Patents

Literature

61results about How to "Reduce the number of seams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

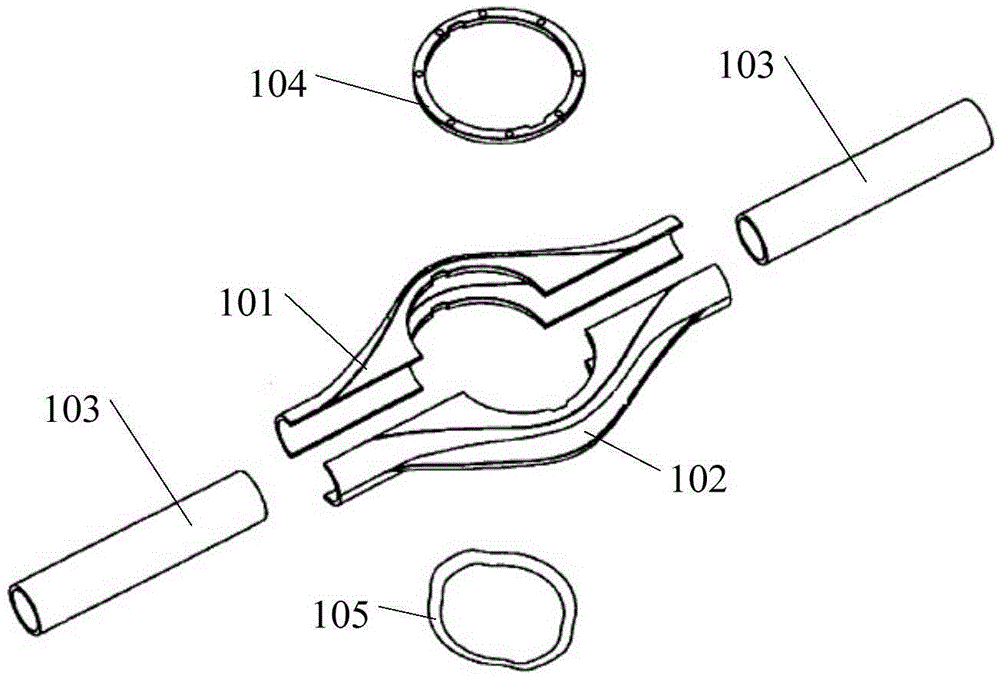

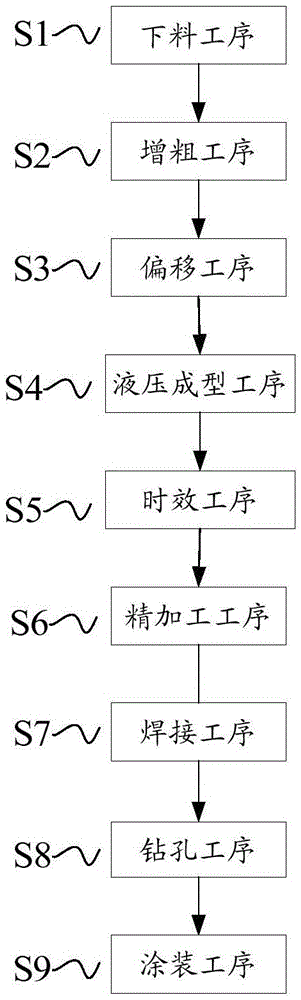

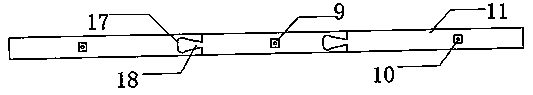

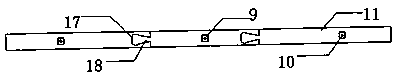

Automobile drive axle housing and manufacturing technology and manufacturing mold of automobile drive axle housing

ActiveCN105619029AHigh strengthReduce the number of seamsAxle unitsStress concentrationManufacturing technology

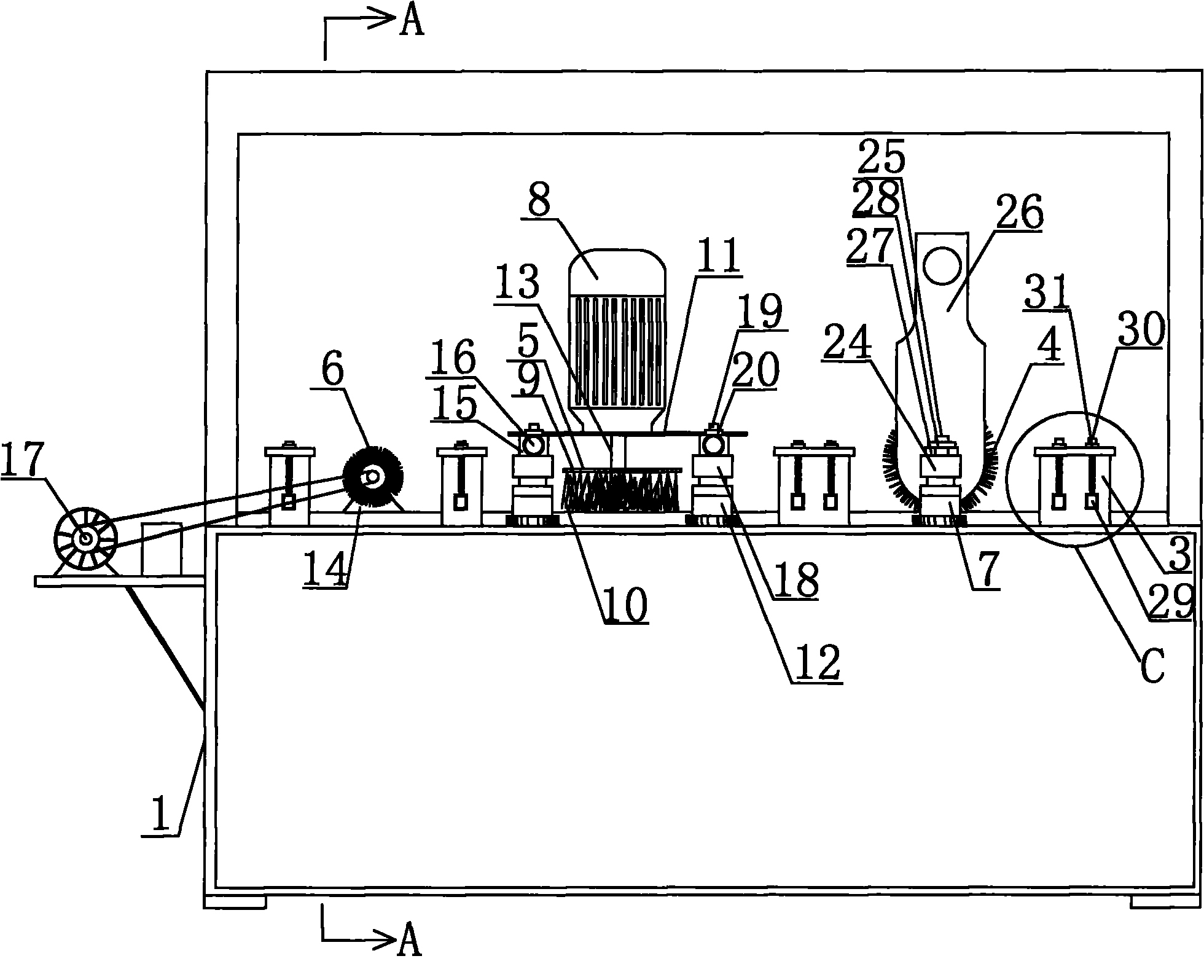

The invention belongs to the technical field of automobile manufacturing and provides an automobile drive axle housing and a manufacturing technology and a manufacturing mold of the automobile drive axle housing. The manufacturing technology comprises a blanking process, a thickening process, a shifting process, a hydraulic molding process, an aging process, a finish machining process, a welding process, a drilling process and a coating process. According to the automobile drive axle housing and the manufacturing technology and the manufacturing mold of the automobile drive axle housing, by additionally arranging the thickening process, the shifting process and the hydraulic molding process, the welding positions of the automobile drive axle housing and the juncture number of parts are reduced, so that the finish machined axle housing is of a structure formed integrally; the problems of stress concentration and cold joint caused by the welding process are avoided, the finished product sealing performance of the whole axle housing is ensured, and occurring of the oil leakage phenomenon is reduced; in addition, by means of the structure formed integrally, the strength of the automobile drive axle housing can be improved, fracture is prevented, and the reliability of the whole automobile drive axle housing is improved; accordingly, the axle housing is light in weight, and the cost is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Method for preparing embossed decorative veneer

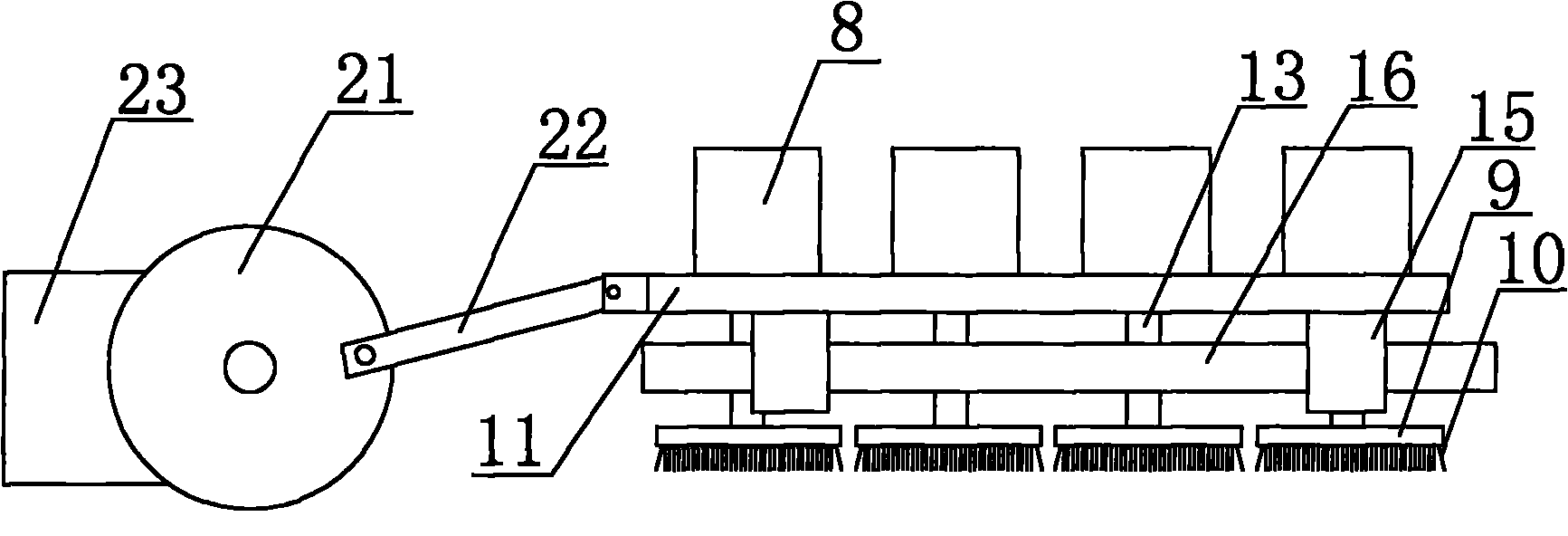

ActiveCN102059730AReduce the number of seamsReduce workloadWood veneer joiningWood layered productsDrive motorWood grain

The invention discloses a method for preparing an embossed decorative veneer, which comprises the steps of selecting, hydrothermal softening, slicing, veneering, cold inspection, rinsing, and wire drawing, wherein the wire drawing step comprises three processes of direct drawing, sweeping and polishing; during direct drawing, a groove is formed on the surface of a board by a front steel wire roller on a wire drawing machine and grains are deepened; during sweeping, a plurality of disc brushes are arranged on the wire drawing machine, each disc brush is driven to rotate by a respective drive motor and comprises a disc and steel wires which are densely arranged on the lower end face of the disc, and the plurality of disc brushes rotate to widen the grains of the groove on the surface of the board, so that the grains on the surface of the board are wider, and the embossed effect is more vivid; and during polishing, first two groups of brushed parts of the board are polished by a rear steel wire roller on the wire drawing machine, so that a finished product has smooth feeling, and the embossed effect is achieved on the surface of the veneer. Compared with the prior art, the method ensures that wood grains are more three-dimensional, vivid and natural.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

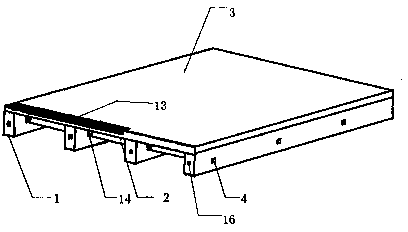

Assembly type bamboo bridge with variable expansion coefficients

ActiveCN103452035AHigh tensile strengthNo possibility of crackingSynthetic resin layered productsBridge structural detailsPolymer sciencePolymer chemistry

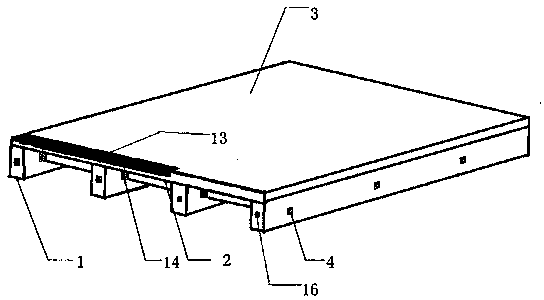

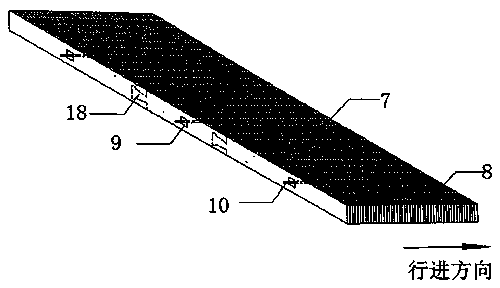

The invention provides an assembly type bamboo bridge. The assembly type bamboo bridge comprises bamboo longitudinal beams (1), bamboo transverse beams (2), bamboo panels (3), transverse pre-stressing tendons (4) and longitudinal pre-stressing tendons (16), the outer surface of a bamboo is sequentially and uniformly coated with a layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resorcinol formaldehyde resin, and the expansion coefficients of the four coating layers are sequentially lessened from the outer surface of the bamboo to outside. The assembly type bamboo bridge provided by the invention has the advantages that the structural strength is large, the ductility is good, a selected material is environment-friendly, standardization degree and assembling degree of structural members are high, the structural integrity is good, the advantages of the material can be fully expressed, and the requirements on normal use and durability of a bridge structure can be met.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Processing method for renewable waste plastic glass fiber building formwork

InactiveCN102900229AImprove integrityHigh surface hardnessForming/stuttering elementsGlass fiberEngineering

The invention discloses a processing method for a renewable waste plastic glass fiber building formwork. The processing method is characterized by comprising the following steps of: firstly, sorting materials and manually sorting, cleaning and drying different materials; secondly, crushing and drying the sorted materials; thirdly, mixing and blending the crushed materials; fourthly, mixing and granulating; fifthly, conveying the granulated materials to an extruding machine hopper; sixthly, heating and melting; seventhly, casting; eighthly, carrying out compression moulding forming; ninthly, cooling and setting; and tenthly, shearing. The processing method has the advantages of favorable strength, small deformation, high turnout frequency, favorable demoulding effect, 100 percent of recovery of waste plates, environment friendliness and energy saving.

Owner:任聪

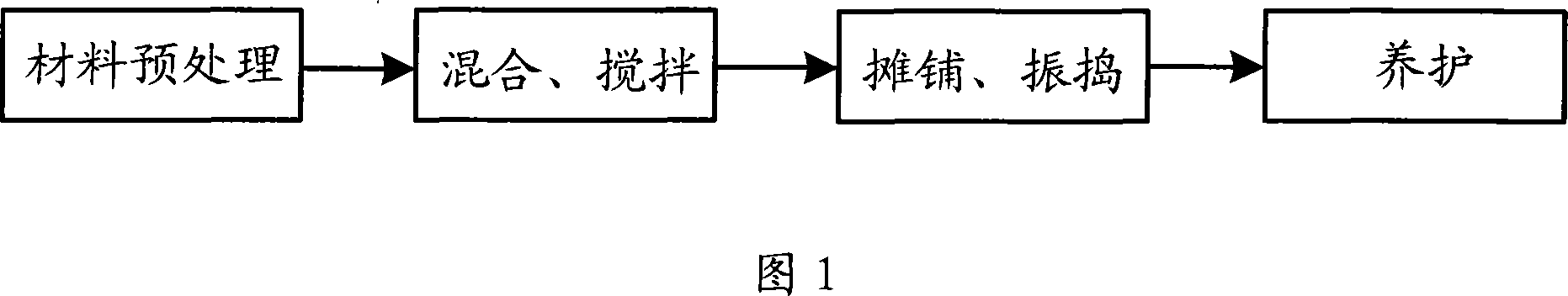

Highway dredging mud ceramicite cement concrete and method for preparing the same

InactiveCN101134658AExcellent driving noiseReduce the number of seamsSolid waste managementSludgeCrushed stone

The present invention discloses one kind of sludge haydite-cement concrete for road and its preparation process. The sludge haydite-cement concrete is mixture of sludge haydite, cement, crushed stone, sand, water and admixture in certain weight proportion. It is prepared through wetting sludge haydite and mixing the materials; and is used through spreading, vibrating and curing. The sludge haydite-cement concrete has excellent performance, environment friendship and low production cost.

Owner:OCEAN UNIV OF CHINA

Erbium-containing oceangraphic engineering and goods stock aluminum alloy and plate manufacturing method thereof

ActiveCN108342626ARaise the recrystallization temperaturePromote precipitationTechnology researchCorrosion resistant

The invention discloses erbium-containing oceangraphic engineering and goods stock novel corrosion-resistant aluminum alloy and a plate manufacturing method thereof, relates to aluminum alloy and a plate manufacturing method thereof and aims at finishing large-dimension plates with the plate width not lower than 3500mm and industrial production technology researches. The aluminum alloy disclosed by the invention is prepared from the elements of Mg, Mn, Er and Zr. The method comprises the steps:1, preparing materials; 2, smelting; 3, casting; 4, evenly annealing; 5, hot rolling; 6, annealing; 7, stretching; 8, saw cutting to obtain the erbium-containing oceangraphic engineering and goods stock aluminum alloy. Under the premise of meeting material corrosion resistance environment and hot processing technology performance, comprehensive performance of the prepared erbium-containing ocean engineering and goods stock aluminum alloy plate disclosed by the invention is improved by 10% or above; thus, the alloy can meet requirements of oceangraphic engineering and goods stock materials, and the plate manufacturing method disclosed by the invention can be applied to the field of aluminum alloy manufacturing.

