Prefabricated assembled hollow pier with built-in rib plates and construction method

A technology of prefabricated assembling and ribbing, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of weak stability, unsuitability, difficult inspection, repair and replacement of pier columns and pier walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

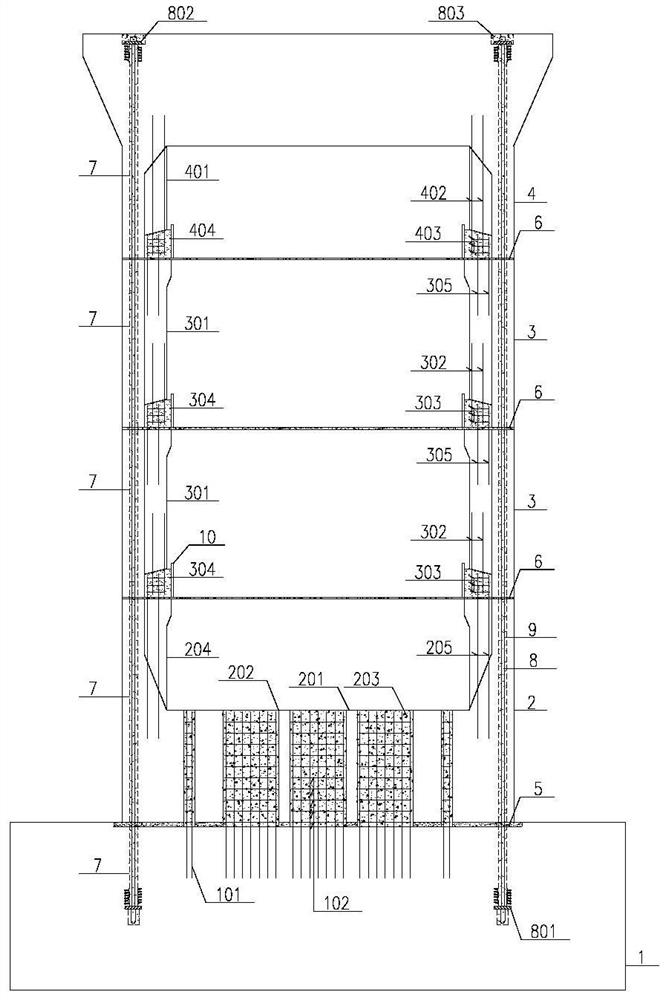

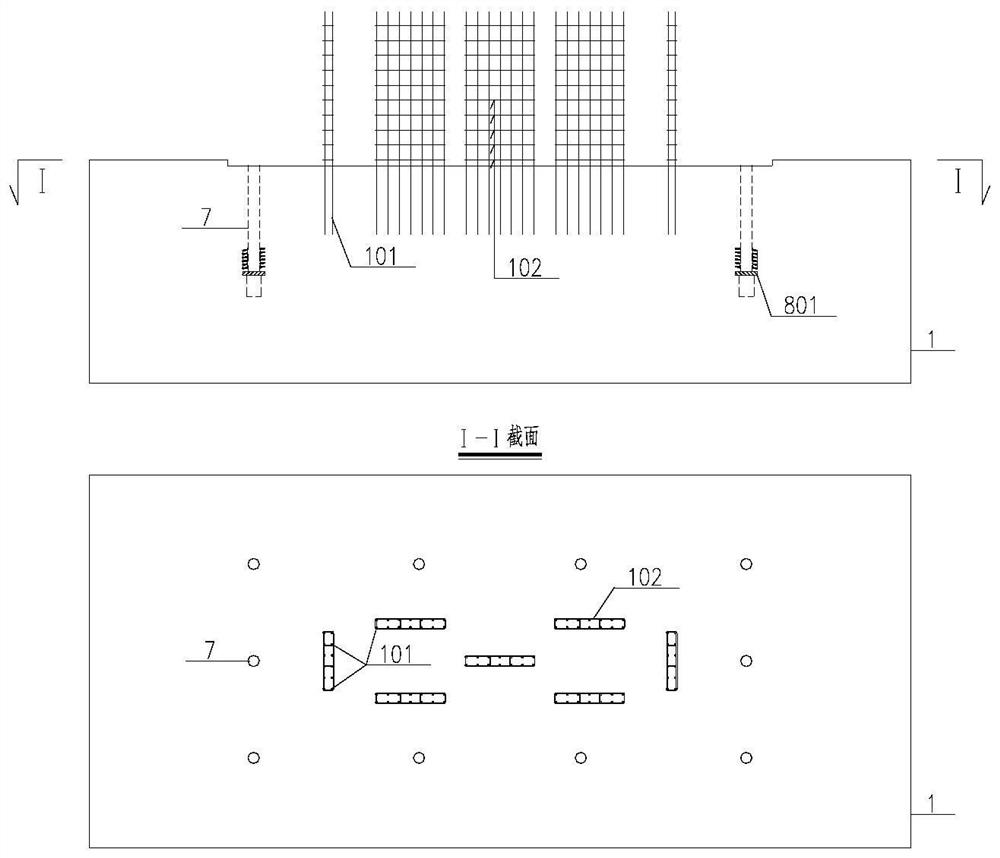

[0081] like Figure 1-9 As shown, a prefabricated assembled hollow pier with built-in ribs includes foundation 1, bottom segment 2, middle segment 3, and top hat segment 4 from bottom to top. Stirrups 102 are arranged on the embedded steel bars 101 to make the pre-embedded steel bars 101 have a certain rigidity and ensure their verticality;

