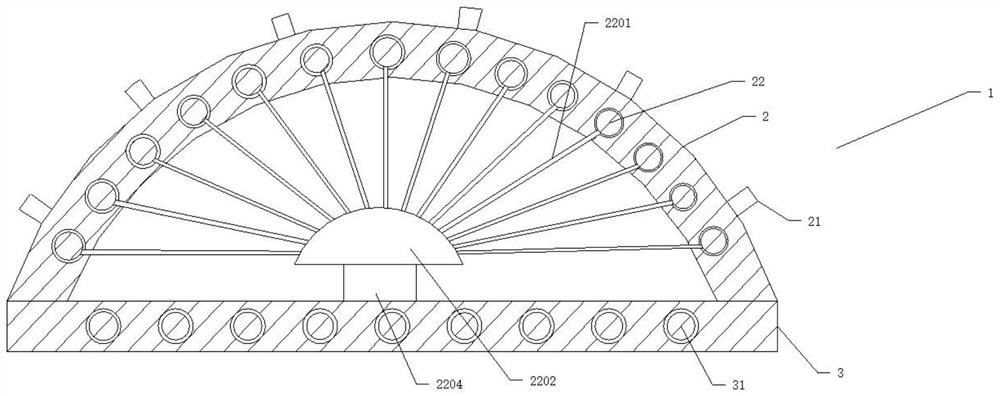

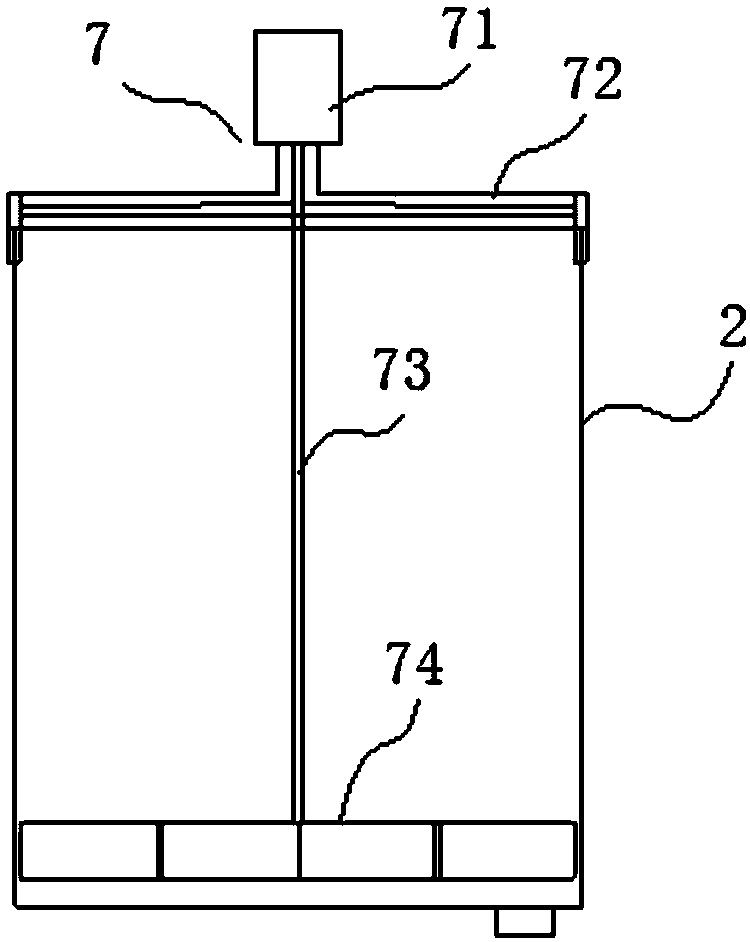

Radial flow dividing and concentrating apparatus for water-erosion-monitored district

PendingCN108562720ASolve the dead angle problemEasy to cleanEarth material testingInstabilityWater flow

