Patents

Literature

231results about How to "Avoid concentrated stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medicinal porous titanium implant and method for preparing same

InactiveCN101518467AAchieve long-term stabilityIncrease initiativeDental implantsImpression capsStress concentrationMicrosphere

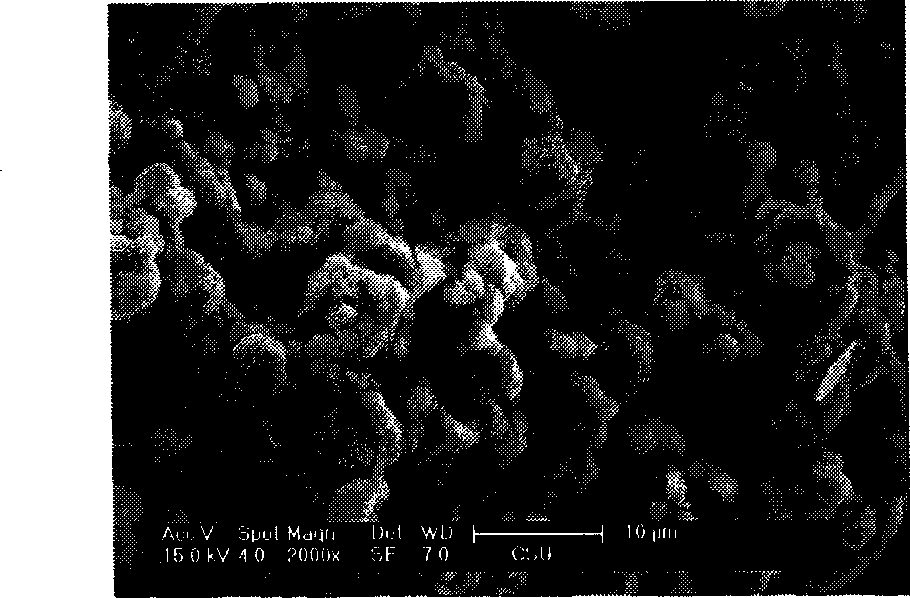

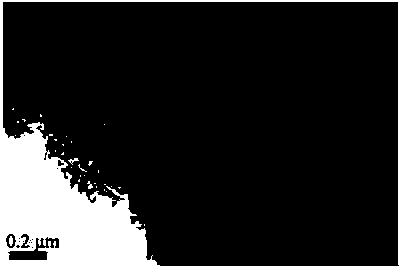

The invention discloses a medicinal porous titanium implant and a method for preparing the same. The porous titanium implant is prepared by a powder coinjection molding method; and a nano HA and TGF loaded sustained-release gelatin microsphere compound coating is deposited on the porous outer layer of the product. The outer layer of the implant has a communicated porous structure, the thickness of the porous layer is 0.4 to 1.1 millimeters, the porosity of the porous layer is 50 to 70 percent, and the aperture of the porous layer is 50 to 400 mum; the surface of the porous layer is deposited; and the binding strength of the outer layer and an inner core is 150 to 300MPa. Compared with the prior medicinal titanium implant material, the material of the medicinal porous titanium implant has higher mechanical strength, is in accordance with the mechanical performance of osseous tissue, avoids stress concentration and stress shielding, promotes stress transmission and growth of new bones, reduces time for osseointegration, and ensures the long-term stability of the implant. The method adopts once-for-all molding without post machining, thereby considerably reducing the cost.

Owner:CENT SOUTH UNIV

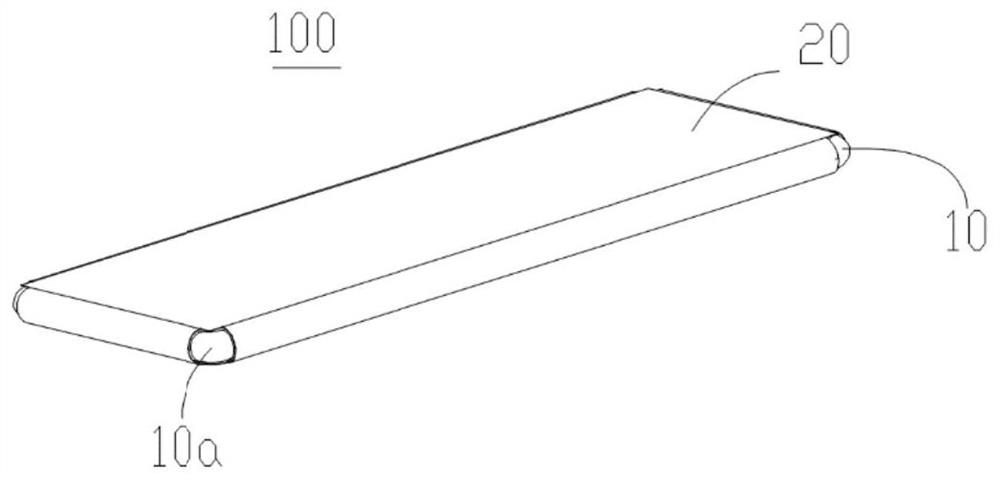

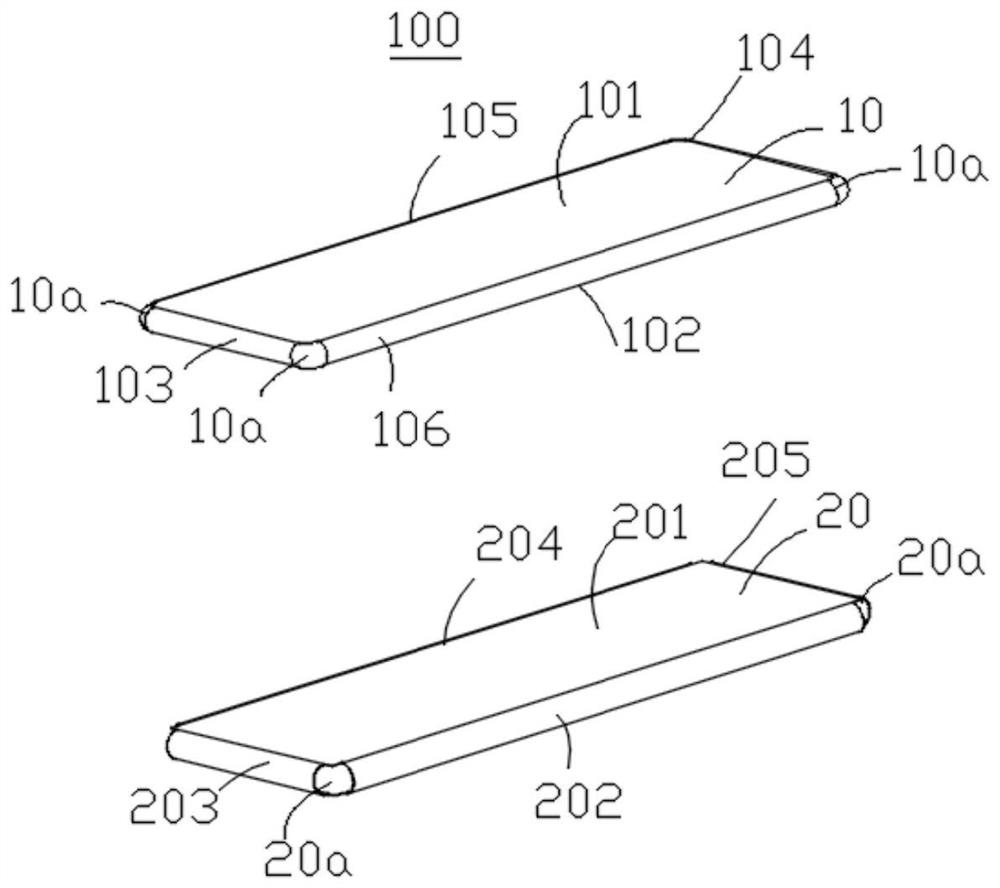

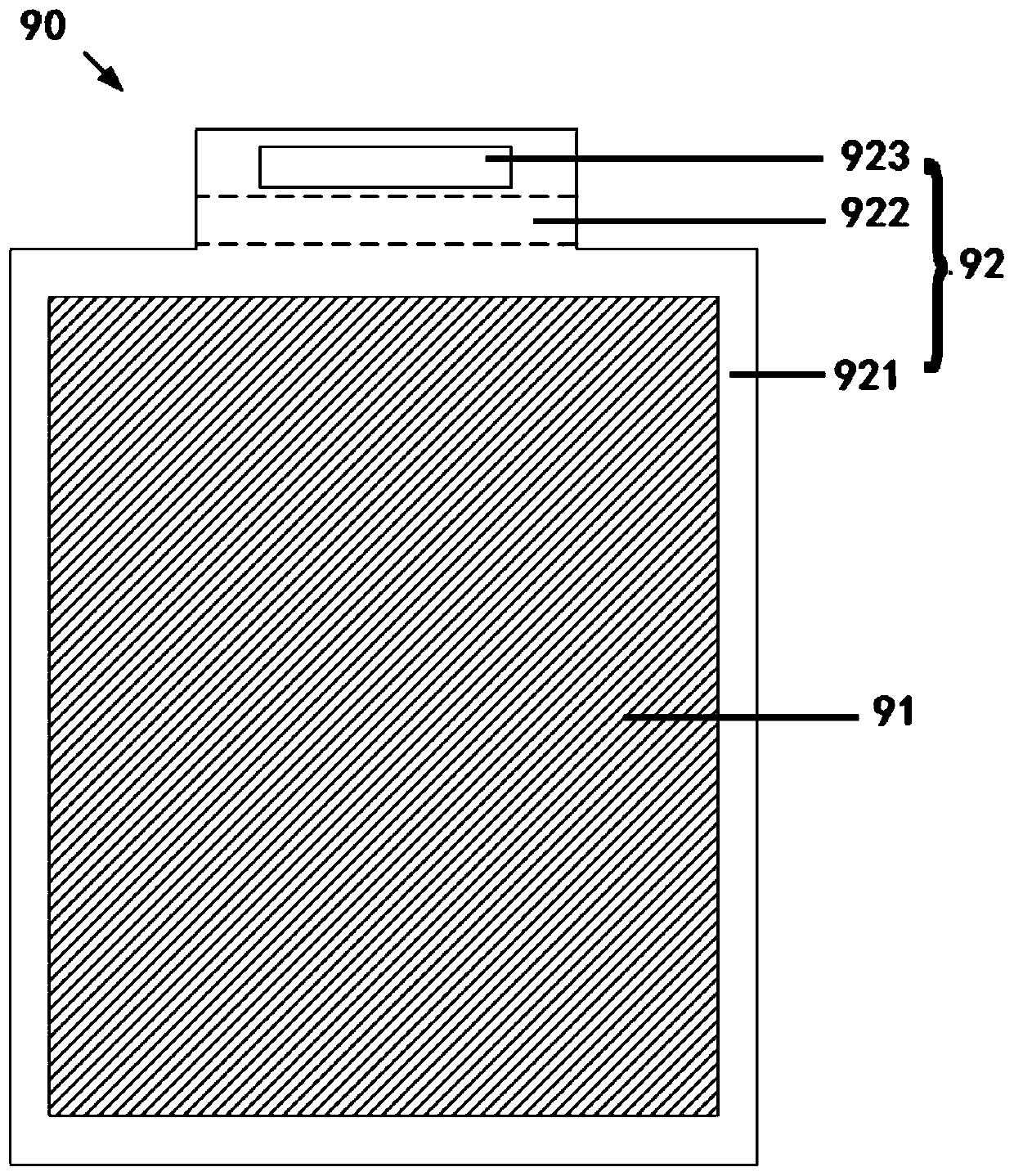

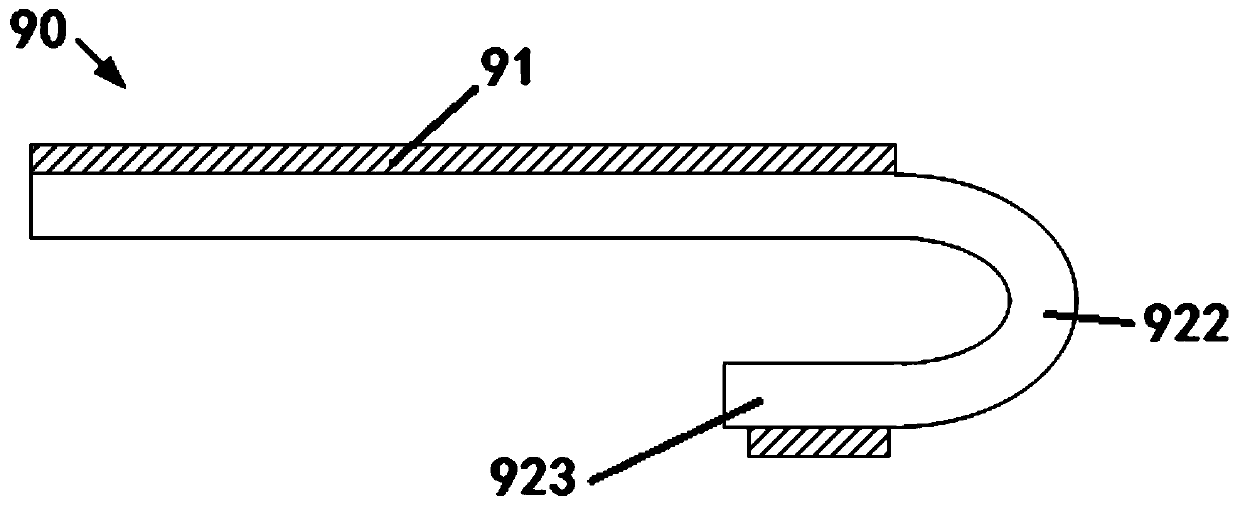

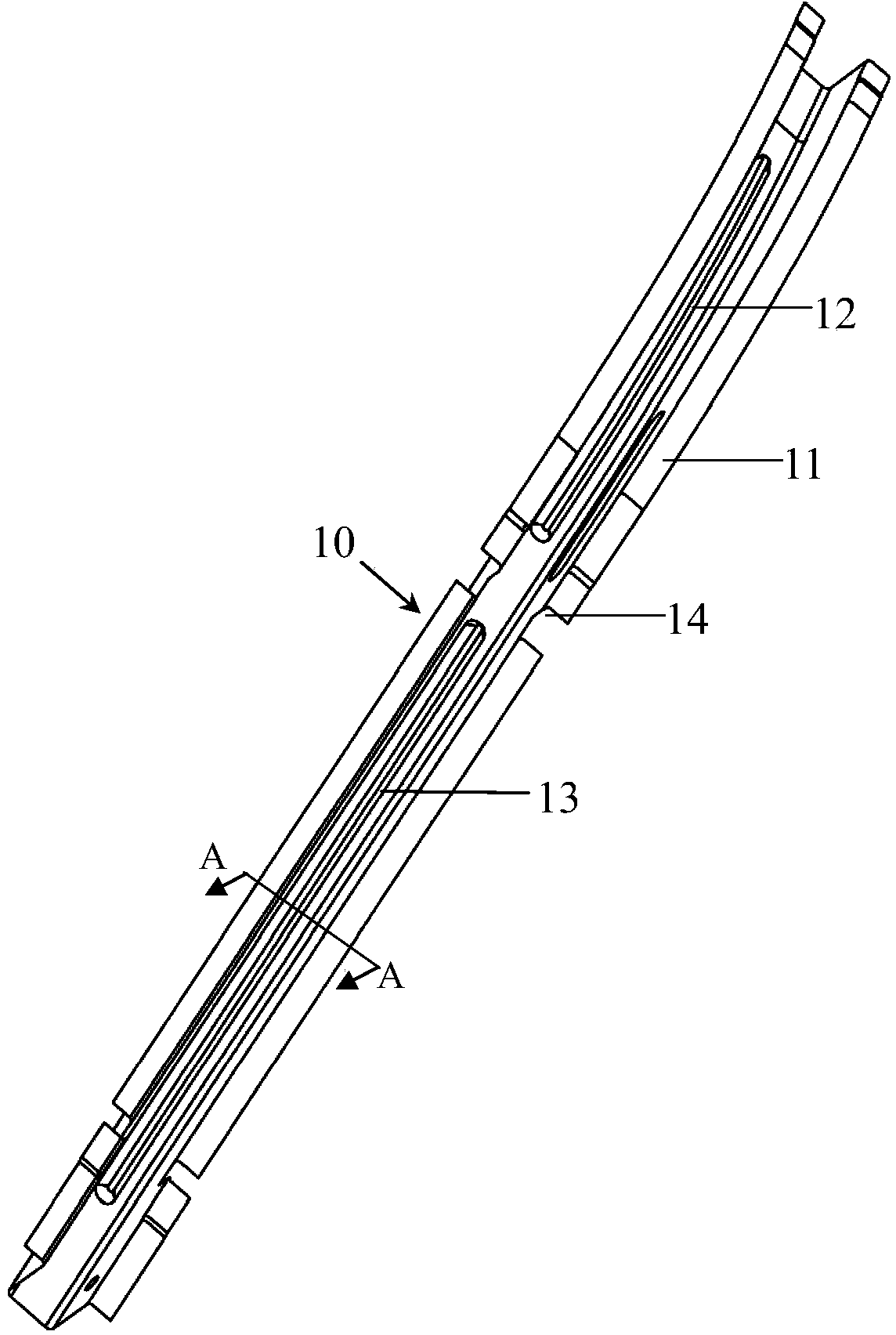

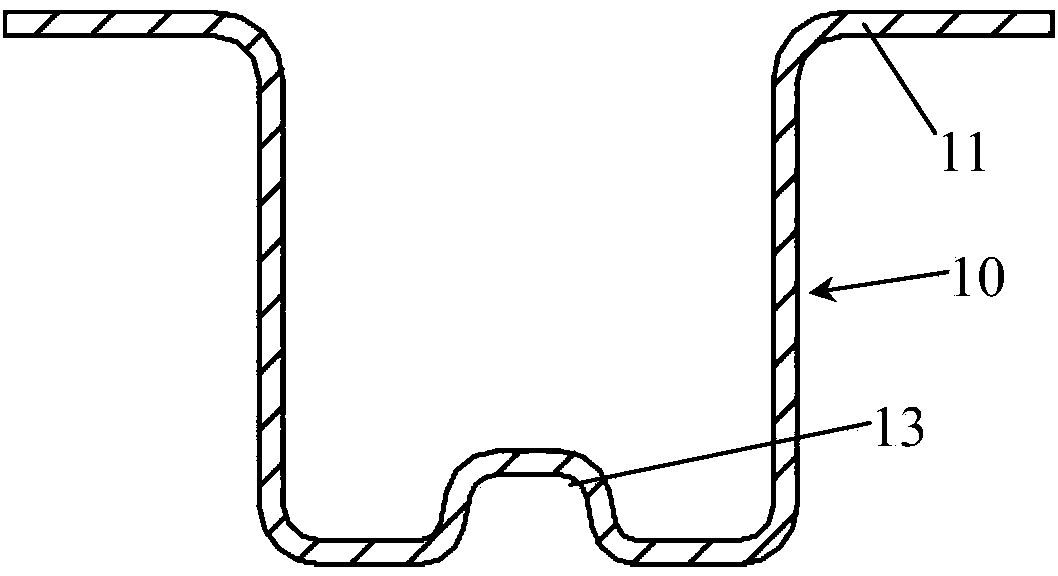

Foldable supporting structure and display device

ActiveCN110853510AAvoid concentrated stressDigital data processing detailsCasings with display/control unitsDisplay deviceStructural engineering

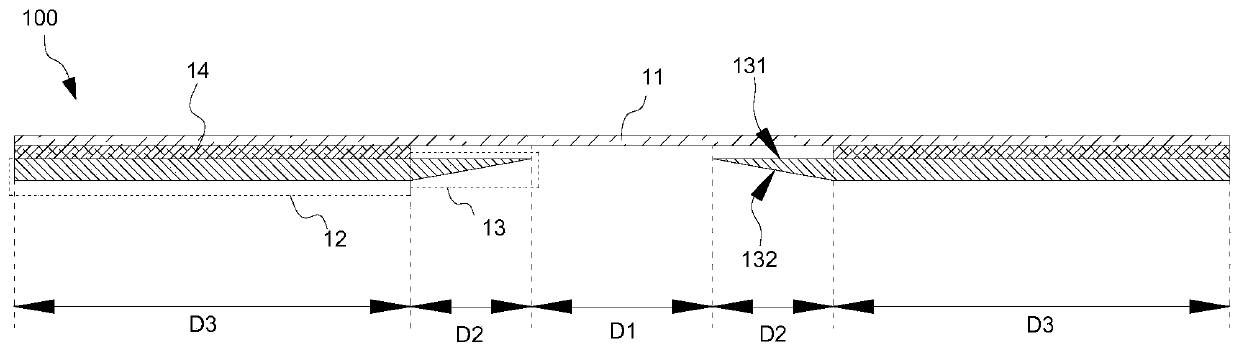

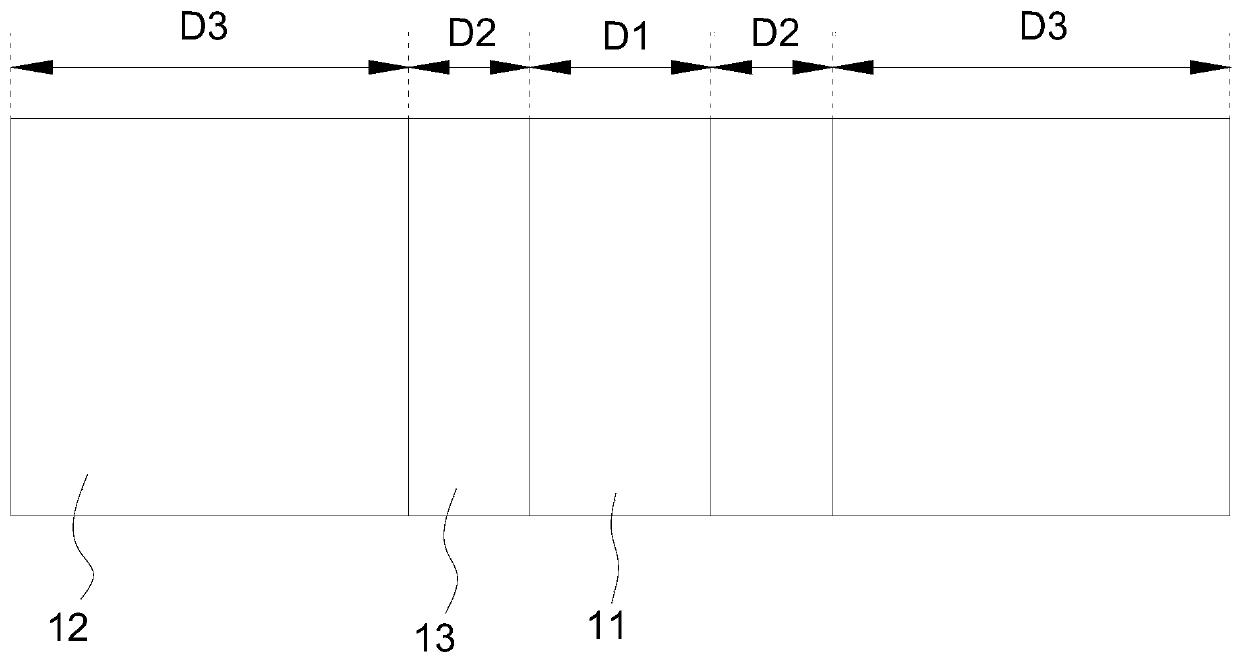

The application provides a foldable supporting structure and a flexible display device. The supporting structure comprises a flexible substrate, first supporting parts and second supporting parts; theflexible substrate is used for arranging an external to-be-folded object; the side, back on to the to-be-folded object, of the flexible substrate comprises a bending area, transition areas and non-bending areas; the non-bending areas are located on two sides of the bending area, and the bending area and the non-bending areas are connected through the transition areas; the first supporting parts are fixedly arranged in the non-bending areas; the second supporting parts are arranged in the transition areas and connected with the first supporting parts; and the thickness of the second supportingparts is decreased progressively from the ends close to the non-bending areas to the ends close to the bending areas. Through the arrangement that the thickness of the second supporting parts is gradually reduced, when the flexible substrate and the external to-be-folded object arranged on the flexible substrate are folded, smooth transition can be achieved to form a standard drop-shaped structure in the bending area and the transition areas.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

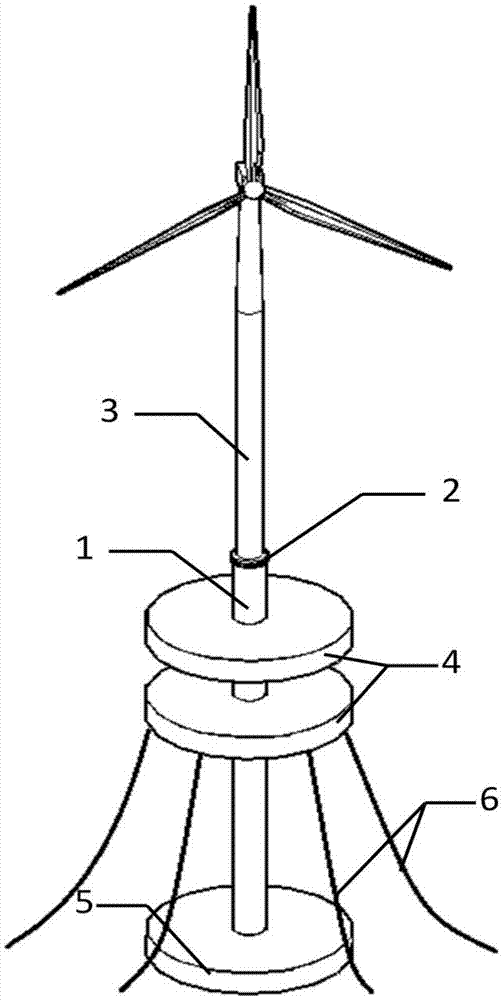

Offshore wind power spar buoyant foundation capable of towing

ActiveCN105438411AReduce resistanceSkip the dry mopping processFoundation engineeringFloating buildingsStress concentrationFatigue damage

