Patents

Literature

100results about How to "The structural force is clear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

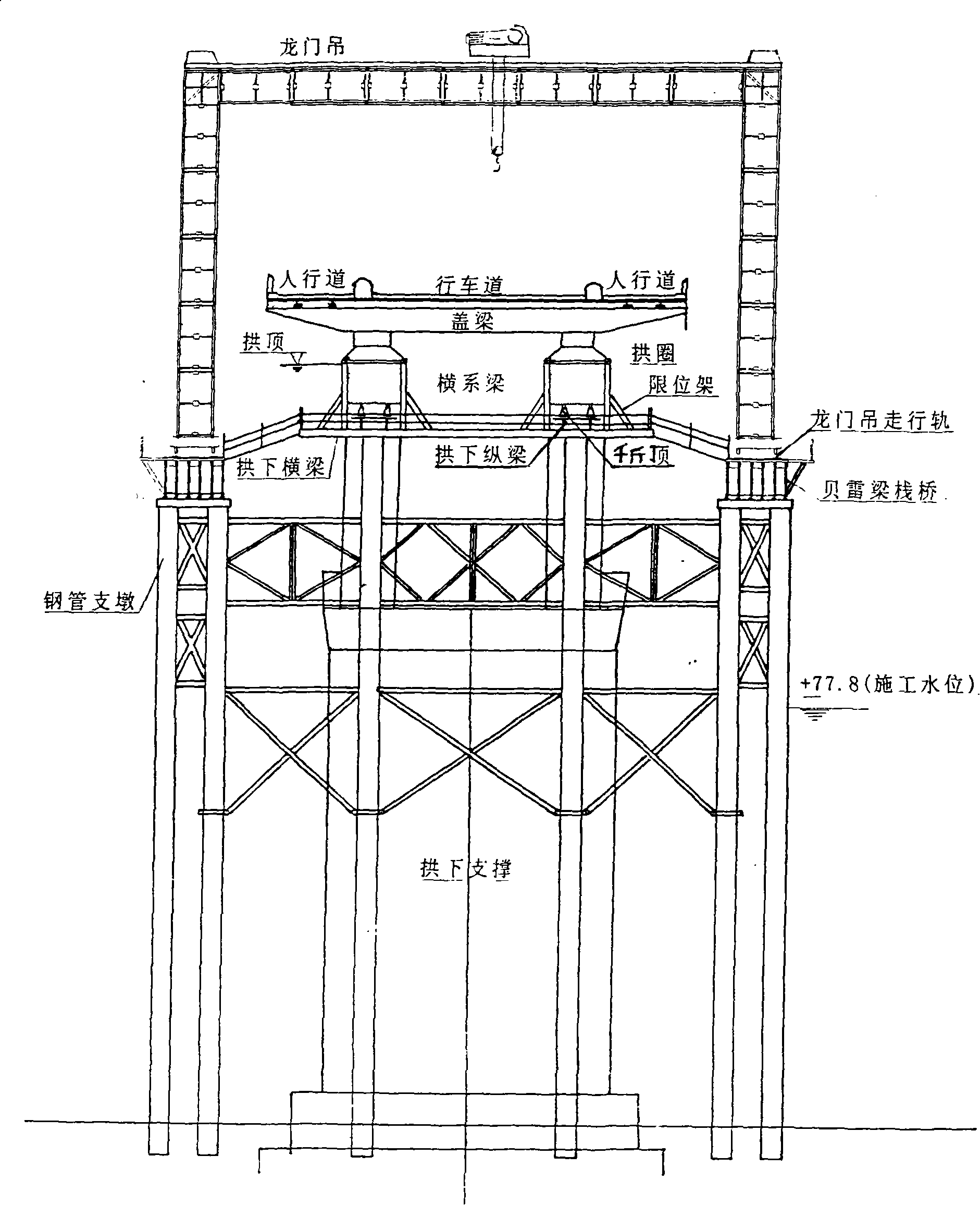

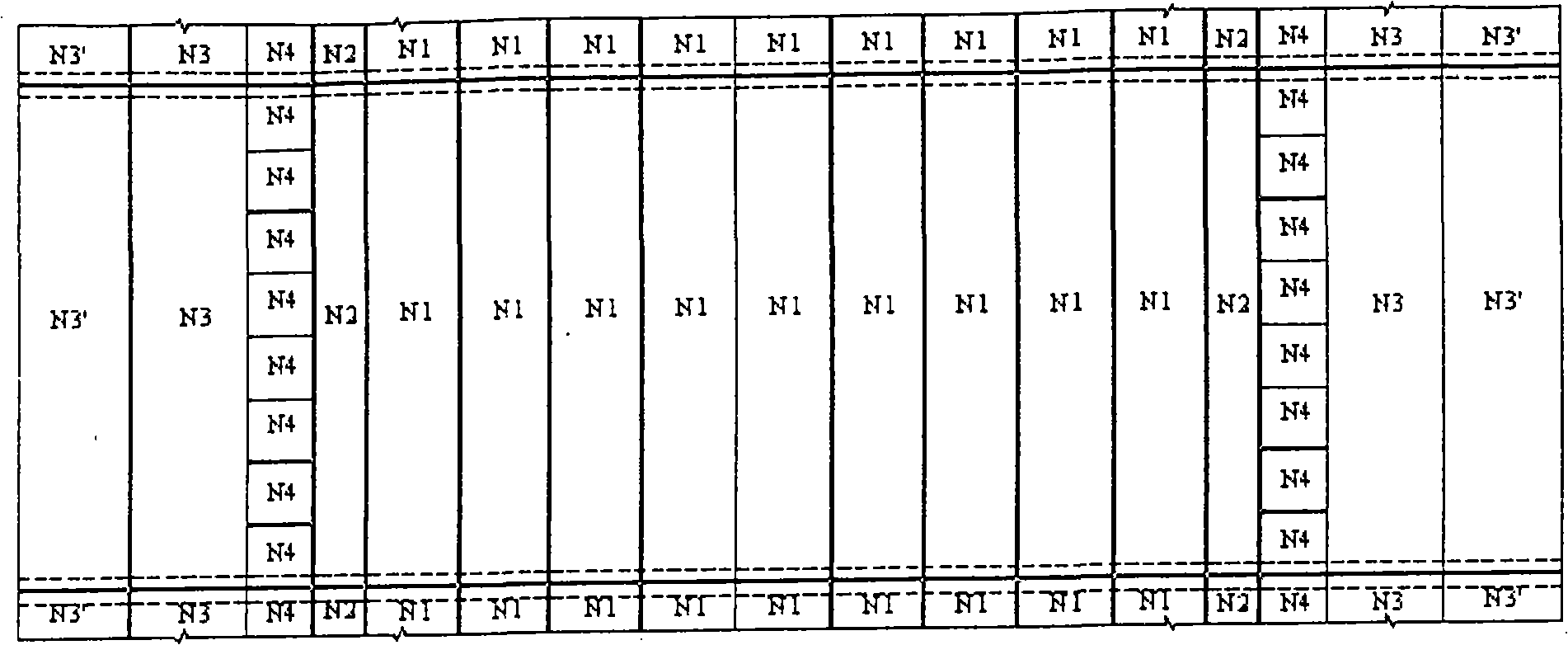

Method for dismantling arch bridge for protection

InactiveCN101265690AShort construction periodEnsure construction safetyBuilding repairsSocial benefitsReverse order

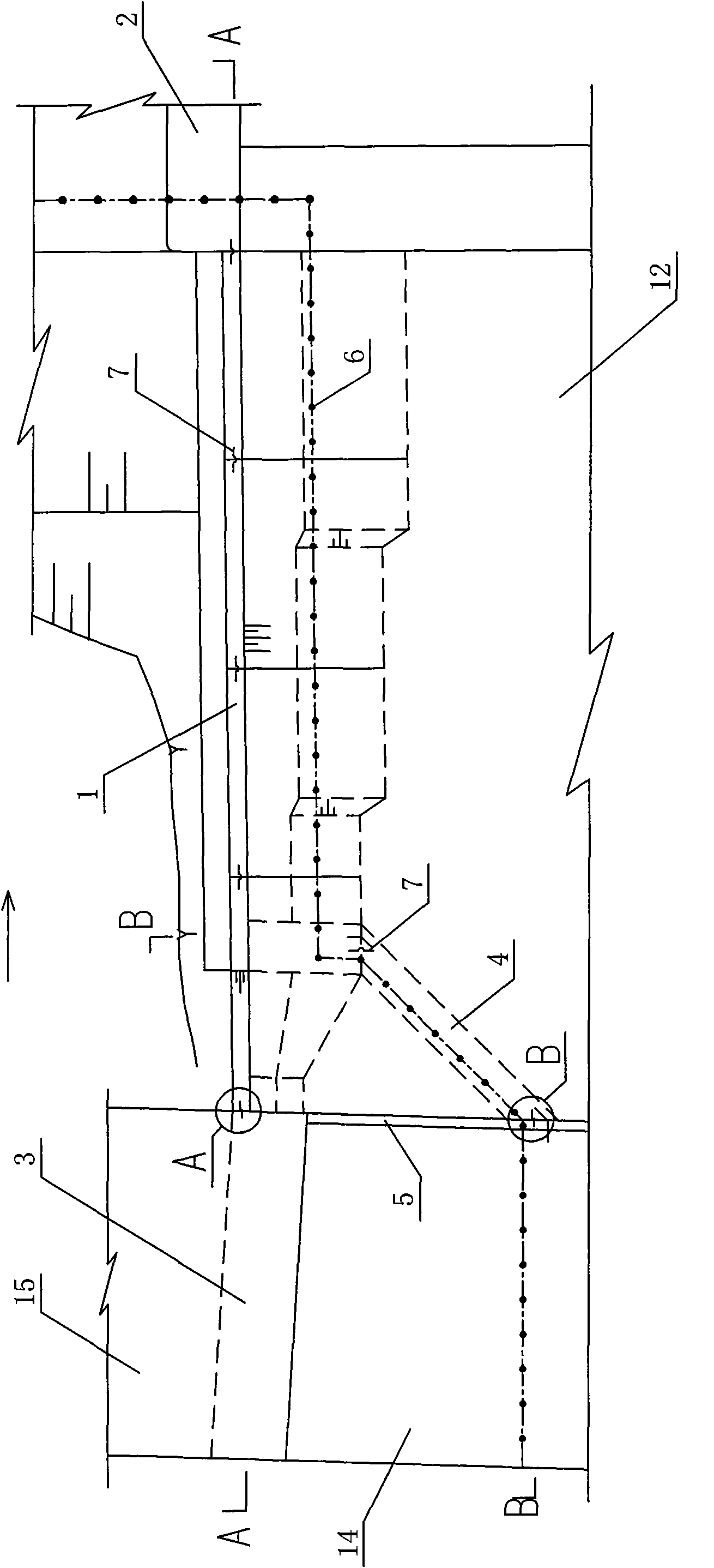

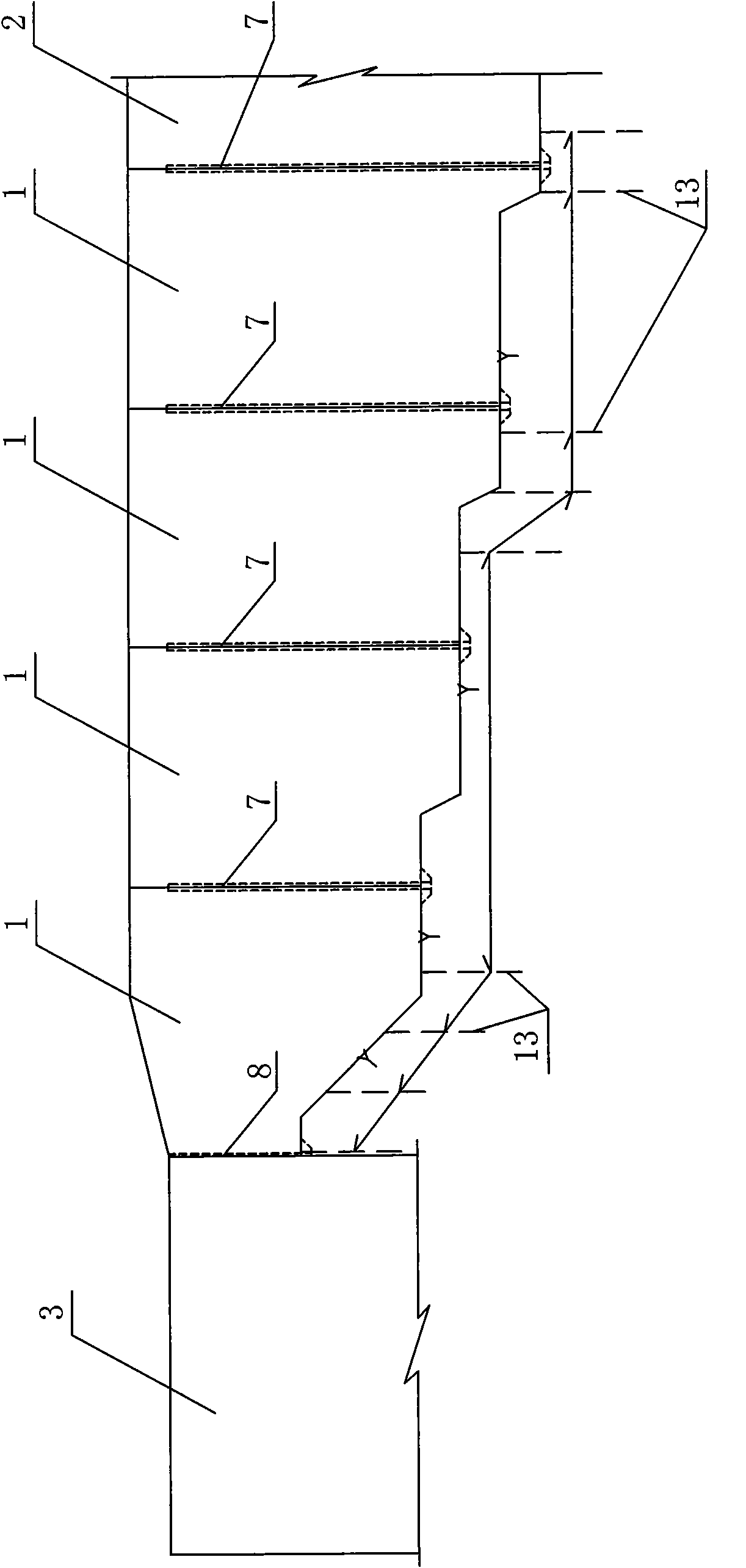

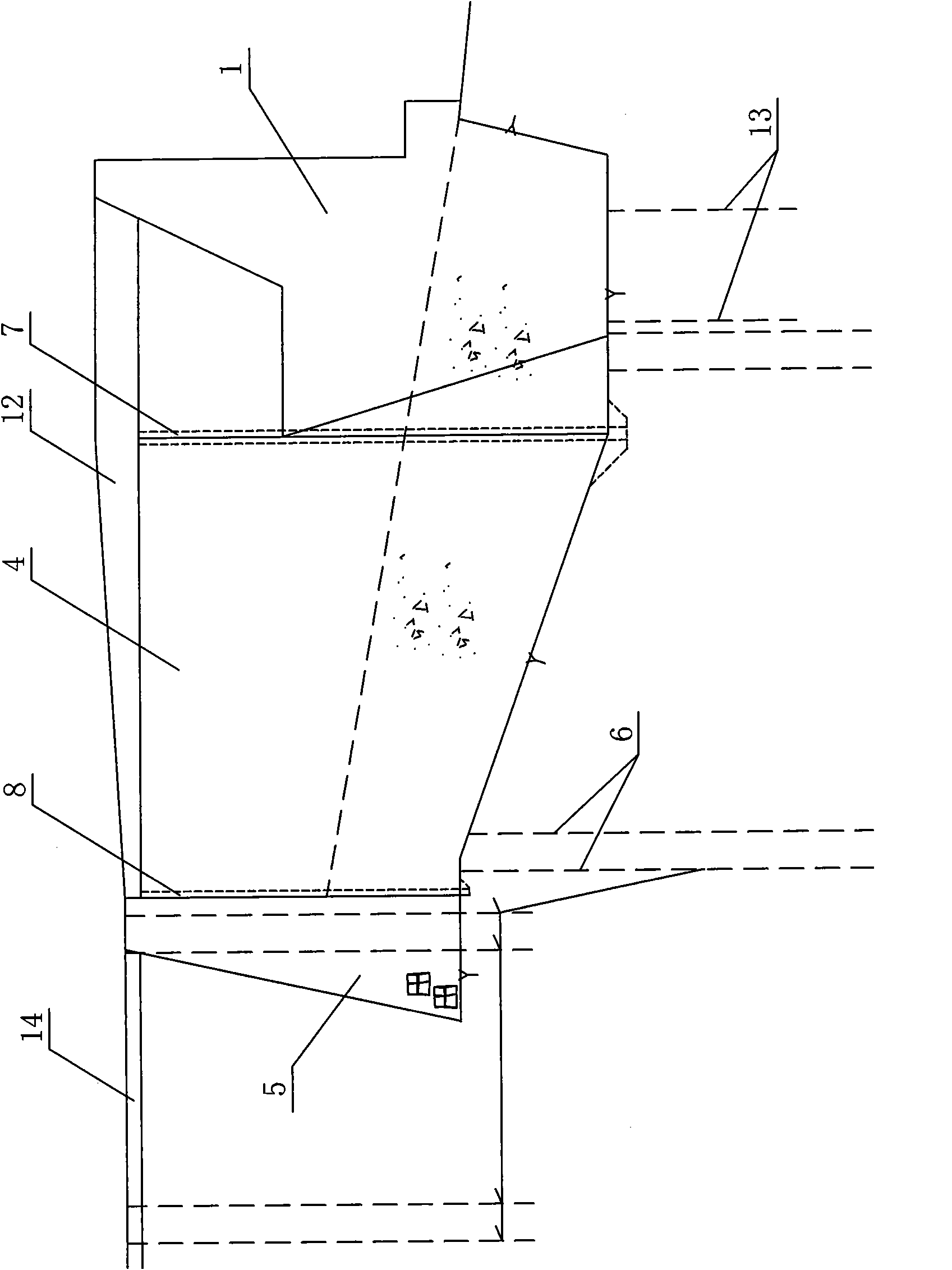

The invention provides a protective method for removing an arch bridge, which belongs to the technology field of bridge removal. The method aims to provide a protective bridge removal method with safety, high efficiency and no pollution. The technical points include: building up a new trestle, erecting a gantry crane, carrying out the bridge removal in a reverse order of the bridge building including bridge decking, coping, column, beam, arch rib and arch support in sequence. The removal stage of the arch rib especially includes removing by adopting methods of top-supporting under the arch, arch box transverse stop and horizontal restraining rope, which better solves the difficult problem of the protective bridge removal with safety, high efficiency and no pollution in a complex construction environment of guaranteeing under-arch navigation, high security level, short construction period and various unpredictable elements, manages to meet the design requirements of the removal safety factor in the protective bridge removal process and the limit control under various removal working conditions and guarantees the removal quality and the construction safety. The removal method has low cost and remarkable social benefit reflected in the direct economic analysis, which is a protective removal method of large-span bridges with safety, high efficiency and practicability.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

