Method for forming grating for machine tool measurement in two-step solidifying rolling pressing forming manner

A molding method and rolling technology, applied in diffraction grating, optics, opto-mechanical equipment, etc., can solve the problems of high mass production cost and large equipment investment, achieve low cost, high production efficiency, avoid deformation and stress concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

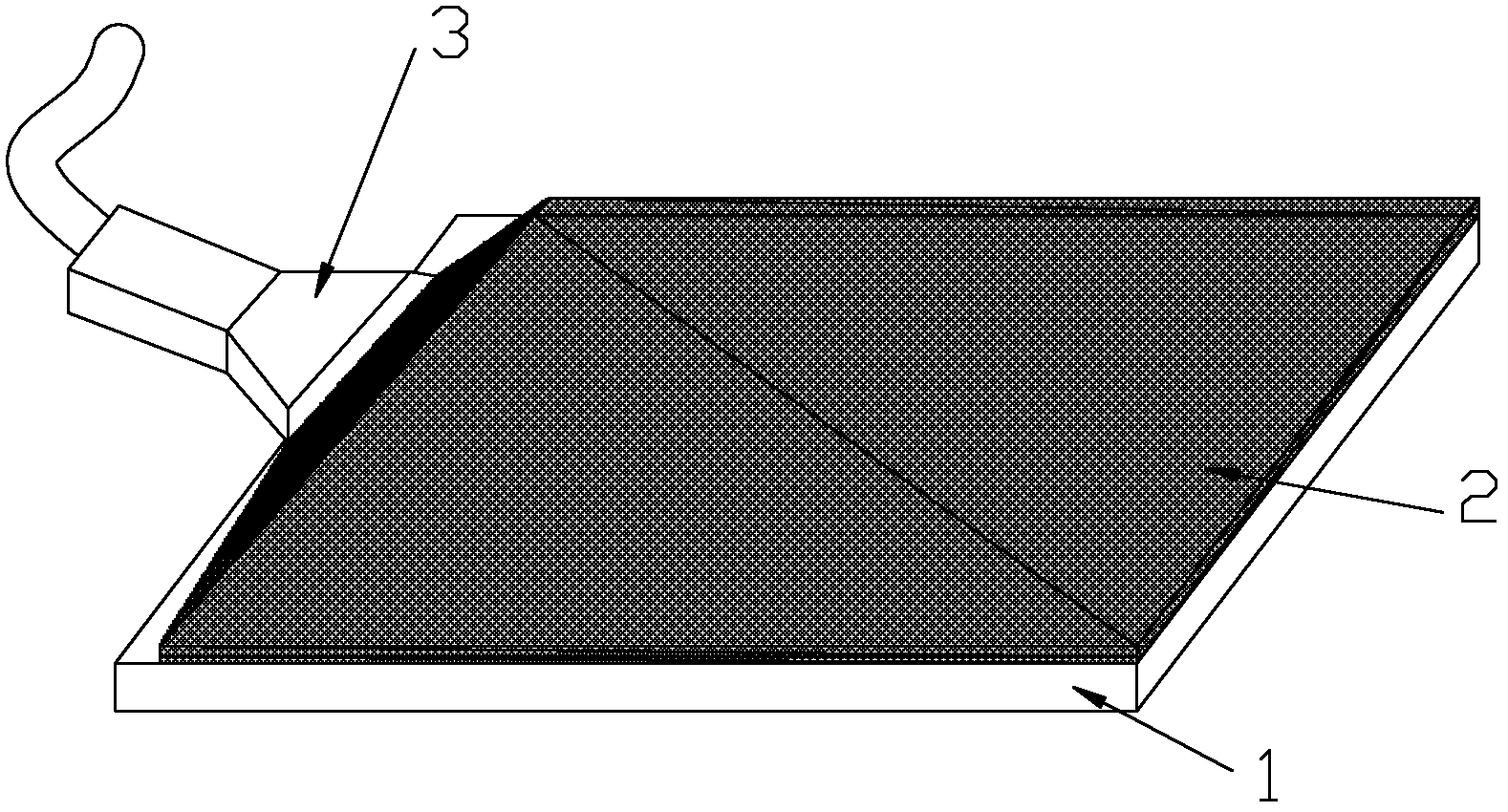