The invention relates to an offshore wind power buoyant foundation form and in particular relates to an offshore wind power spar buoyant foundation capable of towing, which comprises a connecting column and is characterized in that the upper end of the connecting column is connected with a fan through a flange ring, a plurality of flat columnar closed air flotation boxes are arranged at the middle part of the connecting column, the closed air flotation boxes are not communicated with the connecting column, and the bottom of the connecting column is communicated with a loading cabin; a column body of the connecting column is provided with a detachable gear required for towing; and a mooring rope is arranged at the center of gravity of the buoyant foundation. Compared with the prior art, the offshore wind power spar buoyant foundation provided by the invention has the beneficial effects that the construction is convenient, rolling towage can be realized, the resistance of a wave flow is reduced, the stress concentration and fatigue damage caused by the traditional spar foundation in a wet towing process are avoided, the construction difficulty and construction cost are greatly reduced, and the offshore wind power spar buoyant foundation can be recycled. The additional mass and viscous damping of heave motion are effectively improved by virtue of the flat air flotation boxes, the water surface profile area of a buoy is effectively increased by virtue of the flat air flotation boxes on the water surface, a relatively large restoring moment is provided, the structure stability is relatively good, the center of gravity is lower than the center of flotation, and the resistance to capsizing is good.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

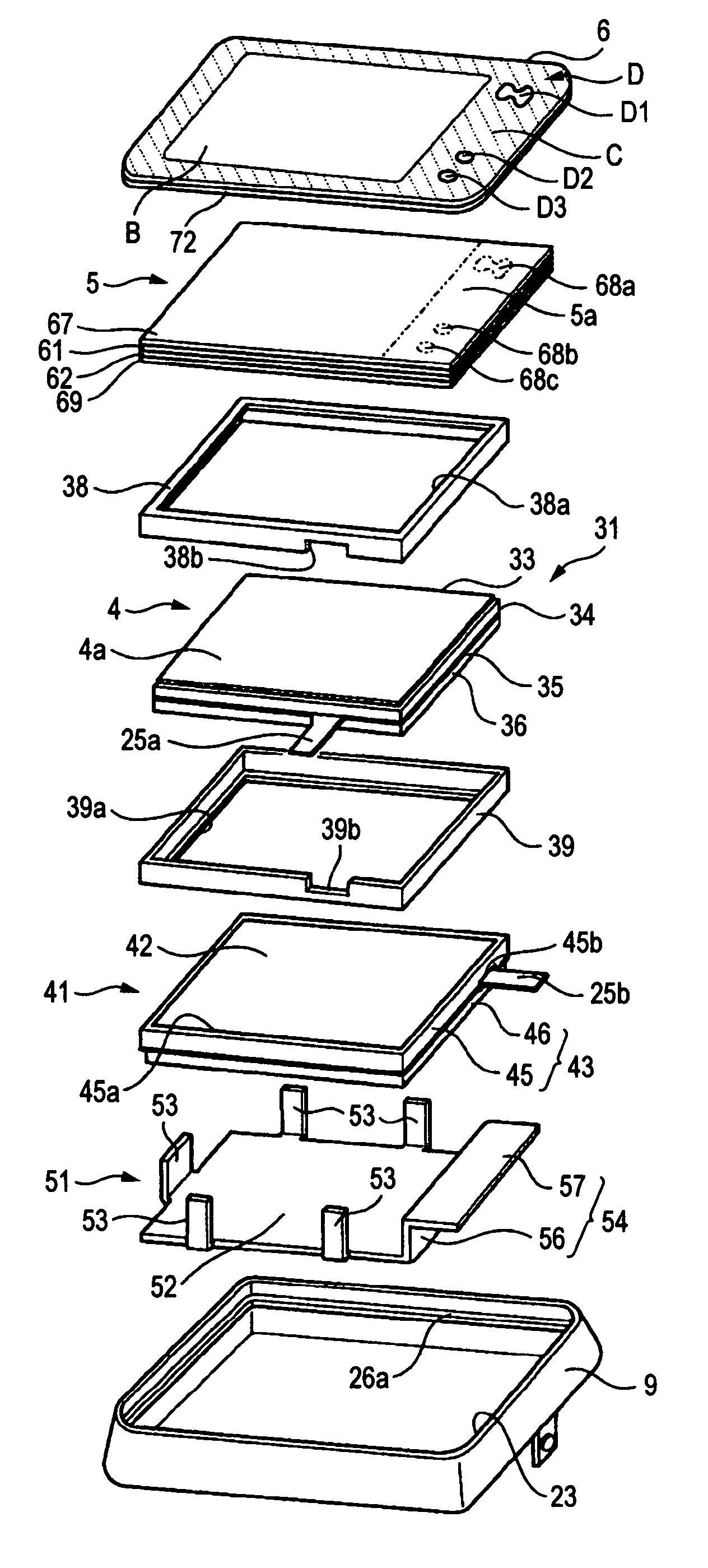

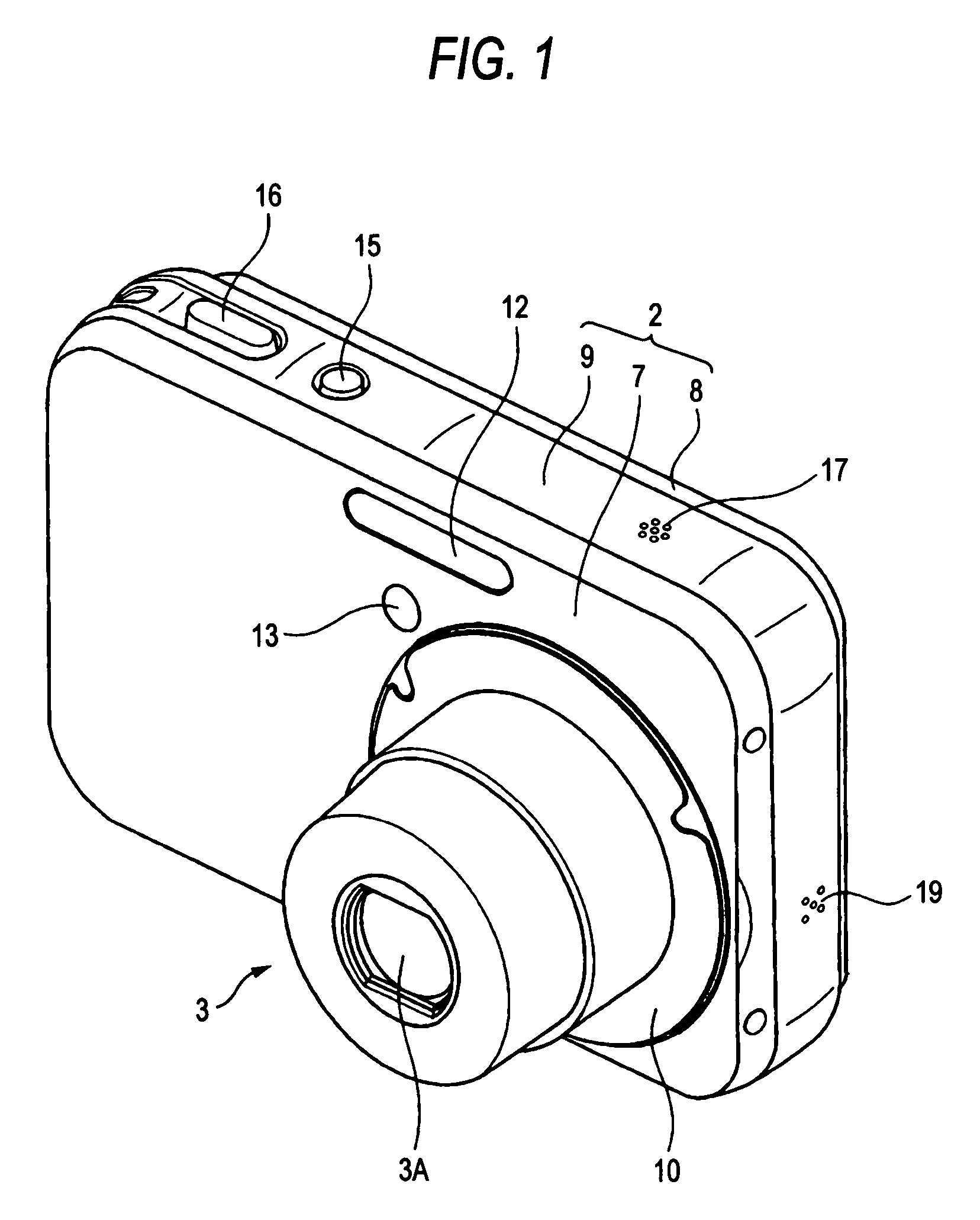

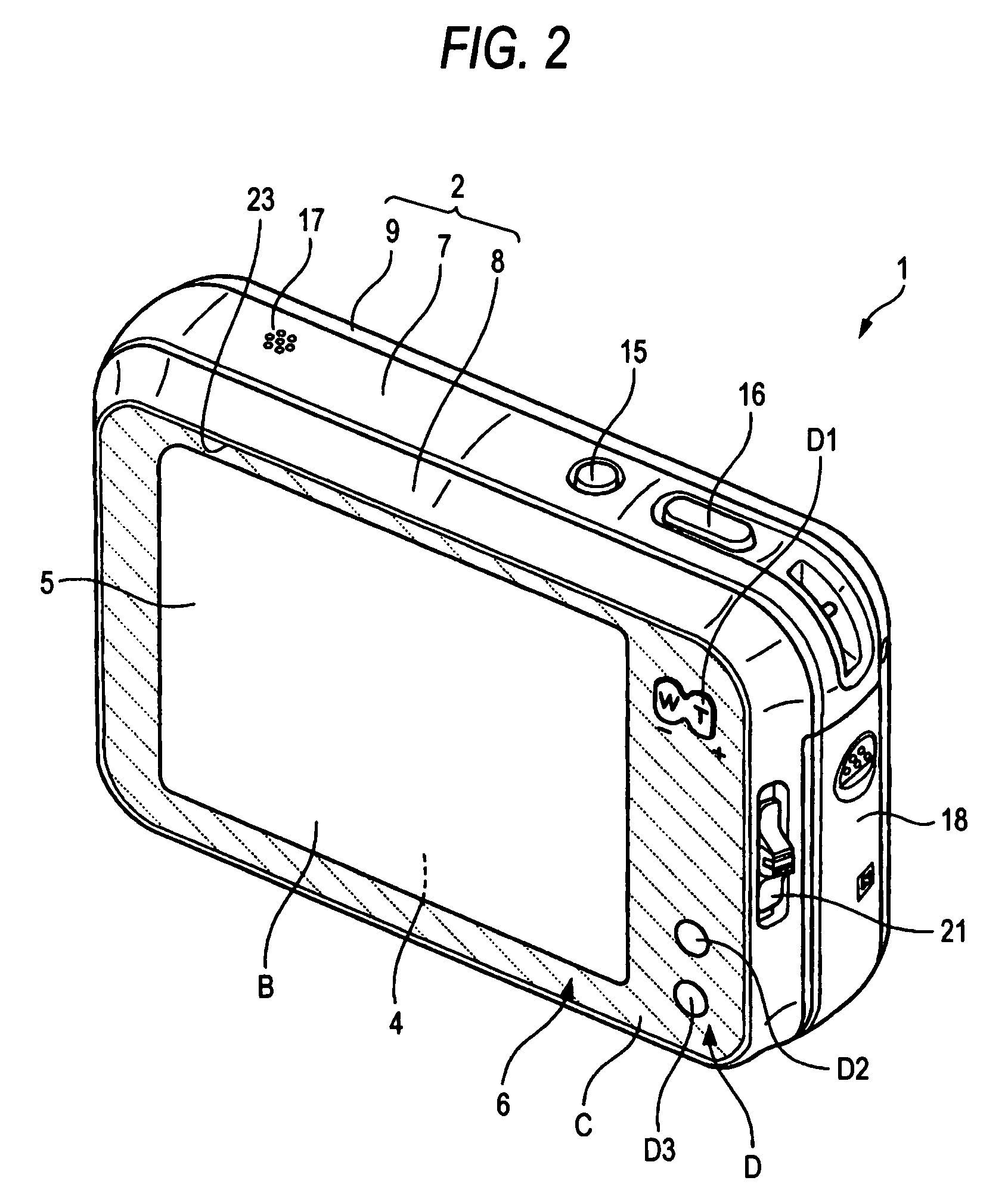

Display device equipped with a touch panel

InactiveUS8749492B2Fine surfaceImprove visual qualityCasings/cabinets/drawers detailsFixed capacitor terminalsDisplay boardTouchpad

A display device equipped with a touch panel may include a device chassis provided with an opening section, a display panel having a display surface disposed accessible through the opening section, a touch panel disposed on the display surface of the display panel and capable at least of selecting a function displayed on the display surface in response to a pressing operation on the touch panel, and a surface sheet for covering the touch panel on the opposite side to the display panel, and closing the opening section to form a substantially the same surface with the device chassis, wherein a reinforcing area for improving resistivity against pressing force applied from the outside may be provided in a predetermined range of the surface sheet.

Owner:SONY CORP

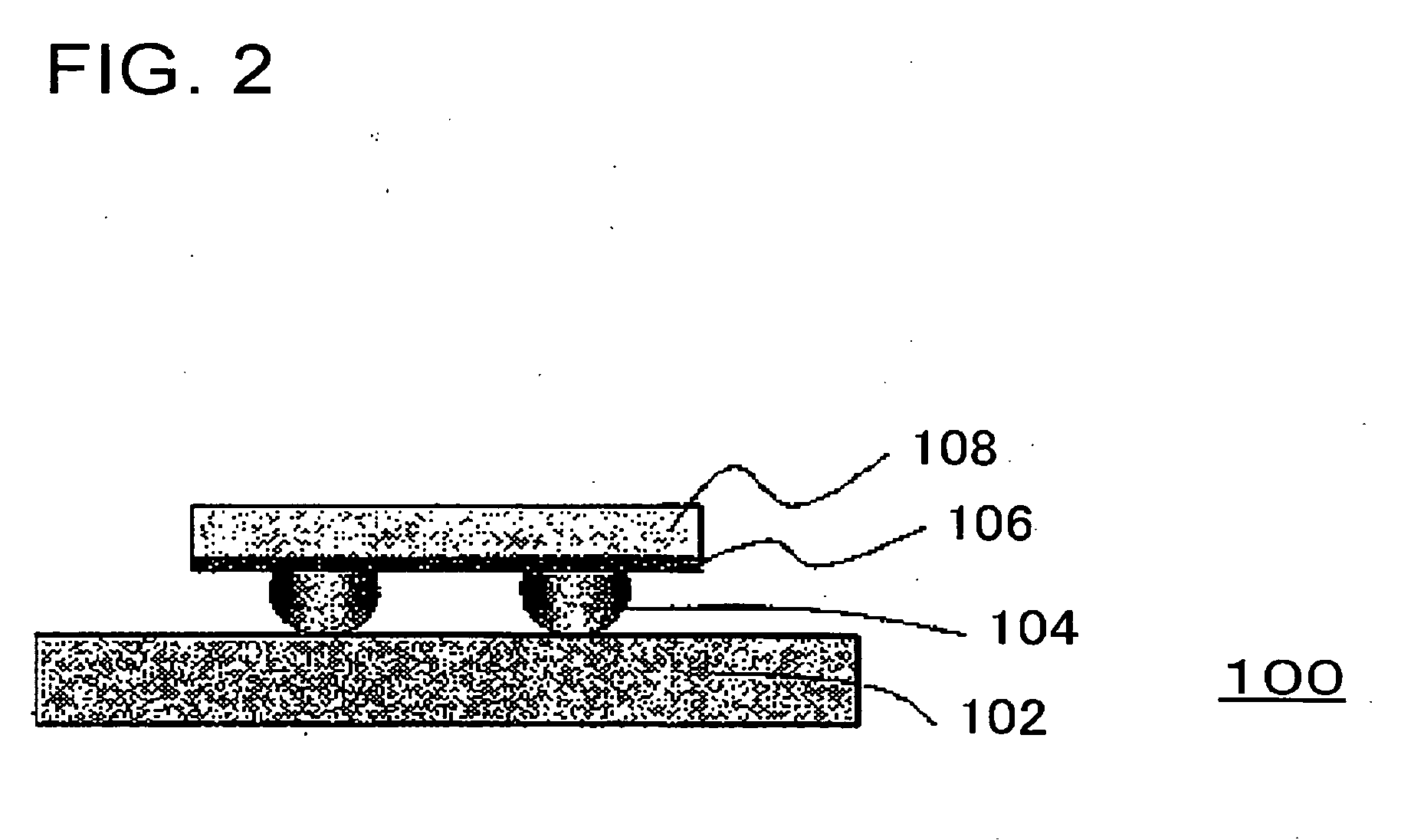

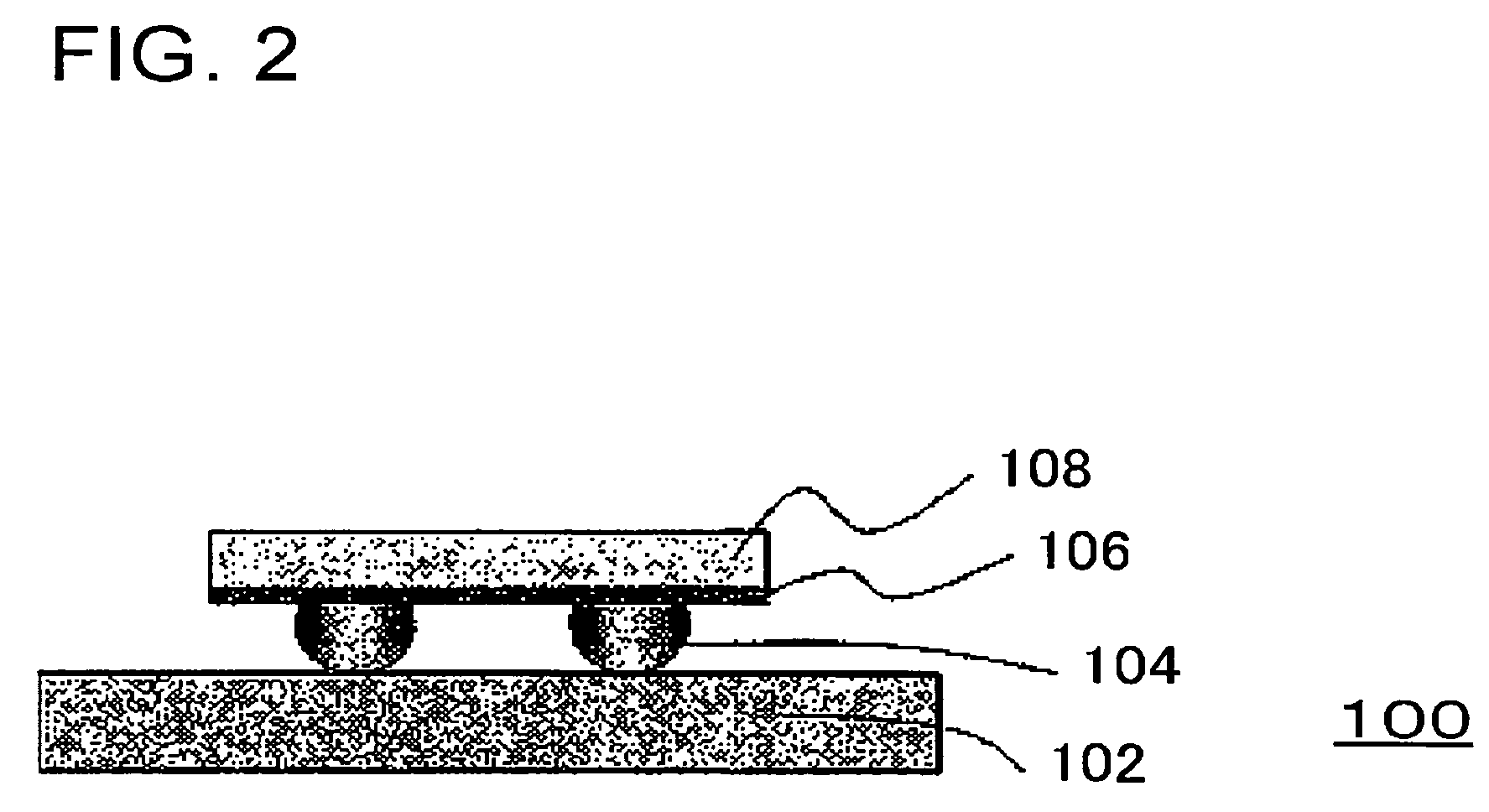

Semiconductor device

ActiveUS20060278984A1Reduce thermal stressReduce stress levelSemiconductor/solid-state device detailsSolid-state devicesAluminum electrodeDevice material

The present invention provides a semiconductor device exhibiting an improved reliability. A semiconductor device comprises a semiconductor chip having an electrode on a surface thereof and a mounting substrate, and the electrode (aluminum electrode) of the semiconductor chip is coupled to the mounting substrate through a bump (solder bump 104). A plurality of diffusion barrier films (UBM 112) for preventing a diffusion of a material composing the bump is provided between the electrode and the bump, and the diffusion barrier film is formed to have a plurality of divided portions via spacings therebetween.

Owner:RENESAS ELECTRONICS CORP

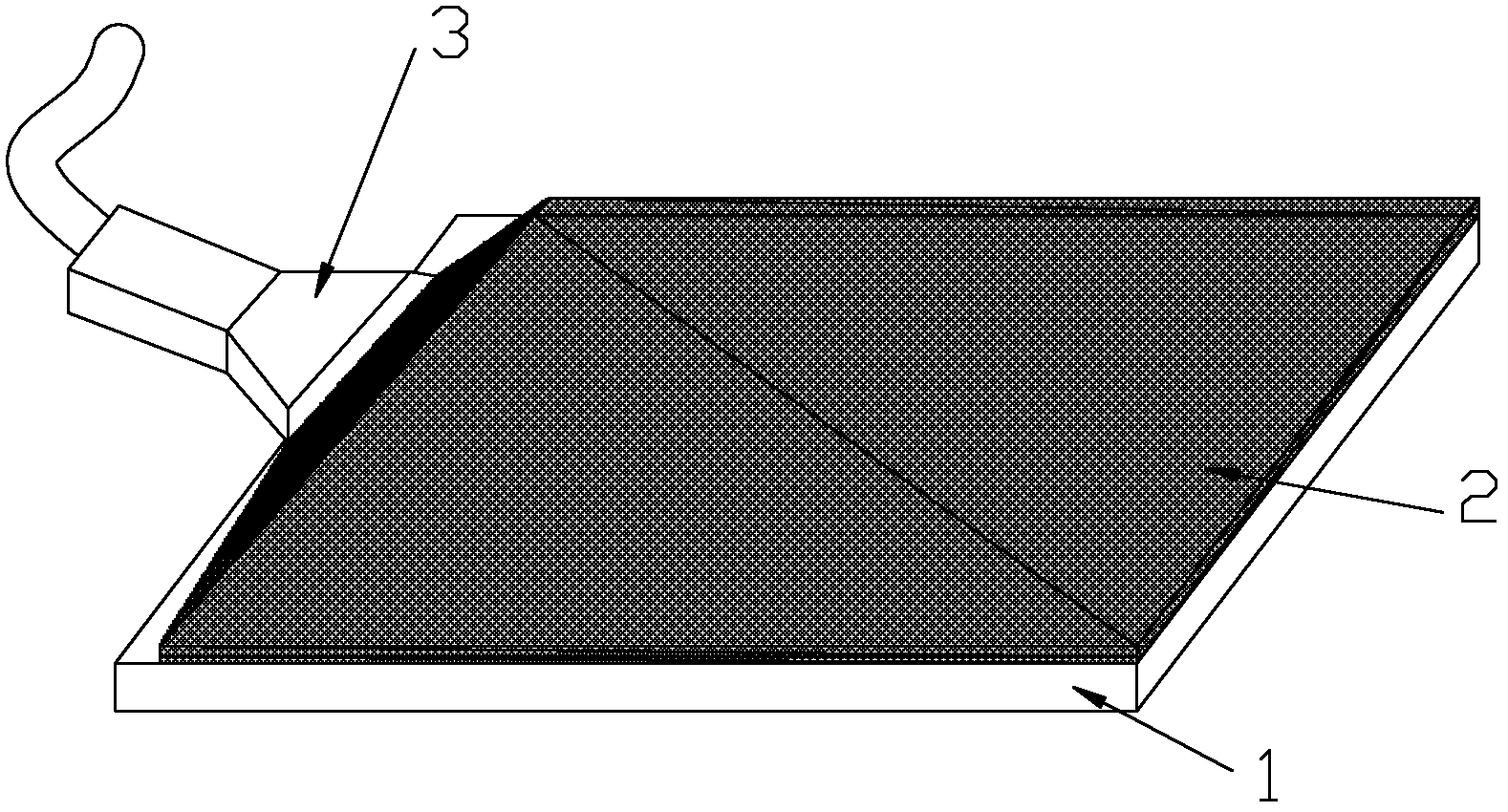

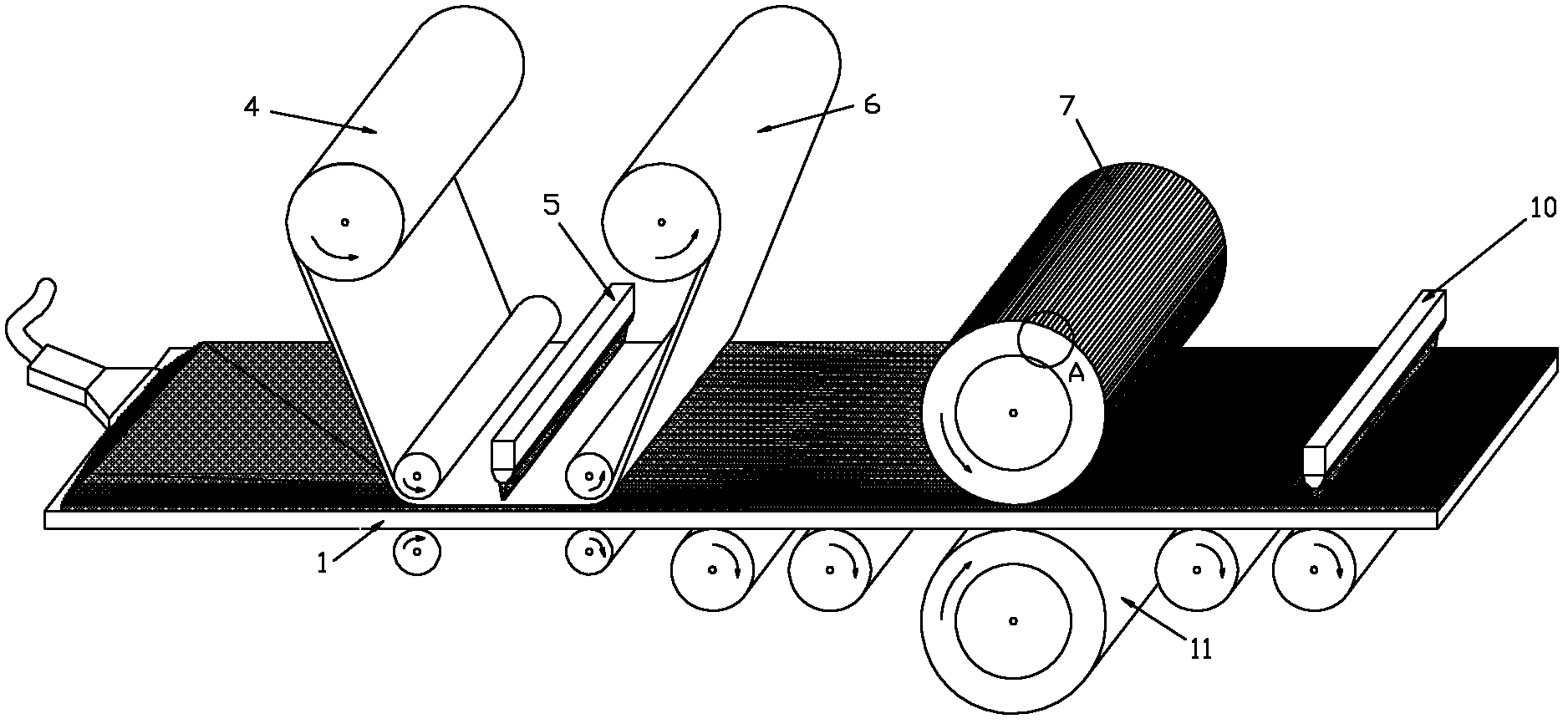

Method for forming grating for machine tool measurement in two-step solidifying rolling pressing forming manner