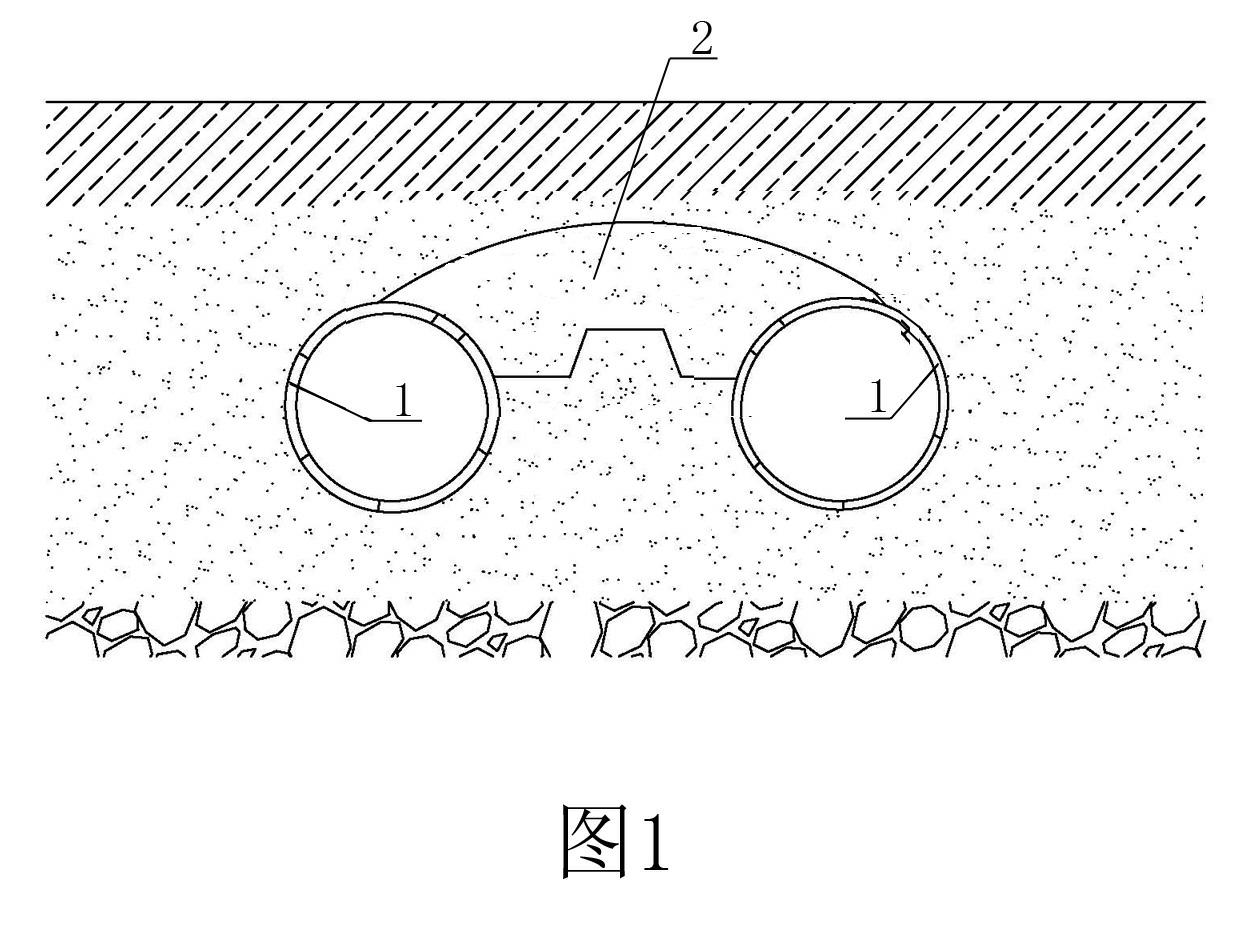

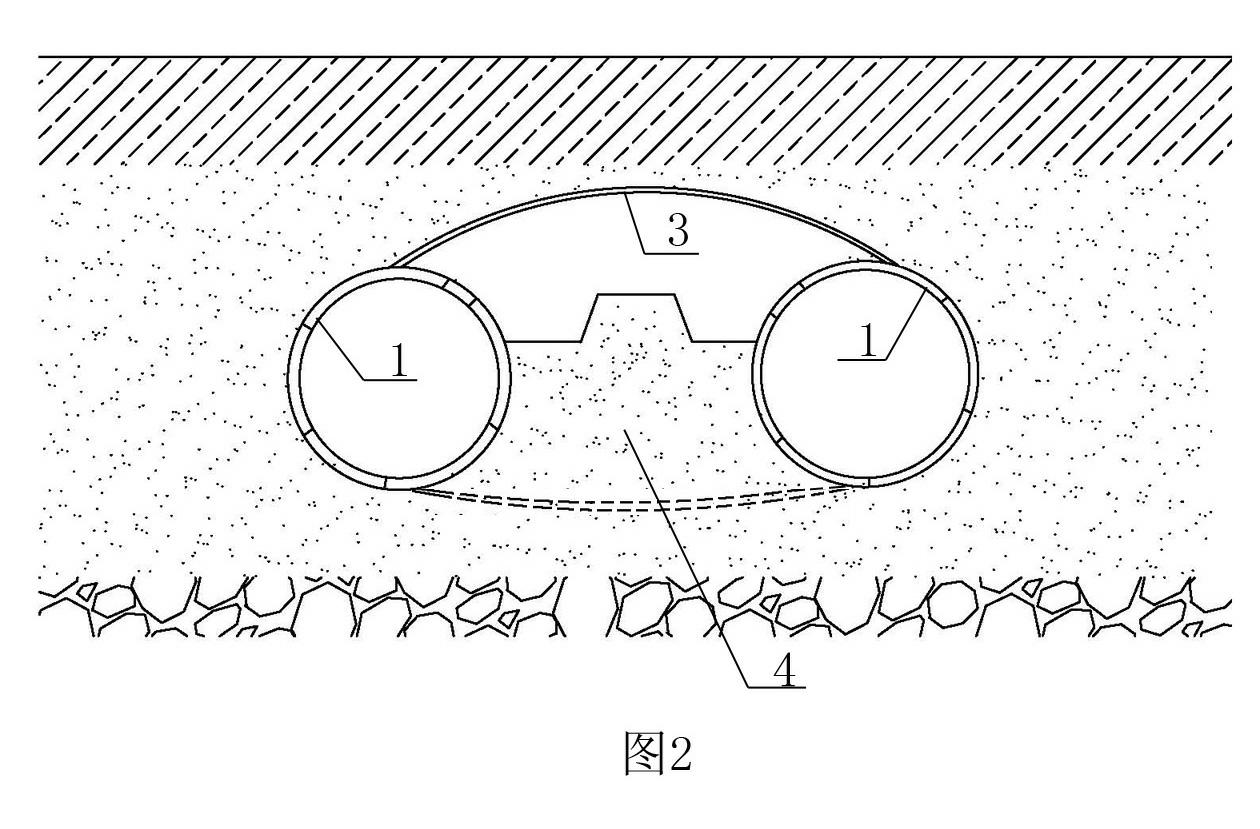

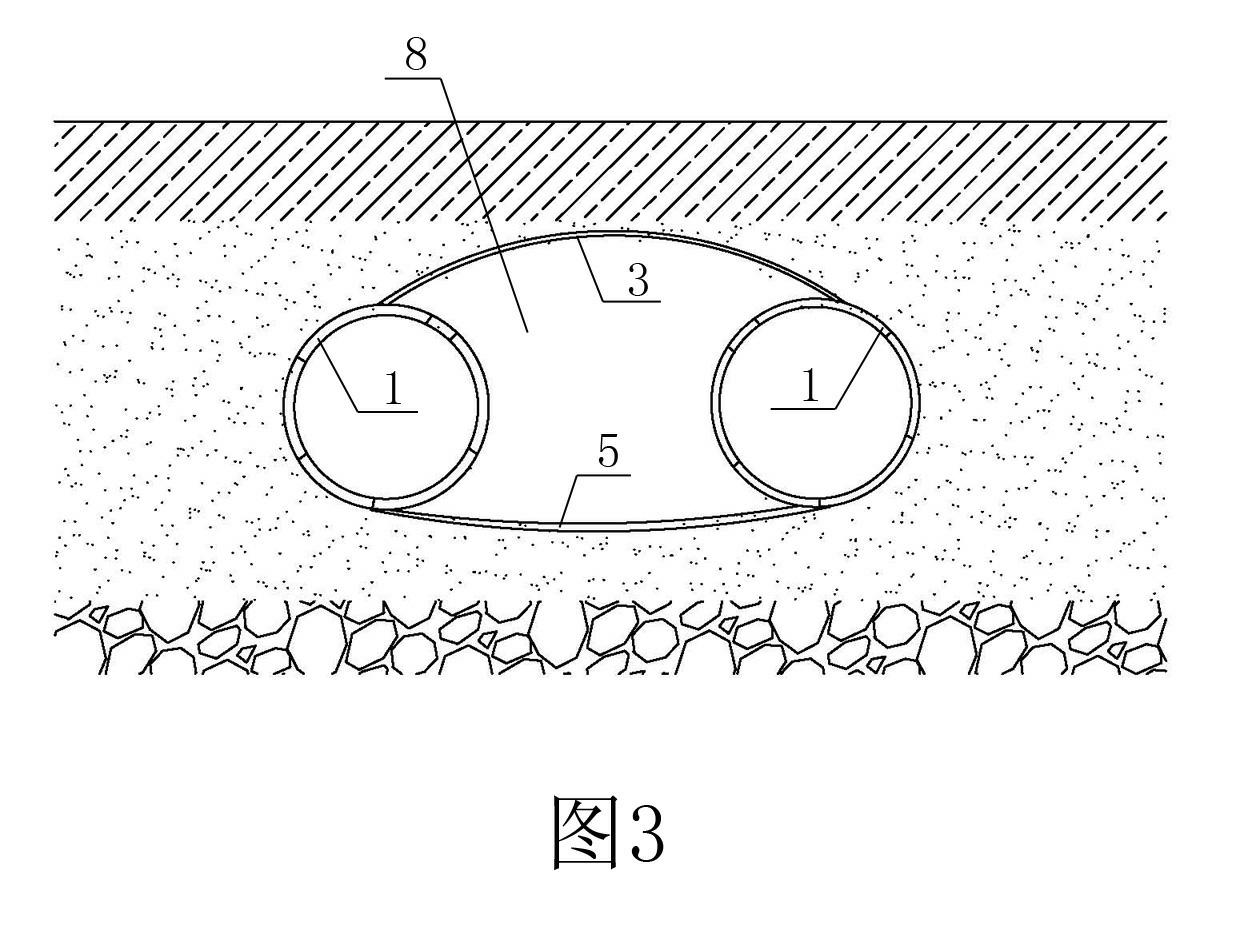

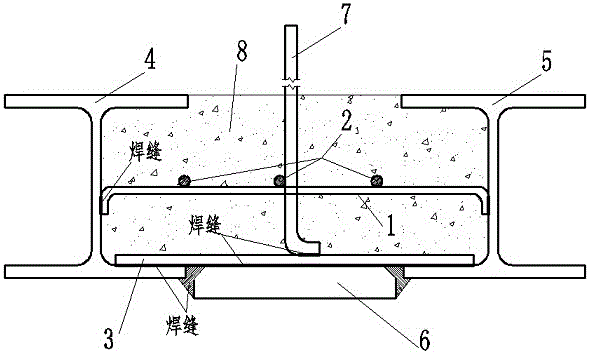

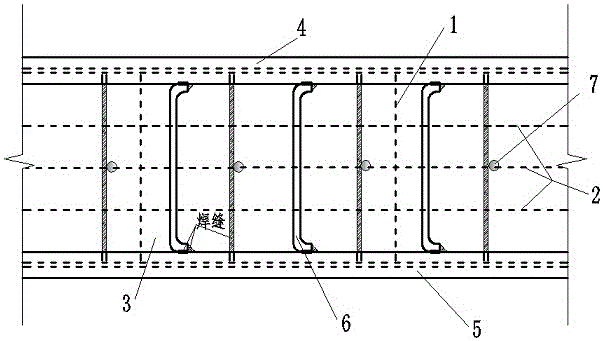

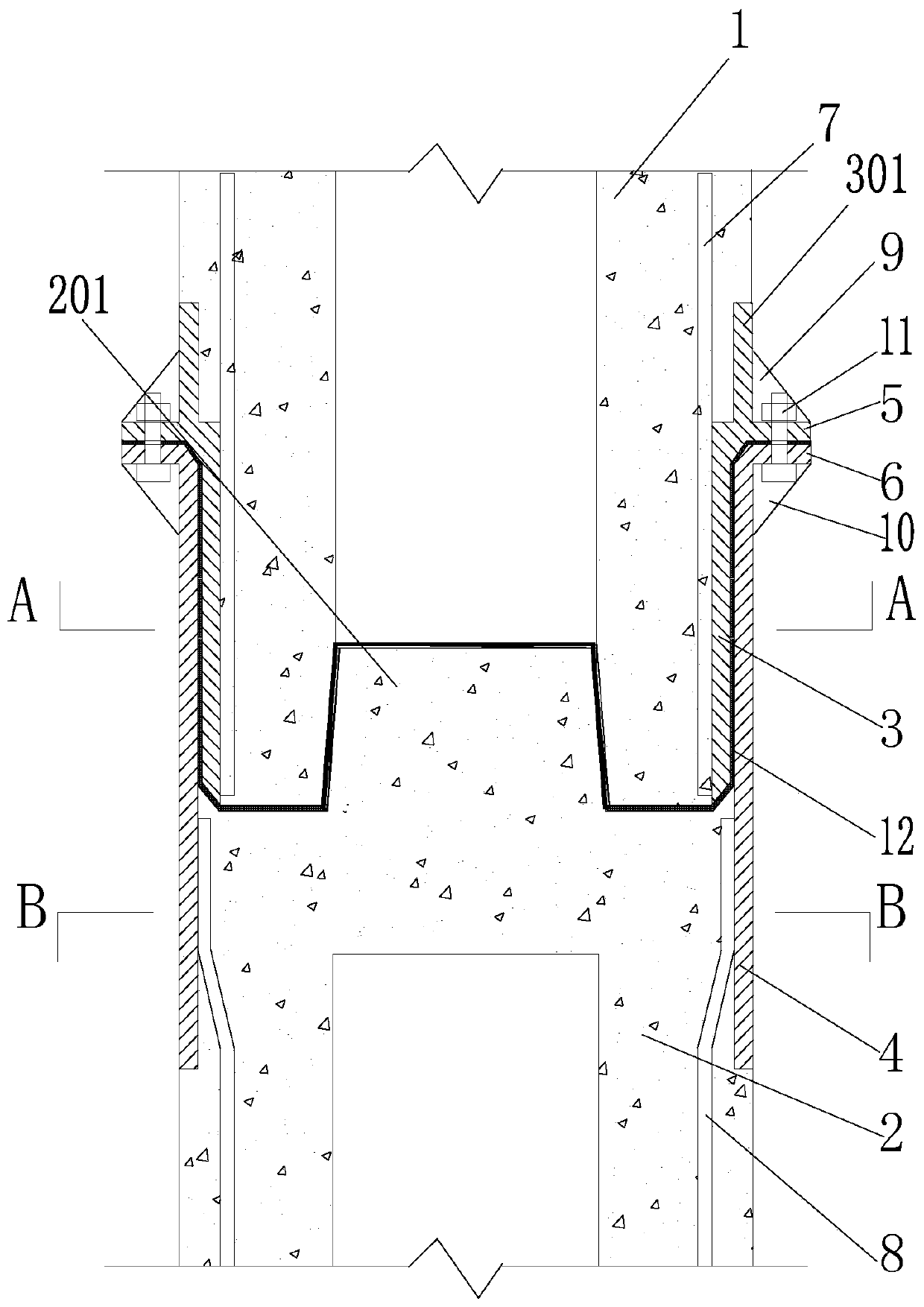

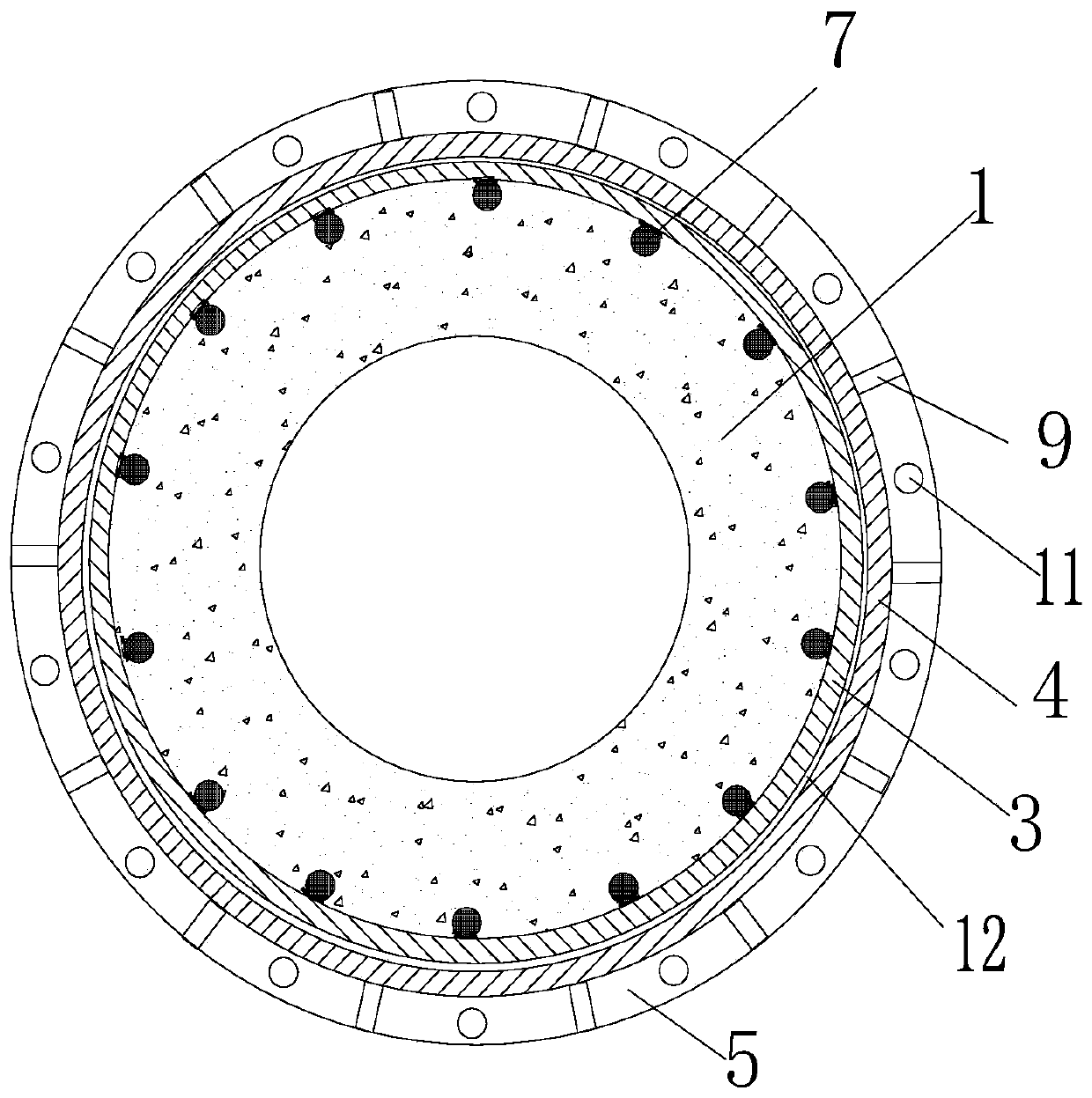

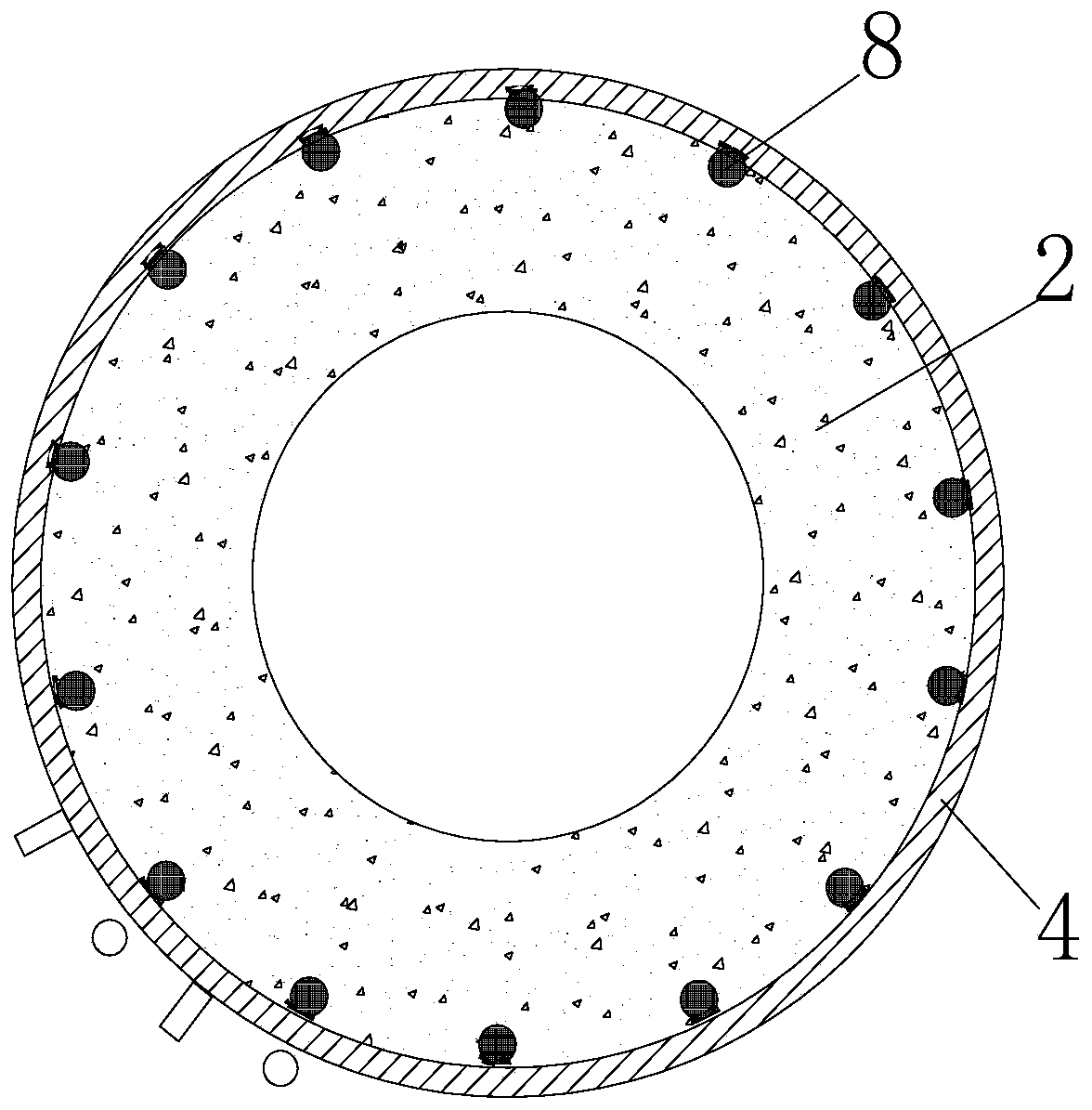

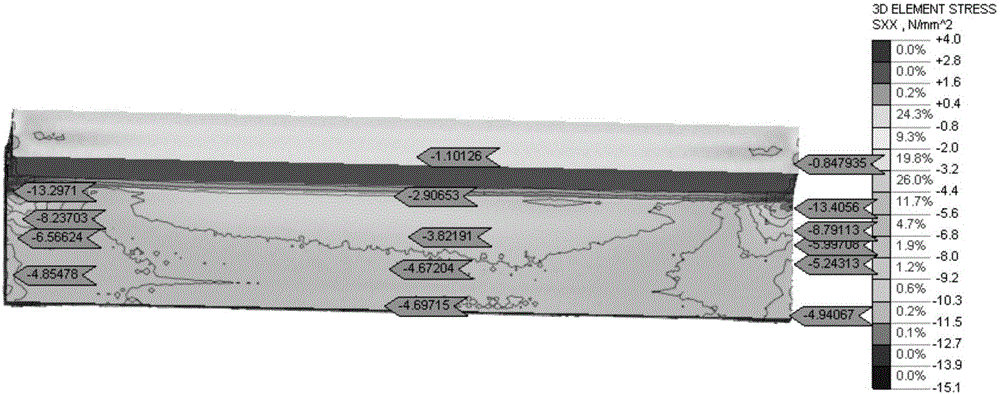

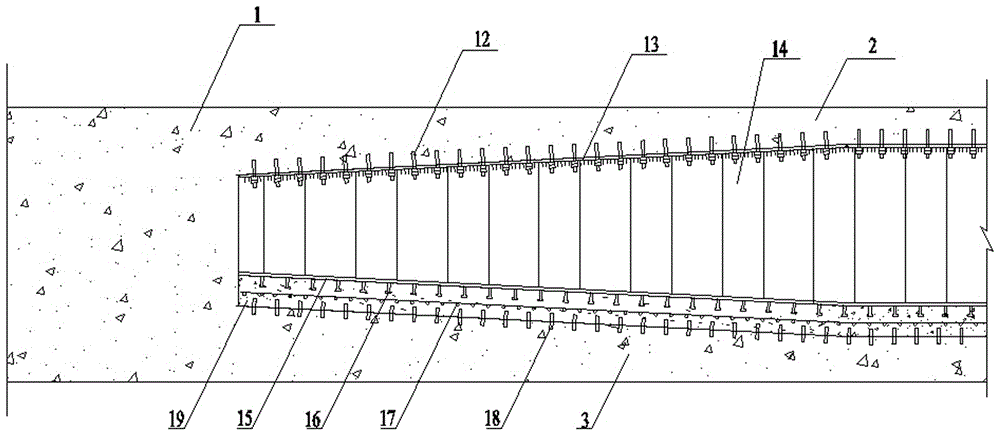

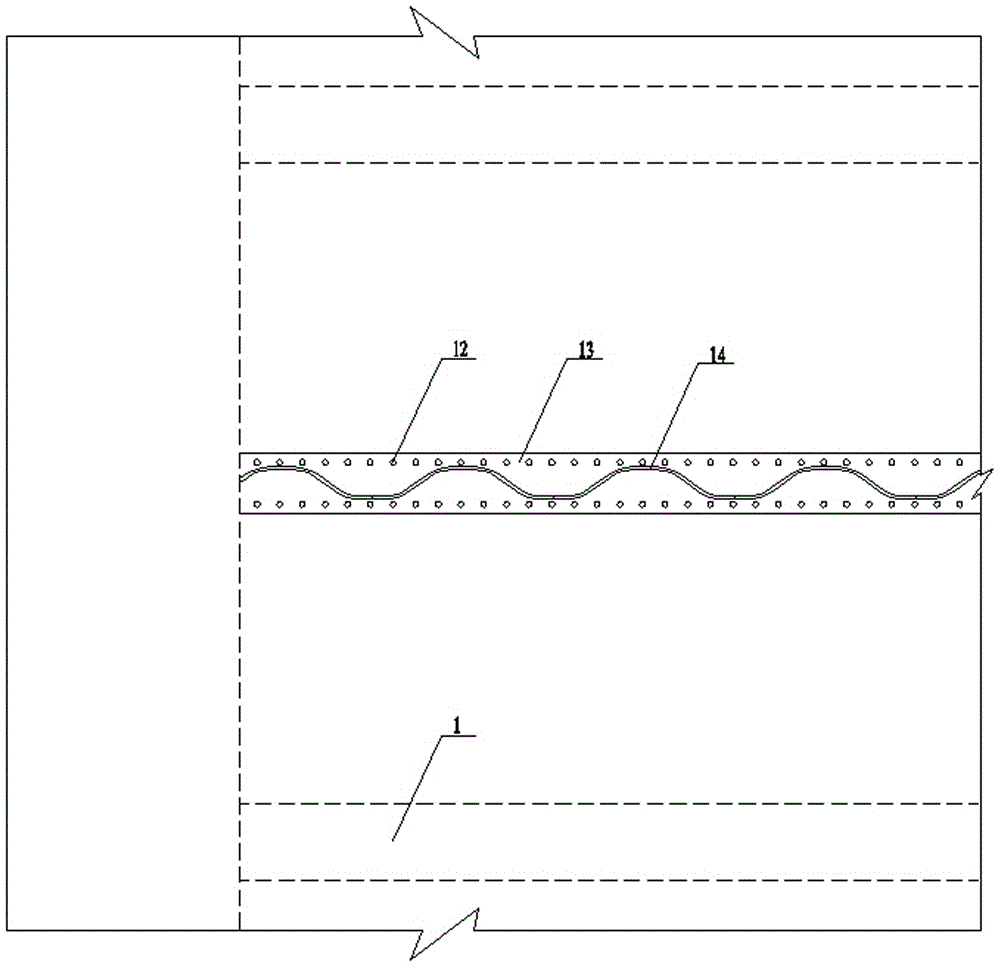

Method for constructing underground space by shield-shallow buried covered excavation composite method

InactiveCN102094649AReduce disturbanceReduce construction riskUnderground chambersTunnel liningStructural engineeringShield tunnelling

The invention relates to a method for constructing an underground space by a shield-shallow buried covered excavation composite method, and belongs to the technical field of construction methods of the underground space. The construction method comprises the following steps of: constructing two or more shield tunnels in advance by a shield method; and excavating a soil body between the shield tunnels by a shallow buried covered excavation method. By the method, the construction of the underground space with a large cross section is safe and high-efficiency, a structure is definitely stressed, construction speed is high and construction cost is low. The method can be used for constructing large-scale underground spaces in various forms.

Owner:乐贵平 +1

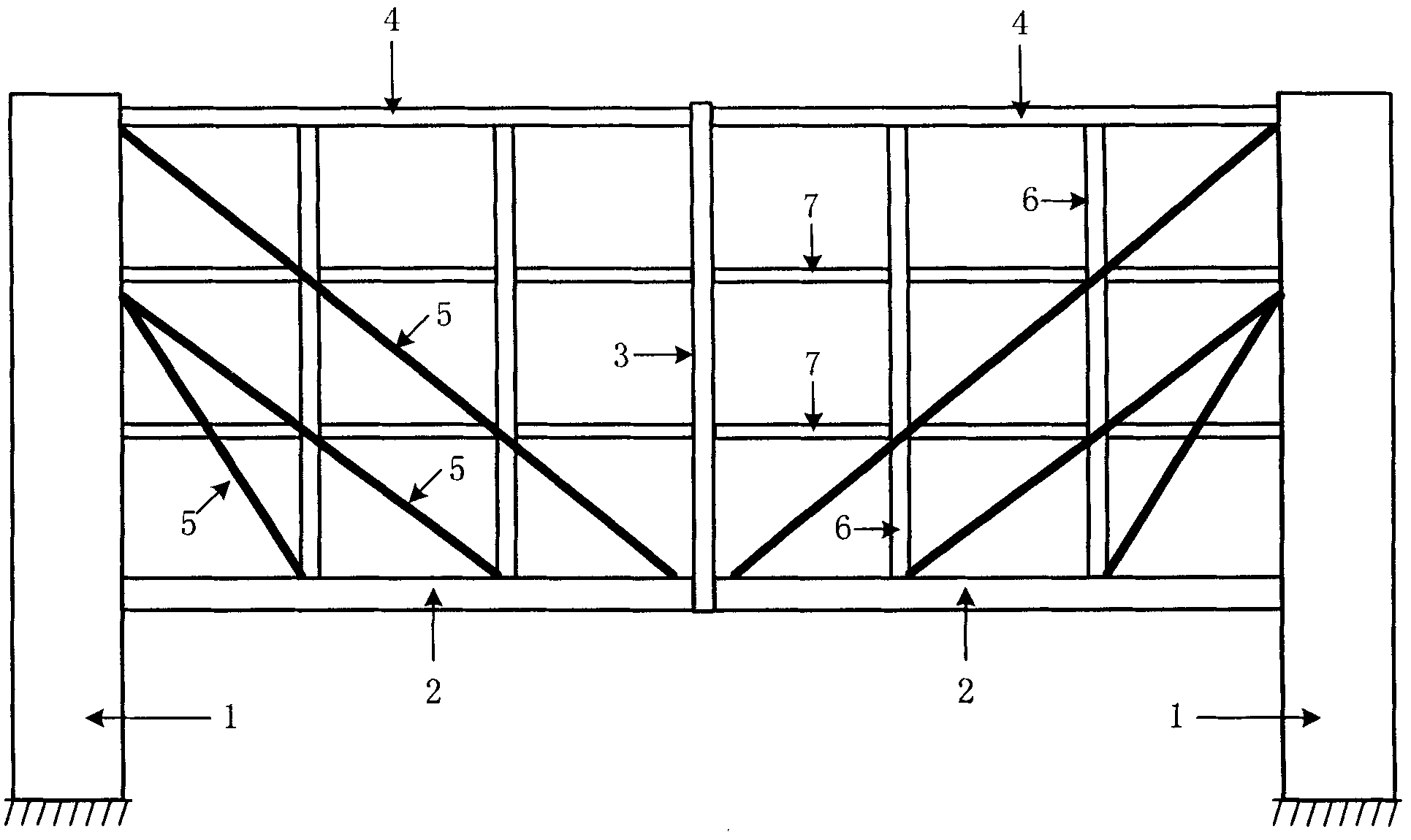

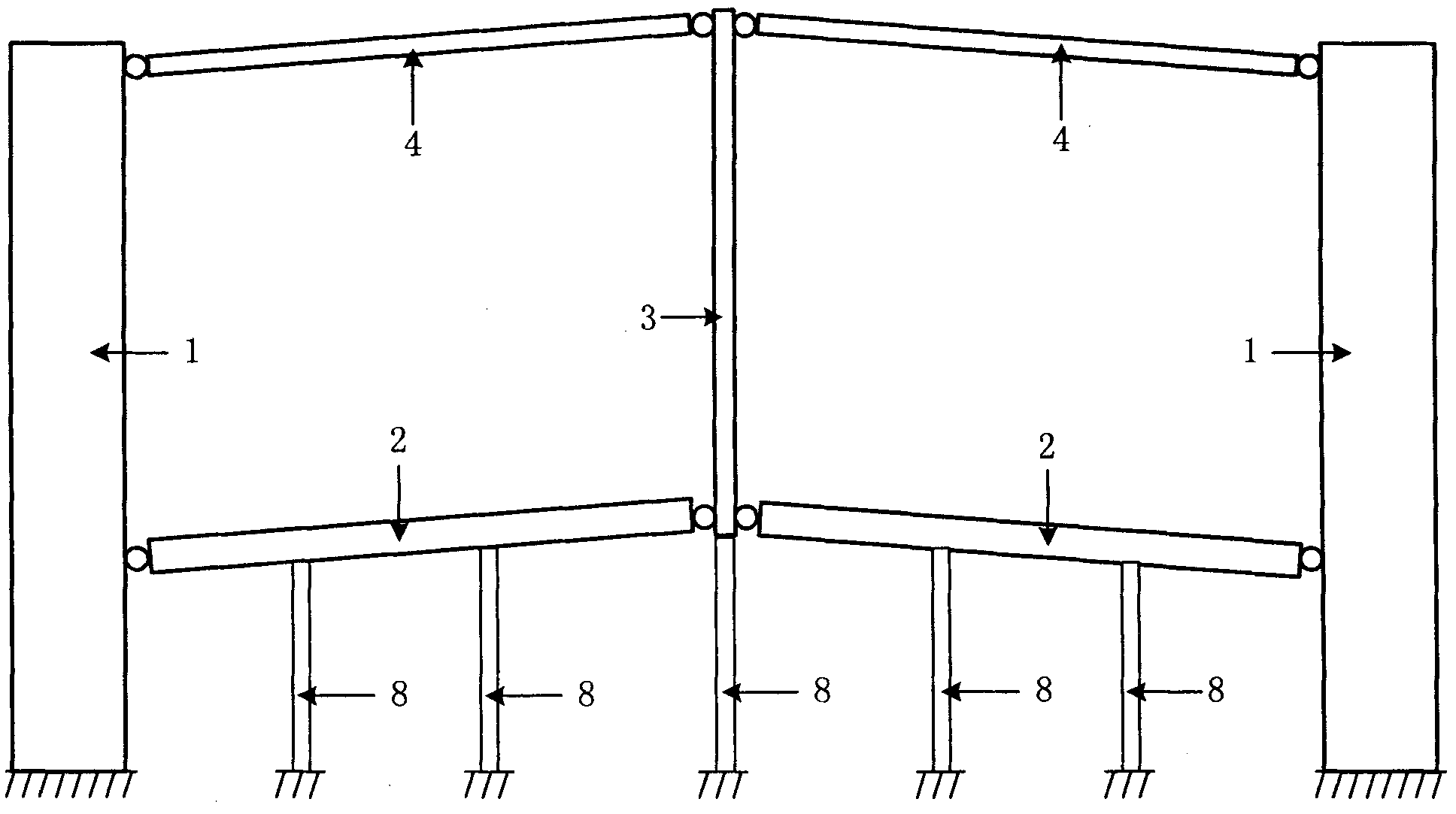

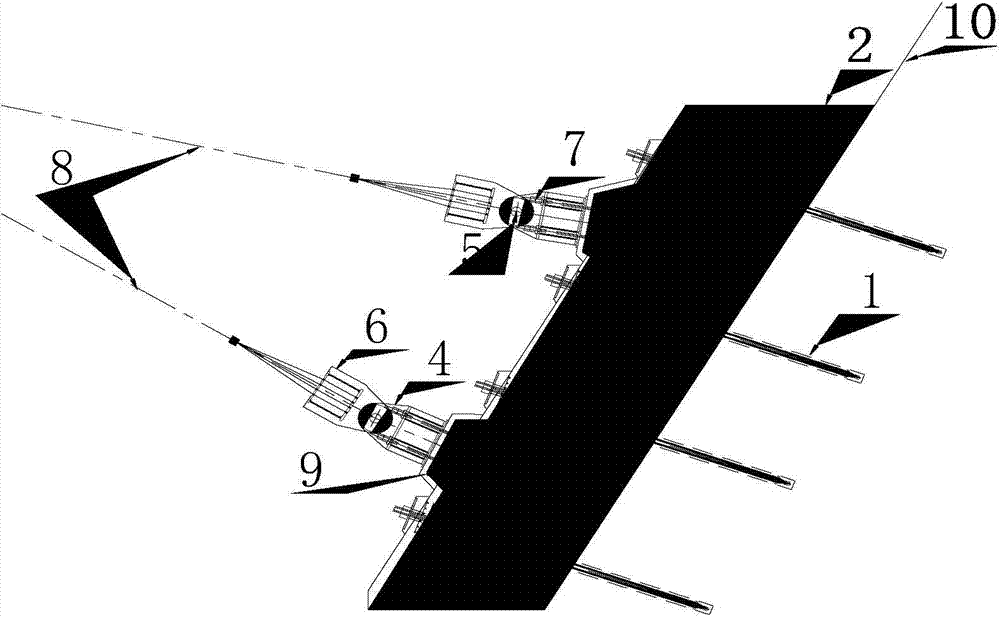

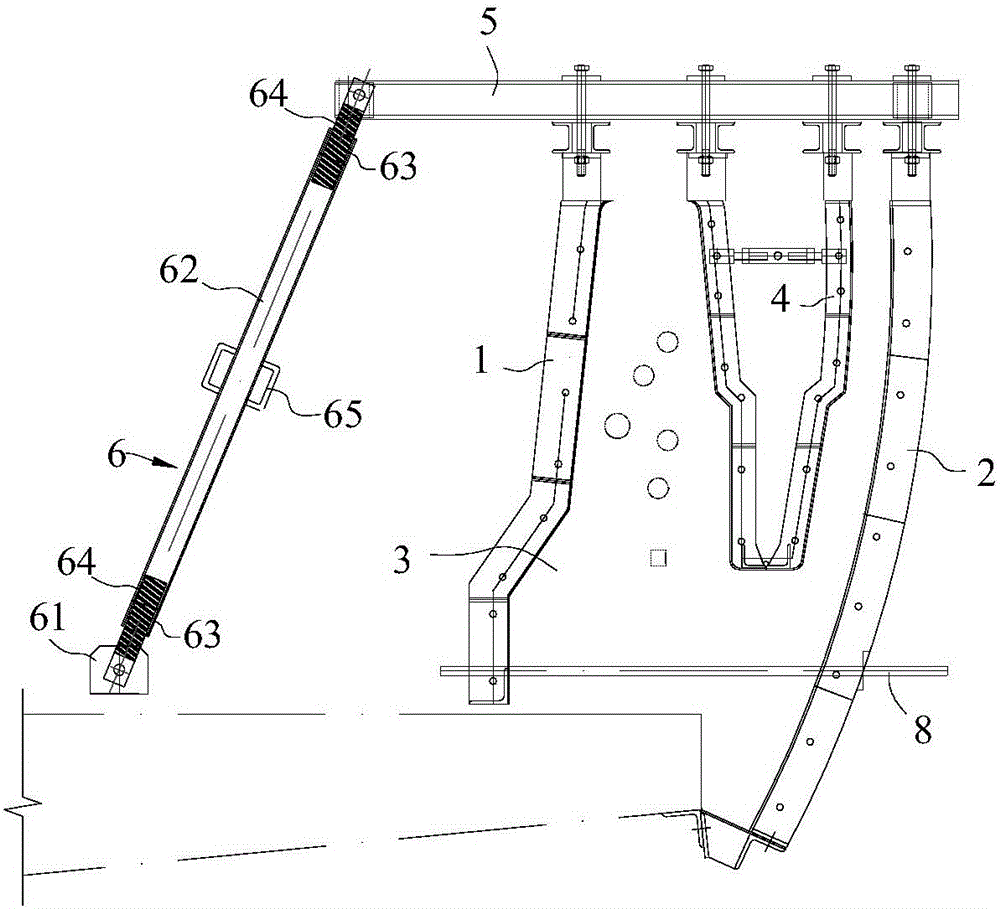

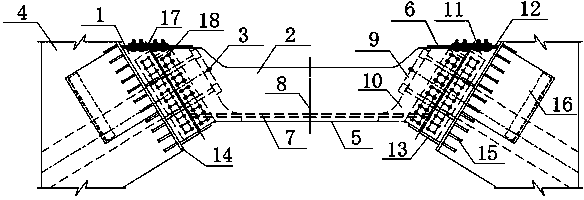

Cable-stayed multi-layer framework structure and construction control method thereof

