Steel framework and modified ECC concrete slab composite fully-enclosed sound barrier

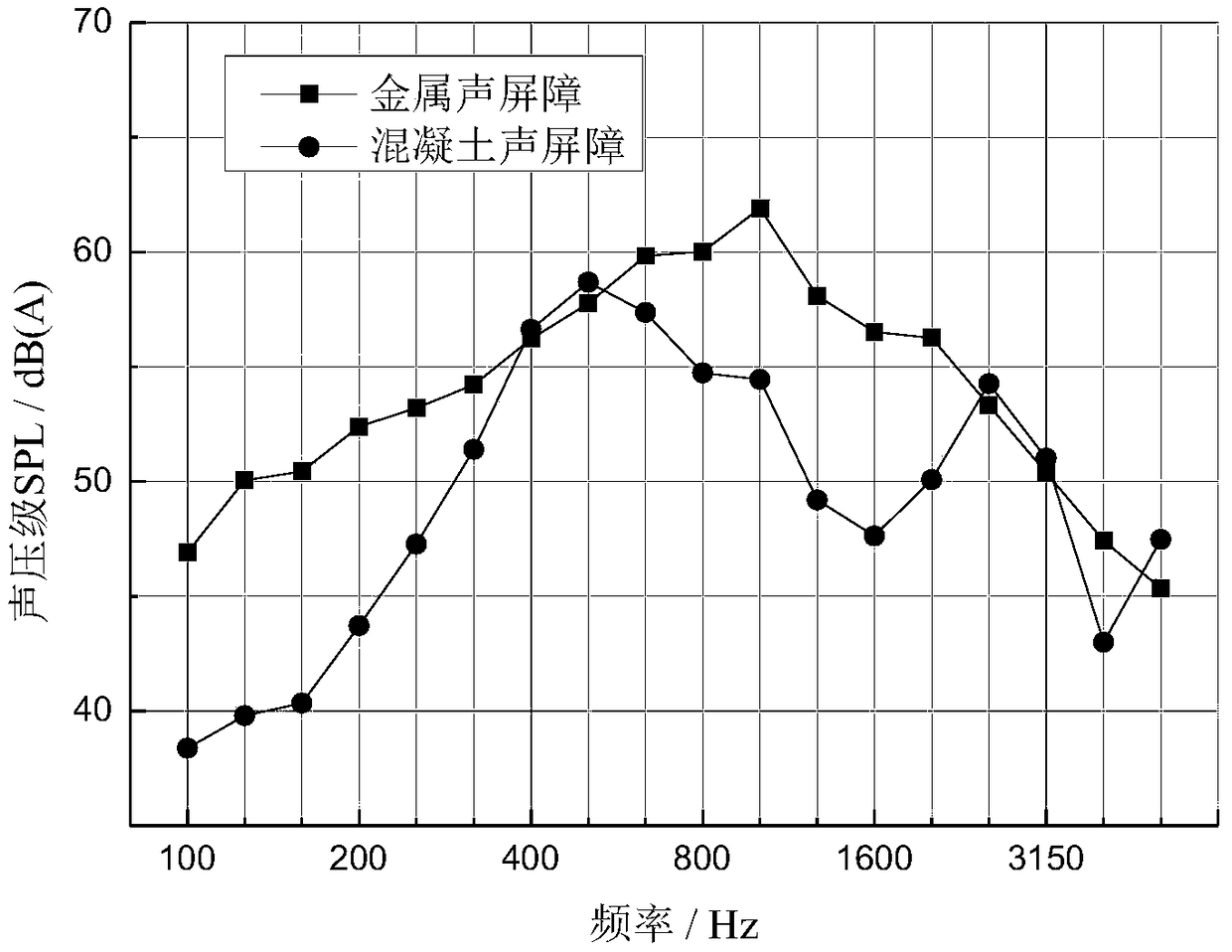

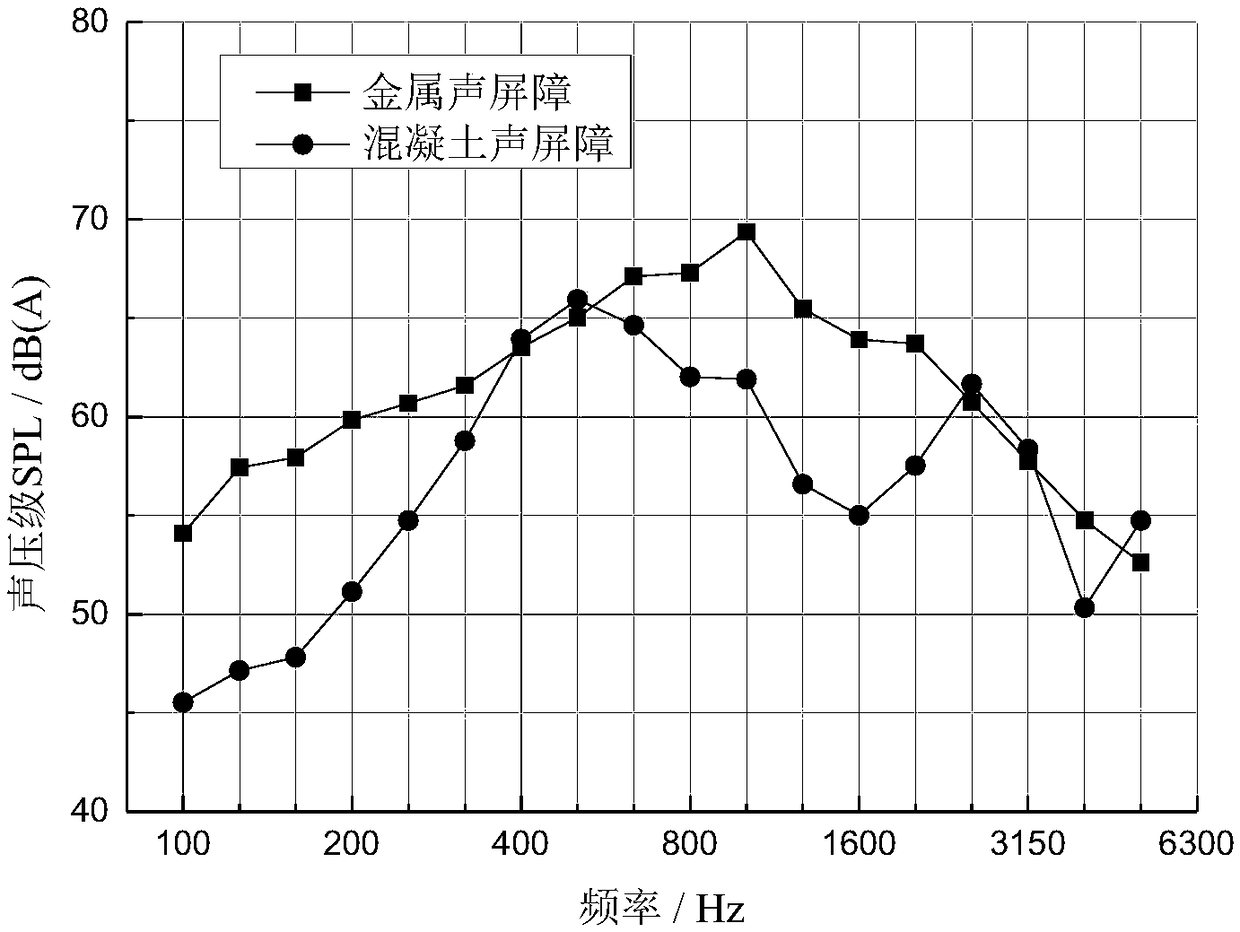

A technology of concrete slabs and steel skeletons is applied in noise absorption devices, climate change adaptation, construction, etc., and can solve problems such as economic losses, unsatisfactory noise reduction effects, and inability to better adapt to curved shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

