Prefabricated assembled hollow pier with transverse partition plates and construction method

A technology of prefabricated assembly and diaphragm, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., which can solve the problems of low ductility and insufficient energy consumption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

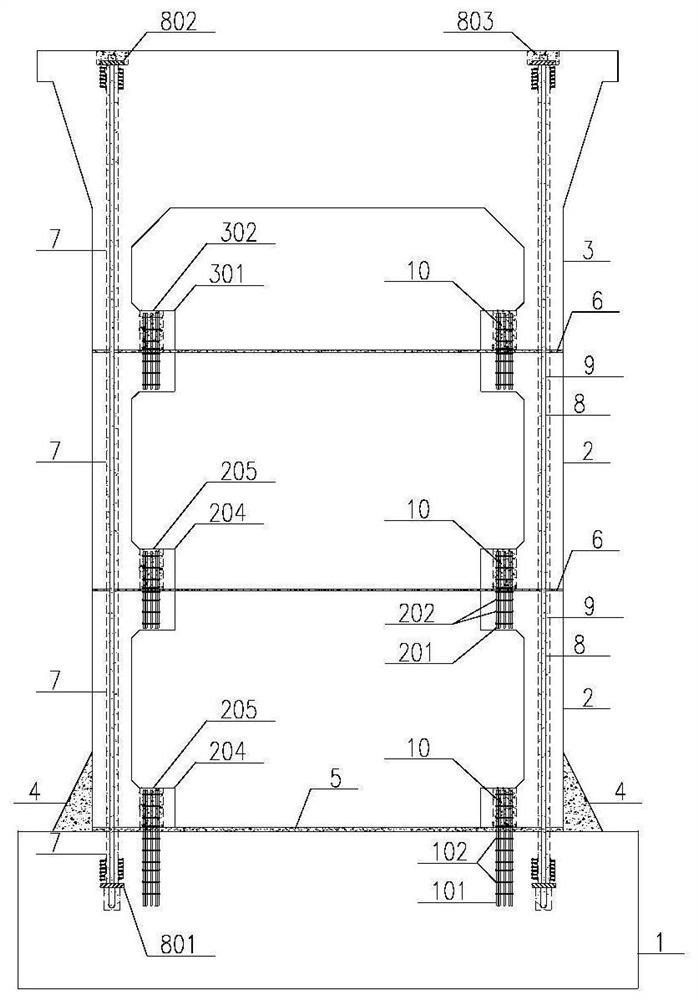

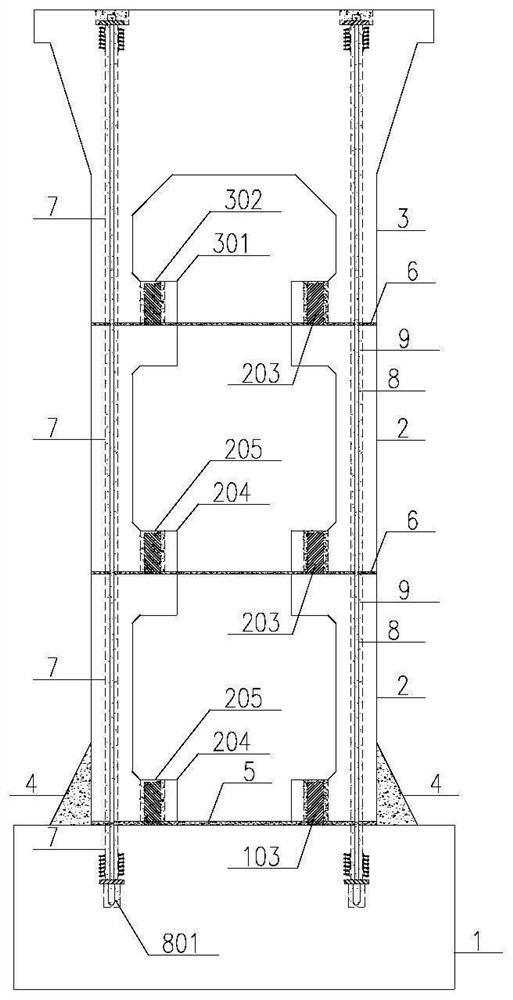

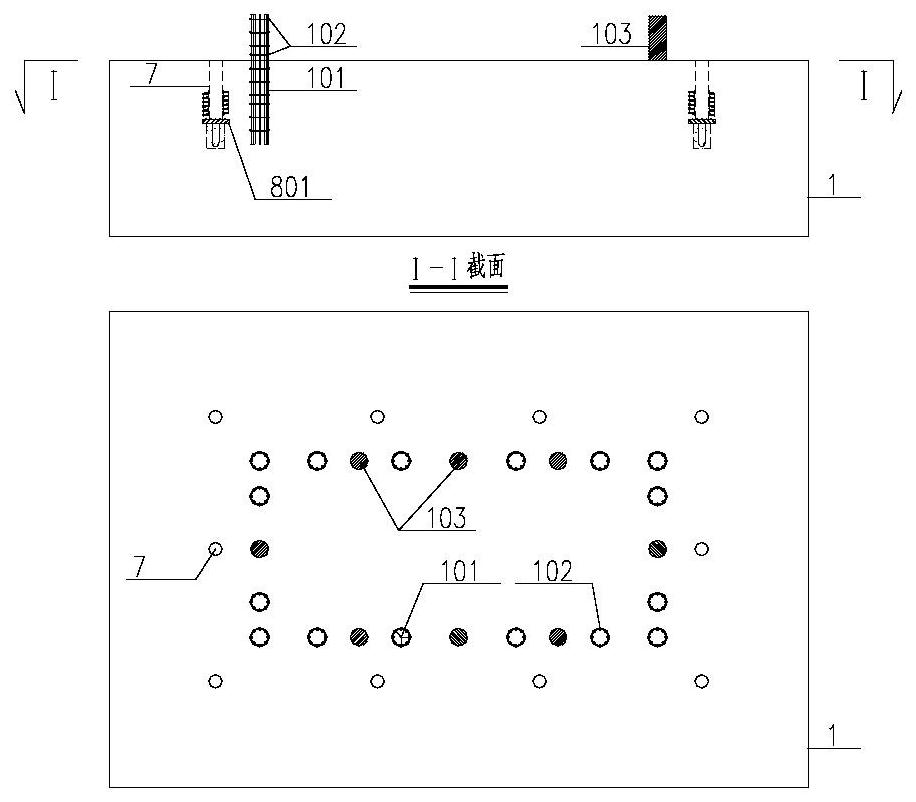

[0073] Such as figure 1 — Figure 9 As shown, it is a schematic diagram of the corresponding structure of the prefabricated assembled hollow piers with transverse diaphragms provided in this embodiment, combined below Figure 1-Figure 9 The program is described as follows:

[0074] The prefabricated assembled hollow pier with a transverse diaphragm provided in this embodiment includes a foundation 1, a general segment 2 and a top hat segment 3 from bottom to top, and a connecting steel bar 101 and a connecting column 103 are arranged on the top of the foundation 1; The top and bottom of the general segment 2 are provided with general segment diaphragms 204, the general segment diaphragm 204 at the bottom is provided with a general segment reserved groove 205, and the general segment diaphragm 204 at the top is provided with connecting Steel bar 201; top hat segment diaphragm 301 is arranged at the bottom of top hat segment 3, and top hat segment reserved groove 302 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com