ActiveCN102193310ALow costIncrease productivityDiffraction gratingsPhotomechanical exposure apparatusStress concentrationGrating

The invention relates to a method for forming a grating for machine tool measurement in a two-step solidifying rolling pressing forming manner, which comprises the following steps: 1) coating an ultraviolet light solidifying adhesive layer on a grating blank substrate; 2) manufacturing a rolling mould having a prototype grating structure on the surface of a cylindrical mould, making an alignment mark, and polishing and performing low surface energy treatment on the surface of the rolling mould; 3) coating a flexible film on the adhesive layer on the grating blank substrate, carrying out primary exposure and peeling the film; 4) comparing the alignment mark on the grating blank substrate with an acquired alignment mark image on the surface of the rolling mould, adjusting and calibrating; 5) gluing the rolling mould with the grating, applying a pressing force, and compounding the prototype grating structure on the surface of rolling mould on the adhesive layer on the surface of the substrate; 6) carrying out exposure on the compounded ultraviolet light solidifying adhesive layer; and 7) collecting and packaging the grating. According to the method, the required pressing force is small, and thus, the substrate deformation and stress concentration are avoided. The method has high production efficiency and can be used for realizing the mass production of the grating for large-area and altitude machine tool measurement.

Owner:XI AN JIAOTONG UNIV

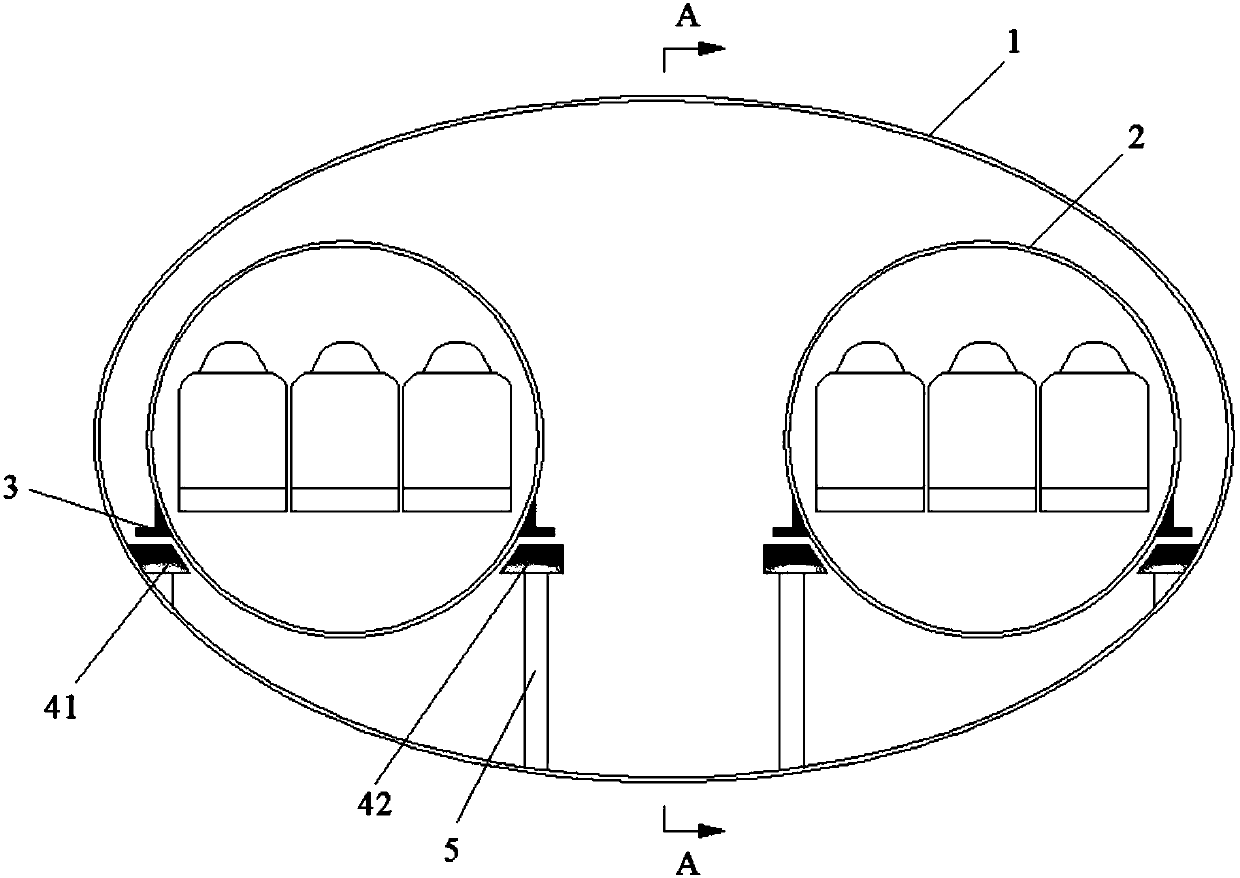

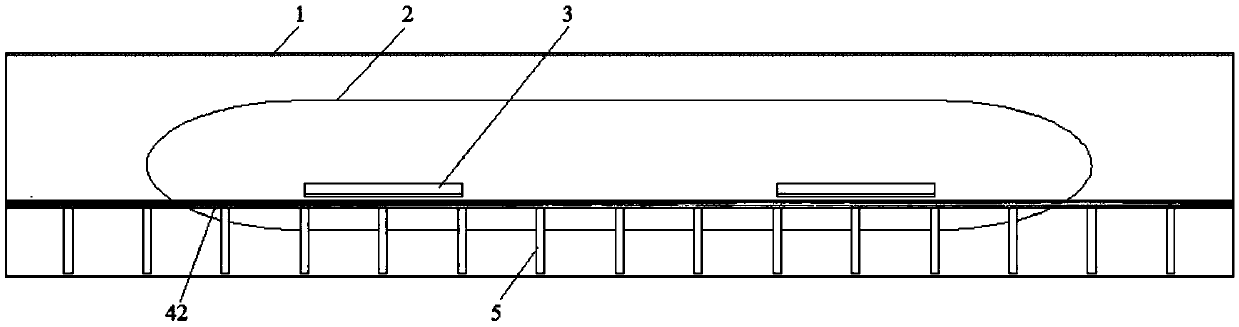

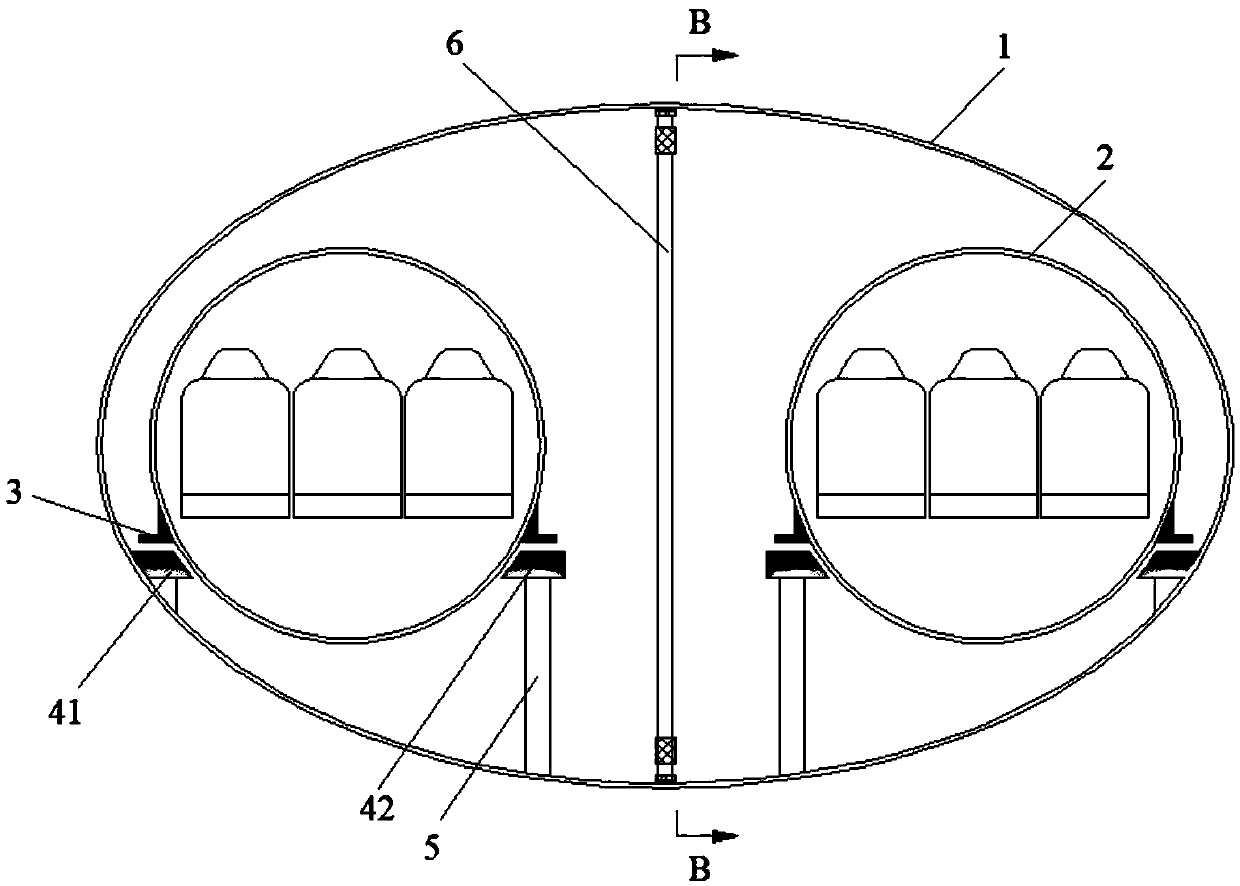

Oval single-tube two-way vacuum pipeline traffic system

An oval single-tube two-way vacuum pipeline traffic system comprises an oval pipeline. The oval pipeline is internally provided with a two-way travelling vehicle, vehicle upward suspension magnetic poles are arranged on the two sides of the travelling vehicle and matched with an outer suspension track and an inner suspension track correspondingly, and the outer suspension track is connected to theinner wall of the oval pipeline. The inner suspension track is supported on the inner wall of the oval pipeline through a track first support. A support rod is arranged at the position of a short shaft of the oval section of the oval pipeline, a semi-oval groove-shaped support seat is arranged along the exterior of the oval pipeline, and tight-pushing clamps are arranged on the position, on the horizontal positions of the two sides of the exterior of the pipeline, of the upper portion of the groove-shaped support seat along the long axis of the section of the oval pipeline. Adjusting and fixing are conducted through adjusting bolts. As for a vehicle with the same section, the blockage ratio in two-way double pipelines is slightly decreased, and the train travelling pneumatic resistance isreduced; and pipeline manufacturing materials are reduced, the pipeline erecting work procedure is reduced, the cost is reduced, the effective clearance in the pipeline is greatly increased, and mounting, examining and maintaining are conveniently facilitated.

Owner:BEIJING JIUZHOU ARTERY TUNNEL TECH CO LTD

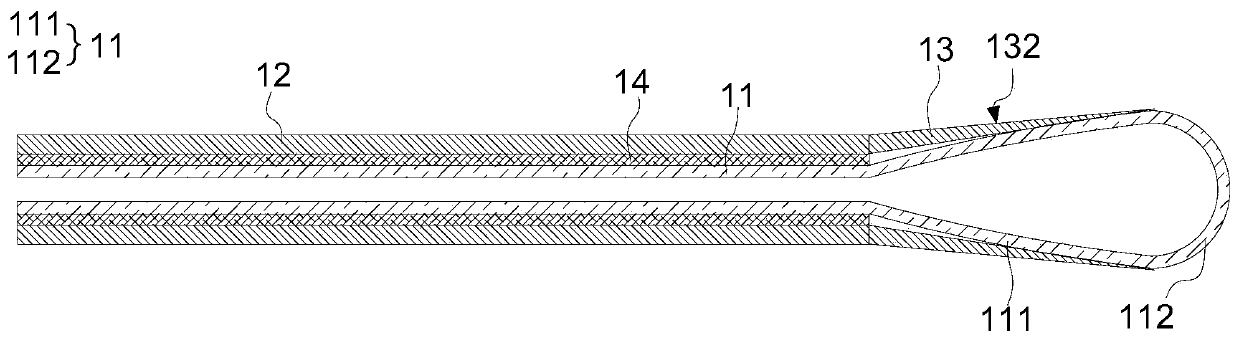

Low-loss large-effective-area fiber and preparation technology therefor

ActiveCN106125192AImprove roundnessIncrease the effective areaGlass optical fibreOptical fibre with multilayer core/claddingRelative refractive indexLength wave

The invention relates to a low-loss large-effective-area fiber and a preparation technology therefor. The low-loss large-effective-area fiber comprises a core layer, wrapping layers and coating layers from inside to outside in sequence. The core layer is a pure silica glass layer with the radius of 5-7 [mu]m. An inner wrapping layer is a fluorine-doped inner wrapping layer with the radius r2 of 5-12 [mu]m and the relative refractive index difference of from -0.4% to -0.2%. The radius r3 of a middle wrapping layer is 12-25 [mu]m. An outer layer is a pure quartz glass layer with the radius r4 of 25-45 [mu]m. The coating layers adopt polyacrylate and comprise an inner coating layer and an outer coating layer, the diameter of the inner coating layer is 192 [mu]m, and the diameter of the outer coating layer is 245 [mu]m. The preparation technology comprises a perform rod preparation process, a fiber fusion annealing process and a fiber drawing and curing process. The fiber provided by the invention is advantaged in that comprehensive properties such as cut-off wavelength, bending loss and dispersion are good in an application waveband; the fiber can be used in long-distance fiber communication by crossing bad conditions of gobi, deep sea and the like; the roundness of each layer of the fiber is good, so that the appearance is enabled to be round; and the strain of the fiber can reach 2% or more.

Owner:ZHONGTIAN TECH FIBER OPTICS +2

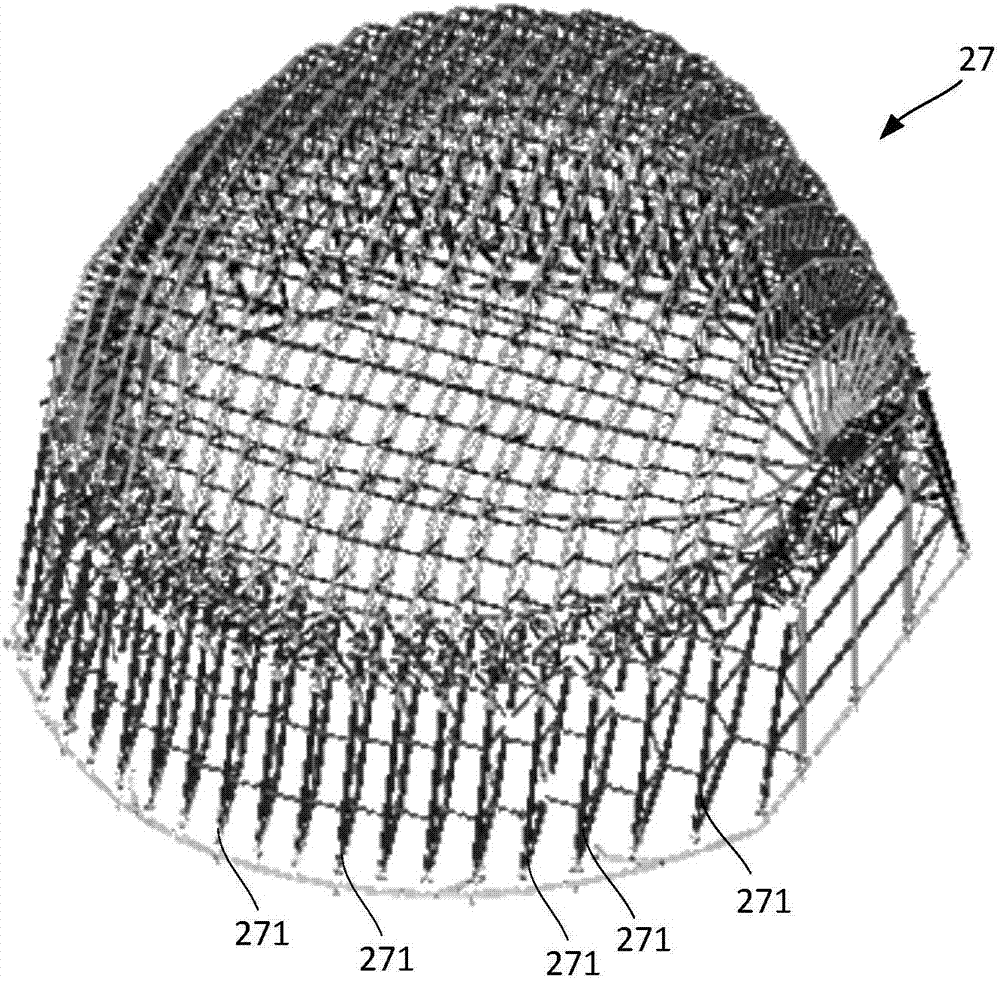

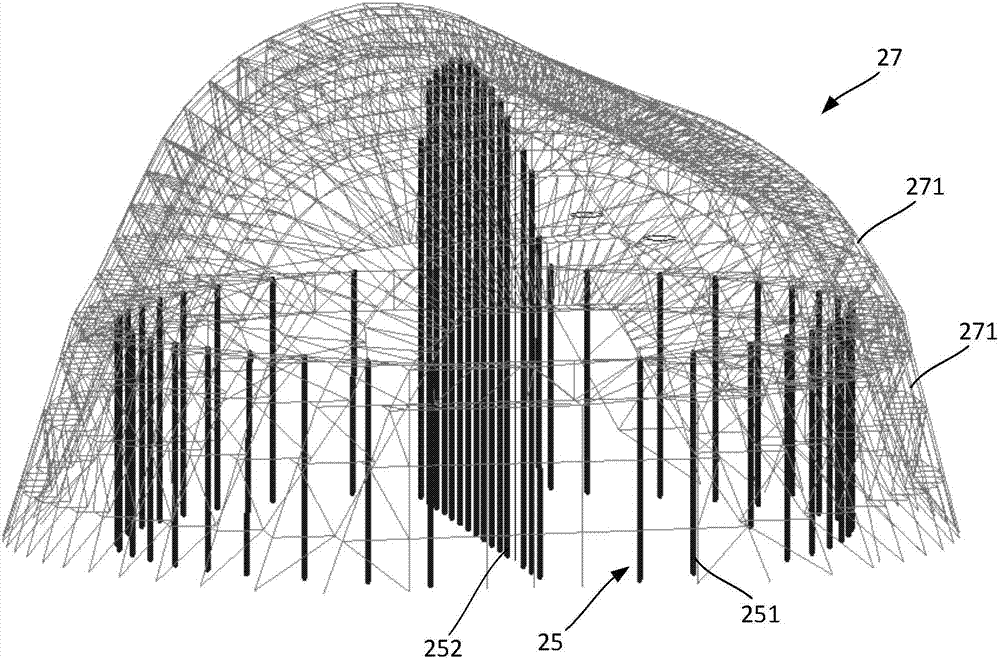

Construction method of large-span thin wall planar arch truss based on stiffened ring beam

ActiveCN107090932AAvoid uniformityAvoid concentrated stressBuilding roofsGirdersForce structureStress concentration

The invention relates to a construction method of a large-span thin wall planar arch truss based on a stiffened ring beam. The construction method comprises the steps: constructing an annularly closed ring beam foundation at the top of a main body structure; mounting a support seat on the ring beam foundation; arranging a support system at the top of the main body structure; arranging a single arch truss with an irregularly shape in the local area subsidence; forming multi-section truss units by segmenting the single arch truss; mounting the truss units two-symmetrically from bottom to top; connecting the adjacent two single arch trusses together through a connecting rod to form a roof cover structure; unloading the support system. By adopting the way of two- two symmetrically installation, the load of the installed truss unit on the support system is balanced; the truss unit is connected into a whole by the connecting rod to form a stable whole force structure, thus the problems of the unevenness of the force of the arch truss with the irregularly shape and concentrated stress are avoided.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

