Bridgehead roadbed composite structure for preventing bumping at bridgehead and construction method

A composite structure, bridge head jumping technology, applied in infrastructure engineering, roads, bridges, etc., can solve problems such as insufficient bearing capacity of bridge head subgrade, poor subgrade structure stability, complicated construction, etc., to reduce uneven settlement and good durability. , the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

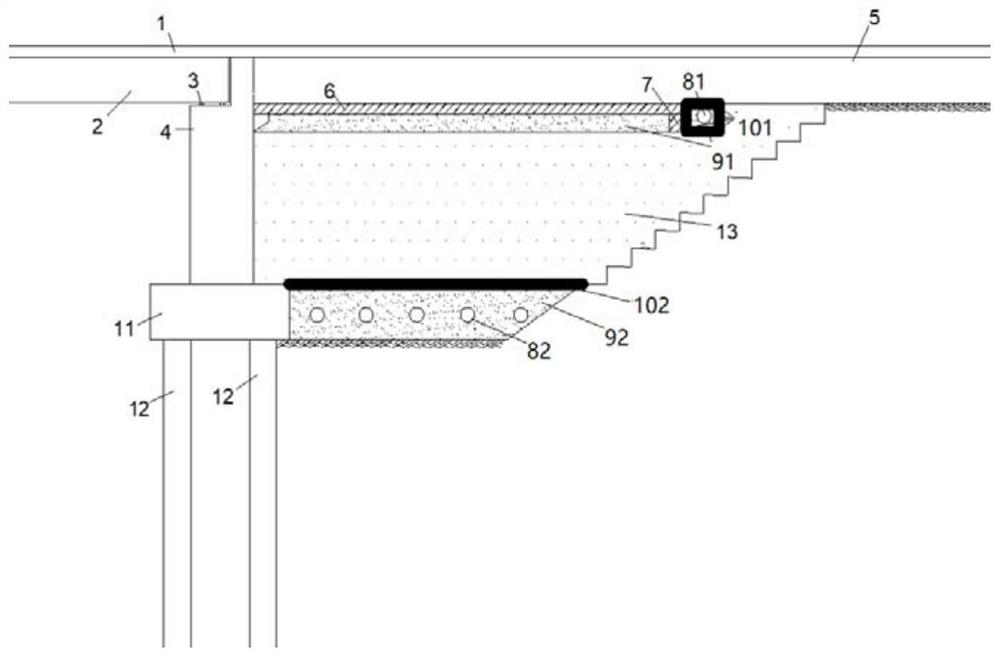

[0034] Such as figure 1 As shown, a bridge head subgrade composite structure to prevent bridge head jumping is arranged at the bridge head cap 11, and the upper end of the cap 11 is integrally formed with the abutment ear back wall 4 with corbels, which includes asphalt surface layer 1, The pavement structure layer 5, the board 6 and the corbel 7; one end of the board 6 is lapped on the corbel of the ear wall 4 of the abutment and is in contact with the abutment, and the other end is lapped on the corbel 7, and the corbel 7 is horizontally setting, the upper end reserves steel bar joints, and the integrity of the corbel 7 and the board 6 is realized through the steel bar joints; the first grade of crushed stone cushion 91 is set under the board 6 and on both sides of the corbel 7, and the first grade of gravel The cushion layer 91 has a built-in soft permeable pipe 81, and the soft permeable pipe 81 is connected to the drainage system on both sides of the roadbed through the t...

Embodiment 2

[0042] A bridge head subgrade composite structure and construction method for preventing vehicle jumping at the bridge head, which is basically the same as Embodiment 1, except that 5 rows of soft permeable pipes are horizontally embedded in the second graded crushed stone cushion.

[0043] To sum up, the present application provides a composite bridge head subgrade structure and construction method for preventing vehicle jumping at the bridge head. The bridgehead subgrade composite structure includes asphalt surface layer, pavement structure layer, strapping board and corbel beam from top to bottom; On the corbel, the integrity of the corbel and the slab is realized through steel joints; the first-grade crushed stone cushion is set under the slab and on both sides of the bolster, and the first-grade crushed stone cushion has built-in drainage facilities; the first The outer surface of the graded crushed stone cushion is wrapped with a non-woven geotextile anti-filter layer, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com