Supporting node

A technology of joints and ball joints, applied in the field of joints, can solve problems such as difficulty in ensuring installation accuracy, impossibility of optimization, unclear internal force of joints, etc., to achieve the effect of ensuring machining accuracy and quality, facilitating factory mass production, and easily guaranteeing machining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

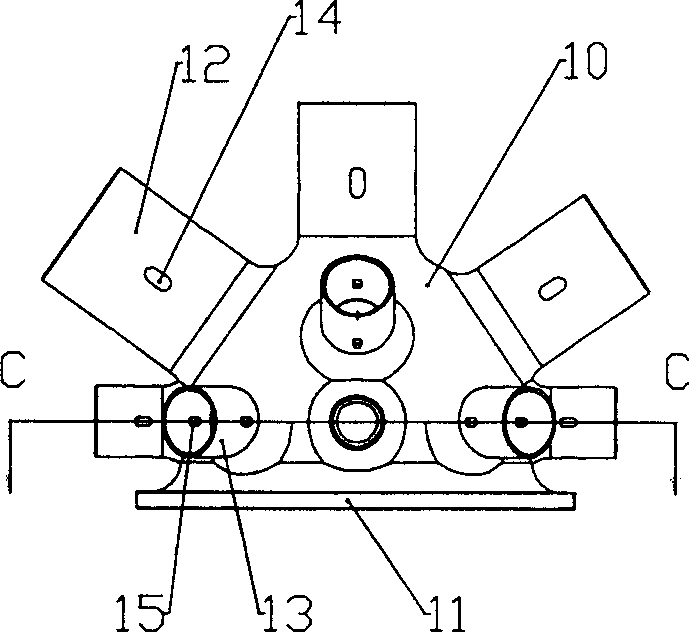

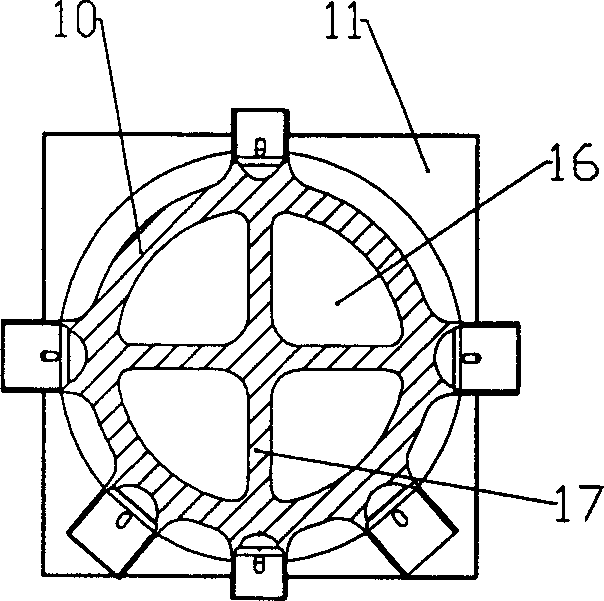

[0033] Figure 2 to Figure 7 A structural schematic diagram of a support node of the present invention is shown. It consists of a hemispherical body 10, a mounting base 11 with a flat bottom, and circular tubes 12, 13 on the hemispherical body 10.

[0034] Depend on Figure 6 to Figure 7 It can be seen that the hemisphere 10 and the mounting support 11 are integrated, that is, the periphery of the bottom of the hemisphere protrudes outwards to form a square mounting support for easy installation on the support column. According to installation requirements, through holes can be provided on the outwardly protruding edge of the mounting support 11 so as to be installed by means of bolt fixing.

[0035] Such as Figure 6 , Figure 7 As shown, the round pipes 12, 13 and the hemisphere 10 connected to the rods or pipes in the truss or grid structure also adopt an integral structure, so that the supporting nodes form a whole, which can be produced by casting, and the product can...

Embodiment 2

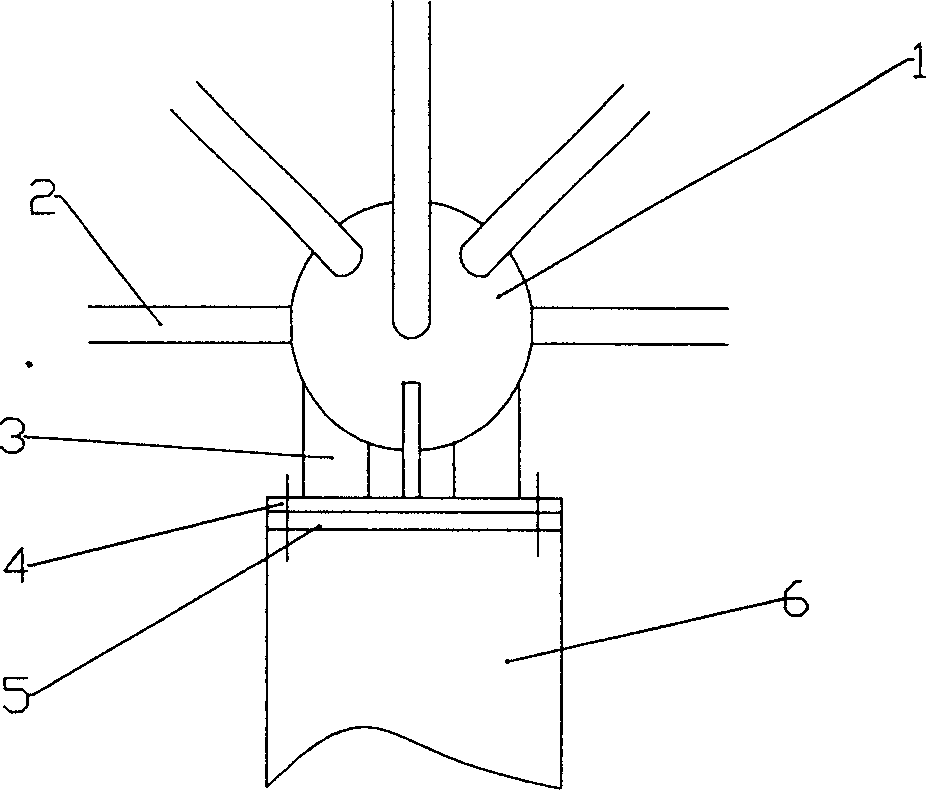

[0044] Such as Figure 8 As shown, the node part of the supporting node in this embodiment is composed of a hemisphere 10 and a round tube 12 on the hemisphere 10, and its structure is the same as that in Embodiment 1, and will not be described again in this embodiment. The difference from Embodiment 1 is that the mounting support part is a combined displacement support, including a box body 60 that can be fixed on the support column, and a guide rail 40 is installed in the box body 60 to slide on the bottom of the box body 60. The base 30 of the base 30 has an arc-shaped groove on the upper surface of the base 30, and a center core 20 whose lower surface is a hyperboloid or a spherical crown surface is housed in the groove, and a loam cake 80 is formed above the center core 20, and the center core 20 passes through the groove The structure is embedded in the bottom of the upper cover 80 and interlocked together. An elastic element composed of a bow-shaped leaf spring 61 is in...

Embodiment 3

[0050] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 2 is that the node part is an intersecting node, which is composed of a plurality of protruding circular tubes 100 converging together. There are through holes 110 for plug welding on the circular tubes. The entire node The part is integrally cast with the upper cover 80 of the combined displacement support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com