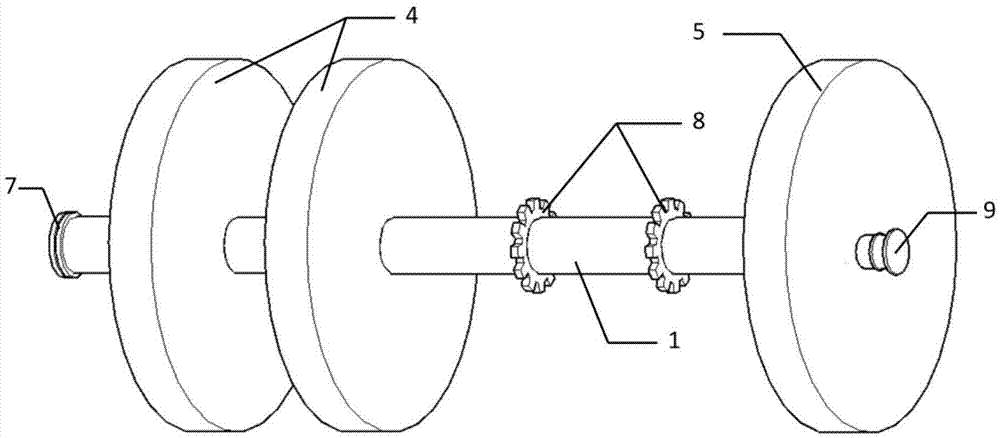

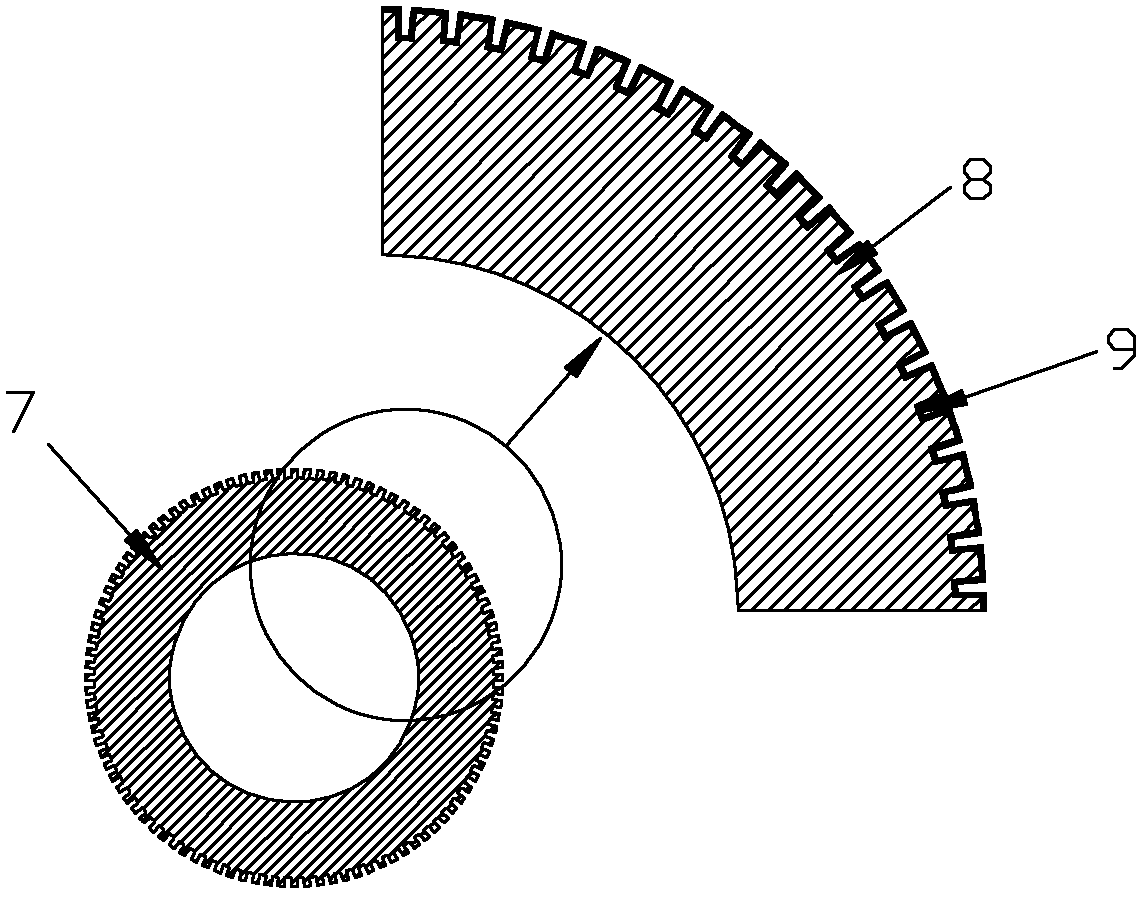

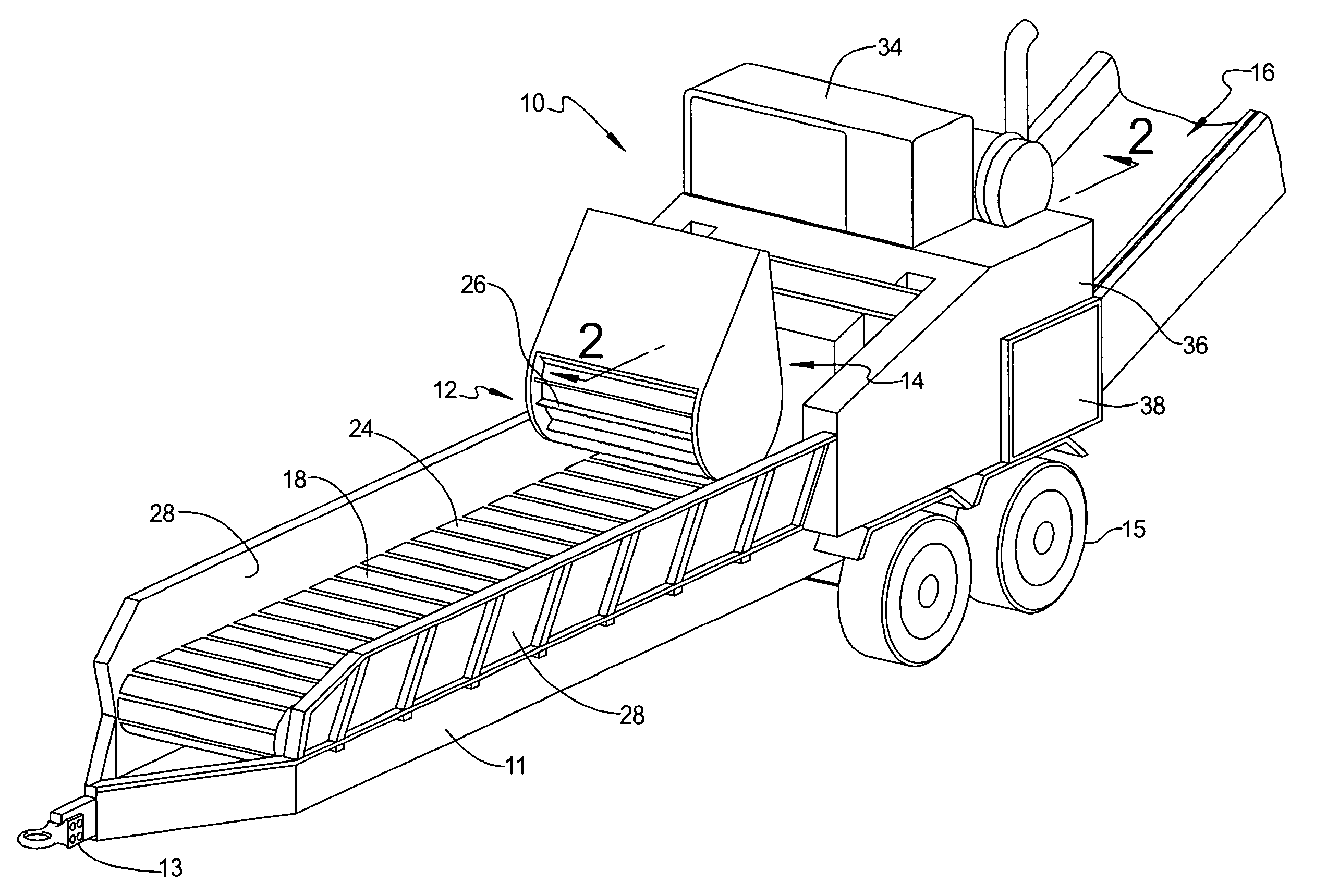

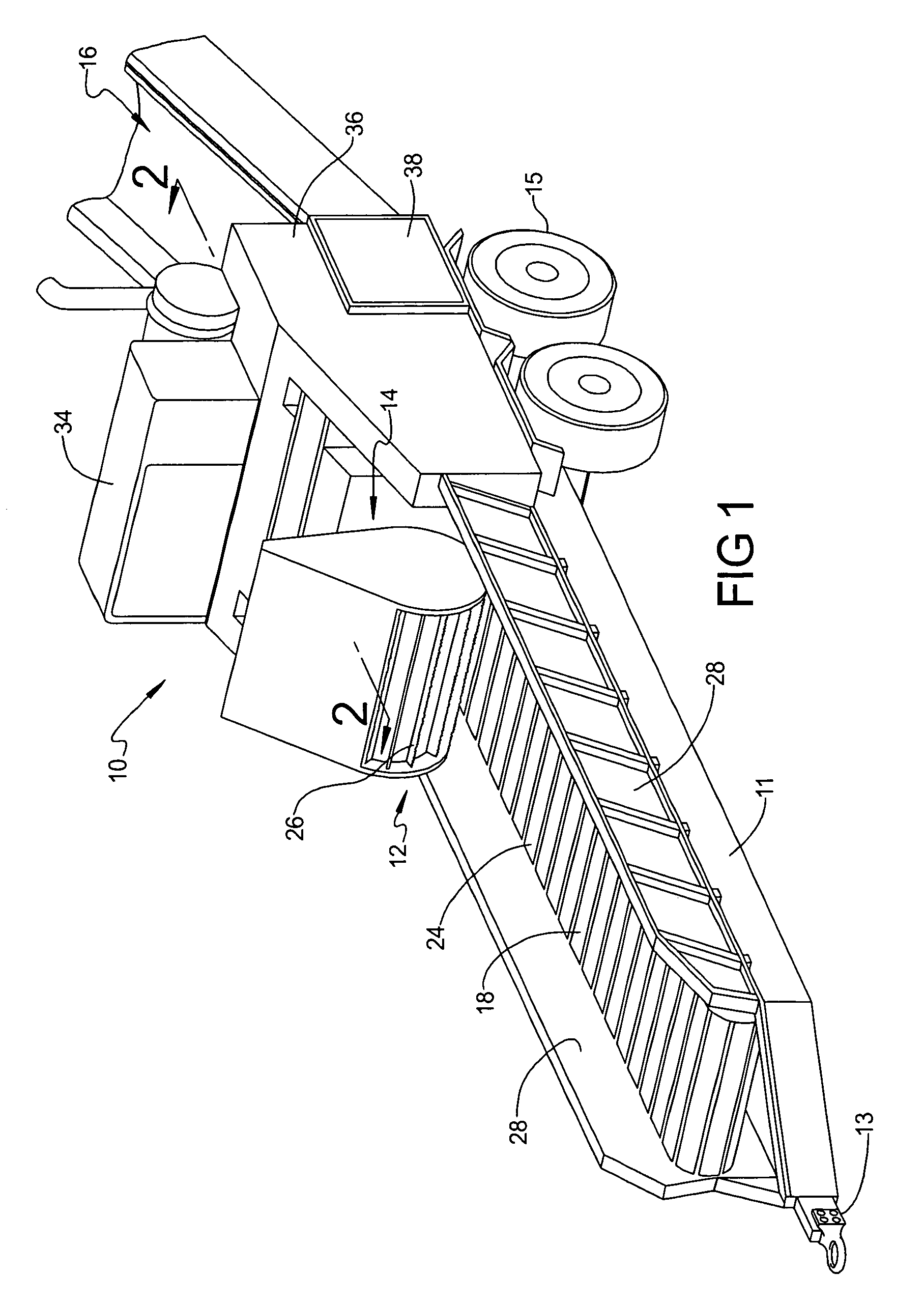

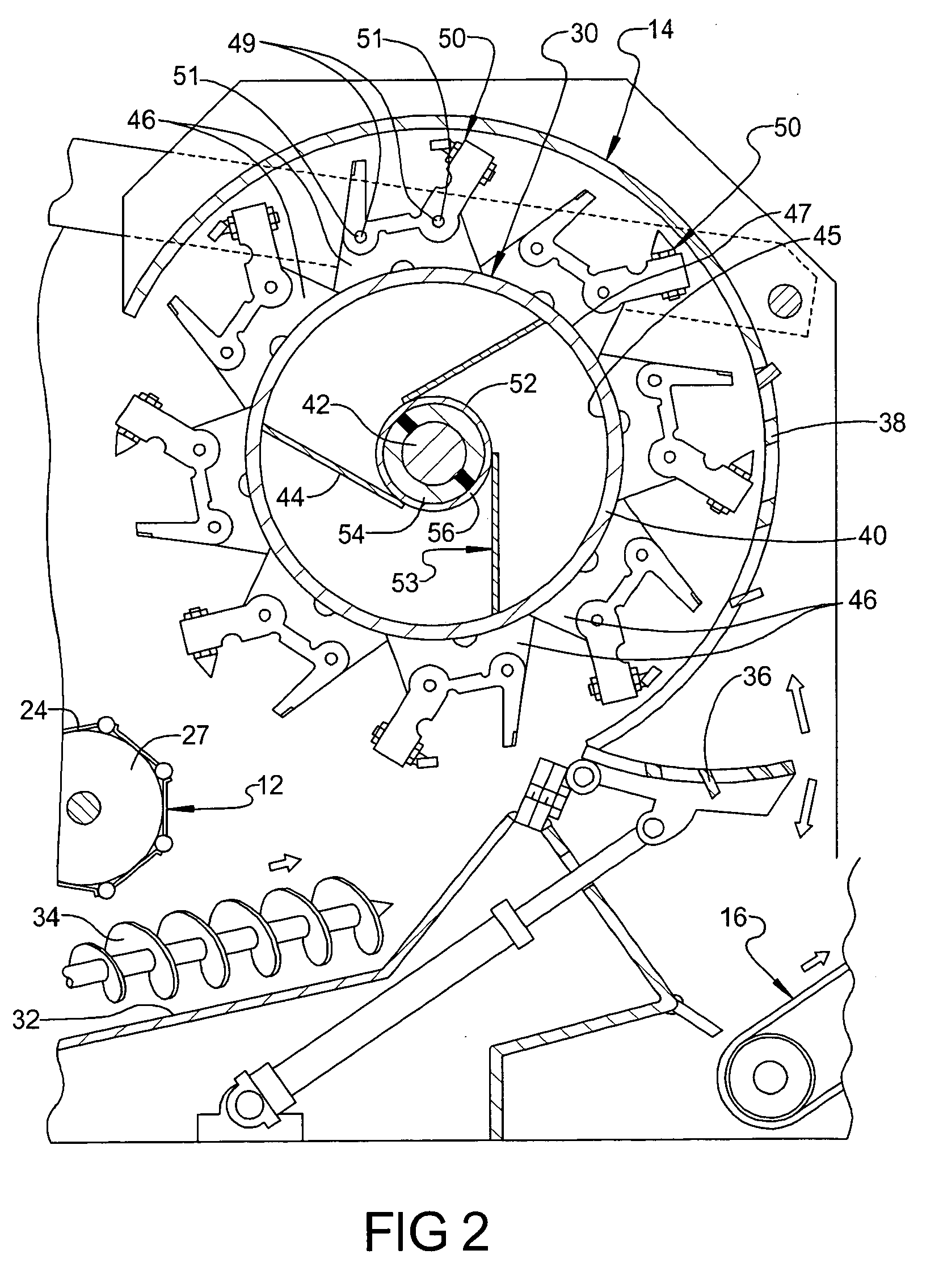

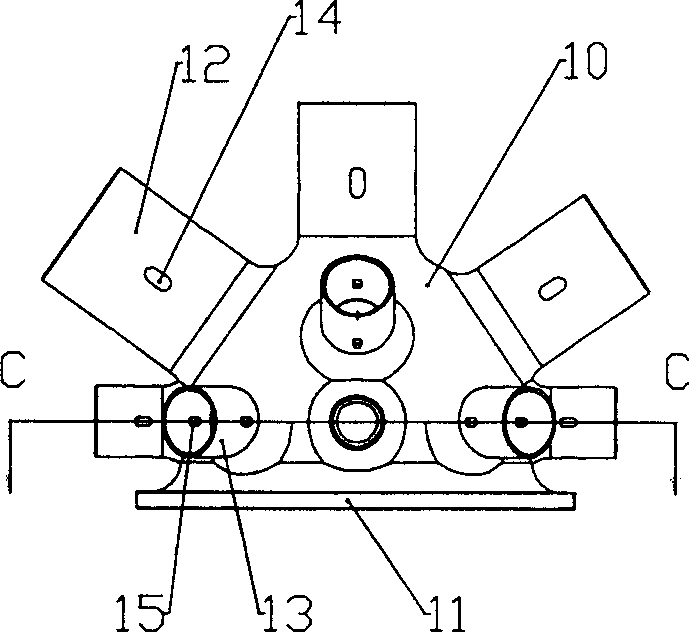

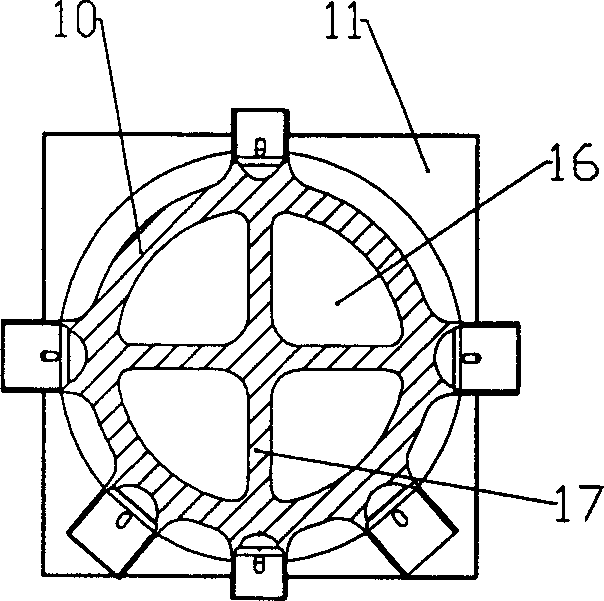

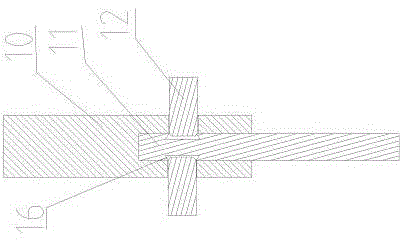

Rotatable assembly for machines

InactiveUS7163166B1Less-detrimental shock and concentrated loadingAvoid concentrated stressSortingGrain treatmentsEngineeringMechanical engineering

A rotatable assembly for a machine includes a rotatable shaft having a longitudinal axis and a rotatable member disposed about the shaft. The rotatable assembly also includes at least one first connecting member operatively mounted to the rotatable member and to the shaft at a first location along the longitudinal axis of the shaft. The rotatable assembly includes at least one second connecting member operatively mounted to the rotatable member and located at a second location spaced from the first location along the longitudinal axis of the shaft. The rotatable assembly further includes a bearing operatively mounted to the shaft, wherein the second connecting member is operatively mounted to the bearing to allow the shaft to twist without permanent deformation when a concentrated load is subjected to the shaft as the rotor is rotated.

Owner:SMORACY

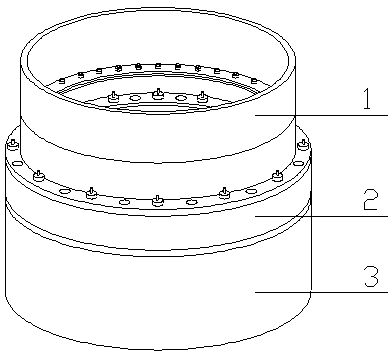

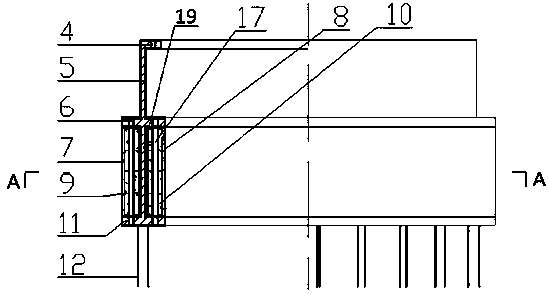

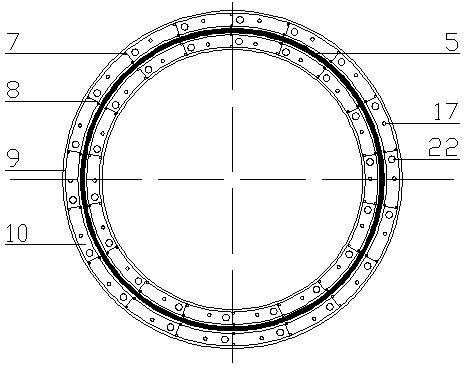

Connection device of prestress concrete and steel combination wind power generation tower

ActiveCN103994034AUniform stress distributionAvoid uneven distributionWind energy generationWind motor componentsTension stressWind force

The invention relates to a connection device of a prestress concrete and steel combination wind power generation tower. The lower surface of a lower connection flange is provided with anchor bars connected with a concrete tower section. The connection device is further provided with prestress application components, a tension anchor flange and the lower connection flange are respectively and uniformly provided with flange holes for the prestress application components to pass, and the flange holes of the tension anchor flange are the same as those of the lower connection flange in quantity and correspond to the flange holes of the lower connection flange in a one-to-one mode in the vertical direction. The prestress application components sequentially penetrate through the flange holes of the anchor flange and the flange holes of the lower connection flange and penetrate through the concrete tower section on the lower portion. The top ends of the prestress application components are anchored on the top face of a lower section connection steel cylinder through anchorage devices after the prestress application components are tensioned. Concrete is poured between the tension anchor flange and the lower connection flange to form a prestress concrete structure. Due to the connection mode, the concrete on the flange connection section is uniformly stressed, stress concentration is reduced, the tensile stress level of the concrete is improved, and the situation that the concrete cracks is avoided.

Owner:HUNAN UNIV

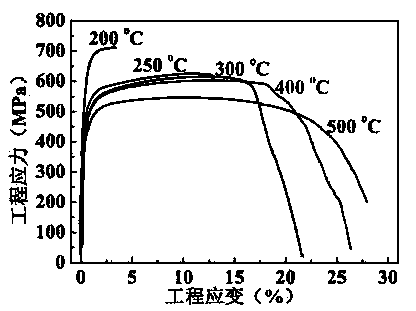

Nanostructure tungsten-zirconium carbide alloy and preparation method thereof

ActiveCN104388789AGood mechanical properties and high temperature stabilityAvoid stress concentration and embrittlementEmbrittlementZirconium alloy

The invention discloses a nanostructure tungsten-zirconium carbide alloy. The nanostructure tungsten-zirconium carbide alloy comprises the following components by weight percentage: 98-99.8% of tungsten, and 0.2-2.0% of zirconium carbide with the grain diameter of 5-300 nm, wherein the zirconium carbide grains are mostly uniformly distributed in the interiors of the tungsten crystal grains. The invention further discloses a preparation method of the alloy. The prepared alloy has good mechanical property and high-temperature stability; the zirconium carbide nanograins can be uniformly distributed in the interiors of the tungsten crystal grains, so that stress concentration and embrittlement generated by coarse particle in the tungsten crystal grains are avoided; the strength and high-temperature performance can be improved by pinning dislocation, and meanwhile, the toughness is ensured.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

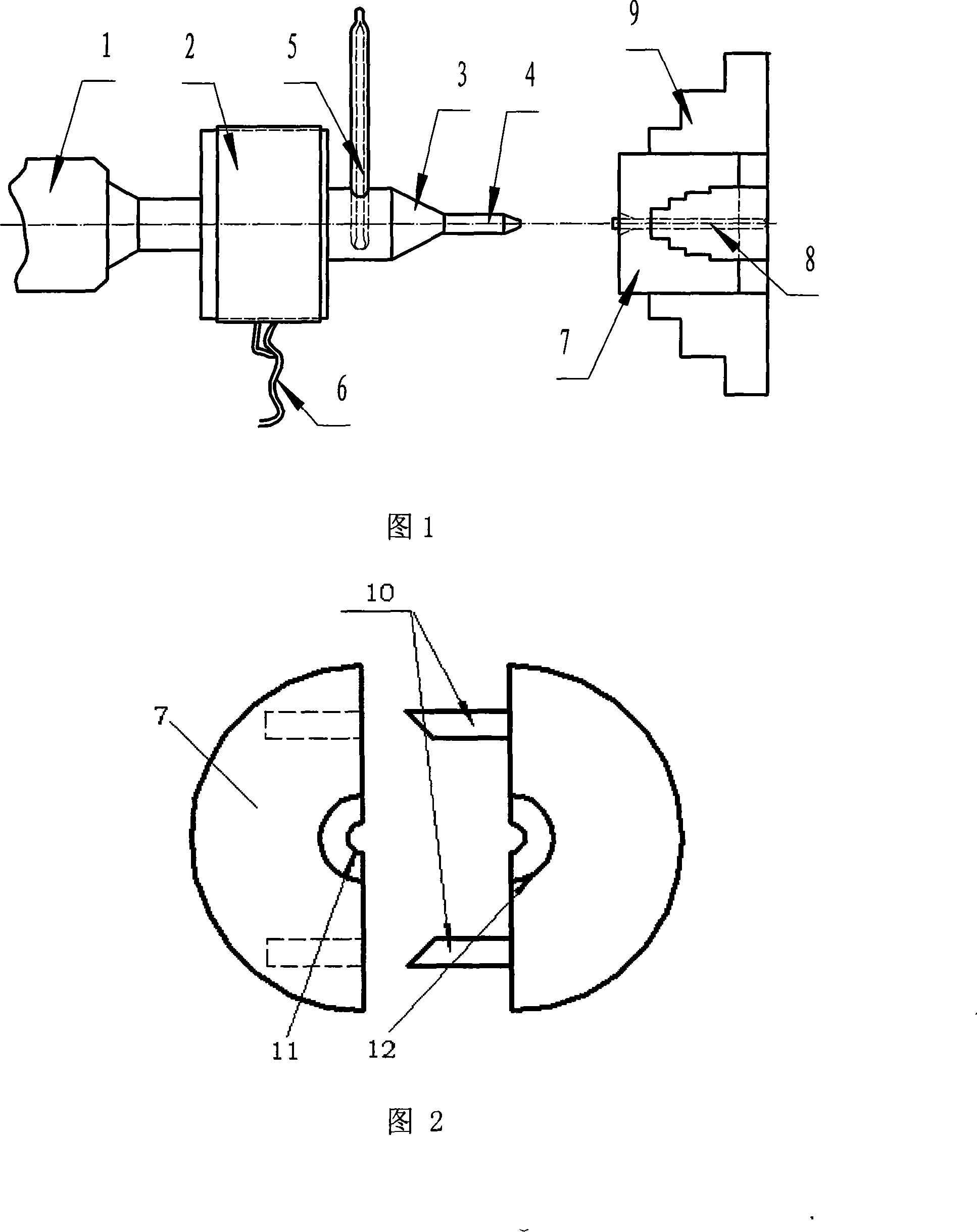

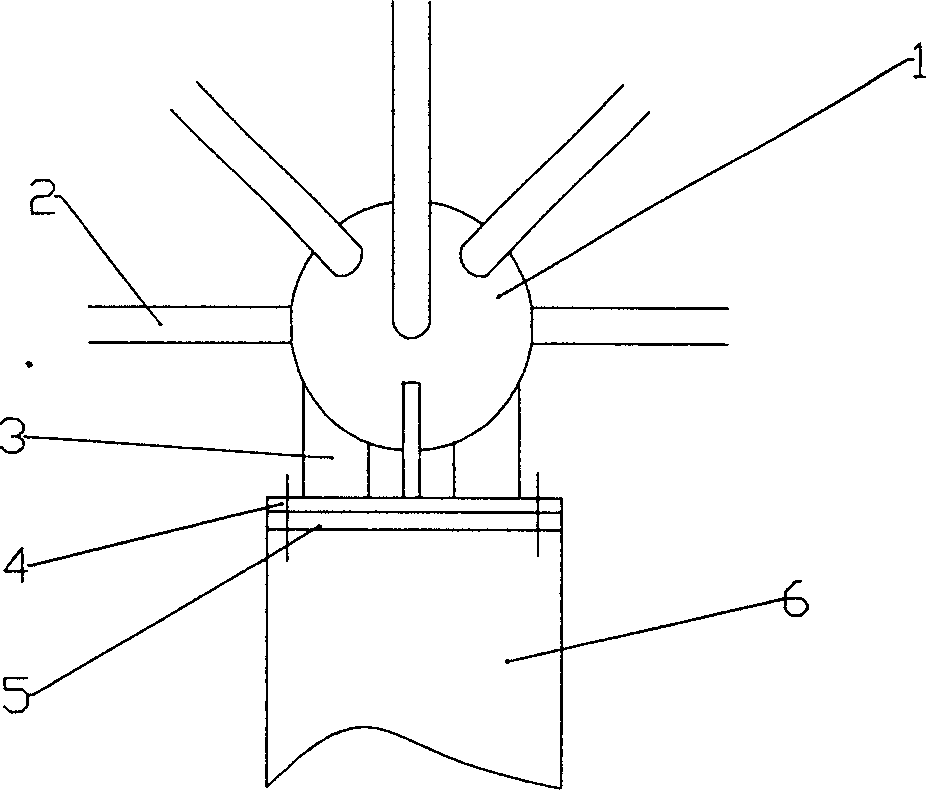

Producing method forming and model hot enlarge fluorine plastic tube

The invention relates to a preparation method and a molding mold of thermal flared end fluoroplastic pipe, which is that a flared end fluoroplastic pip is clamped in a mounting hole of a flared end cavity die with a trumpet flared end and rotates with a chuck of a lathe spindle; a male die expander with a heater and temperature control device is used for heating the head the flared end to flaring temperature and the head the flared end is fed through a lathe tail spindle to ensure that the fluoroplastic pipe is intenerated in rotating and tightly joined and matched with trumpet flared end of the flared end cavity die and cooled to form mold. The heater is fixedly connected on a the male die expander and electrically connected with the temperature control device controlled the temperature of the flared end; the flared end cavity die clamped in a rotator comprises two symmetrical clutch semicylinders is positioned on the same central line with the flared end head of flared end cavity die. The utility model takes advantage of the cold flow property of fluoroplastic to solve the defects that stress centralizes and leaves at the flared end, material is easily decomposed and the flared end is easily cracked. The invention ensures that the wall thickness of expanded trumpet flared end is more uniform and the surface of the flared end is smoother and avoids the occurrences of crinkle, forting and rippling.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Supporting node

This invention discloses a supporting joint used in girders or rack, characterized in that it comprises an erection support connected with a supporting member, and connected with several joints formed from the integrated component. Said supporting joint is easy to manufacture and install, and it has firm structure and high precision, in addition, it can be used for force analysis and computing.