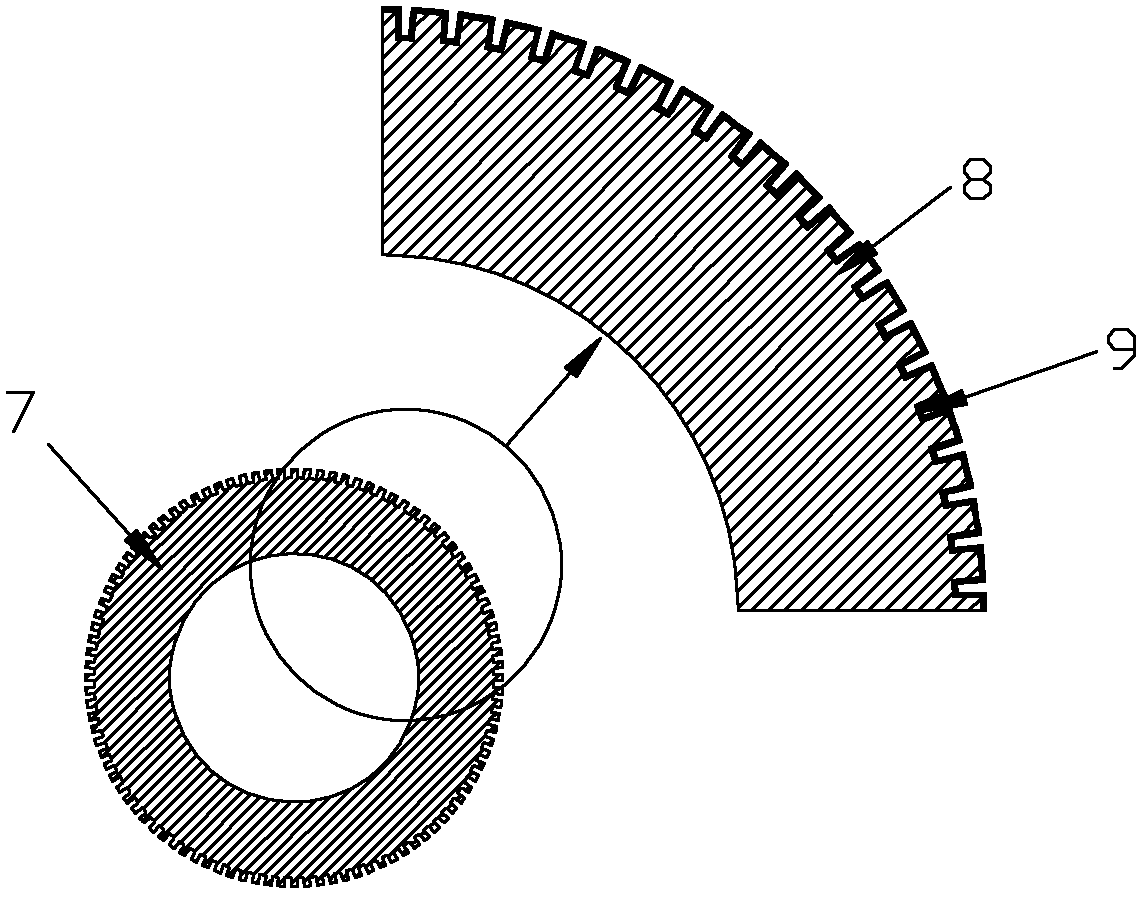

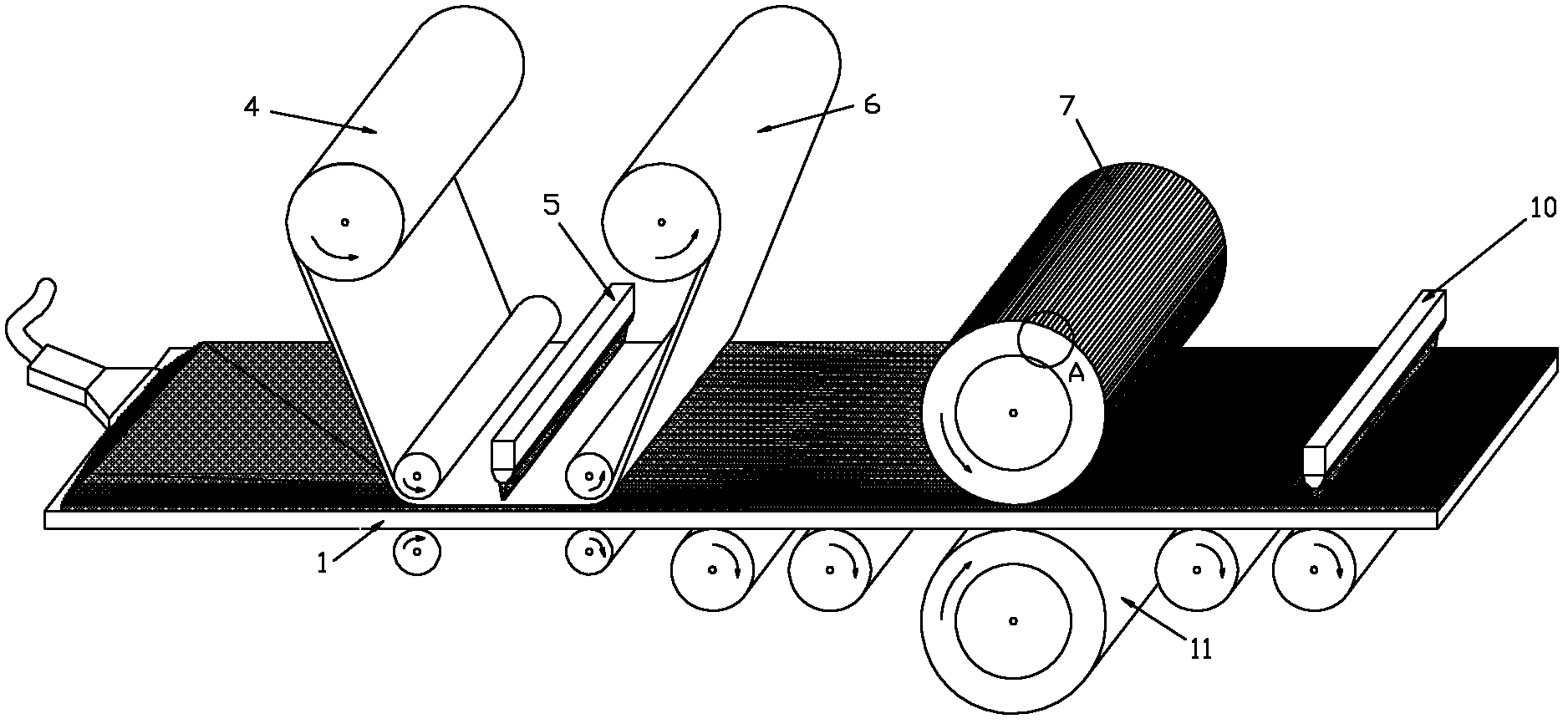

[0038] The system includes feeding link, lamination link, primary exposure link, peeling link, roll pressing copy link, secondary exposure link and product collection and packaging link. Among them, the laminating link and the peeling link adopt the feeding and feeding mechanism and the tension control mechanism in the printing machine. The core part of the roll embossing system, the roll embossing link, includes the clamping part of the mold and the embossing force control part. In order to facilitate the assembly and disassembly of the mold, the axial sleeve is pre-tightened by the axial sleeve for the mold clamping. The imprint force control part is equipped with a pressure sensor to continuously feed back pressure information and perform precise pressure control. The first and second exposure links use cold ultraviolet light source, and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com