Semi-precast lightweight white concrete curtain wall and construction method thereof

A concrete and semi-prefabricated technology, applied to walls, building components, buildings, etc., can solve problems such as difficult to meet the pursuit of component taste, and achieve the effect of light weight, neat and beautiful outer surface, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the semi-prefabricated lightweight white concrete curtain wall has a sandwich structure. The curtain wall includes a left side formwork, a right side formwork and a middle interlayer, and the left side formwork and the right side formwork are lightweight The white concrete modeling component, the middle interlayer is a self-compacting concrete layer.

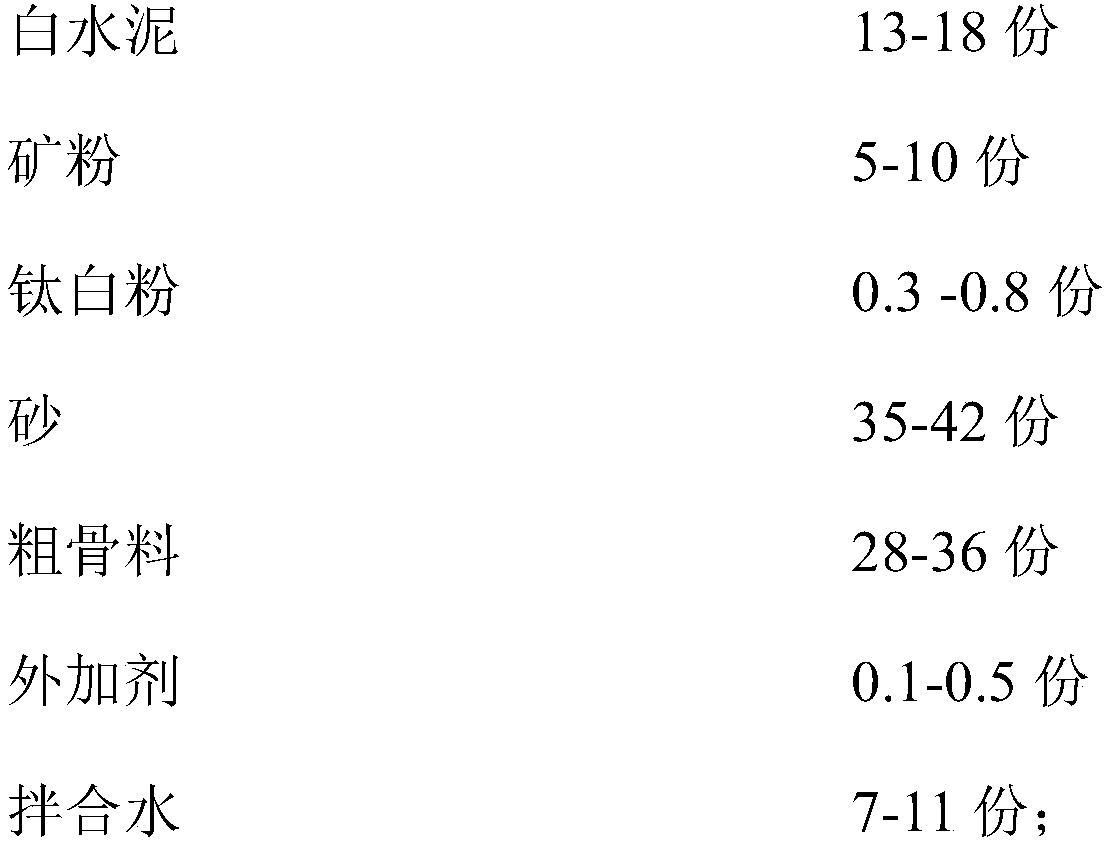

[0036] The lightweight white concrete component and parts by weight described in the present embodiment are composed as follows:

[0037]

[0038] The 28d standard maintenance compressive strength of the light white concrete reaches 20MPa, and the bulk density is 1580kg / m 3 .

[0039] Preferably, the strength grade of the white cement in this embodiment is 52.5, and the mineral powder grade is S105.

[0040] As a further preference, the sand in this embodiment is quartz sand, the fineness modulus of the quartz sand is 2.3, the mud content of the sand is 0.08%, and the crushing value index is 3.5%;...

Embodiment 2

[0048] In this embodiment, the semi-prefabricated lightweight white concrete curtain wall has a sandwich structure. The curtain wall includes a left side formwork, a right side formwork and a middle interlayer, and the left side formwork and the right side formwork are lightweight The white concrete modeling component, the middle interlayer is a self-compacting concrete layer.

[0049] The lightweight white concrete component and parts by weight described in the present embodiment are composed as follows:

[0050]

[0051]

[0052] The 28d standard maintenance compressive strength of the light white concrete reaches 20MPa, and the bulk density is 1600kg / m 3 .

[0053] Preferably, the strength grade of the white cement in this embodiment is 52.5, and the mineral powder grade is S105.

[0054] As a further preference, the sand in this embodiment is quartz sand, the fineness modulus of the quartz sand is 2.5, the mud content of the sand is 0.09%, and the crushing value inde...

Embodiment 3

[0062] In this embodiment, the semi-prefabricated lightweight white concrete curtain wall has a sandwich structure. The curtain wall includes a left side formwork, a right side formwork and a middle interlayer, and the left side formwork and the right side formwork are lightweight The white concrete modeling component, the middle interlayer is a self-compacting concrete layer.

[0063] The lightweight white concrete component and parts by weight described in the present embodiment are composed as follows:

[0064]

[0065] The 28d standard maintenance compressive strength of the light white concrete reaches 20MPa, and the bulk density is 1580kg / m 3 .

[0066] Preferably, the strength grade of the white cement in this embodiment is 52.5, and the mineral powder grade is S105.

[0067] As a further preference, the sand in this embodiment is quartz sand, the fineness modulus of the quartz sand is 2.6, the mud content of the sand is 0.07%, and the crushing value index is 3.8%;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com