Owner:徐国彬 +1

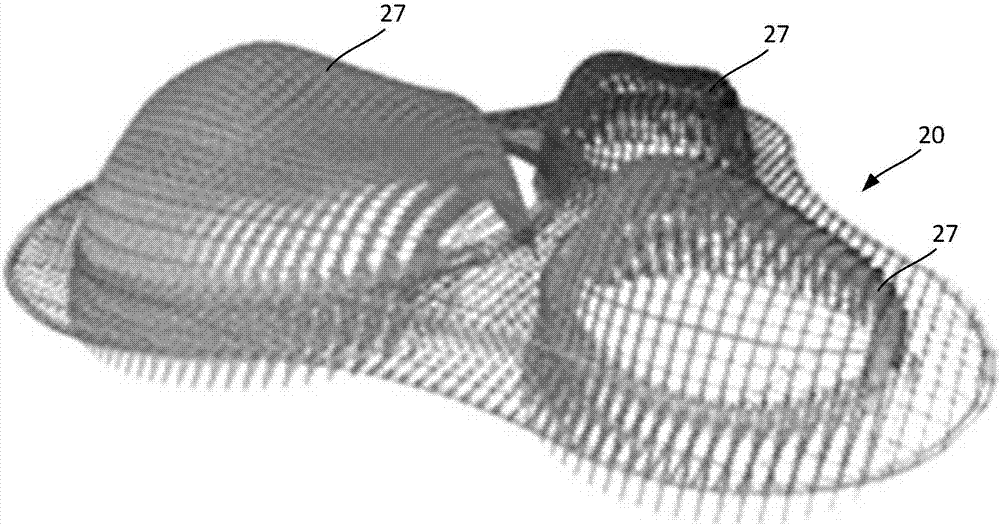

Flexible display module, display device and manufacturing method of display device

InactiveCN112420896AAvoid concentrated stressIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceEngineering

The invention provides a flexible display module, a display device and a manufacturing method of the display device. The flexible display module comprises a display area and a peripheral area surrounding the display area; the peripheral area is provided with a first retaining wall and a second retaining wall; a first buffer structure is arranged between the first retaining wall and the second retaining wall; and the first buffer structure is sequentially covered with a first inorganic packaging layer, an organic packaging layer and a second inorganic packaging layer.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

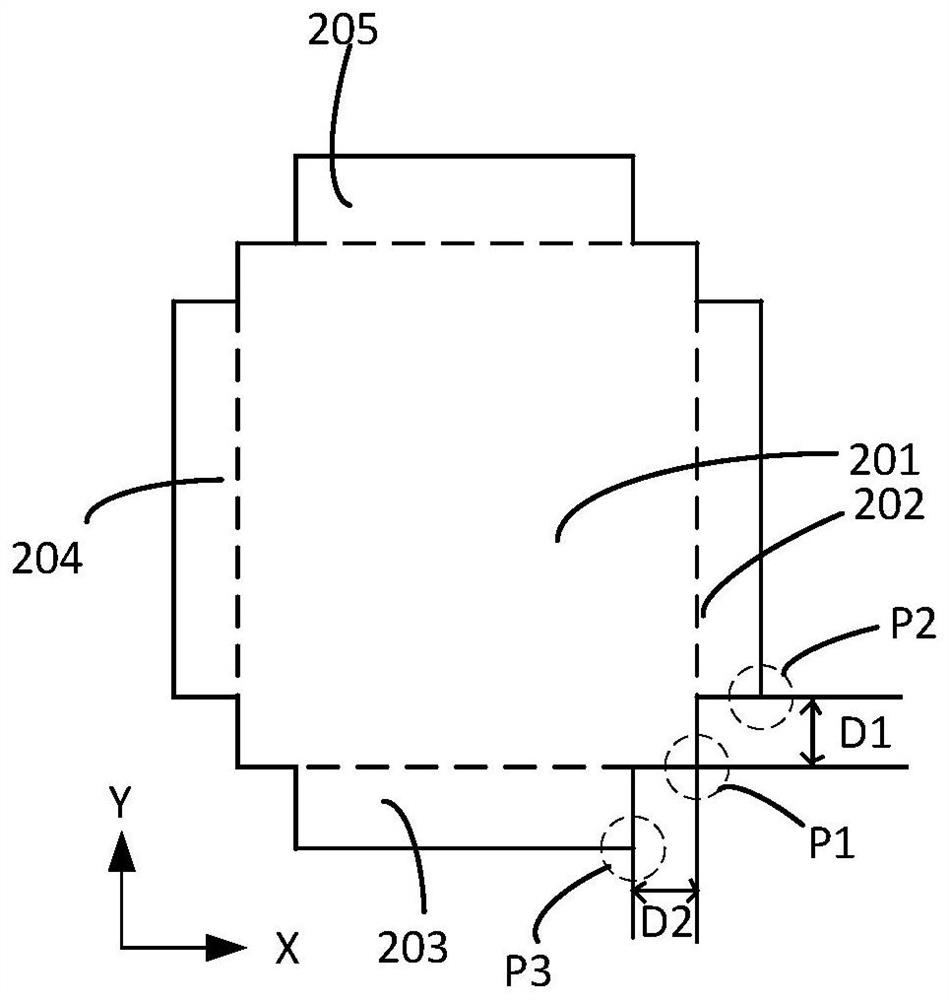

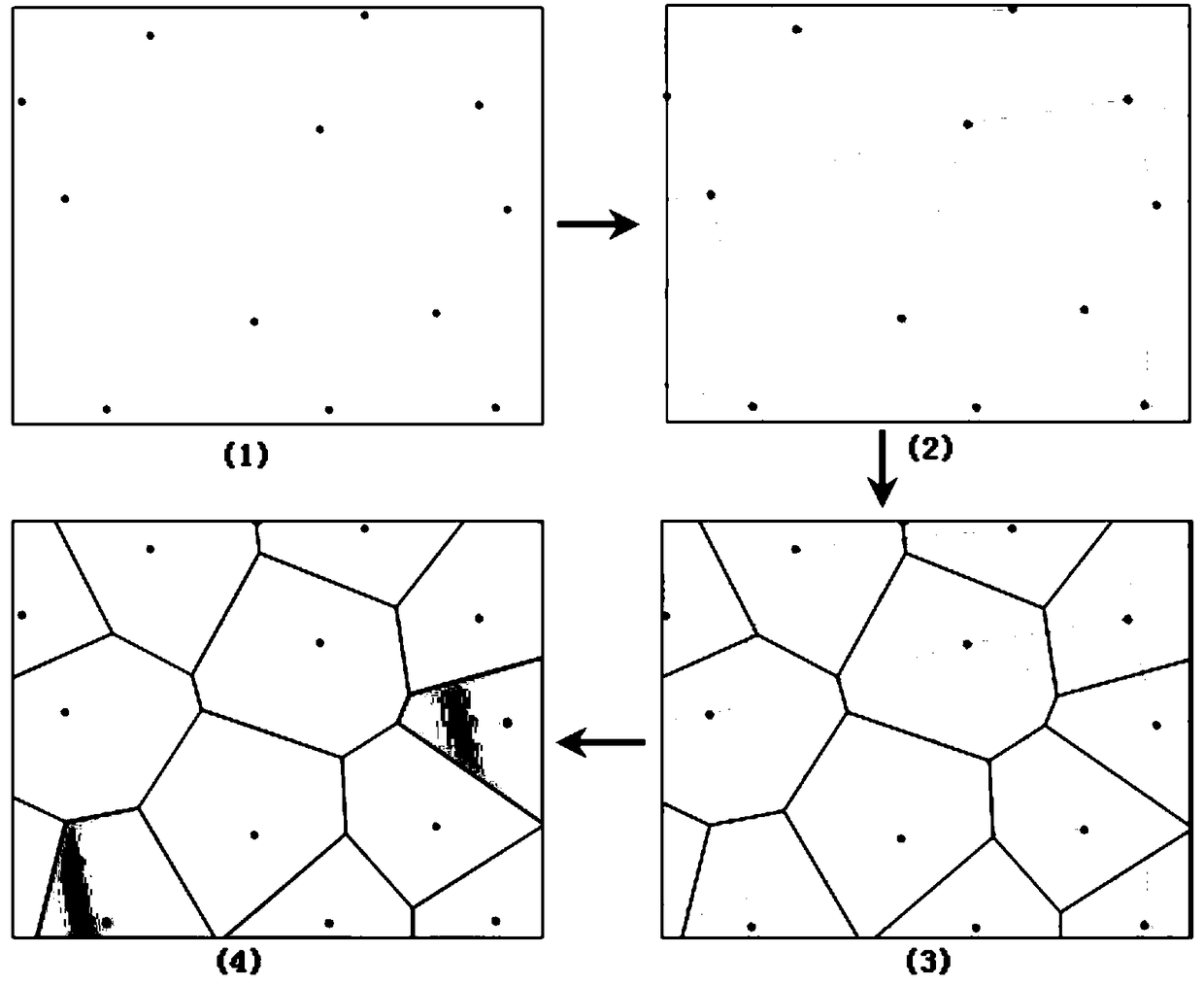

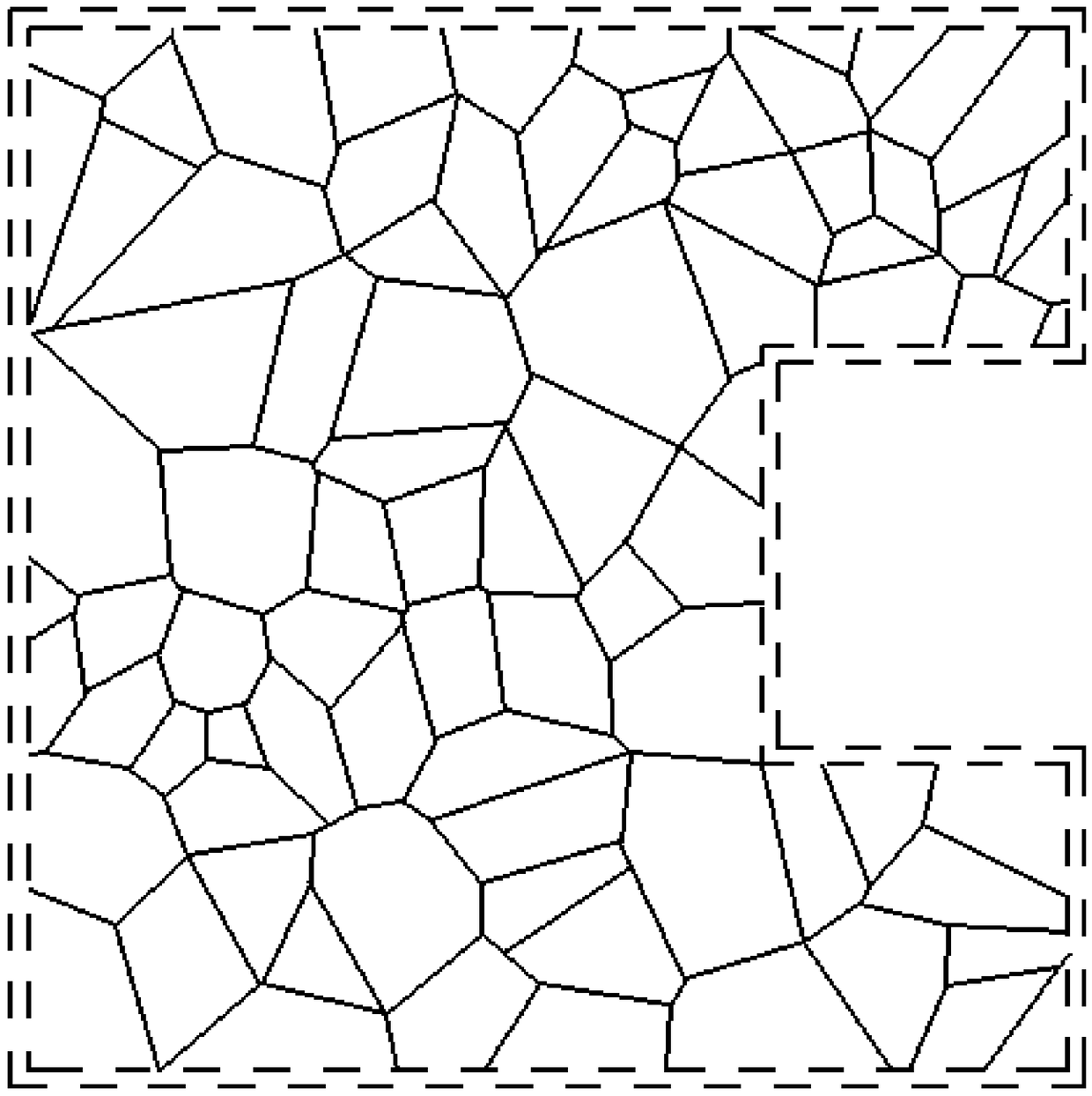

Scanning method used for metal laser selective melting forming process

ActiveCN109434104AReduce residual stressAvoid concentrated stressAdditive manufacturing apparatusIncreasing energy efficiencyStress concentrationMetal

The invention relates to a scanning method used for a metal laser selective melting forming process. By means of the method, the probability that thermal stress concentration, stress concentration, cracking and other defects happen in the metal part forming process is greatly reduced, and the forming quality of final parts is ensured. The method comprises the main steps that (1) contour offset iscarried out; (2) multiple Thiessen polygons are constructed in an inner contour area; (3) the inner contour area is canned; (4) a narrow-side outer contour area is scanned; (5) the steps from 1 to 4 are repeated till scanning of all of N-1 layers of sections is completed; and (6) the Nth section is scanned.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

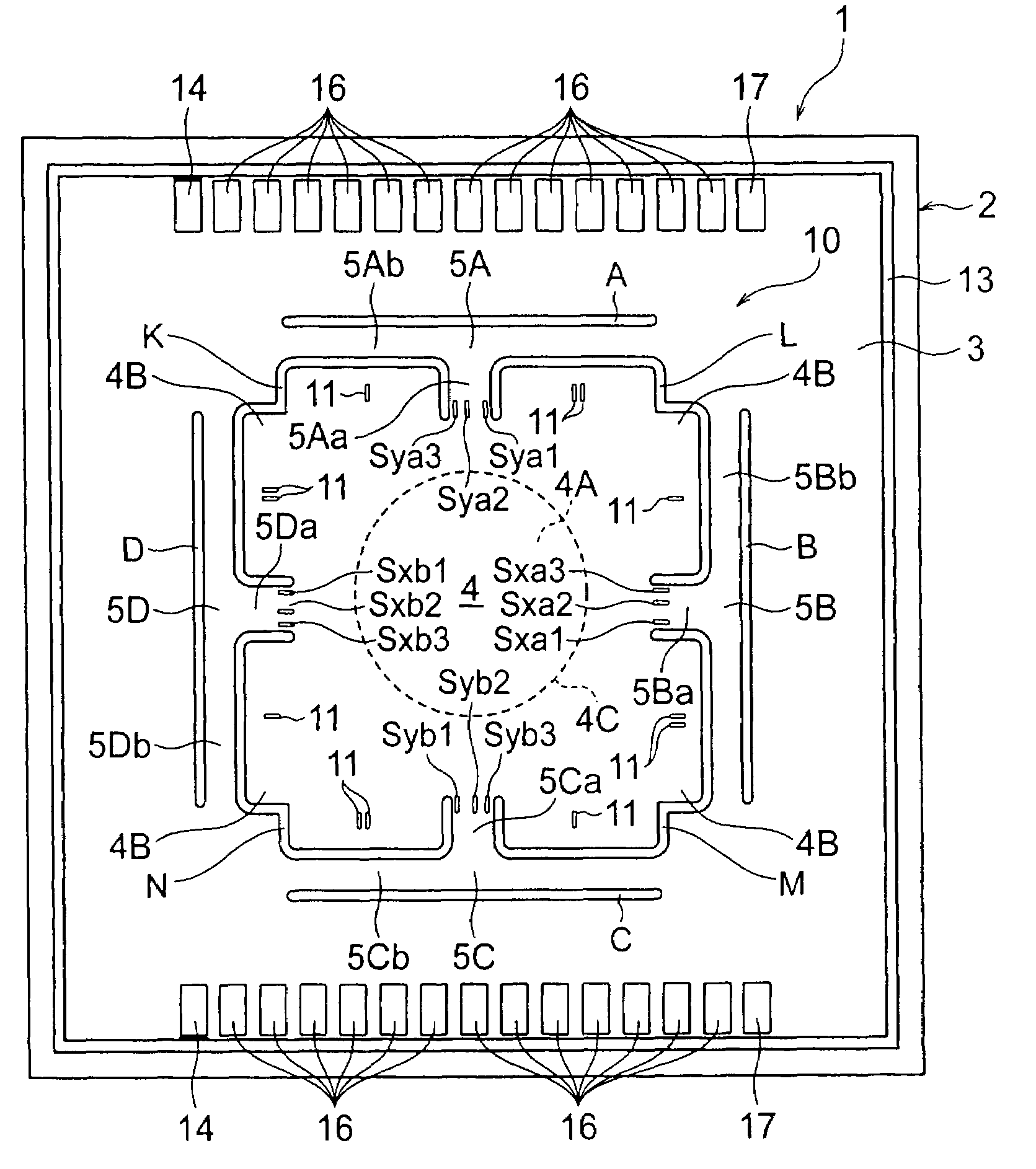

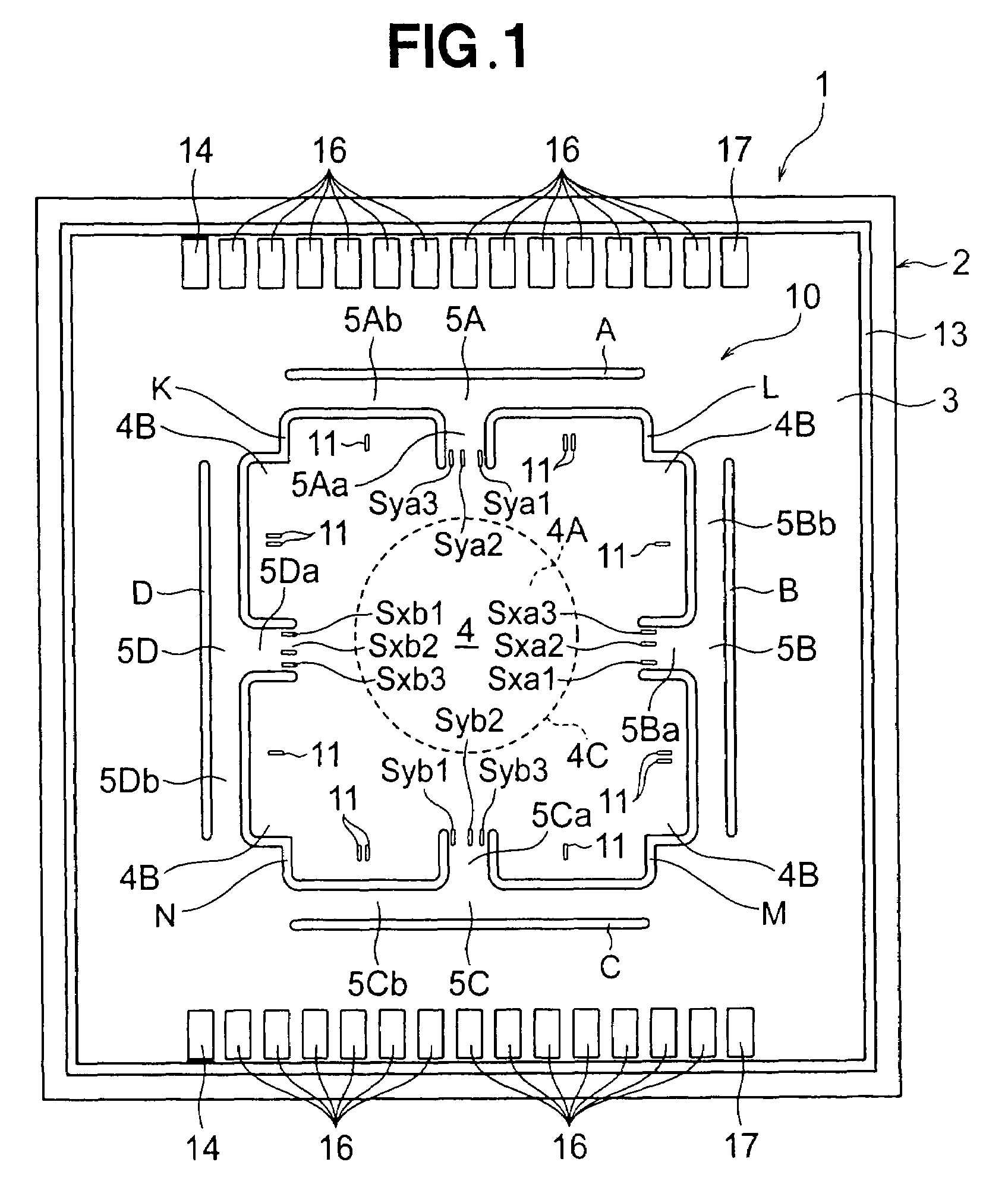

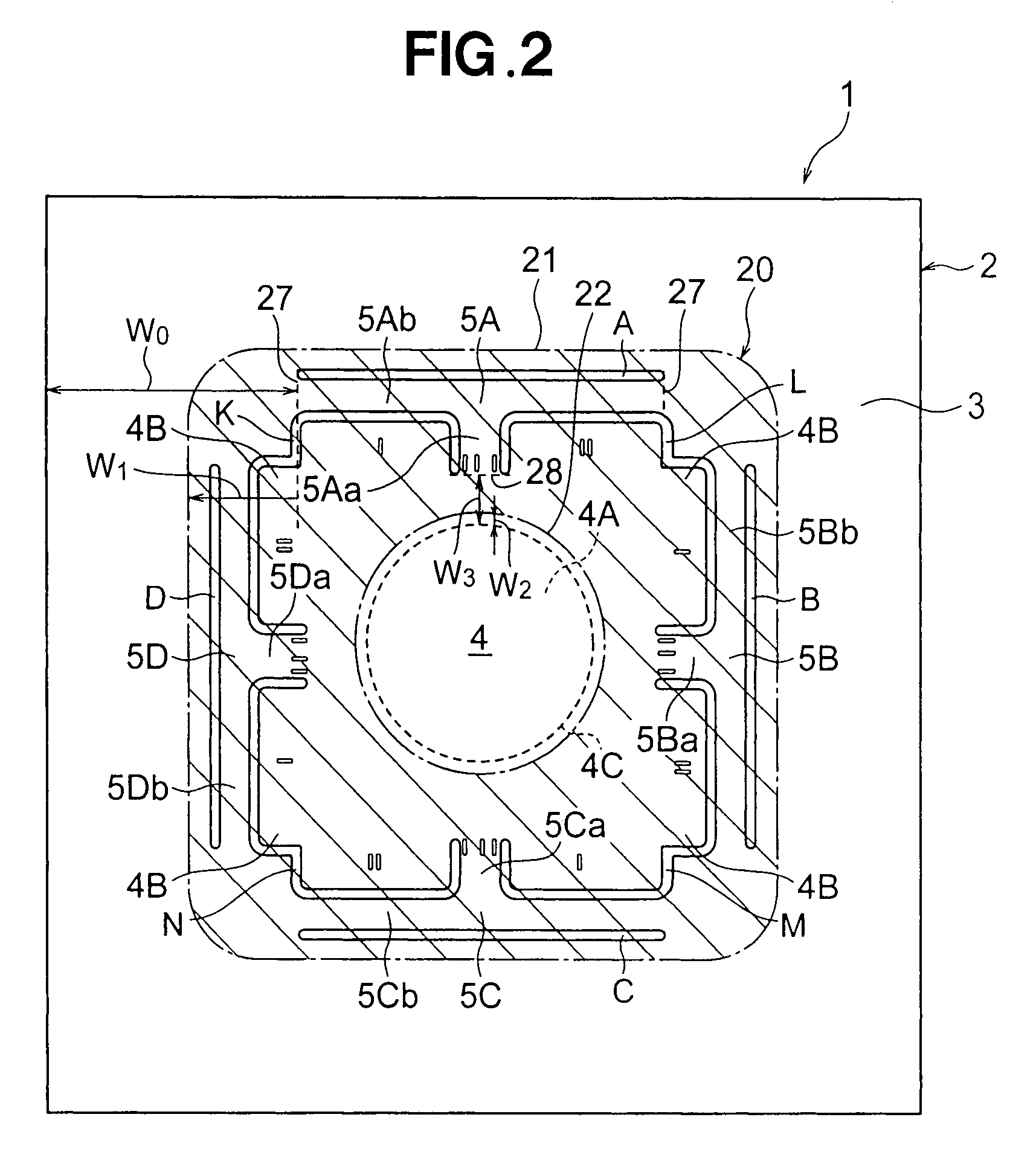

Force sensor chip

ActiveUS7536923B2Improve balanceHigh detection sensitivityForce measurementApparatus for force/torque/work measurementOperating pointEngineering

A force sensor chip having a multiaxial force sensing function is disclosed. The force sensor chip comprises a base member having an operating part provided with an external force application area, a supporting part for supporting the operating part, connecting parts for connecting the operating part and the supporting part, and strain resistance elements disposed in the connecting parts or within boundaries between the connecting parts and the operating part. The base member has a thin area formed with a small thickness, and the boundaries of the thin area are disposed in the supporting part and operating part.