InactiveCN101787732AOvercome the disadvantages of multiple tensioning in stagesReduce construction costsBuilding reinforcementsBuilding material handlingPull forceCable stayed

The invention relates to a cable-stayed multi-layer framework structure and a construction control method thereof. The method is characterized in that the construction of a cable-stayed multi-layer framework structure can be completed through specific steps, thereby avoiding cable tension. The cable-stayed multi-layer framework structure consists of an anchor structure (1), a supporting beam (2), a framework column (6), a framework beam (7), a floor panel and a stay cable (5). According to the construction control method, the supporting beam (2) is hinged with connecting joints at the two ends of the framework column (4) on the top layer during construction; the supporting beam can be lifted for a certain height above the design configuration through adjusting the length of the stay cable (5); the framework column, the framework beam and the floor panel are then arranged on the supporting beam layer by layer, and along with the increase of the building height, the supporting beam can gradually deform downwards, and tensile force can be gradually produced in the stay cable; the supporting beam is just in the horizontal position when the installation of the structure is completed; and finally the hinged joints are converted into rigid joints through the technology of converting hinged joint connection into rigid connection.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

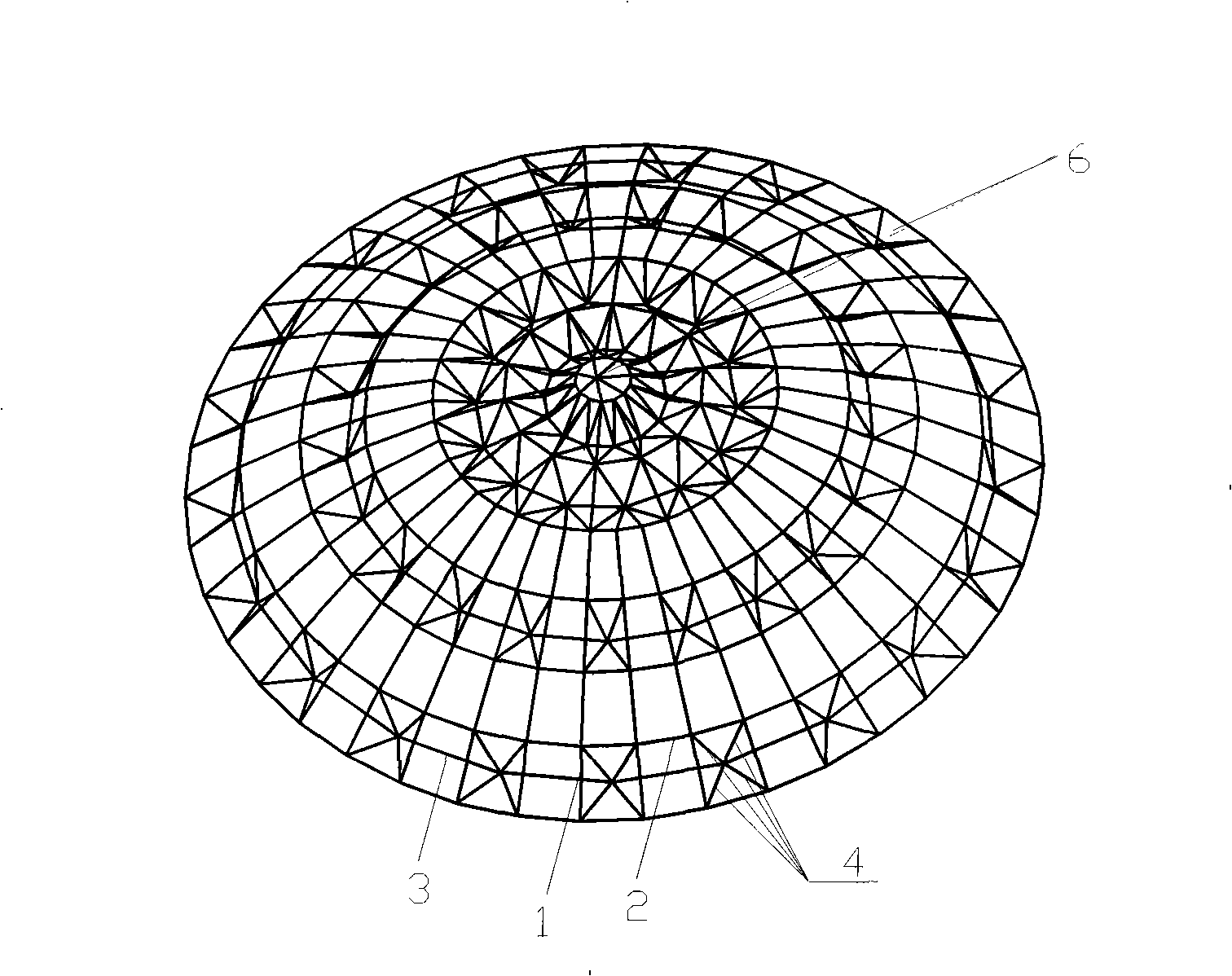

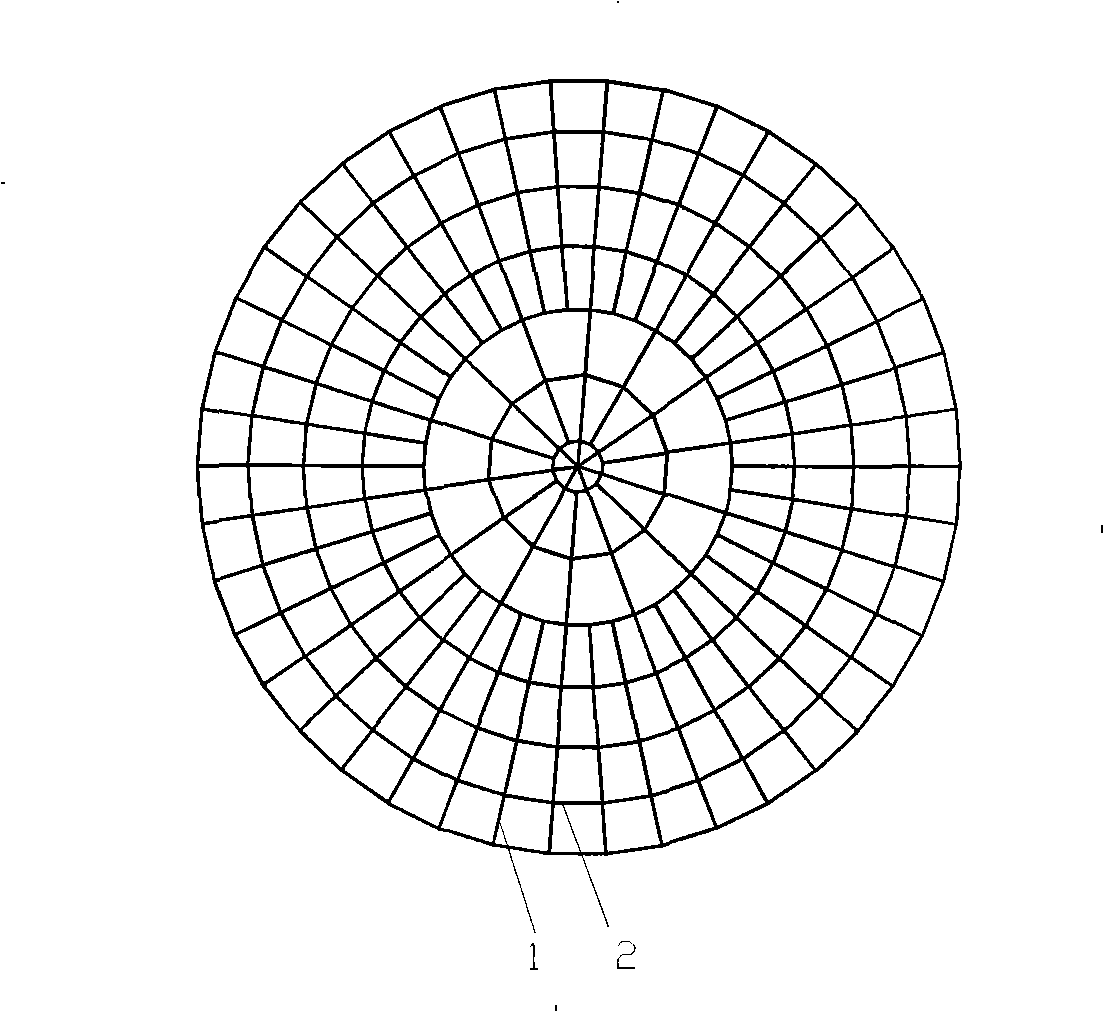

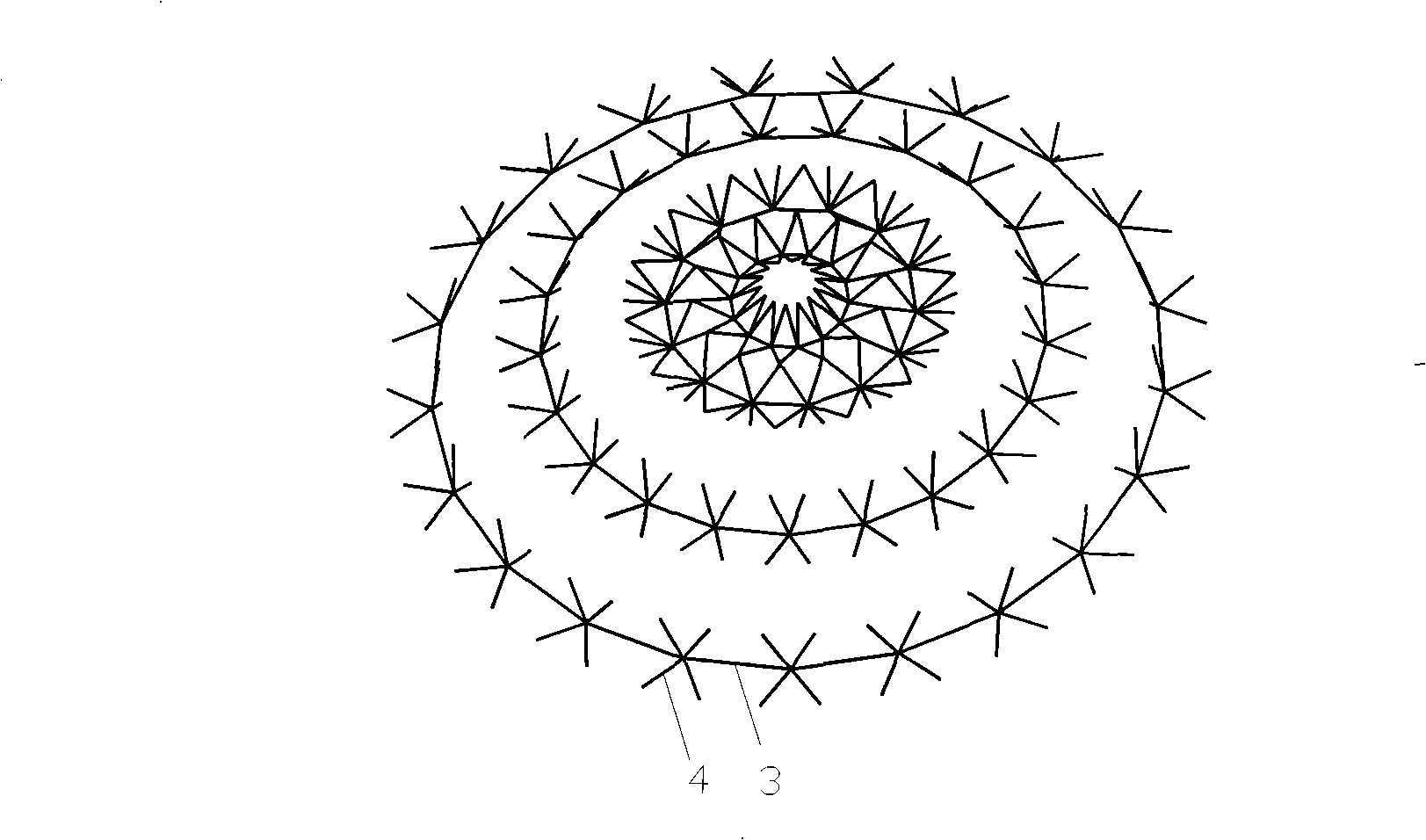

Local double layer open chord spherical reticulated shell

ActiveCN101260704AReduce steel consumptionSparsely arrangedBuilding roofsArched structuresPre stressEngineering

The invention discloses a local double-layer string reticulated spherical shell, comprising an upper layer, a middle layer and a lower layer, wherein, the upper layer is a spherical surface which consists of radial bars and circumferential bars and is arranged in a heel ring grid shape, a plurality of circumferential bars are connected to form the woof of the spherical surface, radial bars are connected between connections of the radial bars of two adjacent woofs to form the warp of the spherical surface, the connections of the circumferential bars are connected with one ends of the radial bars, while the other ends of the radial bars are hinged with the top point in the center of the spherical shell; the middle layer comprises a plurality of unit pyramids which are uniformly and alternately arranged on the heel ring grid of the upper layer along the warp direction and the woof direction and have cone tops connected with circumferential ropes of the lower layer; and the circumferential ropes are in closed arrangement along the circumferential direction, and inherent stress is exerted through tensioning the circumferential ropes in the structure. The local double-layer string reticulated spherical shell has the advantages of clear structure stress, concise and permeable construction effect, is a self equilibrating system under the deadweight effect without horizontal thrust, and has each upper chord joint provided with a web member so as to improve the stability of the structure.

Owner:SHENGYUAN GROUP +1

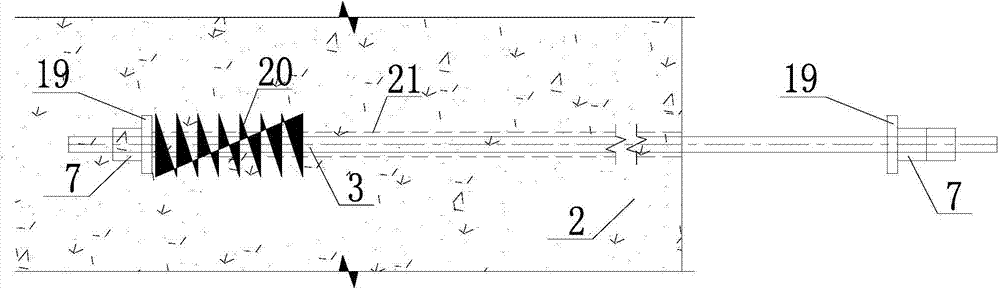

Buckling anchor system combined rock anchor

InactiveCN103572701AThe structural force is clearEasy constructionBridge structural detailsBridge erection/assemblyRebarReinforced concrete

A buckling anchor system combined rock anchor comprises a reinforced concrete girder, a prestressed anchor cable, prestressed anchor ribs, an anchor seat, an anchor box and an anchor block; the anchor seat is hinged to the anchor box connected with a balance cable by a P-shaped anchor; the anchor seat is fixed on the anchor block of the reinforced concrete girder by multiple prestressed anchor ribs; one section of each prestressed anchor rib penetrates through the reinforced concrete girder while the other section penetrates into the anchor seat; the prestressed anchor cable penetrates through the reinforced concrete girder. The buckling anchor system combined rock anchor is clear in stressing, safe, reliable and convenient to construct and effectively overcomes the difficult problem that an anchorage is difficult to set under the condition of a steep side slope. The side slope does not need to be excavated in the construction process of the buckling anchor system combined rock anchor, the concrete pouring volume is less, and the defects of a heavy anchorage side slope that the excavating volume of side slope earth and rocks is large, the side slope protective work is influenced, the concrete pouring volume is large and the cost is high are overcome.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