Owner:NORTHEAST LIGHT ALLOY CO LTD

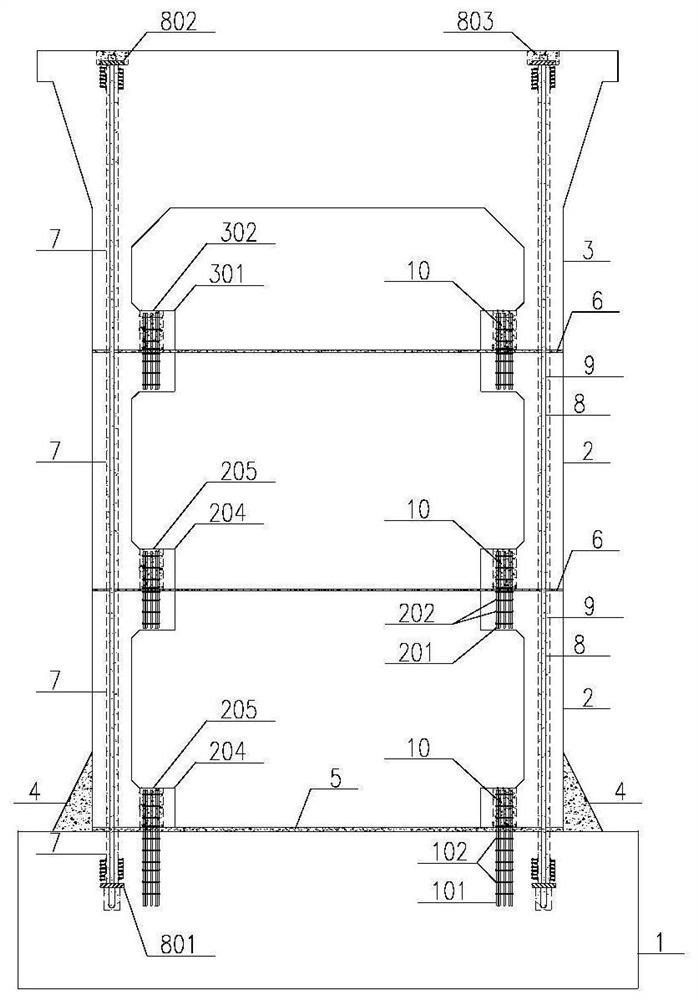

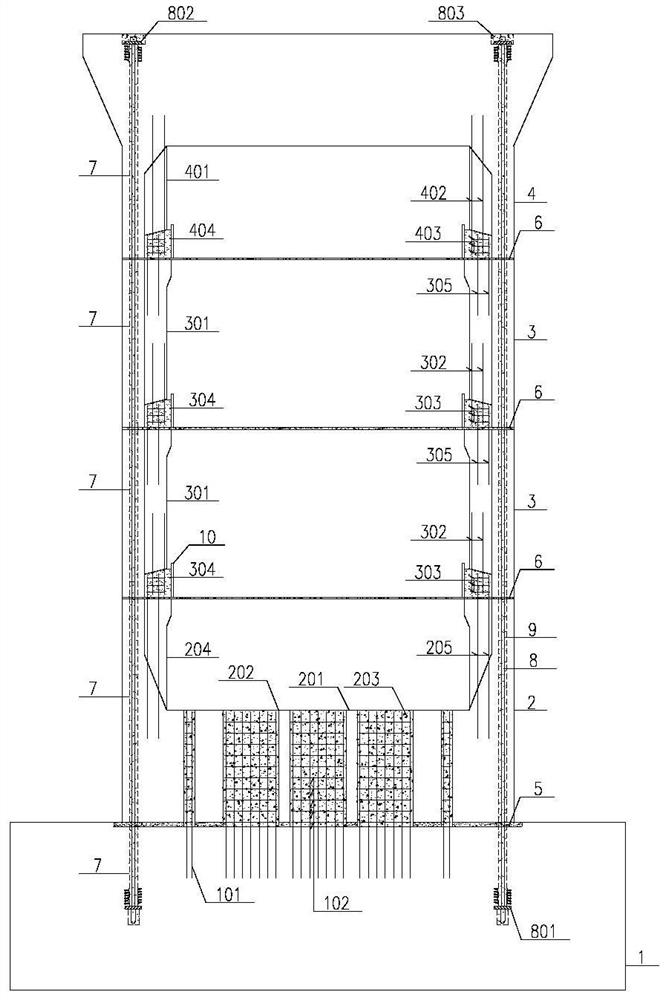

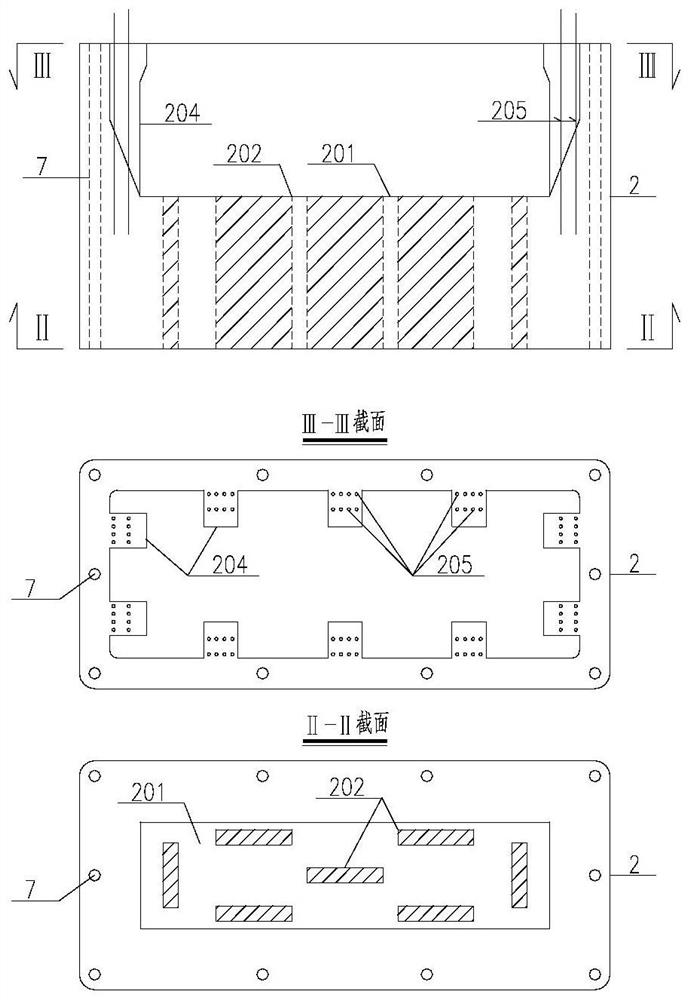

Prefabricated assembled hollow pier with transverse partition plates and construction method

PendingCN111827092ASuitable for erosive environmentFlexible layoutBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

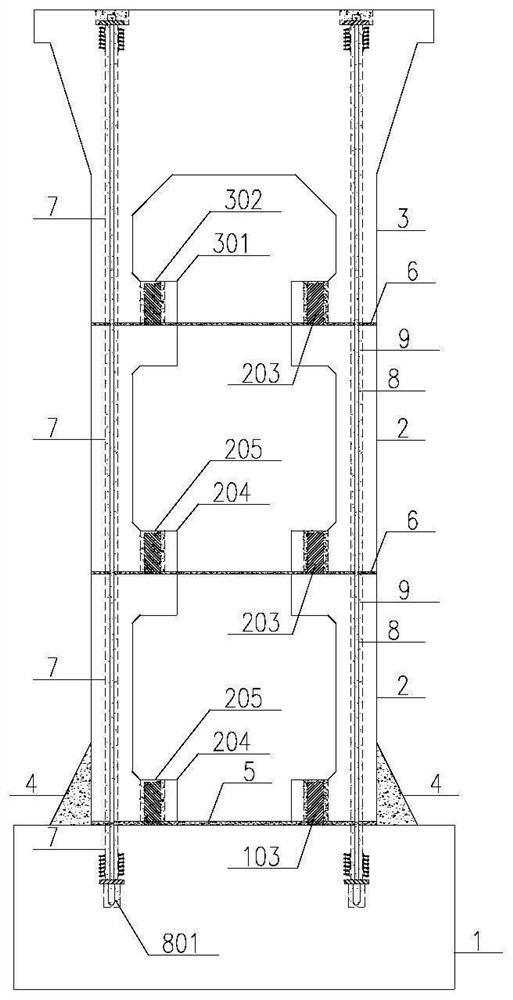

The invention provides a prefabricated assembled hollow pier with transverse partition plates and a construction method, and relates to the technical field of bridge construction. The hollow pier sequentially comprises a foundation, a general section and a top cap section from bottom to top, and foundation connecting steel bars and foundation connecting columns are arranged at the top of the foundation; general section transverse partition plates are arranged at the top and the bottom of the general section, a general section reserved groove is arranged in the general section transverse partition plate located at the bottom, and a general section connecting steel bar is arranged on the general section transverse partition plate located at the top; a top cap section transverse partition plate is arranged at the bottom of the top cap section, and a top cap section reserved groove is formed in the top cap section transverse partition plate at the bottom; during splicing, the connecting steel bars and the connecting columns located on a lower portion extend into the corresponding reserved grooves located on the upper portion, and a high-strength slurry is poured into the reserved grooves; and prestressed pipelines are pre-buried in the foundation, the general section and the top cap section, and connection is performed by penetrating through full-length prestressed tendons. By theadoption of the scheme, a prestress on a pier wall can be flexibly arranged, and manufacturing is easy and convenient.

Owner:CHINA RAILWAYS CORPORATION +1

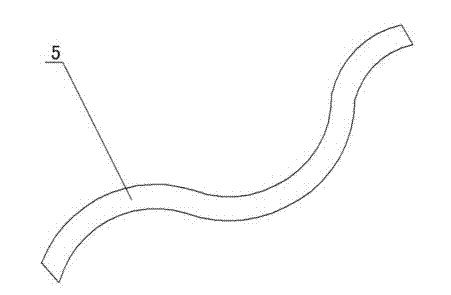

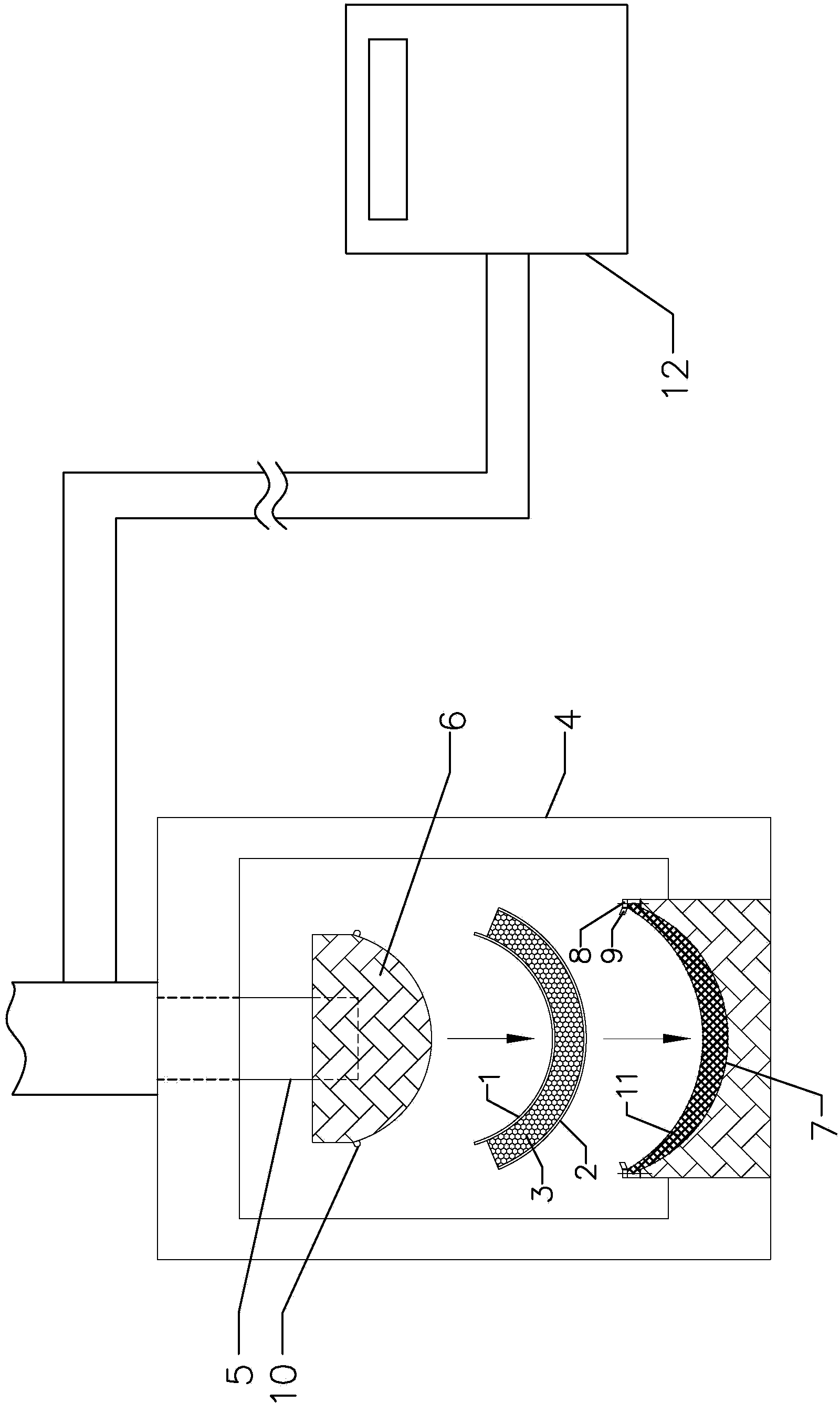

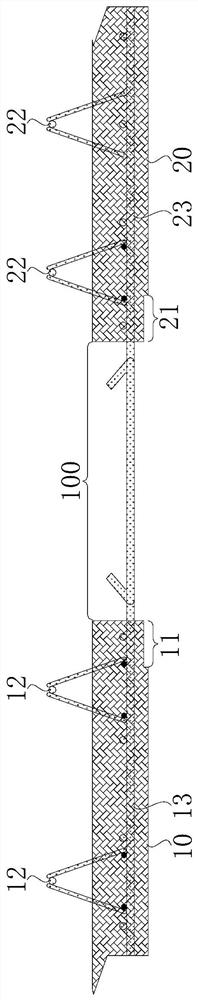

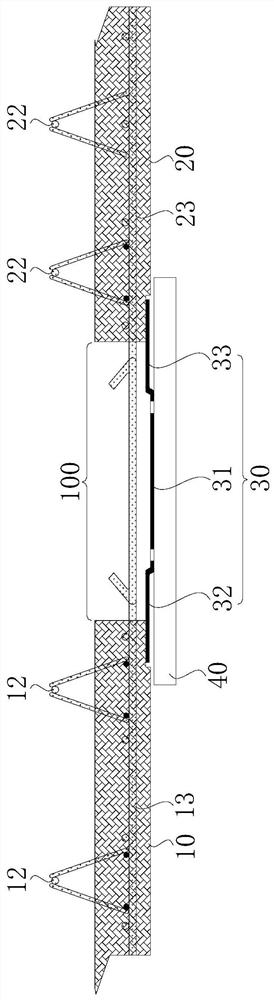

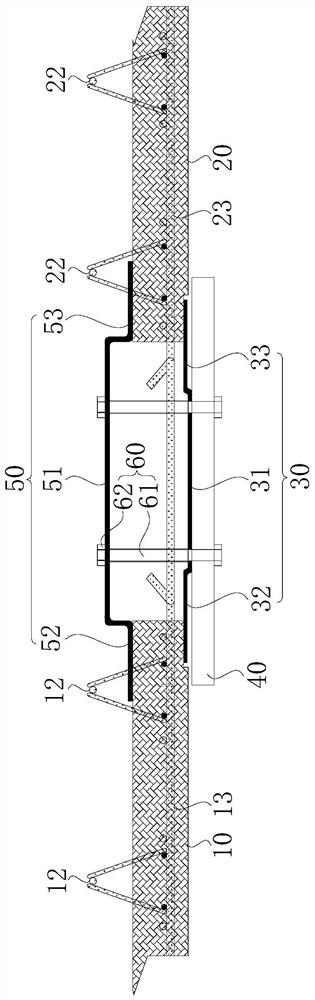

Processing apparatus and processing technology for arc-structured thermal-insulation board

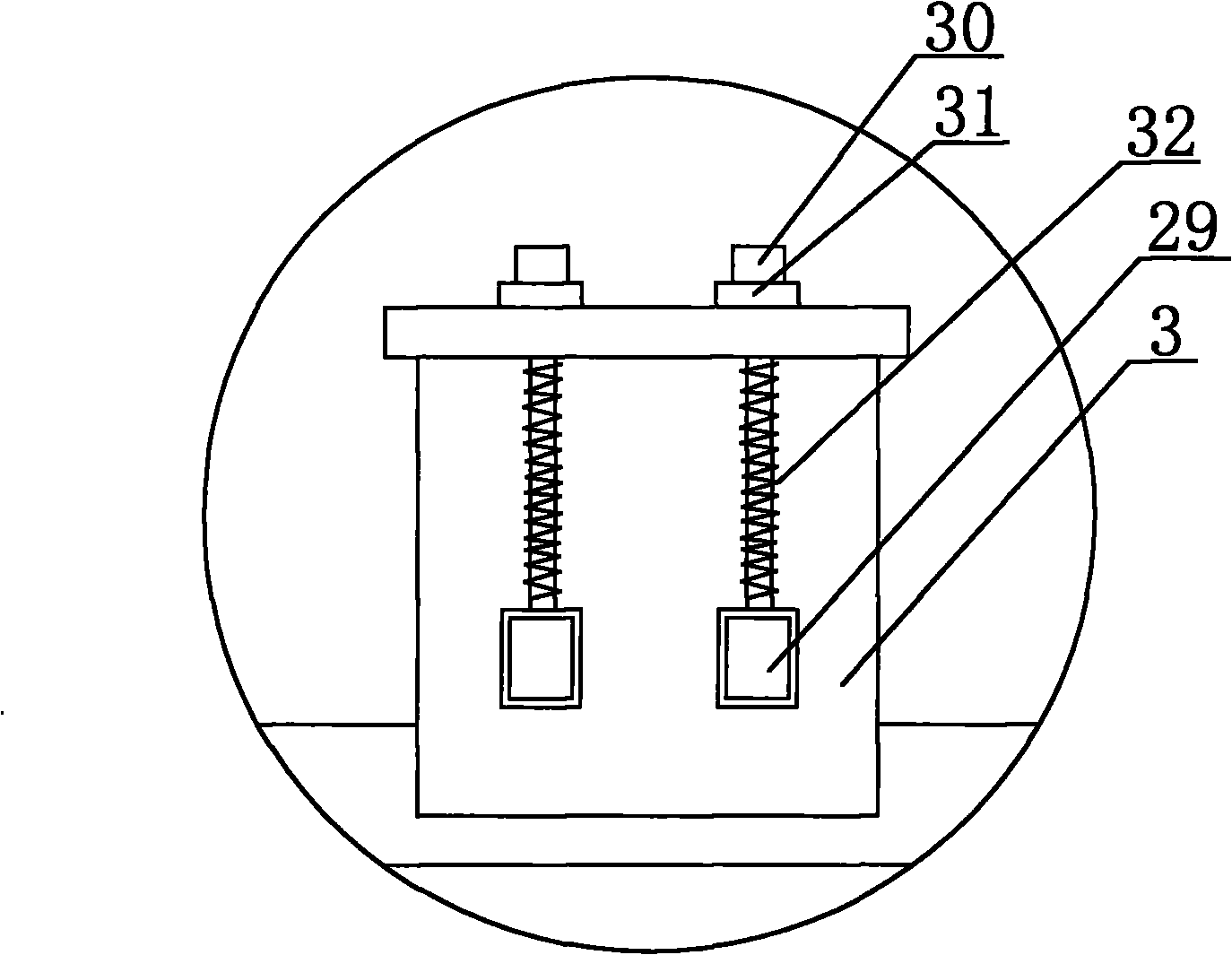

ActiveCN103640313AReduce the number of seamsImprove insulation effectLamination ancillary operationsLaminationHydraulic cylinderSurface layer

The invention discloses a processing apparatus for an arc-structured thermal-insulation board. The processing apparatus comprises a downwardly pressing mechanism and a supporting seat. The arc-structured thermal-insulation board processed by the processing apparatus is of a multilayer composite structure and comprises an upper surface layer, a lower surface layer and an intermediate thermal-insulation core layer sandwiched between the upper surface layer and the lower surface layer. The downwardly pressing mechanism comprises a support frame, a downwardly pressing straight rod and a downwardly pressing head, wherein the downwardly pressing straight rod is a telescoping rod of a pneumatic cylinder or hydraulic cylinder, a pneumatic cylinder or hydraulic cylinder body is fixed at the upper end of the support frame, the downwardly pressing straight rod vertically extends into the upper end surface of the support frame, the downwardly pressing head is fixed at the lower end surface of the downwardly pressing straight rod, and the lower end surface of the downwardly pressing head is a cambered surface which is a semi-arc surface preferably. The supporting seat is located under the downwardly pressing head, the upper end surface of the supporting seat is an arc-shaped groove, and the arc-shaped edges of the arc-shaped groove of the supporting seat can be detached and fixed. With such a technical scheme, the downwardly pressing straight rod drives the downwardly pressing head to directly cooperate with the arc-shaped groove at the surface of the supporting seat so as to form the arc-structured thermal-insulation board through compression and molding.