The invention discloses a radial flow dividing and concentrating apparatus for a water-erosion-monitored district. The radial flow dividing and concentrating apparatus comprises a flow concentrating barrel and more than one flow dividing barrel, wherein the flow dividing barrels are successively connected in series; the head-end flow dividing barrel is connected with the concentrated radial flow of the district; and the tail-end flow dividing barrel is connected with the flow concentrating barrel. The radial flow dividing and concentrating apparatus for the water-erosion-monitored district avoids the problem of existence of blind angles in the barrels, can realize faster sampling, and is more convenient to clean since a discharge opening is reserved in the bottom; flow stabilizing grids are arranged in the flow dividing barrels so as to effectively prevent the difference of multi-hole flow division caused by instability of flow rate when rainfall is large, improve flow division stability and observation precision and guarantee uniform flow velocity of water flow, and flow division holes are consistent in pore diameters and uniformly distributed at a same level, which allows higherflow division precision to be obtained; a detachable stirring device realizes rapid and easy stirring of a sample, so sampling precision is effectively improved; and the stirring device can conveniently clean residual radial flow after observation and can exert ideal effect in cleaning.

Owner:NANJING FORESTRY UNIV

Transformation and construction method used for facing bare concrete of existing building outer wall

ActiveCN103470067BMeet the stiffness requirementsEasy to fixBuilding repairsForms/shuttering/falseworksRebarMaterials science

Owner:WUDA JUCHENG STRUCTURE CO LTD

Preparation method of cement foamed heat insulation board

The invention discloses a preparation method of cement foamed heat insulation board, and belongs to the field of building materials. The preparation method comprises the following steps of : taking raw materials in parts by weight, afterwards, firstly uniformly agitating and mixing cement, a silicon-acrylate emulsion, a water reducer and a catalyst in the raw materials, adding water, agitating, next, adding a compound foaming agent and an additive in the raw materials, continuously agitating, then collecting an agitated mixture, and standing, foaming, standing at a room temperature and demolding to obtain a demolded matter, and maintaining and drying the demolded matter, so that the cement foamed heat insulation board can be obtained. The preparation method has the beneficial effects that pores of the cement foamed heat insulation board are consistent in aperture size and uniformly distributed; meanwhile, the cement foamed heat insulation board has higher compression strength, and is worth to be popularized and used.

Owner:CHANGZHOU SIYU ENVIRONMENTAL PROTECTION MATERIAL SCI & TECH

A kind of capacitive pressure sensor and preparation method thereof

ActiveCN109781312BHigh sensitivityHigh dielectric constantForce measurementCapacitive pressure sensorEngineering

The invention belongs to the technical field of capacitive pressure sensors, and particularly relates to a capacitive pressure sensor and a preparation method thereof. The sensor comprises electrodes,an ionic gel dielectric layer and wires, wherein the electrode is composed of a substrate of which the surface is provided with a silver nanowire layer; a wire extending to the outside of the silvernanowire layer is embedded in the silver nanowire layer; the ionic gel dielectric layer is arranged on the surfaces of the silver nanowire layers on the top electrode and the bottom electrode; the structure of the ionic gel dielectric layer is as follows: columnar ionic gel is distributed on the surface of a substrate layer; wherein the substrate layer in the ionic gel dielectric layer is arrangedon the silver nanowire layer of one electrode, and the silver nanowire layer of the other electrode is arranged on the columnar ionic gel in the ionic gel dielectric layer. The prepared sensor is high in sensitivity, small in hysteresis and good in repeatability, and can be widely applied to electronic skin, wearable products, implantation equipment and multifunctional sensor systems.

Owner:三三智能科技(日照)有限公司

Hazardous waste sludge drying machine

InactiveCN108996883AConsistent particle sizeReduce moisture contentSludge treatment by de-watering/drying/thickeningCombustion chamberSludge

