Transformation and construction method used for facing bare concrete of existing building outer wall

A technology of fair-faced concrete and existing buildings, which is applied in the field of architectural decoration. It can solve the problems of complex formwork installation and fixing, and the inability to realize thin-layer fair-faced concrete wall construction, etc., and achieve the effect of improving appearance quality, simple installation and fixing steps, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

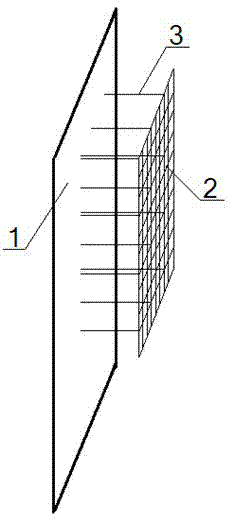

[0108] see figure 1 , a kind of construction method of the fair-faced concrete finish renovation of existing building exterior wall, this construction method comprises the following steps successively:

[0109] Step 1: template processing:

[0110] (1) Cut the formwork into blocks according to the width of the exterior wall of the existing building, where the formwork adopts a steel plate with a thickness of 4mm;

[0111] (2) Use an angle grinder and an electric wire brush to grind and derust the inner surface of the formwork obliquely, and then apply a layer of universal glue or building structure adhesive evenly on the inner surface of the formwork that has been polished and derusted. A stainless steel plate with a thickness of 0.4-0.8mm is pasted on the inner surface of the painted formwork to form a clear water formwork;

[0112] (3) The outer corrugation and transverse back ribs around the clear water formwork are reinforced with equilateral angle steel supports with sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com