Owner:DALIAN QUACENT NEW BUILDING MATERIALS

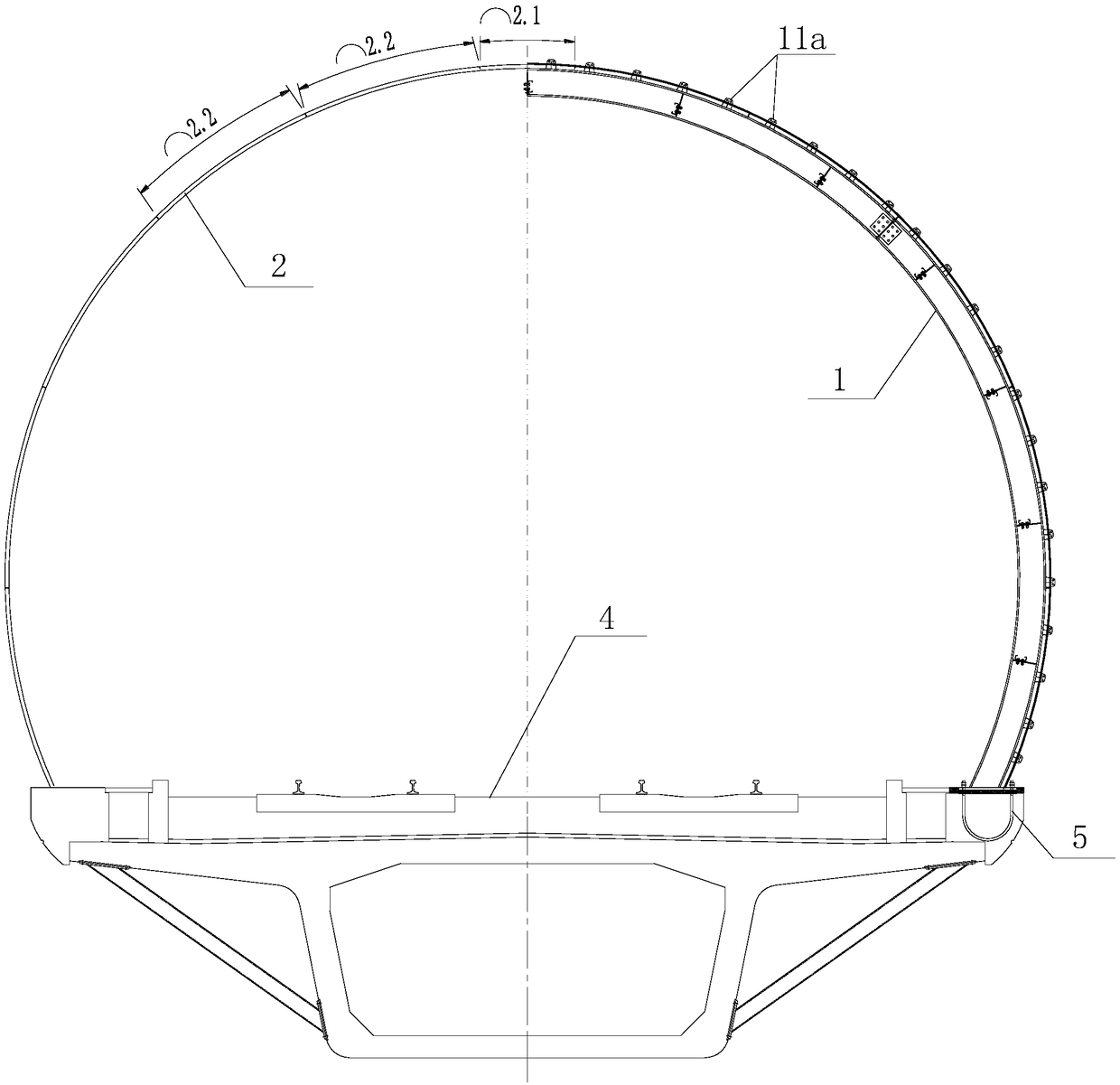

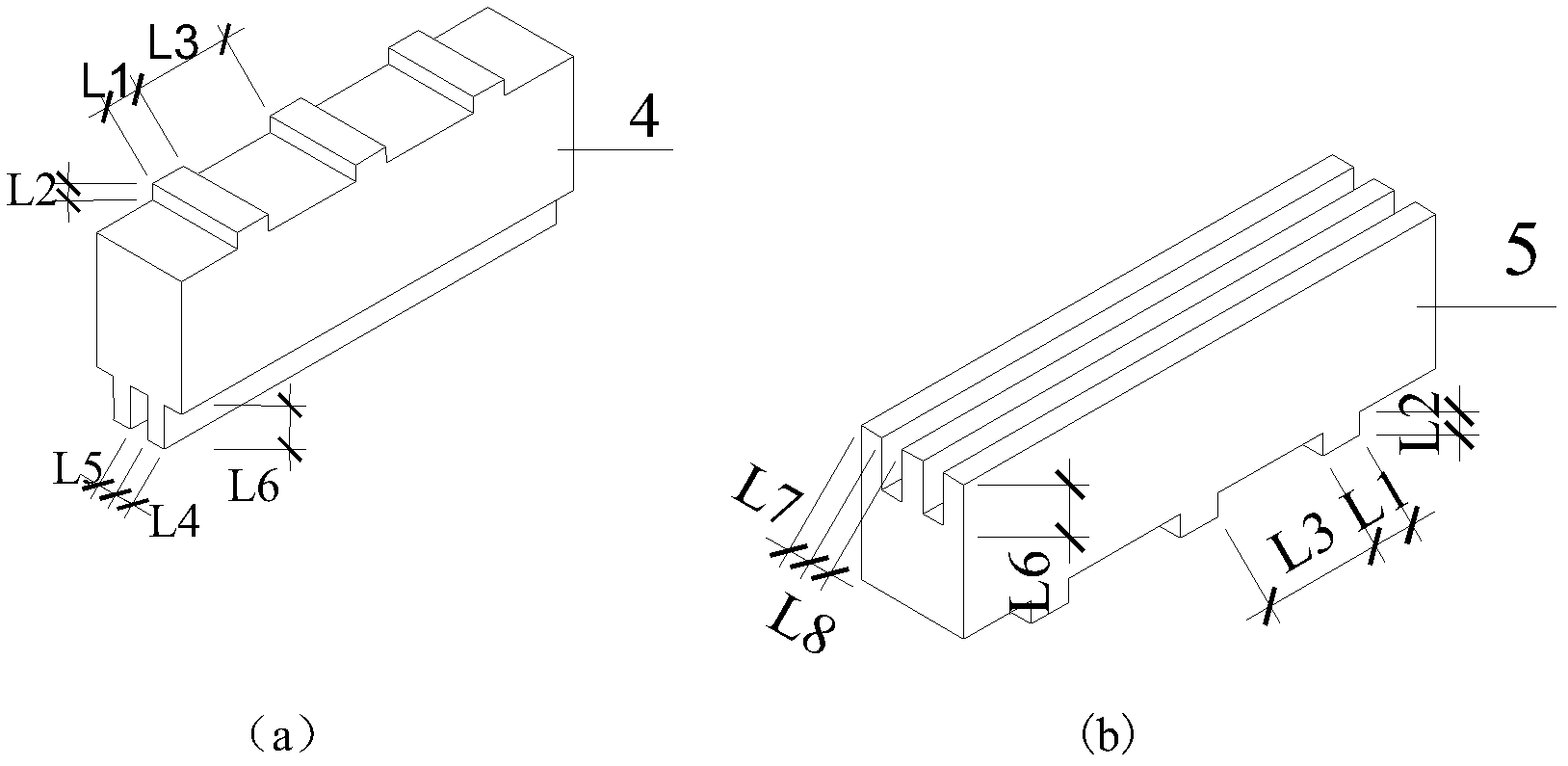

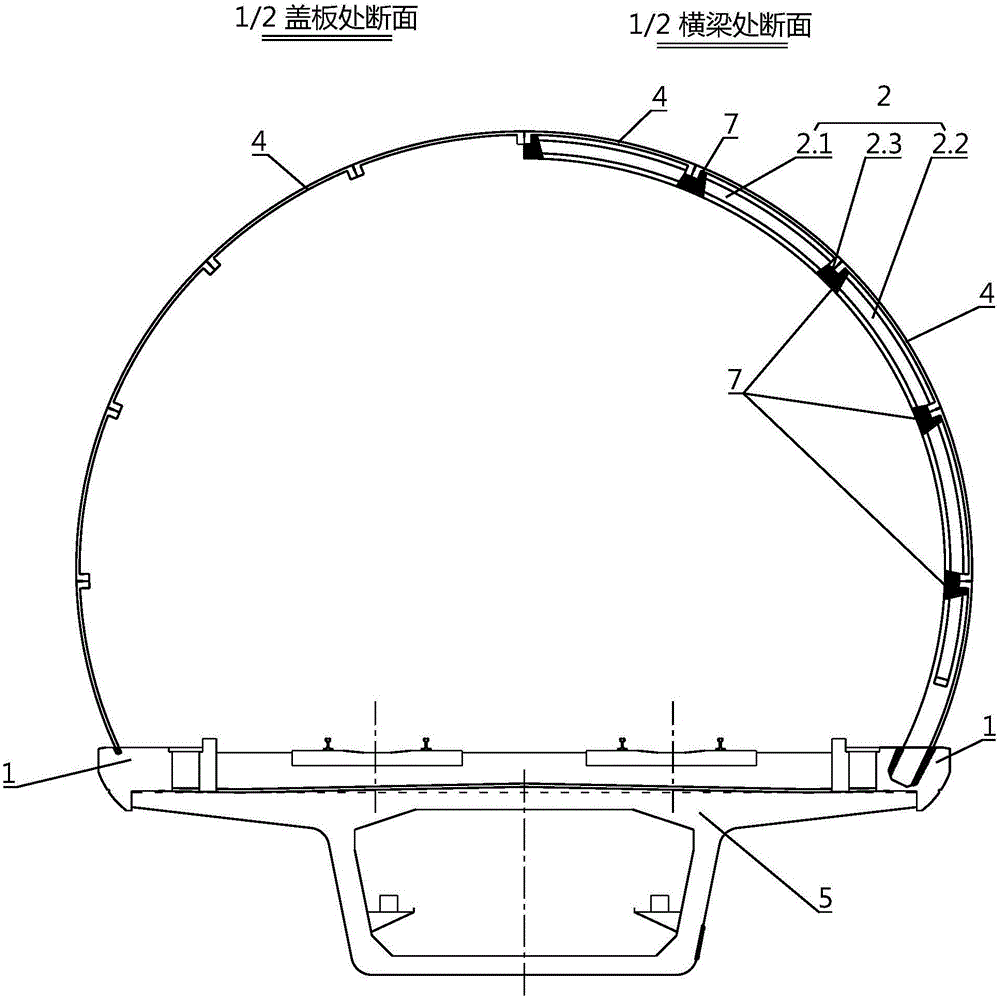

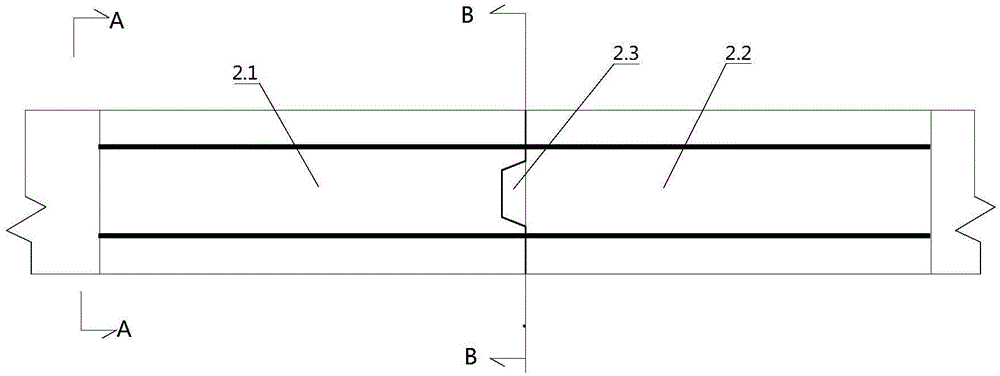

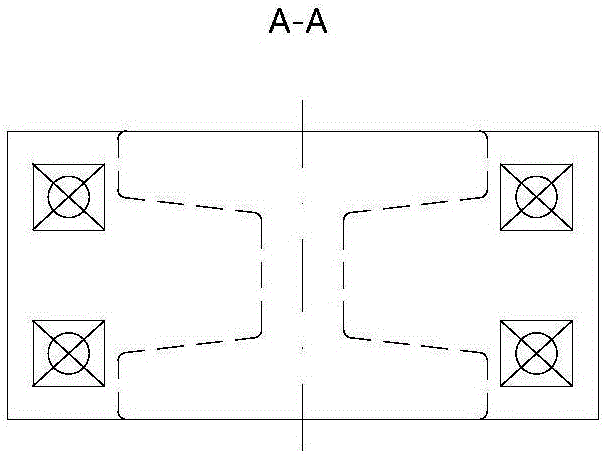

Steel framework and modified ECC concrete slab composite fully-enclosed sound barrier

PendingCN109295870AAvoid deformationReduce in quantityClimate change adaptationNoise reduction constructionEngineeringRadian

The invention discloses a steel framework and modified ECC concrete slab composite fully-enclosed sound barrier. The steel framework and modified ECC concrete slab composite fully-enclosed sound barrier is characterized by comprising annular cross beams stretching across a railway line and arranged in the longitudinal direction of the railway line in a spaced manner; longitudinal beams are arranged between the two adjacent cross beams; cover plates matched with the external surfaces of the cross beams in radian are arranged between the external surfaces of the two adjacent cross beams; the widths of the cover plates in the transverse direction of the railway line are 1-3 m; the thicknesses of the cover plates in the transverse direction of the railway line are 3-8 cm; and the cover platesare preformed by using a high tenacity fibre reinforced cement composite. The steel framework and modified ECC concrete slab composite fully-enclosed sound barrier has the characteristics of good sound insulation effect, good durability, good fire resistance, good aerodynamic performance and good economic efficiency.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

