Processing apparatus and processing technology for arc-structured thermal-insulation board

A technology of structural insulation board and arc structure, which is applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problem of failure to consider the flexural performance of arc-shaped member section, long processing and construction time, and violation of structural insulation problems such as panels, to save processing and installation time, simplify decoration procedures, and save specialized materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

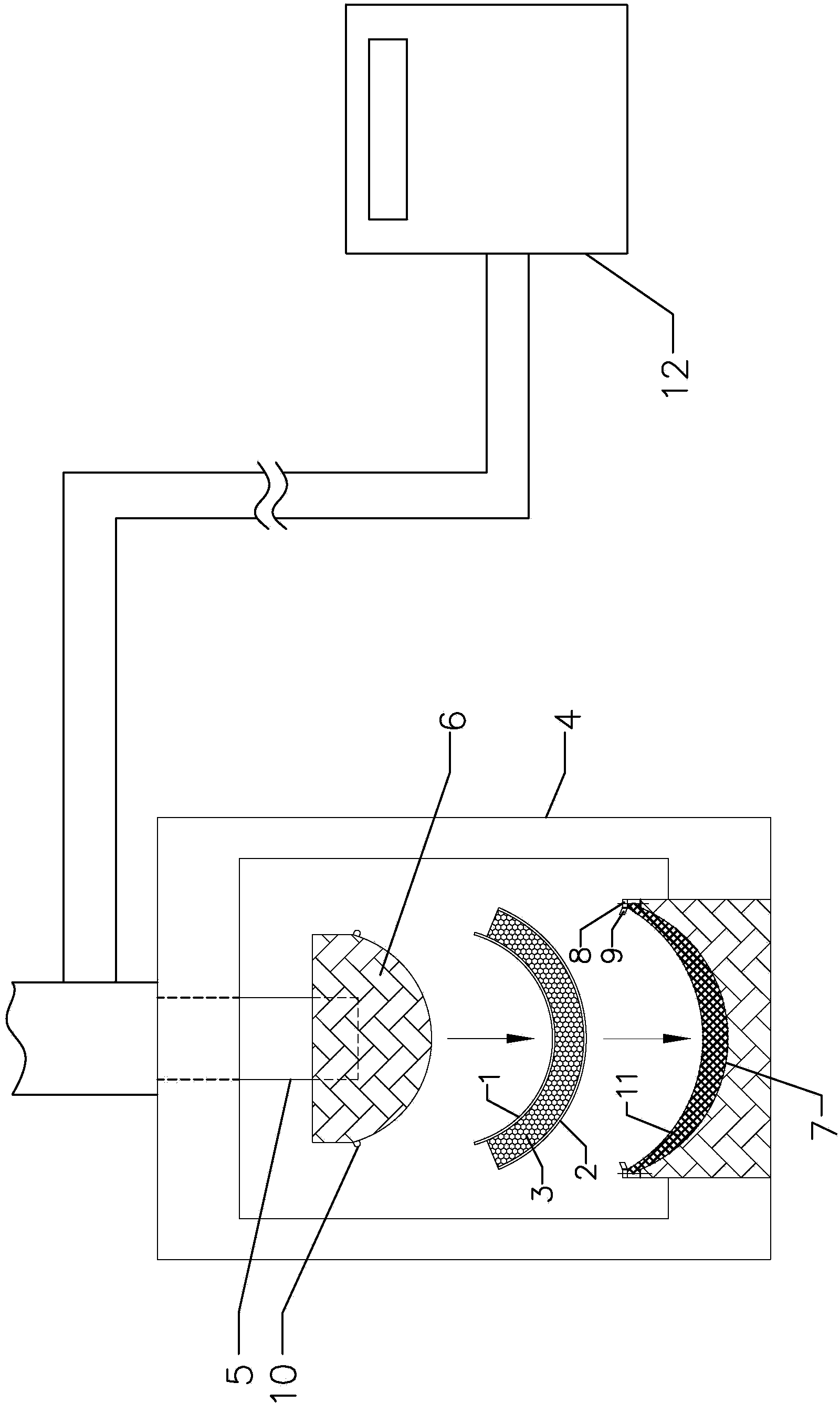

[0034] Such as figure 1 The arc-shaped structure insulation board processing device shown includes a pressing mechanism and a support seat, and the structure insulation board processed by this device is a multi-layer composite structure, including the upper layer 1, the lower layer 2 and the upper layer clamped 1 and the middle insulation core layer 3 between the lower layer 2;

[0035] The pressing mechanism comprises a support frame 4, a pressing straight rod 5 and a pressing head 6; the pressing straight rod 5 is a telescoping rod of a pneumatic cylinder or a hydraulic cylinder, and the pneumatic cylinder or hydraulic cylinder body is fixed on the support frame 4 upper ends; The pressing mechanism at the place can also be realized by other mechanisms capable of linearly driving the pressing straight bar 5 to press down;

[0036] Press down the straight bar 5 and extend vertically into the upper end surface of the support frame 4, and the lower pressing head 6 is fixed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com