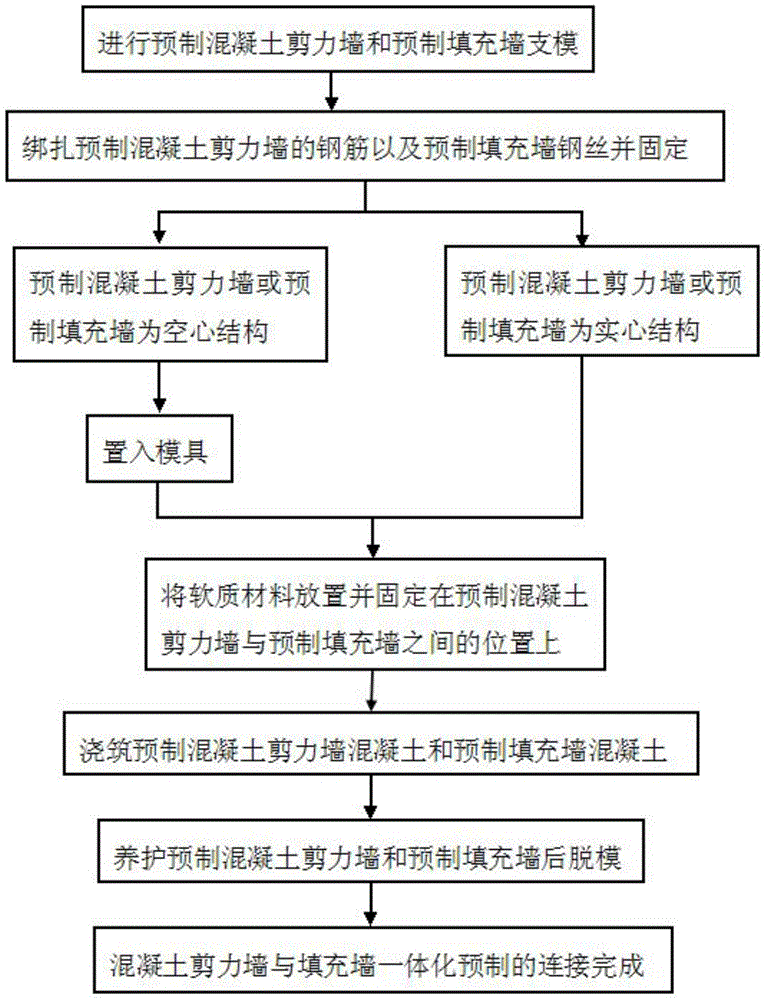

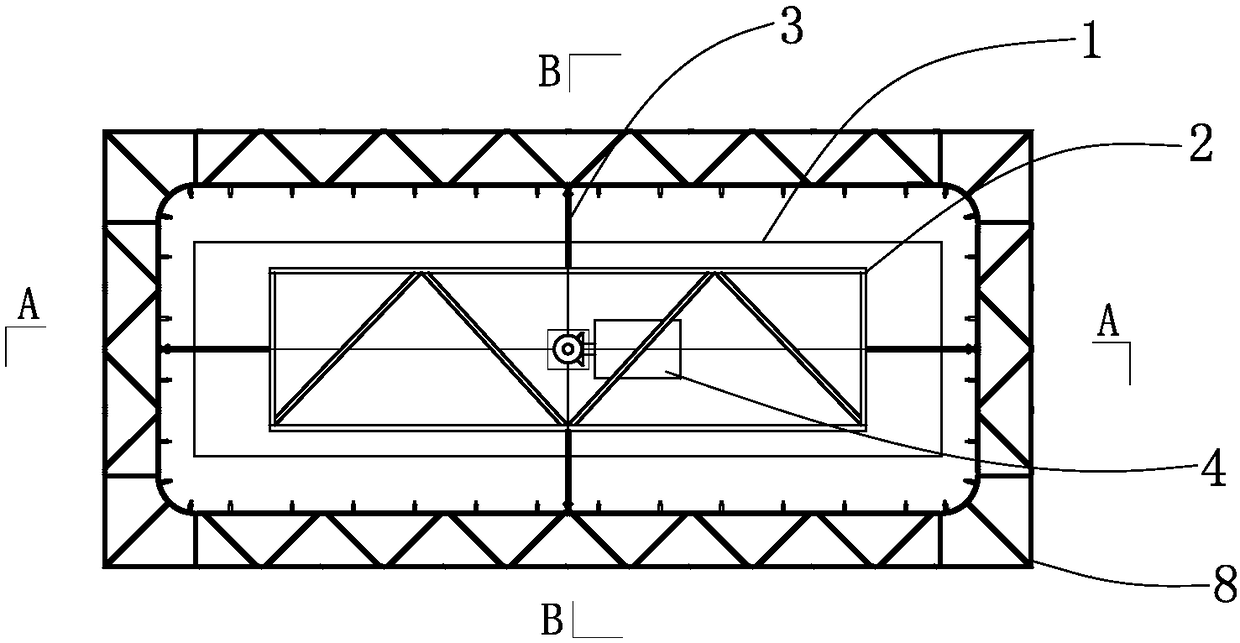

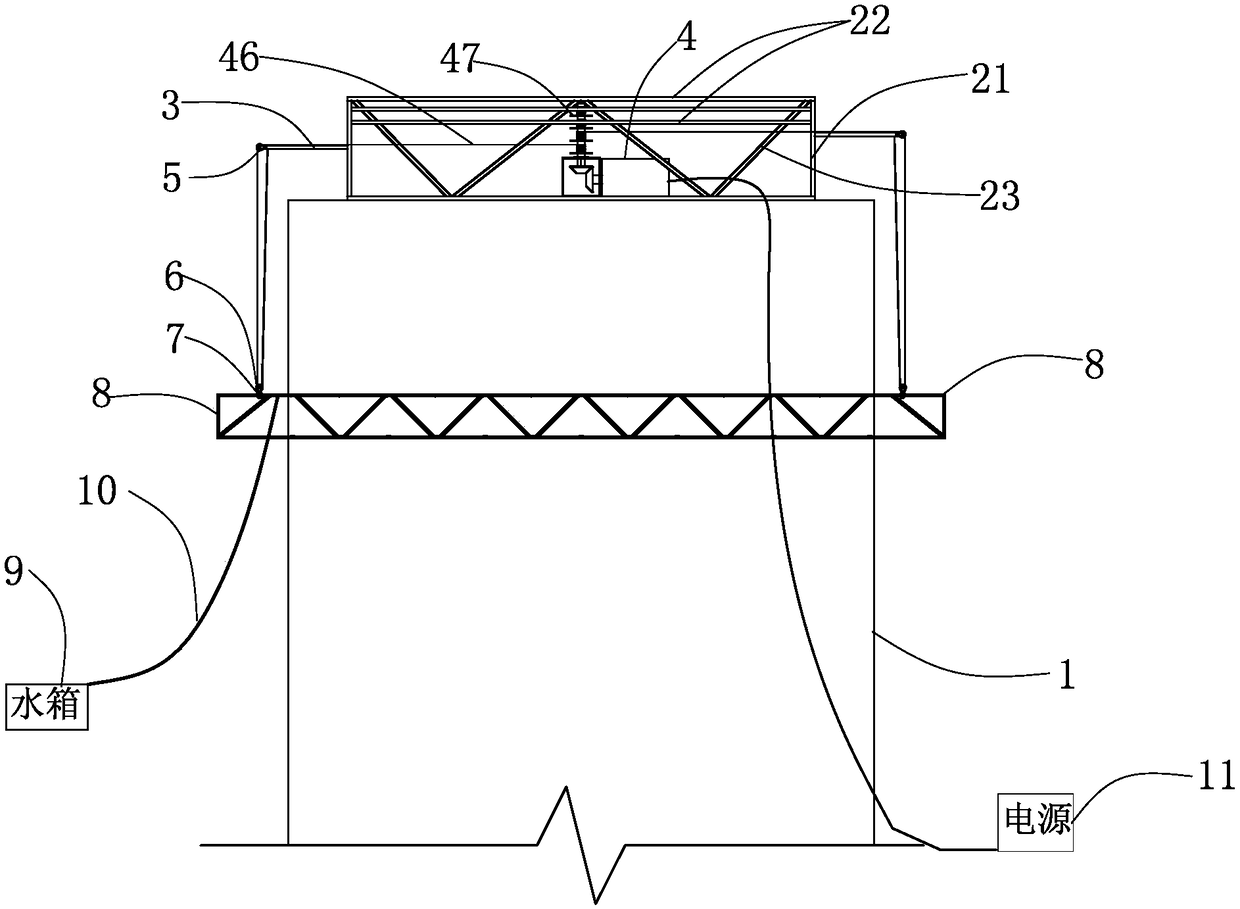

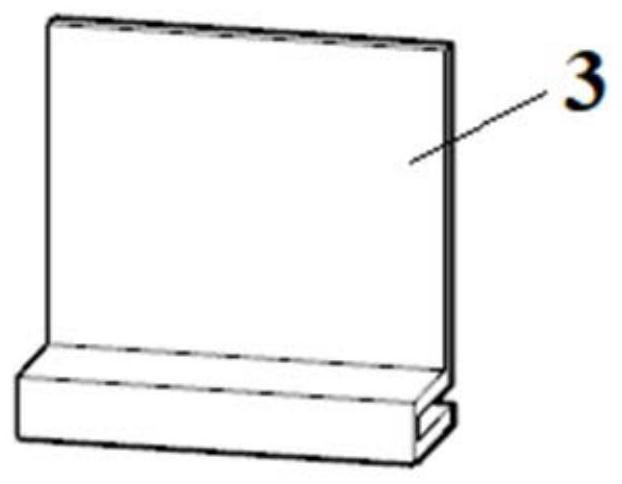

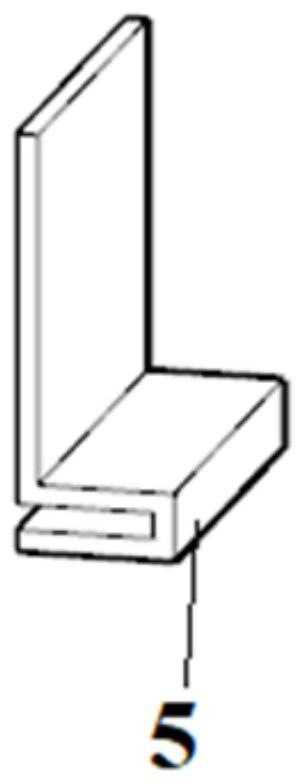

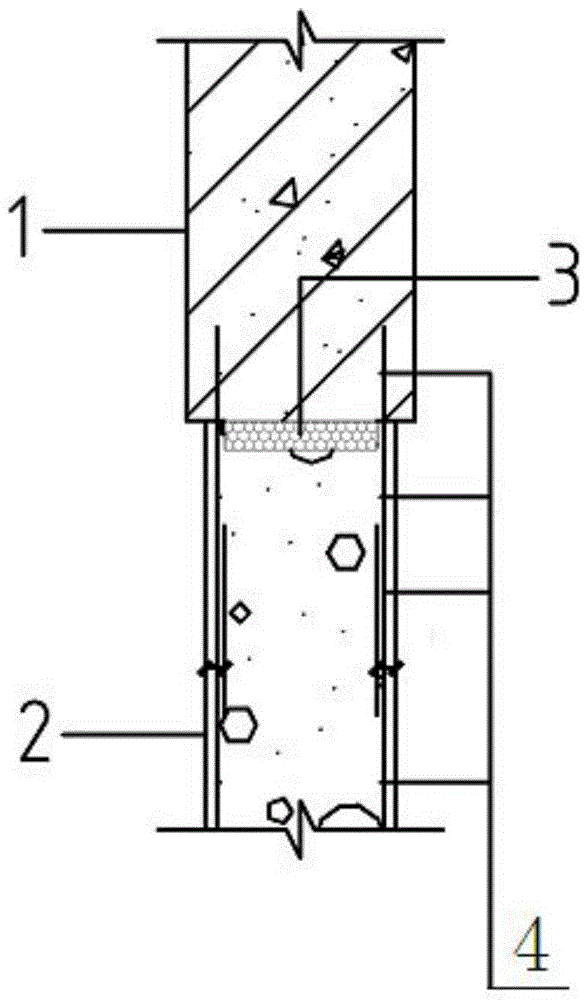

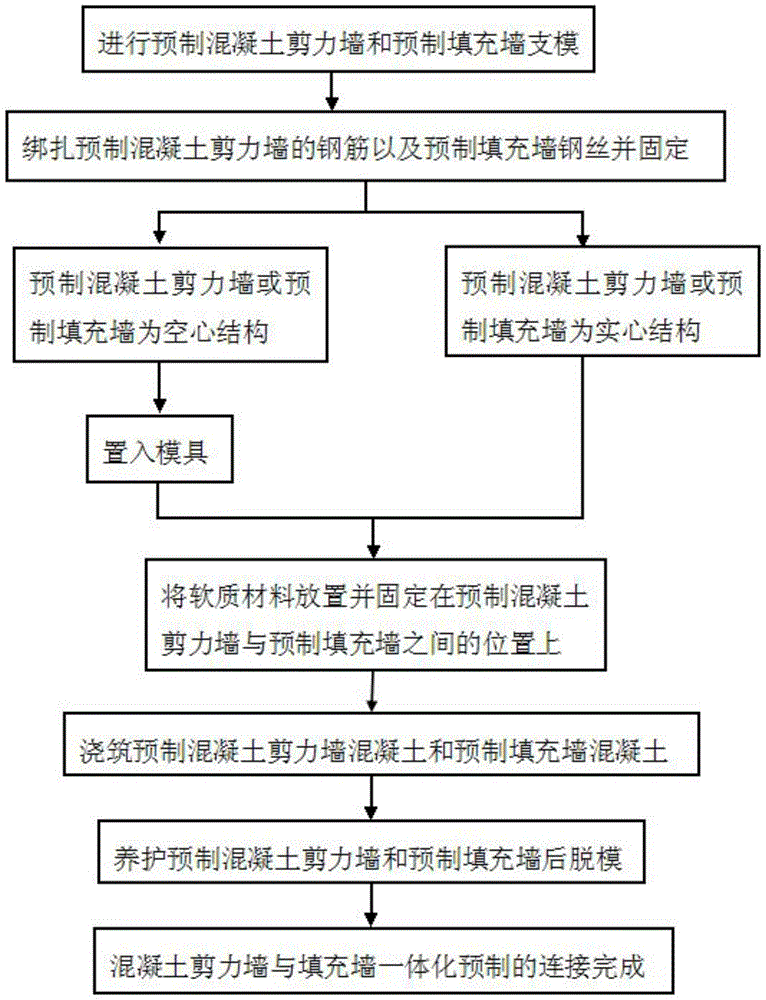

Integrated prefabrication method for connecting concrete shear wall and filler wall

The invention relates to an integrated prefabrication method for connecting a concrete shear wall and a filler wall, and belongs to the technical field of buildings. The integrated prefabrication method comprises a prefabricated concrete shear wall, a prefabricated filler wall, a soft material and prefabricated filler wall steel wires. The integrated prefabrication method is realized through the following steps: carrying out form erecting according to design requirements; binding reinforcing steel bars and steel wires of a wall body; putting corresponding molds into the prefabricated concrete shear wall and the prefabricated filler wall if the prefabricated concrete shear wall and the prefabricated filler wall are hollow; putting the soft material between the prefabricated concrete shear wall and the prefabricated filler wall; pouring wall body concrete for demolding after maintenance. The method can ignore the influence of the filler wall on the lateral-displacement-resistant rigidity of the overall structure, the structure stress is accurate, the force transmission lines are clear, and the reliability of the structure is guaranteed; moreover, the integrated prefabrication method is simple, the production and construction mounting of prefabricated parts are facilitated, the quality and efficiency are improved, the construction cost is reduced, and the method has positive meanings for the development of prefabricated concrete construction.

Owner:凡林装配式建筑科技有限公司

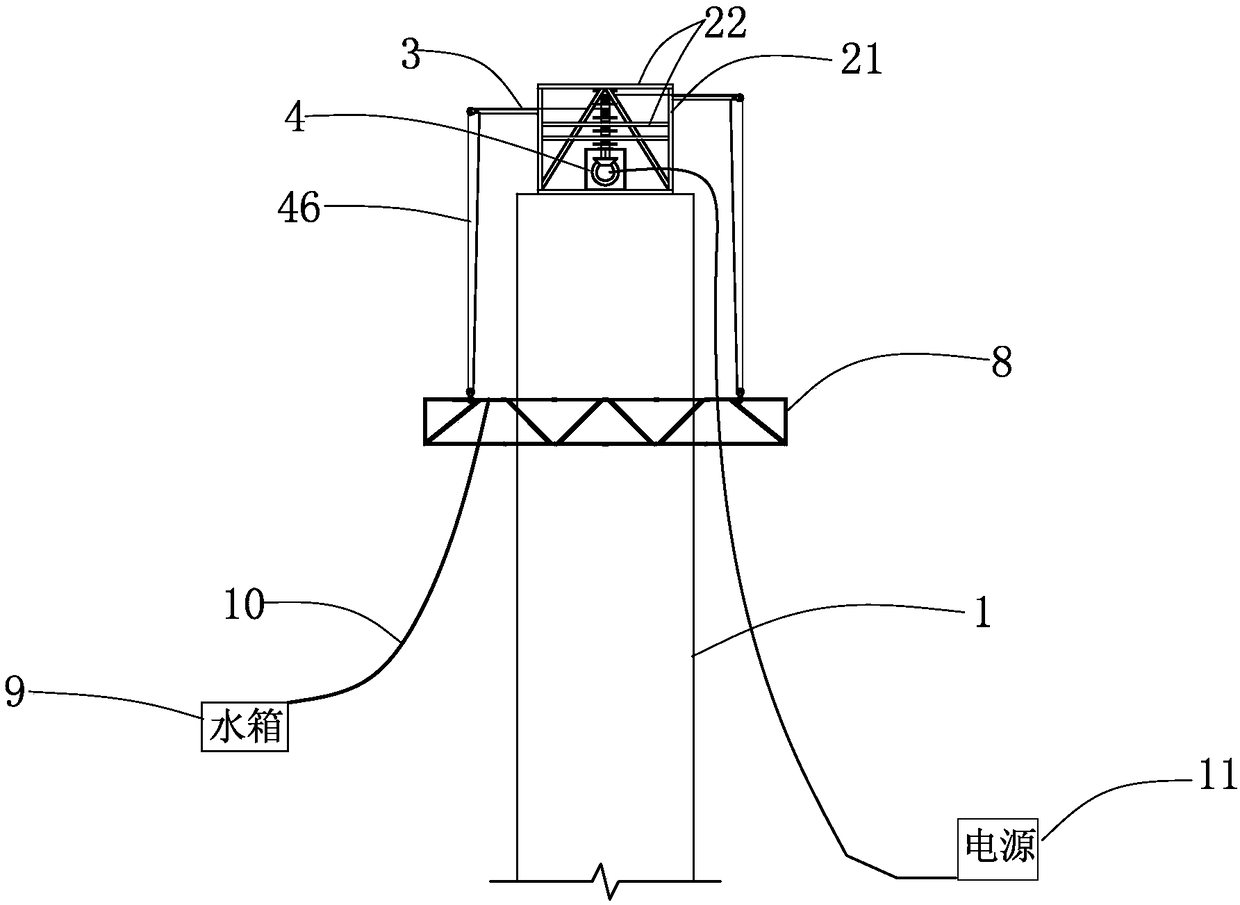

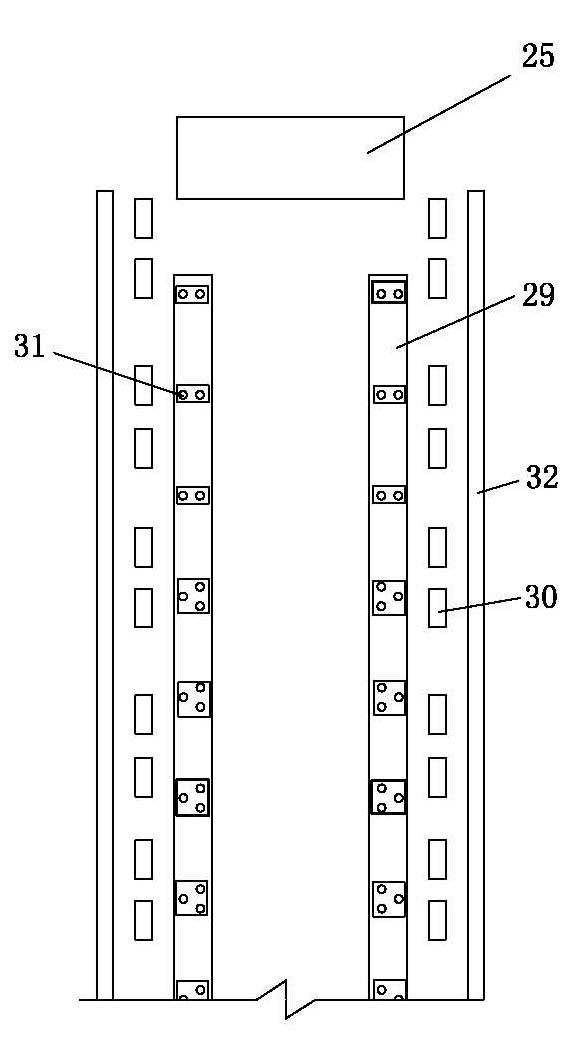

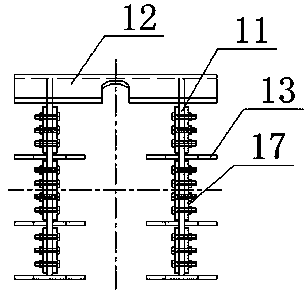

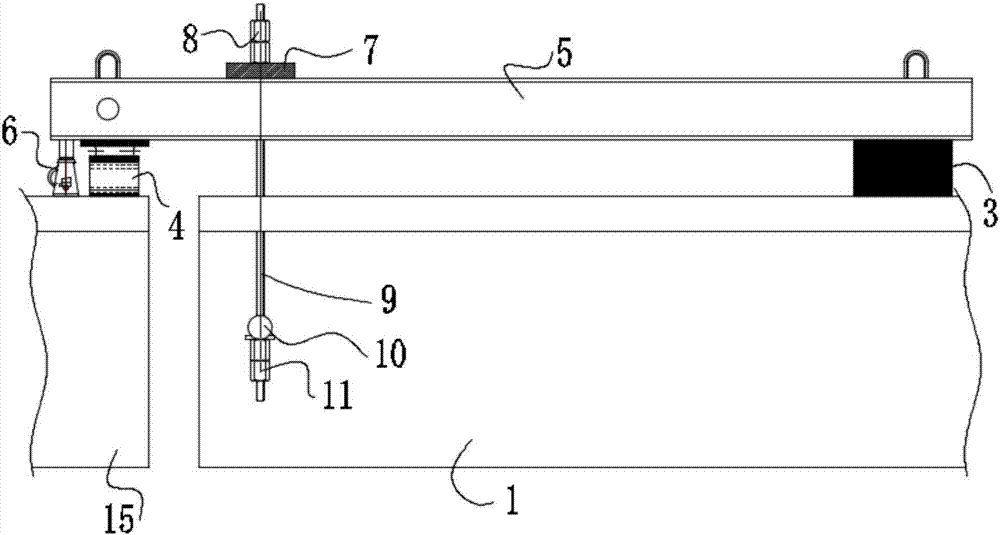

Pier column automatic spraying health system

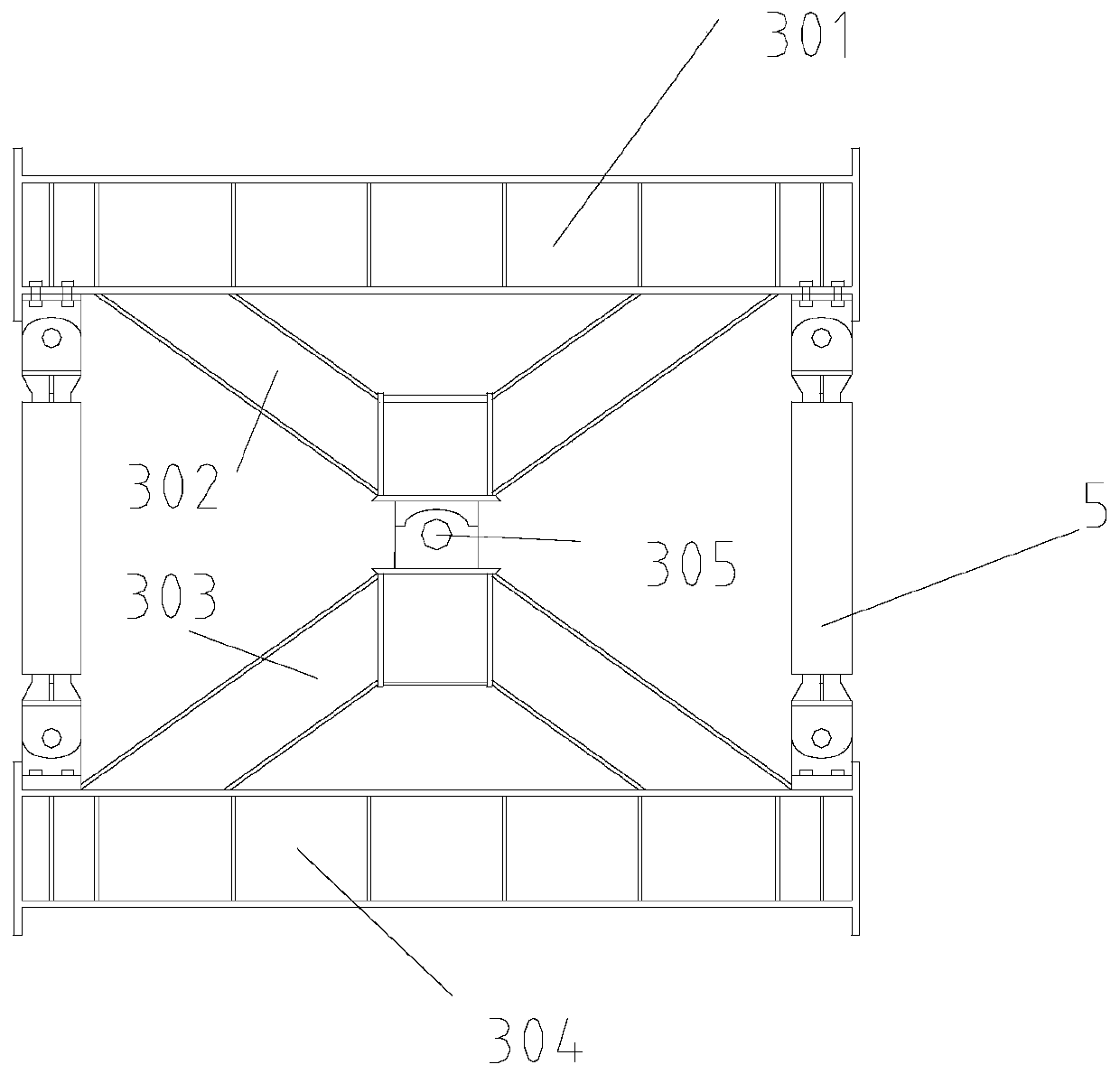

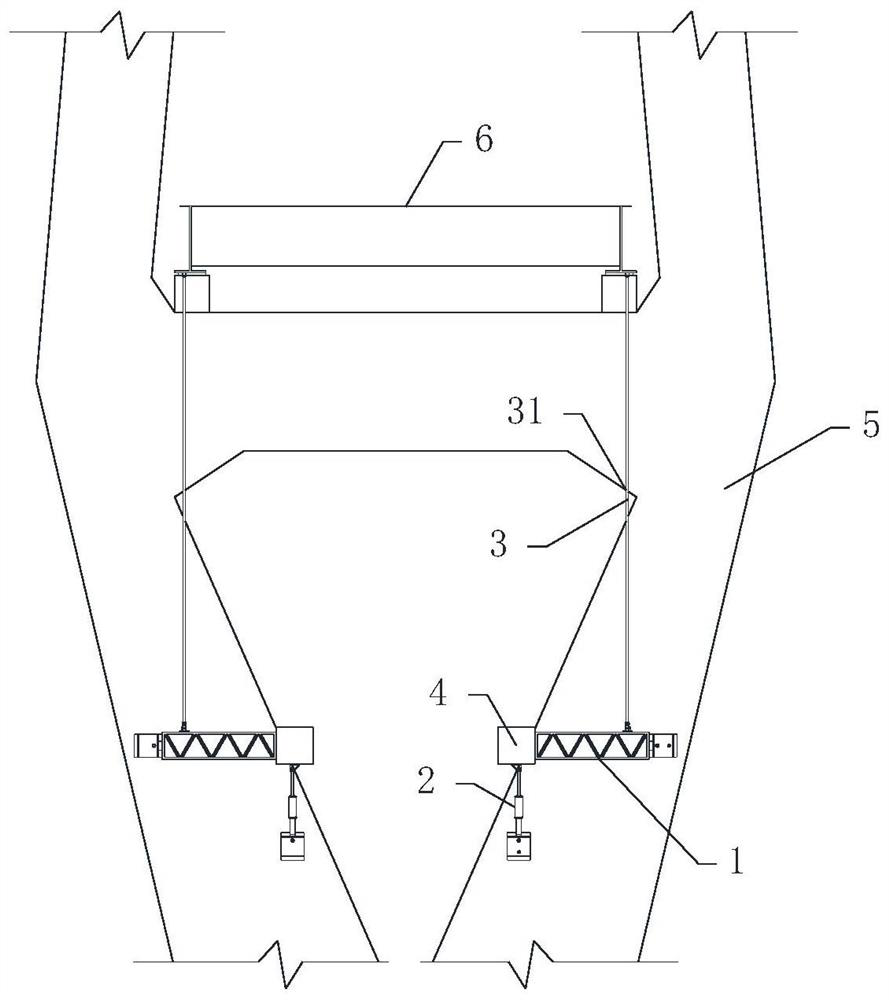

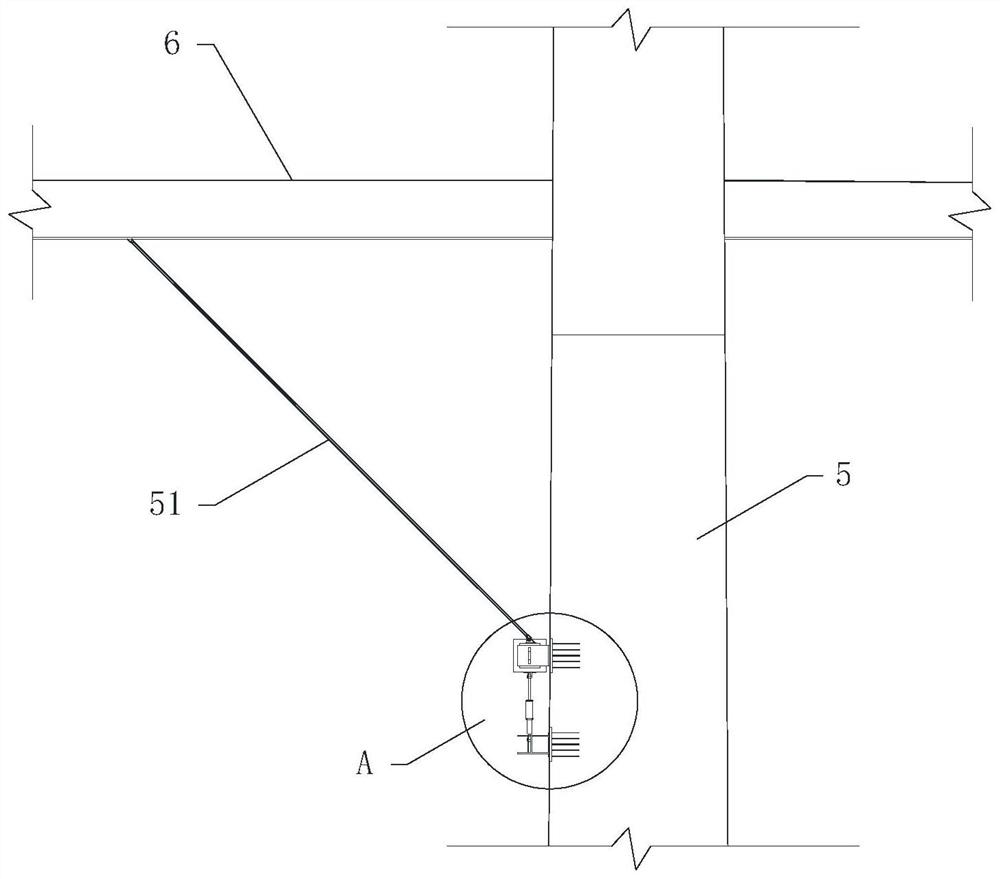

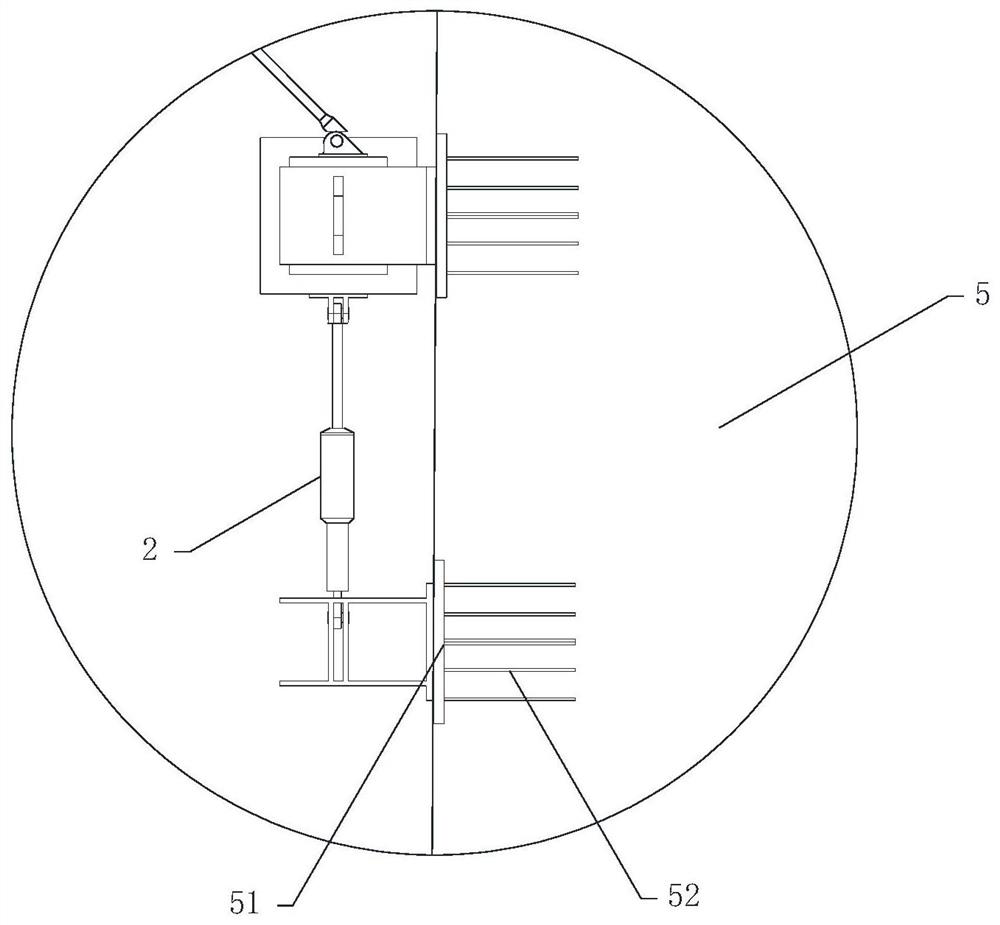

PendingCN108487077AThe structural force is clearLight weightBridge erection/assemblyAgricultural engineeringPulley

The invention provides a pier column automatic spraying health system. The health system is provided with a bracket and a hoist at the top of the pier column. A spray rack is arranged around the pier,and a plurality of spray heads are arranged on the spray rack. The hoist traction rope pulls the spray frame up and down by setting the pulley block on the bracket to spray and reheat the pier column. The health system is used for spraying and curing the concrete pier column, which can achieve automatic operation. The device can be repeatedly used with uniform spray and good curing effect on thepier column.