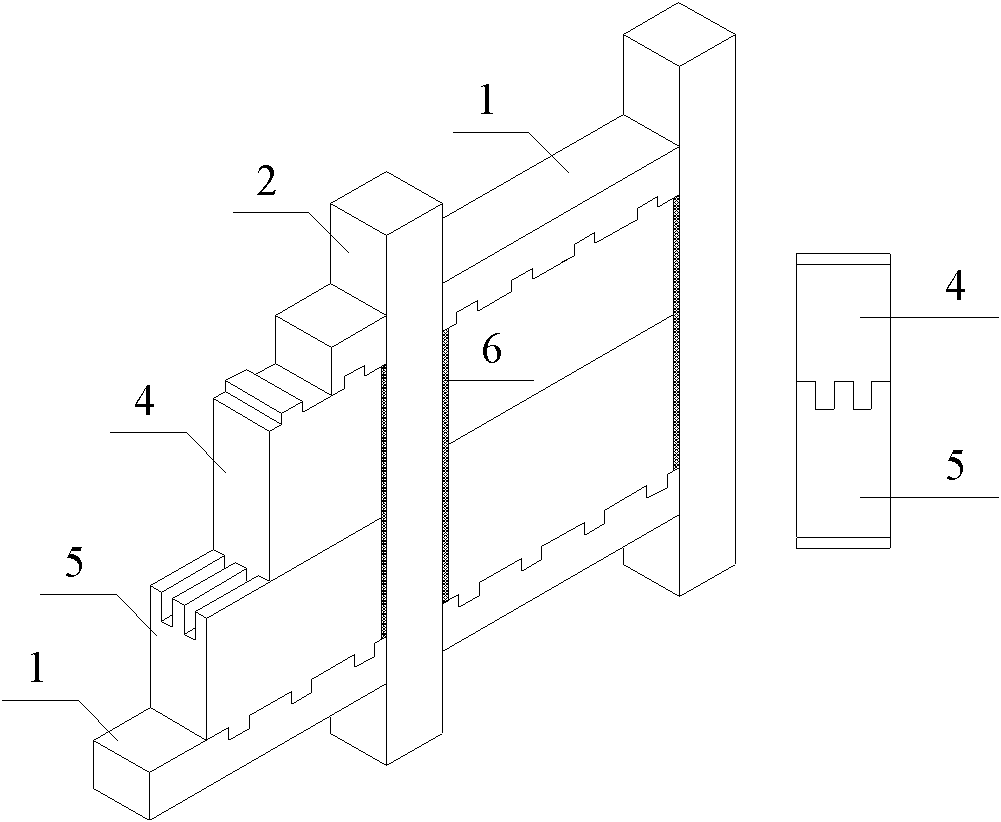

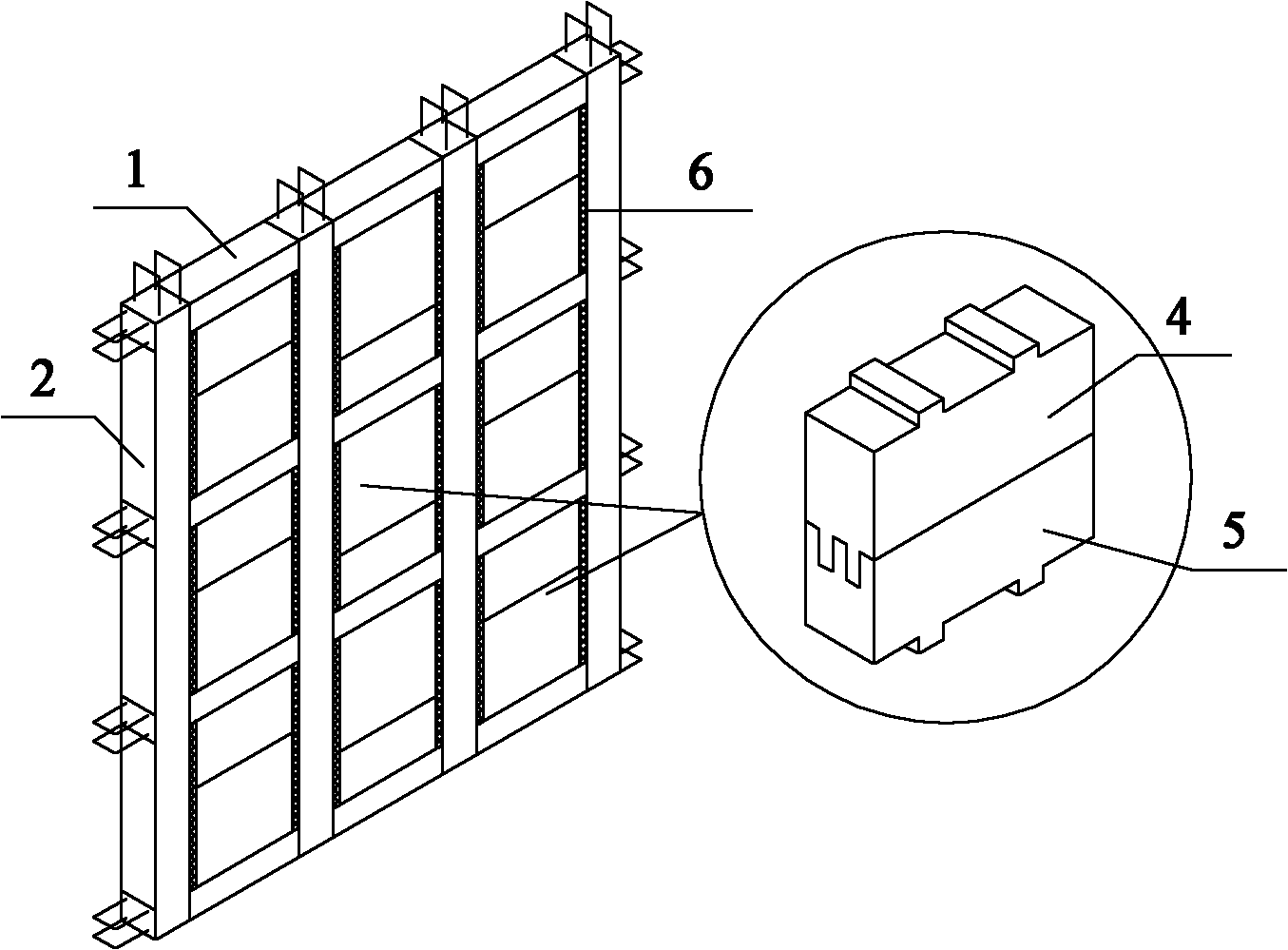

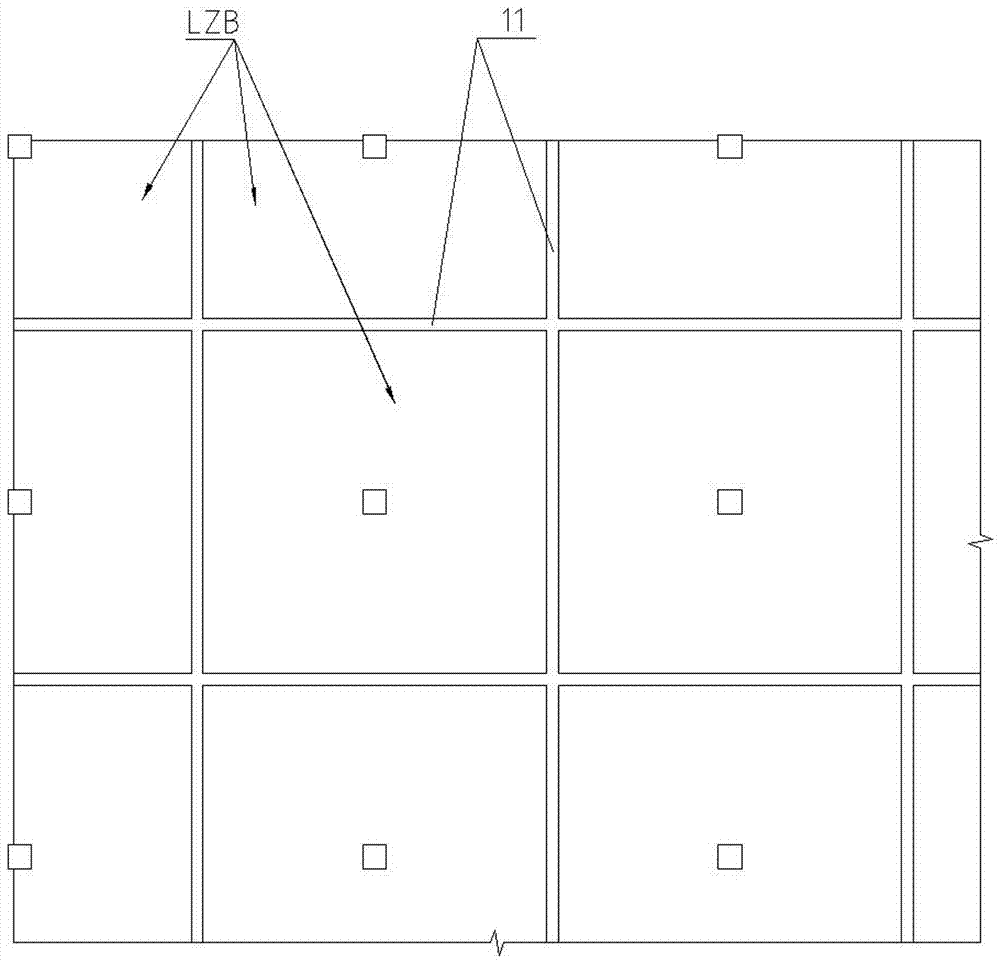

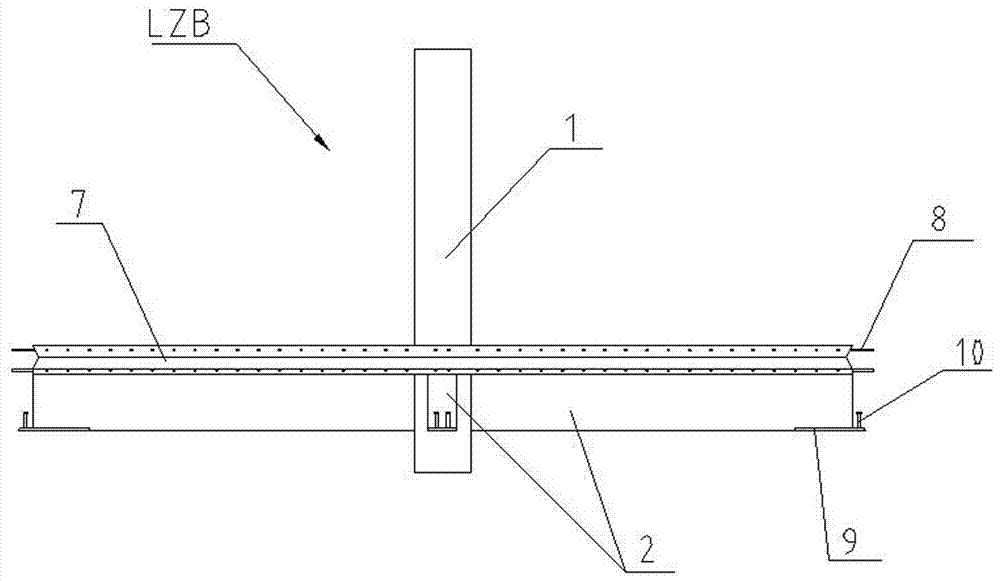

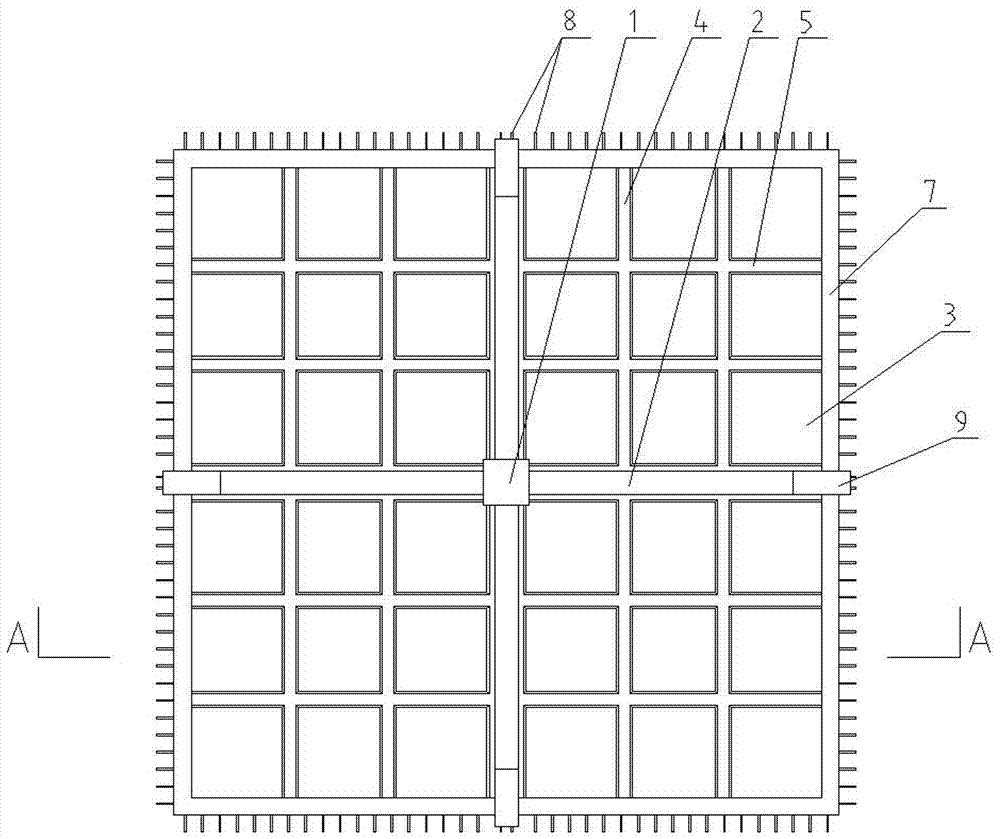

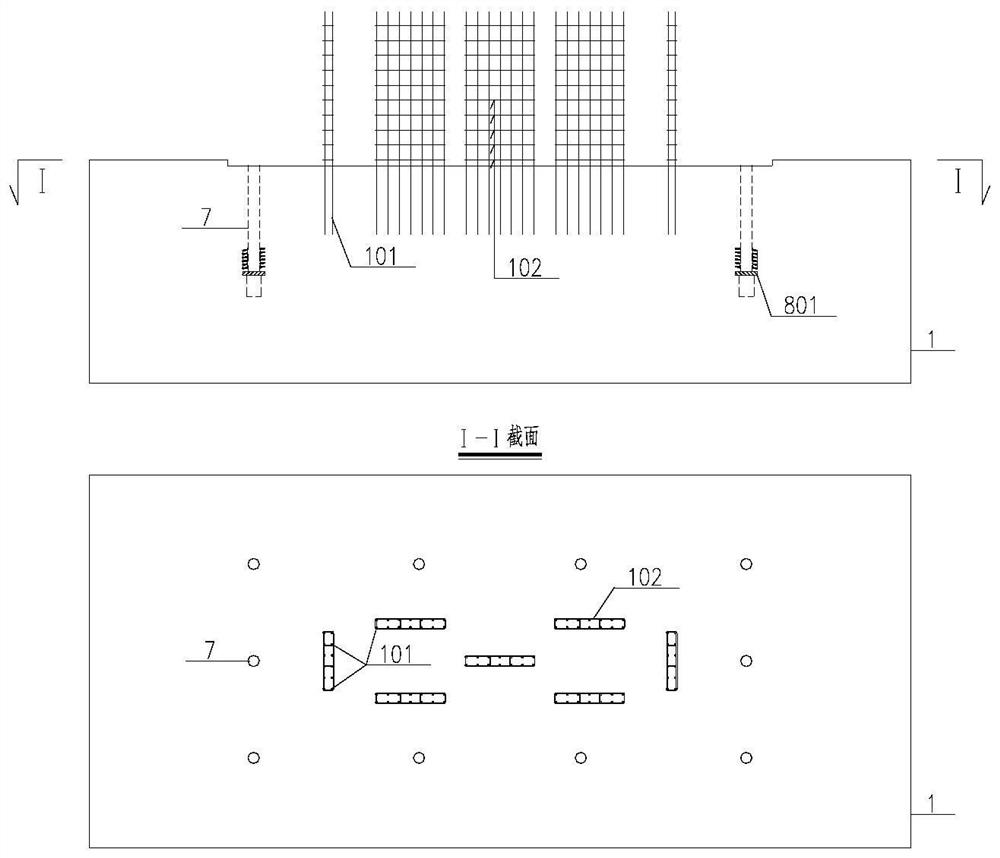

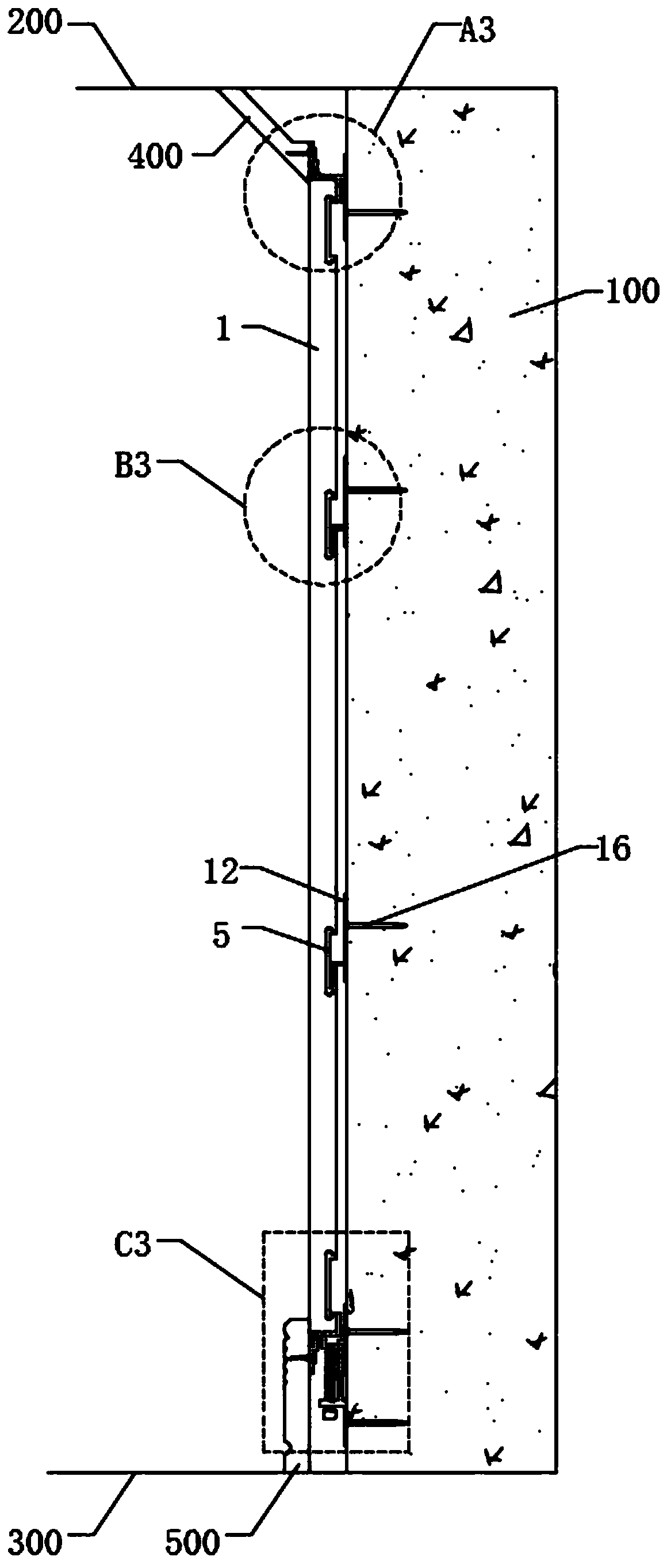

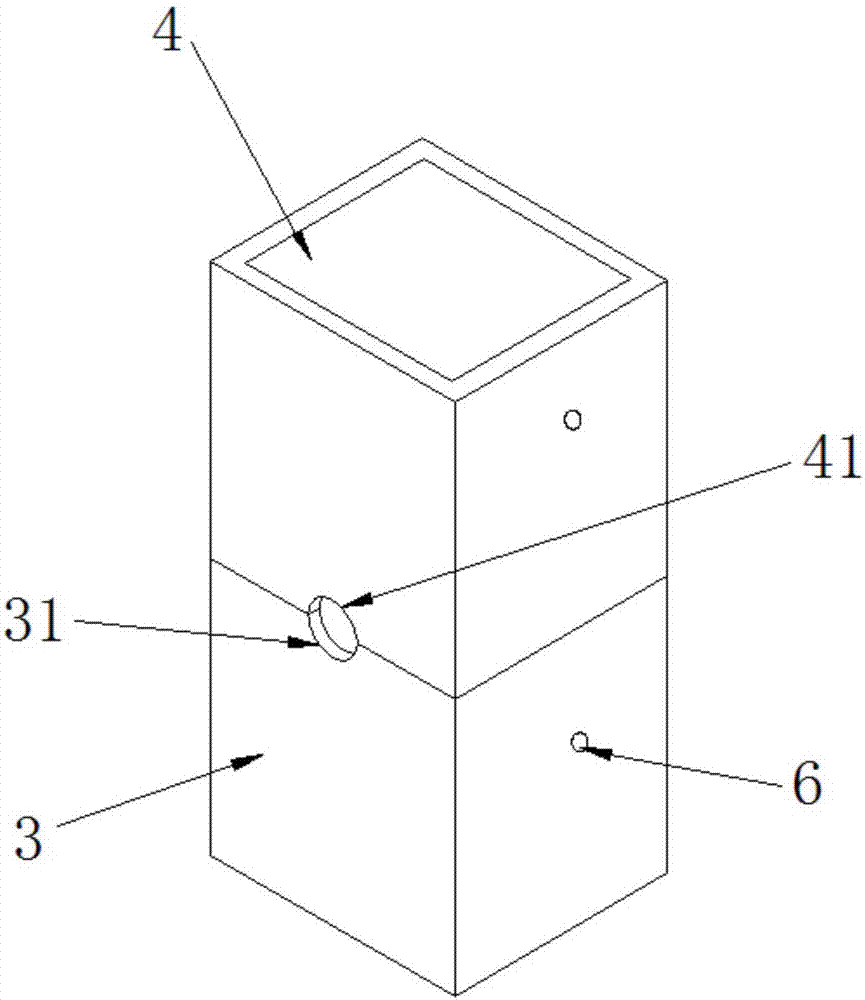

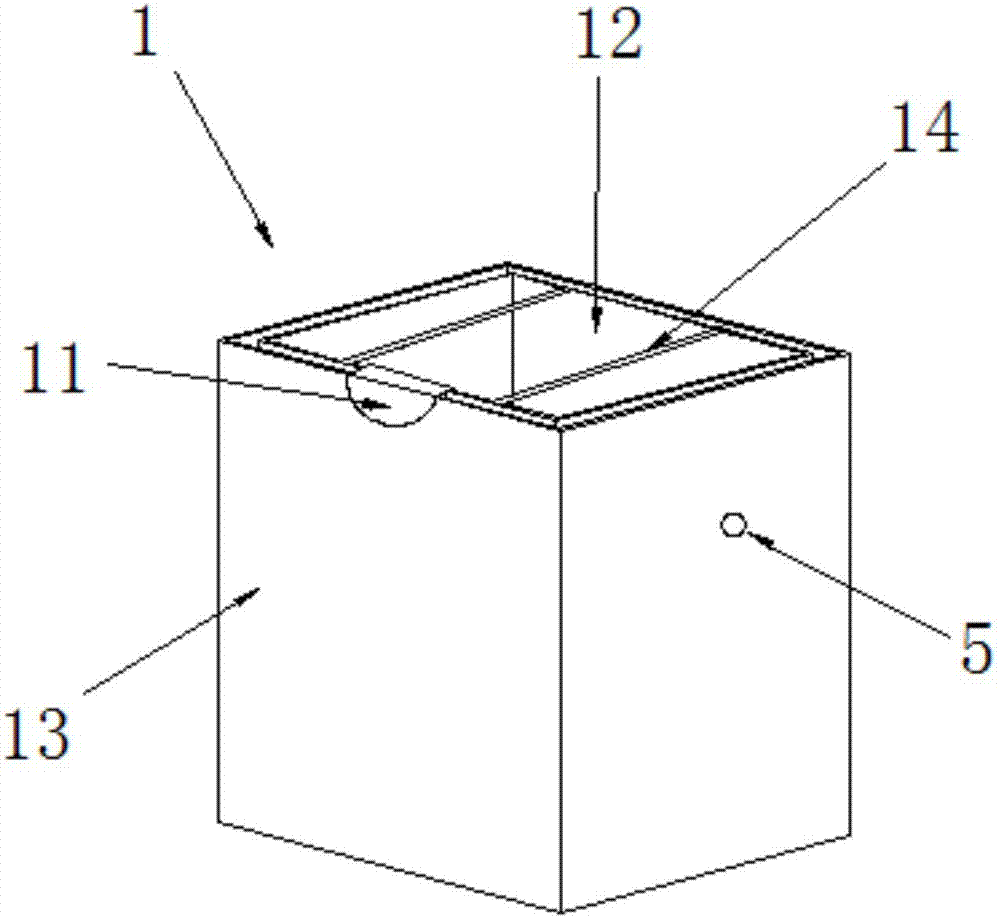

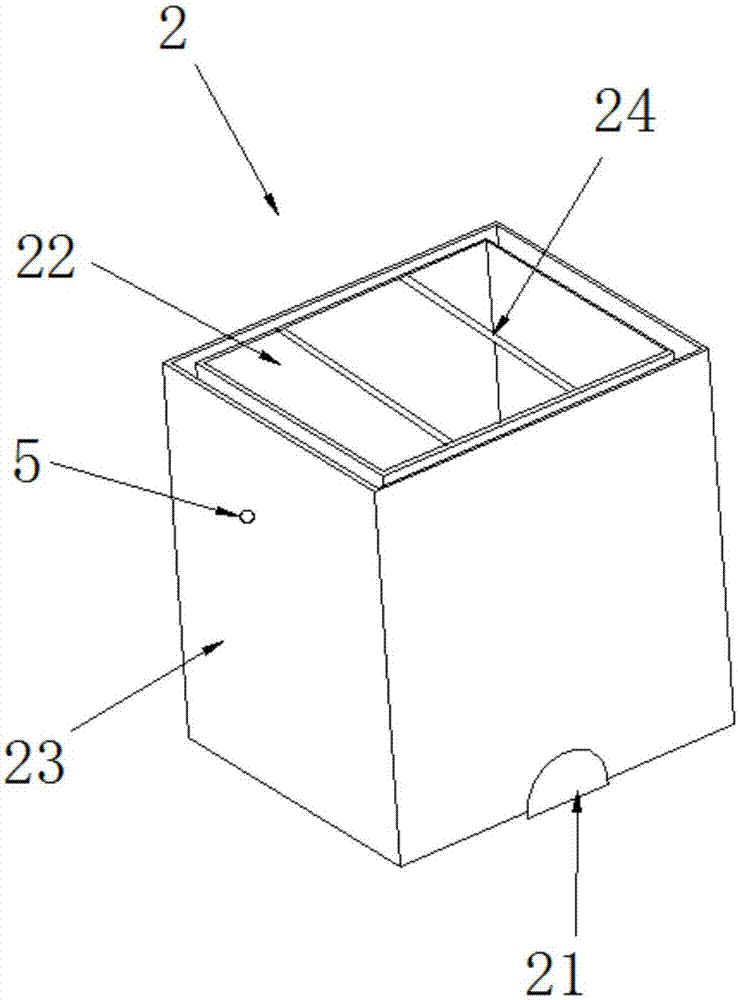

Multi-ribbed composite wallboard internally provided with special-shaped filling building blocks

InactiveCN102155060AImproved frictional energy dissipationIncrease the areaWallsShock proofingFilling materialsArchitectural engineering

The invention provides a multi-ribbed composite wallboard internally provided with special-shaped filling building blocks; the multi-ribbed composite wallboard comprises rib beams (1), rib columns (2), the special-shaped filling building blocks (3) and a flexible filling material (6), wherein the rib beams (1) and the rib columns (2) form sashes; each sash is provided with a special-shaped filling building block (3) which comprises an upper special-shaped filling building block (4) and a lower special-shaped filling building block (5); the upper special-shaped filling building block (4) and the lower special-shaped filling building block (5) are meshed at a contact surface of the upper special-shaped filling building block (4) and a lower special-shaped filling building block (5); the upper special-shaped filling building block (4) and a lower special-shaped filling building block (5) horizontally and relatively slide under the action of external force; and the flexible filling material (6) is filled in gaps among the special-shaped filling building blocks (3) and the rib columns (2). The multi-ribbed composite wallboard not only can increase the frictional energy consumption effect of multi-ribbed composite walls and reduce the seismic response of the multi-ribbed structure, but also can avoid the condition that excessive building blocks are filled in the sashes, avoid the occurrence of external plane dropping of the sashes and ensures the whole service behavior of the building blocks in the sashes.

Owner:BEIJING JIAOTONG UNIV

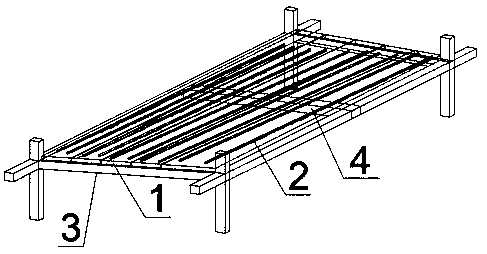

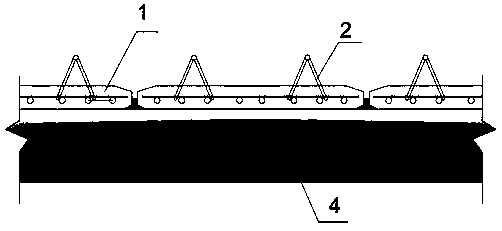

Novel energy-saving bamboo bridge

InactiveCN103498412AHigh tensile strengthNo possibility of crackingLighting elementsReed/straw treatmentLight equipmentEngineering

The invention provides a novel energy-saving bamboo bridge. The novel energy-saving bamboo bridge comprises longitudinal bamboo beams (1), transverse bamboo beams (2), bamboo panels (3), transverse pre-stressed trusses (4) and longitudinal pre-stressed trusses (16). A layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resorcinol formaldehyde coat the outer surfaces of all the bamboo materials of the bamboo bridge in sequence. The bamboo bridge further comprises lighting devices and a brightness sensor, and the lighting devices are controlled to be started through the numerical value measured by the brightness sensor. The novel bamboo bridge can start the lighting device according to the brightness and save energy sources.

Owner:ZHONGBEI UNIV