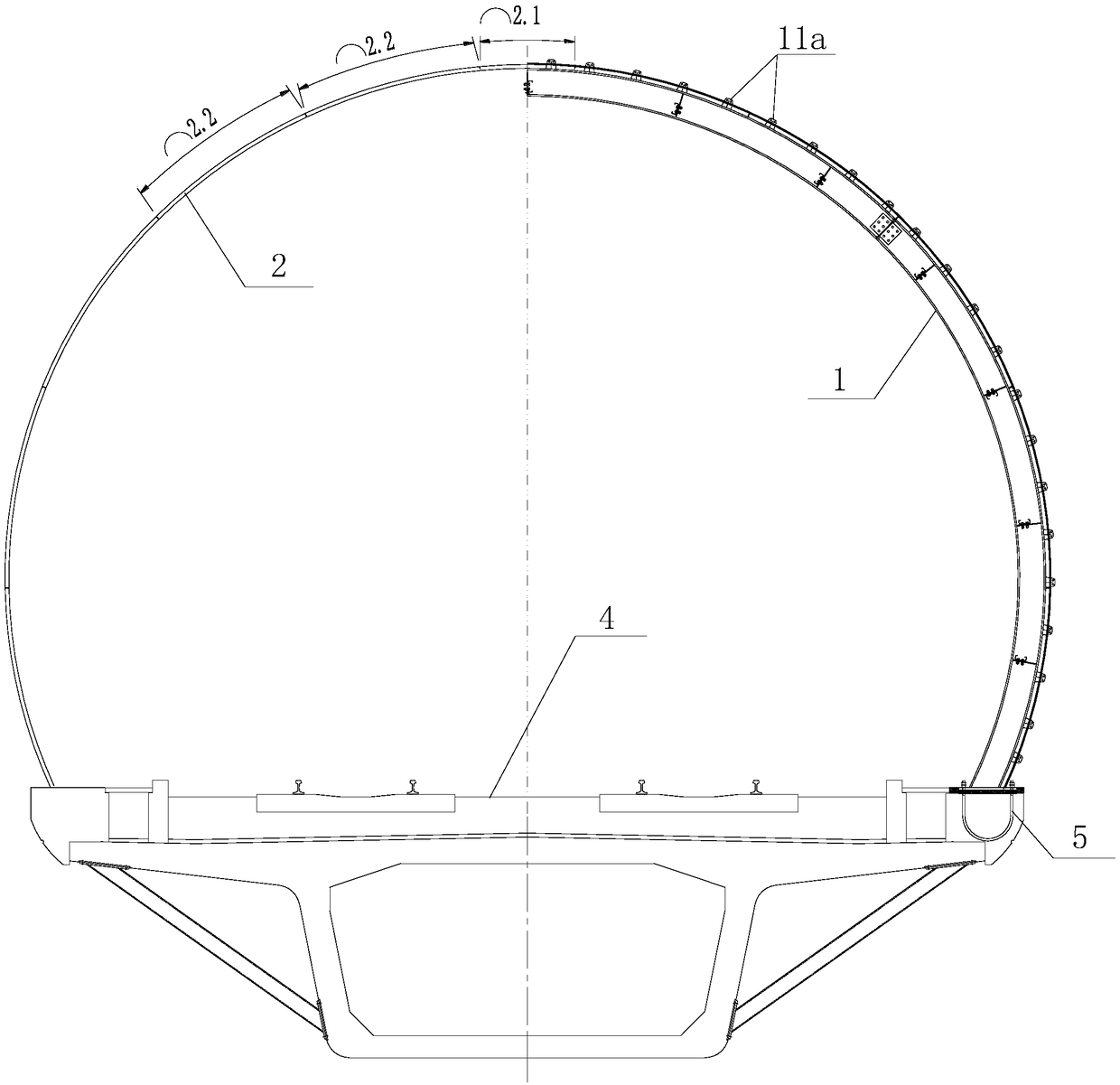

[0028] Embodiment: As shown in the figure, a fully enclosed sound barrier structure composed of a steel skeleton and a modified ECC concrete slab includes ring-shaped beams 1 spanning above the railway 4 and arranged at intervals along the longitudinal direction of the railway. The two sides of the railway 4 are provided with footnote embedded parts 5 , and the two ends of the beam 1 and the footnote embedded parts 5 are fixed by high-strength bolts 10 . A longitudinal beam 3 is arranged between the two adjacent beams 1, and an X-shaped support beam 9 is arranged in the unit cell formed by the cross beam 1 and the longitudinal beam 3, and the cross beam 1, the longitudinal beam 3 and the X-shaped support beam 9 Together they form a force-bearing skeleton. A cover plate 2 matching the radian of the outer surface of the beam 1 is provided on the force-bearing frame.

[0029] Wherein, the crossbeam 1 is spliced by a plurality of I-beams along the length direction, and the part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com