Owner:ROAD & BRIDGE INT +1

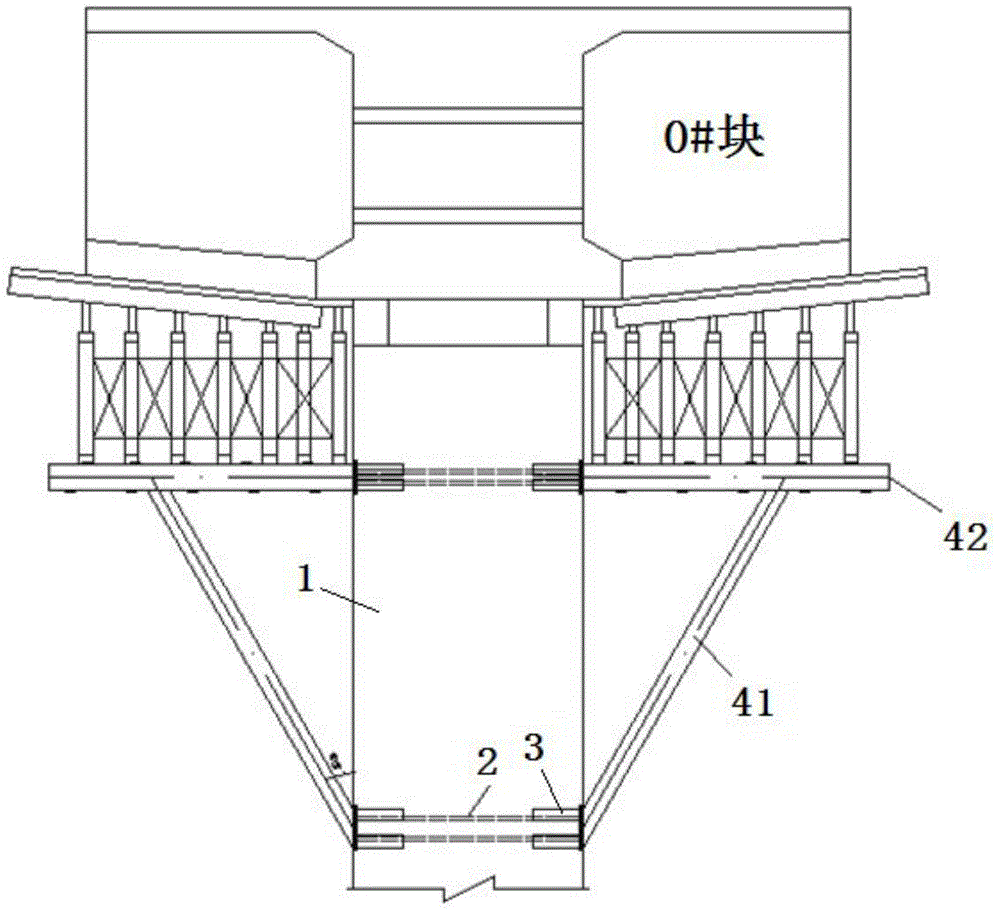

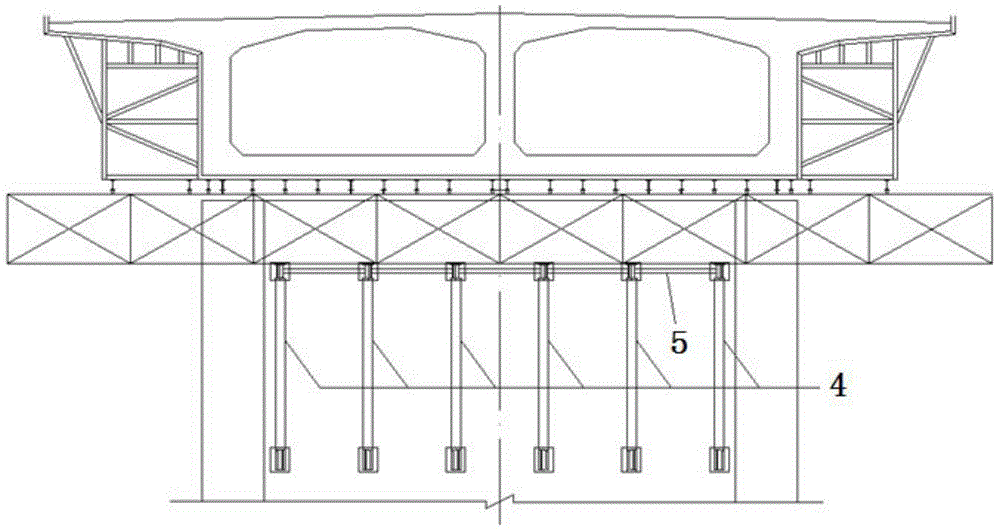

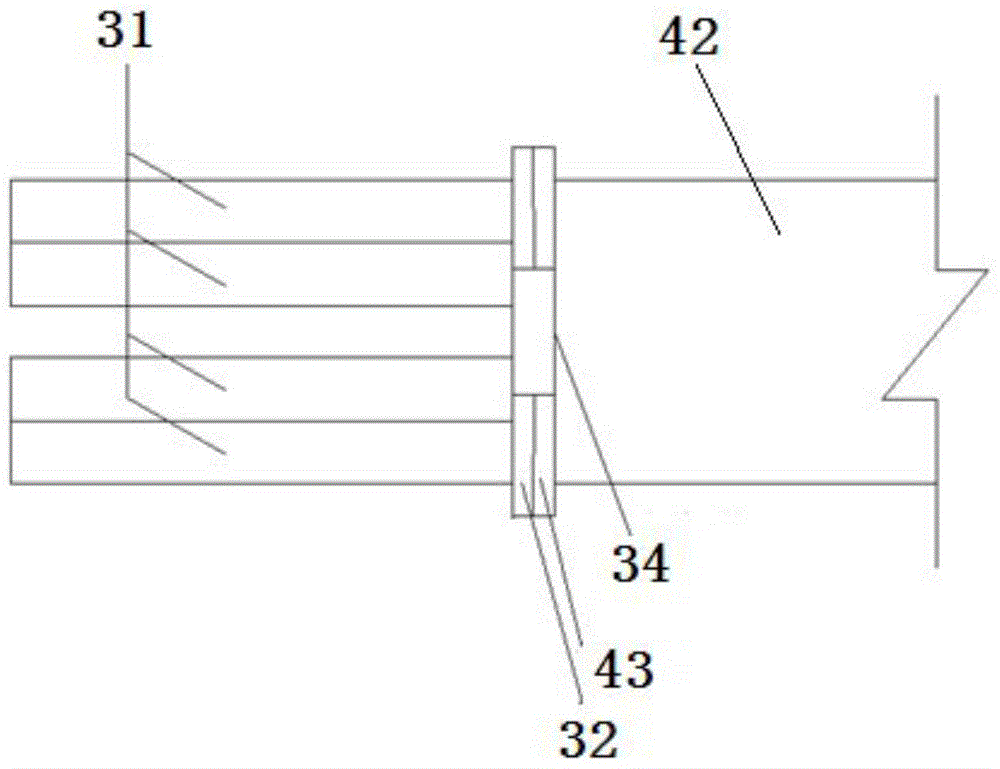

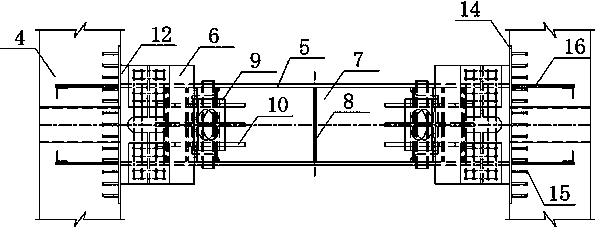

Fastener connecting structure for cantilever box beam triangle brackets

ActiveCN104314012AImprove shear resistanceThe structural force is clearBridge erection/assemblyWhole bodyShear capacity

The invention provides a fastener connecting structure for cantilever box beam triangle brackets, and relates to the technical field of bridge construction. The fastener connecting structure comprises a pier, wherein triangle brackets are symmetrically arranged on the two sides of the pier; embedded parts are arranged in the pier; the triangle brackets are fixedly mounted on the side walls of the pier through the embedded parts; the triangle brackets symmetrically on the two sides of the pier are connected through an anchoring system; the embedded parts and the triangle brackets are connected through steel plate fastener pins; the triangle brackets on the same side of the pier are connected into a whole body through a transverse connecting system. The load is transferred by utilizing the steel plate fastener pins, so that the shear capacity is improved, and the influences that concrete is heated and fractured and steel plates are deformed caused by direct welding and thermal cutting on the embedded parts are completely eradicated.

Owner:ANHUI XINLU CONSTR ENG GRP

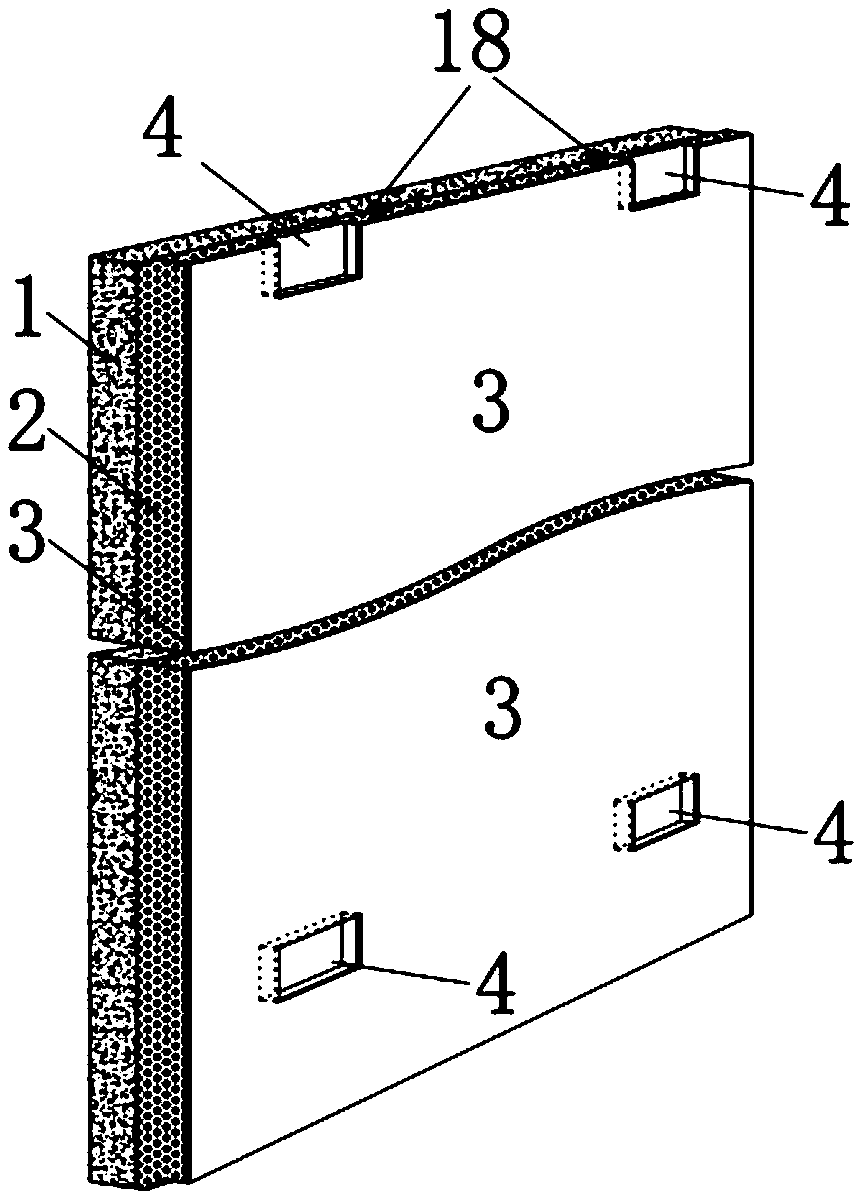

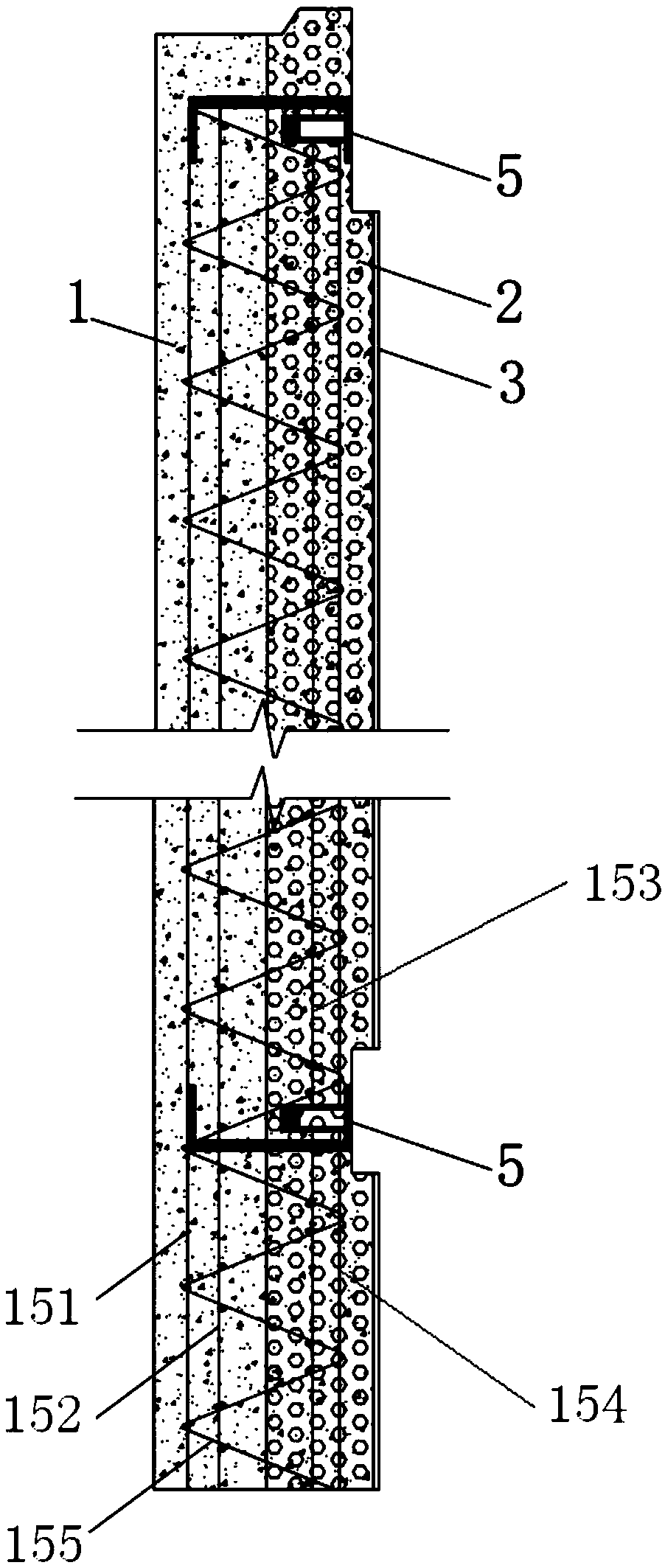

Prefabricated light compound insulation wallboard as well as manufacturing method and mounting method thereof

InactiveCN108842944ASolve universalityGuaranteed sound insulationWallsCeramic shaping apparatusThermal insulationRebar

The invention provides a prefabricated light compound insulation wallboard as well as a mounting method thereof, and belongs to the technical field of building energy conservation. The prefabricated light compound insulation wallboard comprises an outer wallboard, a thermal insulation layer and an inner wallboard from outside to inside in sequence, wherein the outer wallboard and the thermal insulation layer are connected through a steel bar truss, and the thermal insulation layer and the inner wallboard are bonded by pressing; the outer wallboard is made of concrete, and the thermal insulation layer is made of a light insulation material; connecting parts connected with the steel bar truss are arranged between the outer wallboard and the thermal insulation layer. The invention provides amanufacturing method and the mounting method of the prefabricated light compound insulation wallboard. The manufacturing method comprises following steps: prefabricating the outer wallboard and the thermal insulation layer; pre-embedding the steel bar truss; pre-embedding U-shaped connecting pieces; laying the thermal insulation layer; compounding the inner wallboard and the thermal insulation layer. The mounting method comprises following steps: connecting L-shaped connecting pieces with the U-shaped connecting pieces through bolts; welding the L-shaped connecting pieces and a main structureof a building; blocking gaps. The prefabricated light compound insulation wallboard is light, thermal-insulating and sound-insulating, has universality, is widely applied, simple in structural connection and rapid to mount and facilitates industrial production.

Owner:宝业集团浙江建设产业研究院有限公司

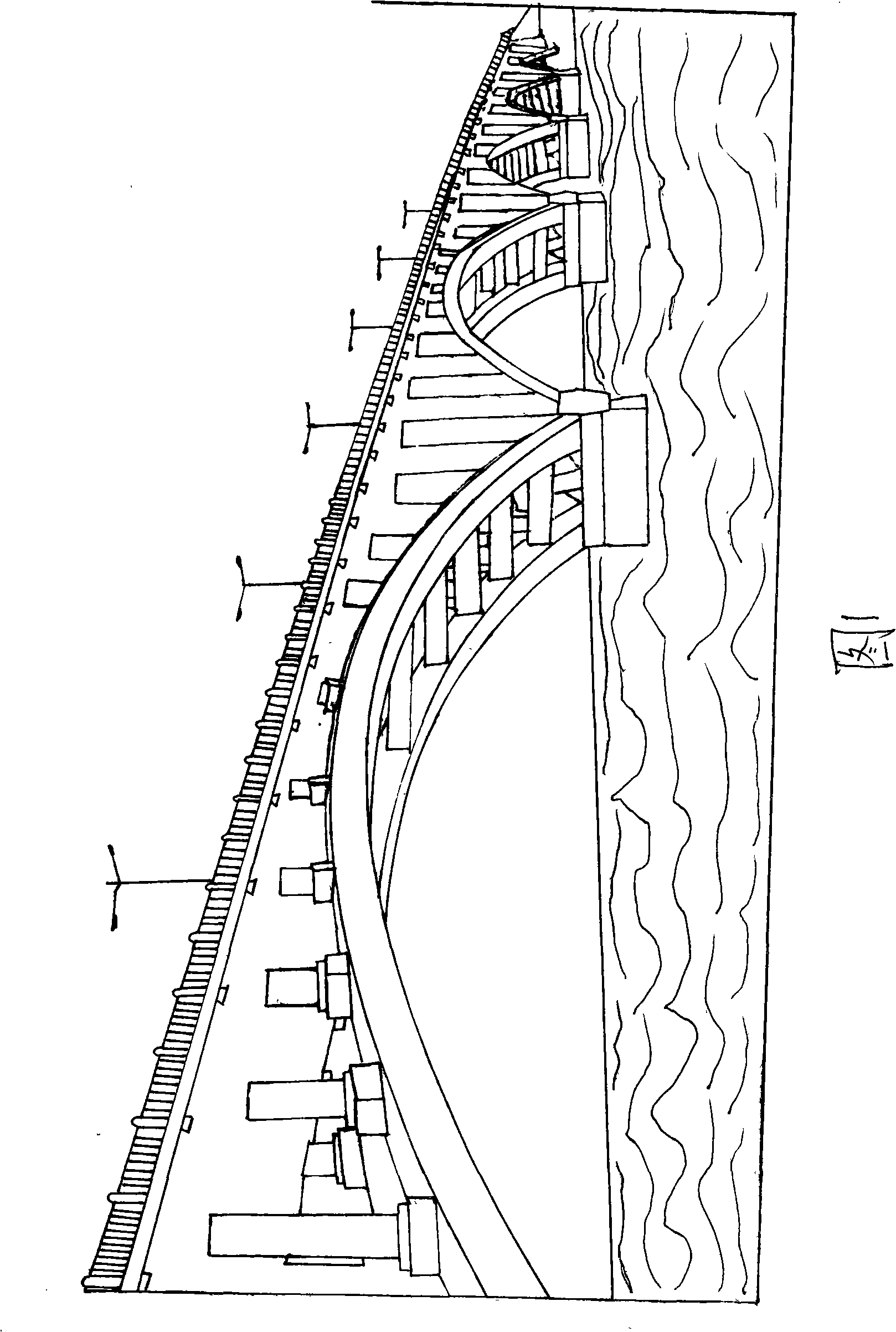

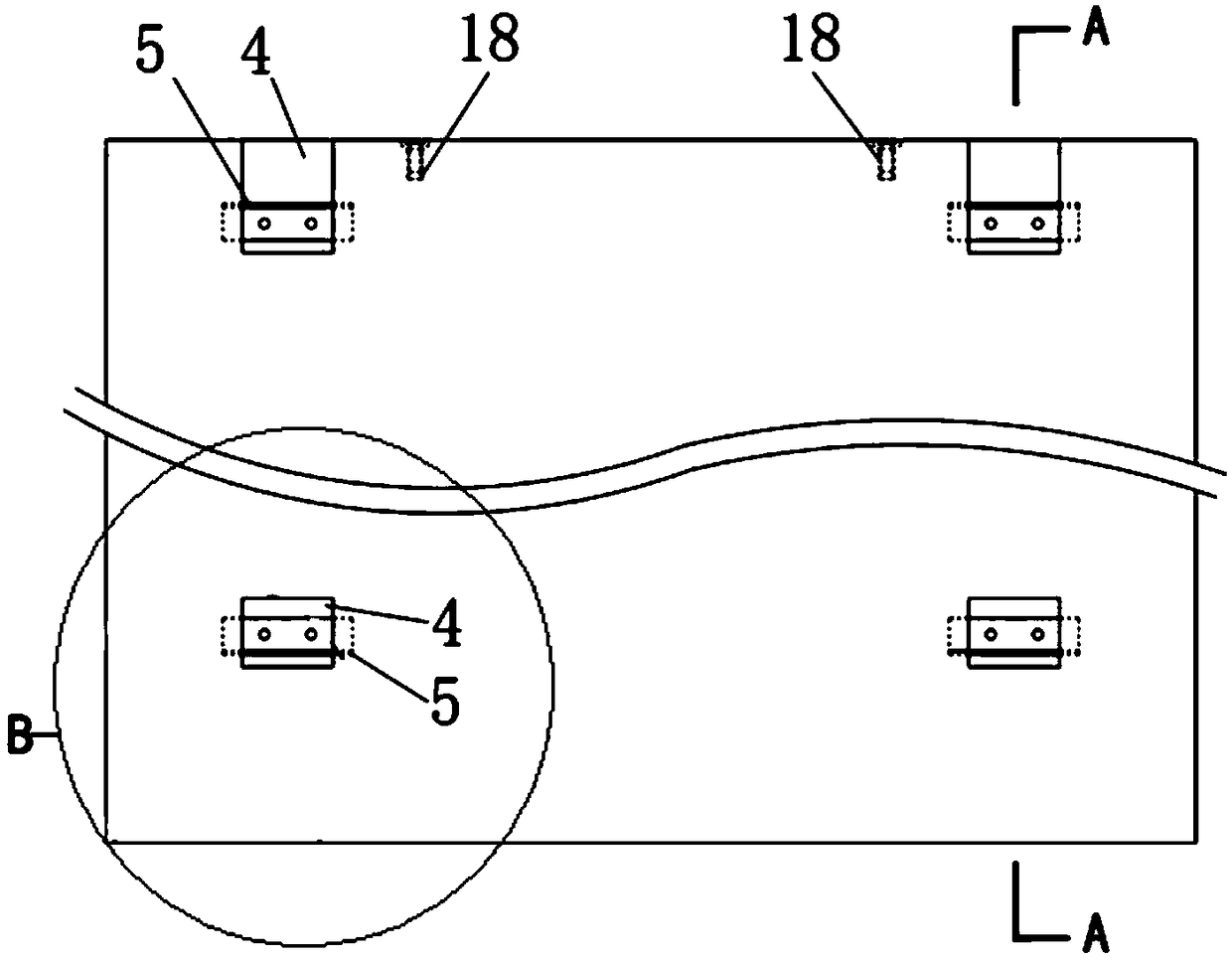

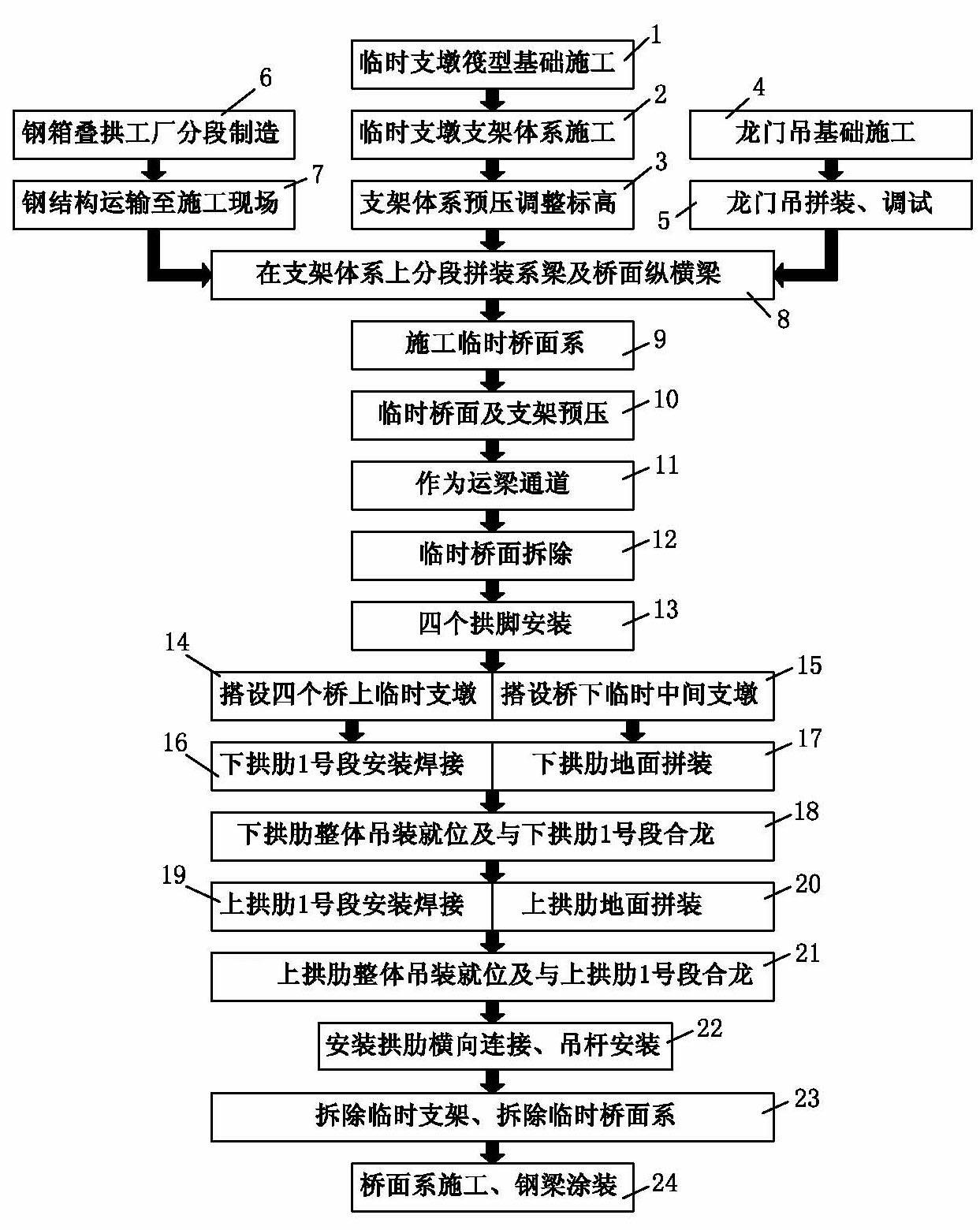

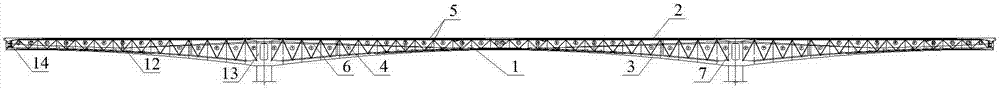

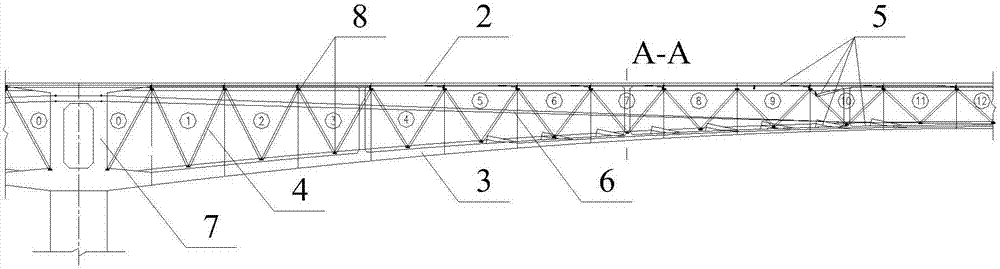

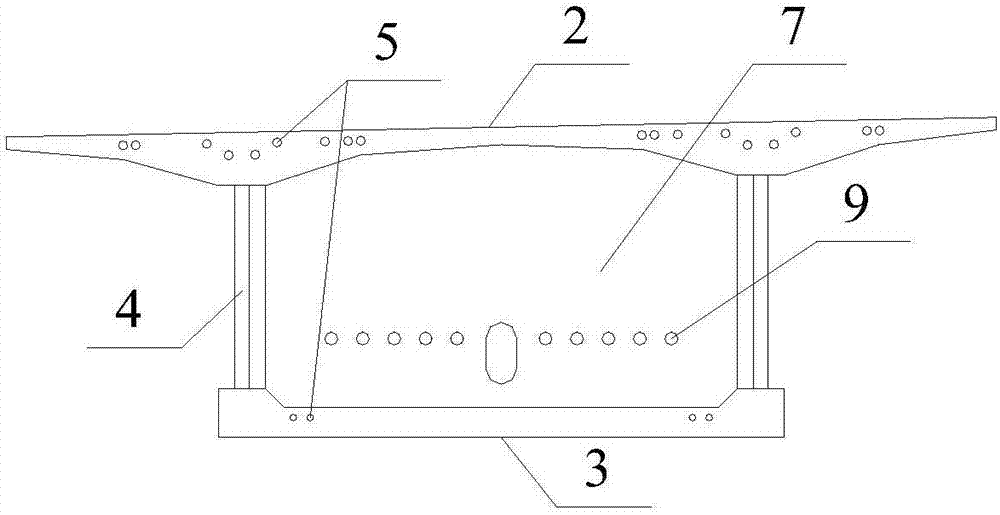

Arch-after-girder construction method of large-span steel box tacked arch bridge

ActiveCN102154988AReduce construction investmentThe structural force is clearBridge structural detailsFoundation engineeringSurface engineeringFalsework

The invention relates to an arch-after-girder construction method of a large-span steel box tacked arch bridge. The construction method comprises the following steps of: respectively building two temporary reinforced concrete bar-shaped bases on the ground at the bottom parts of steel girders on two sides of a to-be-built steel-structure bridge; mounting a plurality of temporary supporting piers on the reinforced concrete bar-shaped bases; respectively mounting steel girder assembling platforms on two external sides of the two bar-shaped bases; and paving portal crane rails on two sides of the steel girder assembling platforms and mounting two portal cranes. In the construction method, arch ribs, lifting rods and bridge surfaces engineering are carried out after system girders, end transverse girders and vertical transverse girders are mounted to form a whole stressed system by combining with temporary main supporting piers. The construction method has the advantages of low construction investment, specific structure stress, and simple and convenient construction process, and can realize parallel construction; all the steel components are hoisted by adopting the running-type portal canes, thereby reducing a great amount of mounting and dismantling work of the scaffoldings in the high altitude, and reducing the mounting period of the box girders; and the steel components can beassembled under the bridge during the transporting time of thebox girders, which increases the safety coefficients, and improves the structural quality.

