Double-rectangular column type pier of high speed railway

A technology for high-speed railways and rectangular columns, applied in bridges, bridge parts, bridge construction, etc., can solve the problems affecting construction quality and construction period, difficult to fully guarantee construction quality, and difficult internal mold construction, etc., to achieve convenient and fast construction. Quick turnaround and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

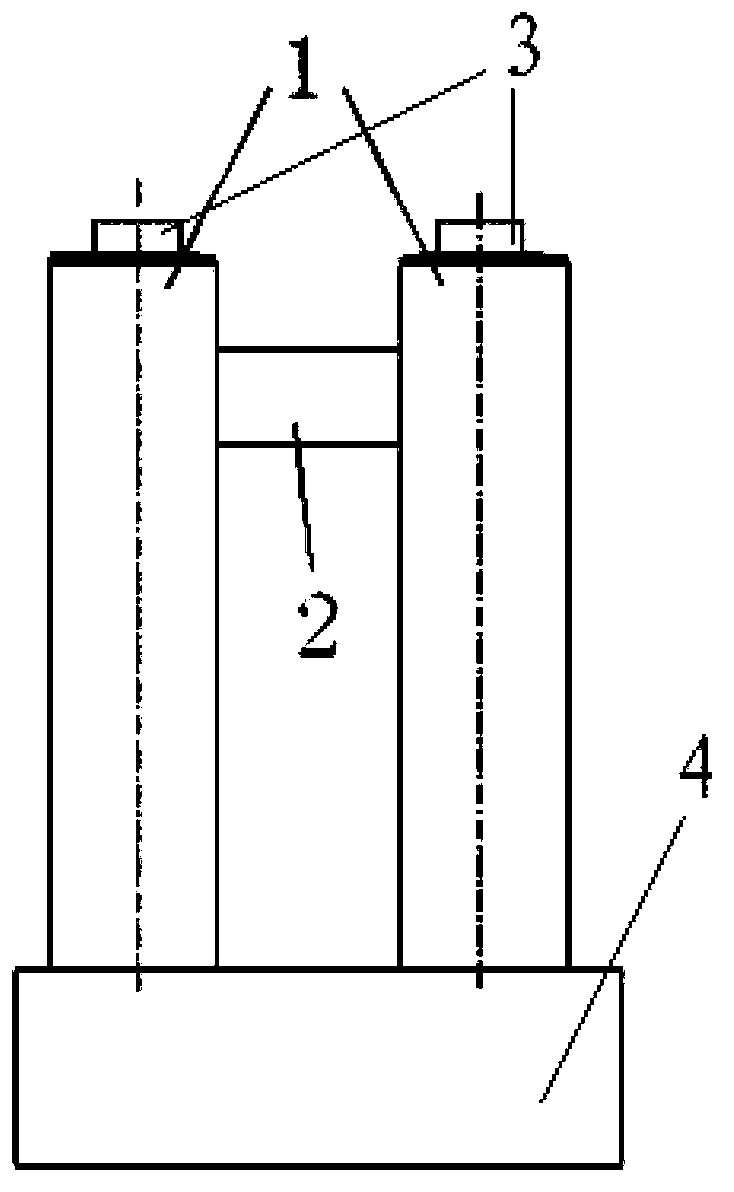

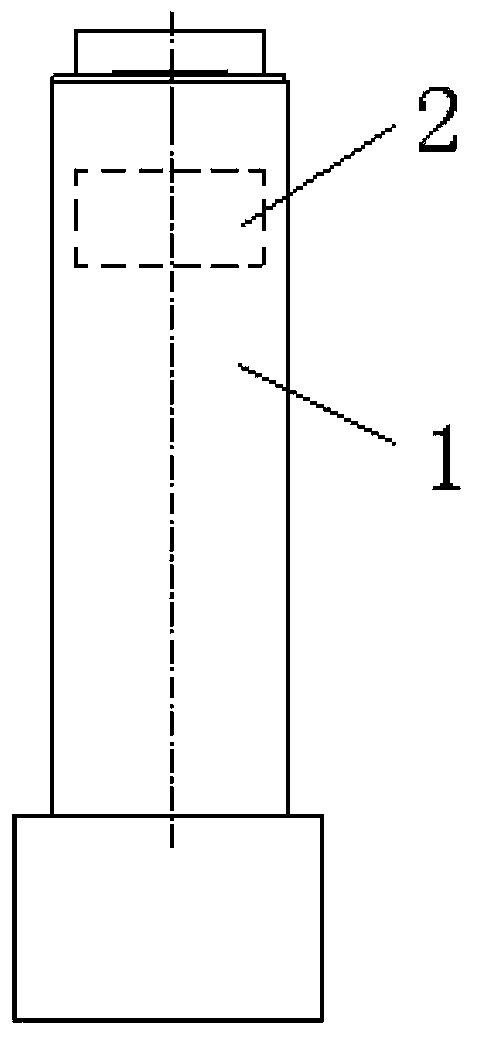

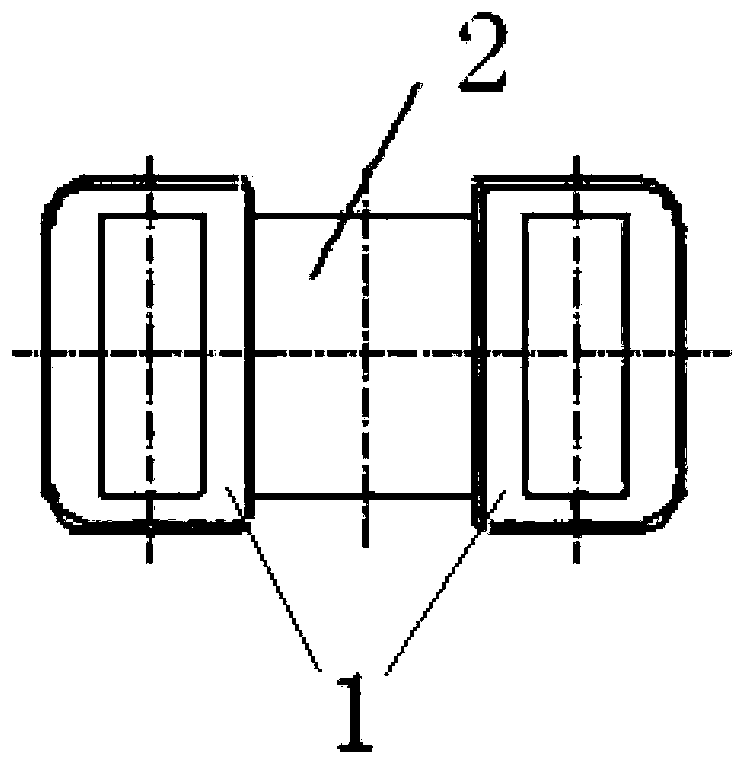

[0013] Such as Figure 1-3 The shown high-speed railway double rectangular column bridge pier includes two pier columns 1 fixed on the base 4 and a tie beam 2 located on the upper part of the pier column 1, and the two ends of the tie beam 2 are respectively fixed inside the two pier columns 1, and the set tie beam 2. It not only satisfies the requirement of lateral rigidity of high-speed bridge piers, but also can take into account the operation platform for inspection and maintenance. Pier 1 is a solid concrete rectangular structure with a small volume and a height of 100-150m, and the force of the whole structure is clear. The top of the pier column 1 is provided with a support seat 3, which can be conveniently contacted with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com