Super-high performance concrete frame structure fabricated building and construction method thereof

An ultra-high-performance, frame structure technology, applied in buildings, building components, building structures, etc., can solve problems such as complex reinforcement, corner damage, and low strength, so as to improve the seismic performance of structures and reduce the number of joints , the effect of reducing the weight of the building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

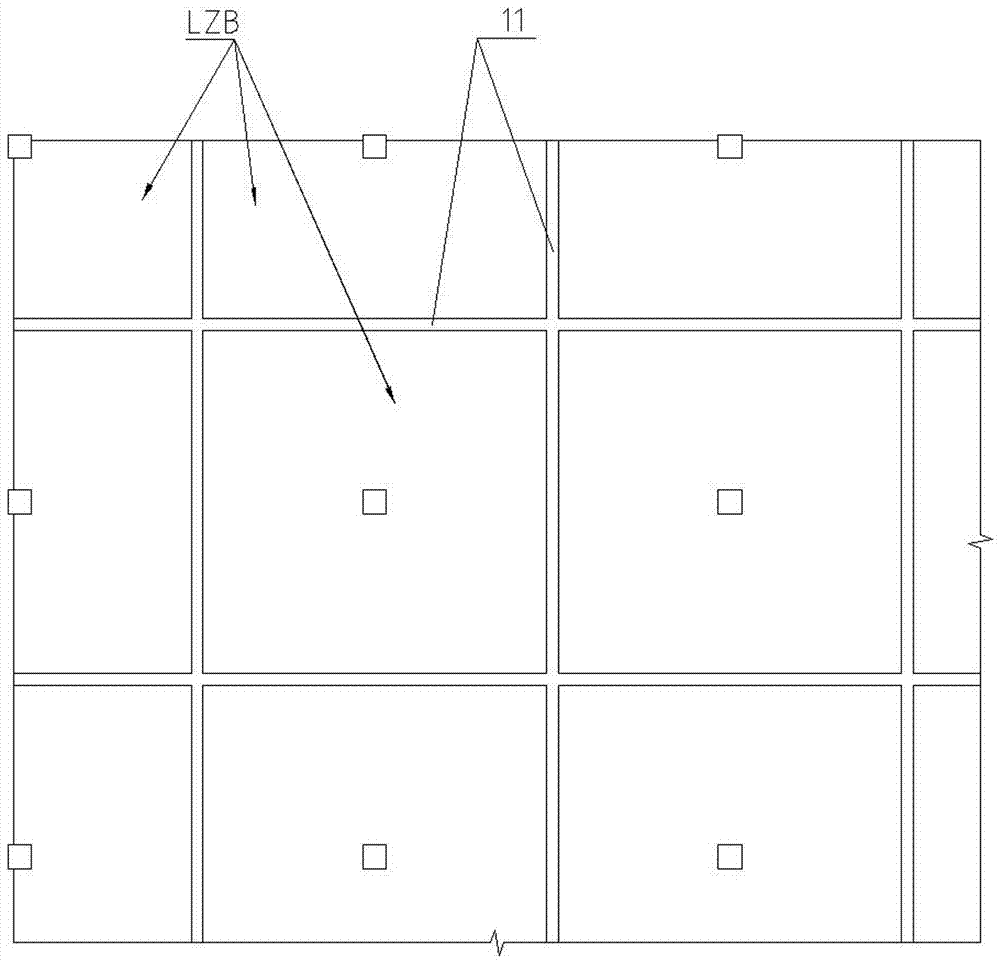

[0050] Embodiment 1. The prefabricated building disclosed in this embodiment is suitable for buildings where the distance between columns on the building plane is less than 10m. The upper and lower floors are connected by beams, columns, and columns of the overall floor slab. Beams, columns, and floor slabs LZB are prefabricated with ultra-high-performance concrete. The bending tensile strength of ultra-high-performance concrete is above 20MPa, and the compressive strength is above 100MPa.