Owner:CCCC TUNNEL ENG

Method for reinforcing cast-in-place framed flower bed type anti-collision wall formwork of urban overpass

ActiveCN106049285AThe structural force is clearSave reinforcement materialsBridge structural detailsBridge erection/assemblyStructural stressCantilever

The invention discloses a method for reinforcing a cast-in-place framed flower bed type anti-collision wall formwork of an urban overpass, wherein the method is used for the technical field of bridge construction. The method includes the following steps that an inside outer die, an outside outer die, an inner die and end dies are prefabricated; the inside outer die is installed, a top beam in the transverse bridge direction is arranged at the top of the inside outer die, a connecting rod is connected between the inner end of the top beam and a connecting seat on an inside beam body of the inside outer die, a cantilever is formed at the outer end of the top beam and connected with the inner die, the outside outer die is installed, the top of the outside outer die is connected with the cantilever, the bottom of the outside outer die is connected with the beam body, and the end dies are installed; the length of the connecting rod is adjusted to correct the perpendicularity of a formwork system, a pull rod is tensioned and fastened between the inside outer die and the outside outer die after the elevation of the inside outer die, the elevation of the outside outer die and the elevation of the inner die are adjusted; and concrete is poured, and the formwork system is detached after the concrete reaches the die detaching strength. By the adoption of the method, the structural stress is clear, safety and reliability are achieved, reinforcing materials are saved, a construction period is short, operation is easy and convenient, the overall stability is high, and die cracking is unlikely to happen.

Owner:CRPCEC SHENZHEN ENG +1

Method for reinforcing fractured lining of existing railway tunnel

InactiveCN106593466AEfficient governanceAvoid secondary interferenceUnderground chambersTunnel liningRailway tunnelSheet steel

The invention relates to a method for reinforcing a fractured lining of an existing railway tunnel. A first steel arch (4), a second steel arch (5), a steel plate (3), three circumferential steel bars (2), longitudinal connecting steel bars (1), steel plate reinforcing steel bars (6), anchor rods (7) and formwork concrete (8) are involved. The method is characterized in that the steel plate (3) is welded to the inner sides of the outer edges of the first steel arch (4) and the second steel arch (5) and bent according to the radians of the site steel arches; the three circumferential steel bars (2) are erected and the longitudinal connecting steel bars (1) are laid between the first steel arch (4) and the second steel arch (5) to form a circumferential steel bar net; the steel plate reinforcing steel bars (6) are welded to the outer side of the steel plate (3) between the outer edges of the first steel arch (4) and the second steel arch (5); the anchor rods (7) are welded to the steel plate (3); and the concrete (8) is poured between the steel plate (3) and a fresh face where broken concrete is chiseled away.

Owner:LANZHOU JIAOTONG UNIV

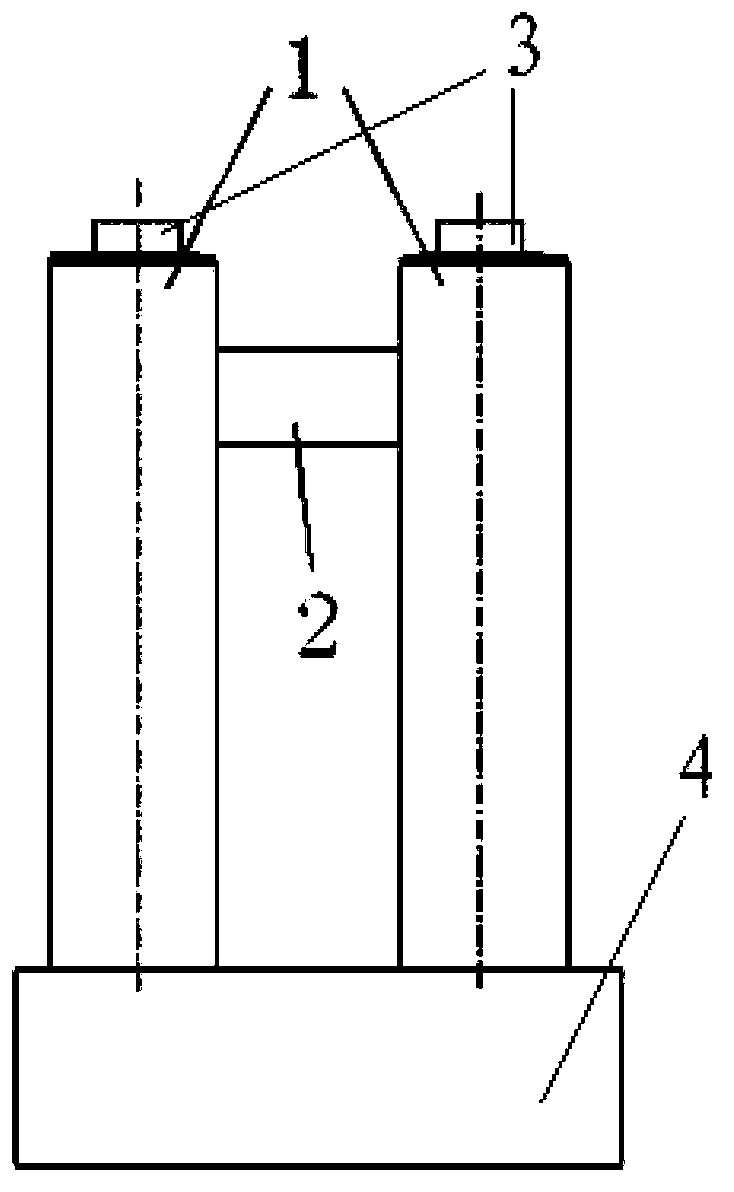

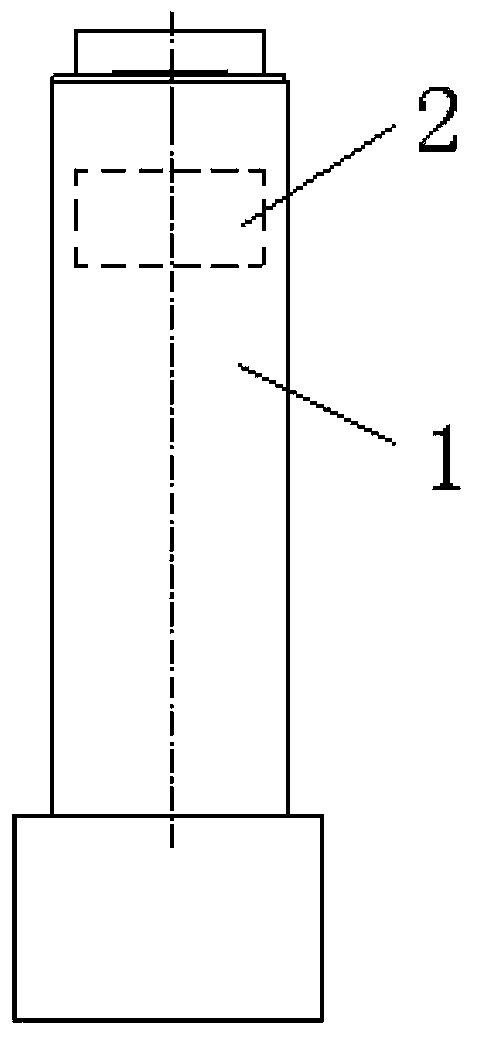

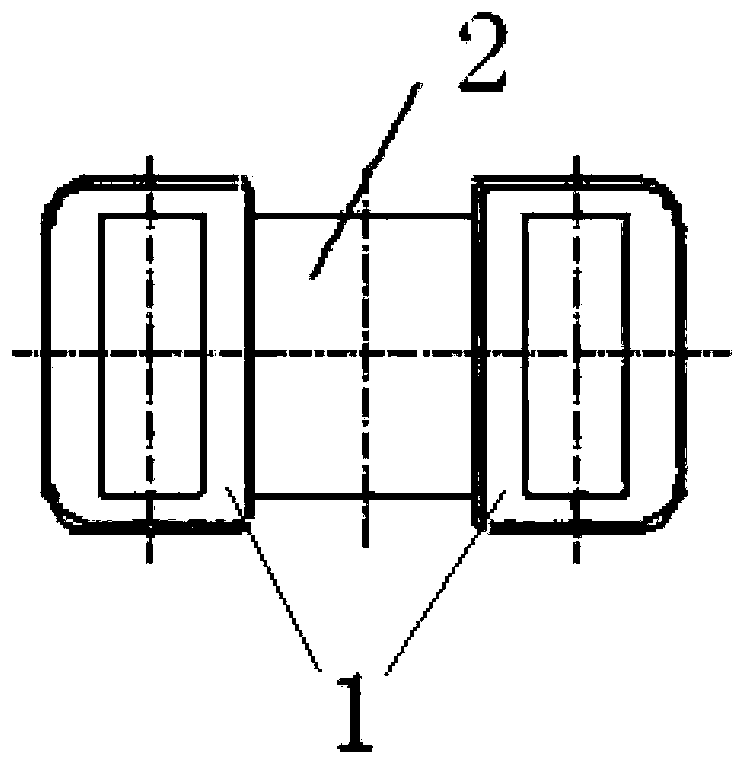

Double-rectangular column type pier of high speed railway

InactiveCN103835227AReasonable structureEasy constructionBridge structural detailsTemplate designUltimate tensile strength

The invention relates to the technical field of a bridge structure, and particularly relates to a double-rectangular column type pier of a high speed railway. The double-rectangular column type pier of the high speed railway comprises two piers fixed on a base seat and straining beams located on the top portion of the piers, and two ends of the straining beams are fixed inside the two piers respectively. The double-rectangular column type pier of the high speed railway is reasonable in structure, simple in construction, convenient and fast to maintain, good in durability, the two piers with relative small mass are arranged below a supporting base of a bridge beam, and stress of the whole structure is clear. The straining beams are arranged below the tops of the piers, the requirement of a transverse stiffness of the high speed piers is met, and the straining beams can be used as an operation platform for checking and maintaining. The pier structure is clear in stress, the structure is reasonable, economy is good, requirements of the strength and the stiffness of the high speed piers are met, the construction is convenient and fast, the template design is simple, the construction process can move fast, and service life of the structure is assured.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

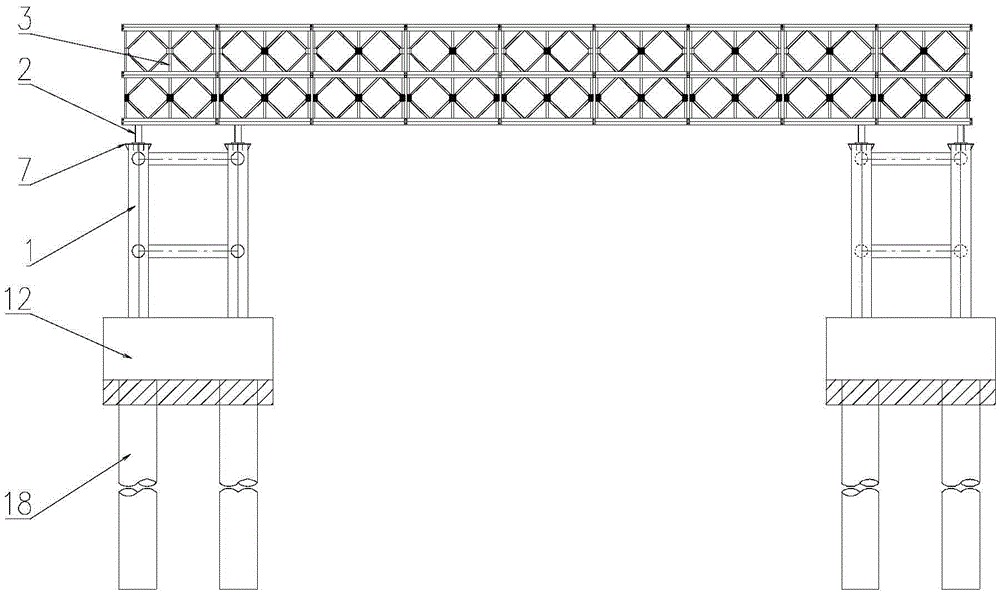

Spanning type bailey beam bracket and construction method thereof

ActiveCN105484164AReduce usagePrevent subsidenceBridge erection/assemblyBridge materialsEconomic benefitsBuilding construction

The invention discloses a spanning type bailey beam bracket and a construction method thereof. The spanning type bailey beam bracket comprises bracket bases positioned on two sides of the bailey beam bracket, cross beams which are in horizontal arrangement are arranged at the tops of the bracket bases in a supporting manner, and the tops of the cross beams on two sides are fixedly connected with two longitudinal ends of a bailey beam. During implementation, after the construction of a box beam on one side is completed, the bracket is wholly put down to a bearing platform on the same side as the box beam, a railway and traversing devices are paved between the bearing platforms on two sides, the bracket is enabled to wholly glide to the bearing platform on the other side, and then on the other side, the bracket is wholly lifted to a proper position, so that the construction period is substantially shortened, the construction efficiency is greatly improved, and the economic benefits are further increased.

Owner:CCCC SECOND HARBOR ENG +2

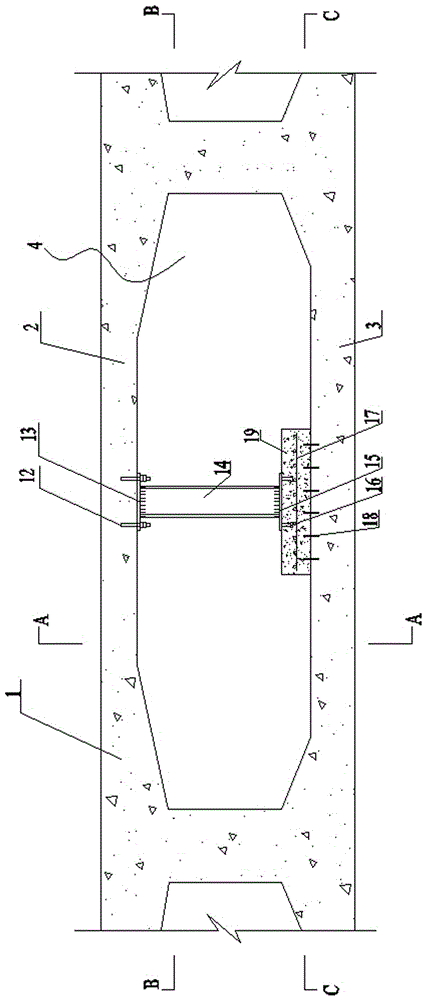

Broken line type dam joint structure and construction method thereof

ActiveCN101603299AThe structural force is clearEasy constructionBarrages/weirsArtificial islandsSlagStructural stress

The invention relates to a broken line type dam joint structure and a construction method thereof. The invention is aimed at solving the technical problem of providing a broken line type dam joint structure and a construction method thereof to solve the problem of designing the dam joint structure under conditions of urban drainage pipes embedded in side slopes, a large area of dwelling houses, man-made slag heaps, small tributary import and the like in accordance with the requirements of structural stress, basic seepage prevention and seepage around the dam of the dam joint structure. For solving the problem, the method adopts a technical proposal that: the broken line type dam joint structure comprises dam concrete gate piers, built bridge concrete piers, a road masonry retaining wall and a built road, and is characterized in that a concrete retaining wall is built between the dam concrete gate piers and the concrete piers, that each structural seam of the concrete retaining wall is sealed by a waterproof sheet copper and that the inner side of the road masonry retaining wall, one end of the concrete retaining wall and one end of the built road have concrete thorn walls. The broken line type dam joint structure and the construction method thereof are applicable to water conservancy and hydropower projects and urban flood control projects.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

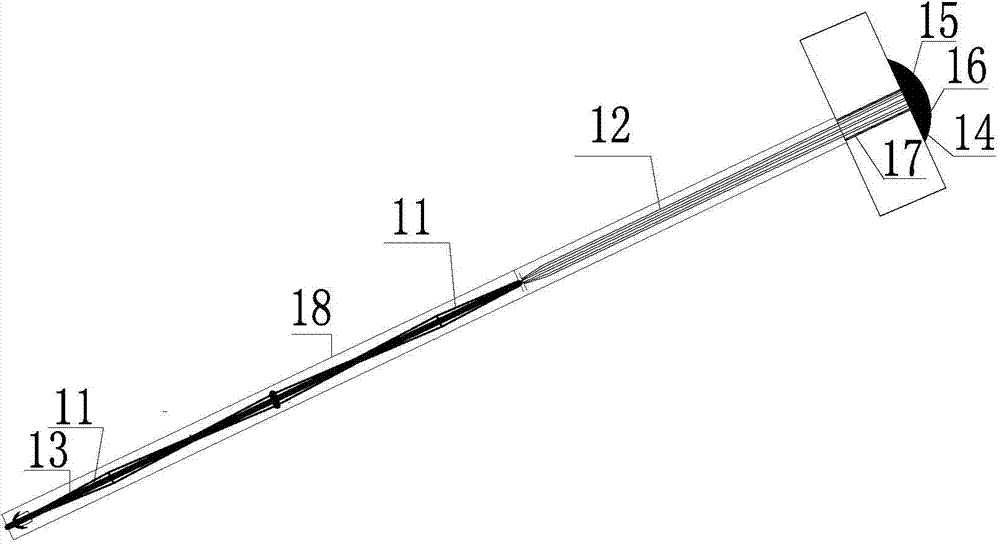

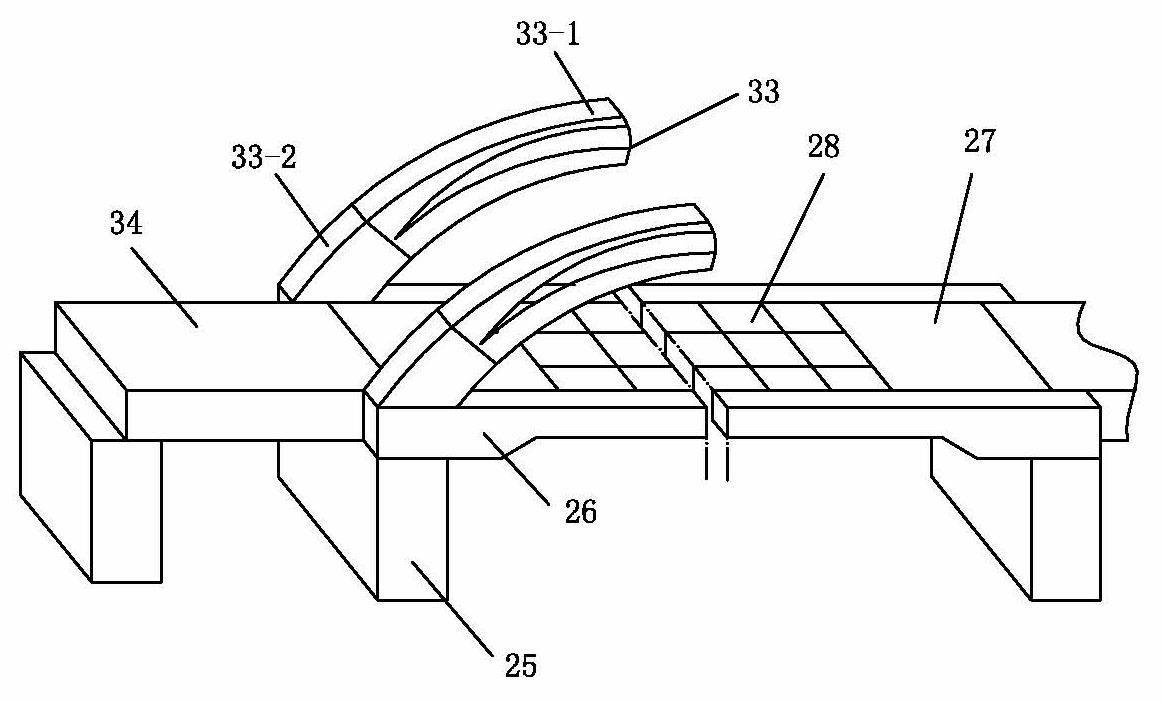

Steel anchor beam without corbels

ActiveCN103981807ASolve the height limit requirementReduce steel consumptionCable-stayed bridgeBridge structural detailsClassical mechanicsTower

The invention provides a steel anchor beam without corbels. The steel anchor beam without the corbels comprises end supports (1), a middle balance beam (2) and stay cable anchoring heads (3). The end supports (1) are connected with tower walls (4) through shear studs (15) or PBL shear keys (16), and the end supports (1) are connected with a web (5) and top plates (6) of the middle balance beam (2) through high-strength bolts. The stay cable anchoring heads (3) are symmetrically arranged on a bottom plate (7) located on the inner sides of the two ends of the web (5) of the middle balance beam (2), and under-anchor #-shaped plates (10) of the stay cable anchoring heads (3) are connected with the web (5), the top plates (6) and the bottom plate (7) of the middle balance beam (2). The steel anchor beam without the corbels has the advantages that the overall height of the steel anchor beam structure is reduced; when a stay cable is tensioned, the middle balance beam slides on connecting bolt hole positions in a self-adaptive mode in the cable force direction, constraint in the horizontal direction of the middle balance beam is released, so that deformation is generated, and the middle balance beam bears the horizontal component balance part of the stay cable. According to the steel anchor beam without the corbels, it is guaranteed that the steel anchor beam bears the most horizontal component of the stay cable, the problem of height limit of the steel anchor beam is solved, meanwhile steel consumption is reduced, and therefore the application range of the steel anchor beam is widened.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD +1

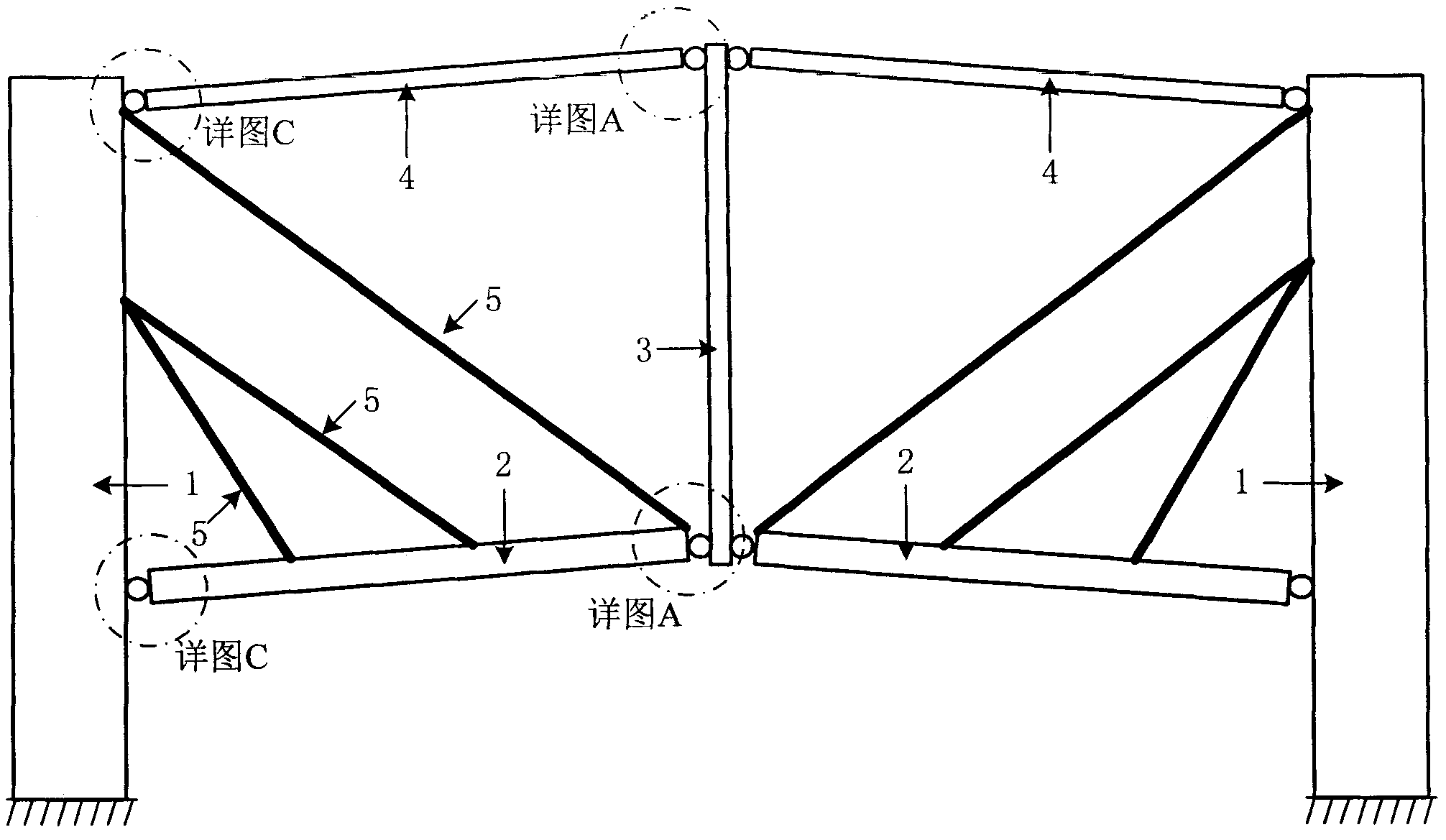

Full swing structural system containing swing columns and swing walls and construction method of full swing structural system

PendingCN109853779AThe structural force is clearImprove lateral stiffnessWallsProtective buildings/sheltersStructural systemEngineering

The invention provides a full swing structural system containing swing columns and swing walls and a construction method of the full swing structural system. The full swing structural system is mainlycomposed of a swing wall part, a frame part and energy dissipation components. The swing walls are hinged to a foundation, and anti-buckling supports are arranged at the two ends of the wall bottoms.The frame part is composed of the elastically recoverable swing columns and frame beams, and the upper ends and the lower ends of the swing columns are connected with the frame beams through recoverable column feet. The swing walls are connected with frames through energy dissipation dampers. Under the action of a horizontal earthquake, the structural system transmits lateral stiffness and interlayer shear force through the swing walls, so that the structural deformation is uniform. The seismic energy is dissipated through the energy dissipation dampers arranged at the side edges of the swingwalls and the anti-buckling supports at the bottoms of the swing walls. The elastic deformation of the swing columns ensures that a frame body does not have yield failures. After the earthquake, thestructural system can be repaired by replacing the anti-buckling supports at the bottoms of the swing walls and the energy dissipation dampers at the side edges of the swing walls.

Owner:CHONGQING UNIV

Damping vibration attenuation device for controlling vortex-induced vibration of large-span bridge girder

PendingCN112663484AControl vortex induced vibrationControlling Multi-Order Vortex-Induced VibrationBridge structural detailsBridge materialsVibration attenuationBridge engineering

The invention relates to the technical field of bridge engineering, and discloses a damping vibration attenuation device for controlling vortex-induced vibration of a large-span bridge girder, which comprises a rigid arm arranged on a bridge pier column in the transverse direction of a bridge, and one end of the rigid arm is hinged with the bridge pier column; a viscous damper, wherein one end of the viscous damper is hinged to the bridge pier stud, the other end of the viscous damper is hinged to the rigid arm, and the viscous damper and the rigid arm are not collinear; and a connecting device which is arranged between the bridge girder and the rigid arm and is used for connecting the bridge girder with the rigid arm. The device has the following advantages and effects that firstly, vortex-induced vibration of the main beam is controlled by arranging an amplification structure formed by the viscous damper and the rigid arm; and secondly, the amplifying device formed by combining the connecting device, the rigid arm and the viscous damper can adapt to broad-spectrum vibration frequency, so that the device is wide in bridge application range, large in span, reliable in transmission displacement, clear in structural stress and capable of controlling multi-order vortex-induced vibration of the main beam.

Owner:中铁桥研科技有限公司 +2

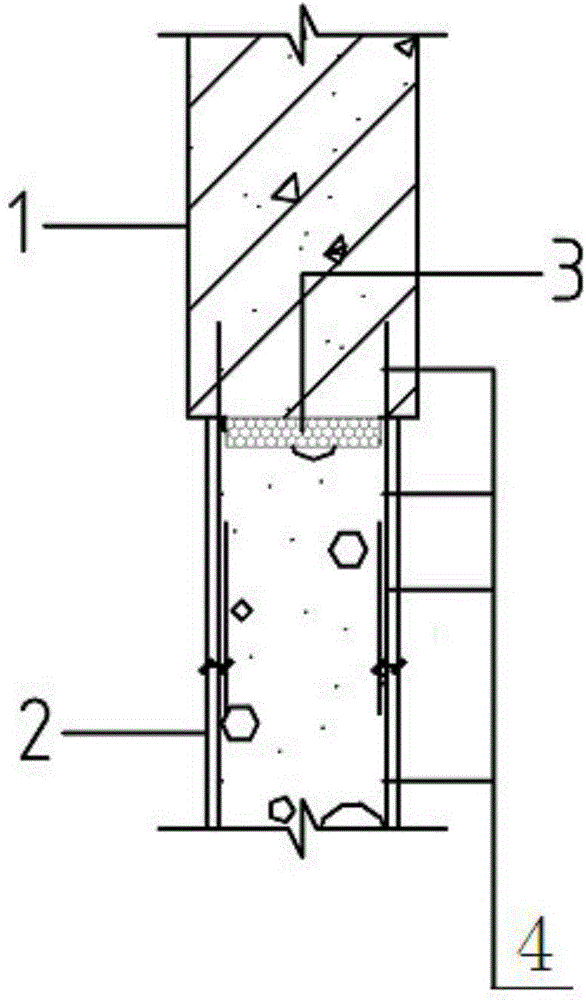

Concrete column high-seismic-resistance fabricated connecting structure

InactiveCN110820546AGuaranteed carrying capacityImprove seismic performanceBridge structural detailsProtective buildings/sheltersEarthquake resistanceArchitectural engineering

The invention discloses a concrete column high-seismic-resistance fabricated connecting structure which comprises an upper segment and a lower segment. The upper segment and the lower segment are sleeved with each other through sleeves and fixedly connected through a flange structure. By adopting the structures of convex-convex pluggable connection, sleeving of the sleeves and flange connection, joint faces, which are connected, of an upper body and a lower body are located at three portions along the height of a column, the phenomenon that weak joint portions are concentrated on the same section is avoided, a bridge pier can bear changeable loads such as pressure, shearing force and bending moment, the good seismic resistance is achieved, and therefore the concrete column high-seismic-resistance fabricated connecting structure is applicable to the bridge pier, in particular to large bridges. Meanwhile, construction can be performed by adopting a factory prefabrication on-site assembling mode, the construction period can be greatly shortened, the construction cost can be lowered, and due to the assembling mode, the whole bridge pier has the good adaptability for diversified loads.The service life of the bridge pier is prolonged, and the remarkable technical and economic comprehensive benefits are achieved.