The invention relates to a hazardous waste sludge drying machine. The hazardous waste sludge drying machine comprises a combustion chamber, and a motor arranged on one side of a drying cylinder far away from the combustion chamber; the combustion chamber is communicated with the drying cylinder through a feeding ring; the feeding ring is provided with a feed inlet; the drying cylinder comprises aninternal cylinder connected with an inner ring of the feeding ring through rotation connection, and an external cylinder fixedly connected with an outer ring of the feeding ring; the wall of the internal cylinder is provided with a plurality of through holes; a rotating shaft of the motor is connected with a rotating rod stretching into the internal cylinder; the rotating rod is fixedly connectedwith the internal cylinder; the rotating rod is connected with the external cylinder through rotating connection; the periphery of the rotating rod stretching into the internal cylinder is provided with a plurality of agitating rods; a chimney is arranged on the upper part of one end of the external cylinder close to the motor, and a discharge pipe is arranged on the lower part of the end; the chimney and the discharge pipe are communicated with the external cylinder. In drying process, electroplating sludge is subjected to agitating, and rotation collision, so that water content is reduced effectively; the diameters of the through holes on the internal cylinder are the same, so that it is ensured that the particle sizes of particles capable of passing through the through holes are the same, and the water content is ensured to be consistent.

Owner:YANGXIN PENGFU MINING CO LTD

Low-shrinkage porous ceramic component, injection feed and preparation method thereof

ActiveCN112552074ALow shrinkagePrevent shrinkage deformationCeramic shaping apparatusCeramic materials productionPlasticizerFilling materials

The invention relates to the field of ceramics, and particularly discloses a low-shrinkage porous ceramic component, an injection feed and a preparation method thereof. The porous ceramic component comprises inorganic framework whiskers, an inorganic bonding material and an inorganic filling material, and the inorganic framework whiskers comprise one or more of SiC whiskers, Al2O3 whiskers, SiO2 whiskers and AlN whiskers; the preparation method comprises the following steps: uniformly ball-milling the treated ceramic components, internally mixing with an injection accelerator, an injection skeleton agent, an injection filler and a plasticizer, adding into a granulator to prepare the injection feed after the internal mixing is completed, finally injecting the injection feed into a ceramic green body, discharging glue, and sintering to obtain the low-shrinkage porous ceramic. The low-shrinkage porous ceramic disclosed by the invention can be applied to the fields of electronic cigarettes, atomization medical treatment and atomization cosmetic instruments, and has the advantages of low shrinkage rate, controllable size, high product percent of pass and the like.

Owner:山东丁鼎科技发展有限公司 +1

Perforating device for crop mulching film planting

InactiveCN111115323AReduce jitterHelp productionMetal working apparatusWebs handlingMotor driveGear wheel

The invention belongs to the technical field of crop mulching film planting, and discloses a perforating device for crop mulching film planting. The perforating device comprises a machine body, a controller, a first motor and a second motor, wherein the first motor and the second motor are arranged inside the machine body; the perforating device also comprises a perforating assembly, a transmission driving assembly and a conveying device; a separation plate is arranged inside the machine body; the first motor is arranged on the upper surface of the separation plate; the perforating assembly comprises a transmission wheel, a transmission rod, a gear head, a movable rod, a rack, a mounting plate and a perforating head; and the mounting plate is arranged at one side of the separation plate. The perforating device has the advantages that the perforating assembly is arranged; the assembly uses a motor driving mode; the gear and the rack are in engaged transmission; the perforating head is arranged at the front end of the movable rod; the engaged transmission precision is high; under the effect of a position limiting ring, during perforating, the movable rod shaking is small; the perforating efficiency is improved; the perforating quality is ensured; the hole diameter is consistent; and the crop production is facilitated.

Owner:周正东

A kind of preparation method of zirconia ceramic ultrafiltration membrane

ActiveCN110270230BNarrow distributionGood pore size consistencyUltrafiltrationCellulosePolyvinyl alcohol

The invention discloses a method for preparing a zirconia ceramic ultrafiltration membrane. The method is characterized in that: a sol-gel method is used to prepare a zirconia sol; Mix one or more of vinyl alcohol, methyl cellulose, and glycerin evenly to prepare a coating solution; impregnate the coating solution on the surface of the ceramic filter membrane substrate; dry the coated substrate, and then immerse it in a high-pressure reaction In the nitric acid aqueous solution with a pH of 1-3 in the kettle, a hydrothermal reaction is carried out at 180-220°C to form a ceramic ultrafiltration membrane with a uniform pore size of 10-20nm.

Owner:翁志龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com