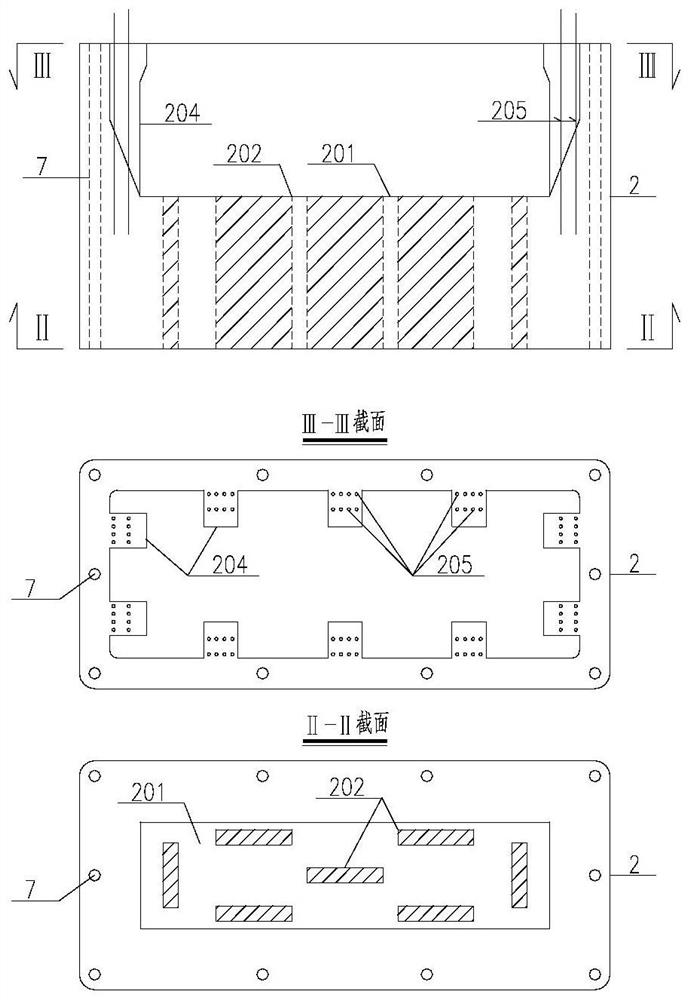

[0082] A solid section 201 is set under the bottom section 2, and the bottom section 2 and the solid section 201 are prefabricated together to ensure the integrity of the bottom section 2 and the solid section 201. The connecting steel bar tunnel 202 is reserved on the solid section 201, and the diameter of the connecting steel bar tunnel 202 Dimensions are 5cm larger than each side of the pre-embedded steel bar 101 of the foundation 1, which is convenient for it to penetrate.

[0083] The post-cast concrete 203 is filled with micro-expansion concrete or high-performance concrete in the tunnel of the pre-embedded steel bar 101, and ancho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com