Hot melt laminating device and method of membrane filter material

A film-covering device and hot-melting technology, applied in lamination devices, chemical instruments and methods, layered products, etc., can solve the problems of teflon surface film damage, drop in filtration efficiency, and high surface temperature, and achieve service life. Long, consistent pore size, and the effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

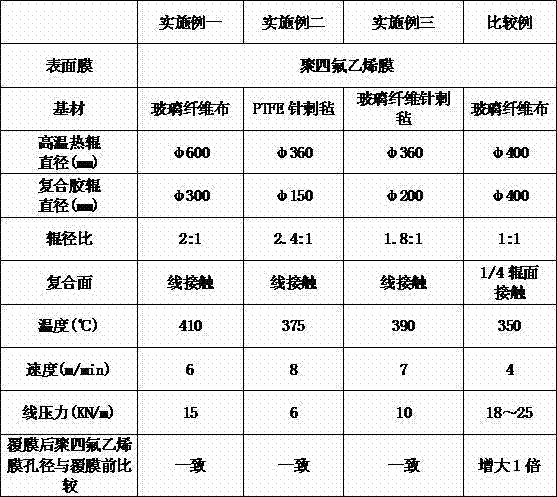

[0028] Embodiment 1: Polytetrafluoroethylene film and glass fiber cloth hot-melt coating.

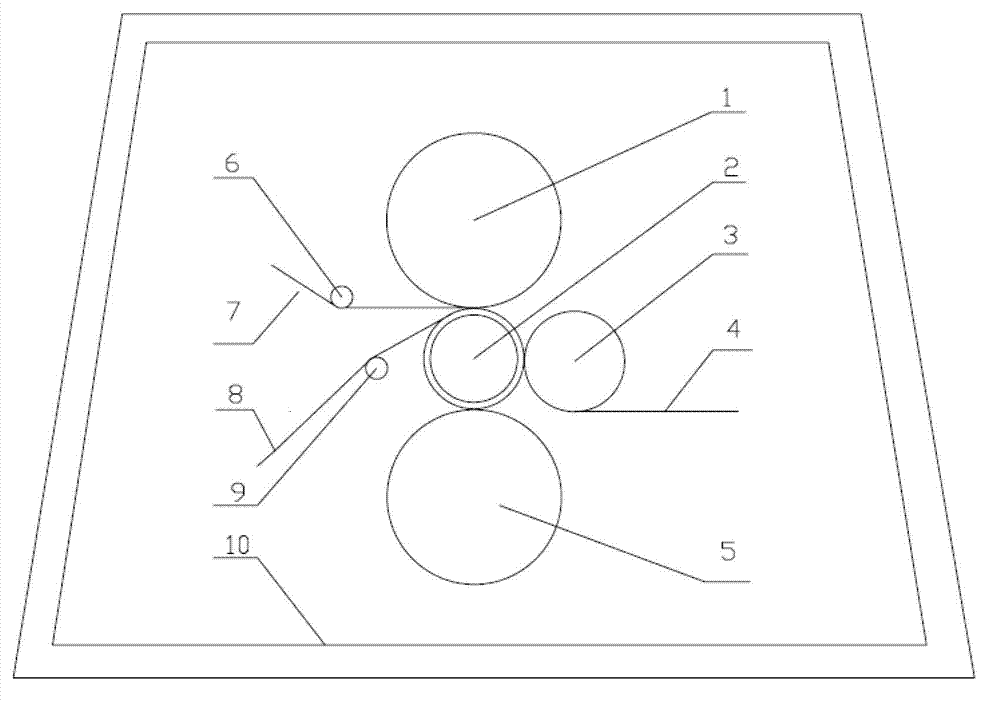

[0029] The manufacturing method of the film covering of the membrane filter material is as follows: firstly, the temperature of the high-temperature hot roller 1 is raised to 410°C, and the polytetrafluoroethylene membrane 7 (commercially available, specification FM10) and glass fiber cloth 8 (commercially available, specification EWTF750) are respectively Through the film guide roller 6 and the cloth guide roller 9, between the high-temperature hot roller 1 and the composite rubber roller 2 of the hot-melt coating device synchronously input at a linear speed of 6m / min, the polytetrafluoroethylene film 7 and the glass fiber cloth 8 are The temperature of 410°C and the linear pressure of 15KN / m are hot-melt and combined, and the stripping roller 3 is quickly separated from the high-temperature hot roller 1 to obtain the glass fiber cloth-coated polytetrafluoroethylene membrane filter mate...

Embodiment 2

[0032] Embodiment 2: polytetrafluoroethylene film and polytetrafluoroethylene (PTFE) needle felt hot-melt coating.

[0033] The manufacturing method of the film covering of the membrane filter material is as follows: firstly, the temperature of the high-temperature hot roller 1 is raised to 375°C, and the polytetrafluoroethylene membrane 7 (commercially available, specification FM10) and the polytetrafluoroethylene (PTFE) needle felt 8 ( Commercially available, specification PTFENW700) pass through the film guide roller 6 and the cloth guide roller 9 respectively, and are synchronously input between the high-temperature hot roller 1 and the composite rubber roller 2 of the hot-melt coating device at a line speed of 8m / min, and the polytetrafluoroethylene film 7 and polytetrafluoroethylene (PTFE) needle felt 8 are thermally melted and compounded at a temperature of 375°C and a linear pressure of 6KN / m, and the stripping roller 3 is quickly detached from the high-temperature hot ...

Embodiment 3

[0036] Example 3: Polytetrafluoroethylene film and glass fiber needle felt hot-melt coating.

[0037] The manufacturing method of the film covering of the membrane filter material is as follows: first, the temperature of the high-temperature hot roller 1 is raised to 390°C, and the polytetrafluoroethylene membrane 7 (commercially available, specification FM10) and glass fiber needle felt 8 (commercially available, specification GENW800 ) pass through the film guide roller 6 and the cloth guide roller 9 respectively, and are synchronously input between the high-temperature hot roller 1 and the composite rubber roller 2 of the hot-melt coating device at a linear speed of 7m / min. The polytetrafluoroethylene film 7 and the glass fiber needle The needled felt 8 is thermally melted and compounded at a temperature of 390°C and a linear pressure of 10KN / m, and is quickly detached from the high-temperature hot roller 1 by the peeling roller 3 to obtain a glass fiber needle felt-coated P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com