Owner:HONDA MOTOR CO LTD

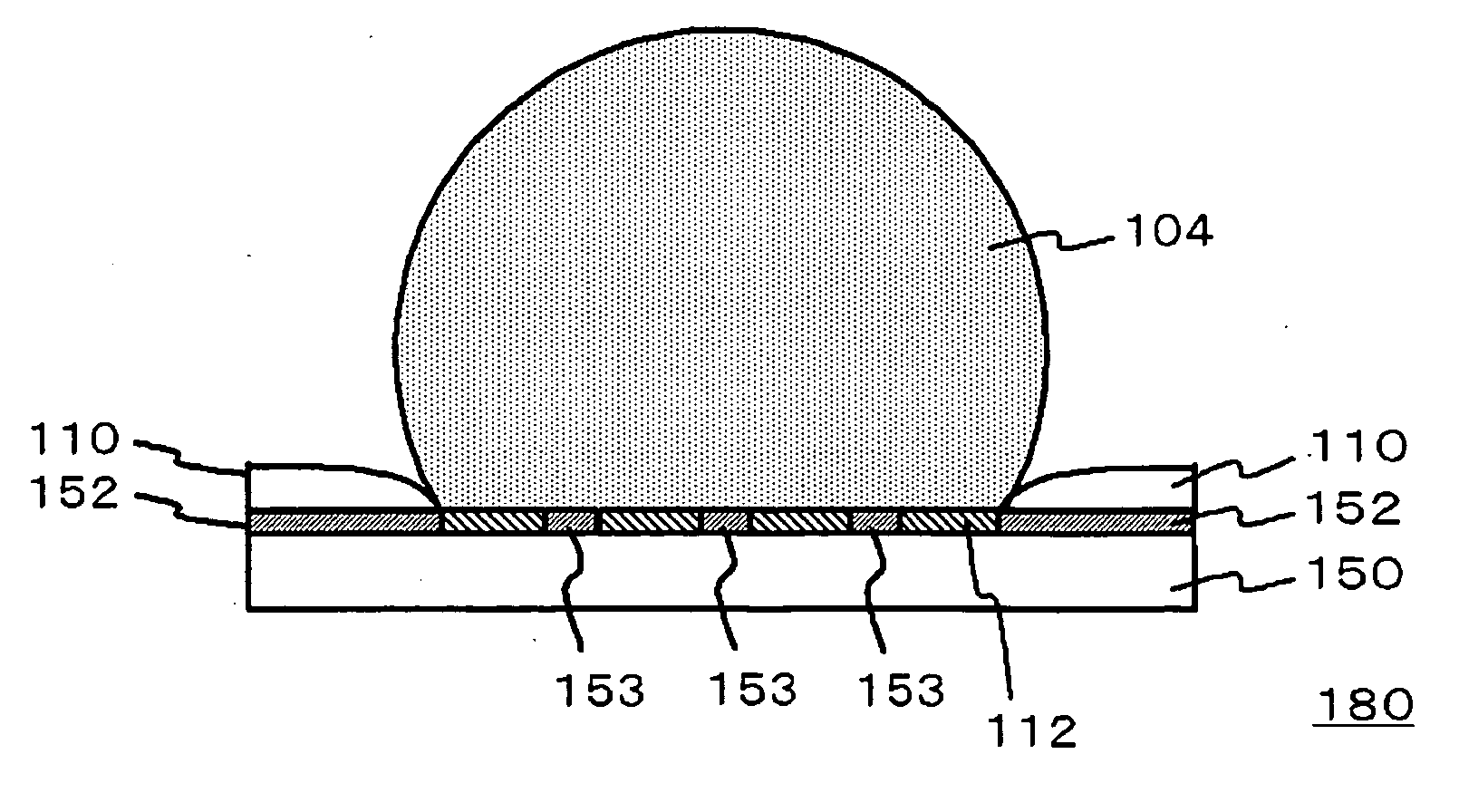

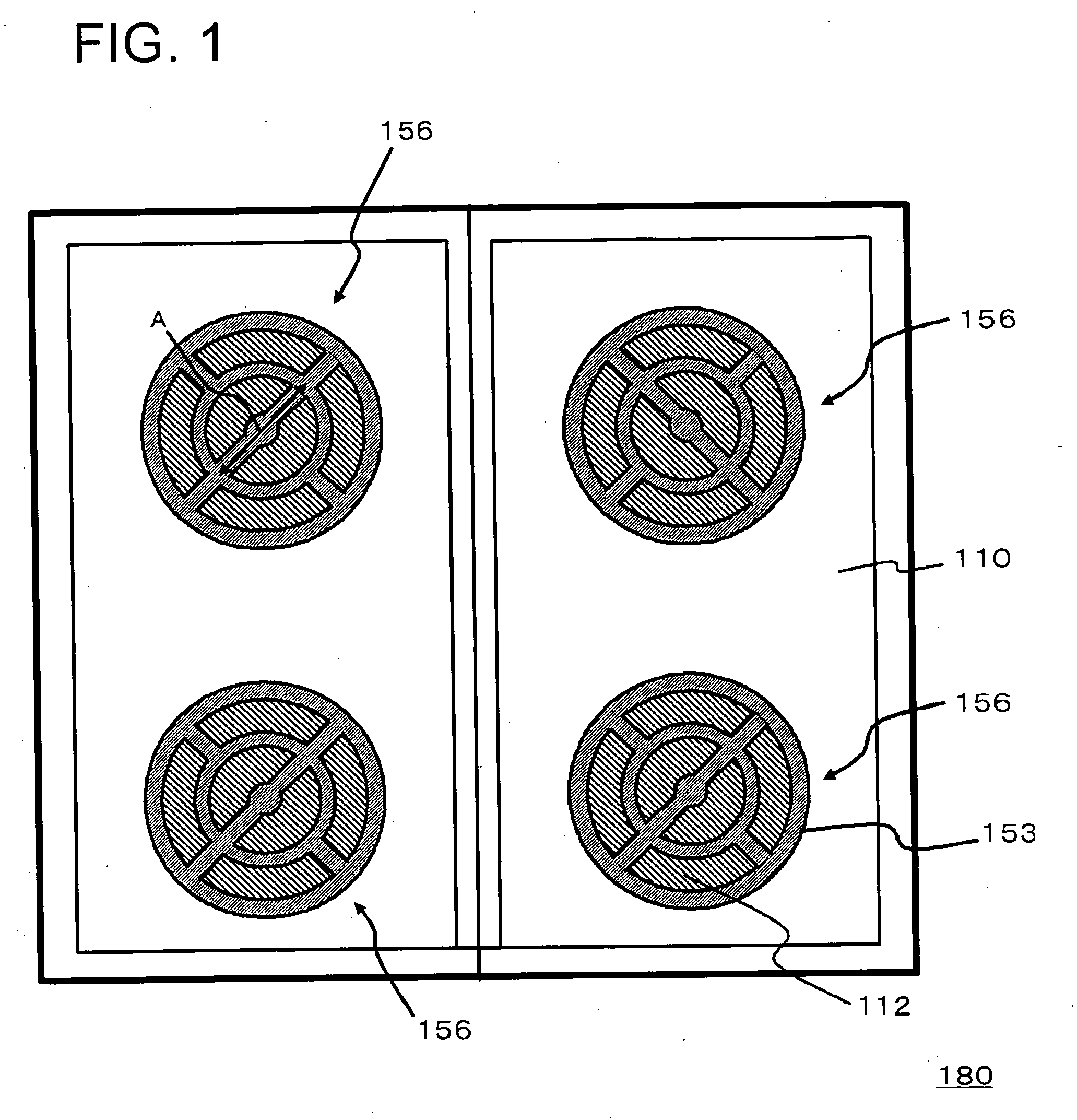

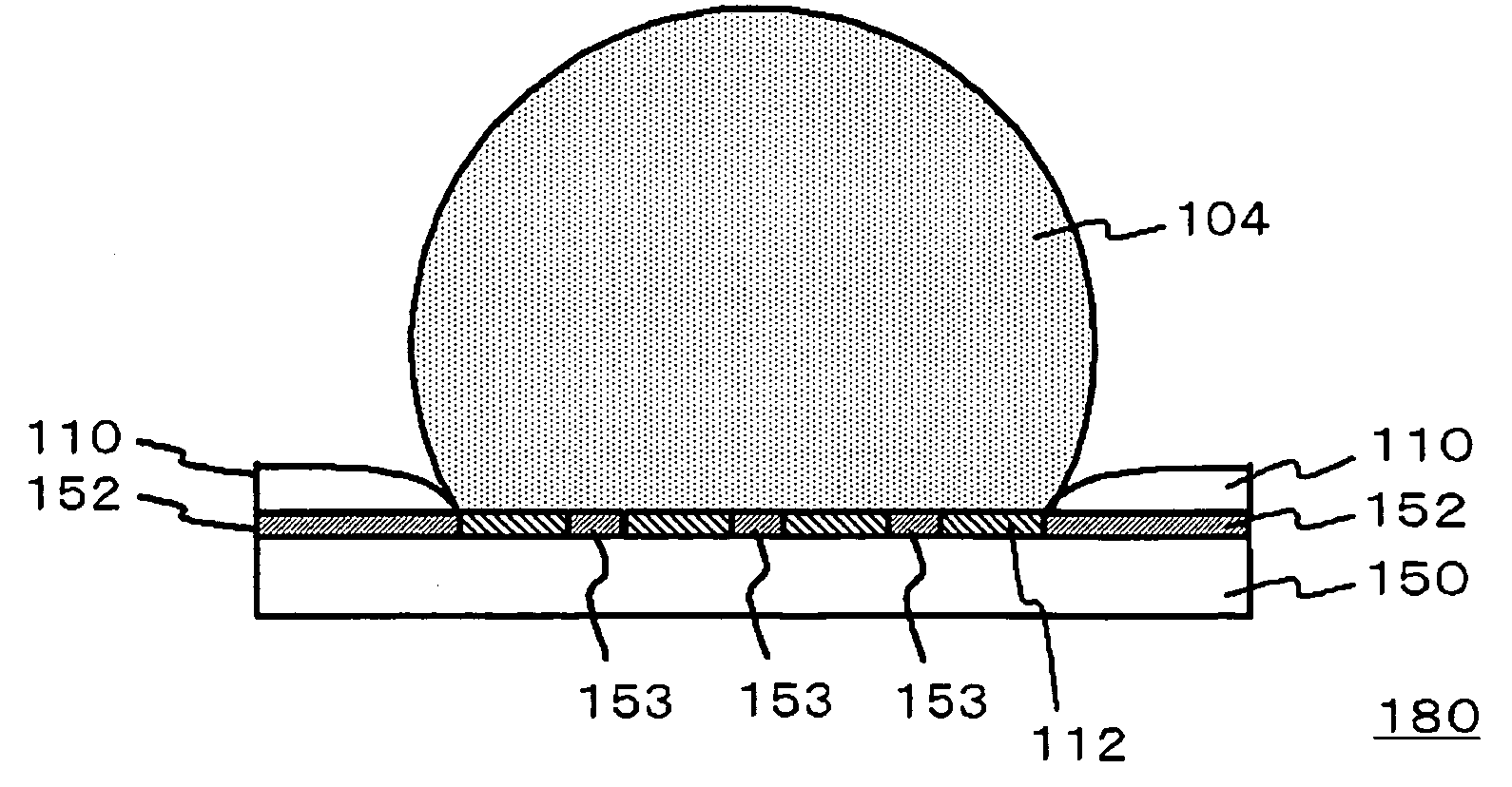

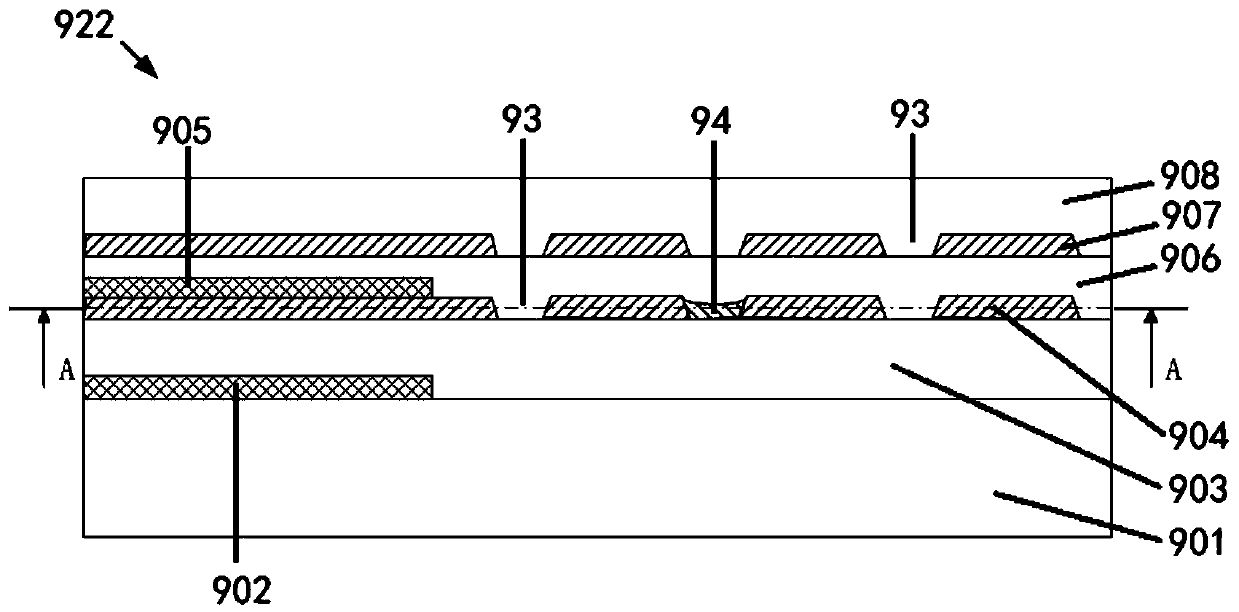

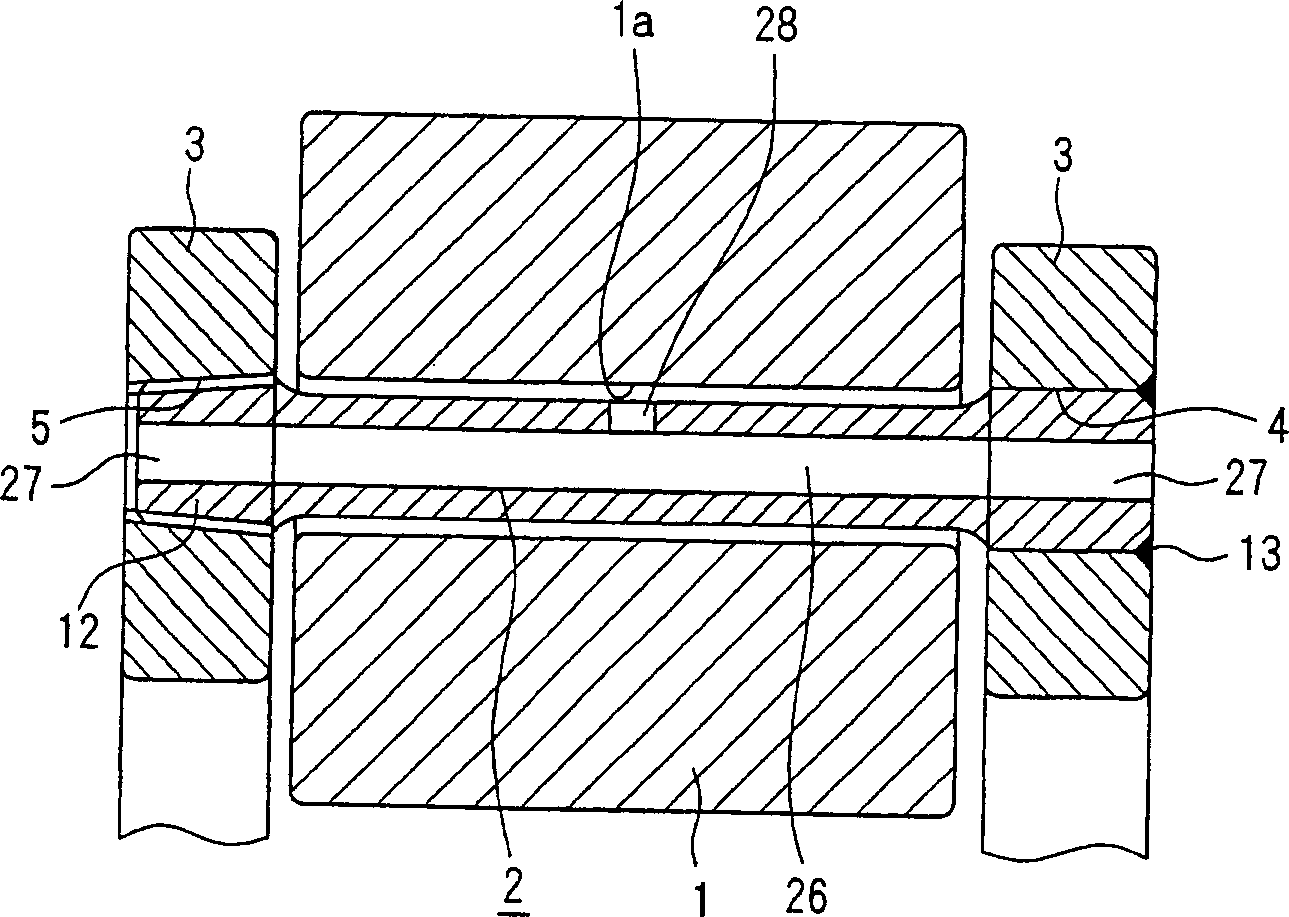

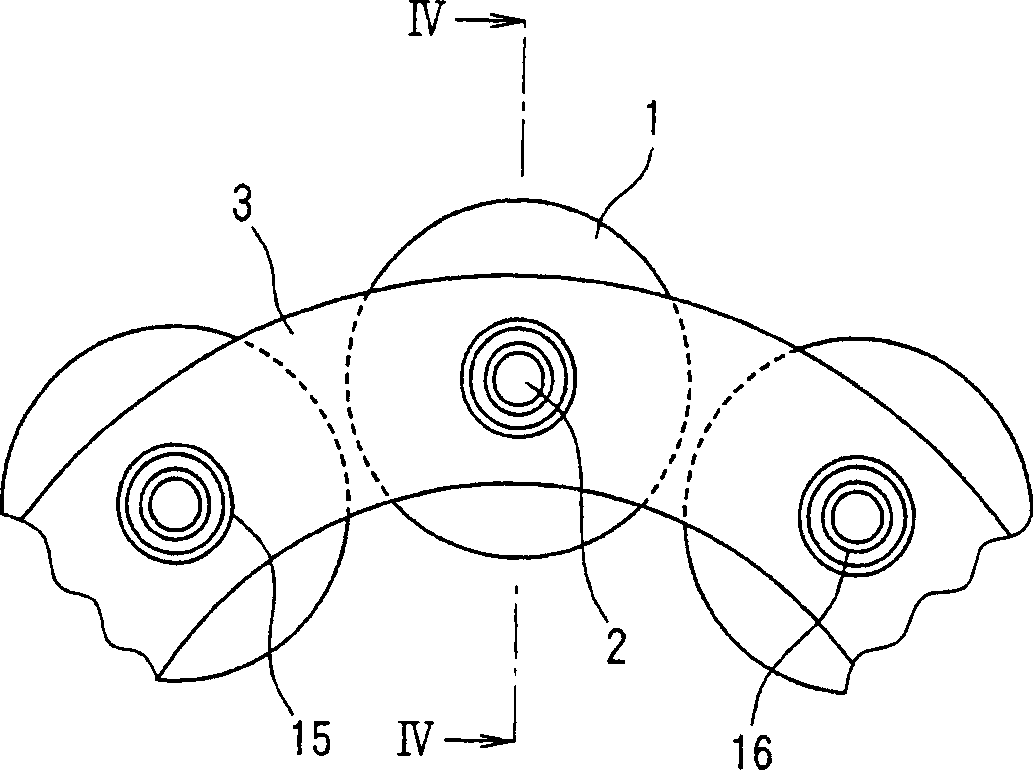

Semiconductor device with a diffusion barrier film having a spacing for stress relief of solder bump

ActiveUS7663201B2Avoid concentrated stressEffective dispersionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipStress relief

The present invention provides a semiconductor device exhibiting an improved reliability. A semiconductor device comprises a semiconductor chip having an electrode on a surface thereof and a mounting substrate, and the electrode (aluminum electrode) of the semiconductor chip is coupled to the mounting substrate through a bump (solder bump 104). A plurality of diffusion barrier films (UBM 112) for preventing a diffusion of a material composing the bump is provided between the electrode and the bump, and the diffusion barrier film is formed to have a plurality of divided portions via spacings therebetween.

