Bridge head jumping prevention structure based on concrete composite pavement and its laying method

A composite road and bridge head jumping technology is applied to the bridge head jump prevention structure based on concrete composite road and its laying field, which can solve the problems of shortening the service life of the vehicle, increasing the vibration and damage of the vehicle, and improving the bearing capacity of the foundation. Insufficient, reduce differential settlement deformation, enhance the effect of bearing capacity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be described in further detail below in conjunction with the accompanying drawings.

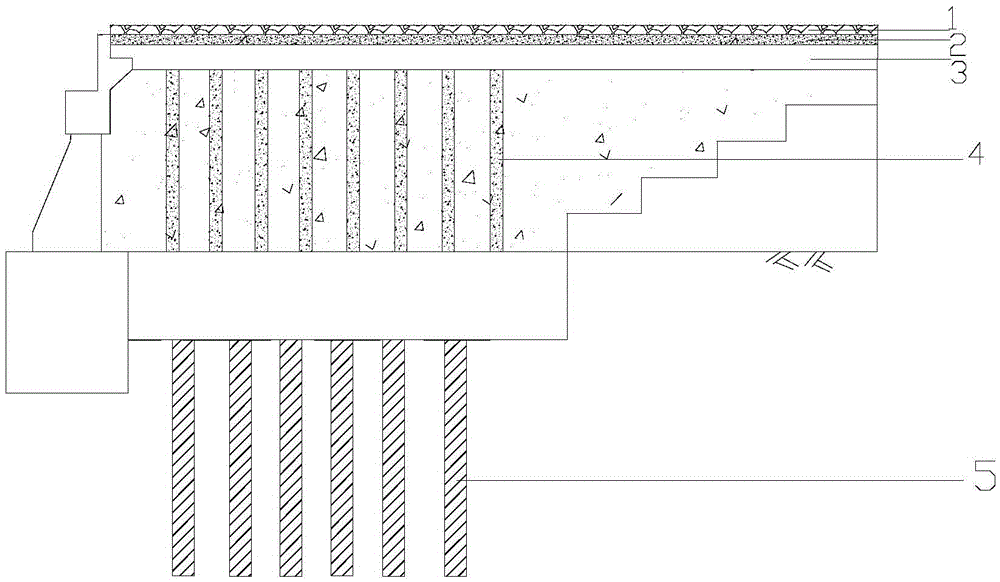

[0026] see figure 1 , the bridge head vehicle jumping prevention structure based on the concrete composite road surface includes a composite foundation 5 of lime-soil compaction piles, and a composite roadbed 4 with internally driven cement piles is laid on the composite foundation 5 of lime-soil compaction piles. The cement piles are of equal height and equidistant For setting, a base layer 3 is laid on the composite subgrade 4, an oblique prestressed concrete layer 2 is laid on the base layer 3, and an asphalt layer 1 is laid on the oblique prestressed concrete layer 2.

[0027] In the present invention, the composite roadbed 4 is a roadbed in which cement piles are driven in, wherein the cement piles are arranged at equal heights and at equal distances, the pile diameter of the cement piles is 400mm, the pile distance is 1.5m, and the pile length is 6m.

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com