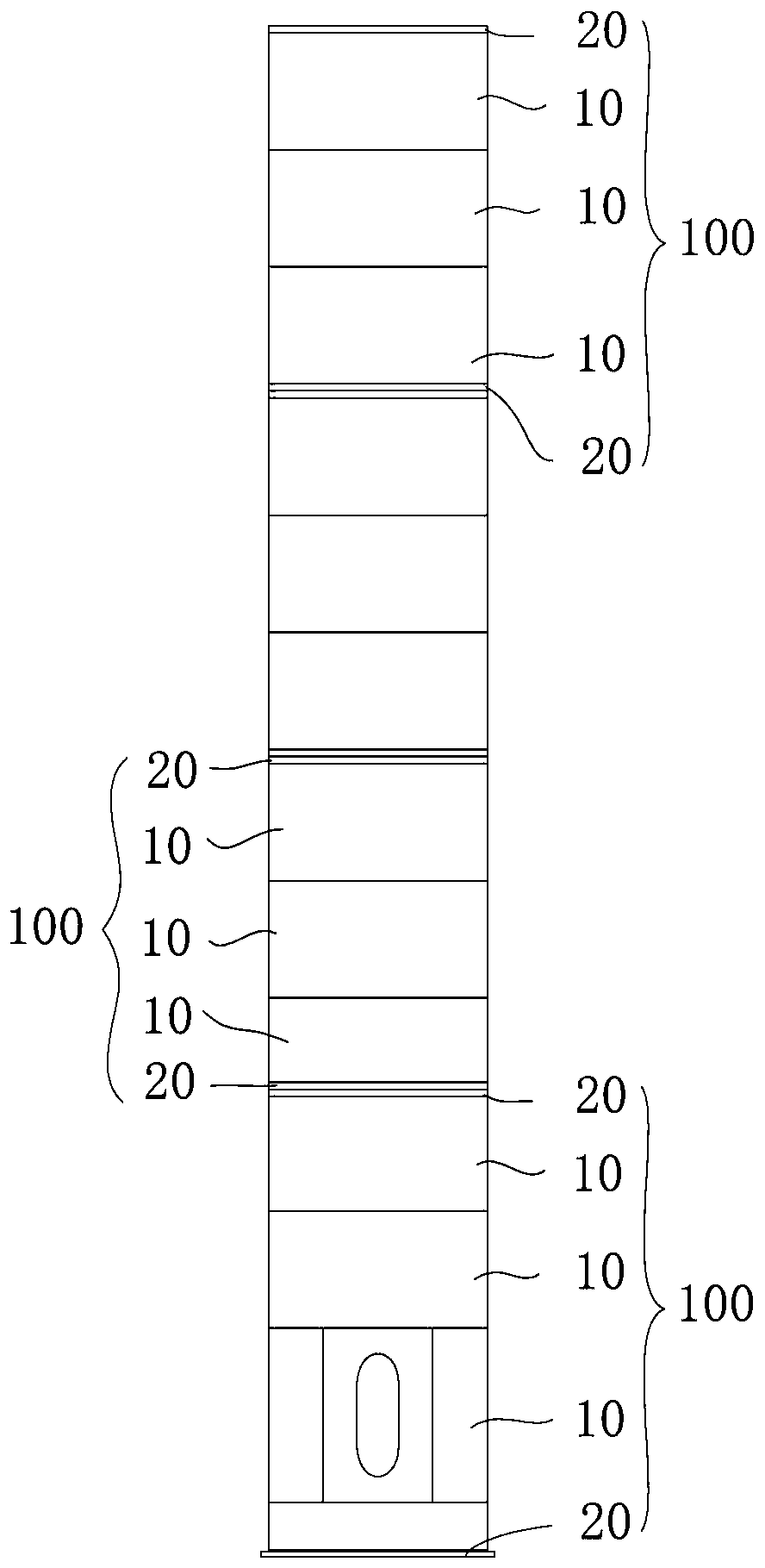

Super-high performance concrete frame structure fabricated building and construction method thereof

The invention discloses a super-high performance concrete frame structure fabricated building and a construction method thereof. A splicing unit at least comprises beam, column and floor integrated pieces prefabricated by super-high performance concrete. The height of each column is the height of a building storey; the beams are perpendicular to the side walls of the columns; the floors are located on the upper surfaces of the beams; connecting parts are arranged on the side edges of the floors; and the two ends of the columns stretch out of the end faces of the floors and the beams. When fabricating is constructed, after the prefabricated integrated pieces adjacent to the building plane, the super-high performance concrete is poured into joints between the connecting parts of the side edges of the floors to enable the prefabricated integrated pieces to form a whole. The upper storey and the lower storey of the building are connected through the columns of the beam, column and floor integrated pieces. The prefabricated integrated pieces adopt the super-high performance concrete as structure materials, and the reasonable connecting arrangement is configured, so that the average thickness of the floor and the amount of connectors and the joints between prefabricated members both are decreased substantially. The self-weight of the building is reduced substantially under the premise of guaranteeing the rigidity and strength of the building, and construction difficulty is reduced.

Owner:HUNAN UNIV

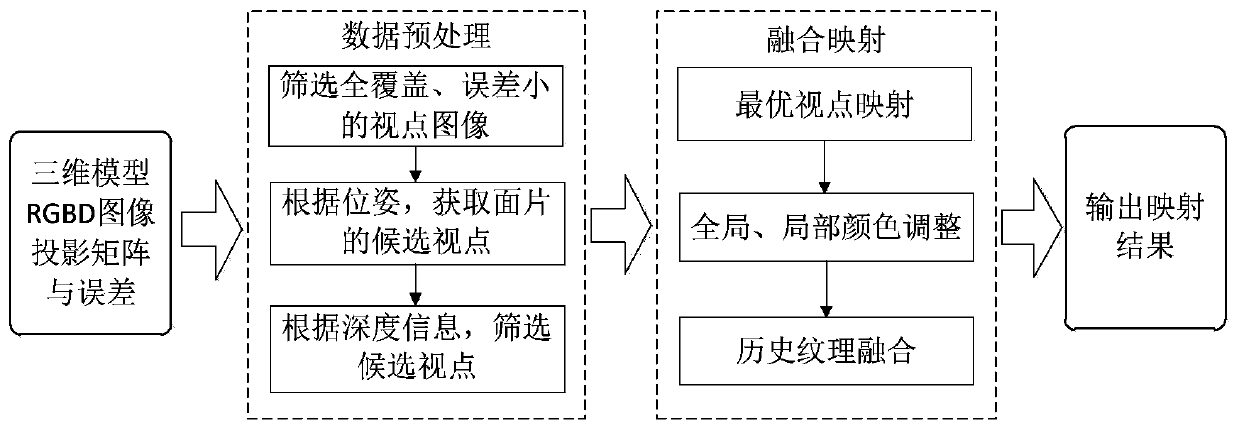

Seamless texture mapping method of three-dimensional model

PendingCN111369660ASuppress texture distortionImprove accuracy and consistency3D-image renderingThree dimensional modelColor difference

The invention discloses a seamless texture mapping method for a three-dimensional model. The method comprises the following steps: inputting a known three-dimensional model, an RGBD image, a projection matrix and a projection matrix error; screening out an RGB image which completely covers the three-dimensional model and has the minimum pose estimation error sum; calculating a pose relationship between each surface patch in the three-dimensional model and the screened RGB image, and determining a candidate viewpoint corresponding to each surface patch; eliminating the candidate viewpoints withwrong textures in all the candidate viewpoints; selecting an optimal viewpoint from the remaining candidate viewpoints after elimination to perform texture mapping; adjusting the color and brightnessof the three-dimensional model after texture mapping; and if occlusion exists in the optimal viewpoint, mapping historical textures to an occlusion area of the three-dimensional model after joint fusion processing to obtain a complete texture mapping three-dimensional model. According to the method, the brightness color difference of adjacent textures is effectively reduced, texture distortion caused by joint fusion is inhibited, and the accuracy and consistency of the overall texture of the three-dimensional model are improved.