Owner:RENESAS ELECTRONICS CORP

Display panel and manufacturing method thereof

ActiveCN110071124AAvoid it happening againAvoid concentrated stressSolid-state devicesSemiconductor/solid-state device manufacturingStress concentrationEngineering

The invention provides a display panel and a manufacturing method thereof. A display area and a bending area are defined on the display panel, the display panel comprises a flexible substrate, a firstinorganic insulating layer, a first organic insulating layer, a first metal layer, a second organic insulating layer, a second inorganic insulating layer, a second metal layer and a third organic insulating layer which are arranged in a stacking mode. The manufacturing method of the display panel comprises the following steps of: providing a flexible substrate, manufacturing a first inorganic insulating layer, manufacturing a first organic insulating layer, manufacturing a first metal layer, manufacturing a second organic insulating layer, manufacturing a second inorganic insulating layer, manufacturing a second metal layer and manufacturing a third organic insulating layer. According to the invention, the second inorganic insulating layer of the bending area is arranged on the second organic insulating layer, so that residues of the second inorganic insulating layer generated in the through holes of the first metal layer are avoided, the risk of stress concentration or film peeling generated by a first signal line under bending stress is avoided, and the product yield is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

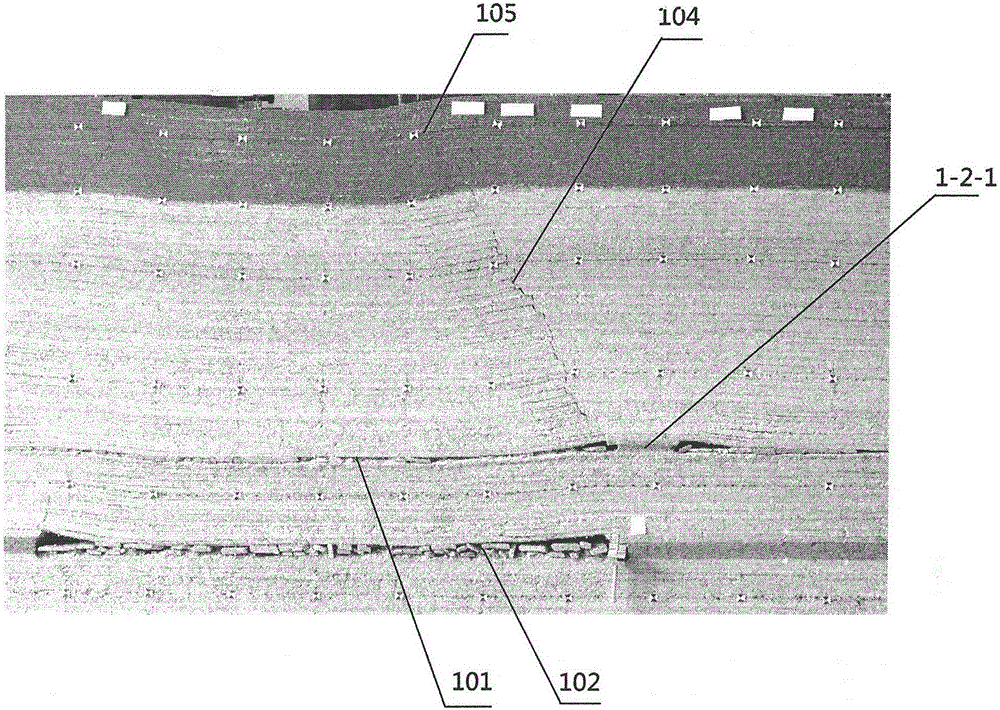

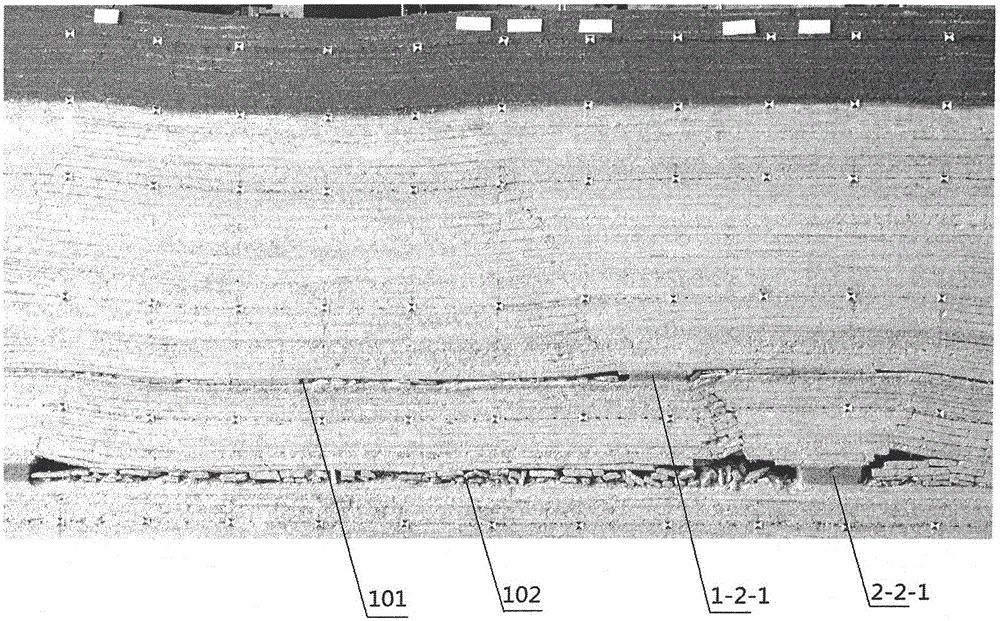

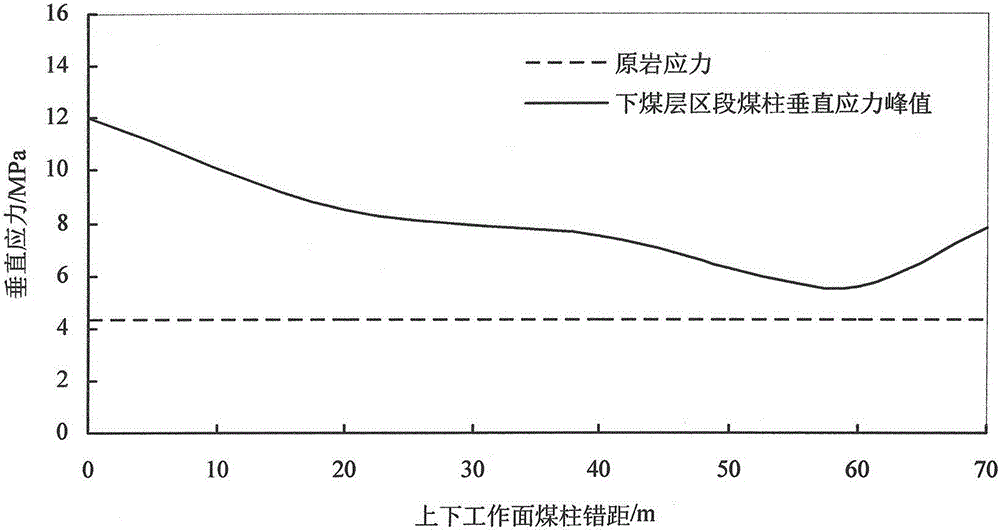

Design method of optimal coal pillar alternate distance of shallow buried multi-seam working face

InactiveCN105787185AReduce sinking disturbanceEven settlementGeometric CADData processing applicationsSurface concentrationStress concentration

The invention provides a design method of the optimal coal pillar alternate distance of a shallow buried multi-seam working face. The reasonable coal pillar alternate distance of an upper coal seam and a lower coal seam is determined through a terrestrial surface displacement law and a coal pillar concentrated stress propagation law, the stress concentration area of the upper coal seam is avoided, the disturbance of ground depression happening after shallow buried multi-seam mining is reduced, terrestrial surface concentration cracks are avoided, terrestrial surface uniformly sediments, and an environment-friendly development method integrating safe mining and terrestrial surface damage reduction is provided for shallow buried multi-seam mining.

Owner:XIAN UNIV OF SCI & TECH

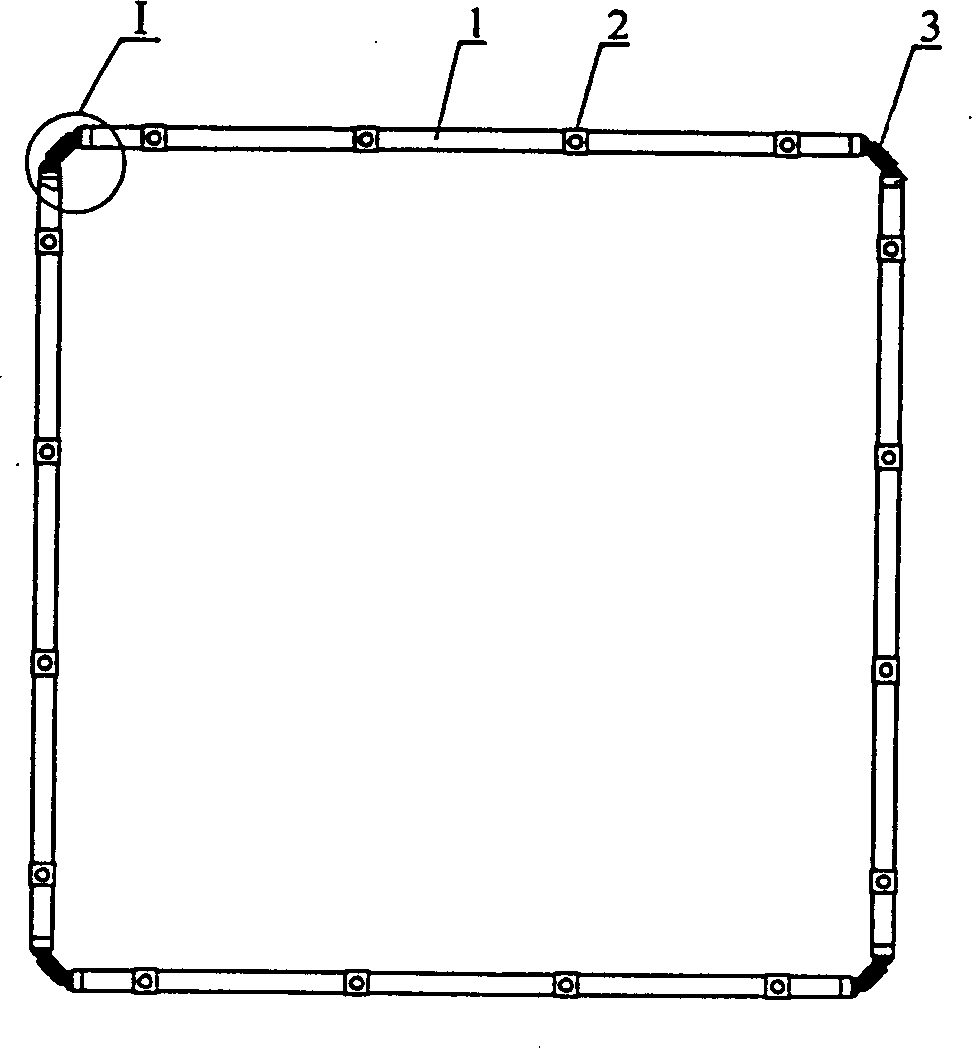

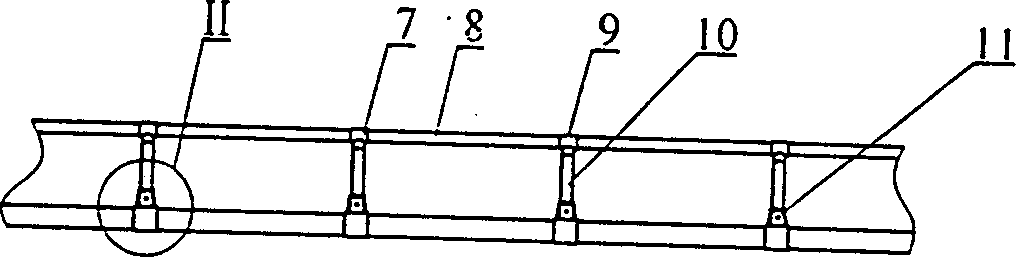

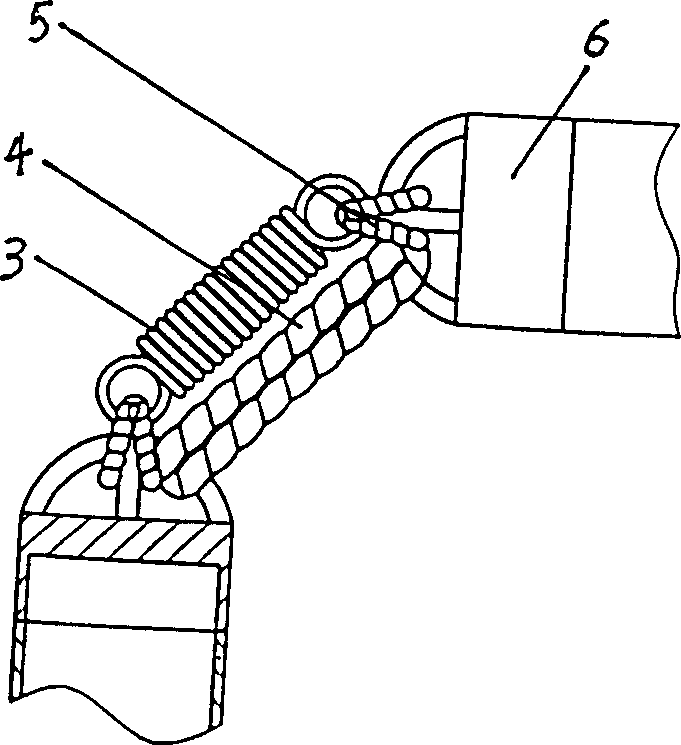

Flexible juncture net cage frame

InactiveCN1271925CImprove the force characteristicsImprove wind and wave resistanceClimate change adaptationPisciculture and aquariaStress concentrationEngineering

The present invention provides a flexible connected net cage frame, it includes main floating tube, main floating tube three-way, guard bar tube, guard bar tube three-way and guard bar upright column tube. It is characterized by that the described main floating tube at least has four independent vertical main floating tubes which are head-to-tail successively movably connected together by means of connecting components, and can be relatively moved between them to form polygon net cage frame having at least four sides, and every side can be independently moved with wave so as to raise its capability for resisting wave.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Tin-bismuth composite alloy and preparation method thereof

The invention discloses a tin-bismuth composite alloy and a preparation method thereof. The method comprises the following steps: synthesizing conductive polymer nano fiber, and preparing a metal coating layer on the surface of the conductive polymer nano fiber; adding the conductive polymer nano fiber with the metal coating layer into an organic solvent, and dispersing; performing secondary doping treatment; preparing nano tin powder and nano bismuth powder respectively; adding the obtained nano tin powder and nano bismuth powder into the organic solvent, and performing acid pickling treatment; performing purification treatment to obtain pure nano composite powder; mixing the obtained conductive polymer nano fiber after the secondary doping treatment, the obtained nano composite powder and a soldering flux, and stirring to obtain uniform tin-bismuth composite powder; performing sintering treatment on the tin-bismuth composite powder to obtain the tin-bismuth composite alloy. Through the method, a low-temperature tin-bismuth composite alloy material with a low melting point and high toughness is obtained.

Owner:HOERSON ELECTRONICS TECH +1

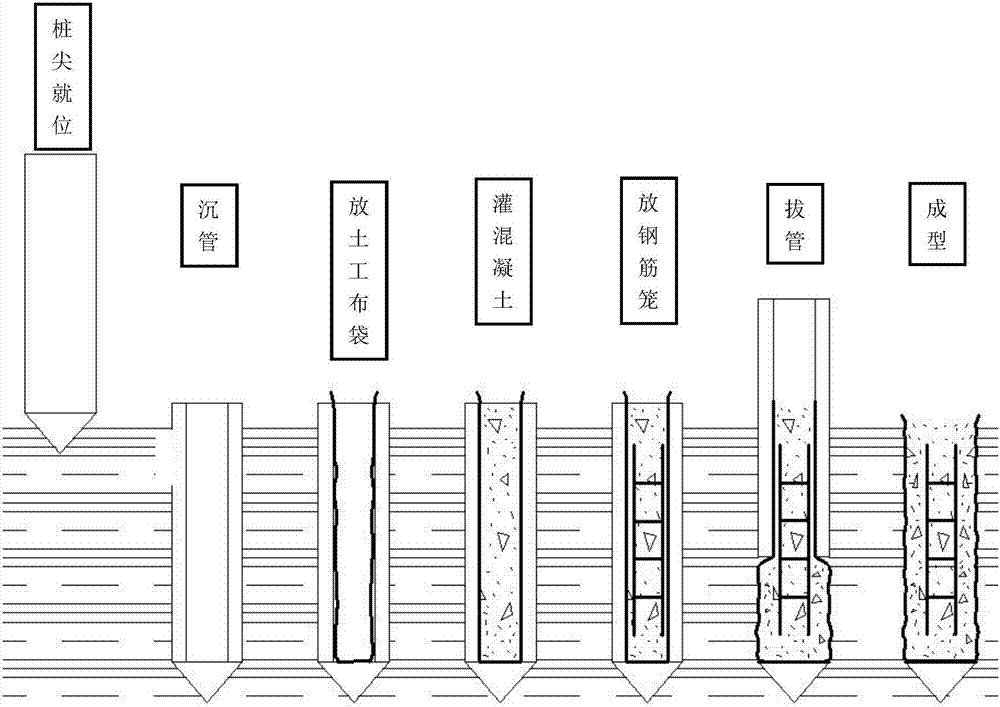

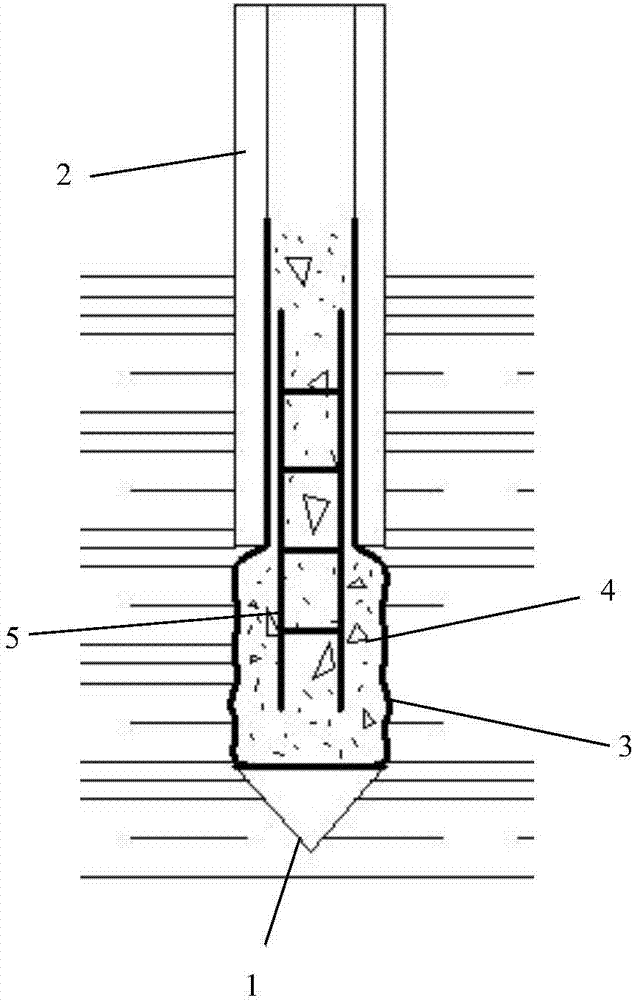

Tube-sinking cast-in-situ pile and construction technology thereof

The invention belongs to the technical field of foundation reinforcement, and discloses a tube-immersed cast-in-situ pile and its construction technology. The tube-immersed cast-in-place pile involves a pile tip, a pile pipe, a geotextile bag, a pile body and a reinforcement cage. The technological process is as follows: 1) 2) Immerse the pipe; 3) Put it into a geotextile bag; 4) Pouring concrete; 5) Hanging the reinforcement cage; 6) Pulling out the pipe; 7) Forming. The invention avoids common problems such as necking piles, broken piles, stilted piles and pile tip water inflow in the traditional sinking tube pouring pile process, and ensures the formation of the pouring piles, thereby effectively increasing the bearing capacity of the piles.

Owner:ANHUI UNIV OF SCI & TECH

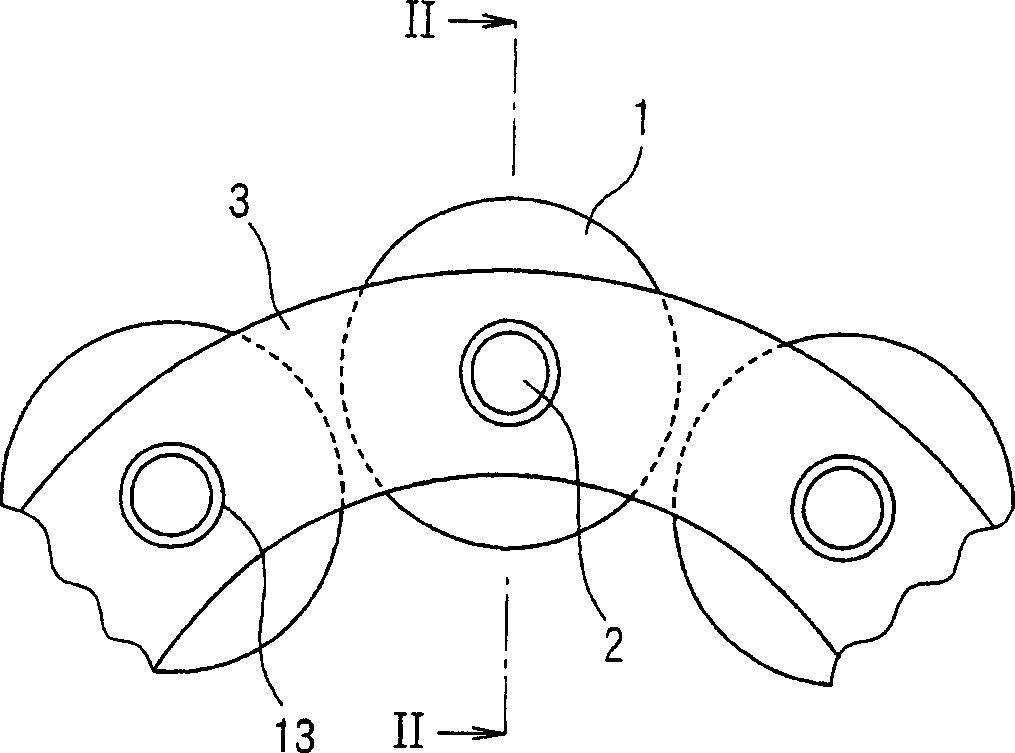

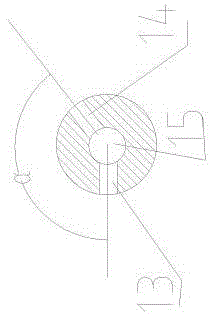

Retainer for roller bearing

InactiveCN1784556AGuaranteed connection strengthAvoid concentrated stressRoller bearingsBearing componentsEngineeringRoller bearing

The ends of the pins (2) rotatably supporting the rolling bodies (1) are fitted in pin receiving holes (4) in the annular side plates (3). The interference between the pin receiving hole (4) and the outer diameter of the pin (2) is in the range of 5 to 40 μm. The end of the pin (2) is welded to the annular side plate (3), wherein the end of the pin (2) is pressed into the pin receiving hole (4) with an interference of 5-40 μm.

Owner:NSK LTD

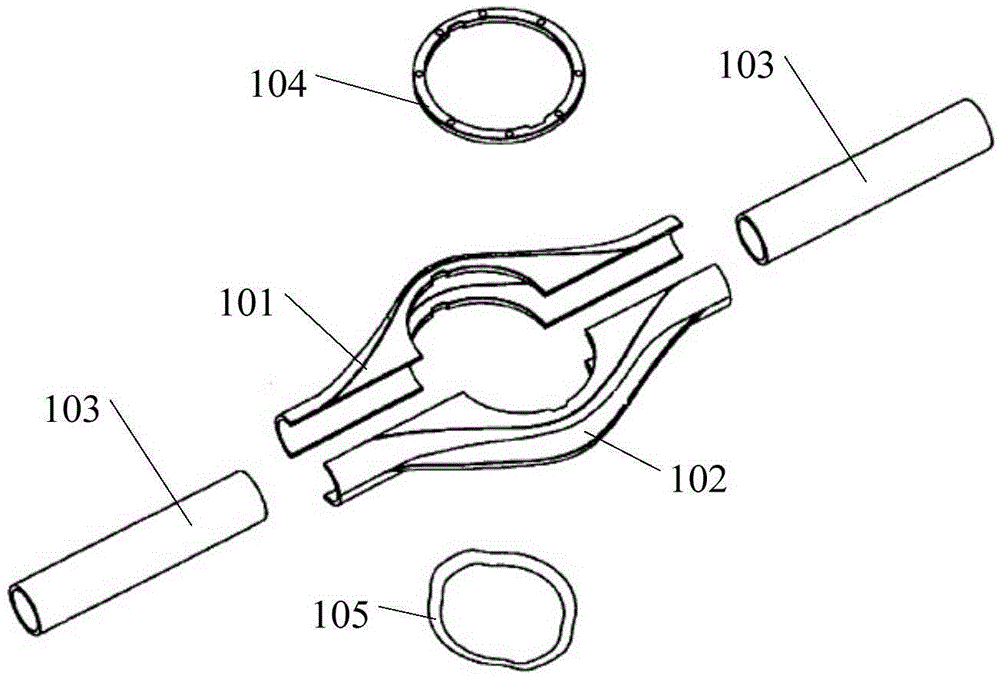

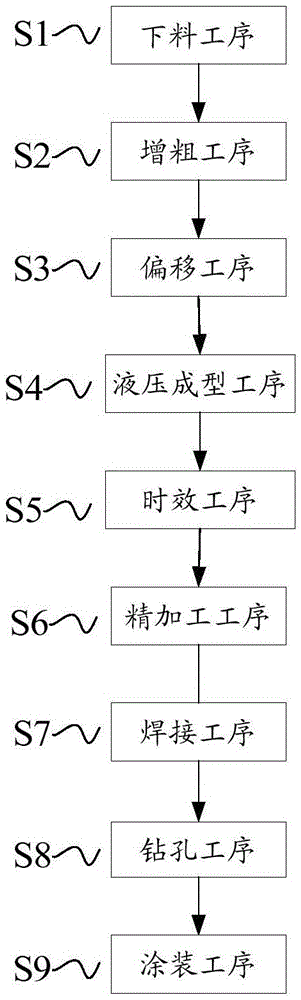

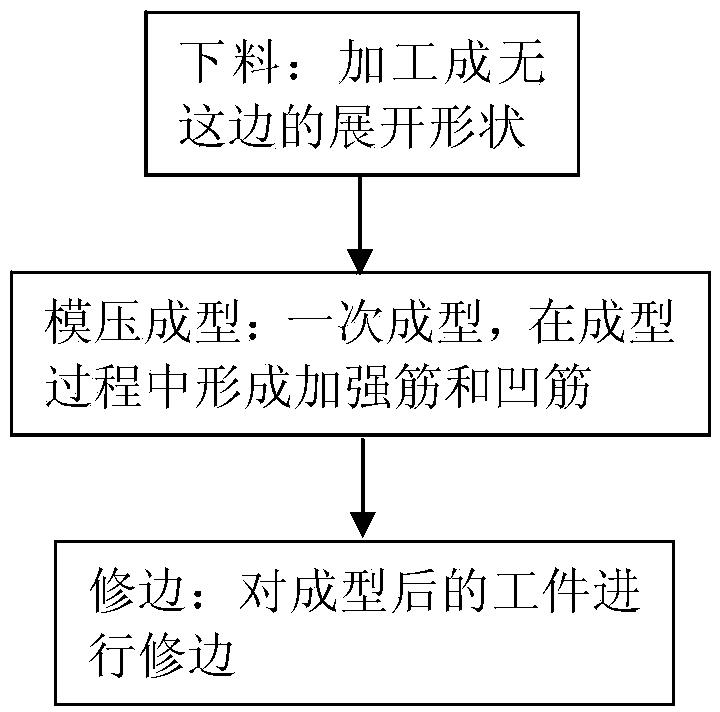

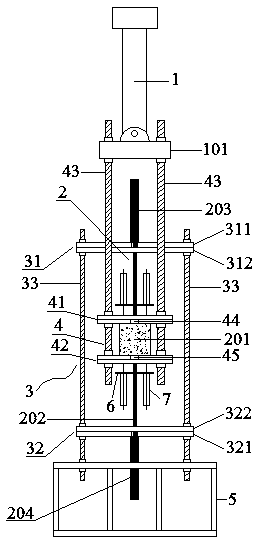

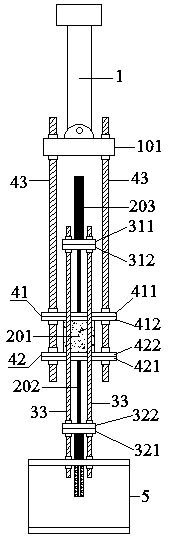

Automobile drive axle housing and manufacturing technology and manufacturing mold of automobile drive axle housing