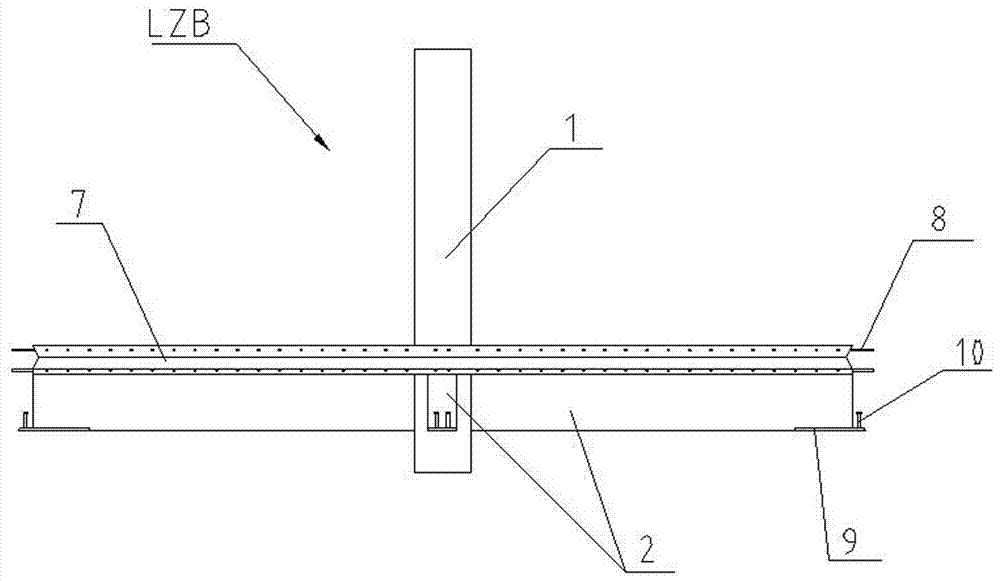

[0051] from figure 1 It can be seen that the building plane is rectangular, so the layout of beams, columns and floor slab integral parts LZB will have corners, edges and middle positions. Beams 2 are arranged vertically on the adjacent second, third and fourth side walls of the column 1, respectively. combine figure 1 with figure 2 It can be seen that the two ends of the column 1 protrude from the beam 2 and the floor 3 respectively.

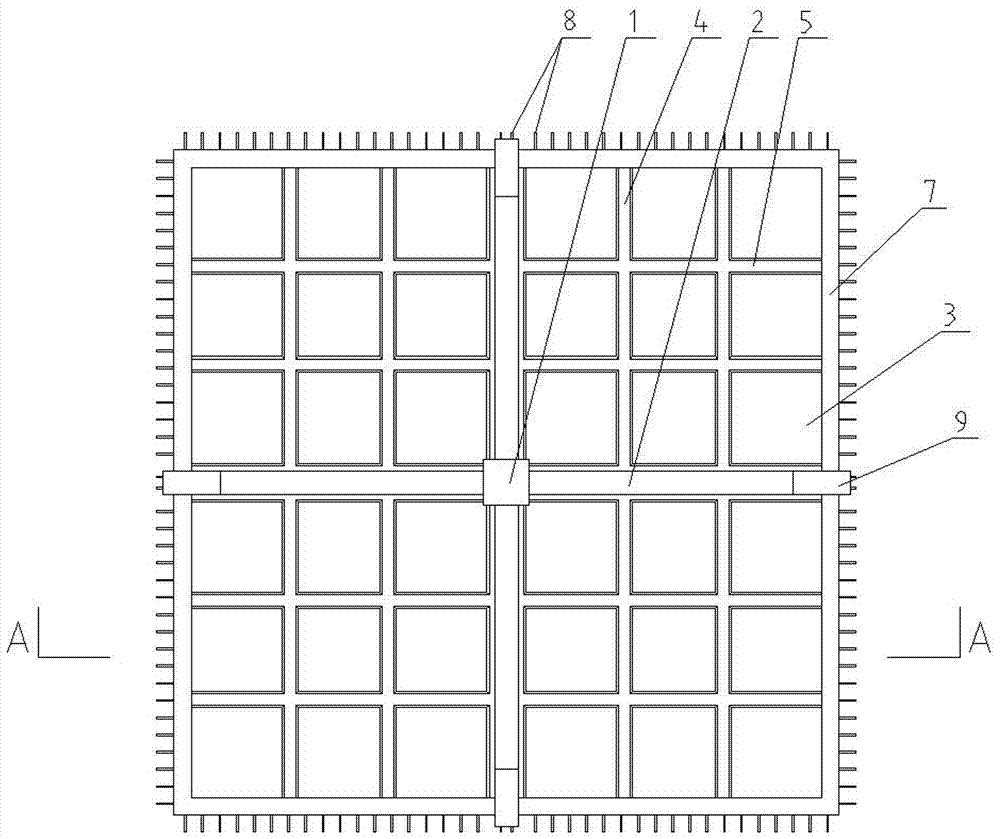

[0052] from image 3 It can be seen that beams...

Embodiment 2

[0063] Embodiment 2. This embodiment is applicable to buildings with a distance between columns of the building plane of 6-50 m, and the structural main body of the building plane is spliced by two kinds of splicing units. One kind of splicing unit is the beam, column, and floor integral part LZB similar to Embodiment 1, and the other is the beam, floor integral piece, and the two splicing units are spliced along the longitudinal and transverse directions of the building plane. Beams and floor slabs are also prefabricated with ultra-high performance concrete.

[0064] Since the distance between the building plane column and the column in this embodiment is relatively large, and the length of the building plane is greater than the width, the length and width are respectively regarded as the long span and the short span, and the distance between the adjacent beams, columns, and floor slabs in the direction of the short span Class I beams and integral floor slabs with small d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com