Owner:HANGZHOU EBOYLAMP ELECTRONICS CO LTD

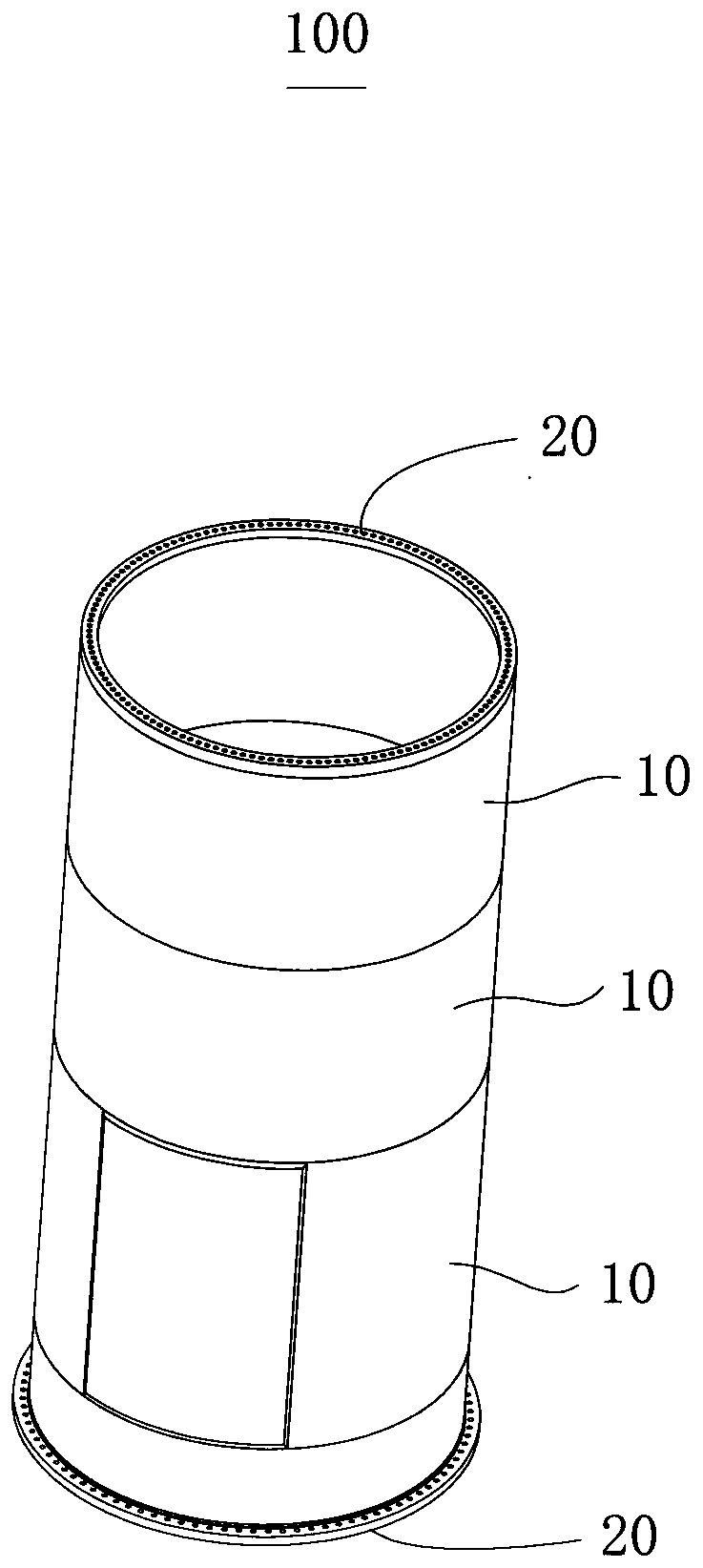

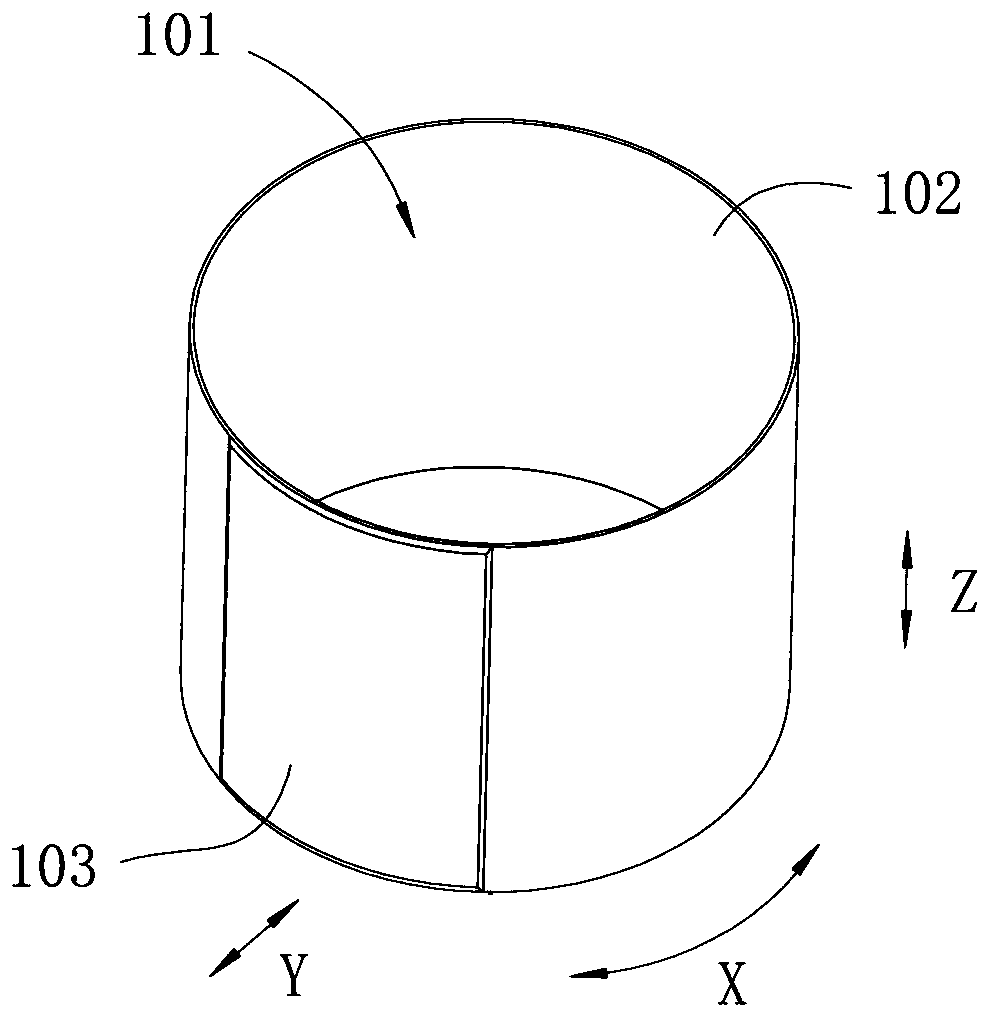

Barrel shell, tower barrel section and forming method of barrel shell

PendingCN109854458AReduce the number of seamsExtended service lifeWelding/cutting auxillary devicesWind motor supports/mountsWind drivenBarrel Shaped

The invention relates to a barrel shell, a tower barrel section and a forming method of the barrel shell. The barrel shell is used in the tower barrel section and is of a barrel-shaped structure whichis provided with a hollow chamber; the barrel shell comprises a foundation part and a reinforcing part which are circumferentially continuously distributed; the foundation part and the reinforcing part are integrally structured; and the thickness of the reinforcing part is beyond the thickness of the foundation part in the radial direction of the barrel shell. According to the barrel shell, the tower barrel section and the forming method of the barrel shell in the embodiment, tower barrel accessories can be easily arranged through the barrel shell, and moreover, the bearing capacity of the tower barrel section adopting the barrel shell is high, so that the service life of the whole tower barrel is prolonged, and the use safety of the whole tower barrel is improved; and the generation benefit of a wind-driven generation set is increased.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Prestressed composite floor slab construction method without support

InactiveCN110005110AQuality assuranceStable structureConstruction materialFloorsSupporting systemFloor slab

The invention discloses a prestressed composite floor slab construction method without support. A large-span prestressed composite floor slab is invented by researching the large-span floor compositeslab, the large-span prestressed composite floor slab forms a composite structure with one or more beams in the construction process, the complicated processes of assembly, formwork support, bottom support arrangement, joint treatment and the like of a traditional floor panel are solved, no formwork support system is needed in construction, construction period is effectively shortened, and the construction cost is saved.

Owner:智聚装配式绿色建筑创新中心南通有限公司

Integral quenching method of overlong and superhard high-wear-resistant alloy tool steel guide rail

ActiveCN103695607AImprove rigidityReduce the number of seamsFurnace typesHeat treatment furnacesFurnace temperatureTemperature control

The invention discloses an integral quenching method of an overlong and superhard high-wear-resistant alloy tool steel guide rail. The integral quenching method comprises the following steps: (1) processing alloy tool steel before quenching; (2) quenching, wherein the preheating temperature is kept at 800-850 DEG C, the heating temperature is kept at 950-1200 DEG C, the heat is preserved for 15-50min, air with room temperature is used as the quenching medium, and the quenching temperature is controlled within + / -1 DEG C; (3) straightening: taking out a workpiece to carry out straightening operation when the workpiece is integrally quenched and cooled to 220+ / -5 DEG C before martensite transformation, and controlling the length at + / -0.20 / 1000mm; (4) tempering, wherein the furnace temperature is controlled at 500-580 DEG C; (5) roughly and finely grinding the shape of the workpiece and deburring; (6) straightening, wherein the length is controlled at + / -0.20 / 1000mm; and (7) secondarily tempering, wherein the furnace temperature is controlled at 500-580 DEG C. The guide rail produced by using the process disclosed by the invention overcomes defects of easiness to wear, multiple seams and low precision of a guide rail manufactured by using the traditional process.

Owner:SHANGHAI CONSTJET MACHINERY TOOLS

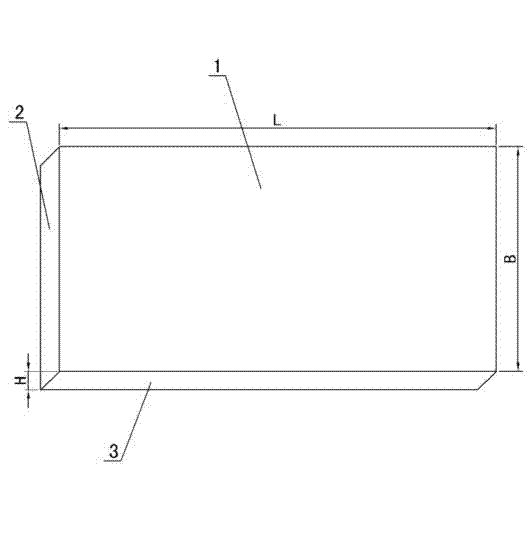

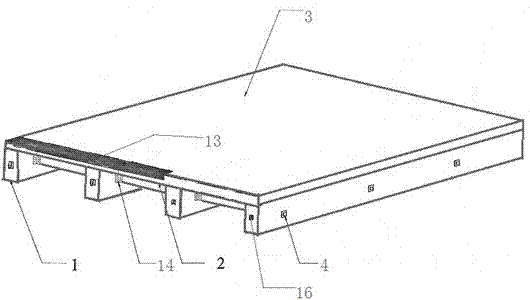

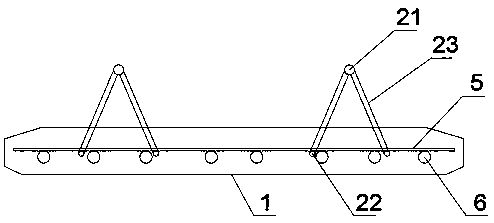

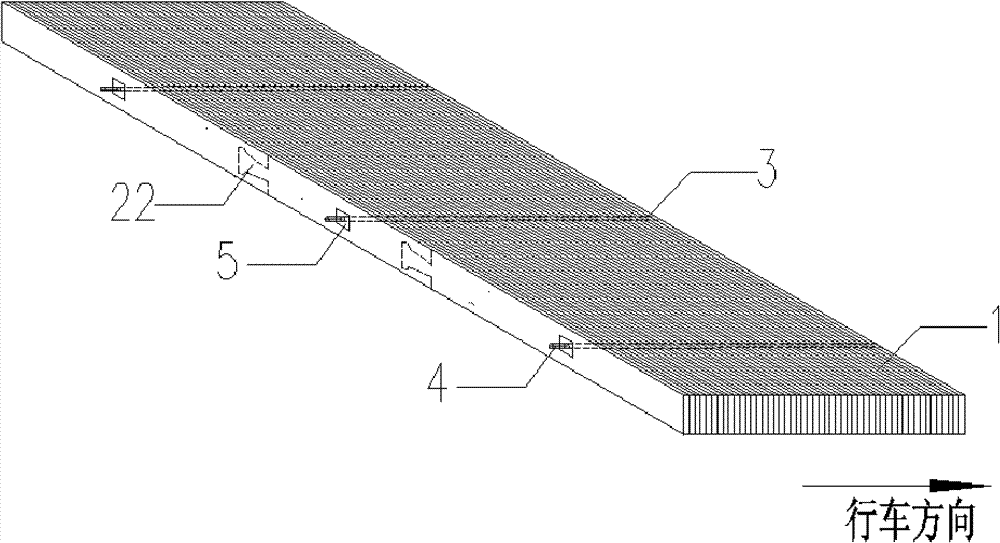

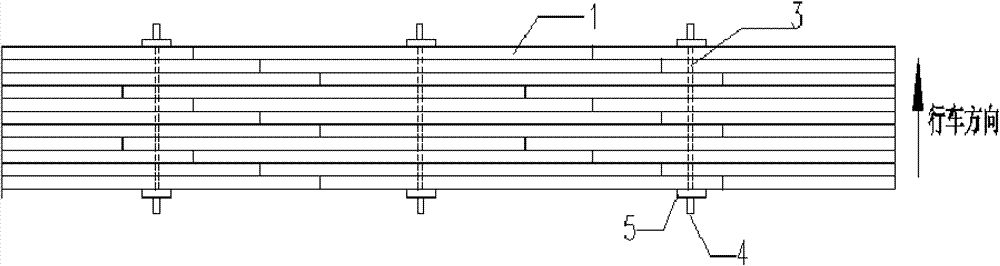

Assembly type bamboo bridge

ActiveCN103437271AHigh tensile strengthNo possibility of crackingSynthetic resin layered productsBridge structural detailsPolymer sciencePolymer chemistry

The invention provides an assembly type bamboo bridge. The assembly type bamboo bridge consists of bamboo longitudinal beams (1), bamboo transverse beams (2), bamboo panels (3), a transverse pre-stressing tendon (4) and a longitudinal pre-stressing tendon (16). All bamboos used by the assembly type bamboo bridge are soaked in a gum dipping tank which contains polyurethane resin and phenolic resin before being assembled, and boiled for 10-15 minutes at 100 DEG C-110 DEG C, wherein the volume ratio of the polyurethane resin to the phenolic resin is (2-2.5):1; and then, the bamboos are got out and dried, and a layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resurcinolformaldehyde resin are uniformly coated on the outer surfaces of all bamboos in sequence. The assembly type bamboo bridge is large in structural strength, good in drawability, green and environment-friendly in used materials, standard in structural components, high in assembly degree, good in structural integrity, and capable of sufficiently bringing the advantages of the materials into play, and satisfying the normal use and durability needs of the bridge beam structure.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Bidirectional laminated slab concrete structure and integral type joint seam construction method

PendingCN111608314AIncrease the passage spaceIncrease stiffnessFloorsBuilding reinforcementsFloor slabArchitectural engineering

The invention belongs to the technical field of concrete structures and particularly relates to a bidirectional laminated slab concrete structure and an integral type joint seam construction method.The bidirectional laminated slab concrete structure processed through the construction method comprises a first laminated slab prefabricated layer, a second laminated slab prefabricated layer, a laminated slab cast-in-situ layer and a flexible anti-crack structure. the bidirectional laminated slab concrete structure has the following advantages: 1, a support frame body of a bottom die plate at ajoint seam does not need to be set up during the construction process to improve the construction efficiency; 2, the construction space is saved, the worker passing space and the material transportation space are increased during the construction process, and the construction efficiency is indirectly improved; 3, a larger role is played in the hogging moment born by a resisting floorslab mainly;4, the proper amount of the integral type support frame body at the joint seam can be considered to meet the bearing capacity of the largest bending moment of the floorslab; and 5, the flexible anti-crack structure is adopted for filling treatment at the junction of the laminated slab prefabricated layers and the laminated slab cast-in-situ layer, so that the risk that the junction surface of newand used concrete generates a crack is reduced to improve the project quality.

Owner:中甄住工建设科技(湖北)有限公司

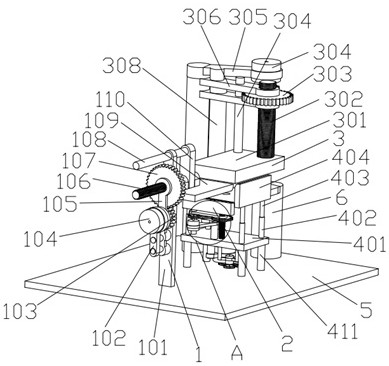

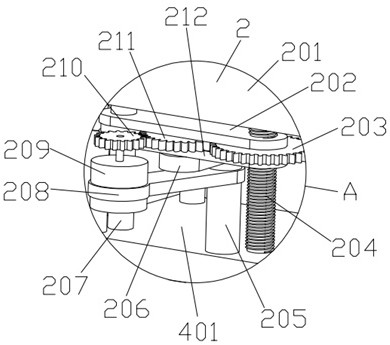

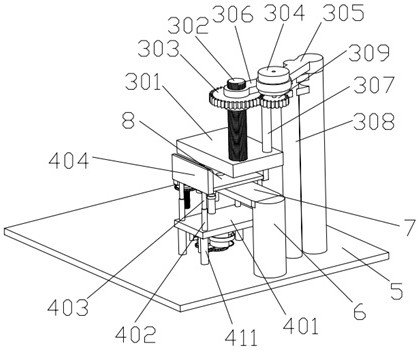

Packaging box forming equipment

InactiveCN111761872AGuarantee molding qualityGuaranteed molding accuracyEnvelopes/bags making machineryPaper-makingPaperboardStructural engineering

The invention discloses packaging box forming equipment. The packaging box forming equipment comprises a capping module, an auxiliary module, a fixing module, a forming module, a bottom plate, a fixedtable supporting plate bracket, a fixed table supporting plate and a fixed table, wherein the fixed table is arranged above a bottom plate, the fixed table supporting plate is fixedly connected withthe lower surface of the fixed table, and the fixed table supporting plate is fixedly connected with the bottom plate through the fixed table supporting plate bracket. By means of the fixing module, apaperboard can be fixed to the upper surface of the fixed table, so that forming quality of the paperboard is guaranteed; and by means of the forming module, two sides of the paperboard can be bent upwards, the surface of the paperboard is attached to the surface of a fixed plate, and therefore, forming precision of the paperboard is ensured; and the capping module and the auxiliary module are arranged, finishing work of the final forming of the paperboard is realized, the L-shaped paperboard can be formed, and thus, the number of butt seams of the paperboard is reduced.

Owner:隋干辉

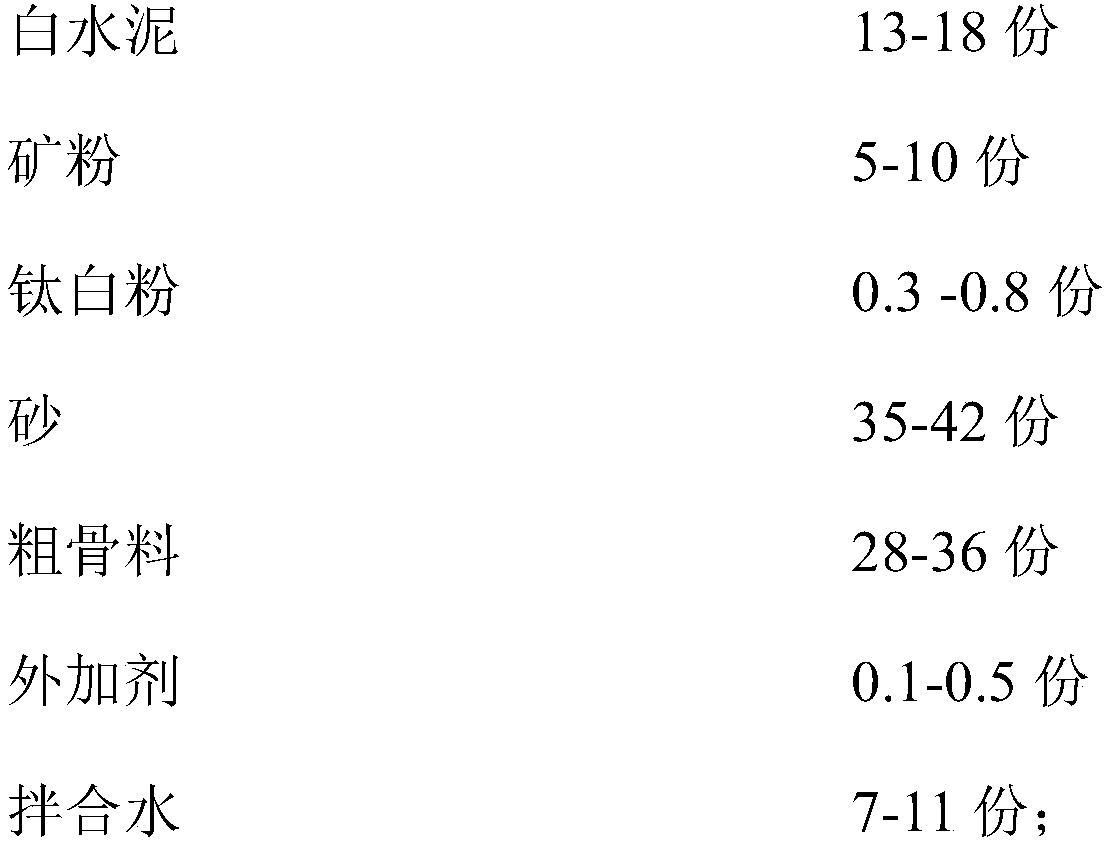

Semi-precast lightweight white concrete curtain wall and construction method thereof