ActiveCN105619029AHigh strengthReduce the number of seamsAxle unitsStress concentrationManufacturing technology

The invention belongs to the technical field of automobile manufacturing and provides an automobile drive axle housing and a manufacturing technology and a manufacturing mold of the automobile drive axle housing. The manufacturing technology comprises a blanking process, a thickening process, a shifting process, a hydraulic molding process, an aging process, a finish machining process, a welding process, a drilling process and a coating process. According to the automobile drive axle housing and the manufacturing technology and the manufacturing mold of the automobile drive axle housing, by additionally arranging the thickening process, the shifting process and the hydraulic molding process, the welding positions of the automobile drive axle housing and the juncture number of parts are reduced, so that the finish machined axle housing is of a structure formed integrally; the problems of stress concentration and cold joint caused by the welding process are avoided, the finished product sealing performance of the whole axle housing is ensured, and occurring of the oil leakage phenomenon is reduced; in addition, by means of the structure formed integrally, the strength of the automobile drive axle housing can be improved, fracture is prevented, and the reliability of the whole automobile drive axle housing is improved; accordingly, the axle housing is light in weight, and the cost is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

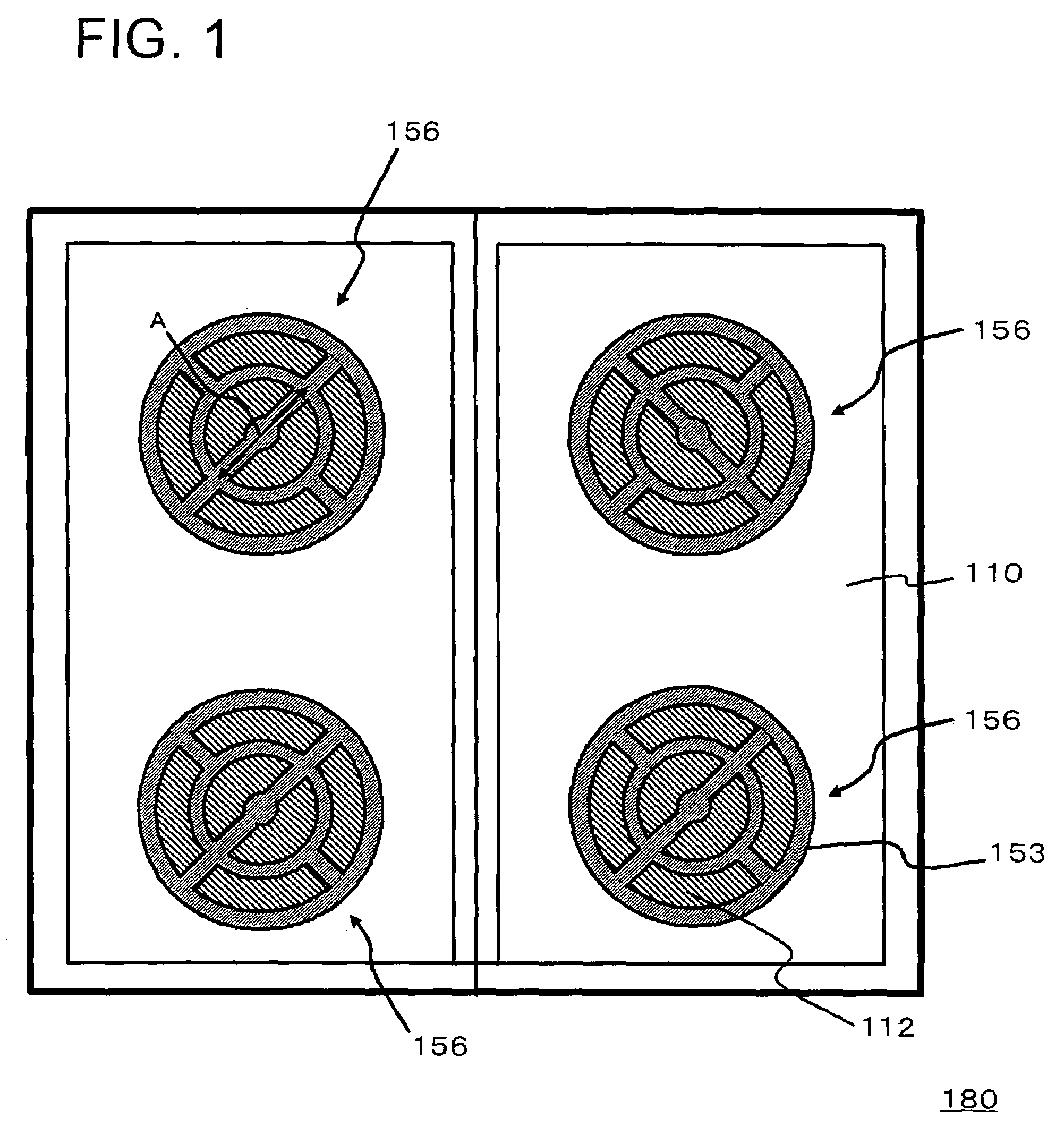

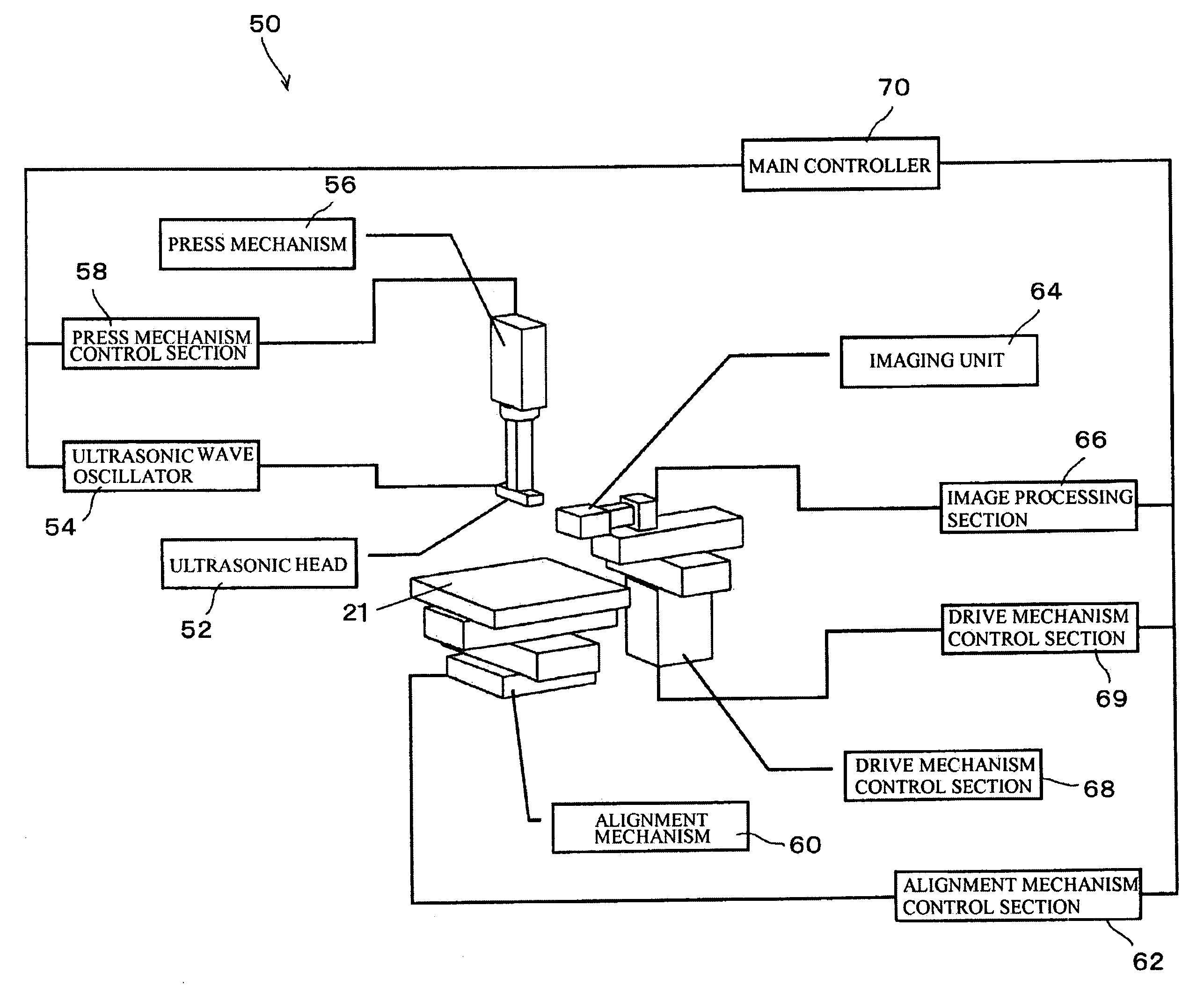

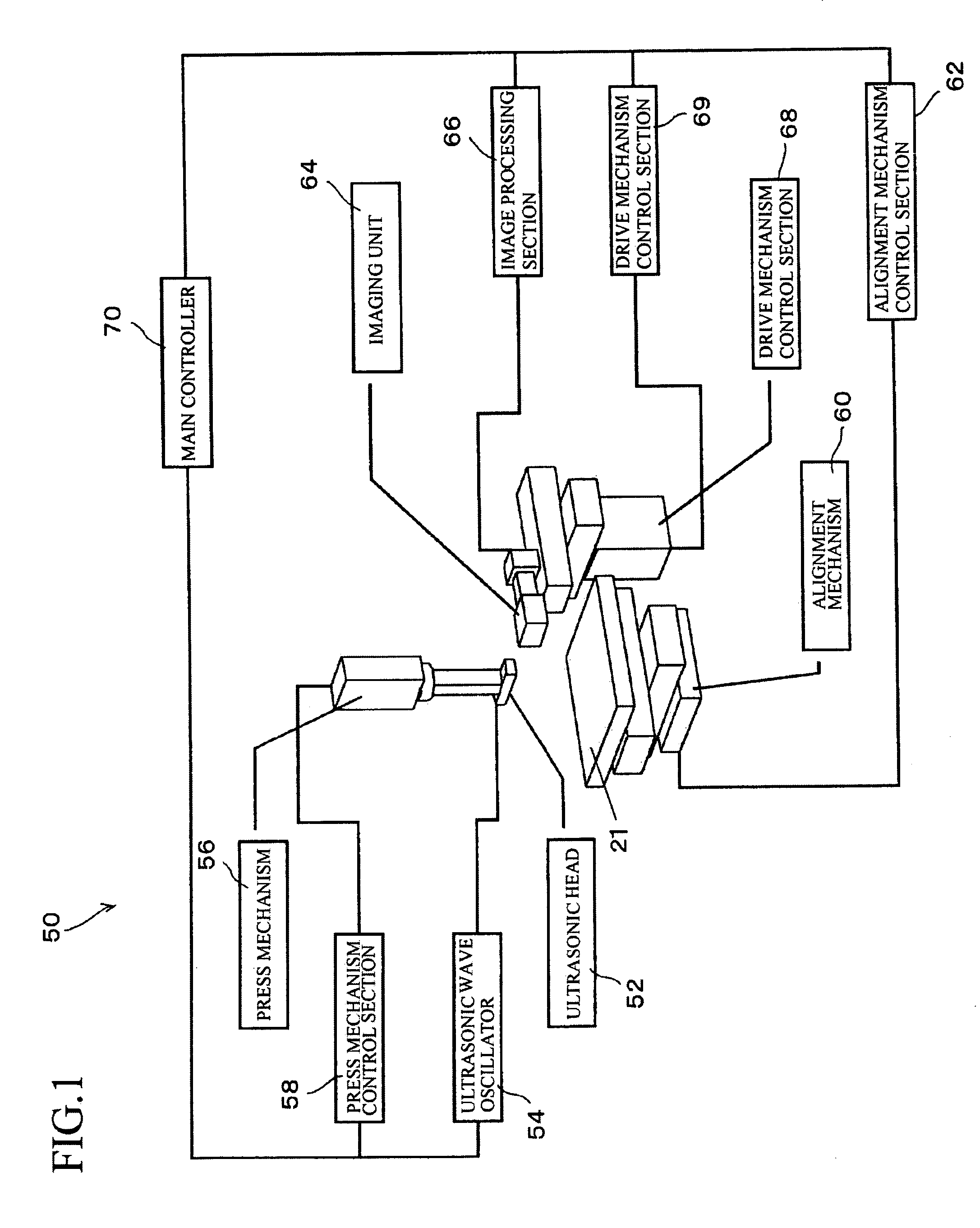

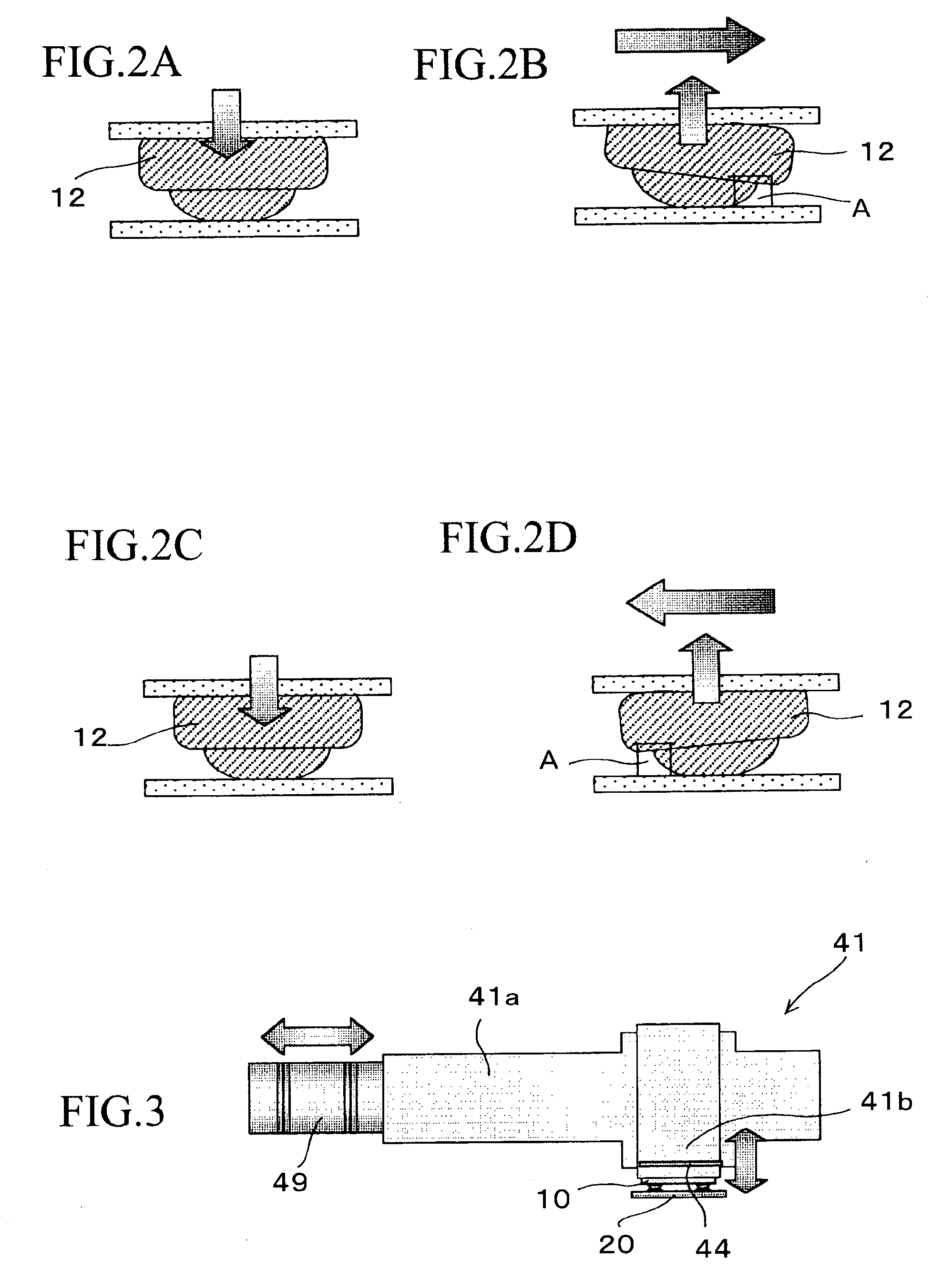

Method of ultrasonic-mounting electronic component and ultrasonic mounting machine

InactiveUS7208059B2Improve reliabilityEvenly bondedLamination ancillary operationsControlling laminationUltrasonic vibrationElectronic component

The ultrasonic mounting method is capable of uniformly bonding bumps of an electronic component to a circuit board and improving reliability of ultrasonic-mounting the electronic component. The method comprises the step of applying ultrasonic vibrations to the electronic component so as to flip-chip-bond the electronic component to the circuit board having electrodes. The ultrasonic vibrations are applied in a direction parallel to a surface of the electronic component, and loads are vertically applied to the surface of the electronic component in conjunction with vibration cycles of the ultrasonic vibrations.

Owner:FUJITSU LTD

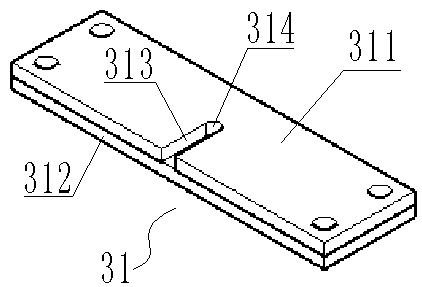

Window stand column and forming method thereof

InactiveCN103879420AAvoid concentrated stressAvoid distortionAxle-box lubricationRailway bodiesStress concentrationWrinkle skin

The invention relates to the field of decorations in vehicles and discloses a window stand column and a forming method of the window stand column. The window stand column comprises a stand column body, the stand column body is bent, turnups are arranged on the two sides of the stand column body, and a reinforcing rib is longitudinally arranged on the outer side of the stand column body. Because the reinforcing rib is longitudinally arranged on the outer side of the stand column body, stress concentration and distortion can be avoided in the forming process of the window stand column, adjustment and repair are not need for the forming, and the forming quality and the production efficiency are improved. Further, concave ribs are arranged at the ends of the stand column body, excessive material at the ends can be absorbed, wrinkles are eliminated, and forming manufacturability, product quality and product rigidity are improved.

Owner:CRRC QINGDAO SIFANG CO LTD

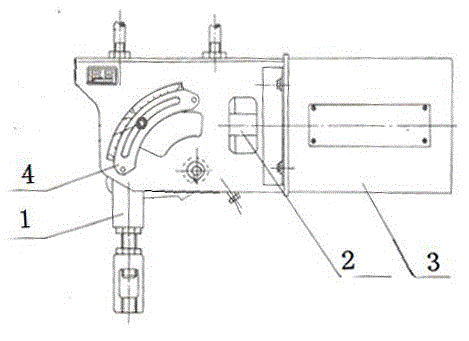

Testing device and method for bidirectional tensile bonding of weak-rigidity reinforcement

ActiveCN108760495AAccurate measurementOvercome the effects of slippageMaterial strength using tensile/compressive forcesBond slipActuator

The invention discloses a testing device and method for bidirectional tensile bonding of weak-rigidity reinforcement. The testing device comprises a bidirectional actuator, a test piece, a counterforce frame and a loading frame, wherein the test piece comprises a concrete test block and a reinforcement, the reinforcement penetrates the concrete test block and is bonded with the concrete test block, the bidirectional actuator can drive the loading frame to apply bidirectional force to the concrete test block in the length direction of the reinforcement through a converter; when the loading frame applies force to the concrete test block in the length direction of the reinforcement, the counterforce frame applies counterforce to the reinforcement. Relative slip between the weak-rigidity reinforcement and the concrete test block can be measured, so that the bond-slip constitutive relationship of the weak-rigidity reinforcement under the action of bidirectional stress load can be established, and reliable and real theoretical support can be provided for practical engineering.

Owner:ZHENGZHOU UNIV

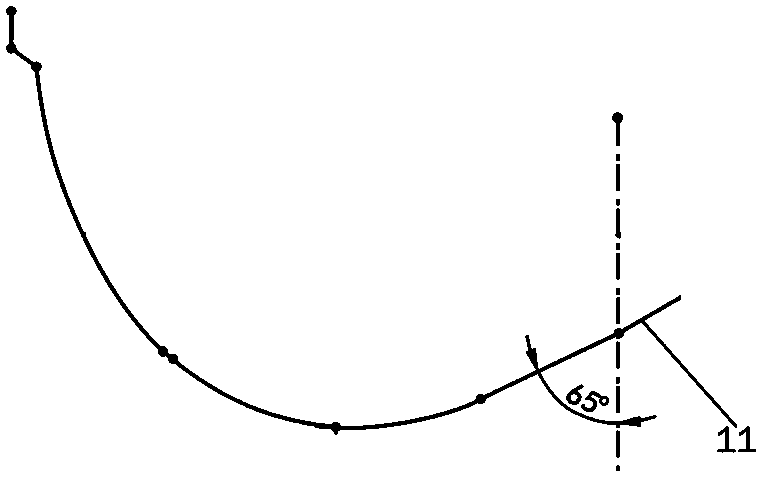

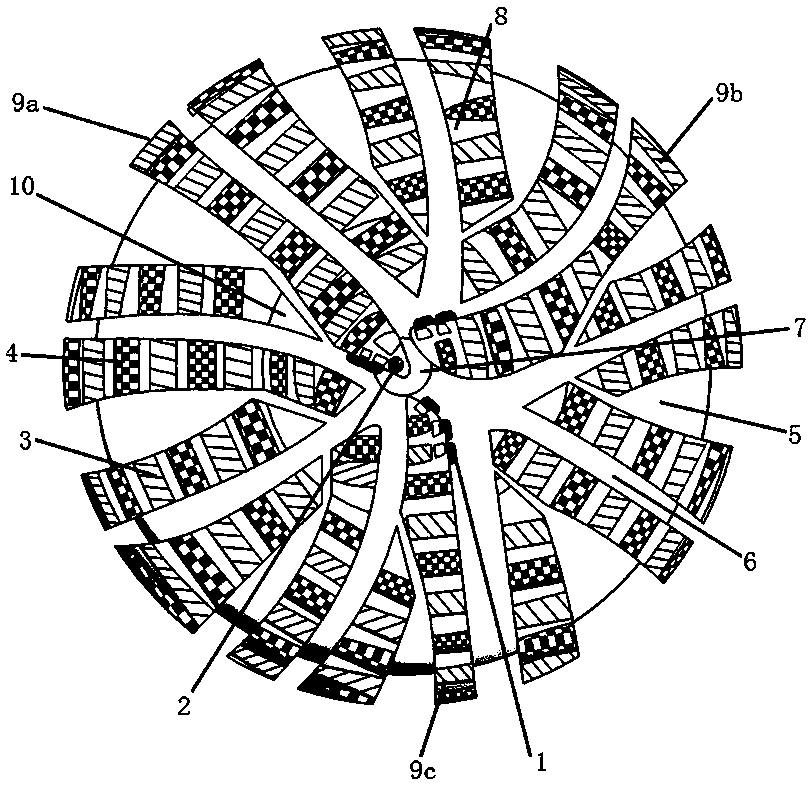

Cutting-grinding type impregnated diamond blocks and PDC clad sheet mixed drill bit

ActiveCN108194026AGuaranteed stabilityWith adaptive formation characteristicsDrill bitsConstructionsSection planeHardness

The invention relates to a cutting-grinding type impregnated diamond blocks and PDC clad sheet mixed drill bit which is a cutter wing type drill bit. Trapezoid cutter wings are adopted, the section shape of a crown part is a straight line-circular arc-circular arc type bipyramid crown part section, first impregnated blocks and second impregnated blocks are arranged alternately on three main cutterwings and two auxiliary cutter wings to achieve the capability that a shaft bottom can be completely covered, the diamond grit of the first impregnated blocks is 80 meshes, the concentration is 120%,and the alloy hardness is 60 HRC. The diamond grit of the second impregnated blocks is 60 meshes, the concentration is 100%, and the alloy hardness is 45 HRC. The included angle between every two adjacent main cutter wings is 100-140 degrees, the first main cutter wing has a super top structure, and one round wedge-shaped PDC tooth is arranged at the center of the drill bit, seven cylindrical PDCteeth are distributed around the round wedge-shaped PDC tooth. The cutting-grinding type impregnated diamond block and PDC clad sheet mixed drill bit solves the problem that existing PDC drill bits,roller bits and diamond drill bits are simplex to adapt to stratum.

Owner:CHENGDU DEEP DIAMOND BIT

Constant support and hanger

The invention discloses a constant support and hanger which comprises a shell, a pull rod assembly, a locking device and a load assembly. The load assembly comprises an upper pull rod and a lower pull rod, a longitudinal counter bore is formed in the lower end of the upper pull rod, inner threads are arranged in the longitudinal counter bore, outer threads are arranged on the periphery of the lower pull rod, the upper pull rod and the lower pull rod are connected to form a whole through the threads, a first transverse through hole and a second transverse through hole are transversely formed in the bore wall of the longitudinal counter bore in the radial direction, the center line of the first transverse through hole and the center line of the second transverse through hole are both perpendicular to the center line of the longitudinal counter bore, and an included angle alpha is formed between the center line of the first transverse through hole and the center line of the second transverse through hole and is an obtuse angle. Grooves corresponding to the first transverse through hole and the second transverse through hole respectively are formed in the peripheral face of the upper end of the lower pull rod. When connection is carried out, transverse rods are inserted into the first transverse through hole and the second transverse through hole respectively, and one end of each transverse rod is inserted into the corresponding groove. The constant support and hanger is convenient to use and firm in connection.

Owner:JIANGSU DALICHENG ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com