Owner:SHENZHEN UNIV

Box type web simply supported U-shaped girder of double-track railway

InactiveCN105696455AStrong torsion resistanceImprove torsional load capacityBridge structural detailsStress levelPre stress

The invention discloses a box type web simply supported U-shaped girder of a double-track railway. The box type web simply supported U-shaped girder comprises a roadbed slab; a set of edge box girders is symmetrically arranged at two side end parts of the width direction of the roadbed slab; end cross beams are arranged at two end bottoms of the length direction of the roadbed slab; the roadbed slab is provided with multiple weep holes at intervals in the length direction; the edge box girders extend out from two sides of the roadbed slab, and are hollow cavity structures; multiple first longitudinal prestressed tendons parallel to the length direction of the roadbed slab and multiple transverse prestressed tendons parallel to the width direction of the roadbed slab are arranged in the roadbed slab and a baseplate; multiple second longitudinal prestressed tendons parallel to the length direction of the roadbed slab are arranged in the side walls of the hollow cavities; and multiple vertical prestressed tendons are arranged in the side walls of the hollow cavities at intervals. The box type web simply supported U-shaped girder is higher in torsion resistance and horizontal resistance, is excellent in all beam stress level, has no web splitting problem, needs no additional powerful web stiffening ribs, is simple in structure, and can reach maximum horizontal width.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

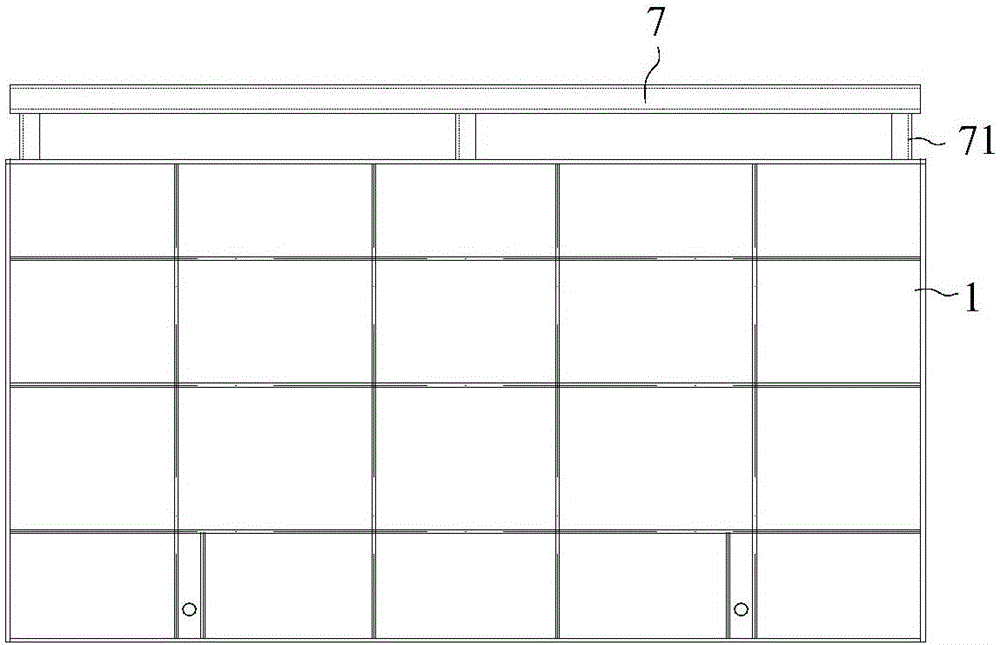

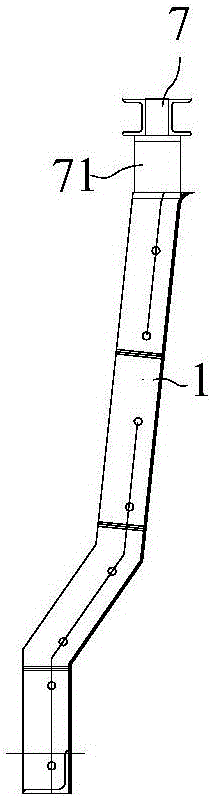

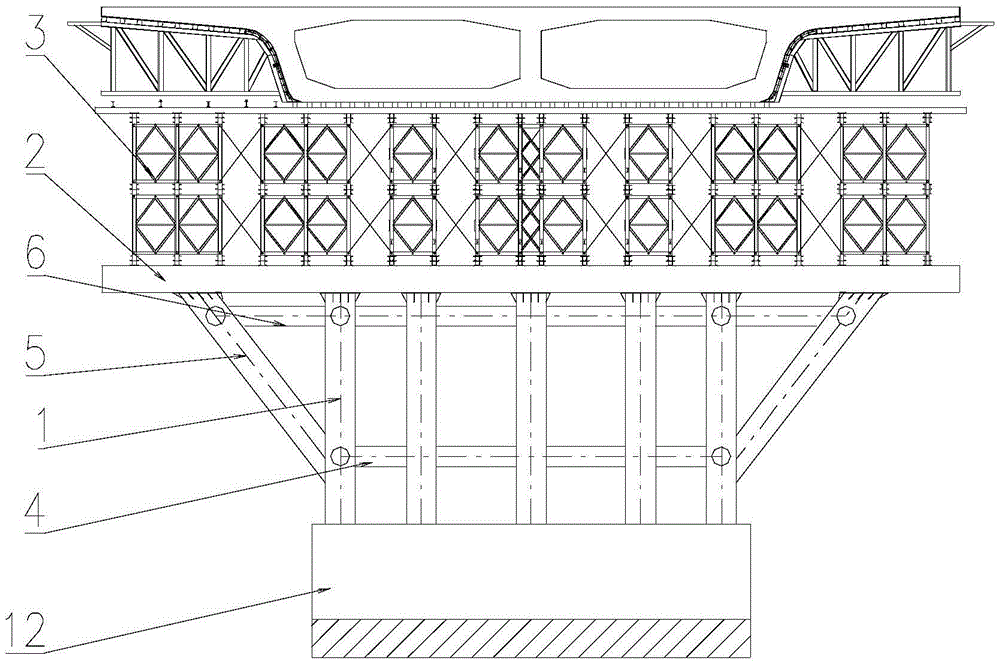

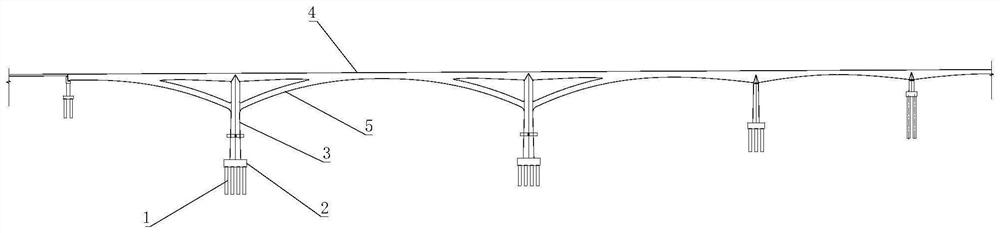

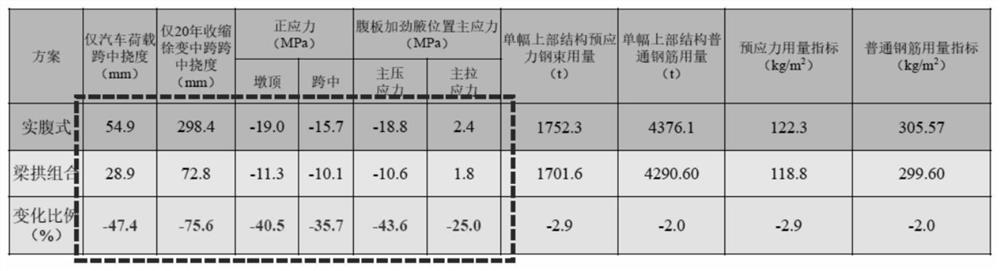

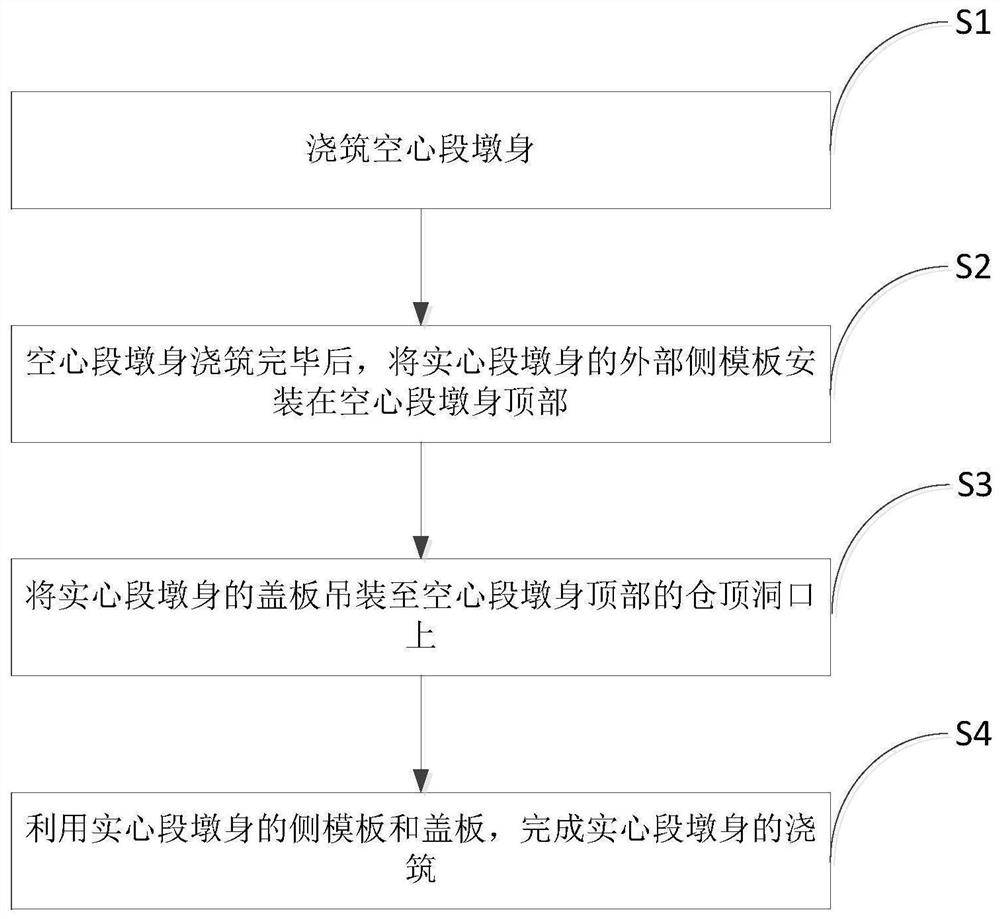

Beam-arch combined rigid frame bridge and construction method of piers thereof

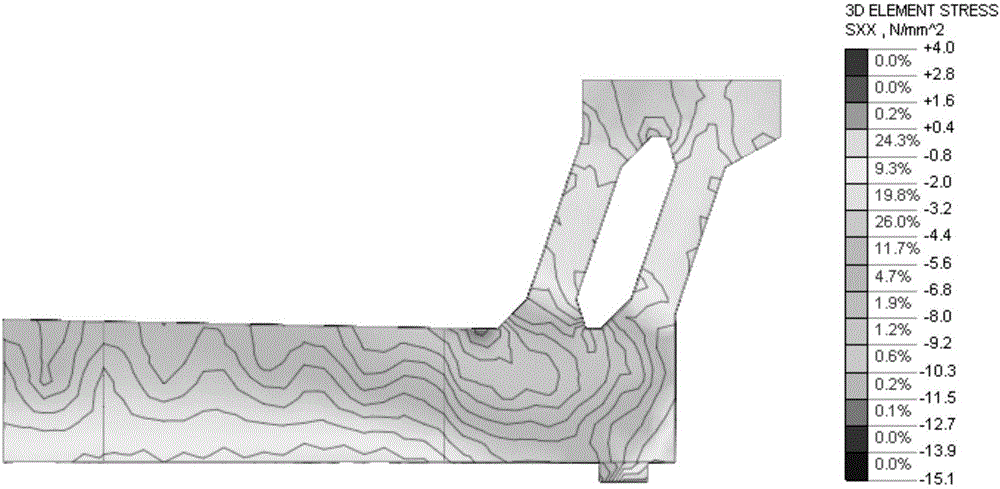

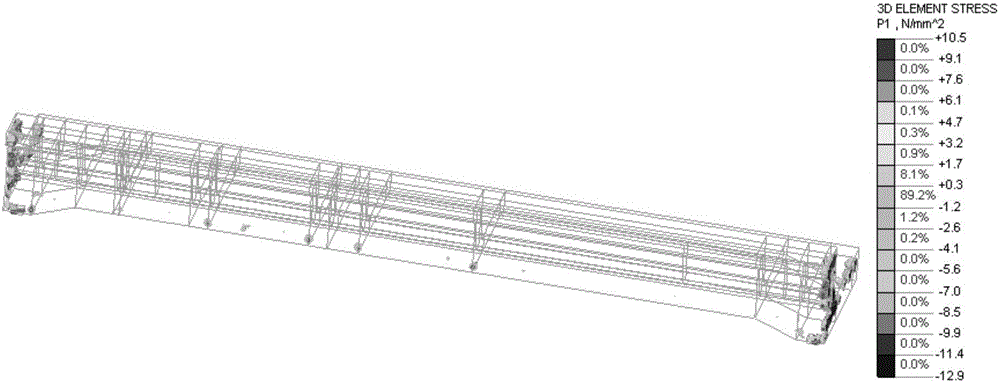

InactiveCN111749133AGive full play to the ability to resist pressureThe structural force is clearBridge structural detailsBridge erection/assemblyArchitectural engineeringStructural system

The invention belongs to the technical field of bridge construction, and particularly relates to a beam-arch combined rigid frame bridge. The rigid frame bridge comprises pile foundations; a bearing platform which is poured on the pile foundation; bridge piers which are arranged corresponding to the bearing platforms, the multiple bridge piers are arranged in the bridge direction at intervals, andthe bridge piers are arranged on the corresponding bearing platforms; a beam body which is supported by a plurality of bridge piers; lower chord supporting beams, one ends of which are connected to the bridge piers, the other ends are connected to the bottom of the beam body, the lower chord supporting beams are located between every two adjacent bridge piers, and the bottom edge lines of the lower chord supporting beams change according to a 2.2-time parabola rule. The combined structure system is clear in structural stress and attractive and novel in appearance.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD

Installation method of no-bracket prefabricated bracket intermediate beam

ActiveCN107165053AReduce construction impact issuesLarge spanBridge erection/assemblyBridge materialsFixed BeamBuilding construction

The invention discloses an installation method of a no-bracket prefabricated bracket intermediate beam. The method of the no-bracket prefabricated bracket intermediate beam comprises the following steps that two ends of the prefabricated bracket intermediate beam are provided with reverse balance arm hanging frames correspondingly first, and each reverse balance arm hanging frame comprises a suspender assembly, a support cushion block and a transverse rod made from I-shaped steel; the middle of each transverse rod is connected with the end part of the prefabricated bracket intermediate beam through the corresponding suspender assembly, one end of each transverse rod is supported on the prefabricated bracket intermediate beam through the corresponding support cushion block, and the other end of each transverse rod stretches out from the end part of the prefabricated bracket intermediate beam; then the prefabricated bracket intermediate beam is conveyed to the installation position through a bridge erecting machine; a jack is arranged on a fixed beam end and below each transverse rod, and the jack is used for adjusting elevation of the whole prefabricated bracket intermediate beam and fixed through a temporary cushion block; by adjusting the length of each suspender assembly, the level degree and the elevation of the whole prefabricated bracket intermediate beam are adjusted, and adjustment and position of the prefabricated bracket intermediate beam are completed after the adjustment is completed; and then welding, pouring and fixing are conducted on the prefabricated bracket intermediate beam. The installation method of the no-bracket prefabricated bracket intermediate beam is simple in structure, and the problem of the construction impact caused by installing the prefabricated beam by traditional brackets is reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

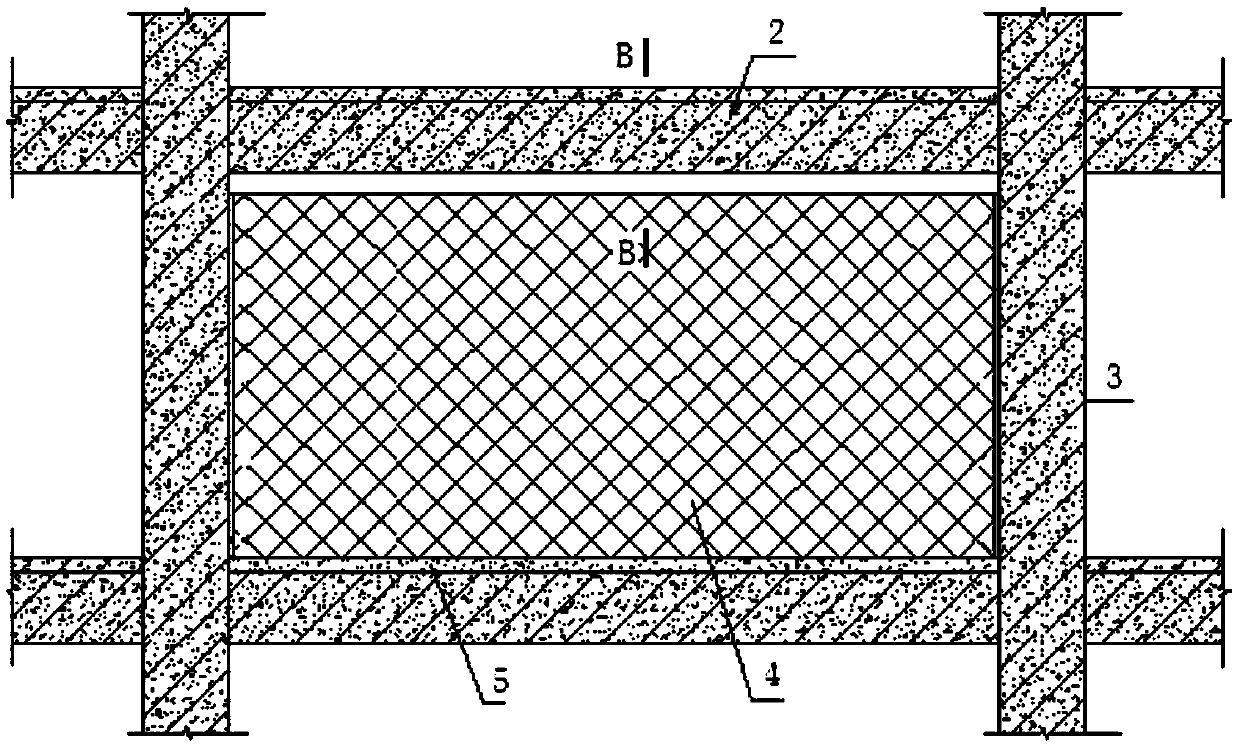

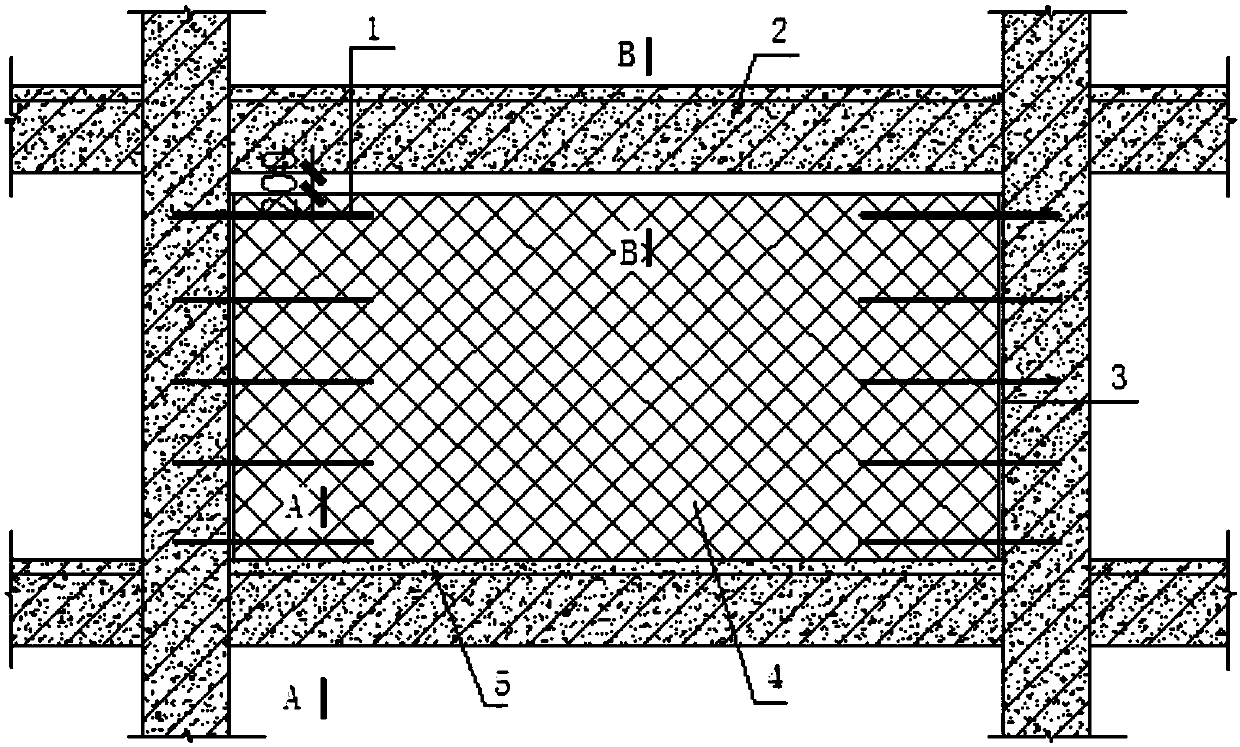

Construction method for carrying out shear strengthening on concrete box girder by adopting corrugated steel web

ActiveCN104695339AEasy to shrinkMake up for shrinkageBridge erection/assemblyBridge strengtheningBox girderFlange

The invention discloses a construction method for carrying out shear strengthening on a concrete box girder by adopting a corrugated steel web. The construction method sequentially comprises the following steps: performing construction layout positioning on a box girder top plate and a box girder bottom plate; forming a hole in the box girder top plate; processing and strengthening a junction surface; drilling an anchor bolt hole in the top surface of the box girder bottom plate; blanking the corrugated steel web; drilling a hole in a lower flange plate, and polishing the lower flange plate; welding and mounting the corrugated steel web; pouring concrete into the hole of the box girder top plate. The construction method has the advantages that by mounting a longitudinal corrugated steel web component in a box chamber of a box girder, the number of webs of the box girder is increased, and the principal tensile stress of an original concrete web of the box girder is reduced, so that the aim of shear strengthening of a box girder bridge is achieved.

Owner:HENAN PROVINCIAL TRANSPORTATION RES INST

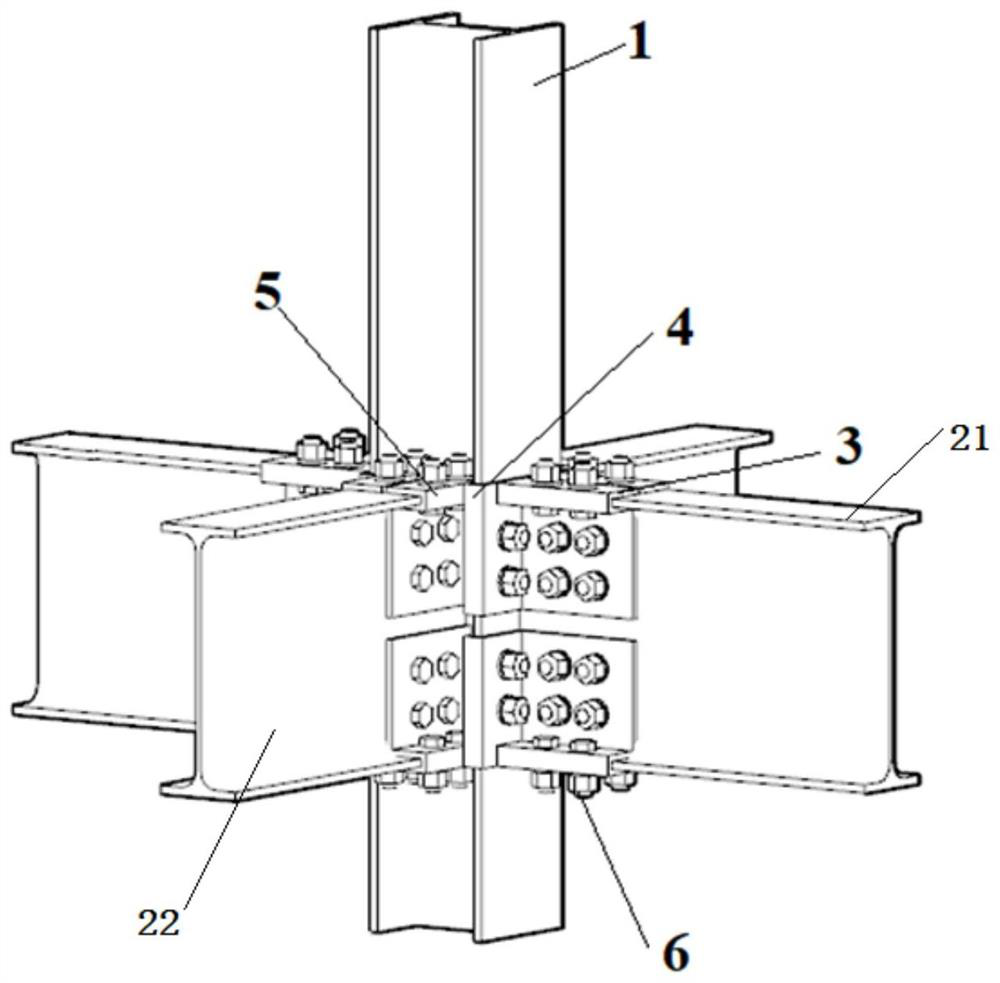

Fabricated joint capable of integrally connecting major and minor axes of I-shaped beam columns

PendingCN111962671AAchieving an all-in-one connection designEasy to assembleBuilding constructionsGusset plateShaped beam

The invention discloses a fabricated joint capable of integrally connecting major and minor axes of I-shaped beam columns. A first I-shaped beam directly faces a flange of an I-shaped column; a secondI-shaped beam directly faces a web plate of the I-shaped column; the upper side of a minor axis gusset plate is buckled and fixed at one end of the second I-shaped beam; the lower side of the minor axis gusset plate is fixed on a web plate of the second I-shaped beam; a column flange gusset plate is buckled and fixed on the flange of the I-shaped column; the upper side of a major axis gusset plate is buckled and fixed on the flange of the first I-shaped beam; the lower side of the major axis gusset plate is fixed to a web of the first I-shaped beam, the end part of the major axis gusset plateis fixed to one side of the column flange gusset plate, the end part of the upper side of the minor axis gusset plate is fixed to the other side of the column flange gusset plate, and the joint can achieve integrated connection of a major axis and a minor axis.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A connection method of integrated prefabrication of concrete shear wall and filling wall

ActiveCN104831829BReduce consumptionGuaranteed reliabilityWallsArchitectural engineeringSoft materials

A connection method for integrated prefabrication of concrete shear walls and infill walls, which belongs to the technical field of construction, including prefabricated concrete shear walls, prefabricated infill walls, soft materials, and prefabricated infill wall steel wires, and is realized through the following steps: According to the design Formwork is required; wall reinforcement and steel wires are bound; if precast concrete shear walls and prefabricated infill walls are hollow, corresponding molds should be placed; soft materials between precast concrete shear walls and prefabricated infill walls should be placed; pouring The wall concrete is demoulded after curing. The present invention can ignore the impact of the filling wall on the anti-sway stiffness of the overall structure, the structural force is clear, the force transmission route is clear, and the reliability of the structure is guaranteed; at the same time, the integrated prefabrication method is simple, which is convenient for the production, construction and installation of prefabricated components, and improves It improves the quality and efficiency, reduces the construction cost, and has positive significance for the development of prefabricated concrete buildings.