The invention discloses a semi-precast lightweight white concrete curtain wall, which is characterized in that the curtain wall is sandwich sandwich structure, and the curtain wall comprises a left side surface template, a right side surface template and a middle sandwich layer, wherein the left side surface template and the right side surface template are lightweight white concrete molding members, and the middle sandwich layer is a self-compacting concrete layer. A light white concrete component and a weight portion thereof are as follow: (img file= 'DDA0001745311660000011. TIF' wi= '700' he= '534' / ) The beneficial effects of the present invention are: The invention provides a concrete curtain wall form integrating decoration, heat preservation and structure, which is neat and beautiful,the number of splicing joints is small and the weight is light.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

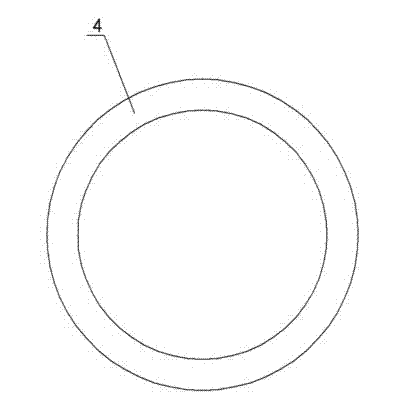

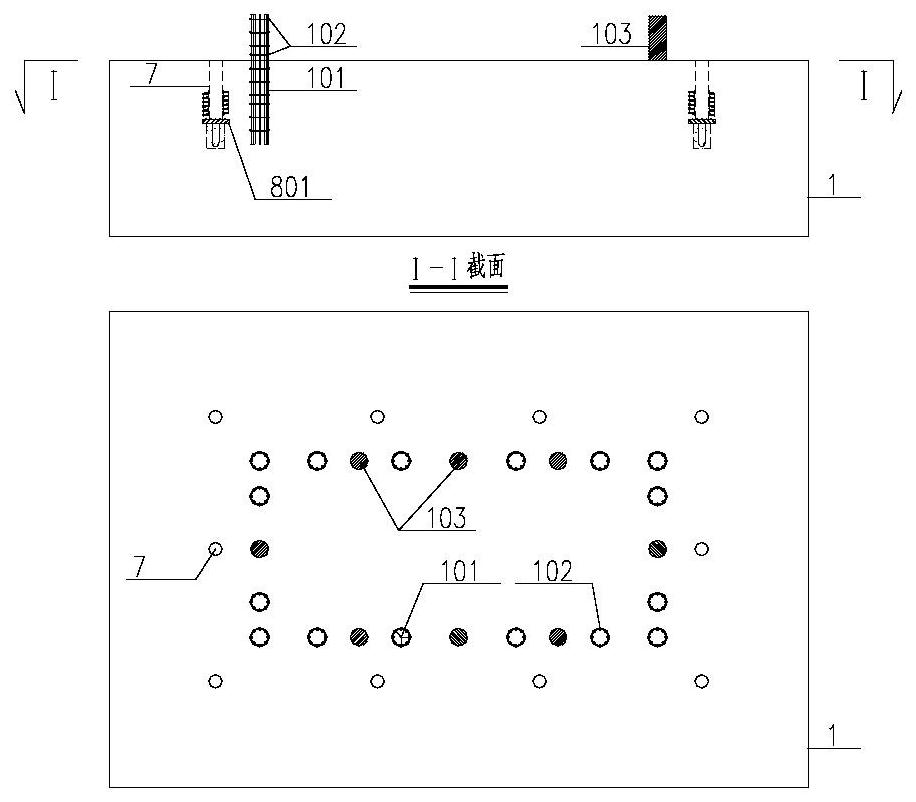

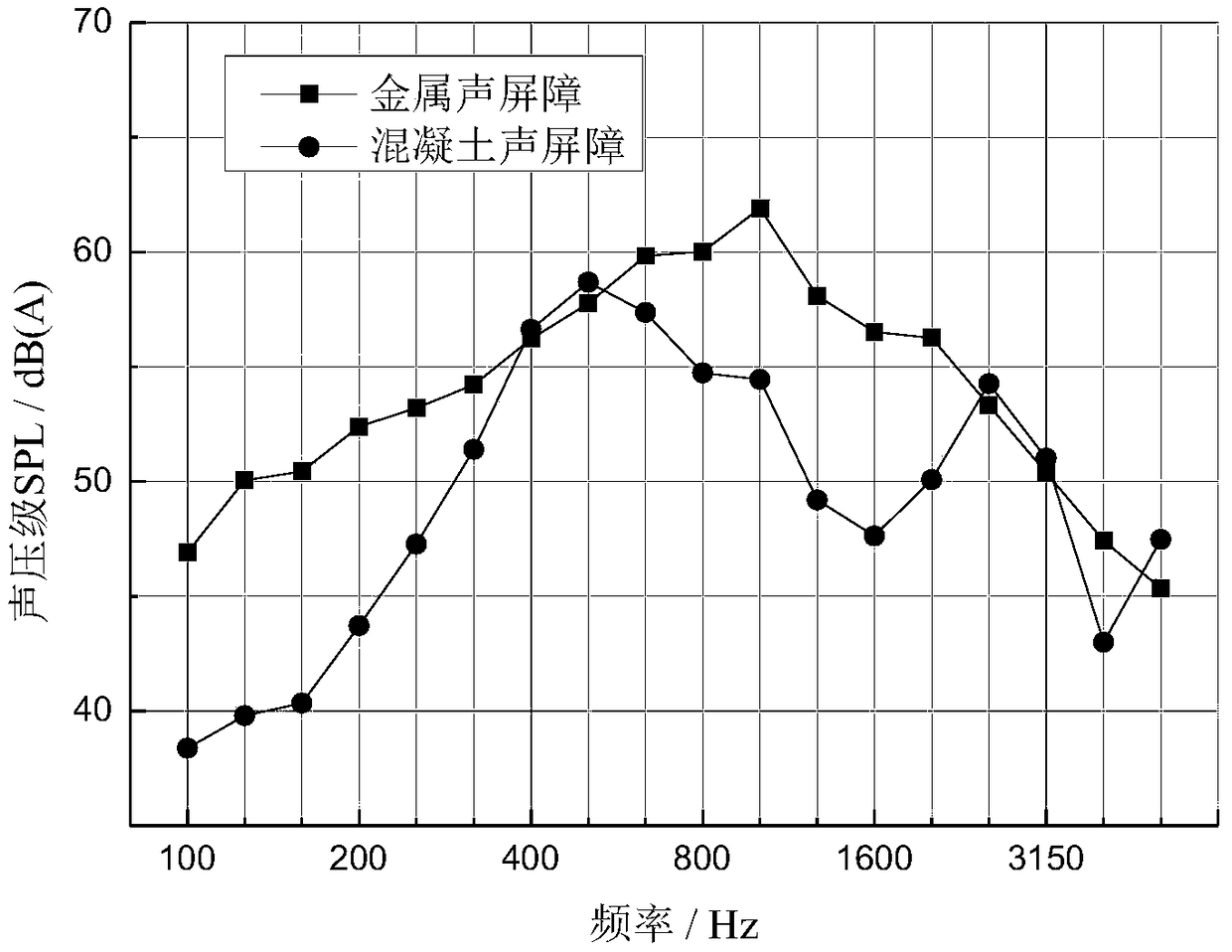

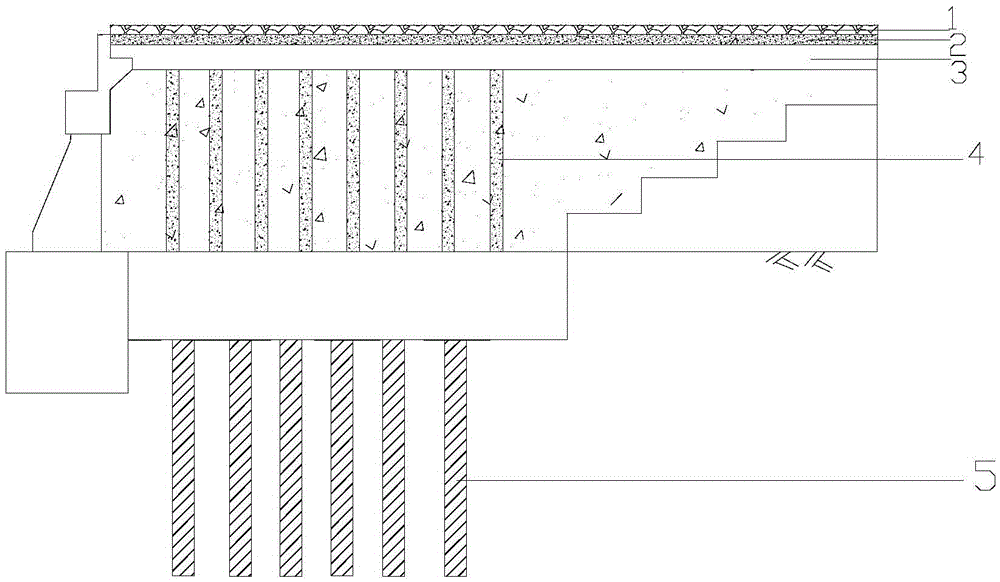

Assembled concrete full-closed noise barrier

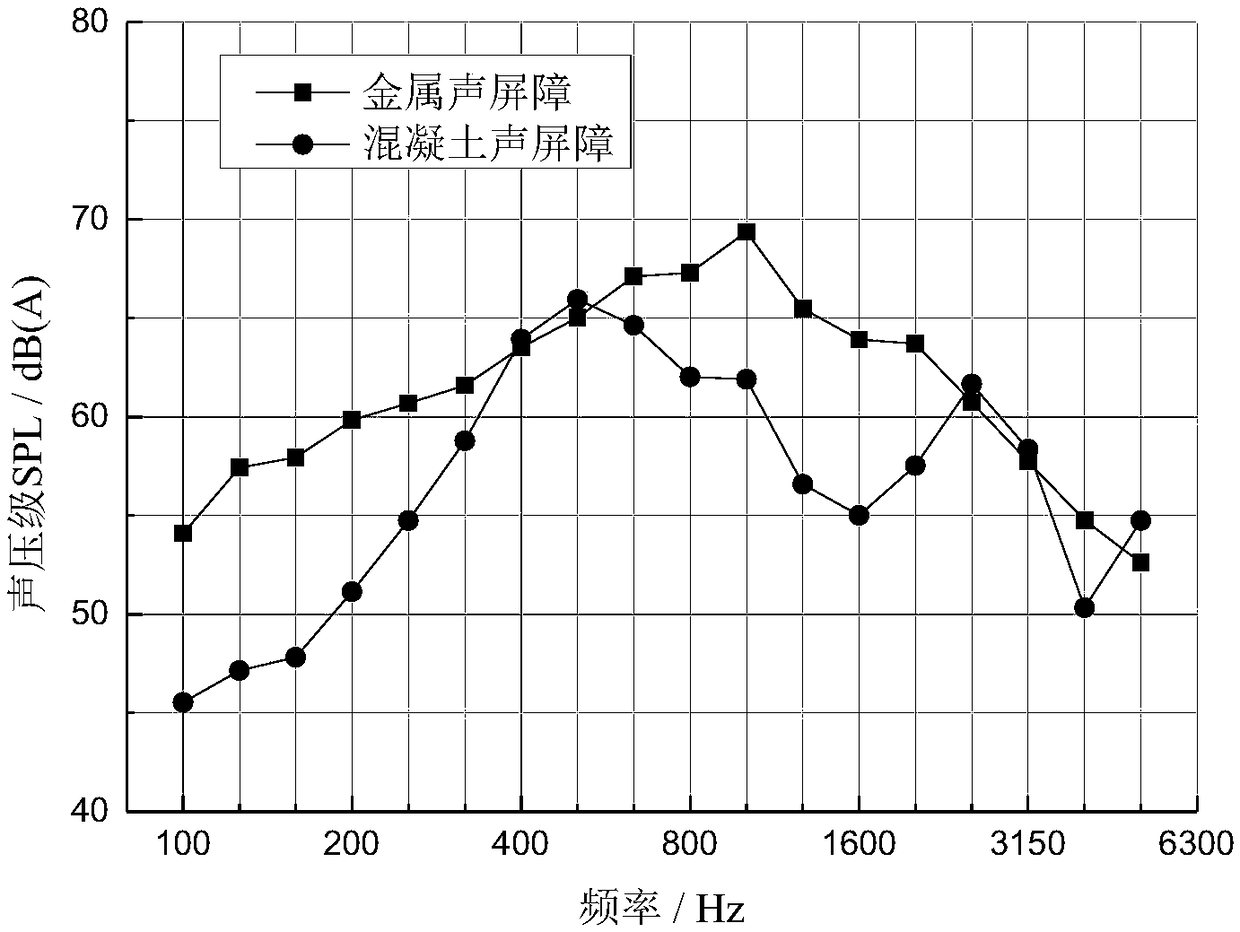

InactiveCN106758903AImprove sound insulationIncreased durabilityClimate change adaptationNoise reduction constructionNoise barrierBridge deck

The invention discloses an assembled concrete full-closed noise barrier. The assembled concrete full-closed noise barrier comprises noise barrier bases, a plurality of cross beams and cover plates, wherein the cross beams are arranged in a bridge direction at intervals and shaped like a closed circle; the cover plates are laid between the surfaces of the adjacent cross beams and the sections of the cover plates are consistent with the sections of the cross beams in the bridge direction; each cross beam comprises a top cross beam and two side cross beams; one ends of the side cross beams are fixedly connected with the noise barrier, the other ends of the side cross beams are fixedly connected with the top cross beams, and the connected parts of the side cross beams and the top cross beams are concave-convex tooth mouth engaged structures; and the section of each cross beam in a transverse bridge direction is elliptic or circular, and the maximum width of the section of each cross beam in the transverse bridge direction is larger than the width of a bridge deck. Compared with the traditional steel cross beam, the assembled concrete full-closed noise barrier has the advantages that the assembled concrete full-closed noise barrier does not need to maintain and the durability of the assembled concrete full-closed noise barrier is good; the steel usage is reduced and the economic efficiency of the assembled concrete full-closed noise barrier is enhanced; the sound insulation effect is good, the durability is good, the manufacturing cost of the assembled concrete full-closed noise barrier is low and the fireproof performance is greatly enhanced; and through adoption of a convex integral curve form, the aerodynamic performance of the assembled concrete full-closed noise barrier is better than that of the traditional vertical noise barrier.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Prefabricated assembled hollow pier with built-in rib plates and construction method

PendingCN111827095ASuitable for erosive environmentFlexible layoutBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention provides a prefabricated assembled hollow pier with built-in rib plates and a construction method, and relates to the technical field of bridge construction. The hollow pier sequentiallycomprises a foundation, a bottom section, a middle section and a top cap section from bottom to top. Embedded steel bars are arranged at the top of the foundation, and stirrups are arranged on the embedded steel bars; a solid section is arranged below the bottom section, the bottom section and the solid section are prefabricated together, a connecting steel bar hole channel is reserved in the solid section, and a diameter of the connecting steel bar hole channel is 5 cm larger than that of each side of the embedded steel bar at the top of the foundation; post-cast concrete is filled in pore channels of the embedded steel bars; the rib plates are arranged on the bottom section, the middle section and the top cap section, each rib plate is provided with a connecting reinforcing steel bar, each connecting reinforcing steel bar extends out of the corresponding rib plate, and the connecting reinforcing steel bars between the sections are in lap joint with one another by more than 10 timesof the diameter of the reinforcing steel bars; and prestressed pipelines are pre-buried in the foundation, the bottom section, the middle section and the top cap section and are connected by penetrating through full-length prestressed tendons. By adopting the scheme, defects of insufficient energy consumption and low ductility of prestressed assembled piers can be overcome.

Owner:CHINA RAILWAYS CORPORATION +1

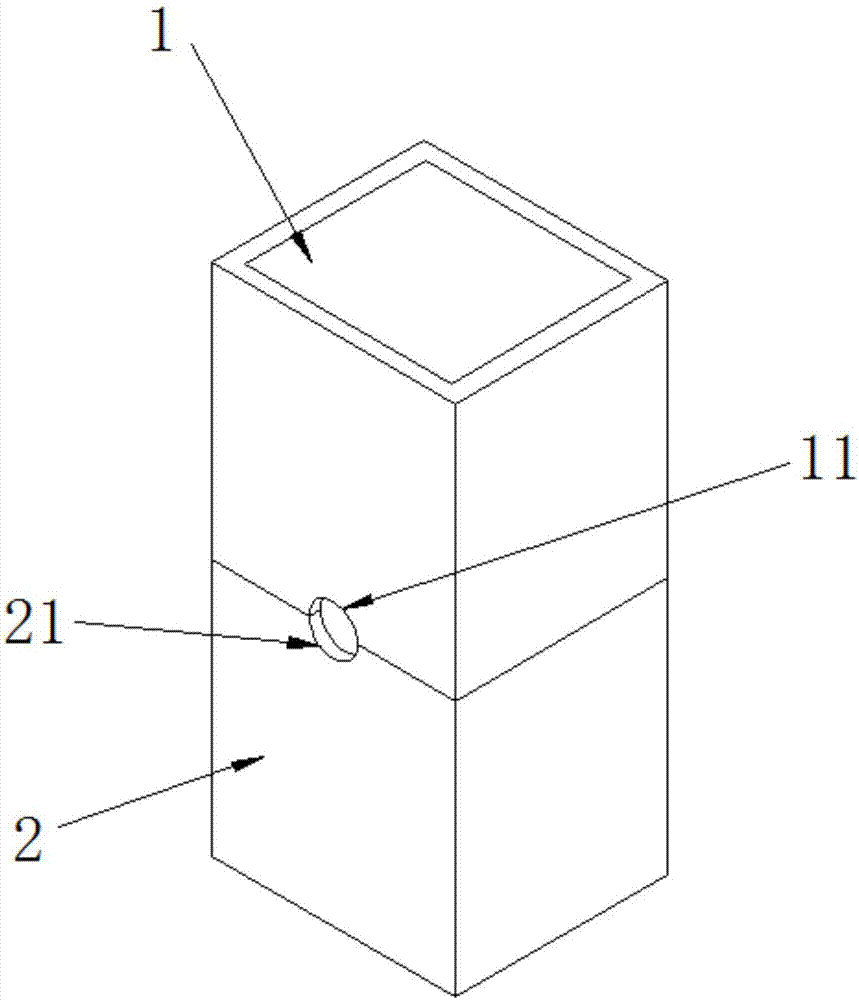

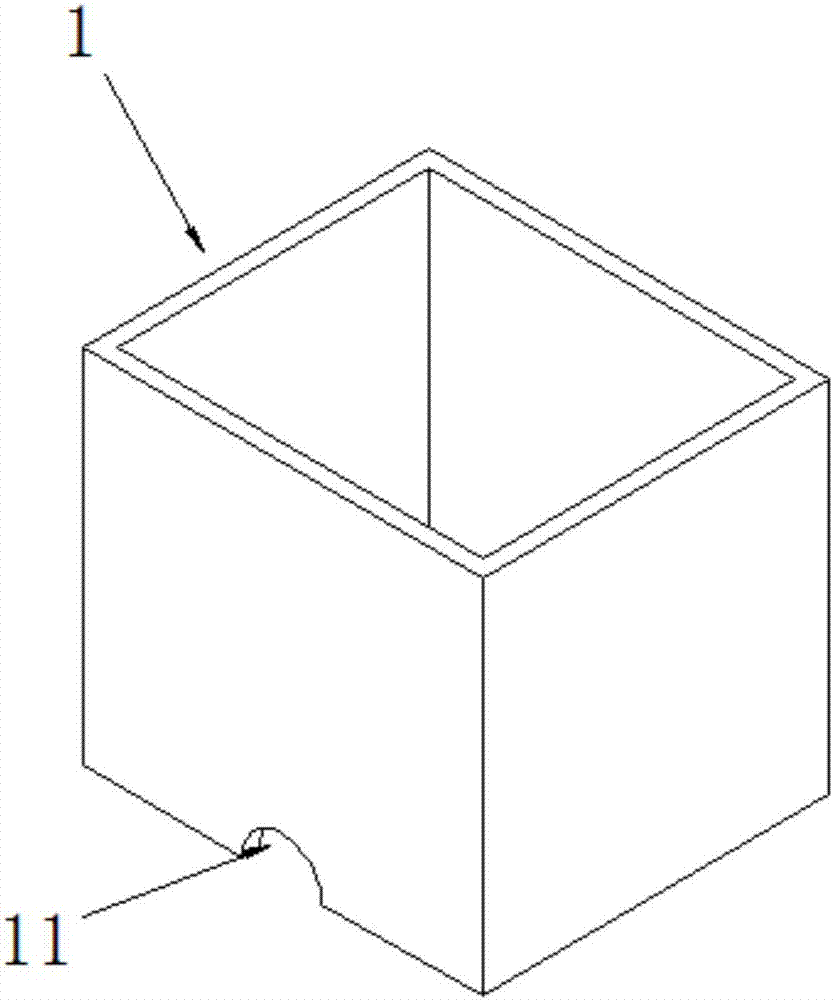

Gutter inlet

The invention provides a gutter inlet. The gutter inlet comprises a gutter inlet well body and a gutter inlet base, the gutter inlet well body is detachably installed on the gutter inlet base, the gutter inlet well body comprises a plurality of first flank walls, the left sides and the right sides of the first flank walls are fixedly connected to each other in sequence, a first cylindrical body is formed, and first openings are formed in the lower ends of the first flank walls and used for installing reserved rainwater branch pipes; the gutter inlet base comprises a bottom plate and a plurality of second flank walls, the left sides and the right sides of the second flank walls are fixedly connected to each other in sequence, a second cylindrical body is formed, second openings are formed in the upper ends of the second flank walls and used for installing the reserved rainwater branch pipes, the lower end of the second cylindrical body is fixedly connected with the bottom plate in a sealing mode, and the upper end of the second cylindrical body is detachably connected with the lower end of the first cylindrical body in a matched mode. When the second cylindrical body is connected with the first cylindrical body in a matched mode, the first openings are connected with the second openings in a matched mode.