Owner:凡林装配式建筑科技有限公司

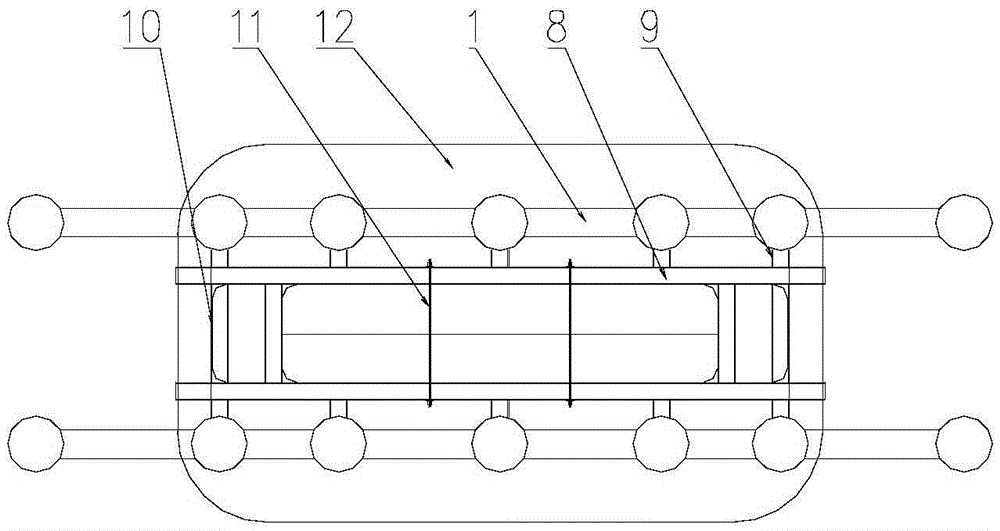

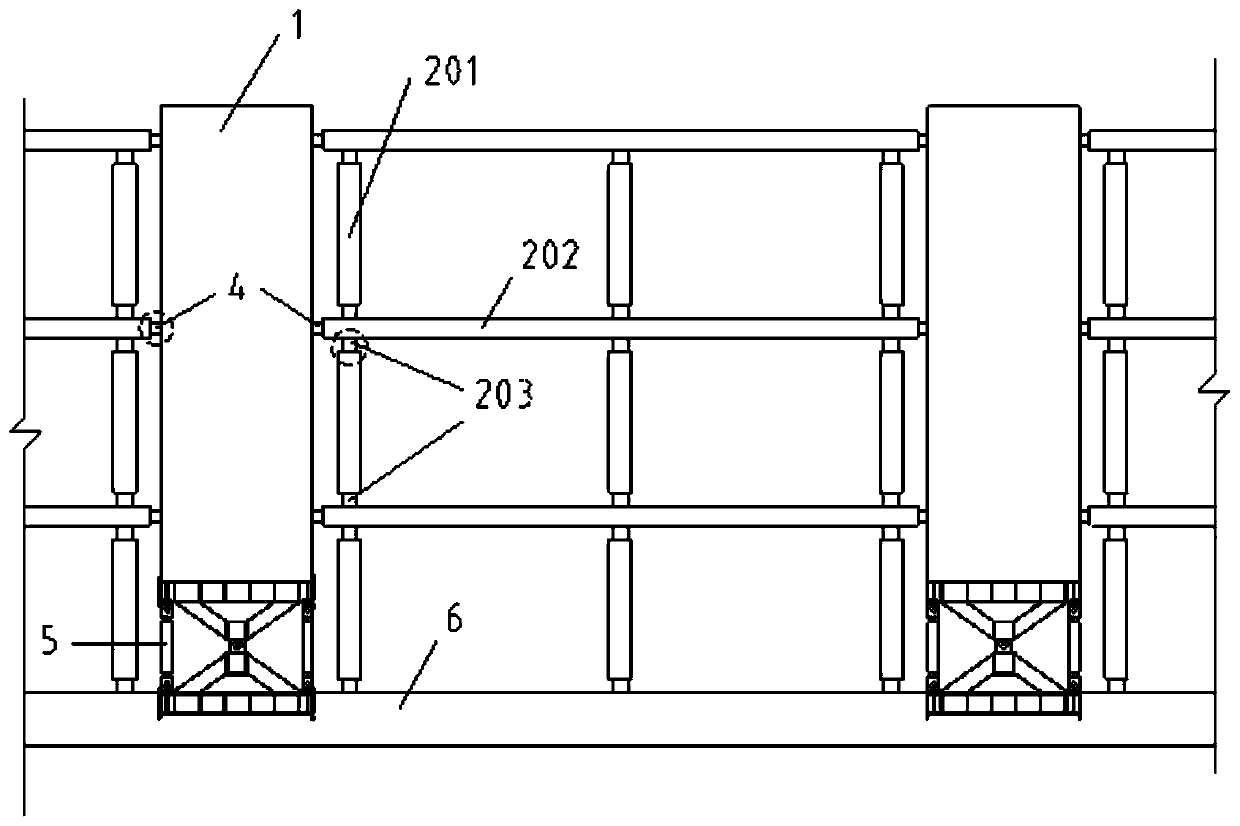

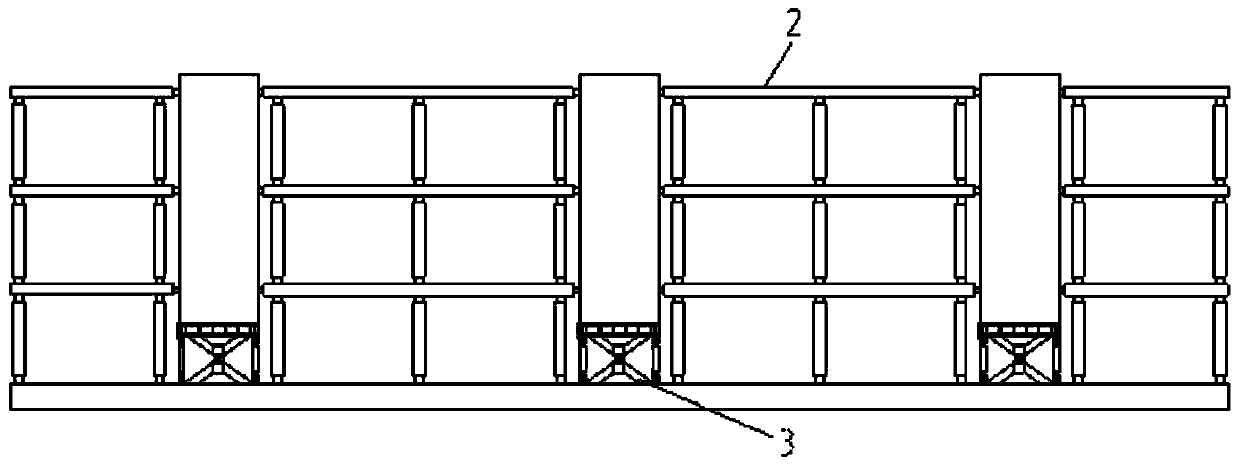

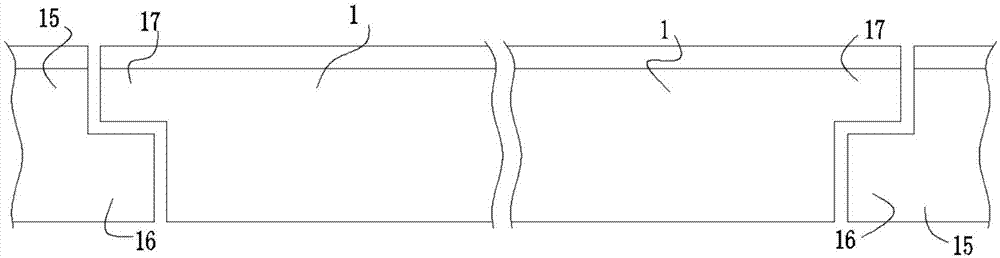

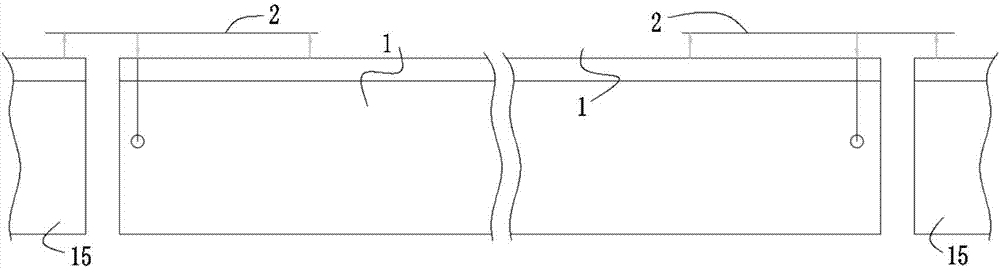

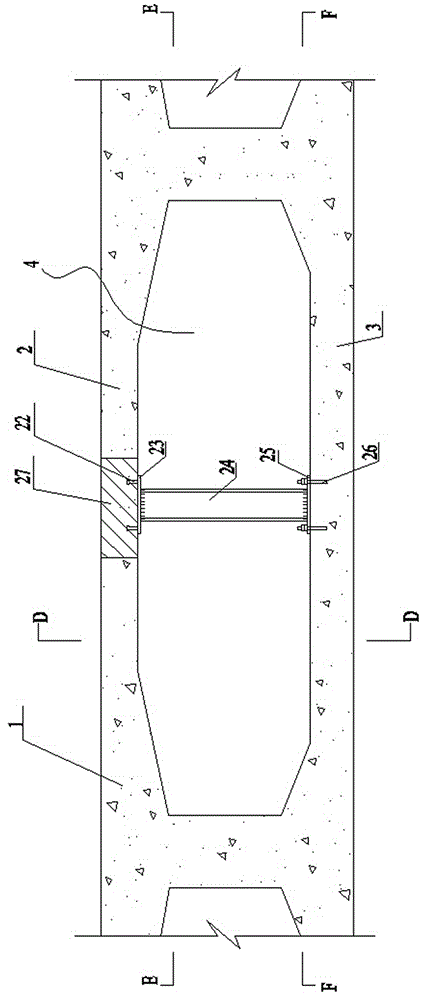

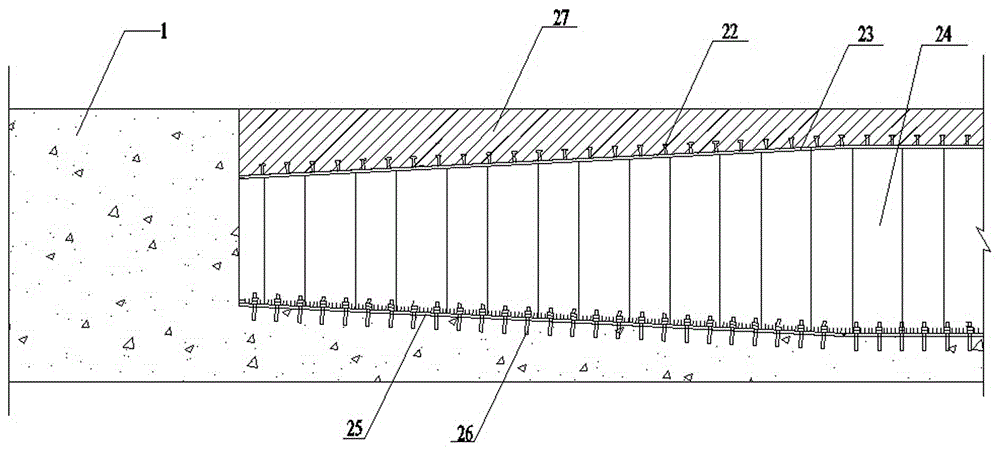

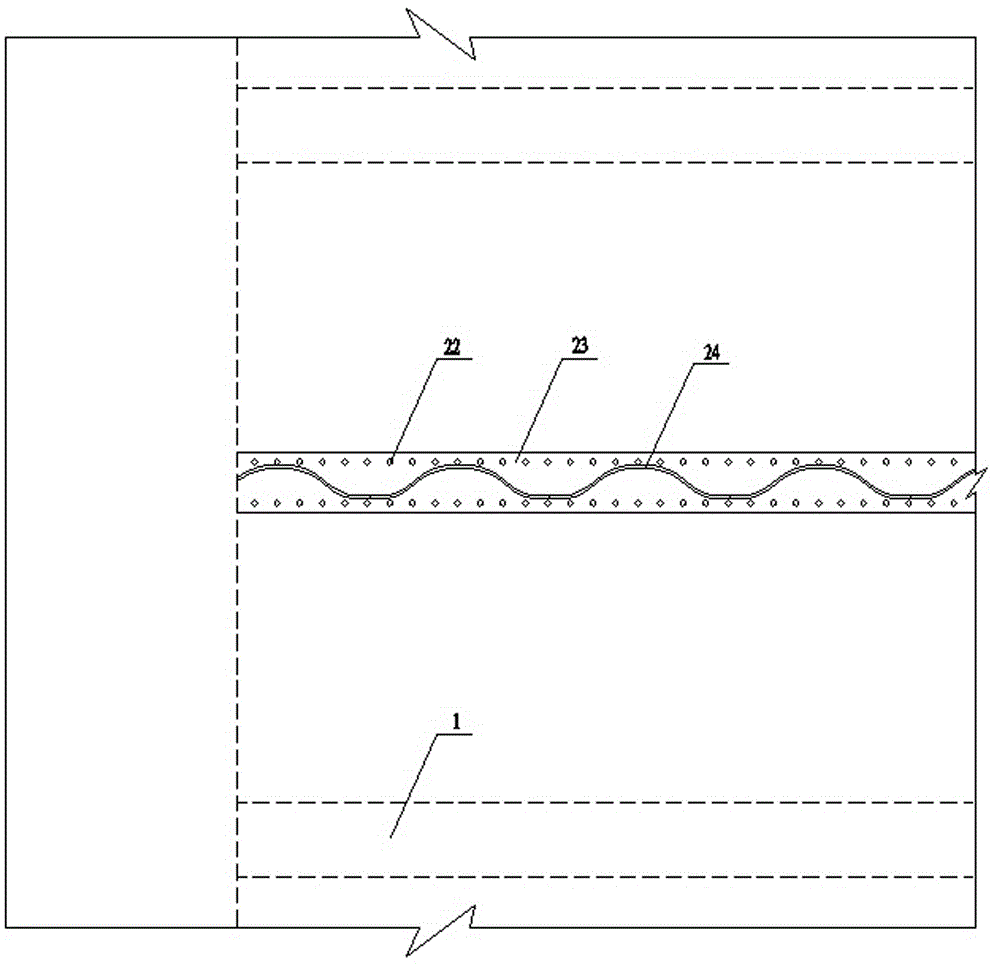

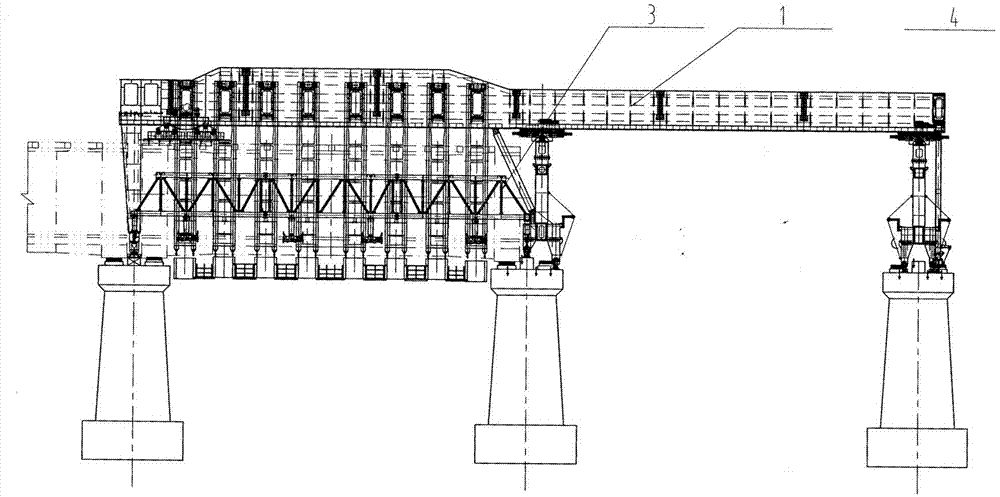

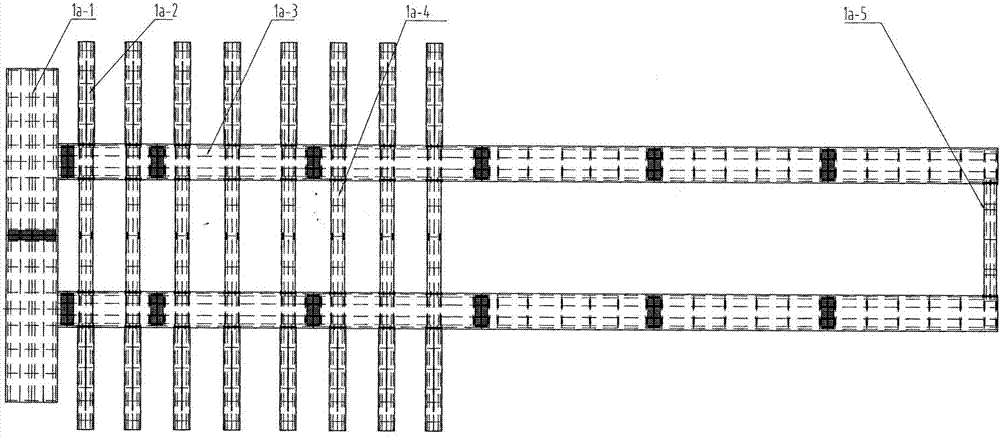

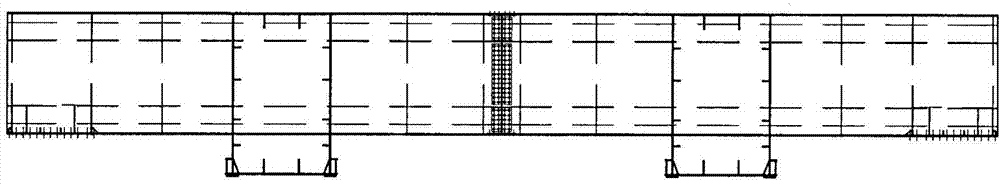

Self-propelled movable formwork for construction of double-rectangle water conservancy aqueduct

ActiveCN103526697BSimple structureReduce the amount of processingBridge erection/assemblyElectric controlAqueduct

A self-propelled mobile formwork for the construction of a double rectangular water conservancy aqueduct, including an outer beam system (1), an outer formwork system (2), an inner beam system (3), an outer formwork system (4), and an electric control system (5 ) and the hydraulic system (6); the outer beam system (1) is the main bearing system of this equipment, mainly composed of the outer beam (1a), the No. 1 leg of the outer beam (1b), and the No. 2 leg of the outer beam (1c), outer girder No. 3 leg (1d), outer girder No. 4 leg (1e), and outer girder rear travel (1f); the outer girder (1a) is in the form of a box-shaped composite girder, which is in the form of double girders. The beam center distance is 9.5 meters, and the two beams are formed as a whole by two sets of end connecting beams, 8 sets of intermediate connecting beams, and 16 sets of left and right symmetrical cantilever beams; the outer main beam is the main load-bearing structure of the slot machine, and the pouring state is passed The No. 3 and No. 4 outriggers transmit the load to the top of the pier before and after the pouring span respectively.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

Construction Method of Shear Reinforcement of Concrete Box Girder Based on Corrugated Steel Web

ActiveCN104695340BIncrease the number of websAchieve shear reinforcementBridge erection/assemblyBridge strengtheningSteel barBox girder

The invention discloses a construction method of shear resistance and strengthening of concrete box beams based on corrugated steel webs. The construction method successively comprises the following steps: performing construction lofting and positioning on top plates and bottom plates of box beams; performing and strengthening bonding surfaces; drilling anchor bolt holes in the bottom surfaces of the top plates of the box beams; drilling holes and planting steel bars in the top surfaces of the bottom plates of the box beams; performing laying-off on the corrugated steel webs; drilling holes and performing polishing on upper flange plates; welding and mounting the corrugated steel webs; mounting reinforced mesh slices; erecting a model and pouring concrete. The construction method disclosed by the invention has the advantage that the purposes of shear resistance and strengthening of the concrete box beams are achieved by mounting longitudinal corrugated steel web components in box chambers of box beams, increasing the number of webs of the box beams and reducing the main tensile stress of original concrete webs of the box beams.

Owner:HENAN PROVINCIAL TRANSPORTATION RES INST

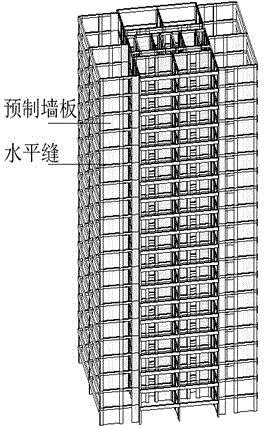

Construction method and structure system of prefabricated large plate filled wall concrete structure

InactiveCN109653404AReduce the number of seamsReduce construction costsWallsFloor slabConcrete beams

The invention discloses a construction method and a structure system of a prefabricated large plate filled wall concrete structure. The prefabricated large plate filled wall concrete structure systemcomprises a cast-in-place concrete structure and a prefabricated large plate filled wall, the cast-in-place concrete structure comprises a cast-in-place concrete column, wall and beam, and the insideof the cast-in-place concrete structure is filled with the prefabricated large plate filled wall. The construction method includes the steps: firstly, mounting the prefabricated large plate filled wall serving as a peripheral protective wall and an inner wall on a certain layer of a building once, and reserving a gap between the top of the filled wall and the bottom of the cast-in-place concrete beam; secondly, setting templates such as a main structure concrete column, a shear wall, a beam and a floor slab and binding reinforcement, taking the side face of a wall plate as part of a wall column side template and pouring main structure concrete; finally, reliably connecting the top of the filled wall with the bottom of the concrete beam to reliably connect the filled wall with a cast-in-place concrete main structure. The technical problems of low construction speed, poor quality and integrity, difficulty in hoisting and the like of a prefabricated large plate filled wall in a traditional construction mode are solved.

Owner:马杰

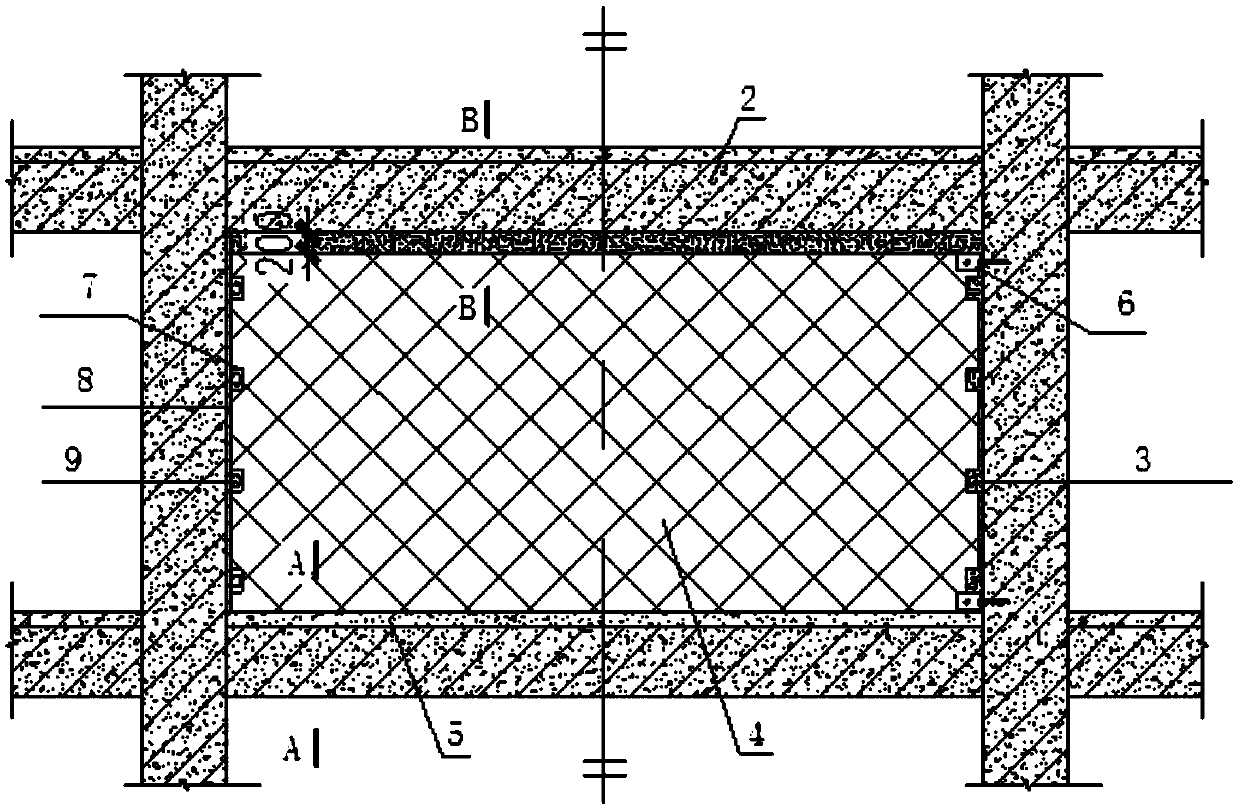

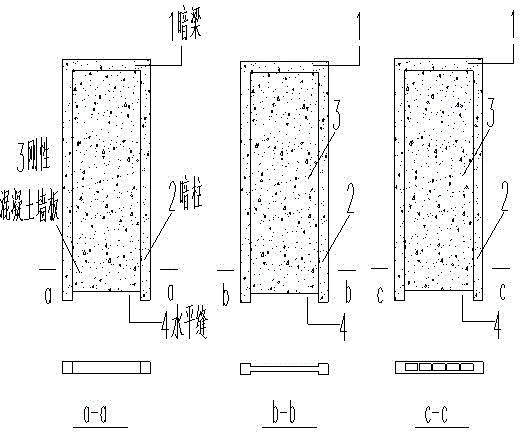

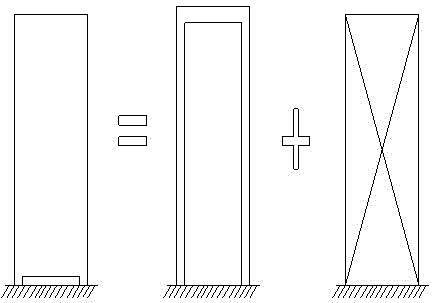

Precast concrete frame support shear wall panel

InactiveCN104060757AReduce dosageReduce in quantityConstruction materialWallsArchitectural engineeringHollow core

The invention belongs to the field of civil engineering, and particularly relates to an assembly type building structure and a concrete structure. A precast concrete frame support shear wall panel is composed of embedded columns, hidden beams and a middle rigid concrete wallboard, wherein the embedded columns and the hidden beams are arranged in a wall. A rectangular-section solid or hollow wallboard can be adopted as the middle rigid concrete wallboard. The fact that the precast concrete frame support shear wall panel is utilized for forming a frame support shear wall structure system does not mean that supports are arranged in the structure system but means that the supports are enabled to be equivalent to the frame support structure system in stress mode and fracture morphology by arranging the precast concrete frame support shear wall panel and adjusting boundary conditions. For the precast concrete frame support shear wall structure system, only the embedded columns need to be connected in the vertical direction, so that the number of connecting parts is reduced, on-site installation and construction are facilitated, the construction speed is increased, and meanwhile structural stress is more definite. According to the wall panel, as consideration is given to the middle rigid concrete wallboard according to the supports, the thickness of the wall can be reduced properly, or the wall is changed to be hollow, in this way, the consumption of concrete can be effectively lowered, the structural self-weight can be reduced, and the earthquake action of the structure can be relieved.

Owner:SHENYANG JIANZHU UNIVERSITY +2

Steel pipe web prestress steel mixing combination main beam structure and construction method

ActiveCN107142830AImprove carrying capacityAddresses vulnerability to wind loadsBridge materialsPre stressArchitectural engineering

The invention discloses a steel pipe web prestress steel mixing combination main beam structure and a construction method. The structure comprises concrete top plates, concrete bottom plates, web steel pipes, body prestress steel strands, external steel cables and transverse partition plates. The web steel pipes are embedded between the concrete top plates and the concrete bottom plates; the top end and bottom end of the adjacent two web steel pipes are connected through a shear key bolt plate to form a longitudinal triangular stable structure; a plurality of steel pipes are connected to each other sequentially to form a beam body web for bearing the beam body shear and part of the bending moment. The body prestress steel strands are embedded in the top plate concrete and bottom plate concrete; the external steel cables are arranged inside a steel mixing combination beam frame; the transverse partition plates are located inside the steel mixing combination beam frame and are arranged at a distance from each other, and poured with the top plate concrete and bottom plate concrete to form an unity.

Owner:SHANDONG JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com