Owner:广州市第三市政工程有限公司

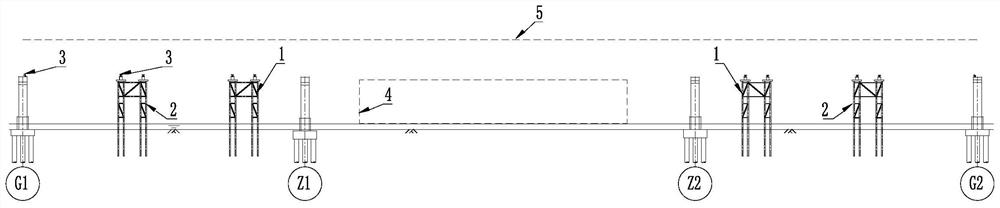

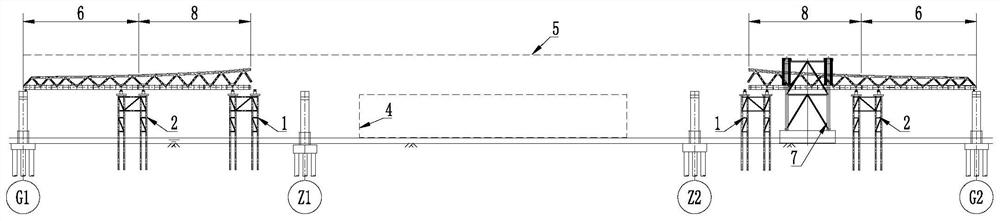

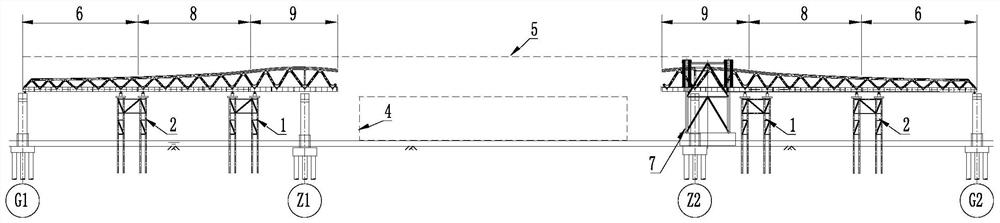

Rapid construction method for steel truss and steel box combined girder bridge in offshore height-limited and navigation-limited area

PendingCN113605255AReduce offshore operationsEco-friendlyTruss-type bridgeBridge erection/assemblyGirder bridgePier

The invention provides a rapid construction method for a steel truss and steel box combined girder bridge in an offshore height-limited and navigation-limited area. The method mainly comprises the following steps that auxiliary piers are respectively constructed at two sides of a main navigation channel, wherein the auxiliary piers comprise a main pier, a transition pier and a temporary pier between the main pier and the transition pier, a steel beam connecting and guiding buffering device and steel beam three-way displacement adjusting equipment are installed on the tops of the auxiliary piers; and then side span construction, middle span construction, side span steel beam cantilever flange construction, closure and steel beam positioning are carried out. A non-total-section large-section installation method is adopted for the steel beam side span, a full-section large-section installation method is adopted for the steel beam middle span, the hoisting capacity of hoisting equipment can be fully utilized, and the specification of the hoisting equipment is reduced; the requirements of navigation and aviation height limitation can be met; the offshore operation amount can be reduced, and the environmental protection, safety and quality risks of offshore operation are reduced; rapid construction can be achieved, and the construction period is shortened.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

Bridge head jumping prevention structure based on concrete composite pavement and its laying method

InactiveCN103628376BImprove the problem of insufficient bearing capacityChanging the holding power characteristicsRoadwaysBridge structural detailsProcess qualityRoad surface

The invention discloses a bridgehead vehicle bumping prevention structure based on a concrete composite pavement and a laying method thereof. The bridgehead vehicle bumping prevention structure comprises a lime-soil compaction pile composite foundation, wherein a composite foundation, in which concrete piles are built, is laid on the composite foundation; the concrete piles are in equal height and equal distance; a base layer is laid on the composite foundation; an oblique prestressed concrete layer is laid on the base layer; an asphalt layer is laid on the oblique prestressed concrete layer. According to the structure, the foundation has enough bearing force and is filled with the concrete piles, so that the bearing force of the foundation can be further improved, and uneven settlement of the foundation is alleviated. According to the method, the construction process quality is controllable, continuous operation is realized, the problems of bridgehead vehicle bumping accidents, early pavement damage and the like due to uneven settlement of the back of a bridge abutment can be effectively reduced, the bridgehead vehicle bumping accidents troubling the highway management department for many years can be avoided, the service performance of the pavement can be greatly improved, the service life of the pavement is obviously prolonged, and the bridgehead vehicle bumping prevention structure has obvious economic benefits.

Owner:CHANGAN UNIV

Film coated decorative steel plate and preparation thereof

InactiveCN101239517AReduce thicknessReduce material usageLamination ancillary operationsLaminationSheet steelMaterials science

A synthetic film decorative steel sheet is characterized in that a synthetic film is arranged on the steel sheet. The preparation of the steel sheet includes a first step of films being respectively formed of PET resins and PMMA-PP resins, a second step of integrating films to be printed after being cut, a third step of obtaining a synthetic film which is to be adhered with the steel sheet for producing a synthetic film decorative steel sheet. Accordingly, the present invention which can be used in wall decoration, house-hold appliance faceplate and senior furniture decorating has the advantages of non-toxic, tasteless, no pollution, no harmful radiation, excellent processability and a low cost.

Owner:SHANGHAI TUOPU PRECISION STEEL BELT

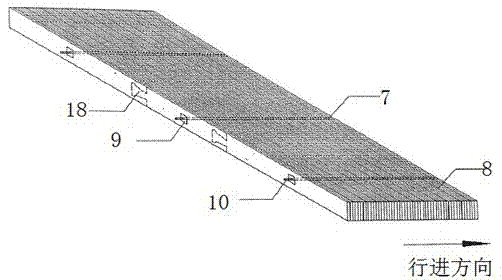

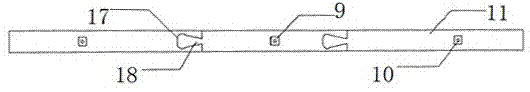

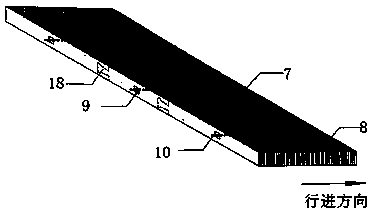

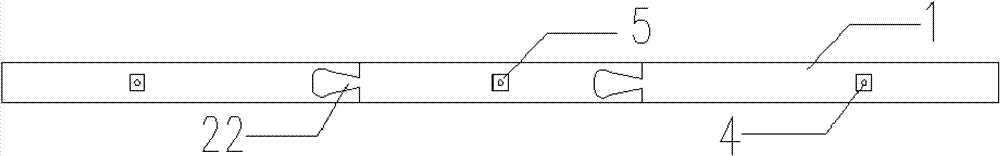

Bamboo bridge deck

InactiveCN102561180BIncrease the lengthReduce the degree of prestress lossBridge structural detailsPre stressArchitectural engineering

The invention discloses a bamboo bridge deck, which comprises prestressed ribs and a plurality of superposed bridge deck sheets, wherein the prestressed ribs penetrate through the bridge deck sheets; two ends of the prestressed ribs penetrate through shim plates and are fixed and tightened by using anchorage devices to constrain the bridge deck sheets; and each bridge deck sheet is formed by sequentially joggling a plurality of single bridge decks made of bamboo veneers end to end, and the joggled parts of the two adjacent bridge deck sheets are staggered. The required width of the bridge deck is achieved in the transverse direction by the method for sequentially joggling the single bridge decks end to end in the cross section width of a bridge. The basic single decks of the bamboo bridge deck can be conveniently prefabricated in a factory and assembled on site to form the bamboo bridge deck; the construction process is simple and fast, and the construction materials are environment-friendly and are easily reclaimed; and the bamboo bridge deck is suitable for a combined structural bridge, and is a bridge deck capable of meeting the using functions and the durability.

Owner:SOUTHEAST UNIV

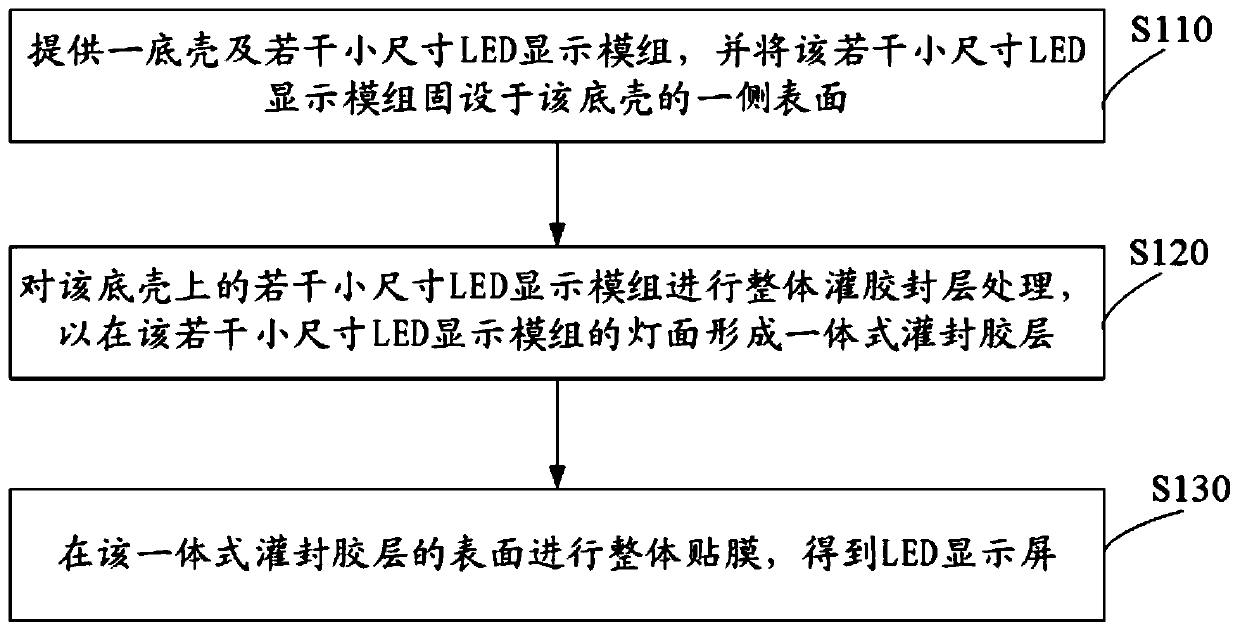

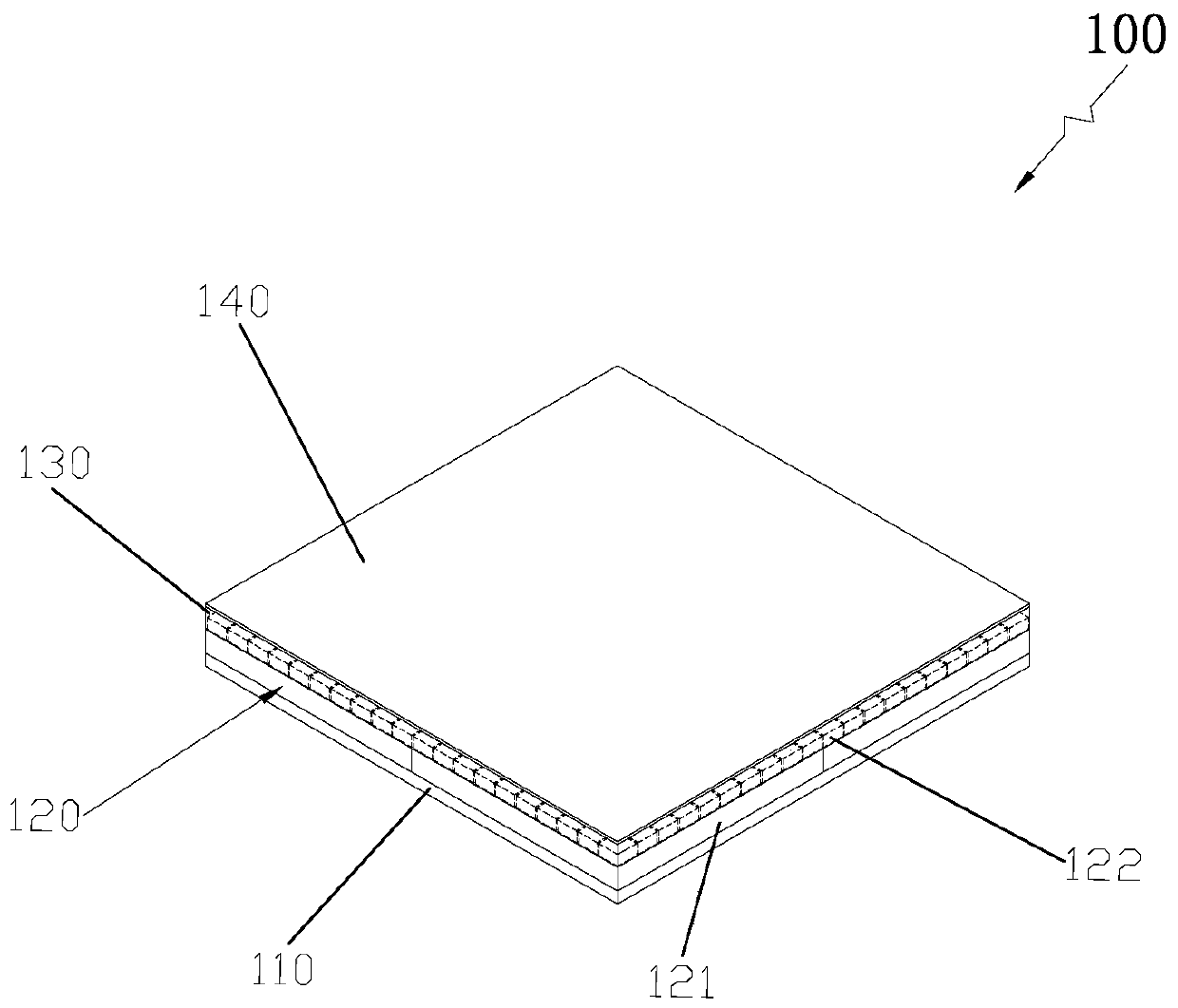

Manufacturing method of LED display screen

ActiveCN111477121AImprove bright line problemImprove flatnessIdentification meansLED displayEngineering

The invention discloses a manufacturing method of an LED display screen, and belongs to the technical field of LED display screen processing. The manufacturing method comprises the steps of providinga bottom shell and a plurality of small-size LED display modules, and the small-size LED display modules are fixedly arranged on the surface of one side of the bottom shell; carrying out integral pouring sealant layer treatment on the plurality of small-size LED display modules on the bottom shell so as to form an integral pouring sealant layer on the lamp surfaces of the plurality of small-size LED display modules; and integrally pasting a film on the surface of the integrated pouring sealant layer to obtain the LED display screen. According to the technical scheme, the bright line problem ofthe LED display screen can be greatly improved, the contrast ratio of the display screen is improved, and the module color difference is reduced.

Owner:UNILUMIN GRP

Detachable integrated wallboard and mounting method thereof

PendingCN110005154ALow wall requirementsImprove flatnessCovering/liningsFlooringWall plateEngineering

Owner:李春祥

Construction method of gutter inlet

InactiveCN107268755AHigh compressive strengthImprove construction efficiencySewerage structuresSewage drainingReinforced concreteEconomic benefits

The invention belongs to the technical field of water supply and drainage works, and mainly provides a construction method of a gutter inlet. Mainly by combining base skeletons and well body skeletons, which have been processed in a prefabricating yard, with multiple sets of base templates and well body templates, and then implementing concrete pouring, a purpose of prefabricating spliced gutter inlet bases and gutter inlet well bodies in batch can be achieved. With the application of the construction method of the gutter inlet provided by the invention, quality problems caused by an insufficient construction space can be effectively solved; moreover, working efficiency can be greatly improved, a construction period can be shortened and good social and economic benefits can be caused; meanwhile, the gutter inlet provided by the invention, which adopts a reinforced concrete structure, is high in compressive strength, so that the gutter inlet can adapt to demands of complex urban roads on gutter inlets; therefore, the construction method has a broad application space in construction of urban road gutter inlets and has a quite high promotional value.

Owner:广州市第三市政工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com